Annealing Effects in Twin-Roll Cast AA8006 Aluminium Sheets Processed by Accumulative Roll-Bonding

Abstract

:1. Introduction

2. Experimental Details

3. Experimental Results

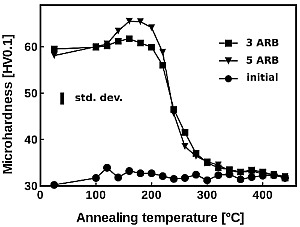

3.1. Mechanical Properties

3.2. LOM

3.3. TEM

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Inst. 1953, 173, 25–28. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel. III Discussion of results. Oric. Phys. Soc. 1951, B64, 747–753. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Korznikov, A.V.; Mulyukov, R.R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. 1993, A168, 141–148. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Chmelik, F.; Gibadullin, I.F.; Biegel, W.; Valiev, R.Z. The nanocrystalline structure formation in germanium subjected to severe plastic deformation. Nanostruct. Mater. 1994, 4, 387–395. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Kashihara, K.; Tsujimoto, Y.; Terada, D.; Tsuji, N. Texture evolution in {112} <111> aluminum single crystals processed by severe plastic deformation. Mater. Charact. 2013, 75, 129–137. [Google Scholar] [CrossRef]

- Schmidt, C.W.; Knödler, P.; Höppel, H.W.; Göken, M. Particle based alloying by accumulative roll bonding in the system Al-Cu. Metals 2011, 1, 65–78. [Google Scholar] [CrossRef]

- Slámová, M.; Sláma, P.; Homola, P.; Uhlíř, J.; Cieslar, M. Multilayer composite Al99.99/AlMg3 sheets prepared by accumulative roll bonding. Int. J. Mater. Res. 2009, 100, 858–862. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and application. Prog. Mater. Sci. 2006, 51, 893–979. [Google Scholar] [CrossRef]

- Huang, X.; Tsuji, N.; Hansen, N.; Minamino, Y. Microstructural evolution during accumulative roll-bonding of commercial purity aluminum. Mater. Sci. Eng. 2003, A340, 265–271. [Google Scholar] [CrossRef]

- Slámová, M.; Sláma, P.; Cieslar, M. The influence of alloy composition on phase transformations and recrystallization in twin-roll cast Al-Mn-Fe alloys. Mater. Sci. Forum 2006, 519–521, 365–370. [Google Scholar] [CrossRef]

- Birol, Y. Thermomechanical processing of a twin-roll cast Al–1Fe–0.2Si alloy. J. Mater. Process. Technol. 2008, 202, 564–568. [Google Scholar] [CrossRef]

- Slámová, M.; Karlík, M.; Cieslar, M.; Chalupa, B.; Merle, P. Structure transformations during annealing of twin-roll cast Al-Fe-Mn-Si (AA 8006) alloy sheets II. Effect of homogenization and heating rate. Kovove Mater. 2003, 41, 51–62. [Google Scholar]

- Cieslar, M.; Slámová, M.; Uhlíř, J.; Coupeau, C.H.; Bonneville, J. Effect of composition and work hardening on solid solution decomposition in twin-roll cast Al-Mn sheets. Kov. Mater. 2007, 45, 91–98. [Google Scholar]

- Birol, Y. Impact of homogenization on recrystallization of a supersaturated Al–Mn alloy. Scr. Mater. 2009, 60, 5–8. [Google Scholar] [CrossRef]

- Homola, P.; Slámová, M.; Sláma, P.; Cieslar, M. Thermal stability of ultrafine grains in Al-Fe-Mn-Si foils prepared by ARB and subsequent rolling. Mater. Sci. Forum 2008, 584–586, 905–910. [Google Scholar] [CrossRef]

- Karlík, M.; Slámová, M.; Homola, P.; Sláma, P.; Cieslar, M. Accumulative roll-bonding (ARB) of sheets of aluminium and its commercial alloys AA8006 and AA5754 at ambient and elevated temperatures. Mater. Sci. Forum 2007, 546–549, 767–774. [Google Scholar] [CrossRef]

- Ham, R.K. The determination of dislocation densities in thin films. Philos. Mag. 1961, 69, 1183–1184. [Google Scholar] [CrossRef]

- Huang, X.; Hansen, N.; Tsuji, N. Hardening by annealing and softening by deformation in nanostructured metals. Science 2006, 312, 249–251. [Google Scholar] [CrossRef] [PubMed]

- Jazaeri, H.; Humphreys, F.J. The transition from discontinuous to continuous recrystallization in some aluminium alloys: II–Annealing behaviour. Acta Mater. 2004, 52, 3251–3262. [Google Scholar] [CrossRef]

- Engler, O.; Vatne, H.E.; Nes, E. The roles of oriented nucleation and oriented growth on recrystallization textures in commercial purity aluminium. Mater. Sci. Eng. 1996, A205, 187–198. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cieslar, M.; Poková, M. Annealing Effects in Twin-Roll Cast AA8006 Aluminium Sheets Processed by Accumulative Roll-Bonding. Materials 2014, 7, 8058-8069. https://doi.org/10.3390/ma7128058

Cieslar M, Poková M. Annealing Effects in Twin-Roll Cast AA8006 Aluminium Sheets Processed by Accumulative Roll-Bonding. Materials. 2014; 7(12):8058-8069. https://doi.org/10.3390/ma7128058

Chicago/Turabian StyleCieslar, Miroslav, and Michaela Poková. 2014. "Annealing Effects in Twin-Roll Cast AA8006 Aluminium Sheets Processed by Accumulative Roll-Bonding" Materials 7, no. 12: 8058-8069. https://doi.org/10.3390/ma7128058

APA StyleCieslar, M., & Poková, M. (2014). Annealing Effects in Twin-Roll Cast AA8006 Aluminium Sheets Processed by Accumulative Roll-Bonding. Materials, 7(12), 8058-8069. https://doi.org/10.3390/ma7128058