Composite and Nanocomposite Metal Foams

Abstract

:1. Introduction

2. Composite Metal Foams

2.1. Metal Foams Reinforced with Ceramic Particles

| Reference | Metal | Ceramic Particle | Manufacturing | Test Conditions | Conclusions |

|---|---|---|---|---|---|

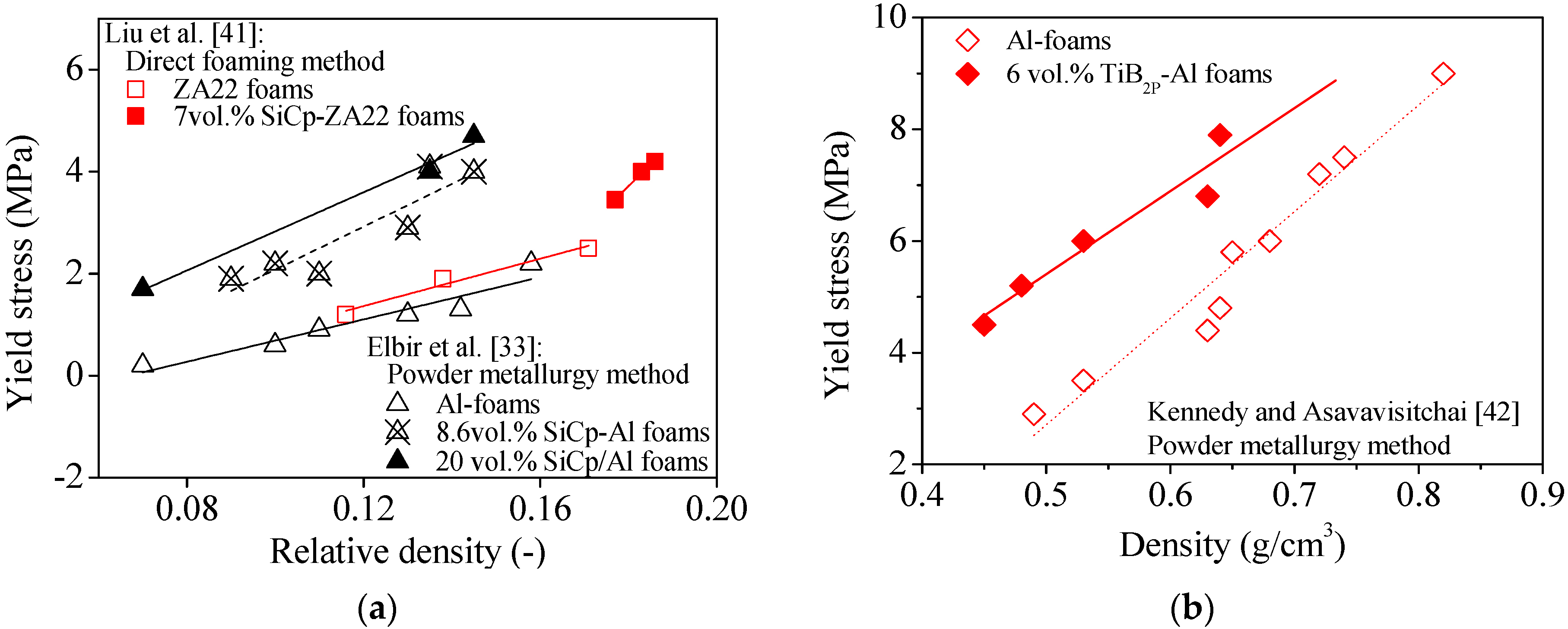

| Elbir et al. [33] | Al | SiC 8.6–20 vol.% Size: 22 μm | Powder Metallurgy Al-powder: <74 μm TiH2-powder: <37 μm | Φ 20 mm × 20 mm Compression: Quasi-static 0.1 mm·s−1 | In comparison to non-reinforced Al foams, SiCp particles reduce the drainage and cell coarsening phenomena, increase linear expansion and compressive strength of Al foams, but induce fluctuations in the plateau region of stress-strain curves and accentuate the brittle behavior of composite foams. |

| Esmaeelzadeh et al. [34] | AlSi7 | SiC up to 10 vol.% Size: 3–16 μm | Powder metallurgy Al powder: <160 μm Si powder: <150 μm TiH2-powder: <63 μm | Φ 30 mm × 40 mm Compression: Quasi-static 1.1 × 10−3 s−1 | Increasing the added amounts of SiCp or decreasing their size reduce the drainage but lead to less homogeneous foam structures. The compressive properties and energy absorption efficiency are degraded due to an accentuation of brittleness in comparison to non-reinforced AlSi7 foams. |

| Kennedy and Asavavisitchai [42] | Al | TiB2 Size: 10 μm 6 vol.% | Powder metallurgy Al powder: 48 μm TiH2 powder: 33 μm | Φ 22 mm × 24 mm Compression: Quasi-static 0.5 mm·min−1 | TiB2 particles significantly enhance the maximum foam expansion but did improve the long-term stability of the foams due to their poor wetting by the molten Al, as evidenced by particles protruding the cell-walls into the gas phase. The stress-strain curves in plateau region are smooth and characterized by a slightly increasing slope, irrespective of the presence or the absence of reinforcement. The maximum yield stress is achieved for TiB2-Al composite foams. |

| Guden and Yuksel [35] | Al | SiC 0–20 vol.% Size: 22 μm | Powder metallurgy Al powder: 34.64 μm TiH2 powder: <37 μm | Φ 13 mm × 13 mm Compression: Quasi-static 3 × 10−3 s−1 | SiCp increase the linear foam expansion by increasing the bulk viscosities. The composite SiCp-Al foams are more brittle in comparison to with Al-foams. |

| Alizadeh and Mirzaei-Aliabadi [30] | Al | Al2O3 Size: 10 μm 0–10 vol.% | Space-holder Al-powder Carbamide: 1.2 mm Ethanol: 1–3 wt.% | Φ 25 mm × 30 mm Compression Quasi-static 0.1 mm·s−1 | Increasing volume fractions of Al2O3p enhance the Young’s modulus and the compressive strength of the composite foams in extends that depend on the porosity fraction. For a given porosity fraction, the plateau region of composite foams is less smooth and shorter than for the Al-foam. The plateau stress and energy absorption capacity increase with Al2O3p content increasing up to 2 vol.%, but this trend is reversed for higher volume fractions. However, contrarily to other literature reports [34,41], the energy absorption efficiency of the composite foams is always higher than that of non-reinforced Al-foams. |

| Luo et al. [36] | AlSi9Mg | SiC 4 vol.% Size: 28 μm | Infiltration process AlSi9 alloy NaCl (0.9–4 mm in size) | 15 mm × 15 mm × 35 mm Compression Quasi-static 10−3 s−1 | SiCp increase yield stress and energy absorption capacity of composite foams increase. Stress-strain curves of composite foams are less smooth than as than those of non-reinforced foams. |

| Zhao et al. [43] | Al | Y2O3 0.3–1.2 wt.% Size: 50 μm | Space holder Al powder NaCl particles: 0.66–0.90 mm | 12.8 mm × 6.5 mm × 35 mm Compression Quasi-static 3 mm·min−1 | Volume fractions of Y2O3p up to 0.8 wt.% enhance bending strength up to a maximum of 20.4 MPa, a trend that is reversed for further added amounts, while the maximum micro hardness is achieved within the range of 0.5–0.8 wt.%. |

| Reference | Metal | Ceramic Particle | Manufacturing | Test Conditions | Conclusions |

|---|---|---|---|---|---|

| Liu et al. [41] | Zn-22Al | SiC Size: 28 μm 7 vol.% | Direct melt foaming ZA22 alloy ingot CaCO3: 44 μm | 15 mm × 15 mm × 30 mm Compression Quasi-static (2.2 × 10−3 s−1) | SiCp accentuate the brittleness and enhanced the stress fluctuations within the plateau region of composite foams. The energy absorption capacity is slightly improved but the energy absorption efficiency is degraded in comparison to non-reinforced foams. |

| Luo et al. [37] | AlSi9Mg | SiC Size: 28 μm 0–20 vol.% | Direct melt foaming AlSi9Mg alloy CaCO3: 44 μm | 15 mm × 15 mm × 35 mm Compression Quasi-static (10−3 s−1) | The same conclusions as above [41]. At a given relative density, yield and collapsing stresses of composite foams increase with increasing SiCp volume fraction. |

