Research on the Mechanical Properties and Modification Mechanisms of Orthogonal Optimization Composite Cement-Based Thin Spray On-Liner

Abstract

:1. Introduction

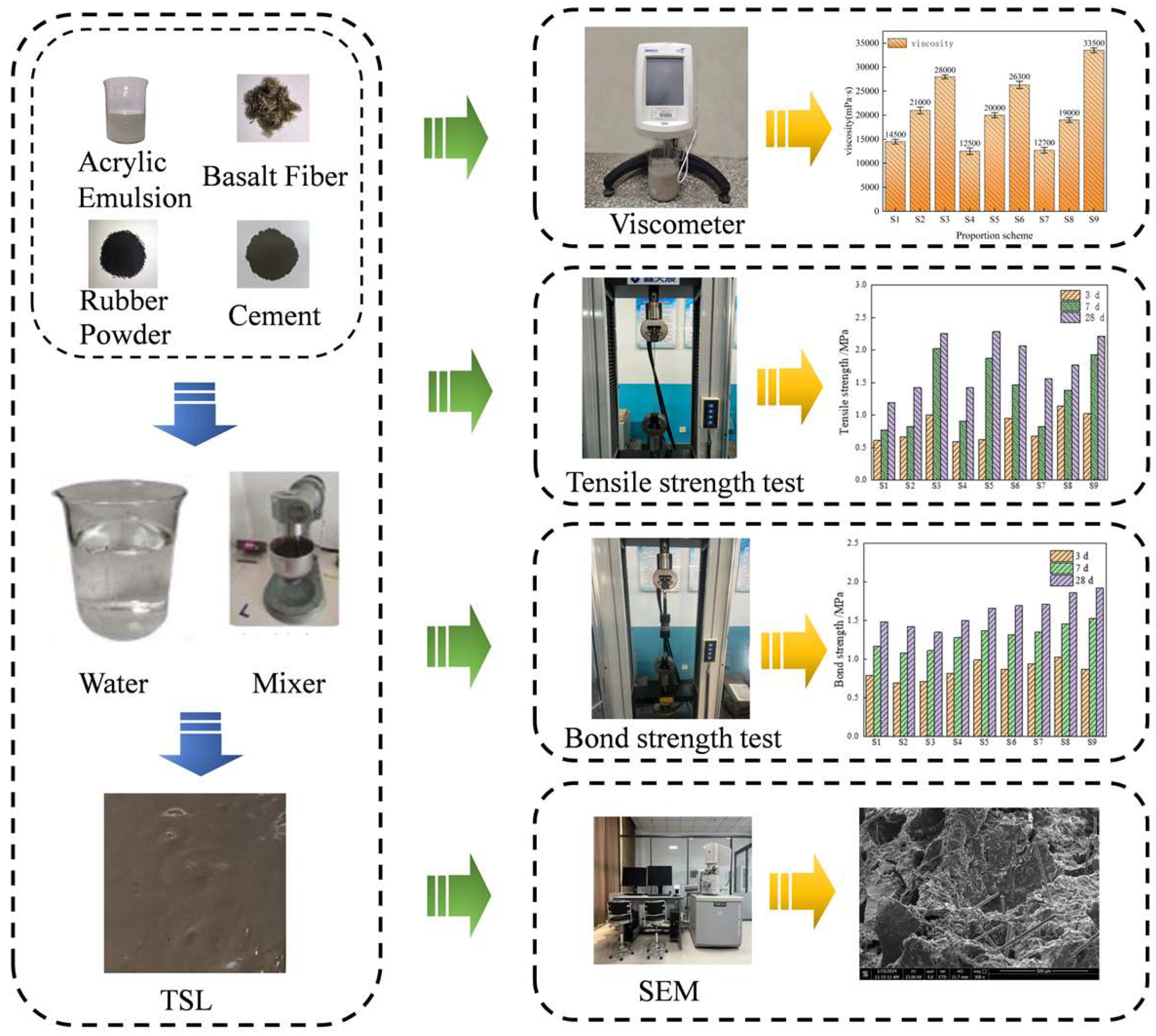

