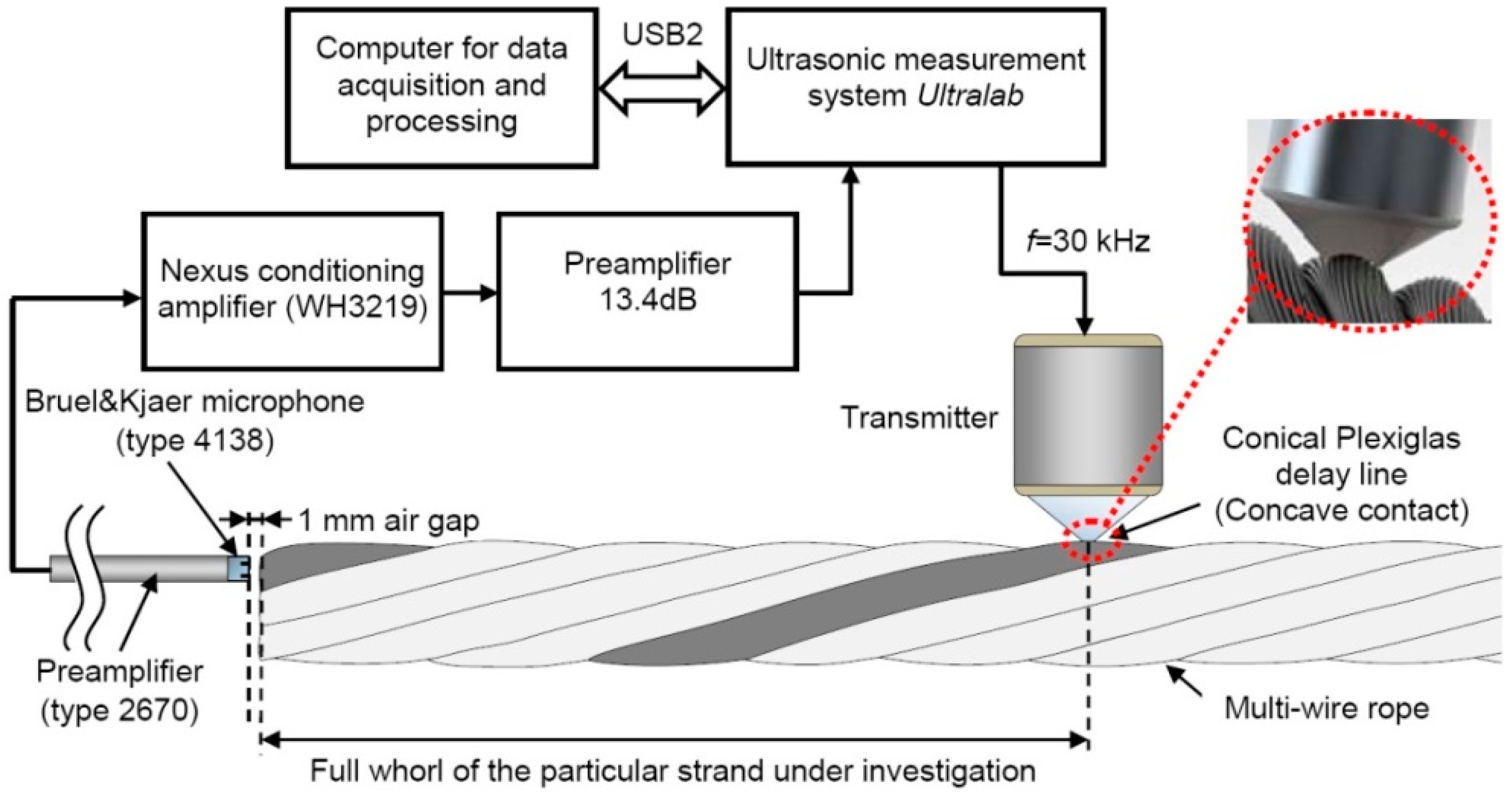

A multi-wire steel rope to be investigated using ultrasound by itself is a complex composite structure in which multiple reflections, scattering, and the presence of multiple wave modes of UGW occur. Therefore, in order to understand the effects of UGW propagating along the multi-wire rope and penetration into the internal structure, determination of type of the acoustic contact between neighboring wires is necessary. In addition, the optimal parameters of UGW used for non-destructive testing of the particular objects are necessary to be investigated and selected.

