Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes

Abstract

:1. Introduction

2. Experimental Section

2.1. Wood Selection

2.2. Fungal Selection

2.3. Colorants

2.3.1. Isolation

2.3.2. Concentration

2.3.3. Application onto Wood

2.3.4. Assessment

3. Results and Discussion

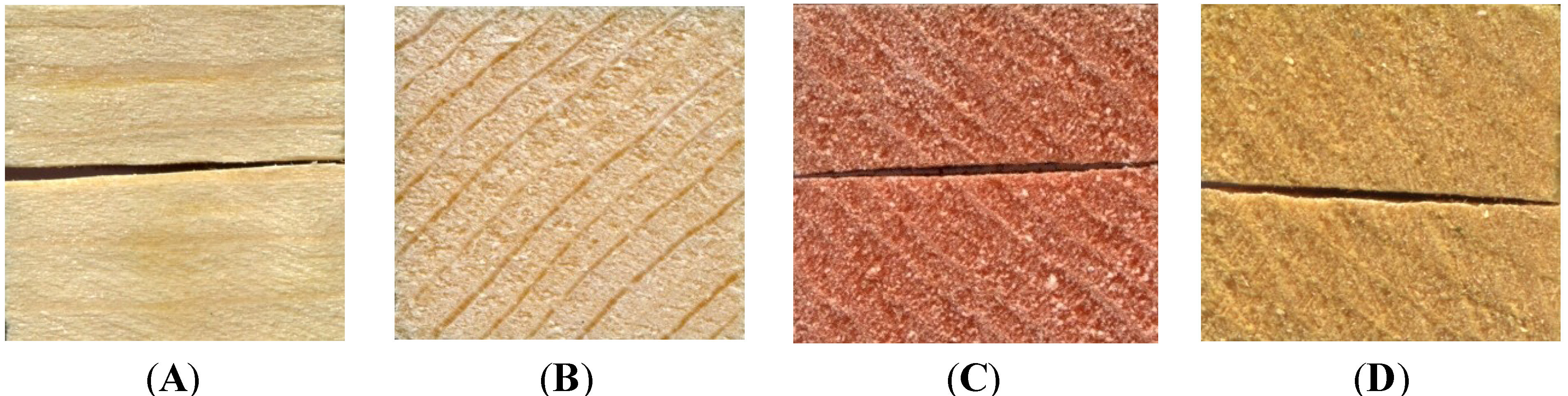

3.1. External

| Wood | Method | Color | External Delta E* | Internal Delta E* | Internal % Coverage |

|---|---|---|---|---|---|

| Ash | aniline dye | blue-green | 144.84 (A) | 53.17 (A) | 16.00 (A) |

| liquid | red | 168.89 (A) | 25.59 (B) | 0 (B) | |

| blue-green | 22.68 (A) | 18.16 (B) | 0 (B) | ||

| yellow | 16.63 (A) | 18.89 (B) | 0 (B) | ||

| wood-agar | red | 100.40 (A) | 1.57 (B) | 0 (B) | |

| blue-green | 100.40 (A) | 11.22 (B) | 0 (B) | ||

| yellow | 23.52 (A) | 18.89 (B) | 0 (B) | ||

| Chinkapin | aniline dye | blue-green | 178.24 (A) | 35.68 (A) | 58.67 (A) |

| liquid | red | 128.94 (ABC) | 10.18 (CD) | 0 (B) | |

| blue-green | 38.95 (E) | 11.84 (CD) | 0 (B) | ||

| yellow | 64.09 (CDE) | 8.81 (D) | 0 (B) | ||

| wood-agar | red | 134.84 (AB) | 27.06 (BC) | 0 (B) | |

| blue-green | 110.52 (BCD) | 27.06 (AB) | 0 (B) | ||

| yellow | 53.38 (DE) | 5.38 (D) | 0 (B) | ||

| Cottonwood | aniline dye | blue-green | 282.86 (A) | 57.47 (B) | 58.67 (A) |

| liquid | red | 264.71 (A) | 0.76 (D) | 0 (B) | |

| blue-green | 64.71 (A) | 2.39 (D) | 0 (B) | ||

| yellow | 368.13 (A) | 97.24 (A) | 0 (B) | ||

| wood-agar | red | 131.78 (A) | 29.62 (C) | 2.9 (B) | |

| blue-green | 99.47 (A) | 36.61 (BC) | 0 (B) | ||

| yellow | 45.49 (A) | 1.43 (D) | 0 (B) | ||

| Lodgepole pine | aniline dye | blue-green | 474.46 (A) | 65.26 (A) | 55.33 (A) |