2. Materials and Methods

2.1. Raw Materials

2.2. Test Proportioning Design

2.3. Test Methods

3. Results and Analysis

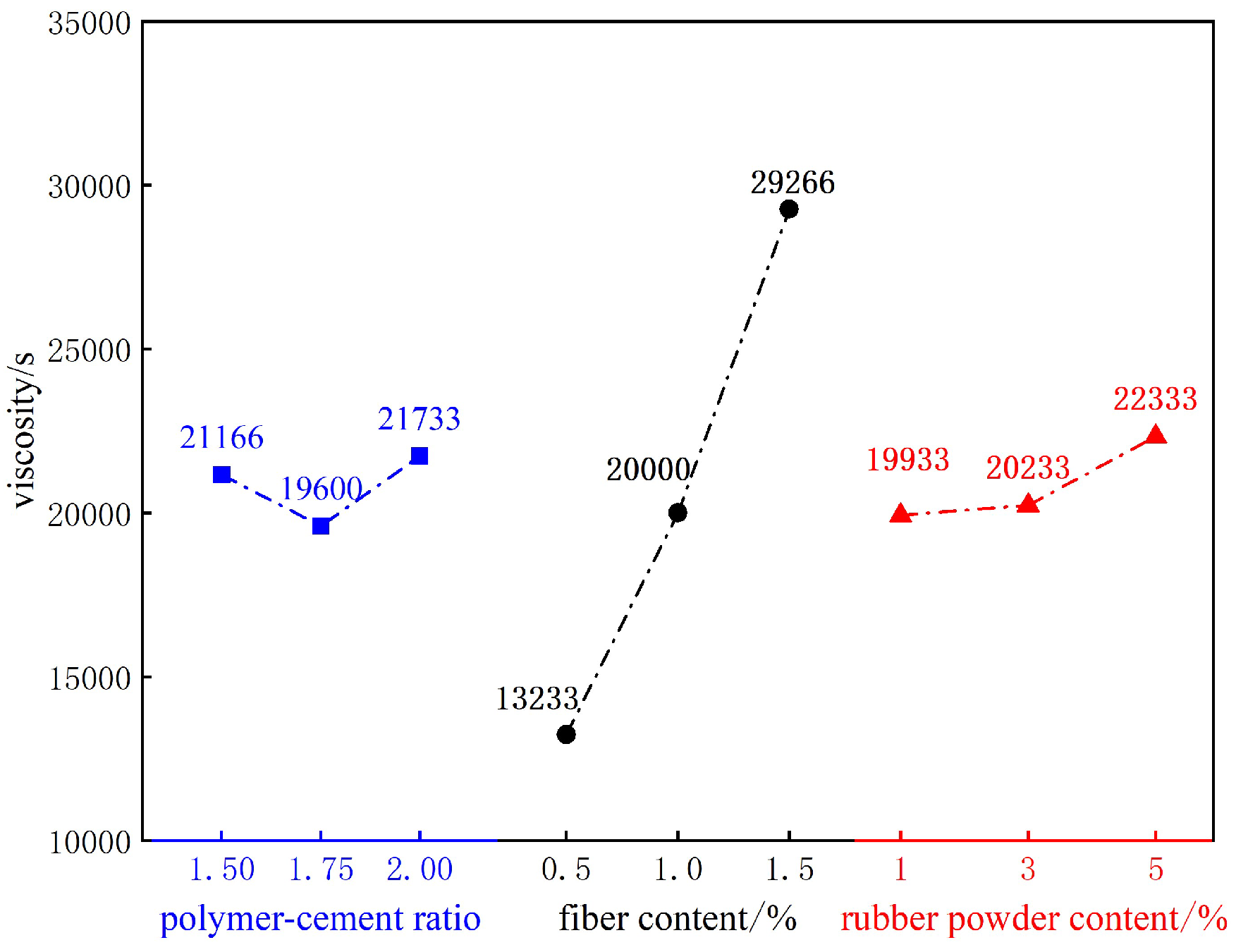

3.1. Viscosity

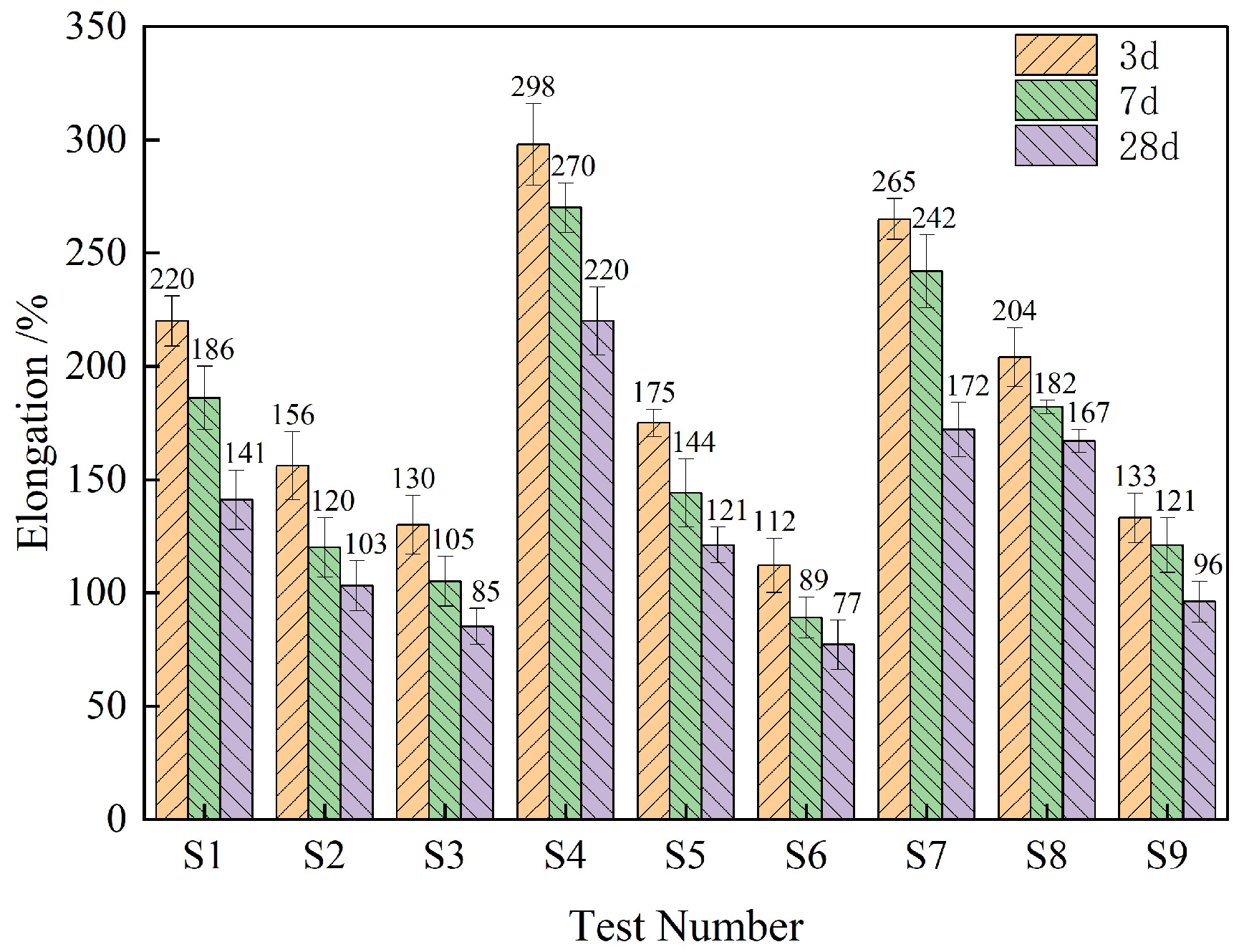