| Yu et al. [38] | Zn-22Al | SiC Size: 28 μm 10 vol.% | Direct melt foaming ZA22-powder: 40 μm CaCO3: 44 μm | 15 mm × 15 mm × 30 mm Compression Quasi-static (2.2 × 10−3 s−1) Φ 70 mm × 10 mm Damping (400 Hz) | The same conclusions as above [37,41]. The damping capacity of composite foams is slightly higher than those of ZA22 alloy and ZA22 foams. |

| Yu et al [39] | AlSi9Mg | SiC Size: 28 μm 10 vol.% | Direct melt foaming AlSi9Mg alloy CaCO3: 44 μm | 15 mm × 15 mm × 35 mm Compression Quasi-static 5 × 10−4–1 × 10−2 s−1 Φ 30 mm × 10 mm High strain rate (600; 1600 s−1) | The same conclusions as above concerning the effects of SiCp on the mechanical properties of composite foams [37,38,41]. The yield stress depends on both relative density and strain rate, being 10 MPa and 40 MPa for quasi static (<10−2 s−1) and dynamic (1600 s−1) loading conditions. |

| Dauod [32] | A359 | Al2O3 0–15 vol.% Size: 50–140 μm | Direct foaming CaCO3 | Compression Quasi-static 3 × 10−3 s−1 | Al2O3p enhance the uniformity of foam microstructure and the resulting compressive stress-strain curves of composite foams are smooth. The mechanical parameters increase almost linearly with increasing the volume fraction of Al2O3p. The energy absorbing capacity is not much sensitive to the volume fraction of Al2O3p up to 10 vol.%, increasing for higher contents. |

| Song et al. [44] | Al-3.7 Pct Si-0.18 Pct Mg | AlN | Solid/liquid reaction Master ingot | 10 mm × 10 mm × 10 mm Compression Quasi-static (1 mm·min−1) | AlNp reveal an effective reinforcing role increasing the mechanical properties of Al-alloy foams. Absence of stress oscillations in the plateau region of strain-stress curves of composite foams, similarly as observed for Al2O3p [32] and TiB2p [42] Al composite foams. |

| SiC Size | SiC (vol.%) | Yield Stress (MPa) | σ0.1 (MPa) | σ0.2 (MPa) | σ0.3 (MPa) | σ0.4 (MPa) |

|---|---|---|---|---|---|---|

| 3 μm | 0 | 1.13 | 1.13 | 1.38 | 1.41 | 1.50 |

| 3 | 1.58 | 1.33 | 1.72 | 1.75 | 1.88 | |

| 6 | 1.25 | 1.13 | 1.33 | 1.41 | 1.88 | |

| 16 μm | 3 | 1.25 | 1.0 | 1.25 | 1.38 | 1.58 |

2.2. Metal Foams Reinforced with Intermetallics

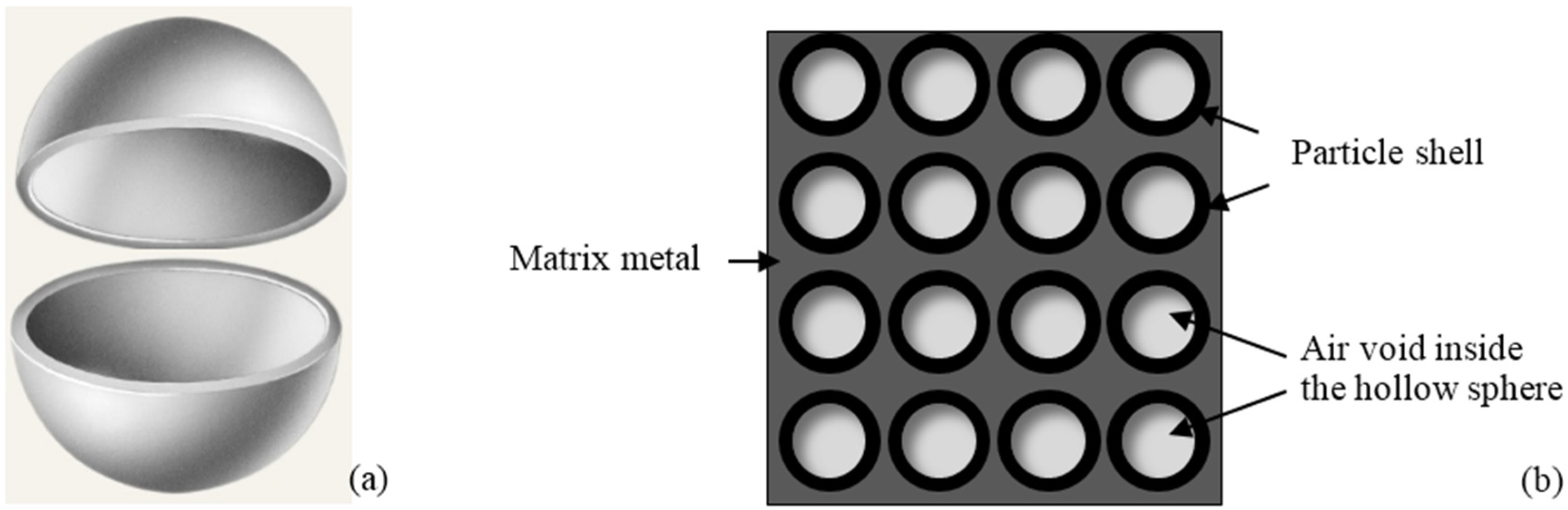

2.3. Composite Foams Reinforced with Hollow Spheres

| Reference | Syntactic Foam Type | Testing Conditions | Results |

|---|---|---|---|

| Licitra et al. [93] | Matrix: A356 alloy Particles: Al2O3, 3 mm diameter and 105 μm wall thickness | Compression Quasi-static (10−3 s−1) High (445–910 s−1) Dynamic Mechanical properties |

|

| |||

| |||

| Cox et al. [95] | Matrix: A356 alloy Particles: SiC,1 mm diameter and 70 μm wall thickness | Compression Quasi-static (10−3 s−1) High (up to1520 s−1) |

|

| |||

| |||

| Balch et al. [96] | Matrix: cp-Al, 7075alloy Particles: crystalline mullite and amorphous silica hollow microspheres | Compression Quasi-static (10−3 s−1) High (up to2300 s−1) |

|

| |||

| |||

| Orbulov et al. [97] | Matrix: Al99.5, AlSi12, AlMgSi1 and AlCu5 alloys Particles: ceramic hollow spheres with Al2O3, SiO2 and Mullite | Compression Quasi-static (free, 10−2 s−1) Quasi-static (Constrained, 10−2 s−1) |

|

| |||

| |||

| Goel et al. [98] | Matrix: Al-2014 Particles: Aluminum cenospheres, 90 μm and 200 μm diameter | Compression Quasi-static (10−3 s−1) High strain (up to1400 s−1) |

|

| |||

| Taherishargh et al. [117] | Matrix: A356 alloy Particles: Pumice, size range: 2.8–4 mm | Compression Quasi-static (3 mm·min−1) |

|

| |||

| Szlancski et al. [111] | Matrix: Al99.5, AlSi12, AlMgSi1 and AlCu5 alloys | Compression Quasi-static (0.01 s−1) |

|

|

| Reference | Syntactic Foam Type | Testing Conditions | Results |

|---|---|---|---|

| Neville and Rabiei [82] | Matrix: low carbon steel or stainless steel Particles: HS-low carbon steel (3.7–1.4 mm) or HS-stainless steel (2 mm) | Quasi-static |

|

| |||

| Castro and Nutt [83] | Matrix: steel Particles: steel or alumina | Compression at 8 × 10−4 s−1 |

|

| |||

| Castro and Nutt [84] | Matrix: steel Particles: steel or alumina | Compression at 8 × 10−4 s−1 |

|

| |||

| |||

| Peroni et al. [79,80] | Matrix: 99.7% pure iron Particles: S60HS (d 30 μm) or iM30 K (d 18 μm) glass hollow particles in 5, 10 and 13 wt.% | Quasi-static (10−2 s−1) Low(10–20 s−1) High (1000–2000 s−1) |

