Coating and Patterning Functional Materials for Large Area Electrofluidic Arrays

Abstract

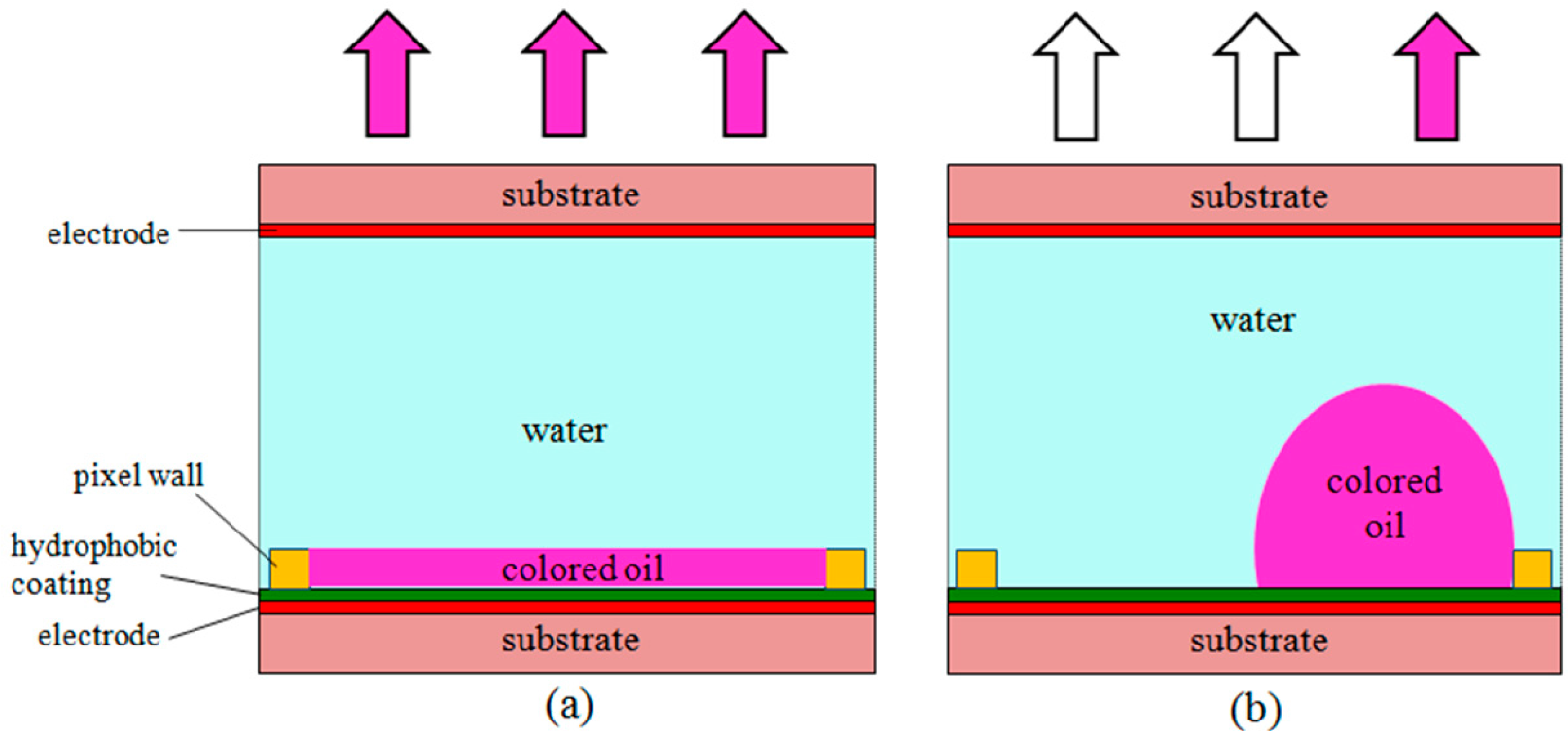

:1. Introduction

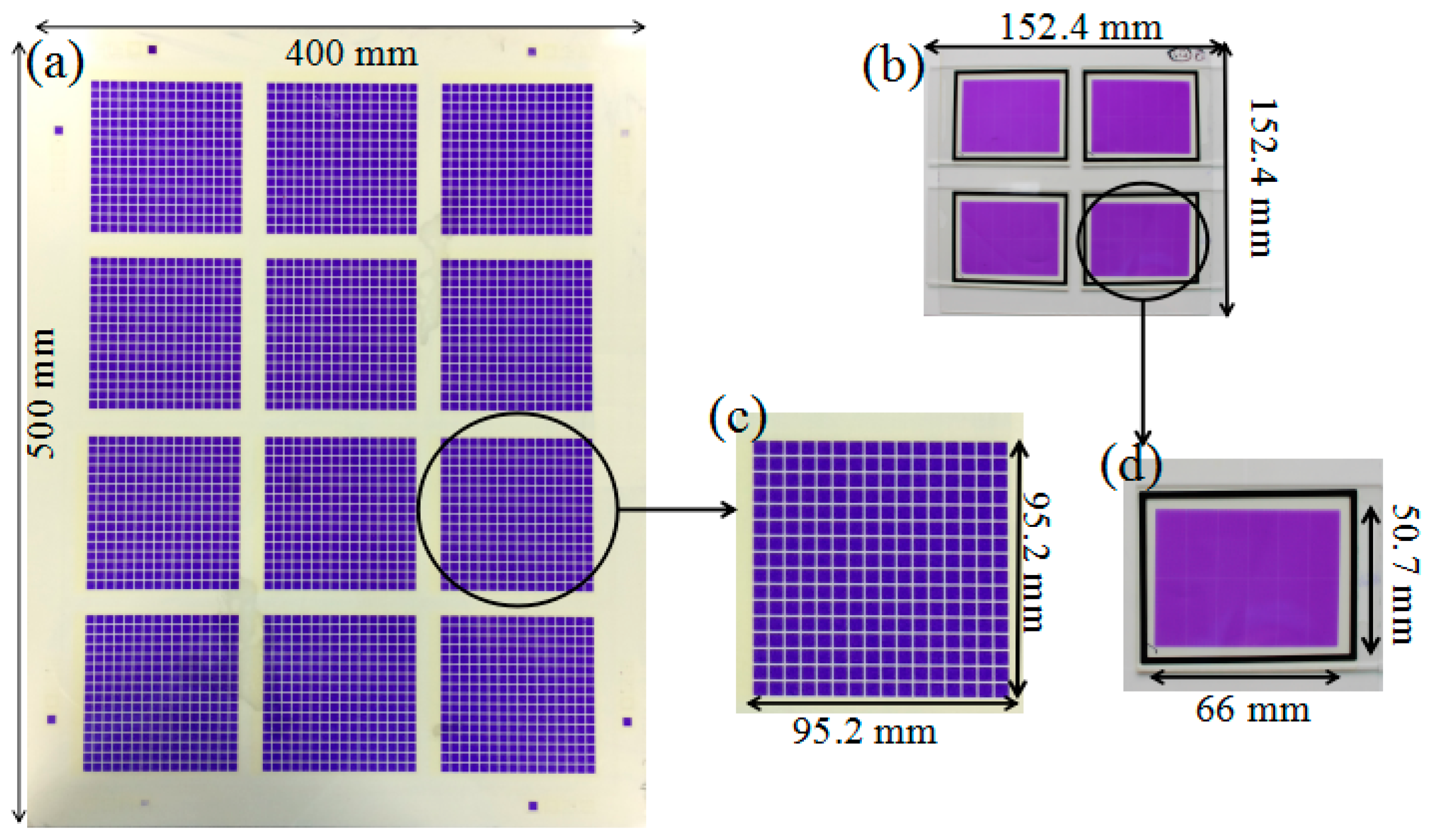

2. Results and Discussion

2.1. Screen Printing of the Amorphous Fluoropolymer

2.2. Slit-Coating Photoresist and Lithographic Patterning

3. Device Performance

3.1. Electrical Characterization of EFD Cells

3.2. Optical Performance of EFD Devices

4. Experimental

4.1. Materials and Equipment

4.2. Fabrication Process

4.3. Characterisation

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| EFD | electrofluidic display |

| LCD | liquid crystal display |

| ITO | indium tin oxide |

References

- Mugele, F.; Baret, J.-C. Electrowetting: From basics to applications. J. Phys. Condens. Matter 2005, 17, R705–R774. [Google Scholar] [CrossRef]

