Improved Tribological Performance of Amorphous Carbon (a-C) Coating by ZrO2 Nanoparticles

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Lubricants

2.2. Tribological Evaluation

2.3. Surface Analysis

3. Results and Discussion

3.1. Tribological Results

3.2. The Synergetic Lubricating Mechanism between a-C and ZrO2-NPs

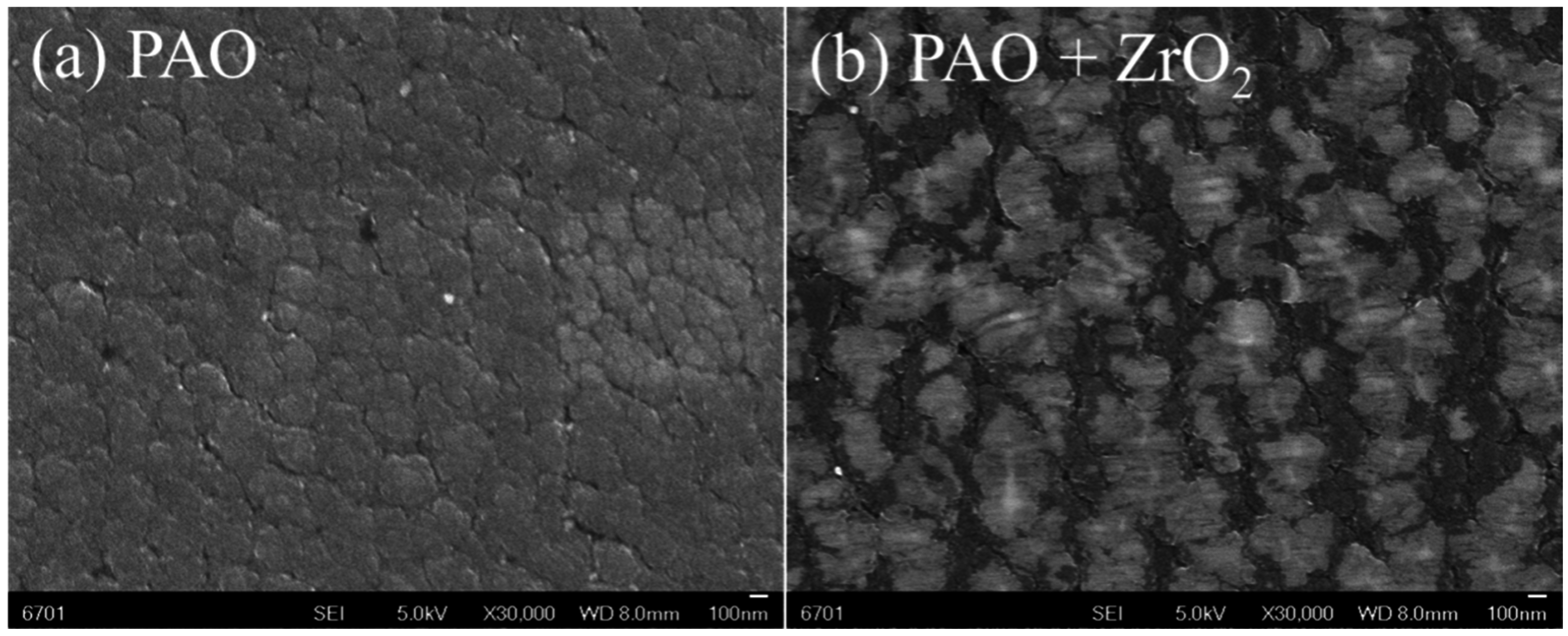

