A Synergic Approach of Deep Learning towards Digital Additive Manufacturing: A Review

Abstract

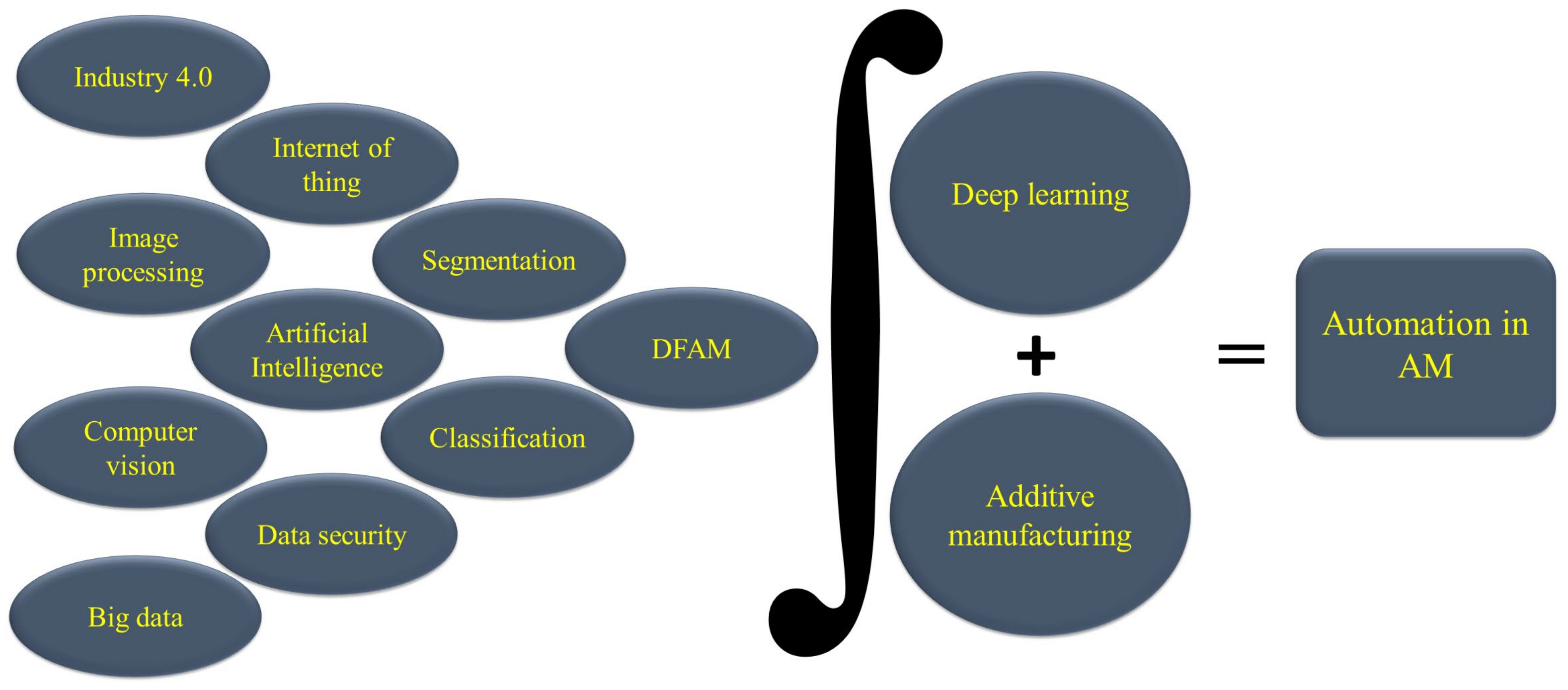

:1. Introduction

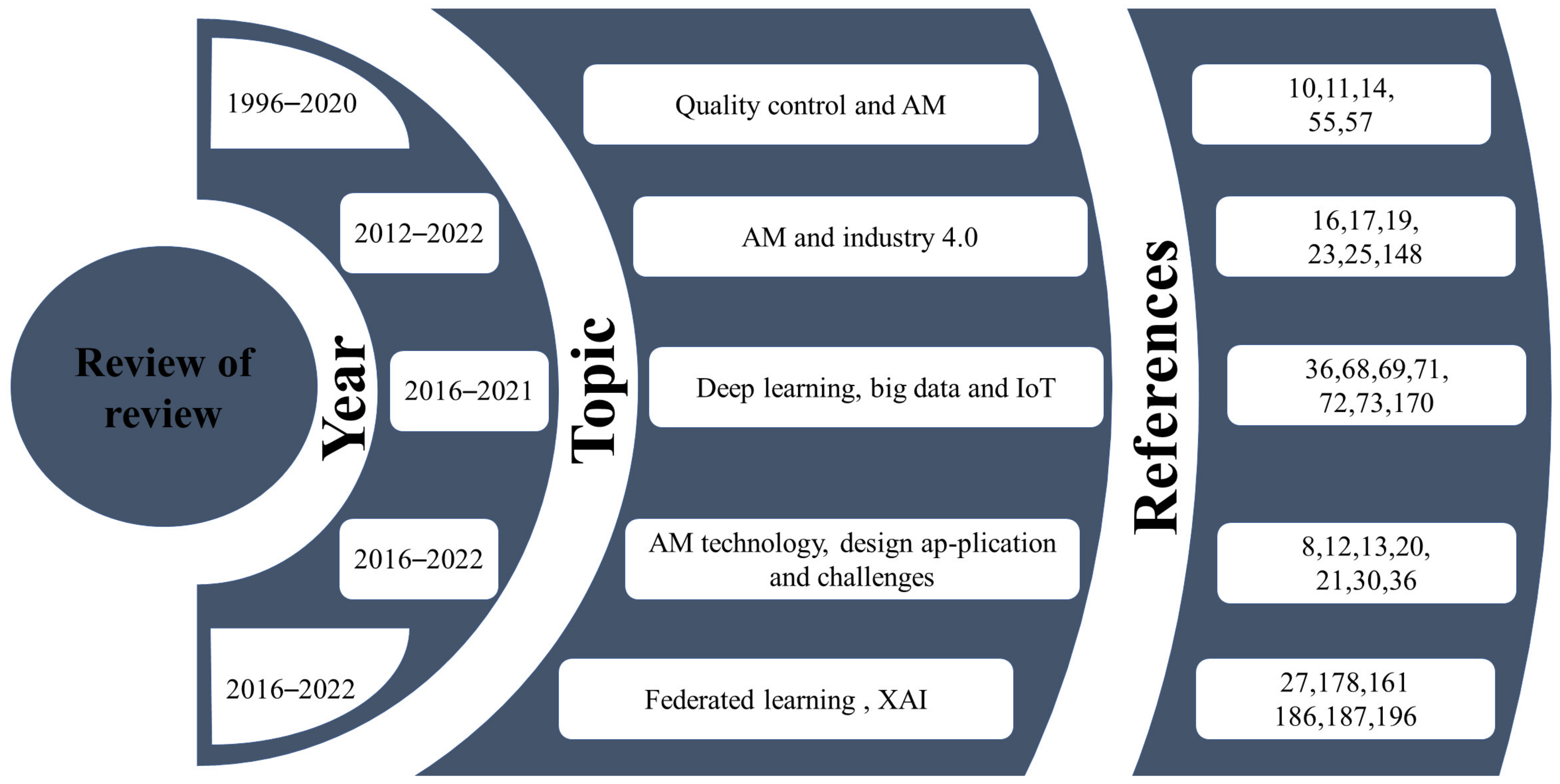