3.2. Elongation

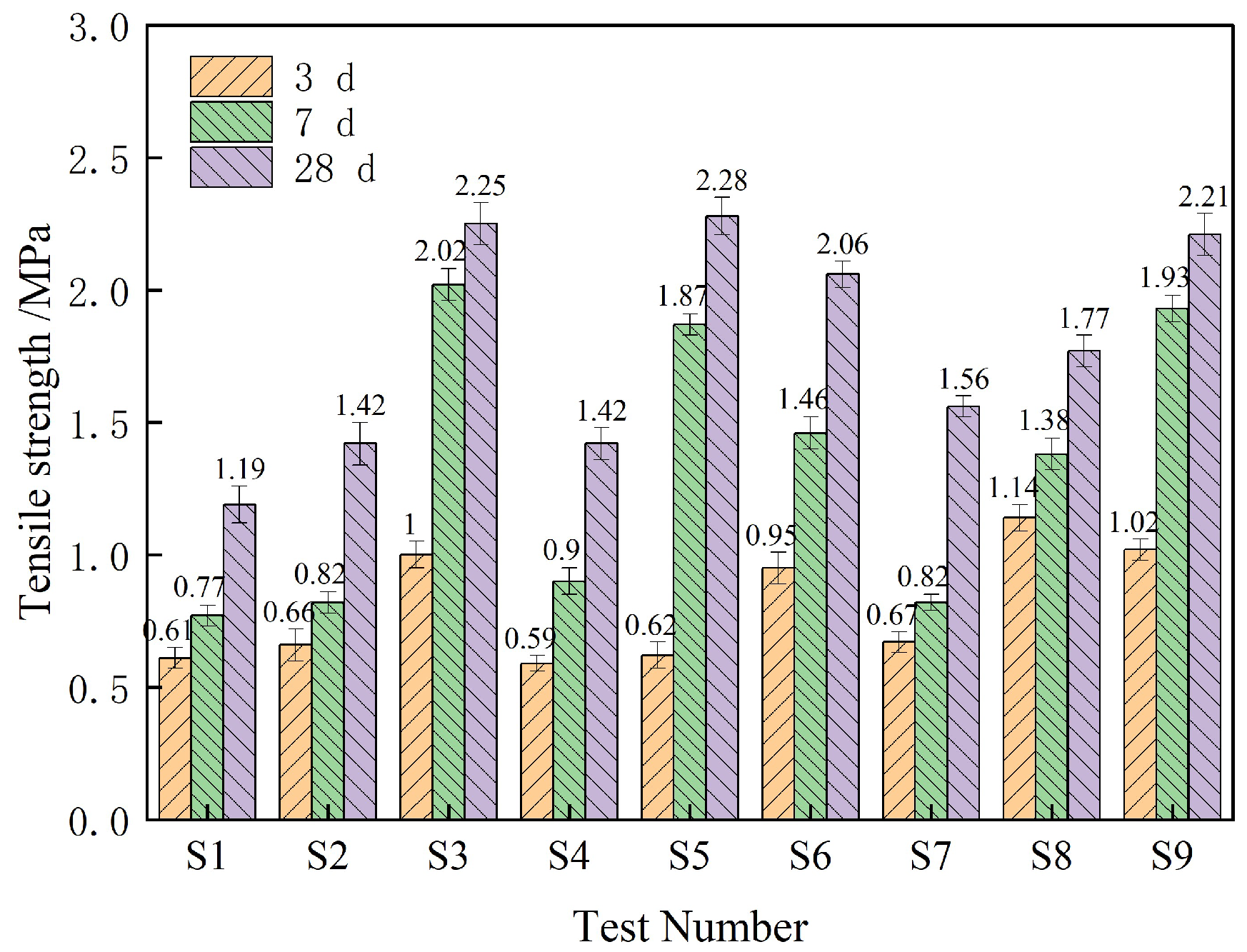

3.3. Tensile Strength Analysis

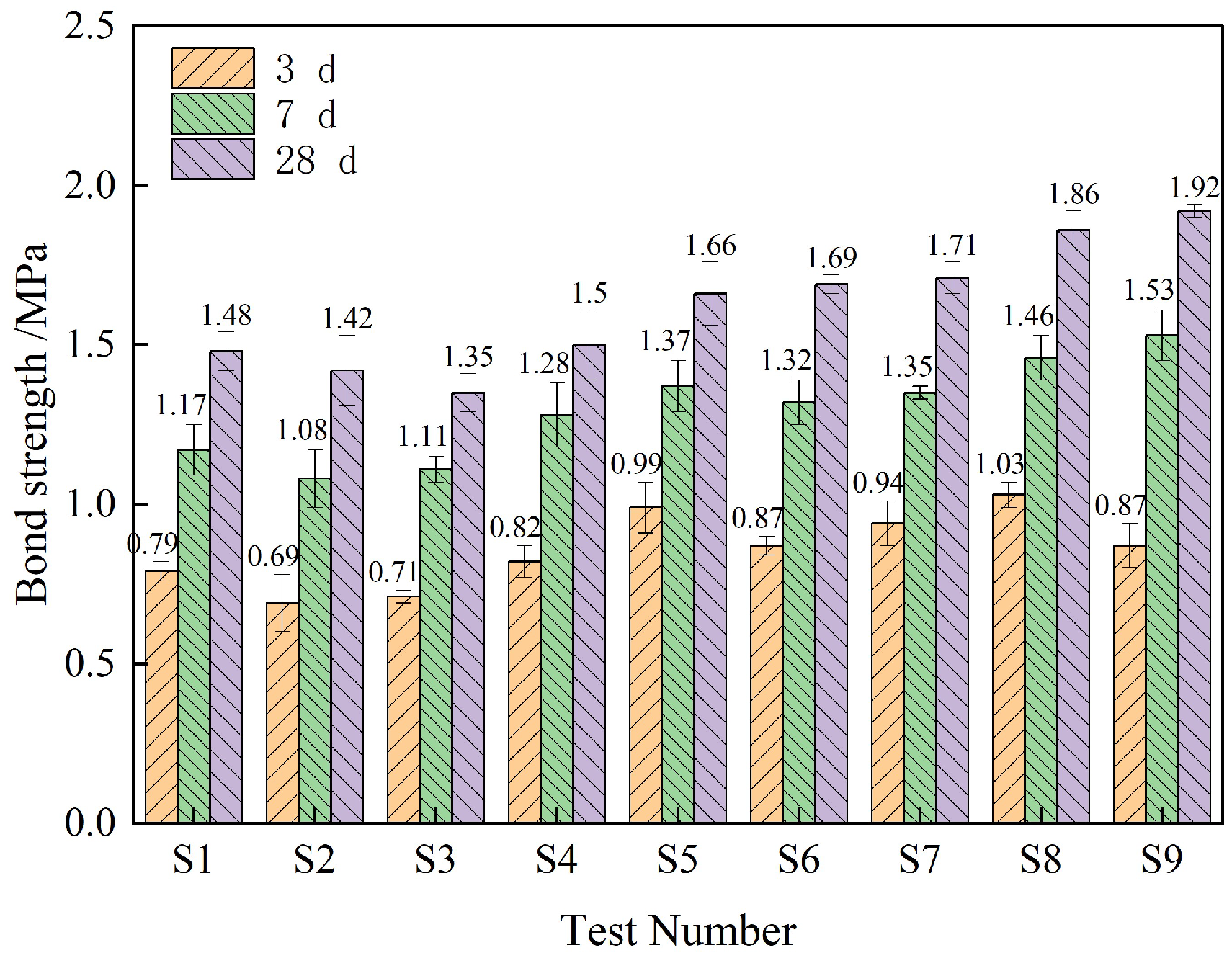

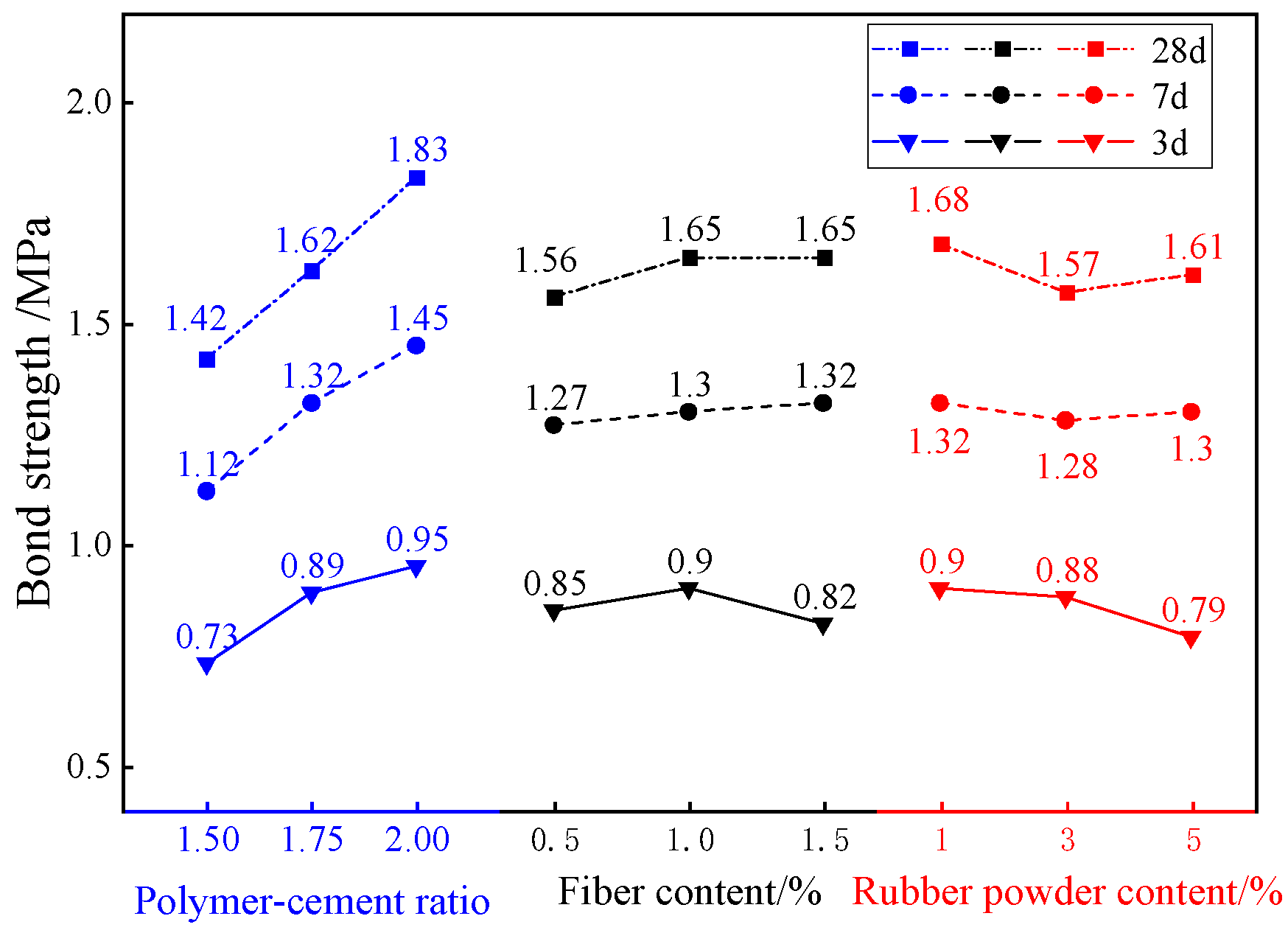

3.4. Bond Strength Analysis