3.2.1. The Characterizations of the Residual ZrO2-NPs on the Worn a-C Surface

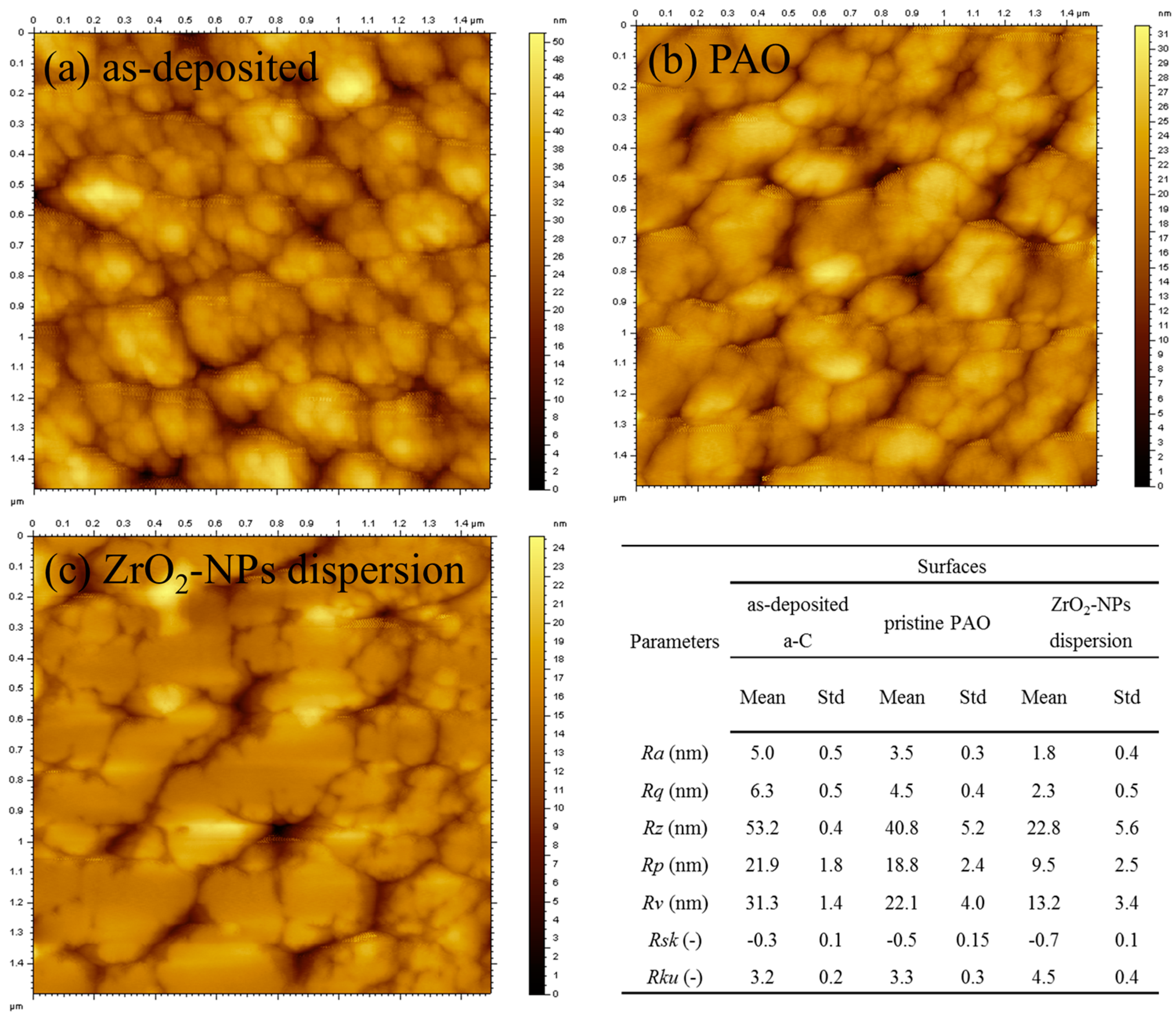

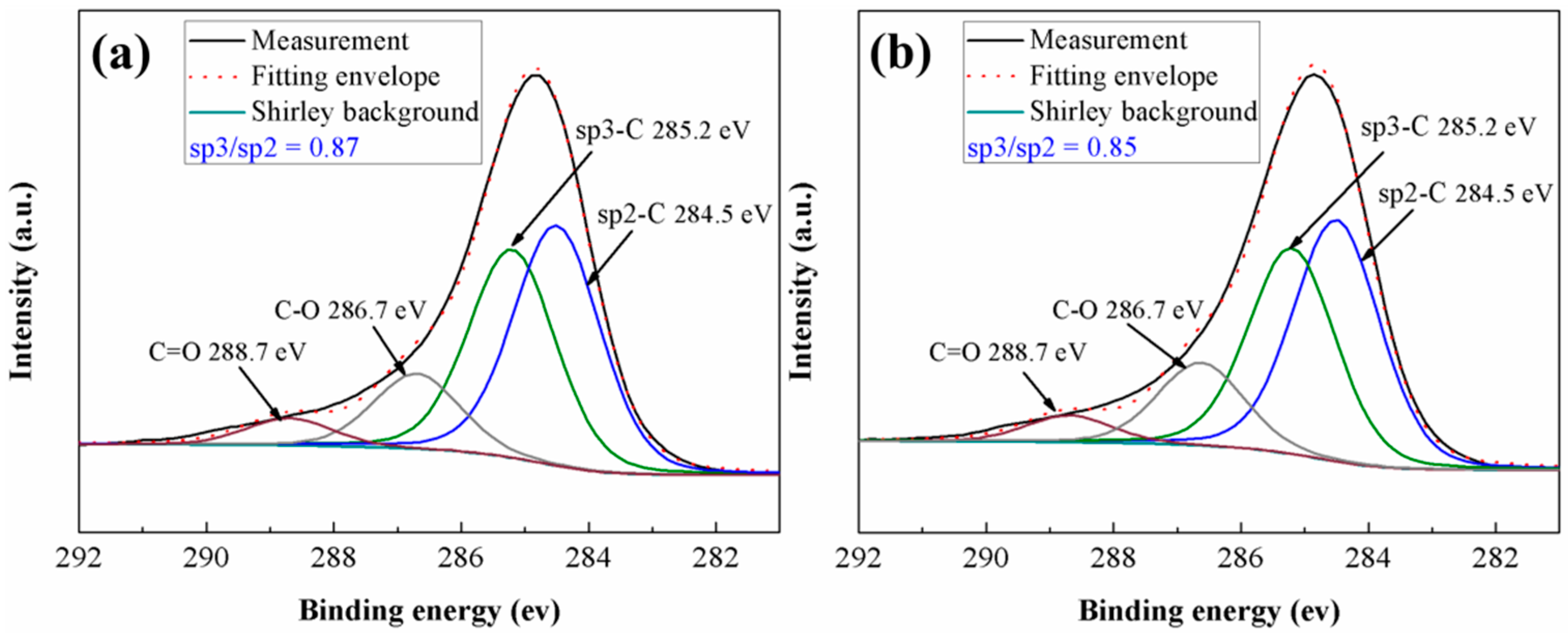

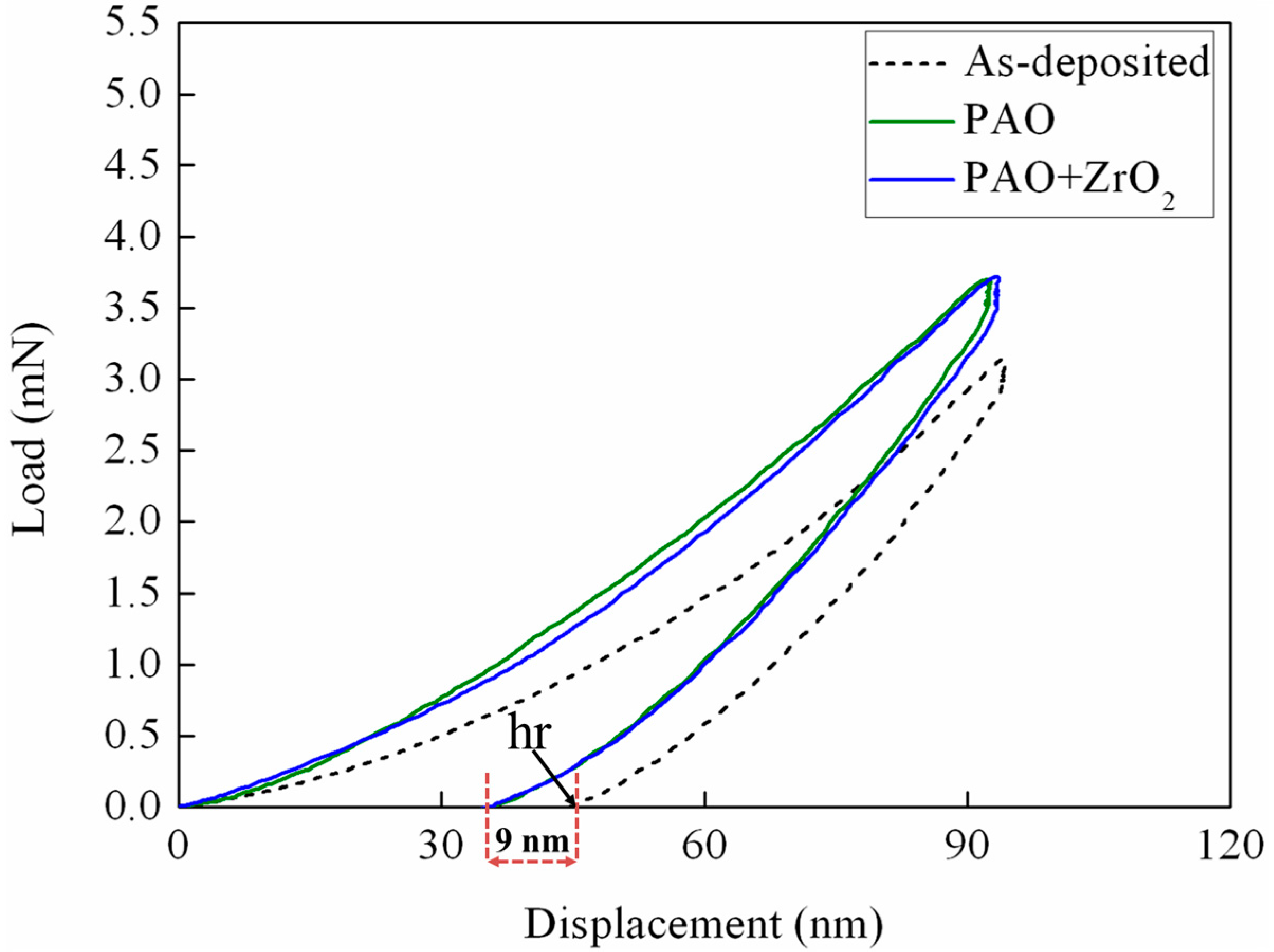

3.2.2. The Characterizations of the Worn a-C Surfaces

3.3. The Tribological Mechanism of ZrO2-NPs in a-C Contacts

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| a-C | Amorphous carbon |

| DLC | Diamond-like carbon |

| ZrO2-NPs | Nanoparticles of zirconia |

| Std | Standard deviation |

| Ra | Arithmetic mean deviation of the profile |

| Rq | Root mean square deviation of the profile |

| Rz | Maximum height of the profile |

| Rp | Maximum profile peak height |

| Rv | Maximum profile valley depth |

| Rsk | Skewness of the profile height distribution |

| Rku | Kurtosis of the profile height distribution |

| hr | Residual depth after completed unloading |

References

- Kalin, M.; Velkavrh, I.; Vižintin, J.; Ožbolt, L. Review of boundary lubrication mechanisms of DLC coatings used in mechanical applications. Meccanica 2008, 43, 623–637. [Google Scholar] [CrossRef]