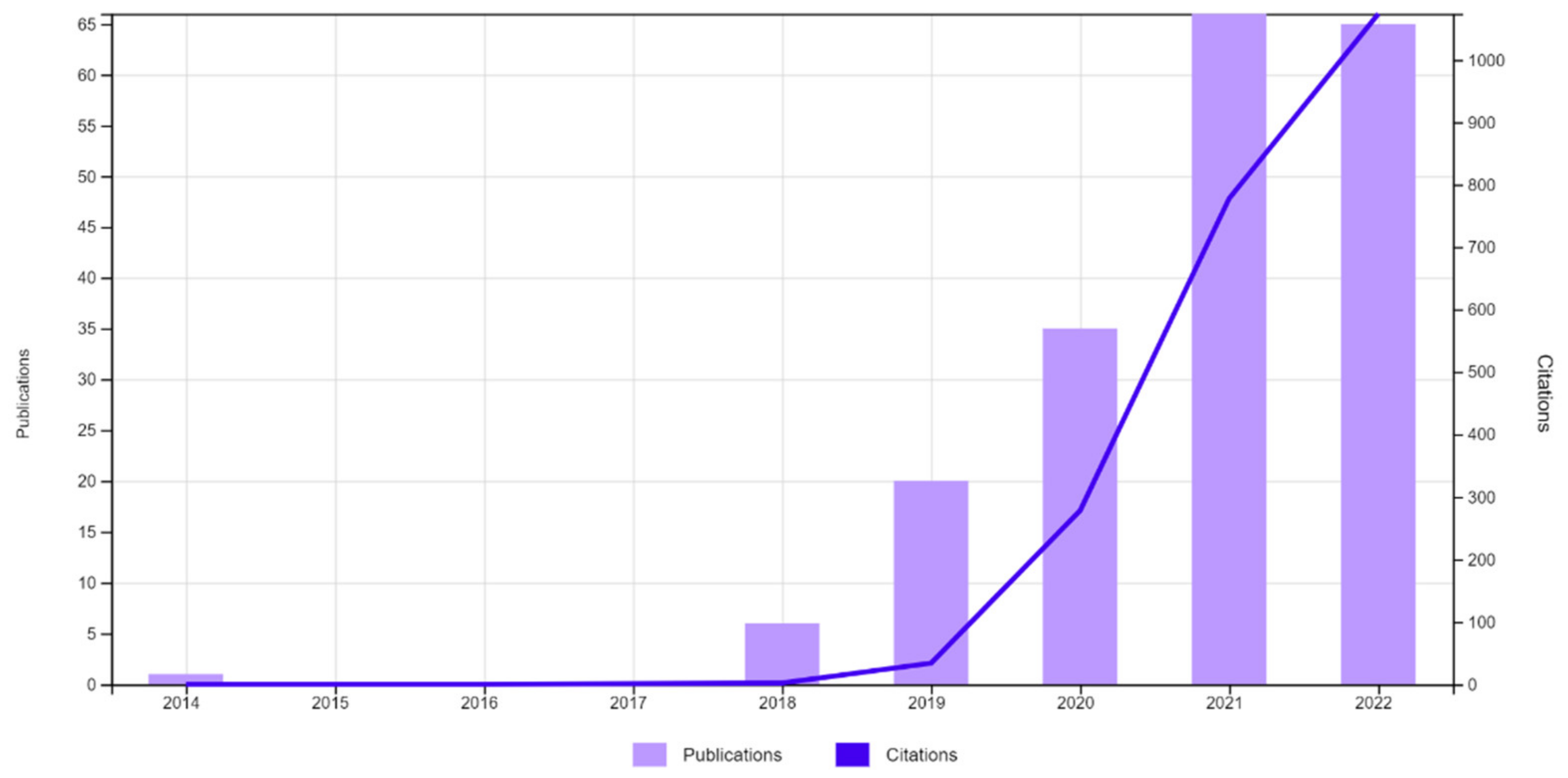

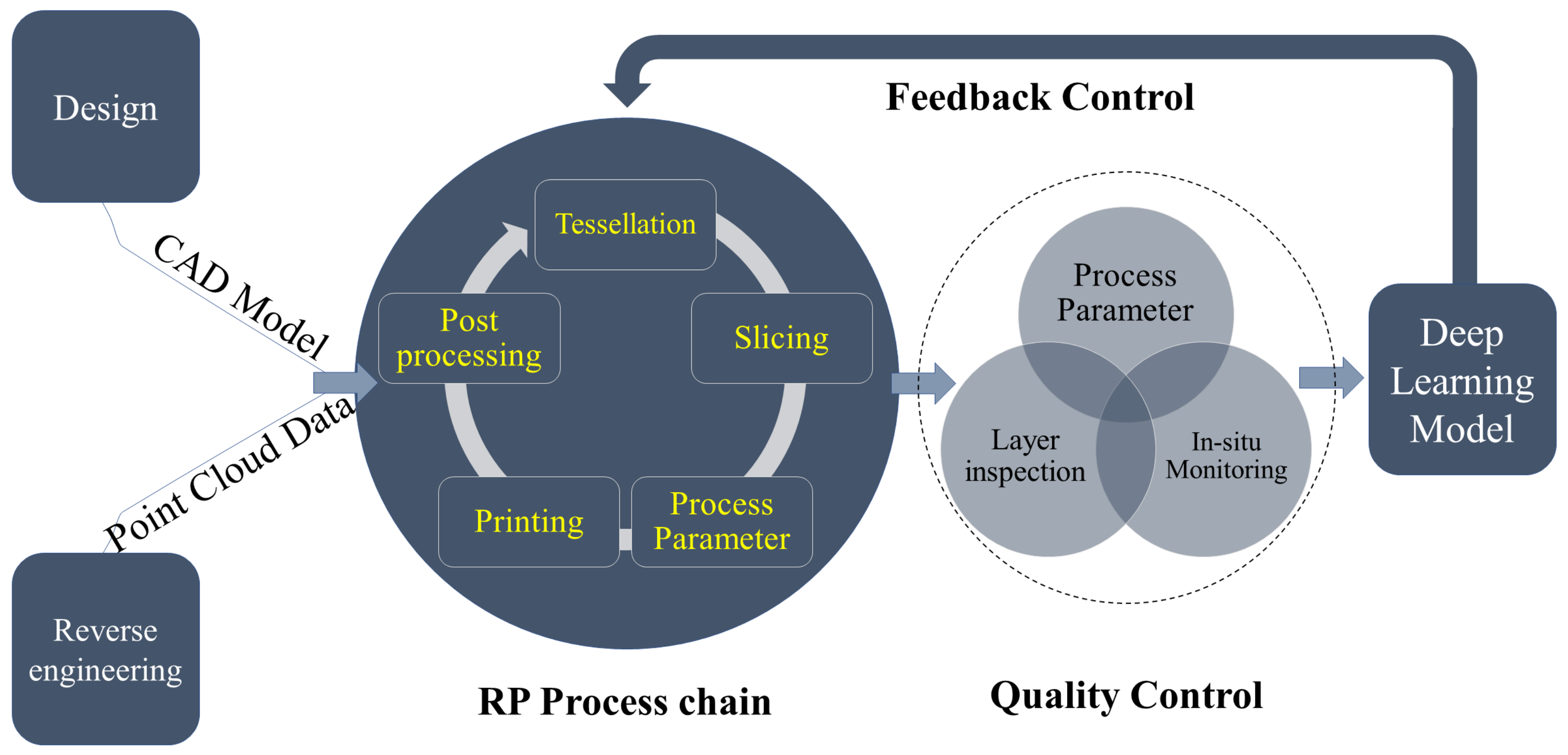

2. Classification and Correlation of Deep Learning with Additive Manufacturing

2.1. Process-Based Classification