| liquid | red | 378.21 (B) | 4.69 (C) | 8.67 (B) | |

| blue-green | 87.95 (D) | 2.39 (C) | 0 (B) | ||

| yellow | 185.69 (C) | 3.79 (C) | 0 (B) | ||

| wood-agar | red | 142.78 (CD) | 16.94 (B) | 0 (B) | |

| blue-green | 113.85 (D) | 24.94 (B) | 0 (B) | ||

| yellow | 182.58 (C) | 2.44 (C) | 0 (B) | ||

| Noble fir | aniline dye | blue-green | 558.15 (A) | 46.96 (A) | 52.33 (A) |

| liquid | red | 182.16 (B) | 4.28 (B) | 6.67 (B) | |

| blue-green | 61.95 (B) | 18.02 (B) | 0 (B) | ||

| yellow | 110.23 (B) | 5.84 (B) | 0 (B) | ||

| wood-agar | red | 202.50 (B) | 5.22 (B) | 0.83 (B) | |

| blue-green | 227.11 (B) | 6.34 (B) | 0 (B) | ||

| yellow | 160.88 (B) | 2.79 (B) | 8.57 (B) | ||

| Oregon maple | aniline dye | blue-green | 162.74 (BC) | 39.91 (A) | 39.33 (A) |

| liquid | red | 136.04 (BC) | 6.70 (B) | 0.67 (B) | |

| blue-green | 58.97 (C) | 6.44 (B) | 0 (B) | ||

| yellow | 70.05 (C) | 5.61 (B) | 0 (B) | ||

| wood-agar | red | 205.97 (AB) | 31.85 (A) | 0.57 (B) | |

| blue-green | 302.87 (A) | 30.76 (A) | 0 (B) | ||

| yellow | 57.28 (C) | 5.89 (B) | 3.67 (B) | ||

| Port orford cedar | aniline dye | blue-green | 415.10 (A) | 61.75 (A) | 60.00 (A) |