- Kano, M. DLC coating technology applied to sliding parts of automotive engine. New Diam. Front. Carbon Coat. 2006, 16, 201–210. [Google Scholar]

- Erdemir, A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol. Int. 2005, 38, 249–256. [Google Scholar] [CrossRef]

- Kalin, M.; Vizintin, J.; Barriga, J.; Vercammen, K.; van Acker, K.; Arnsek, A. The effect of doping elements and oil additives on the tribological performance of boundary-lubricated DLC/DLC contacts. Tribol. Lett. 2004, 17, 679–688. [Google Scholar] [CrossRef]

- Neville, A.; Morina, A.; Haque, T.; Voong, M. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 2007, 40, 1680–1695. [Google Scholar] [CrossRef]

- Equey, S.; Roos, S.; Mueller, U.; Hauert, R.; Spencer, N.D.; Crockett, R. Tribofilm formation from ZnDTP on diamond-like carbon. Wear 2008, 264, 316–321. [Google Scholar] [CrossRef]

- Topolovec-Miklozic, K.; Lockwood, F.; Spikes, H. Behaviour of boundary lubricating additives on DLC coatings. Wear 2008, 265, 1893–1901. [Google Scholar] [CrossRef]

- Kalin, M.; Roman, E.; Ozbolt, L.; Vizintin, J. Metal-doped (Ti, WC) diamond-like-carbon coatings: Reactions with extreme-pressure oil additives under tribological and static conditions. Thin Solid Films 2010, 518, 4336–4344. [Google Scholar] [CrossRef]

- Tasdemir, H.A.; Wakayama, M.; Tokoroyama, T.; Kousaka, H.; Umehara, N.; Mabuchi, Y.; Higuchi, T. The effect of oil temperature and additive concentration on the wear of non-hydrogenated DLC coating. Tribol. Int. 2014, 77, 65–71. [Google Scholar] [CrossRef]

- Tang, J.; Ding, Q.; Zhang, G.; Hu, L. The Influence of Total Acid Number of Ester Oil in Tribological Behavior of DLC Contacts. Tribol. Trans. 2015, 58, 849–858. [Google Scholar] [CrossRef]

- Kalin, M. Designing tribological interface for efficient and green DLC lubrication: The role of coatings and lubricants. Tribol. Online 2012, 7, 112–118. [Google Scholar] [CrossRef]

- Kalin, M. Traditional problems, yet new challenges, in lubrication science. Lubr. Sci. 2013, 25, 249–250. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovsek, J.; Remskar, M. Nanoparticles as novel lubricating additives in a green, physically based lubrication technology for DLC coatings. Wear 2013, 303, 480–485. [Google Scholar] [CrossRef]

- Kogovsek, J.; Remskar, M.; Kalin, M. Lubrication of DLC-coated surfaces with MoS2 nanotubes in all lubrication regimes: Surface roughness and running-in effects. Wear 2013, 303, 361–370. [Google Scholar] [CrossRef]

- Zeng, Q.; Yu, F.; Dong, G. Superlubricity behaviors of Si3N4/DLC Films under PAO oil with nano boron nitride additive lubrication. Surf. Interface Anal. 2013, 45, 1283–1290. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovsek, J.; Kovac, J.; Remskar, M. The Formation of Tribofilms of MoS2 Nanotubes on Steel and DLC-Coated Surfaces. Tribol. Lett. 2014, 55, 381–391. [Google Scholar] [CrossRef]