|

| |||

| |||

| Weise et al. [89] | Matrix: FeNi36 Particles: S60HS (d 30 μm) glass powders | Tension |

|

| |||

| |||

| Weise et al. [85] | Matrix: AI 316L Particles: S60HS (d 30 μm) glass hollow particles at 5.3 and 10 vol.%. | Compression, tension |

|

| |||

| Peroni et al. [86] | Matrix: AISI 316L Particles: glass microspheres S60HS (d 30 μm) glass hollow particles at 40 and 60 vol.% Fillite 106 cenospheres at 40 vol.% | Compression Quasi-static (10−2 s−1) Low(10–20 s−1) High (1000–2000 s−1) |

|

| |||

| |||

| Brown et al. [87] | Matrix: low carbon steel or stainless steel Particles: low carbon steel or stainless steel | Three-point bending |

|

| |||

| |||

| Vendra et al. [88] | Matrix: low carbon steel or stainless Steel Particles: low carbon steel or stainless steel | Compression– compression fatigue |

|

| |||

| Luong et al. [90] | Matrix: iron or FeNi36 Invar Particles: hollow glass microballoons (GMB)—5 and 10 wt.% | Compression Quasi-static 10−3 s−1 High (strain rates up to 2500 s−1) |

|

| |||

|

| Sample Property | MSFs | Hollow Sphere | Conventional Foams | ||||

|---|---|---|---|---|---|---|---|

| PM Carbon Steel | PM SS Foam | Al-LC Cast Foam | Al-SS Cast Foam | SS HSF | Al-Foam | Al-Foam | |

| Sphere OD (mm) | 3.7 | 2.0 | 3.7 | 3.7 | 2–3 | 3 | 3 |

| Wall thickness (mm) | 0.2 | 0.1 | 0.2 | 0.2 | 0.25 | – | – |

| Density (g·cm−3) | 3.06 | 2.95 | 2.43 | 2.45 | 1.4 | 0.4 | 0.24 |

| Relative density (%) | 38.9 | 37.5 | 42.5 | 42.5 | 17.8 | 14.8 | 8.9 |

| Plateau Stress (MPa) | 36.2 | 127 | 60 | 105 | 23 | 5 | 2.5 |

| Densification strain (%) | 54 | 54 | 57 | 57 | 60 | 68 | 50 |

| Strength/density | 12 | 43.7 | 24.4 | 43 | 16 | 12.5 | 10 |

| Energy absorption at densification (MJ·m−3) | 18.9 | 67.8 | 31 | 51 | 13 | 2.6 | 1.32 |

| Matrix | Filler Material | Filler Size | Filler Particle Density (g·cm−3) | MSFs Density (g·cm−3) | Plateau Stress (MPa) | References |

|---|---|---|---|---|---|---|

| Pure Al | Cenosphere | 90–150 μm | 1.00–1.74 | 1.52–1.43 | 63–42 | Wu et al. [121] |

| A356 | Cenosphere | 45–125 μm | 0.7 | 1.25–2.1 | 45–180 | Rohatgi et al. [122] |

| Pure Al | Ceramic HS: 45 SiO2-35 Al2O3-20 Mullite | 100–1450 μm | 0.57–0.81 | 1.43–1.49 | 77 | Orbulov and Ginsztler [123] |

| Pure Al | Ceramic HS: 60 SiO2-40 Al2O3-20 Mullite | 250–500 μm | 0.75 | 1.38 | 62 | Zhang and Zhao [124] |

| Pure Al | Ceramic HS: 60 SiO2-40 Al2O3-20 Mullite | 75–125 μm | 0.6 | 1.45 | 92 | Tao and Zhao [109] |

| A356 | Ceramic HS: SiC | 1 mm | 1.160 | 1.819 | 110 | Luong et. al [94] |

| A356 | Ceramic HS: Alumina | 3 mm | – | 1.6–2.11 | 62.8 | Licitra et al. [93] |

| Pure Al | Glass HS: 60 SiO2-40 Al2O3-15 CaO-Na2O | 0.5–4 mm | 0.95–0.65 | 1.58–1.88 | 42 | Zhang and Zhao [124] |

| A35 | Expanded Perlite | 3–4 mm | 0.18 | 1.05 | 45 | Fiedler et al. [100] |

| A356 | Pumice | 2.8–4 mm | 0.76–0.80 | 1.48–1.50 | 64–76 | Taherishargh et al. [117] |

| Al 99.5 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.41 | 35–39 | Szlancski et al. [111] |

| AlSi12 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.42 | 55–61 | Szlancski et al. [111] |

| AlMgSi1 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.60 | 54–70 | Szlancski et al. [111] |

| AlMgSi1-T6 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.60 | 75–91 | Szlancski et al. [111] |

| AlCu5 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.72 | 47–101 | Szlancski et al. [111] |

| AlCu5-T6 | Iron (Fe pure) HS | 1.92 ± 0.07 mm | 0.093 | 1.72 | 120–162 | Szlancski et al. [111] |

3. Nanocomposite Metal Foams

3.1. Metal Foams Reinforced with Ceramic Nanoparticles

3.2. Metal Foams Reinforced by Metal Deposition

3.3. Metal Foams Reinforced with Carbon Nanotubes

3.4. Metal Foams Reinforced with Short Fibres

3.5. Metal Foams Reinforced with Spinels

4. Future Directions

Conflicts of Interest

References

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams. A Design Guide, 1st ed.; Butterworth Heinemann: Woburn, MA, USA, 2000. [Google Scholar]

- Degischer, H.-P.; Kriszt, B. Handbook of Cellular Metals: Production, Processing, Applications; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2002. [Google Scholar]

- Banhart, J. Manufacture, Characterization and Application of Cellular Metals and Metal Foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Gibson, L.J.; Asbhy, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Banhart, J.; Seeliger, H.-W. Aluminium Foam Sandwich Panels: Manufacture, Metallurgy and Applications. Adv. Eng. Mater. 2008, 10, 793–802. [Google Scholar] [CrossRef]

- Lehmhus, D.; Busse, M.; Herrmann, A.S.; Kayvantash, K. Structural Materials and Processes in Transportation, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013. [Google Scholar]

- Duarte, I.; Teixeira-Dias, F.; Graça, A.; Ferreira, A.J.M. Failure Modes and Influence of the Quasi-static Deformation Rate on the Mechanical Behavior of Sandwich Panels with Aluminum Foam Cores. Mech. Adv. Mater. Struct. 2010, 17, 335–342. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Anžel, I.; Ferreira, J.M.F. Manufacturing and bending behaviour of in situ foam-filled aluminium alloy tubes. Mater. Des. 2015, 66, 532–544. [Google Scholar] [CrossRef]

- Nia, A.A.; Hamedani, J.H. Comparative analysis of energy absorption and deformations of thin walled tubes with various section geometries. Thin Walled Struct. 2010, 48, 946–954. [Google Scholar]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L. Static and dynamic axial crush performance of in-situ foam-filled tubes. Compos. Struct. 2015, 124, 128–139. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, Z.; Cuitino, A.M.; Soboyejo, W.O. Effects of heat treatment on the compressive deformation behavior of open cell aluminum foams. Mater. Sci. Eng. A 2004, 386, 118–128. [Google Scholar]

- Yamada, Y.; Shimojima, K.; Sakaguchi, Y.; Mabuchi, M.; Nakamura, M.; Asahina, T. Effects of heat treatment on compressive properties of AZ91 Mg and SG91A Al foams with open-cell structure. Mater. Sci. Eng. A 2000, 280, 225–228. [Google Scholar] [CrossRef]

- Campana, F.; Pilone, D. Effect of heat treatments on the mechanical behavior of aluminium alloy foams. Scr. Mater. 2009, 60, 679–82. [Google Scholar] [CrossRef]

- Lehmhus, D.; Banhart, J. Properties of heat-treated aluminium foams. Mater. Sci. Eng. A 2003, 349, 98–110. [Google Scholar] [CrossRef]