2.2. Application-Based Classification

3. Errors and Defects Associated with Additive Manufacturing

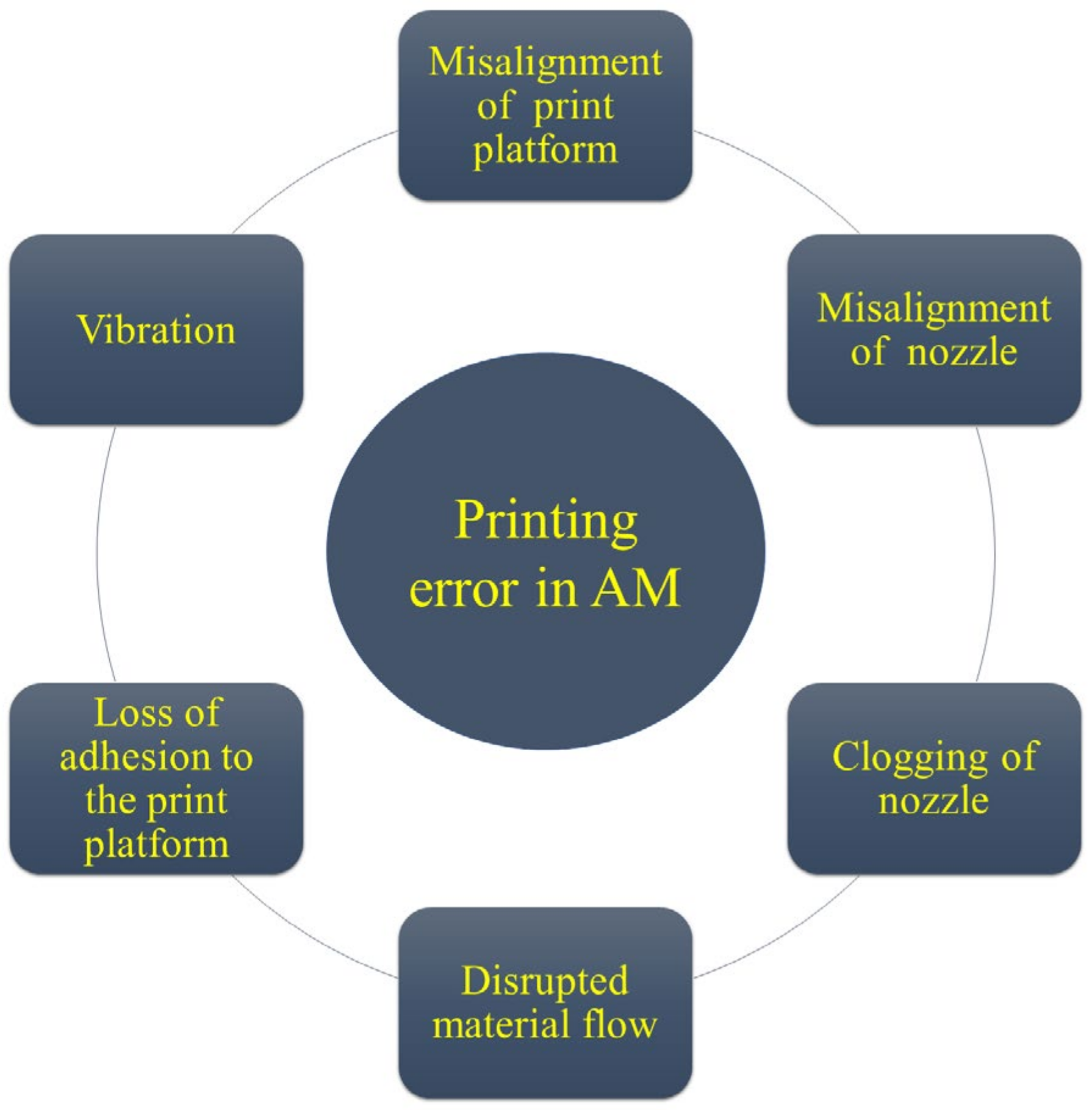

3.1. Printing Errors

3.2. Data Acquisition

3.3. Defect Associated