- Kogovsek, J.; Kalin, M. Various MoS2-, WS2- and C-Based Micro- and Nanoparticles in Boundary Lubrication. Tribol. Lett. 2014, 53, 585–597. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, J.; Wang, L.; Xue, Q. Frictional dependence of graphene and carbon nanotube in diamond-like carbon/ionic liquids hybrid films in vacuum. Carbon 2014, 80, 734–745. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, J.; Wang, L.; Xue, Q. Synergistic Effect of Hybrid Carbon Nanotube-Graphene Oxide as Nanoadditive Enhancing the Frictional Properties of Ionic Liquids in High Vacuum. ACS Appl. Mater. Interfaces 2015, 7, 8592–8600. [Google Scholar] [CrossRef] [PubMed]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M.; Popovitz-Biro, R.; Feldman, Y.; Tenne, R. Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Kato, H.; Komai, K. Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear 2007, 262, 36–41. [Google Scholar] [CrossRef]

- Battez, A.H.; Gonzalez, R.; Viesca, J.L.; Fernandez, J.E.; Fernandez, J.M.D.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Wang, H.; Feng, D. The anti-seizure effect of Ag nanoparticles additive in multialkylated cyclopentanes oil under vacuum condition. Tribol. Int. 2012, 55, 1–6. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Feng, D.; Wang, H. Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 2013, 87, 75–80. [Google Scholar] [CrossRef]

- Guo, D.; Xie, G.; Luo, J. Mechanical properties of nanoparticles: Basics and applications. J. Phys. D Appl. Phys. 2014, 47, 013001. [Google Scholar] [CrossRef]

- Tomala, A.; Vengudusamy, B.; Ripoll, M.R.; Suarez, A.N.; Remskar, M.; Rosentsveig, R. Interaction Between Selected MoS2 Nanoparticles and ZDDP Tribofilms. Tribol. Lett. 2015, 59, 1–18. [Google Scholar] [CrossRef]

- Kaplan-Ashiri, I.; Tenne, R. On the Mechanical Properties of WS2 and MoS2 Nanotubes and Fullerene-Like Nanoparticles: In Situ Electron Microscopy Measurements. JOM 2016, 68, 151–167. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by graphene nanoscroll formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef] [PubMed]

- Alazemi, A.A.; Etacheri, V.; Dysart, A.D.; Stacke, L.-E.; Pol, V.G.; Sadeghi, F. Ultrasmooth Submicrometer Carbon Spheres as Lubricant Additives for Friction and Wear Reduction. ACS Appl. Mater. Interfaces 2015, 7, 5514–5521. [Google Scholar] [PubMed]

- Sun, Y.; Wu, H.; Li, M.; Meng, Q.; Gao, K.; Lü, X.; Liu, B. The Effect of ZrO2 Nanoparticles on the Microstructure and Properties of Sintered WC–Bronze-Based Diamond Composites. Materials 2016, 9, 343. [Google Scholar]

- Cui, L.; Lu, Z.; Wang, L. Toward low friction in high vacuum for hydrogenated diamondlike carbon by tailoring sliding interface. ACS Appl. Mater. Interfaces 2013, 5, 5889–5893. [Google Scholar] [CrossRef] [PubMed]

- Stachowiak, G.W.; Batchelor, A.W. Elastohydrodynamic lubrication. In Engineering Tribology, 3rd ed.; Elsevier: Oxford, UK, 2005; pp. 287–362. [Google Scholar]

- Archard, J.F.; Hirst, W. The wear of metals under unlubricated conditions. In Proceedings of the Royal Society of London Series a-Mathematical and Physical Sciences, London, UK, 2 August 1956; Volume 236, pp. 397–410.