- Xia, X.C.; Chen, X.W.; Zhang, Z.; Chen, X.; Zhao, W.M.; Liao, B.; Hur, B. Effects of porosity and pore size on the compressive properties of closed-cell Mg alloy foam. J. Magnes. Alloy. 2013, 1, 330–335. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, Z.; Zhao, N. Effect of pore size and relative density on the mechanical properties of open-cell aluminum foams. Scr. Mater. 2007, 56, 169–172. [Google Scholar] [CrossRef]

- Everett, R. Metal Matrix Composites: Processing and Interfaces; Elsevier: San Diego, CA, USA, 1991. [Google Scholar]

- Clyne, T.W.; Whiters, P.J. Metal Matrix Composites; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar]

- Tjong, S. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Harris, P. Carbon nanotube composites. Int. Mater. Rev. 2004, 49, 31–43. [Google Scholar] [CrossRef]

- Agarwal, A.; Bakshi, S.; Lahiri, D. Carbon Nanotubes-Reinforced Metal Matrix Composites; Taylor and Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Jin, I.; Kenny, L.D.; Sang, H. Lightweight Foamed Metal and Its Production. International Patent Application WO91/03578, 21 March 1991. [Google Scholar]

- Kaptay, G. Interfacial Criteria for ceramic stabilised metallic foams. In Proceedings of the 1st International Conference on Metal Foams and Porous Metal Structures (MetFoam′99), Bremen, Germany, 14–16 June 1999; Banhart, J., Ashby, M.F., Fleck, N.A., Eds.; MIT Verlag: Bremen, Germany, 1999; pp. 141–146. [Google Scholar]

- Thomas, M.; Kenny, L.D. Production of Particle-Stabilized Metal Foams. PCT Patent WO 94/017218, 21 January 1994. [Google Scholar]

- Zeppelin, F.; Hirscher, M.; Stanzick, H.; Banhart, J. Desorption of hydrogen from blowing agents used for foaming metals. Compos. Sci. Technol. 2003, 63, 2293–2300. [Google Scholar] [CrossRef]

- Gui, M.C.; Wang, D.B.; Wu, J.J.; Yuan, G.J.; Li, C.G. Deformation and damping behaviors of foamed Al-Si-SiCp composite. Mater. Sci. Eng. A 2000, 286, 282–288. [Google Scholar] [CrossRef]

- Banhart, J. Light-metal foams-history of innovation and technological challenges. Adv. Eng. Mater. 2013, 15, 82–111. [Google Scholar] [CrossRef]

- Alizadeh, M.; Mirzaei-Aliabadi, M. Compressive properties and energy absorption behavior of Al-Al2O3 composite foam synthesized by space-holder technique. Mater. Des. 2012, 35, 419–424. [Google Scholar] [CrossRef]

- Mahmutyazicioglu, N.; Albayrak, O.; Ipekoglu, M. Effects of alumina (Al2O3) addition on the cell structure and mechanical properties of 6061 foams. J. Mater. Res. 2013, 28, 2509–2519. [Google Scholar] [CrossRef]

- Daoud, A. Compressive response and energy absorption of foamed A359-Al2O3 particle composites. J. Alloy. Compd. 2009, 486, 597–605. [Google Scholar] [CrossRef]

- Elbir, S.; Yilmaz, S.; Toksoy, A.K.; Guden, M.; Hall, I.W. SiC-particulate aluminum composite foams Produced by powder compacts: Foaming and compression behavior. J. Mater. Sci. 2003, 38, 4745–4755. [Google Scholar] [CrossRef]

- Esmaeelzadeh, S.; Simchi, A.; Lehmhus, D. Effect of ceramic particle addition on the foaming behavior, cell structure and mechanical properties of P/M AlSi7 foam. Mater. Sci. Eng. A 2006, 424, 290–299. [Google Scholar] [CrossRef]

- Guden, M.; Yuksel, S. SiC-particulate aluminum composite foams produced from powder compacts: Foaming and compression behavior. J. Mater. Sci. 2006, 41, 4075–4084. [Google Scholar] [CrossRef]

- Luo, Y.; Yu, S.; Liu, J.; Zhu, X.; Luo, Y. Compressive property and energy absorption characteristic of open-cell. SiCp/AlSi9Mg composite foams. J. Alloy. Compd. 2010, 499, 227–230. [Google Scholar] [CrossRef]

- Luo, Y.; Yu, S.; Li, W.; Liu, J.; Wei, M. Compressive behavior of SiCp/AlSi9Mg composite foams. J. Alloy. Compd. 2008, 460, 294–298. [Google Scholar] [CrossRef]

- Yu, S.; Liu, J.; Luo, Y. Compressive behavior and damping property of ZA22/ SiCp composite foams. Mater. Sci. Eng. A 2007, 457, 325–328. [Google Scholar] [CrossRef]

- Yu, S.; Luo, Y.; Liu, J. Effects of strain rate and SiC particle on the compressive property of SiCp/AlSi9Mg composite foams. Mater. Sci. Eng. A 2008, 487, 394–399. [Google Scholar] [CrossRef]

- Prakash, O.; Sang, H.; Embury, J.D. Structure and properties of A1-SiC foam. Mater. Sci. Eng. A 1995, 199, 195–203. [Google Scholar] [CrossRef]

- Liu, J.; Yu, S.; Zhu, X.; Wei, M.; Li, S.; Luo, Y.; Liu, Y. Correlation between ceramic additions and compressive properties of Zn-22 Al matrix composite foams. J. Alloy. Compd. 2009, 476, 220–225. [Google Scholar] [CrossRef]

- Kennedy, A.R.; Asavavisitchai, S. Effects of TiB2 particle addition on the expansion, structure and mechanical properties of PM Al foams. Scr. Mater. 2004, 50, 115–119. [Google Scholar] [CrossRef]

- Zhao, N.Q.; Jiang, B.; Du, X.W.; Li, J.J.; Shi, C.S.; Zhao, W.X. Effect of Y2O3 on the mechanical properties of open-cell aluminium foams. Mater. Lett. 2006, 60, 1665–1668. [Google Scholar] [CrossRef]

- Song, Y.H.; Tane, M.; Ide, T.; Seimiya, Y.; Hur, B.Y.; Nakajima, H. Fabrication of Al-3.7 Pct Si-0.18 Pct Mg Foam Strengthened by AlN Particle Dispersion and its Compressive Properties. Metall. Mater. Trans. A 2010, 41, 2104–2111. [Google Scholar] [CrossRef]

- Heim, K.; Vinod-Kumar, G.S.; García-Moreno, F.; Rack, A.; Banhart, J. Stabilisation of aluminium foams and films by the joint action of dispersed particles and oxide film. Acta Mater. 2015, 99, 313–324. [Google Scholar] [CrossRef]

- Banhart, J. Metal foams: Production and stability. Adv. Eng. Mater. 2006, 8, 781–794. [Google Scholar] [CrossRef]

- Baumgärtner, F.; Duarte, I.; Banhart, J. Industrialization of powder compact foaming process. Adv. Eng. Mater. 2000, 2, 168–174. [Google Scholar] [CrossRef]

- Duarte, I.; Banhart, J. A study of aluminium foam formation—kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar] [CrossRef]

- Duarte, I.; Oliveira, M. Chapter 3. Aluminium Alloy Foams: Production and Properties. In Powder Metallurgy; Katsuyoshi, K., Ed.; InTech: Rijeka, Croatia, 2012; pp. 47–72. [Google Scholar]

- Duarte, I.M.A.; Banhart, J.; Ferreira, A.J.M.; Santos, M.J.G. Foaming around fastening elements. Mater. Sci. Forum 2006, 514–516, 712–717. [Google Scholar] [CrossRef]

- Kadoi, K.; Nakae, H. Relationship between Foam Stabilization and Physical Properties of Particles on Aluminum Foam Production. Mater. Trans. 2011, 52, 1912–1919. [Google Scholar] [CrossRef]

- Simone, A.E.; Gibson, L.J. Aluminum foams produced by liquid-state processes. Acta Mater. 1998, 46, 3109–3123. [Google Scholar] [CrossRef]

- Babcsán, N.; Leitlmeier, D.; Banhart, J. Metal foams—High temperature colloids Part I. Ex situ analysis of metal foams. Colloid. Surf. A Physicochem. Eng. Asp. 2005, 261, 123–130. [Google Scholar] [CrossRef]