2.1. Dispersion Curves of Propagating Guided Waves

Dispersion curves of propagating UGW along the object under investigation show the distribution of phase or group velocities in a particular frequency bandwidth. Therefore, in order to identify the particular modes of UGW, which propagate along the object under investigation and select suitable ones for non-destructive testing, the dispersion curves of phase and group velocities must be calculated. There are several techniques for calculation of the dispersion curves of UGW: semi-analytical finite element (SAFE) technique [

14,

15,

16,

17,

18,

19,

20] and analytical ones [

21]. The SAFE technique is more attractive for analysis of the objects with an arbitrary geometry of the cross-section (e.g., rails, bars,

etc.). The SAFE technique has been used by Treyssede and Laguerre for investigation of UGW propagation along multi-wire helical strands with a metal cylindrical core [

4,

7,

9,

10,

14]. The wires were assumed to be solidly connected [

4,

9,

14]. They have found that the wave numbers and energy velocities of axisymmetric modes, such as

L(0,1) and

T(0,1), also flexural mode

F(1,1) at low frequencies and small helix lay angles (less than 15 degrees) of helical waveguides are very similar to the straight (not twisted) and twisted (helical) wires of multi-wire helical waveguides [

4,

9,

14]. However, the cut-off region of the

L(0,1)-like mode was observed at a notch frequency [

4,

9,

14]. The advantage of the analytical technique, comparing it to SAFE, is a possibility to determine the frequency dependent guided wave leakage losses in the case of submerged wire ropes, for instance, as in cement grout or rock-embedded wire ropes [

20,

21].

In order to calculate dispersion curves for a multi-wire rope with a polymer core, several tasks are necessary to be solved. At first, the stranding of wires was eliminated and calculation of dispersion curves was divided into several stages. During the first stage, the dispersion curves of UGW were calculated using the SAFE technique for a single wire having the diameter of 2.05 mm (

Figure 2a,b). The material properties used for the SAFE calculations of the dispersion curves are summarized in

Table 1.

During the SAFE calculations the triangular finite elements were used in order to obtain the desired accuracy, the average spatial size of element was set to 1 mm, which corresponds to 15 elements per wavelength, according to the minimum wavelength of the slowest F(1,1) mode at 100 kHz frequency.

Calculation results of UGW propagation along a single wire having the diameter of 2.05 mm (

Figure 2a) demonstrated that only fundamental modes propagate in the frequency band up to 100 kHz (

Figure 2b). The dispersion curves also show that, in the selected frequency region, the fastest mode is longitudinal

L(0,1) and the slowest mode—flexural

F(1,1), whereas the torsional mode

T(0,1) is not dispersive.

The obtained results demonstrated that in this frequency range only fundamental modes propagate in a single wire. Typically, a multi-wire rope structure is more complicated, so, during the second stage the dispersion curves of the strand with 31 wires (the diameter of each wire 2.05 mm) having the overall diameter of 11.15 mm were calculated. In this case it was assumed that there is a solid acoustic contact between neighboring wires at their contact points. The cross-section of the meshed strand of 31 wires (the overall diameter 11.15 mm) is presented in

Figure 3a. The obtained phase velocity dispersion curves and the comparison with the dispersion curves of the single wire (diameter 2.05 mm) are presented in

Figure 3b. It should be noted that in the case of a bundle of wires or multi-wire rope the modes should be named as the axial-like

L(0,1), the flexural-like

F(1,1), and the torsional-like

T(0,1) modes.

However, the numerical analysis of the multi-wire rope with the six strands consisting of 31 wires each and the polymer core is quite complicated due to limited computational resources of SAFE and the expected memory overflow. Therefore, the assumption was made that each strand can be replaced by a solid rod, having the same diameter (11.15 mm). The comparison of the dispersion curves of the UGW propagating in a multi-wire strand of 31 wires and in the solid rod are presented in

Figure 4a,b. Comparison of these two cases demonstrate that the phase velocities of the

F(1,1) and

L(0,1) modes are similar and the velocity of the

T(0,1) mode in the strand of 31 wires is reduced by 23% in comparison to the phase velocities in the case of a solid rod. The calculation results demonstrate that a solid circular rod having the diameter of 11.15 mm is not fully equivalent to the meshed bundle of 31 wires but this replacement can be done for analysis of fundamental modes of UGW (especially

L(0,1) and

F(1,1)) at frequencies below 100 kHz.