3.5. Performance of Composite TSL with Optimal Ratio

4. Microstructure and Mechanism Analysis

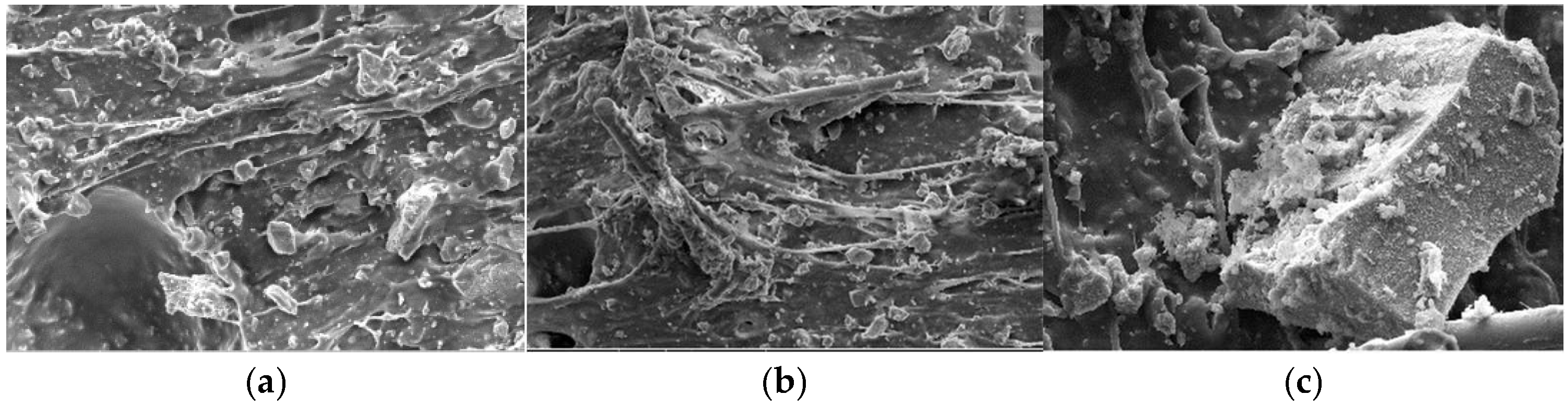

4.1. SEM Micromorphology Analysis

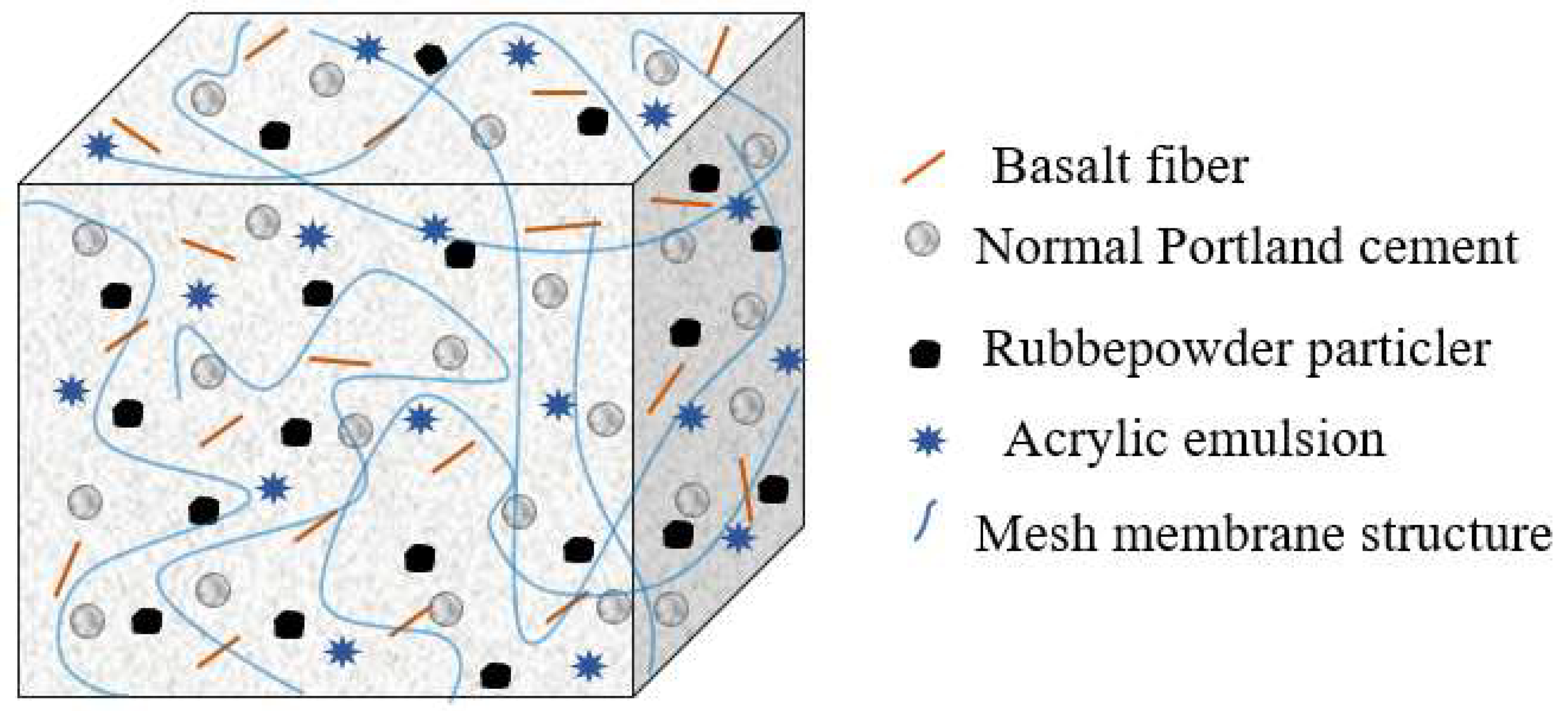

4.2. Mechanism Analysis and Discussion

5. Results and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Yang, W.; Wu, J. Macro and micro experimental study on the effect of water-cement ratio on the tensile properties of thin spray lining materials. Mater. Rep. 2024, 38, 277–283. Available online: http://kns.cnki.net/kcms/detail/50.1078.TB.20231213.1745.004.html (accessed on 12 March 2024).