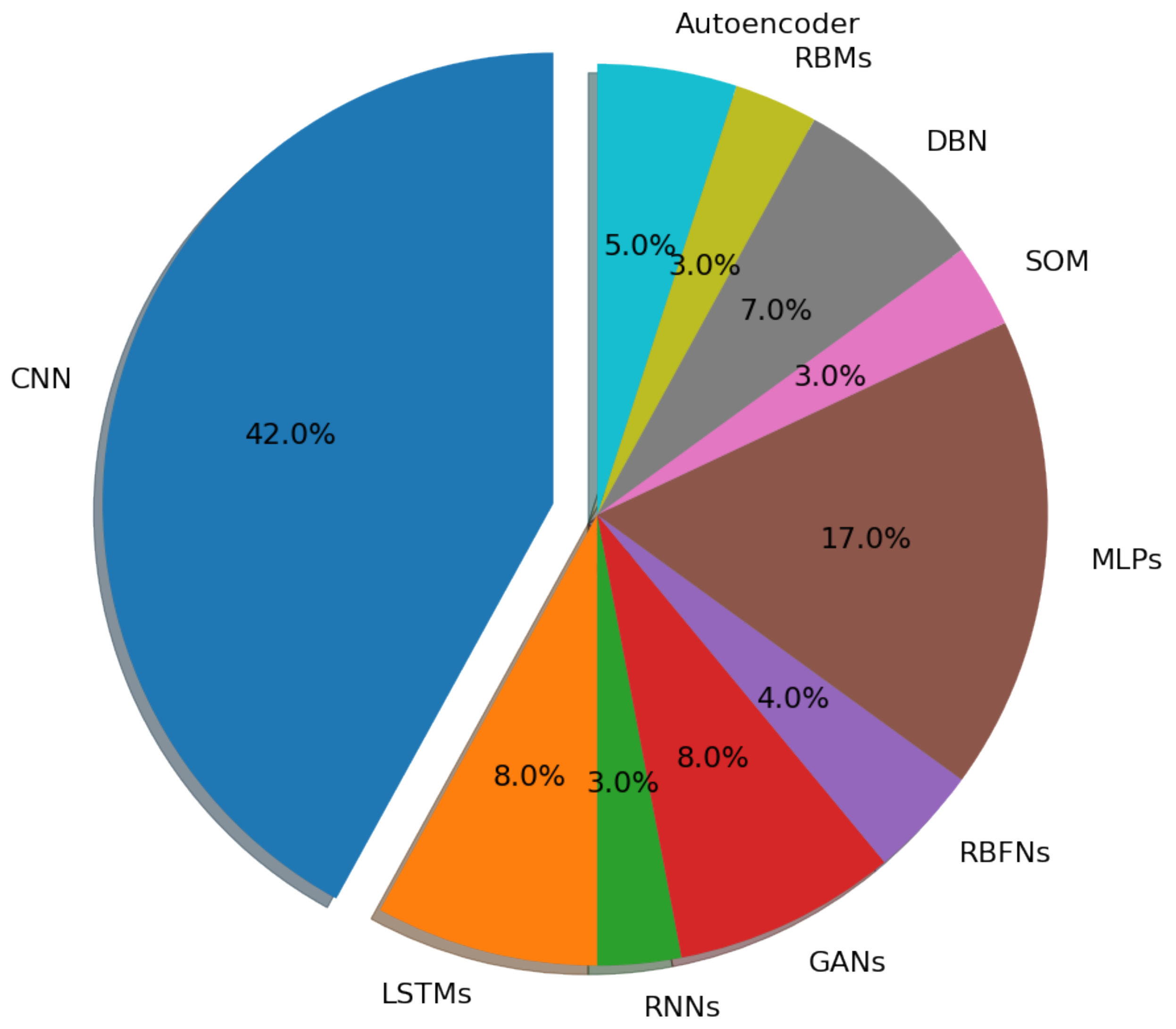

4. Deep Learning Models in Additive Manufacturing

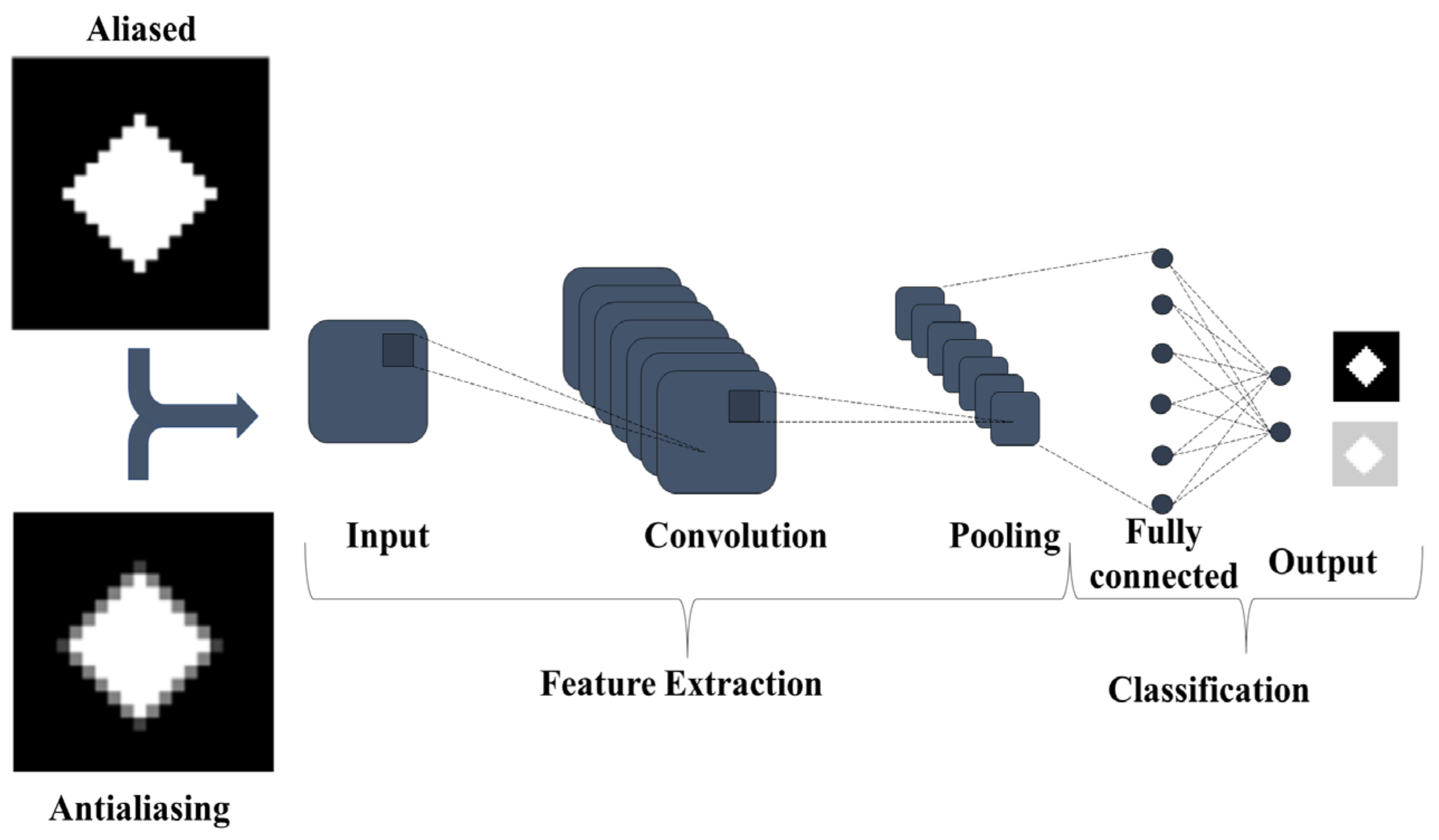

4.1. Convolutional Neural Networks (CNNs)