- Markaki, A.E.; Clyne, T.W. The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater. 2001, 49, 1677–1686. [Google Scholar] [CrossRef]

- Amsterdam, E.; de Hosson, J.T.M.; Onck, P.R. Failure mechanisms of closed-cell aluminum foam under monotonic and cyclic loading. Acta Mater. 2006, 54, 4465–447. [Google Scholar] [CrossRef]

- Gergely, V.; Clyne, B. The FORMGRIP Process: Foaming of Reinforced Metals by Gas Release in Precursors. Adv. Eng. Mater. 2000, 2, 175–178. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Yang, D.H.; Ye, F.; Lu, Z.P. Effects of scandium additions on mechanical properties of cellular Al-based foams. Intermetallics 2012, 28, 71–76. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Ye, F.; Lu, Z.P.; Yang, D.H. Mechanical properties of cellular Al-0.2 wt.% Sc foams. In Proceedings of the 7th International Conference on Porous Metals and Metallic Foams (MetFoam2011), Busan, Korea, 18–21 September 2011; Hur, B.-Y., Kim, B.-K., Kim, S.-E., Hyun, S.-K., Eds.; GS Intervision: Seoul, Korea, 2012; pp. 301–306. [Google Scholar]

- Miyoshi, T.; Hara, S.; Mukai, T.; Higashi, K. Development of a Closed-cell Aluminum Alloy Foam with Enhancement of the Compressive Strength. Mater. Trans. 2001, 42, 2118–2123. [Google Scholar] [CrossRef]

- Miyoshi, T.; Nishi, S.; Furuta, S.; Hamada, T.; Yoshikawa, K. Current activities and new technologies of aluminium foam by melt route. In Proceedings of the 4th International Conference on Porous Metals and Metal Foaming Technology (MetFoam2005), Kyoto, Japan, 21–23 September 2005; Nakajima, H., Kanetake, N., Eds.; Japan Institute of Metals (JIMIC-4): Sendai, Japan, 2006; pp. 255–260. [Google Scholar]

- Shang, X.L.; Zhang, B.; Han, E.H.; Ke, W. The effect of 0.4 wt.% Mn addition on the localized corrosion behaviour of zinc in a long-term experiment. Electrochimica Acta 2012, 65, 294–304. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Doty, H.W.; Kaufman, M.J. The effects of Mn additions on the microstructure and mechanical properties of Al–Si–Cu casting alloys. Mater. Sci. Eng. A 2008, 488, 496–504. [Google Scholar] [CrossRef]

- Xia, X.; Feng, H.; Zhang, X.; Zhao, W. The compressive properties of closed-cell aluminum foams with different Mn additions. Mater. Des. 2013, 51, 797–802. [Google Scholar] [CrossRef]

- Davydov, V.G.; Rostova, T.D.; Zakharov, V.V.; Filatov, Y.A.; Yelagin, V.I. Scientific principles of making an alloying addition of scandium to aluminum alloys. Mater. Sci. Eng. A 2000, 280, 30–36. [Google Scholar] [CrossRef]

- Aguirre-Perales, L.Y.; Robin, A.L.; Jung, I-H. The Effect of In Situ Intermetallic Formation on Al-Sn Foaming Behavior. Metall. Mater. Trans. A 2014, 45, 3714–3727. [Google Scholar] [CrossRef]

- Yang, D.-H.; Yang, S.-R.; Ma, A.-B.; Jiang, J.-H. Compression properties of cellular AlCu5Mn alloy foams with wide range of porosity. J. Mater. Sci. 2009, 44, 5552–5556. [Google Scholar] [CrossRef]

- Aguirre-Perales, L.Y.; Jung, I.-H.; Drew, R.A.L. Foaming Behaviour of Metallurgical Al-Sn Foams. Acta Mater. 2012, 60, 759–769. [Google Scholar] [CrossRef]

- Park, S.-H.; Hur, B.-Y.; Kim, S.-Y.; Ahn, D.-K; Ha, D.-I. A study on the viscosity and surface tension for Al foaming and the effects of addition elements. In Proceedings of the 65th World Foundry Congress, Gyeongju, Korea, 20–24 October 2002; Hong, C.-P., Kim, D.-H., Kim, K.-Y., Eds.; pp. 515–523.

- Gokhale, A.A.; Sahu, S.N.; Kulkarni, V.K.; Sudhakar, B.; Rao, N.R. Materials issues in foaming of liquid aluminium. In Proceedings of the 4th International Conference on Porous Metals and Metal Foaming Technology (MetFoam2005), Kyoto, Japan, 21–23 September 2005; Nakajima, H., Kanetake, N., Eds.; Japan Institute of Metals (JIMIC-4): Sendai, Japan, 2006; pp. 95–100. [Google Scholar]

- Suzuki, S.; Murakami, H.; Kadoi, K.; Saiwai, T.; Nakae, H.; Babcsán, N. Aluminum foam fabrication through the melt route by adding Mg and Bi. In Proceedings of the 7th International Conference on Porous Metals and Metallic Foams (MetFoam2011), Busan, Korea, 18–21 September 2011; Hur, B.-Y., Kim, B.-K., Kim, S.-E., Hyun, S.-K., Eds.; GS Intervision: Seoul, Korea, 2012; pp. 3–6. [Google Scholar]

- Kim, S.Y.; Kang, K.H.; Um, Y.S.; Hur, B.Y. Foaming characteristics of Al-Mg alloy foam. In Proceedings of the 4th International Conference on Porous Metals and Metal Foaming Technology (MetFoam2005), Kyoto, Japan, 21–23 September 2005; Nakajima, H., Kanetake, N., Eds.; Japan Institute of Metals (JIMIC-4): Sendai, Japan, 2006; pp. 115–118. [Google Scholar]

- Helwig, H.-M.; Garcia-Moreno, F.; Banhart, J. A study of Mg and Cu additions on the foaming behaviour of Al-Si alloys. J. Mater. Sci. 2011, 46, 5227–5236. [Google Scholar] [CrossRef]

- Gupta, N.; Rohatgi, P.K. Metal Matrix Syntactic Foams: Processing, Microstructure, Properties and Applications; DEStech Publications, Inc.: Lancaster, PA, USA, 2015. [Google Scholar]

- Ochsner, A.; Augustin, A. Manufacturing, Properties and Application. In Multifunctional Metallic Hollow Sphere Structures; Springer-Verlag: Berlin, Germany, 2009. [Google Scholar]

- Rabiei, A.; O’Neill, A.T.; Neville, B.P. Processing and development of a new high strength metal foam. In Prpceedings of the Materials Research Society Symposium-(2004 MRS Fall Meeting & Exhibit), Boston, MA, USA, 28 November–2 December 2004; Chipara, M., Edwards, D.L., Benson, R.S., Phillips, S., Eds.; Cambridge University Press: Cambridge, UK, 2005; Volume 851, pp. 517–526. [Google Scholar]

- Rohatgi, P.K.; Daoud, A.; Schultz, B.F.; Puri, T. Microstructure and mechanical behavior of die casting AZ91D-fly ash cenosphere composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 883–896. [Google Scholar] [CrossRef]

- Gupta, N.; Luong, D.D.; Cho, K. Magnesium matrix composite foams-density, mechanical properties, and applications. Metals 2012, 2, 238–252. [Google Scholar] [CrossRef]

- Luong, D.; Gupta, N.; Rohatgi, P. The high strain rate compressive response of Mg-Al alloy/fly Ash cenosphere composites. JOM J. Miner. Met. Mater. Soc. 2011, 63, 48–52. [Google Scholar]

- Peroni, L.; Scapin, M.; Avalle, M.; Weise, J.; Lehmhus, D. Dynamic mechanical behavior of syntactic iron foams with glass microspheres. Mater. Sci. Eng. A 2012, 552, 364–375. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Avalle, M.; Weise, J.; Lehmhus, D.; Baumeister, J.; Busse, M. Syntactic iron foams—on deformation mechanisms and strain-rate dependence of compressive properties. Adv. Eng. Mater. 2012, 14, 909–918. [Google Scholar] [CrossRef]

- Weise, J.; Baumeister, J.; Yezerska, O.; Salk, N.; Silva, G.B.D. Syntactic iron foams with integrated microglass bubbles produced by means of metal powder injection moulding. Adv. Eng. Mater. 2010, 12, 604–608. [Google Scholar] [CrossRef]