- Zhang, N.; Wei, Q.; Wu, J. Coal mine roadway spraying flexible film technology and applicability. Coal Sci. Technol. 2022, 50, 78–85. [Google Scholar]

- Zhang, S.; Wu, J.; Wei, Q.; Dong, H. Theory and Practice of Thin Spray Technology in Coal Mine. Coal Sci. Technol. 2017, 45, 7. [Google Scholar] [CrossRef]

- Tian, Y. Experimental Study on Mechanical Properties of Flexible Spray Layer of Cataclastic Surrounding Rock. Master’s Thesis, Shandong University, Jinan, China, 2024. [Google Scholar]

- Stefanidou, M.; Kamperidou, V.; Konstandinidis, A.; Koltsou, P.; Papadopoulos, S. Rheological properties of biofibers in cementitious composite matrix. In Advances in Bio-Based Fiber; Woodhead Publishing: Sawston, UK, 2022; pp. 553–573. [Google Scholar]

- Li, X.; Qu, G.; Yang, C.; Teng, D. Research on new polymer spray material and its jet support technology in weakly cemented roadway. J. Min. Saf. Eng. 2019, 36, 95–102. [Google Scholar] [CrossRef]

- Li, X.; Yang, C.; Teng, D.; Yuan, S.; Guo, P.; Liang, Z. Experimental Study on Material Ratio and Mechanical Properties of New Flexible Spray Layer in Soft Rock Roadway. Coal Eng. 2018, 50, 138–141. [Google Scholar]

- Dondapati, G.K.; Deb, D.; Porter, I.; Karekal, S. Improvement of strength-deformability behaviour of rock-like materials and coal using fibre-reinforced thin spray-on liner (FR-TSL). Rock Mech. Rock Eng. 2022, 55, 3997–4013. [Google Scholar] [CrossRef]

- Qiao, Q.; Chai, H.; Zhang, X.; Zhang, H. Study on redispersible latex powder modified cement-based thin spray material. Silic. Bull. 2022, 41, 3394–3402. [Google Scholar] [CrossRef]

- Dong, Q.; Chen, L.; Cheng, W.; Liu, Z.; Cui, X.; Liu, G.; Shi, Z.; Sun, Z.; Zhang, Y. Material performance tests of the polymer-cement thin spray-on liner. Geofluids 2020, 2020, 6647363. [Google Scholar] [CrossRef]

- Shan, Z.; Porter, I.; Nemcik, J.; Baafi, E. Investigating the behaviour of fibre reinforced polymers and steel mesh when supporting coal mine roof strata subject to buckling. Rock Mech. Rock Eng. 2019, 52, 1857–1869. [Google Scholar] [CrossRef]

- Wei, Q. Study on the Mechanism of Spraying Flexible Film in Bolt Support. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Jiao, H.; Yang, Z.; Zheng, D.; Sun, J. Study on Early Hydration Mechanism of Double-Liquid Grouting Material Modified by Composite Early Strength Agent. Materials 2023, 16, 6475. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y. Study on the Properties and Hydration Characteristics of Polymer Cement-Based Materials. Master’s Thesis, Beijing Jianzhu University, Beijing, China, 2024. [Google Scholar]

- Ji, J.; Wang, H.; Wang, Q.; Suo, Z.; Yuan, Z. Effect of modified waste rubber powder on properties of cement mortar. J. Build. Mater. 2021, 24, 679–686. [Google Scholar]

- Pei, X.; Zhu, Y.; Li, T.; Li, Y. Study on acrylic emulsion modified plaster mortar and its properties. Concrete 2023, 7, 131–135. [Google Scholar]

- Pei, X.; Zhu, Y.; Zhang, S. Study on the performance of acrylic emulsion modified cement reinforced mortar. Portland Not. 2020, 39, 409–415. [Google Scholar] [CrossRef]

- Li, K.; Wei, Z.; Qiao, H.; Lu, C.; Guo, J.; Qiao, G. Research progress on the influence of four types of admixture materials on the properties of polymer modified cement-based materials. Mater. Rep. 2021, 35, 654–661. [Google Scholar]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Mechanical properties of epoxy/basalt polymer concrete: Experimental and analytical study. Struct. Concr. 2018, 19, 366–373. [Google Scholar] [CrossRef]

- Bi, M.; Zhao, D.; Bai, X.; Yang, H.; Sun, H.; Zhang, X. Study on the properties and mechanism of cement-based materials modified by styrene-butadiene emulsion-rubber powder. J. Jinan Univ. (Nat. Sci. Ed.) 2020, 34, 211–217. [Google Scholar] [CrossRef]

- Qin, L. Study on the Properties of Basalt-Polypropylene Hybrid Fiber Modified Cement-Based Materials. Master’s Thesis, Jilin Jianzhu University, Changchun, China, 2024. [Google Scholar]

- Heng, Y.; Zhao, W. Research progress of polymer modified cement-based materials. Silic. Bull. 2014, 33, 365–371. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | AL2O3 | CaO | Fe2O3 | MgO | Other |

|---|---|---|---|---|---|---|

| Percentage (%) | 20.61 | 3.98 | 65.70 | 2.62 | 1.56 | 5.53 |

| Particle Size /mm | Iron Content /% | Fiber Content /% | Sieve Residue /% | Fracture Strength /MPa | Breaking Elongation /% |

|---|---|---|---|---|---|

| 3–6 | 0.02 | 0.00 | 0.021 | 16.4 | 582 |

| Fiber Category | Fiber Diameter /mm | Density /g·cm3 | Breaking Strength /MPa | Elastic Modulus /GPa | Breaking Elongation /% |