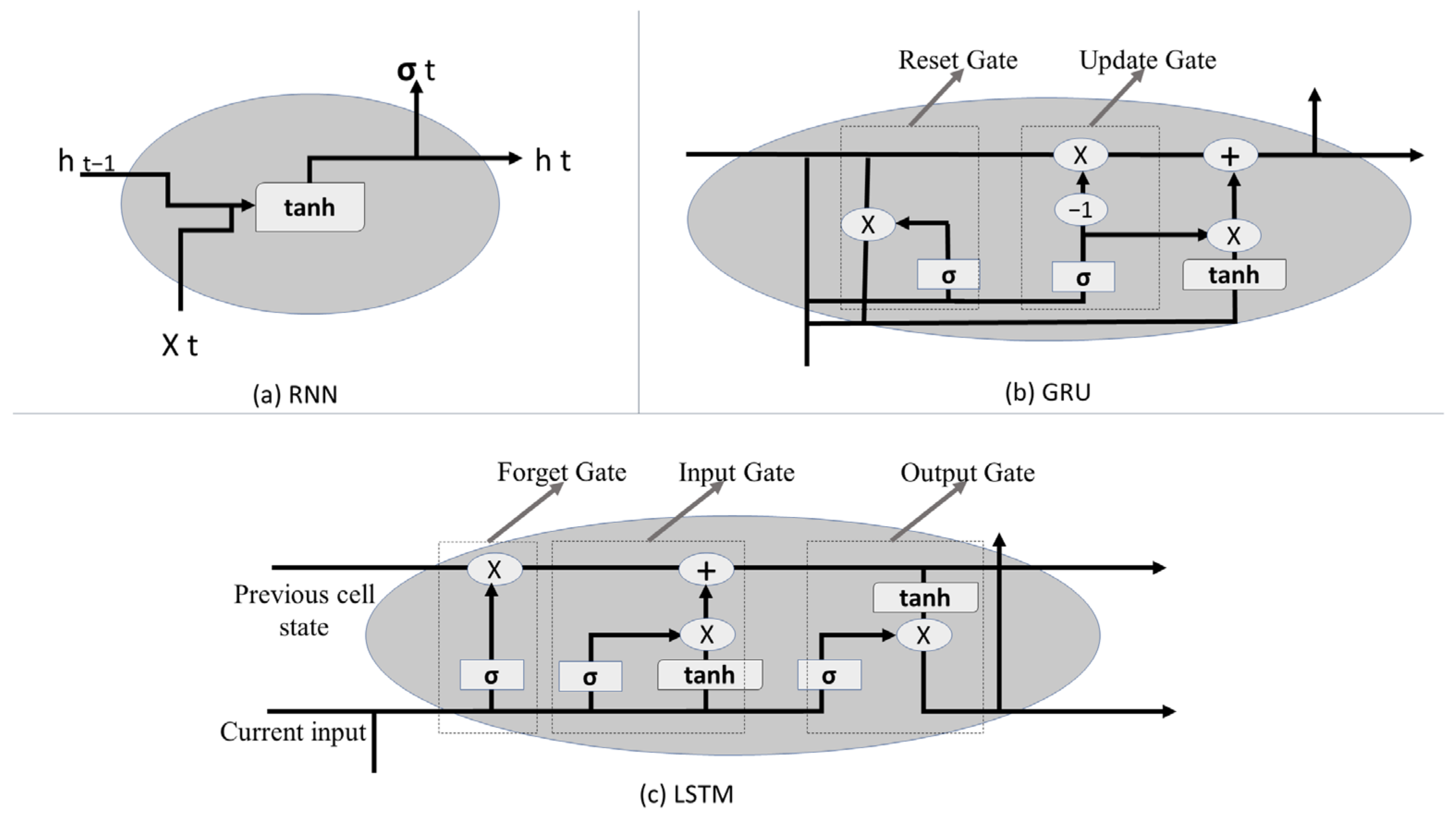

4.2. Recurrent Neural Networks (RNNs), GRU and LSTM

4.3. Generative Adversarial Networks (GANs) and Autoencoder

4.4. Restricted Boltzmann Machines (RBMs) and Deep Belief Networks (DBNs)