- Seyrat, E.; Hayes, R.A. Amorphous fluoropolymers as insulators for reversible low-voltage electrowetting. J. Appl. Phys. 2001, 90, 1383–1386. [Google Scholar] [CrossRef]

- Hayes, R.A.; Feenstra, B. Video-speed electronic paper based on electrowetting. Nature 2003, 425, 383–385. [Google Scholar] [CrossRef]

- Zhou, K.; Heikenfeld, J.; Dean, K.A.; Howard, E.M.; Johnson, M.R. A full description of a simple and scalable fabrication process for electrowetting displays. J. Micromech. Microeng. 2009, 19, 065029. [Google Scholar] [CrossRef]

- He, T.; Jin, M.; Eijkel, J.C.; Zhou, G.; Shui, L. Two-phase microfluidics in electrowetting displays and its effect on optical performance. Biomicrofluidics 2016, 10, 011908. [Google Scholar] [CrossRef] [PubMed]

- Haeberle, S.; Zengerle, R. Microfluidic platforms for lab-on-a-chip applications. Lab Chip 2007, 7, 1094–1110. [Google Scholar] [CrossRef] [PubMed]

- Mark, D.; Haeberle, S.; Roth, G.; von Stetten, F.; Zengerle, R. Microfluidic lab-on-a-chip platforms: Requirements, characteristics and applications. Chem. Soc. Rev. 2010, 39, 1153–1182. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, V.; Pamula, V.K.; Fair, R.B. Droplet-based microfluidic lab-on-a-chip for glucose detection. Anal. Chim. Acta 2004, 507, 145–150. [Google Scholar] [CrossRef]

- Berge, B.; Peseux, J. Variable focal lens controlled by an external voltage: An application of electrowetting. Eur. Phys. J. E 2000, 3, 159–163. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, Y.K.; Won, Y.H. Novel concept electrowetting microlens array based on passive matrix. IEEE Photonics Technol. Lett. 2016, 28, 167–170. [Google Scholar] [CrossRef]

- Thomas, D.; Audry, M.-C.; Thibaut, R.-M.; Kleimann, P.; Chassagneux, F.; Maillard, M.; Brioude, A. Charge injection in dielectric films during electrowetting actuation under direct current voltage. Thin Solid Films 2015, 590, 224–229. [Google Scholar] [CrossRef]

- You, H.; Steckl, A.J. Versatile electrowetting arrays for smart window applications-from small to large pixels on fixed and flexible substrates. Sol. Energy Mater. Sol. Cells 2013, 117, 544–548. [Google Scholar] [CrossRef]

- Zhao, R.; Cumby, B.; Russell, A.; Heikenfeld, J. Large area and low power dielectrowetting optical shutter with local deterministic fluid film breakup. Appl. Phys. Lett. 2013, 103, 223510. [Google Scholar] [CrossRef]

- Pollack, M.G.; Shenderov, A.D.; Fair, R.B. Electrowetting-based actuation of droplets for integrated microfluidics. Lab Chip 2002, 2, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.L.J.; Liu, P.W.; Wu, C.Y.; Cheng, P.P.; Chen, J.L.; Chen, K.C.; Hsieh, W.L. 54.2: Reliable and high performance transparent electrowetting displays. SID Symp. Digest Tech. Pap. 2014, 45, 785–788. [Google Scholar] [CrossRef]

- Raj, B.; Dhindsa, M.; Smith, N.R.; Laughlin, R.; Heikenfeld, J. Ion and liquid dependent dielectric failure in electrowetting systems. Langmuir 2009, 25, 12387–12392. [Google Scholar] [CrossRef] [PubMed]

- Verplanck, N.; Galopin, E.; Camart, J.C.; Thomy, V.; Coffinier, Y.; Boukherroub, R. Reversible electrowetting on superhydrophobic silicon nanowires. Nano Lett. 2007, 7, 813–817. [Google Scholar] [CrossRef] [PubMed]

