New Polylactic Acid Composites Reinforced with Artichoke Fibers

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

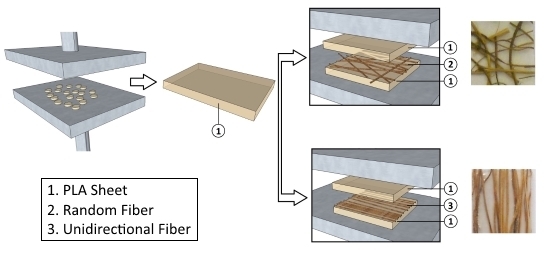

2.2. Composite Preparation

2.3. Characterization

3. Results and Discussion

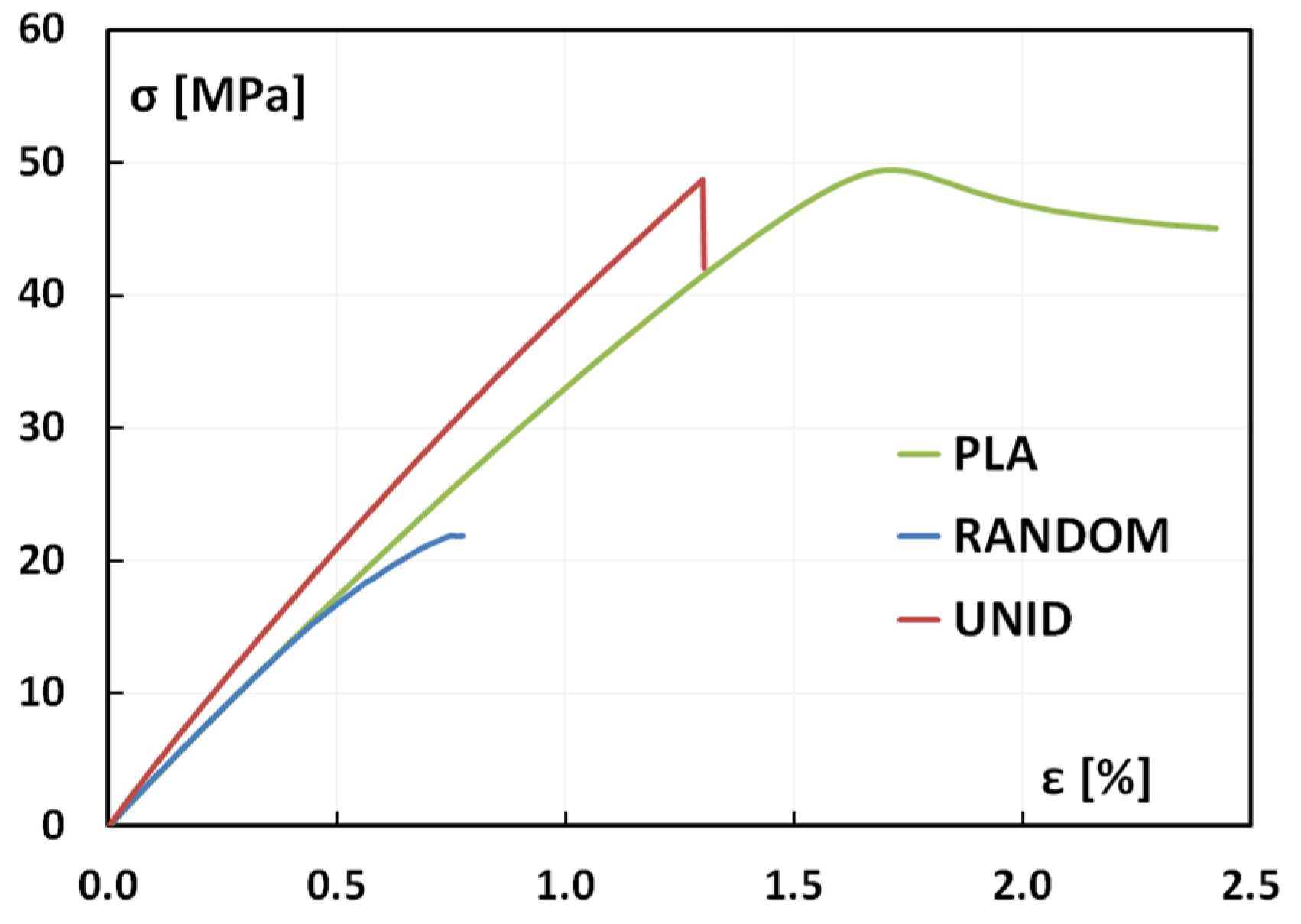

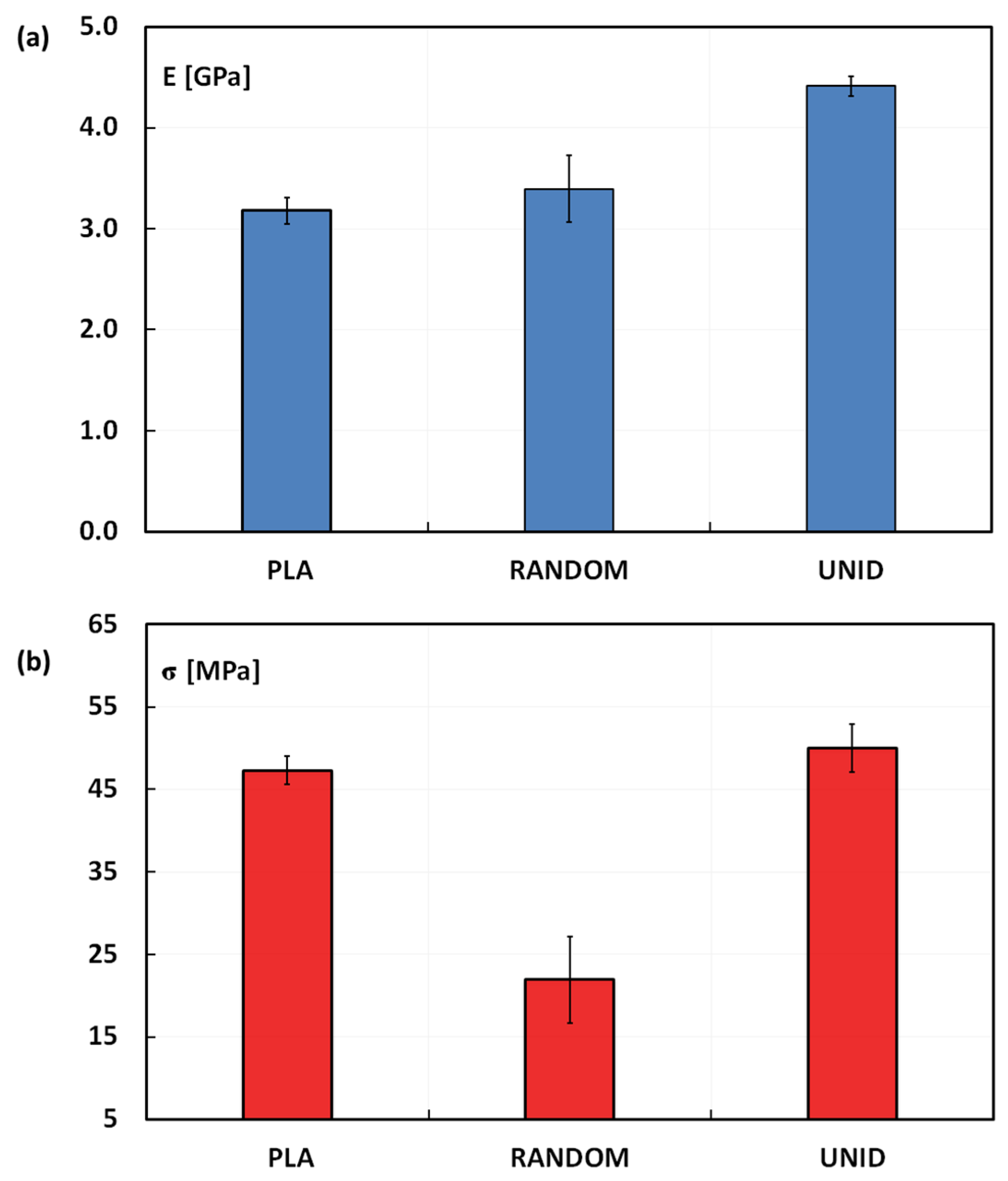

3.1. Experimental Results

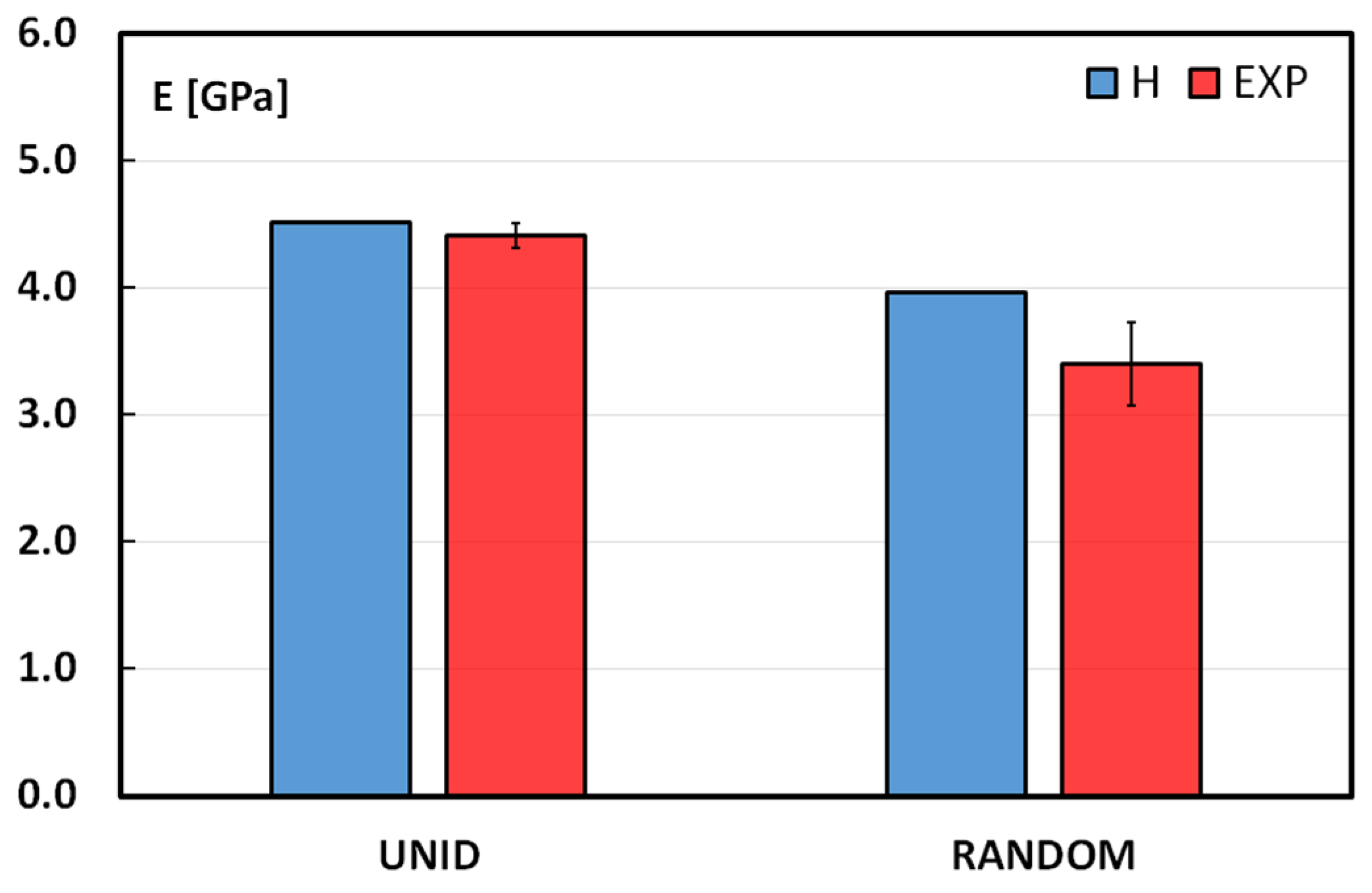

3.2. Hill’s Method for Tensile Modulus Prediction

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Scalici, T.; Fiore, V.; Orlando, G.; Valenza, A. A DIC-based study of flexural behaviour of roving/mat/roving pultruded composites. Compos. Struct. 2015, 131, 82–89. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Biagiotti, J.; Puglia, D.; Torre, L.; Kenny, J.M.; Arbelaiz, A.; Cantero, G.; Marieta, C.; Llano-Ponte, R.; Mondragòn, I. A systematic investigation on the influence of the chemical treatment of natural fibers on the properties of their polymer matrix composites. Polym. Compos. 2004, 25, 470–479. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Das, S.; Saha, A.K.; Choudhury, P.H.; Basak, R.K.; Mitra, B.C.; Todd, T.; Lang, S.; Rowell, R.M. Effect of steam pretreatment of jute fiber on dimensional stability of jute composite. J. Appl. Polym. Sci. 2000, 76, 1652–1661. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Durmuşkahya, C. Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos. B Eng. 2013, 44, 517–523. [Google Scholar] [CrossRef]