- Neville, B.P.; Rabiei, A. Composite metal foams processed through powder metallurgy. Mater. Des. 2008, 29, 388–396. [Google Scholar] [CrossRef]

- Castro, G.; Nutt, S.R. Synthesis of syntactic steel foam using mechanical pressure infiltration. Mater. Sci. Eng. A 2012, 535, 274–280. [Google Scholar] [CrossRef]

- Castro, G.; Nutt, S.R. Synthesis of syntactic steel foam using gravity-fed infiltration. Mater. Sci. Eng. A 2012, 553, 89–95. [Google Scholar] [CrossRef]

- Weise, J.; Lehmhus, D.; Baumeister, J.; Kun, R.; Bayoumi, M.; Busse, M. Production and properties of 316L stainless steel cellular materials and syntactic foams. Steel Res. Int. 2014, 85, 486–497. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Fichera, C.; Lehmhus, D.; Weise, J.; Baumeister, J.; Avalle, M. Investigation of the mechanical behavior of AISI 316L stainless steel syntactic foams at different strain-rates. Compos. Part B Eng. 2014, 66, 430–442. [Google Scholar] [CrossRef]

- Brown, J.; Vendra, L.; Rabiei, A. Bending properties of Al-steel and steel-steel composite metal foams. Metall. Mater. Trans. A 2010, 41, 2784–2793. [Google Scholar] [CrossRef]

- Vendra, L.; Neville, B.; Rabiei, A. Fatigue in aluminum-steel and steel-steel composite foams. Mater. Sci. Eng. A 2009, 517, 146–153. [Google Scholar] [CrossRef]

- Weise, J.; Salk, N.; Jehring, U.; Baumeister, J.; Lehmhus, D.; Bayoumi, M.A. Influence of powder size on production parameters and properties of syntactic invar foams produced by means of metal powder injection moulding. Adv. Eng. Mater. 2013, 15, 118–122. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Lehmhus, D.; Weise, J.; Baumeister, J. Quasi-static and high strain rates compressive response of iron and Invar matrix syntactic foams. Mater. Des. 2015, 66, 516–531. [Google Scholar] [CrossRef]

- Xue, X.; Zhao, Y. Ti matrix syntactic foam fabricated by powder metallurgy: Particle breakage and elastic modulus. JOM J. Miner. Met. Mater. Soc. 2011, 63, 43–47. [Google Scholar]

- Mondal, D.P.; Datta-Majumder, J.; Jha, N.; Badkul, A.; Patel, A.; Gupta, G. Titanium cenosphere syntactic foam made through powder metallurgy route. Mater. Des. 2012, 34, 82–89. [Google Scholar] [CrossRef]

- Licitra, L.; Luong, D.D.; Strbik, O.M., III; Gupta, N. Dynamic properties of alumina hollow particle filled aluminum alloy A356 matrix syntactic foams. Mater. Des. 2015, 66, 504–515. [Google Scholar]

- Luong, D.D.; Strbik, O.M., III; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloy. Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Cox, J.; Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Strbik, O.M.; Cho, K. Dynamic and thermal properties of aluminumalloyA356/silicon carbide hollow particle syntactic foams. Metals 2014, 4, 530–548. [Google Scholar] [CrossRef]

- Balch, D.K.; O’Dwyer, J.G.; Davis, G.R.; Cady, C.M.; GrayIII, G.T.; Dunand, D.C. Plasticity and damage in aluminum syntactic foams deformed under dynamic and quasi-static conditions. Mater. Sci. Eng. A 2005, 391, 408–417. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Májlinger, K. Compressive properties of metal matrix syntactic foams in free and constrained compression. J. Miner. Met. Mater. Soc. 2014, 66, 882–891. [Google Scholar] [CrossRef] [Green Version]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. Des. 2012, 42, 418–423. [Google Scholar] [CrossRef]

- Sulong, M.A.; Taherisharsgh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the mechanical anisotropy of the compressive properties of aluminium perlite syntactic foam. Comput. Mater. Sci. 2015, 109, 258–265. [Google Scholar] [CrossRef]

- Fiedler, T.; Taherishargh, M.; Krstulović-Opara, L.; Vesenjak, M. Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater. Sci. Eng. A 2015, 626, 296–304. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the mechanical properties of heat-treated expanded perlite-aluminium syntactic foam. Mater. Des. 2014, 63, 375–383. [Google Scholar] [CrossRef]

- Mondal, D.P.; Jha, N.; Gull, B.; Das, S.; Badkul, A. Microarchitecture and compressive deformation behavior of Al-alloy (LM13)—Cenosphere hybrid Al foam prepared using CaCO3 as foaming agent. Mater. Sci. Eng. A 2013, 560, 601–610. [Google Scholar] [CrossRef]

- Guo, R.Q.; Rohatgi, P.K.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Ramachandra, M.; Radhakrishna, K. Synthesis-microstructure-mechanical properties-wear and corrosion behavior of an Al-Si (12%)-fly ash metal matrix composite. J. Mater. Sci. 2005, 40, 5989–5997. [Google Scholar] [CrossRef]

- Tao, X.F.; Zhang, L.P.; Zhao, Y.Y. Al matrix syntactic foam fabricated with bimodal ceramic microspheres. Mater. Des. 2009, 30, 2732–2736. [Google Scholar] [CrossRef]

- Kiser, M.; He, M.Y.; Zek, F.W. The mechanical response of ceramic microballoon reinforced aluminum matrix composites under compressive loading. Acta Mater. 1999, 47, 2685–2694. [Google Scholar] [CrossRef]

- Xia, X.; Chen, X.; Zhang, Z.; Chen, X.; Zhao, W.; Liao, B.; Hur, B. Compressive properties of closed-cell aluminum foams with different contents of ceramic microspheres. Mater. Des. 2014, 56, 353–358. [Google Scholar] [CrossRef]

- Orbulov, I.N. Compressive properties of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar] [CrossRef]

- Tao, X.F.; Zhao, Y.Y. Compressive behavior of Al matrix syntactic foams toughened with Al particles. Scr. Mater. 2009, 61, 461–464. [Google Scholar] [CrossRef]

- Dou, Z.Y.; Jiang, L.T.; Wu, G.H.; Zhang, Q.; Xiu, Z.Y.; Chen, G.Q. High strain rate compression of cenosphere-pure aluminium syntactic foams. Scr. Mater. 2007, 57, 945–948. [Google Scholar]

- Szlancsik, A.; Katona, B.; Bobor, K.; Májlinger, K.; Orbulov, I.N. Compressive behavior of aluminum matrix syntatic foams reinforced by iron hollow spheres. Mater. Des. 2015, 83, 230–237. [Google Scholar]

- Vendra, L.J.; Rabiei, A. A study on aluminum-steel composite metal foam processed by casting. Mater. Sci. Eng. A 2007, 465, 59–67. [Google Scholar] [CrossRef]

- Rabiei, A.; O’Neill, A. A study on processing of a composite metal foam via casting. Mater. Sci. Eng. A 2005, 404, 159–164. [Google Scholar] [CrossRef]

- Rabiei, A.; Vendra, L.J. A comparison of composite metal foam’s properties and other comparable metal foams. Mater. Lett. 2009, 63, 533–536. [Google Scholar] [CrossRef]

- Vendra, L; Rabiei, A. Evaluation of modulus of elasticity of composite metal foams by experimentaland numerical techniques. Mater. Sci. Eng. A 2010, 527, 1784–1790. [Google Scholar]

- Rabiei, A.; Garcia-Avila, M. Effect of various parameters on properties of composite steel foams under variety of loading rates. Mater. Sci. Eng. A 2013, 564, 539–547. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Pumice/aluminum syntactic. Mater. Sci. Eng. A 2015, 635, 102–108. [Google Scholar] [CrossRef]

- Chen, S.; Bourham, M.; Rabiei, A. Neutrons attenuation on composite metal foams and hybrid open-cell Al foam. Radiat. Phys. Chem. 2015, 109, 27–39. [Google Scholar] [CrossRef]

- Garcia-Avila, M.; Portanova, M.; Rabiei, A. Ballistic performance of composite metal foams. Compos. Struct. 2015, 125, 202–211. [Google Scholar] [CrossRef]