|---|---|---|---|---|---|

| basalt fiber | 17.0 | 2.705 | 1.71 × 103 | 75.4 | 2.5 |

| Test Number | A (Polymer–Cement Ratio) | B (Basalt Fiber Content)/% | C (Rubber Powder Content)/% |

|---|---|---|---|

| S 1 | 1.50 | 0.5 | 1.0 |

| S 2 | 1.50 | 1.0 | 5.0 |

| S 3 | 1.50 | 1.5 | 3.0 |

| S 4 | 1.75 | 0.5 | 5.0 |

| S 5 | 1.75 | 1.0 | 3.0 |

| S 6 | 1.75 | 1.5 | 1.0 |

| S 7 | 2.00 | 0.5 | 3.0 |

| S 8 | 2.00 | 1.0 | 1.0 |

| S 9 | 2.00 | 1.5 | 5.0 |

| Factor | A | B | C |

|---|---|---|---|

| Extreme difference/mm | 2133.33 | 16,033.33 | 2400.00 |

| primary and secondary factor | Fiber content > rubber powder viscosity > polymer–cement ratio | ||

| optimal proportion | A3 | B3 | C3 |

| Factor | A | B | C |

|---|---|---|---|

| 3 d extreme difference/% | 32 | 136 | 17 |

| The primary and secondary factors of 3 d | Basalt fiber content > polymer–cement ratio > rubber powder content | ||

| The optimal ratio of 3 d | A3 | B1 | C3 |

| 7 d extreme difference/% | 44.67 | 127.67 | 18 |

| The primary and secondary factors of 7 d | Basalt fiber content > polymer–cement ratio > rubber powder content | ||

| The optimal ratio of 7 d | A3 | B1 | C3 |

| 28 d extreme difference/% | 35.33 | 91.67 | 13.67 |

| The primary and secondary factors of 28 d | Basalt fiber content > polymer–cement ratio > rubber powder content | ||

| The optimal ratio of 28 d | A3 | B1 | C3 |

| Factor | A | B | C |

|---|---|---|---|

| 3 d extreme difference/% | 0.21 | 0.28 | 0.08 |

| The primary and secondary factors of 3 d | Basalt fiber content > polymer–cement ratio > rubber powder content | ||

| The optimal ratio of 3 d | A3 | B3 | C1 |

| 7 d extreme difference/% | 0.22 | 0.82 | 0.52 |

| The primary and secondary factors of 7 d | Basalt fiber content > rubber powder content > polymer–cement ratio | ||

| The optimal ratio of 7 d | A3 | B3 | C2 |

| 28 d extreme difference/% | 0.30 | 0.78 | 0.36 |

| The primary and secondary factors of 28 d | Basalt fiber content > rubber powder content > polymer–cement ratio | ||

| The optimal ratio of 28 d | A2 | B3 | C2 |

| Factor | A | B | C |

|---|---|---|---|

| 3 d extreme difference/% | 0.10 | 0.08 | 0.15 |

| The primary and secondary factors of 3 d | rubber powder content > polymer–cement ratio > Basalt fiber content | ||

| The optimal ratio of 3 d | 2 | 3 | 2 |

| 7 d extreme difference/% | 0.46 | 0.15 | 0.06 |

| The primary and secondary factors of 7 d | polymer–cement ratio > Basalt fiber content > rubber powder content | ||

| The optimal ratio of 7 d | 3 | 3 | 2 |

| 28 d extreme difference/% | 0.48 | 0.14 | 0.04 |

| The primary and secondary factors of 28 d | polymer–cement ratio > Basalt fiber content > rubber powder content | ||

| The optimal ratio of 28 d | 3 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, D.; Chen, X.; Jiao, H.; Yang, L.; Liu, X.; Han, Y.; Liu, Z. Research on the Mechanical Properties and Modification Mechanisms of Orthogonal Optimization Composite Cement-Based Thin Spray On-Liner. Materials 2025, 18, 1837. https://doi.org/10.3390/ma18081837

Zheng D, Chen X, Jiao H, Yang L, Liu X, Han Y, Liu Z. Research on the Mechanical Properties and Modification Mechanisms of Orthogonal Optimization Composite Cement-Based Thin Spray On-Liner. Materials. 2025; 18(8):1837. https://doi.org/10.3390/ma18081837

Chicago/Turabian StyleZheng, Diantao, Xinming Chen, Huazhe Jiao, Liuhua Yang, Xiaohui Liu, Yulong Han, and Ziyang Liu. 2025. "Research on the Mechanical Properties and Modification Mechanisms of Orthogonal Optimization Composite Cement-Based Thin Spray On-Liner" Materials 18, no. 8: 1837. https://doi.org/10.3390/ma18081837

APA StyleZheng, D., Chen, X., Jiao, H., Yang, L., Liu, X., Han, Y., & Liu, Z. (2025). Research on the Mechanical Properties and Modification Mechanisms of Orthogonal Optimization Composite Cement-Based Thin Spray On-Liner. Materials, 18(8), 1837. https://doi.org/10.3390/ma18081837