This comparative analysis was made in order to be sure that replacement of the bundle of solidly-connected 31 wires by a single solid rod gives the same or similar results of the calculated dispersion curves. Then the dispersion curves of the whole multi-wire rope could be calculated as the curves of a bundle of solidly-connected six strands (the overall diameter 35 mm). This simplified assumption could reduce the required computational resources and additionally enable us to estimate frequency dependent leakage losses using the simplified analytical technique.

When conducting theoretical analysis on a multi-wire steel rope of a complex structure, an important question arises which is related to the acoustic contact between neighboring wires. Transmission of the appropriate modes between neighboring wires depends on a type of the acoustic contact. For example, in the case of a slip contact there is no transmission of the axial component of the particle velocity of the propagating mode to the neighboring wires. Therefore, only the component of the particle velocity perpendicular to the axis of the rope could be transmitted to the neighboring wires. In the case of a solid contact, the axial component is transmitted to neighboring wires. In order to investigate the influence of the acoustic contact on dispersion curves of the guided waves, the calculations for the simplified structure of the wire rope with the polymer core was performed. The calculations of the dispersion curves were performed for two separate cases. In Case A, it was assumed that the acoustic contact between neighboring wires is solid and in Case B a thin layer of a new material named as “elastic fluid” (

Table 1) with the shear wave velocity close to zero was introduced between the separate strands to simulate the slip contact. The cross-section of the meshed multi-wire rope in the cases of a solid and slip contacts are presented in

Figure 5a,b. The dispersion curves in the case of a solid and slip contact are presented in

Figure 5c.

The results obtained demonstrate that the type of the contact between neighboring straight strands influences the type of modes that propagate in the structure. The phase velocity of the L(0,1)-like mode is the same for both cases at the frequencies below 30 kHz, whereas the phase velocity of the asymmetrical F(1,1)-like mode is shifted down in the case of the slip contact. It can be seen that in the case of the slip contact a large number of higher-order modes propagate in the structure at the frequencies above 10 kHz.

2.2. Investigation of the Acoustic Contact Between Wires Using 3D FE Modelling

Dispersion curves of UGW show what modes may propagate along a multi-wire rope. The most appropriate way to excite UGW in such structures is to apply a normal (perpendicular to the axis of the rope) or tangential force to the outer surface of a wire rope (parallel to the axis of the rope). It is a promising solution for practical applications, based on a single side access to the surface of the rope. Thus, the next stage of investigation must be devoted to the issue whether those UGW modes can be excited from the outer surface and whether such propagating waves penetrate into the whole structure of a wire rope or just propagate only along the outer wires. In this case, a very important task is determination of the type of the acoustic contact between neighboring wires in a rope. Each wire is attached to another one by some force and in general, two types of acoustic contact between wires should be analyzed—a solid contact and a slip one. Those contact types influence what components (perpendicular to the axis of the rope or axial) of the particle velocity can propagate from one single wire to another one and, as a consequence, determine how deeply the propagating guided wave can penetrate into the structure under investigation. In order to get the answer to these questions, two models had been constructed using the finite element method with two different types of the acoustic contact between wires—a solid and a slip contact. In the case of the solid contact vertical (vy) and axial (vz) components of particle velocity are transmitted. Still, in the case of the slip acoustic contact only components (vy) perpendicular to the rope axis are transmitted.

Elastic wave propagation can be described by the Navier equation of motion in the form of matrices [

22]:

where

is the mass matrix,

is the damping matrix,

is the stiffness matrix,

is the load vector,

is the vector of displacements,

is the vector of velocity,

is the vector of accelerations for each degree of freedom. For the undamped forced vibrations, the Equation (1) reduces to:

The equation above was solved using the commercially available ANSYS implicit software and the Newmark’s time integration scheme. In the case of a solid contact it was assumed that the contact layer between the adjacent wires has the properties of steel. In the case of a slip contact the layer between wires was simulated as solid, but with the shear wave velocity close to zero. In this case the shear wave is not transmitted between adjacent wires. The properties of two types of the contact layers between neighboring individual wires are presented in

Table 1.