- Chen, S.; Bourham, M.; Rabiei, A. Attenuation efficiency of X-ray and comparison to gamma ray and neutrons in composite metal foams. Radiat. Phys. Chem. 2015, 117, 12–22. [Google Scholar] [CrossRef]

- Wu, G.H.; Dou, Z.Y.; Sun, D.L.; Jiang, L.T.; Ding, B.S.; He, B.F. Compression behaviors of cenosphere-pure aluminum syntactic foams. Scr. Mater. 2007, 56, 221–224. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Kim, J.K.; Gupta, N.; Alaraj, S.; Daoud, A. Compressive characteristics of A356/fly ash cenosphere composites synthesized by pressure infiltration technique. Compos. Part A Appl. Sci. Manuf. 2006, 37, 430–437. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Ginsztler, J. Compressive behaviour of metal matrix syntactic foams. Acta Polytech. Hung. 2012, 9, 43–56. [Google Scholar]

- Zhang, L.P.; Zhao, Y.Y. Mechanical Response of Al Matrix Syntactic Foams Produced by Pressure Infiltration Casting. J. Compos. Mater. 2007, 41, 2105–2117. [Google Scholar] [CrossRef]

- Prabhu, B.; Suryanarayana, C.; An, L.; Vaidyanathan, R. Synthesis and characterization of high volume fraction Al-Al2O3 nanocomposite powders by high-energy milling. Mater. Sci. Eng. A 2006, 425, 192–200. [Google Scholar] [CrossRef]

- Du, Y.; Li, A.B.; Zhang, X.X.; Tan, Z.B.; Su, R.Z.; Pu, F.; Geng, L. Enhancement of the mechanical strength of aluminum foams by SiC nanoparticles. Mater. Lett. 2015, 148, 79–81. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nanoparticles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Casati, R.; Fabrizi, A.; Timelli, G.; Tuissi, A.; Vedani, M. Microstructural and Mechanical Properties of Al-Based Composites Reinforced with In-Situ and Ex-Situ Al2O3 Nanoparticles. Adv. Eng. Mater. 2015. [Google Scholar] [CrossRef]

- Casati, R.; Fabrizi, A.; Tuissi, A.; Xia, K.; Vedani, M. ECAP consolidation of Al matrix composites reinforced with in-situ γ-Al2O3 nanoparticles. Mater. Sci. Eng. A 2015, 648, 113–122. [Google Scholar] [CrossRef]

- Boonyongmaneerat, Y.; Schuh, C.A.; Dunand, D.C. Mechanical properties of reticulated aluminum foams with electrodeposited Ni-W coatings. Scr. Mater. 2008, 59, 336–339. [Google Scholar] [CrossRef]

- Bouwhuis, B.A.; McCrea, J.L.; Palumbo, G.; Hibbard, G.D. Mechanical properties of hybrid nanocrystalline metal foams. Acta Mater. 2009, 57, 4046–4053. [Google Scholar] [CrossRef]

- Wang, W.; Burgueño, R.; Hong, J.-W.; Lee, I. Nano-deposition on 3-d open-cell aluminium foam materials for improved energy absorption capacity. Mater. Sci. Eng. A 2013, 572, 75–82. [Google Scholar] [CrossRef]

- Sun, Y.; Burgueño, R.; Wang, W.; Lee, I. Effect of annealing on the mechanical properties of nano-copper reinforced open-cell aluminum foams. Mater. Sci. Eng. A 2014, 613, 340–351. [Google Scholar] [CrossRef]

- Sun, Y.; Burgueño, R.; Vanderklok, A.J.; Tekalur, S.A.; Wang, W.; Lee, I. Compressive behaviour of aluminum/copper hybrid foams under high strain rate loading. Mater. Sci. Eng. A 2014, 592, 111–120. [Google Scholar] [CrossRef]

- Antenucci, A.; Guarino, S.; Tagliaferri, V.; Ucciardello, N. Improvement of the mechanical and thermal characteristics of open-cell aluminum foams by the electrodeposition of Copper. Mater. Des. 2014, 59, 124–129. [Google Scholar] [CrossRef]

- Devivier, C.; Tagliaferri, V.; Trovalusci, F.; Ucciardello, N. Mechanical characterization of open-cell aluminium foams reinforced by nickel electro-deposition. Mater. Des. 2015, 86, 272–278. [Google Scholar] [CrossRef]

- Jung, A.; Chen, Z.; Schmauch, J.; Motz, C.; Diebels, S. Micromechanical characterisation of Ni/Al hybrid foams by nano- and microindentation coupled with EBSD. Acta Mater. 2016, 102, 38–48. [Google Scholar] [CrossRef]