- Moon, H.; Cho, S.K.; Garrell, R.L. Low voltage electrowetting-on-dielectric. J. Appl. Phys. 2002, 92, 4080–4087. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, H.; Hayes, R.A.; Li, X.; He, T.; Zhou, G. Screen printing insulator coatings for electrofluidic display devices. Phys. Status Solidi A 2015, 212, 2023–2030. [Google Scholar] [CrossRef]

- Chen, X.; He, T.; Jiang, H.; Wei, B.; Chen, G.; Fang, X.; Jin, M.; Hayes, R.A.; Zhou, G.; Shui, L. Screen-printing fabrication of electrowetting displays based on poly(imide siloxane) and polyimide. Displays 2015, 37, 79–85. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Radspinner, R.; Peyghambarian, N.; Jabbour, G.E. Fabrication of bulk heterojunction plastic solar cells by screen printing. Appl. Phys. Lett. 2001, 79, 2996–2998. [Google Scholar] [CrossRef]

- Krebs, F.C.; Alstrup, J.; Spanggaard, H.; Larsen, K.; Kold, E. Production of large-area polymer solar cells by industrial silk screen printing, lifetime considerations and lamination with polyethylene terephthalate. Sol. Energy Mater. Sol. Cells 2004, 83, 293–300. [Google Scholar] [CrossRef]

- Pardo, D.A.; Jabbour, G.E.; Peyghambarian, N. Application of screen printing in the fabrication of organic light-emitting devices. Adv. Mater. 2000, 12, 1249–1252. [Google Scholar] [CrossRef]

- Roques-Carmes, T.; Hayes, R.A.; Feenstra, B.J.; Schlangen, L.J.M. Liquid behavior inside a reflective display pixel based on electrowetting. J. Appl. Phys. 2004, 95, 4389. [Google Scholar] [CrossRef]

- Siegel, A.C.; Phillips, S.T.; Wiley, B.J.; Whitesides, G.M. Thin, lightweight, foldable thermochromic displays on paper. Lab Chip 2009, 9, 2775–2781. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Heikenfeld, J. Arrayed electrowetting microwells. Appl. Phys. Lett. 2008, 92, 113515. [Google Scholar] [CrossRef]

- Berry, S.; Kedzierski, J.; Abedian, B. Irreversible electrowetting on thin fluoropolymer films. Langmuir 2007, 23, 12429–12435. [Google Scholar] [CrossRef] [PubMed]

| Test Information | Large Area Printing Process | 6 Inch Spin Coating Process |

|---|---|---|

| Cell size | 95.2 mm × 95.2 mm | 66.0 mm × 50.7 mm |

| Capacitance per cell | 36.3 nF | 12.6 nF |

| Dielectric loss factor per cell | 0.066 | 0.040 |

| Capacitance per mm2 | 4.0 × 10−3 nF/mm2 | 3.8 × 103 nF/mm2 |

| Dielectric loss factor per mm2 | 7.3 × 10−6/mm2 | 12 × 10−6/mm2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Tang, B.; Hayes, R.A.; Dou, Y.; Guo, Y.; Jiang, H.; Zhou, G. Coating and Patterning Functional Materials for Large Area Electrofluidic Arrays. Materials 2016, 9, 707. https://doi.org/10.3390/ma9080707

Wu H, Tang B, Hayes RA, Dou Y, Guo Y, Jiang H, Zhou G. Coating and Patterning Functional Materials for Large Area Electrofluidic Arrays. Materials. 2016; 9(8):707. https://doi.org/10.3390/ma9080707

Chicago/Turabian StyleWu, Hao, Biao Tang, Robert A. Hayes, Yingying Dou, Yuanyuan Guo, Hongwei Jiang, and Guofu Zhou. 2016. "Coating and Patterning Functional Materials for Large Area Electrofluidic Arrays" Materials 9, no. 8: 707. https://doi.org/10.3390/ma9080707

APA StyleWu, H., Tang, B., Hayes, R. A., Dou, Y., Guo, Y., Jiang, H., & Zhou, G. (2016). Coating and Patterning Functional Materials for Large Area Electrofluidic Arrays. Materials, 9(8), 707. https://doi.org/10.3390/ma9080707