Just for simplicity not the whole structure of the strand of the multi-wire rope but only a row of five wires located on each other were analyzed (

Figure 6). The diameter of a single wire in the model was 2 mm. The length of the simulated structure was 250 mm. Wires were meshed using SOLID45 elements which are used for modelling of solid structures. Each element had eight nodes with three degrees of freedom each: translation in

x,

y, and

z directions. The average spatial size of the elements was 0.2 mm.

For excitation of the UGW, the appropriate force for a three-period burst and the frequency of 60 kHz with the Gaussian envelope were applied in order to investigate wave propagation effects in more detail. Motivation of selection of 60 kHz frequency was based on the fact that, at a higher frequency, the wavelength of guided waves is two times shorter for the axial-like L(0,1) mode and one and a half times shorter for the flexural-like F(1,1) mode comparing to the case of 30 kHz. The interaction effects of propagating the F(1,1)-like mode with different types of the acoustic contact between the neighboring wires are stronger at the frequency of 60 kHz due to a lower ratio of displacements of radial and axial components. For the L(0,1)-like mode there is no significant difference due to a weak radial component. In addition, at mentioned both frequencies only the fundamental modes (e.g., the L(0,1)-like and the F(1,1)-like) propagate along the single thin wire and the influence of higher modes does not exists.

The symmetric mode in the upper wire was generated by applying a normal force to the edge of it covering the whole cross-section having the area of 3.3 mm

2 (

Figure 6a). The asymmetric mode was generated applying the normal force to the top surface of the same wire, the length of the excitation region was 10 mm and the area of 10.45 mm

2 (

Figure 6b). The bandwidth of the excitation pulse at −6 dB level was equal to 32 kHz. The integration step in the time domain was 0.5 μs. This step is 1/33 of the period in the case of the excitation pulse possessing the central frequency of 60 kHz.

The solution was obtained using numerical integration and in this way the particle velocity distribution in the whole simulated structure at different time instants was obtained. The results are presented in the form of B-scan images (

Figure 7,

Figure 8,

Figure 9 and

Figure 10), defining distribution of different components of a particle velocity along the central line of the upper surface of the first wire and the lower surface of the last (fifth) wire (

Figure 6a,b).

It should be noted that the B-scan images have been acquired in a relatively long time interval, having a duration of 200 μs, and multiple reflections from edges of the simulated upper wire are clearly visible. The modelling results show that in the case of the edge type excitation and a slip contact between wires (Figures

7a,b and

8a,b) flexural

F(1,1) and symmetric

L(0,1) modes are generated in the first wire. However, only the flexural-like

F(1,1) mode after some delay penetrates to the bottom of the structure and can be observed on the lower wires as can be seen in

Figure 8a,b. In the case of a solid contact between wires and edge type excitation (Figures

7c,d and

8c,d), not only the symmetric

L(0,1) mode, but the relatively strong asymmetric

F(1,1) mode is generated as well, and both of them penetrate the whole structure up to the last (fifth) wire (

Figure 6a).

The results obtained in the case of the top side excitation by a normal force (

Figure 6b) in general demonstrate that, in both cases, the dominant flexural-like

F(1,1) mode was generated which penetrates the whole structure (

Figure 9 and

Figure 10). In the case of a solid contact, the symmetric

L(0,1) mode is simultaneously generated also.

On the basis of the simulation results, it has been found that the phase velocities of the F(1,1)-like mode in the cases of solid and slip contacts are different. The analysis shows that in the case of the solid contact between wires, the phase velocity of the F(1,1)-like mode is around 1800 m/s. If the contact (during simulation) is assumed to be slip, the phase velocity decreases approximately by half, down to 900 m/s. This can be explained by the fact that, in the case of the slip contact, even the asymmetric guided wave mode F(1,1)-like propagates separately in each wire.

Therefore, in the case of the slip contact, there is no possibility to generate the F(1,1)-like mode along the overall structure of a multi-wire rope using the excitation (normal force) from the top effectively. In the case of the solid contact, the asymmetric mode F(1,1)-like corresponds to the fundamental mode F(1,1)-like of a much thicker simulated structure compared with the case of the slip contact.

Those results coincide well with the dispersion curves obtained using the analytical technique, which shows that the phase velocity of the

F(1,1) mode in a single wire should be around 900 m/s at the frequency of 60 kHz (

Figure 2).