- Yonezawa, H.; Lee, K.-H.; Murase, K.; Sugimura, H. Self-assembled Multilayer Formed by Alternate Stacking of Zirconium and Terephthalic Acid Layers. Chem. Lett. 2006, 35, 1392–1393. [Google Scholar] [CrossRef]

- Du, W.; Zhang, Y.; Wang, Y.; Liu, J.; Lu, H.; Hou, S.; Zhang, X. Designing synthesis and photocatalytic activities of Gd/ZrO2 nanocomposite. J. Nanopart. Res. 2014, 16, 1–10. [Google Scholar] [CrossRef]

- Silinskas, M.; Grigonis, A. Low energy post-growth irradiation of amorphous hydrogenated carbon (a-C:H) films. Diam. Relat. Mater. 2002, 11, 1026–1030. [Google Scholar] [CrossRef]

- Popescu, A.; Stan, G.; Duta, L.; Nita, C.; Popescu, C.; Surdu, V.-A.; Husanu, M.-A.; Bita, B.; Ghisleni, R.; Himcinschi, C.; et al. The Role of Ambient Gas and Pressure on the Structuring of Hard Diamond-Like Carbon Films Synthesized by Pulsed Laser Deposition. Materials 2015, 8, 3284–3350. [Google Scholar] [CrossRef]

- Jao, J.-Y.; Han, S.; Yen, C.-C.; Liu, Y.-C.; Chang, L.-S.; Chang, C.-L.; Shih, H.-C. Bias voltage effect on the structure and property of the (Ti:Cu)-DLC films fabricated by cathodic arc plasma. Diam. Relat. Mater. 2011, 20, 123–129. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, L.; Wang, Y.; Wang, S.C.; Hu, L.; Xue, Q. Improved Tribological Behavior of DLC Films Under Water Lubrication by Surface Texturing. Tribol. Lett. 2011, 41, 439–449. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Libassi, A.; Tanner, B.K.; Stolojan, V.; Yuan, J.; Brown, L.M.; Rodil, S.E.; Kleinsorge, B.; Robertson, J. Density, sp(3) fraction, and cross-sectional structure of amorphous carbon films determined by X-ray reflectivity and electron energy-loss spectroscopy. Phys. Rev. B 2000, 62, 11089–11103. [Google Scholar] [CrossRef]

- Qi, J.; Wang, L.; Yan, F.; Xue, Q. The tribological performance of DLC-based coating under the solid-liquid lubrication system with sand-dust particles. Wear 2013, 297, 972–985. [Google Scholar] [CrossRef]

| Item | Parameters |

|---|---|

| Coating method | Magnetron sputtering deposition |

| Carbon source | High-purity graphite |

| Intermediate layer | Cr |

| Base pressure | 1 × 10−3 Pa |

| Working pressure | Ar, 16 sccm, 0.12 Pa |

| Bias Voltage | −300 V: Cr intermediate layer |

| −70 V: a-C layer | |

| Target current | 3.0 A: Cr target |

| 3.5 A: Graphite target | |

| Deposition time | 960 s: Cr intermediate layer |

| 18,000 s: a-C layer |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Ding, Q.; Zhang, S.; Wu, G.; Hu, L. Improved Tribological Performance of Amorphous Carbon (a-C) Coating by ZrO2 Nanoparticles. Materials 2016, 9, 795. https://doi.org/10.3390/ma9100795

Tang J, Ding Q, Zhang S, Wu G, Hu L. Improved Tribological Performance of Amorphous Carbon (a-C) Coating by ZrO2 Nanoparticles. Materials. 2016; 9(10):795. https://doi.org/10.3390/ma9100795

Chicago/Turabian StyleTang, Jinzhu, Qi Ding, Songwei Zhang, Guizhi Wu, and Litian Hu. 2016. "Improved Tribological Performance of Amorphous Carbon (a-C) Coating by ZrO2 Nanoparticles" Materials 9, no. 10: 795. https://doi.org/10.3390/ma9100795

APA StyleTang, J., Ding, Q., Zhang, S., Wu, G., & Hu, L. (2016). Improved Tribological Performance of Amorphous Carbon (a-C) Coating by ZrO2 Nanoparticles. Materials, 9(10), 795. https://doi.org/10.3390/ma9100795