- Sarikanat, M.; Seki, Y.; Sever, K.; Durmuşkahya, C. Determination of properties of Althaea officinalis L. (marshmallow) fibres as a potential plant fibre in polymeric composite materials. Compos. B Eng. 2014, 57, 180–186. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Artichoke (Cynara cardunculus L.) fibres as potential reinforcement of composite structures. Compos. Sci. Technol. 2011, 71, 1138–1144. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Botta, L.; Morreale, M.; Scaffaro, R. Effect of small amounts of poly(lactic acid) on the recycling of poly(ethylene terephthalate) bottles. Polym. Degrad. Stab. 2012, 97, 21–24. [Google Scholar] [CrossRef]

- Botta, L.; Mistretta, M.C.; Palermo, S.; Fragala, M.; Pappalardo, F. Characterization and processability of blends of polylactide acid with a new biodegradable medium-chain-length polyhydroxyalkanoate. J. Polym. Environ. 2015, 23, 478–486. [Google Scholar] [CrossRef]

- Fiore, V.; Botta, L.; Scaffaro, R.; Valenza, A.; Pirrotta, A. PLA based biocomposites reinforced with Arundo donax fillers. Compos. Sci. Technol. 2014, 105, 110–117. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Passaglia, E.; Oberhauser, W.; Frediani, M.; di Landro, L. Comparison of different processing methods to prepare poly(lactid acid)-hydrotalcite composites. Polym. Eng. Sci. 2013, 54, 1804–1810. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Zhou, X.; Hong, J.; Zhuang, X.; Yan, X. Mechanical properties of unidirectional continuous fiber self-reinforced polyethylene graded laminates. Polym. Compos. 2015, 36, 128–137. [Google Scholar] [CrossRef]

- Charlet, K.; Béakou, A. Mechanical properties of interfaces within a flax bundle—Part I: Experimental analysis. Int. J. Adhes. Adhes. 2011, 31, 875–881. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous palmyra palm leaf stalk fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Martinez-Hernandez, A.L.; Velasco-Santos, C.; de Icaza, M.; Victor, M.C. Dynamic mechanical and thermal analysis of polymeric composites reinforced with keratin biofibers from chicken feathers. Compos. B Eng. 2007, 38, 405–410. [Google Scholar] [CrossRef]

- Manikandan Nair, K.C.; Thomas, S.; Groeninckx, G. Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos. Sci. Technol. 2001, 61, 2519–2529. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. The effect of silane treated- and untreated-talc on the mechanical and physico-mechanical properties of poly(lactic acid)/newspaper fibers/talc hybrid composites. Compos. Sci. Technol. 2007, 38, 367–379. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botta, L.; Fiore, V.; Scalici, T.; Valenza, A.; Scaffaro, R. New Polylactic Acid Composites Reinforced with Artichoke Fibers. Materials 2015, 8, 7770-7779. https://doi.org/10.3390/ma8115422

Botta L, Fiore V, Scalici T, Valenza A, Scaffaro R. New Polylactic Acid Composites Reinforced with Artichoke Fibers. Materials. 2015; 8(11):7770-7779. https://doi.org/10.3390/ma8115422

Chicago/Turabian StyleBotta, Luigi, Vincenzo Fiore, Tommaso Scalici, Antonino Valenza, and Roberto Scaffaro. 2015. "New Polylactic Acid Composites Reinforced with Artichoke Fibers" Materials 8, no. 11: 7770-7779. https://doi.org/10.3390/ma8115422

APA StyleBotta, L., Fiore, V., Scalici, T., Valenza, A., & Scaffaro, R. (2015). New Polylactic Acid Composites Reinforced with Artichoke Fibers. Materials, 8(11), 7770-7779. https://doi.org/10.3390/ma8115422