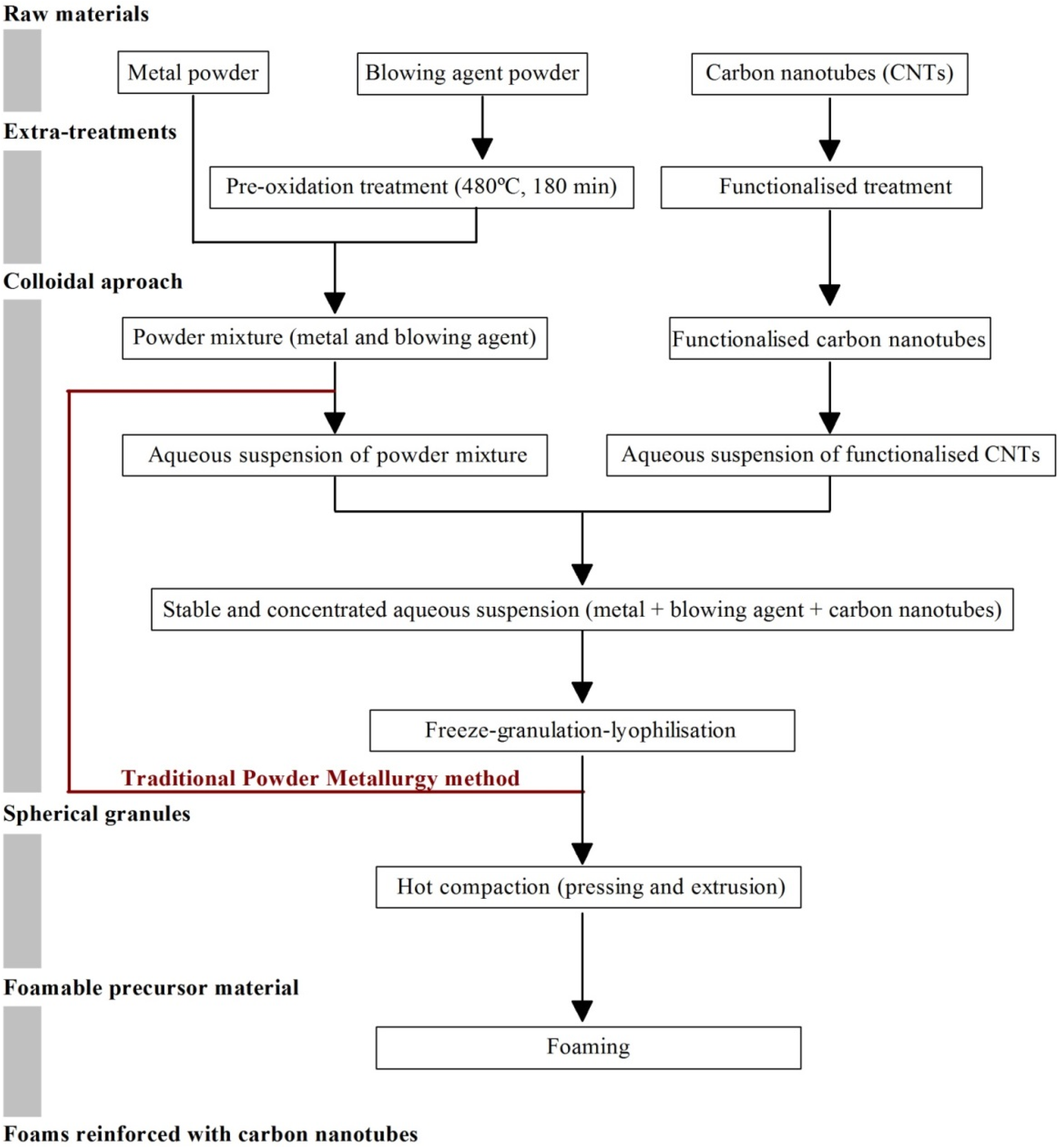

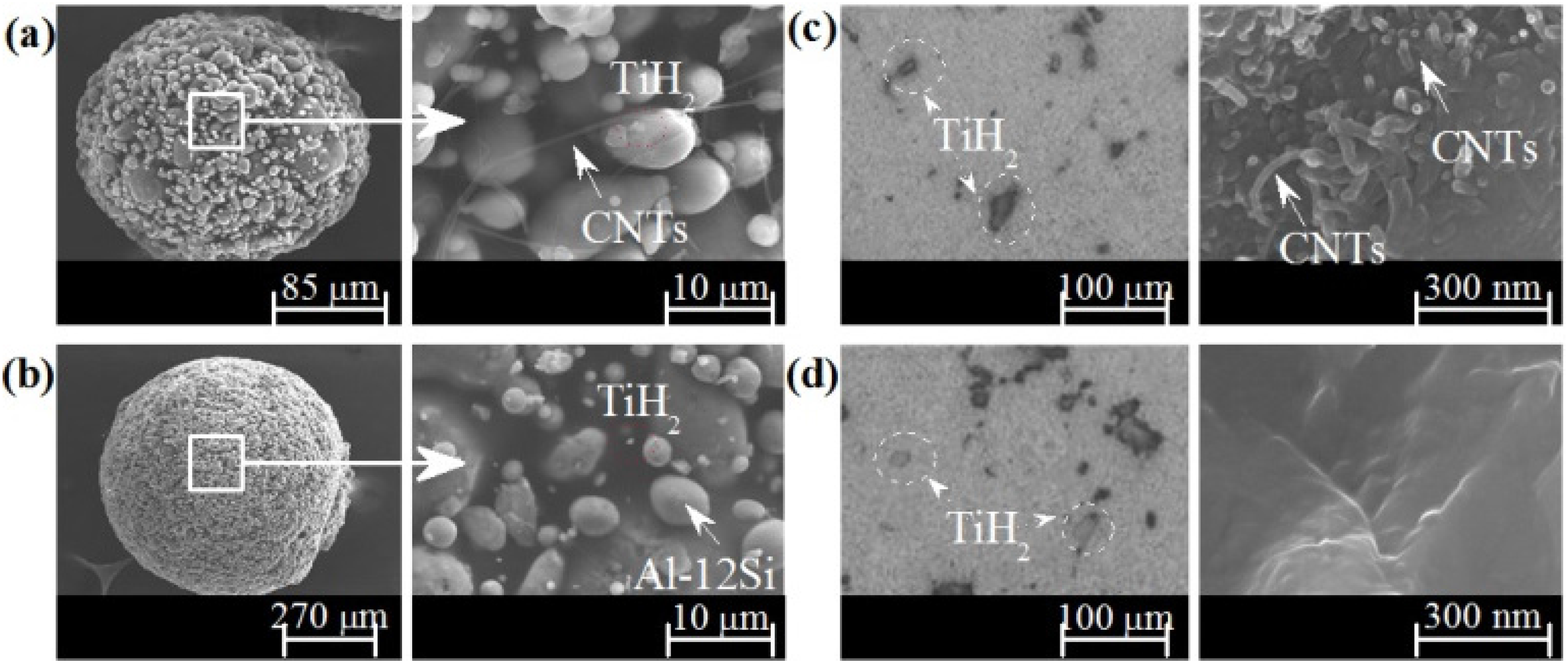

- Duarte, I.; Ventura, E.; Olhero, S.; Ferreira, J.M.F. A novel approach to prepare aluminium-alloy foams reinforced by carbon-nanotubes. Mater. Lett. 2015, 160, 162–166. [Google Scholar] [CrossRef]

- Duarte, I.; Ventura, E.; Olhero, S.; Ferreira, J.M.F. An effective approach to reinforced closed-cell Al-alloy foams with multiwalled carbon nanotubes. Carbon 2015, 95, 589–600. [Google Scholar] [CrossRef]

- Zhang, Z; Ding, J.; Xia, X.; Sun, X.; Song, K.; Zhao, W.; Liao, B. Fabrication and characterisation of closed-cell aluminium foams with differents contents of multi-walled carbon nanotubes. Mater. Des. 2015, 88, 359–365. [Google Scholar]

- Wang, J.; Yang, X.; Zhang, M.; Li, J.; Shi, C.; Zhao, N.; Zou, T. A novel approach to obtain in-situ growth carbon nanotube reinforced aluminum foams with enhanced properties. Mater. Lett. 2015, 161, 763–766. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al-Cu composites. Carbon 2012, 50, 2417–2423. [Google Scholar] [CrossRef]

- Wei, H.; Li, Z.; Xiong, D.-B.; Tan, Z.; Fan, G.; Qin, Z.; Zhang, D. Towards strong and stiff carbon nanotube-reinforced high-strength aluminum alloy composites through a microlaminated architecture design. Scr. Mater. 2014, 75, 30–33. [Google Scholar] [CrossRef]

- Yoo, S.J.; Han, S.H.; Kim, W.J. Strength and strain hardening of aluminum matrix composites with randomly dispersed nanometer-length fragmented carbon nanotubes. Scr. Mater. 2013, 68, 711–714. [Google Scholar] [CrossRef]

- Li, S.; Sun, B.; Imai, H.; Kondoh, K. Powder metallurgy Ti-TiC metal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon 2013, 61, 216–228. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J.; Takahashi, M.; Kondoh, K. Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests. Compos. Sci. Technol. 2015, 113, 1–8. [Google Scholar] [CrossRef]

- Dong, Z.; Keju, J.; Huihui, Z. Foam Metal-Carbon Nanotube Composite Material and Preparation Method Thereof. Patent CN 103434207 A, 11 December 2013. [Google Scholar]

- Wang, Y.; Chin, Y.-H.; Gao, Y.; Aardahl, C.L.; Stewart, T.L. Carbon Nanotube-Containing Structures, Methods of Making, and Processes Using Same. Patent US 7011760 B2, 14 March 2006. [Google Scholar]

- Liu, J.; Yu, S.; Zhu, X.; Wei, M.; Li, S.; Luo, Y.; Liu, Y. Effect of Al2O3 short fiber on the compressive properties of Zn-22Al foams. Mater. Lett. 2008, 62, 3636–3638. [Google Scholar] [CrossRef]

- Liu, J.; Yu, S.; Zhu, X.; Wei, M.; Li, S.; Luo, Y.; Liu, Y. Deformation and energy absorption characteristic of Al2O3f/Zn-Al composite foams during compression. J. Alloy. Compd. 2010, 506, 620–625. [Google Scholar] [CrossRef]

- Kumar, G.S.; Chakraborty, M.; Garcia-Moreno, F.; Banhart, J. Foamability of MgAl2O4 (Spinel)-reinforced aluminum alloy composites. Metall. Mater. Trans. A 2011, 42, 2898–2908. [Google Scholar] [CrossRef]

- Guo, C.; Zou, T.; Shi, C.; Yang, X.; Zhao, N.; Liu, E.; He, C. Compressive properties and energy absorption of aluminum composite foams reinforced by in-situ generated MgAl2O4 whiskers. Mater. Sci. Eng. A 2015, 645, 1–7. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duarte, I.; Ferreira, J.M.F. Composite and Nanocomposite Metal Foams. Materials 2016, 9, 79. https://doi.org/10.3390/ma9020079

Duarte I, Ferreira JMF. Composite and Nanocomposite Metal Foams. Materials. 2016; 9(2):79. https://doi.org/10.3390/ma9020079

Chicago/Turabian StyleDuarte, Isabel, and José M. F. Ferreira. 2016. "Composite and Nanocomposite Metal Foams" Materials 9, no. 2: 79. https://doi.org/10.3390/ma9020079

APA StyleDuarte, I., & Ferreira, J. M. F. (2016). Composite and Nanocomposite Metal Foams. Materials, 9(2), 79. https://doi.org/10.3390/ma9020079