| liquid | red | 246.50 (A) | 0.95 (D) | 12.33 (B) | |

| blue-green | 55.0 (A) | 1.24 (D) | 0 (B) | ||

| yellow | 112.10 (A) | 1.73 (D) | 0 (B) | ||

| wood-agar | red | 187.10 (A) | 10.95 (C) | 4.3 (B) | |

| blue-green | 165.50 (A) | 21.62 (B) | 4.03 (B) | ||

| yellow | 306.10 (A) | 3.50 (D) | 9.33 (B) | ||

| Red alder | aniline dye | blue-green | 142.76 (BC) | 40.38 (B) | 0 (A) |

| liquid | red | 78.27 (C) | 8.59 (C) | 0 (A) | |

| blue-green | 78.27 (C) | 8.37 (C) | 0 (A) | ||

| yellow | 43.49 (C) | 11.92 (C) | 0 (A) | ||

| wood-agar | red | 259.61 (AB) | 57.68 (A) | 0 (A) | |

| blue-green | 318.11 (A) | 41.27 (B) | 0 (A) | ||

| yellow | 150.56 (ABC) | 5.61 (C) | 1.33 (A) | ||

| Sweet cherry | aniline dye | blue-green | 153.23 (B) | 90.35 (A) | 8.33 (A) |

| liquid | red | 63.87 (C) | 11.36 (BC) | 0 (B) | |

| blue-green | 45.34 (C) | 10.73 (BC) | 0 (B) | ||

| yellow | 32.11 (C) | 9.30 (C) | 0 (B) | ||

| wood-agar | red | 241.47 (A) | 94.77 (A) | 0 (B) | |

| blue-green | 193.19 (AB) | 53.88 (AB) | 0 (B) | ||

| yellow | 50.48 (C) | 20.73 (BC) | 0 (B) | ||

| Sugar maple | aniline dye | blue-green | 525.19 (A) | 52.94 (A) | 12.00 (B) |

| liquid | red | 158.52 (B) | 17.61 (BC) | 10.67 (B) | |

| blue-green | 49.53 (B) | 12.60 (CD) | 0 (C) | ||

| yellow | 29.53 (B) | 15.42 (CD) | 0 (C) | ||

| wood-agar | red | 218.02 (B) | 9.94 (D) | 0 (C) | |

| blue-green | 201.77 (B) | 12.43 (CD) | 0 (C) | ||

| yellow | 475.68 (A) | 23.10 (B) | 18.33 (A) |

3.2. Internal

3.3. Comparing Percent Coverage to CIE Lab Values

| Wood | Threshold (Delta E*) |

|---|---|

| ash | 54 |

| chinkapin | 36 |

| cottonwood | 58 |

| lodgepole pine | 66 |

| noble fir | 47 |

| Oregon maple | 40 |

| port orford cedar | 22 |

| red alder | NA |

| sweet cherry | 91 |

| sugar maple | 18 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Michaelsen, H.; Buchholz, R. Von Färben des Holzes. Holzbeizen von der Antike bis in die Gegenwart; Michael Imhof Verlag: Petersberg, EU, 2009. (In German) [Google Scholar]

- Blanchette, R.A.; Wilmering, A.M.; Baumeister, M. The use of green-stained wood caused by the fungus Chlorociboria in Intarsia masterpieces from the 15th Century. Holzforschung 1992, 46, 225–232. [Google Scholar]

- Robinson, S.C. Developing fungal pigments for “painting” vascular plants. Appl. Microbiol. Biotechnol. 2012, 93, 1389–1394. [Google Scholar] [CrossRef]

- Robinson, S.C.; Hinsch, E.; Weber, G.; Freitas, S. Method of extraction and resolubilization of pigments from Chlorociboria aeruginosa and Scytalidium cuboideum, two prolific spalting fungi. Coloration Technol. 2014, in press. [Google Scholar]

- Robinson, S.C.; Tudor, D.; Snider, H.; Cooper, P.A. Stimulating growth and xylindein production of Chlorociboria aeruginascens in agar-based systems. AMB Express 2012, 2. [Google Scholar] [CrossRef]

- Robinson, S.C.; Laks, P.E.; Turnquist, E.J. A method for digital color analysis of spalted wood using Scion Image software. Materials 2009, 2, 62–75. [Google Scholar]

- Von Arx, J.A.; Nilsson, T. Xylogone sphaerospora, a new ascomycete from stored pulpwood chips. Sven Bot Tidskr 1969, 63, 345–348. [Google Scholar]

- Sigler, L.; Carmichael, J.W. Taxonomy of Malbranchea and some other Hyphomycetes with arthroconidia. Mycotaxon 1976, 4, 349–488. [Google Scholar]

- Sigler, L.; Carmichael, J.W. Redisposition of some fungi referred to Oidium microspermum and a review of Arthrographis. Mycotaxon 1983, 18, 495–507. [Google Scholar]

- Wang, C.J.K.; Zabel, R.A. Identification Manual for Fungi from Utility Poles in the EasternUnited States; American Type Culture Collection: Rockville, MD, USA, 1999. [Google Scholar]

- Robinson, S.C.; Tudor, D.; Cooper, P.A. Wood preference by spalting fungi in urban hardwood species. Int. Biodeterior. Biodegradat. 2011, 65, 1145–1149. [Google Scholar] [CrossRef]

- PRA. Colour Consultancy. Available online: http://www.pra-world.com/technical_services/consultancy/colour (accessed on 27 April 2014).

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Robinson, S.C.; Hinsch, E.; Weber, G.; Leipus, K.; Cerney, D. Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes. Materials 2014, 7, 5427-5437. https://doi.org/10.3390/ma7085427

Robinson SC, Hinsch E, Weber G, Leipus K, Cerney D. Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes. Materials. 2014; 7(8):5427-5437. https://doi.org/10.3390/ma7085427

Chicago/Turabian StyleRobinson, Sara C., Eric Hinsch, Genevieve Weber, Kristina Leipus, and Daniel Cerney. 2014. "Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes" Materials 7, no. 8: 5427-5437. https://doi.org/10.3390/ma7085427

APA StyleRobinson, S. C., Hinsch, E., Weber, G., Leipus, K., & Cerney, D. (2014). Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes. Materials, 7(8), 5427-5437. https://doi.org/10.3390/ma7085427