4.5. Other Deep-Learning Networks

5. Challenges and Solution

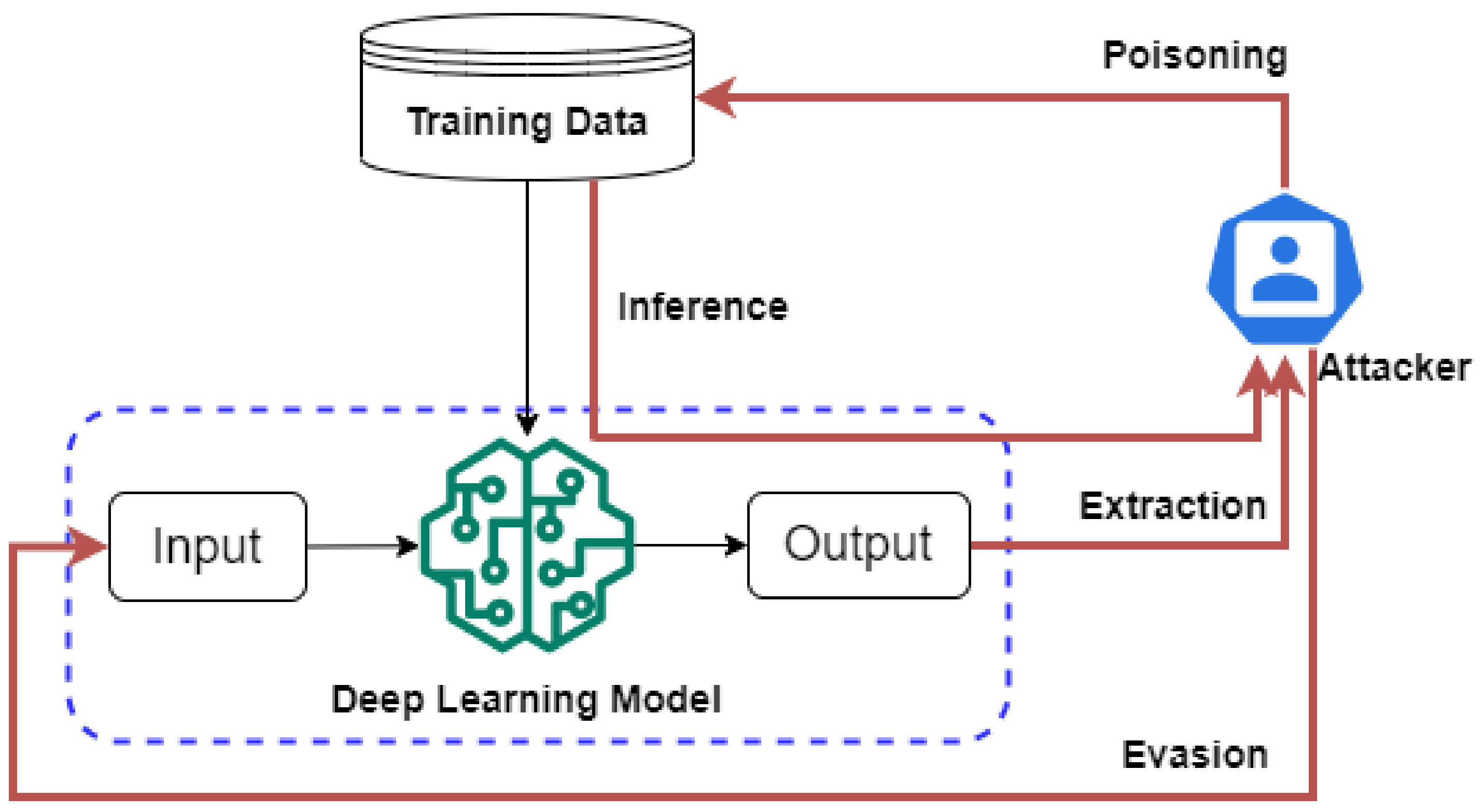

5.1. Data Privacy

- Data leakage: by being aware of the service or application’s flaws, the attacker can steal data (including user data, such as user passwords).

- Denial of service attack: attackers have the power to eliminate an application’s or service’s availability.

- Malicious code injection: through the use of known vulnerabilities, attackers can upload malicious code into software applications.

5.2. Model Generalization

5.3. Computational Time

5.4. Trustworthiness

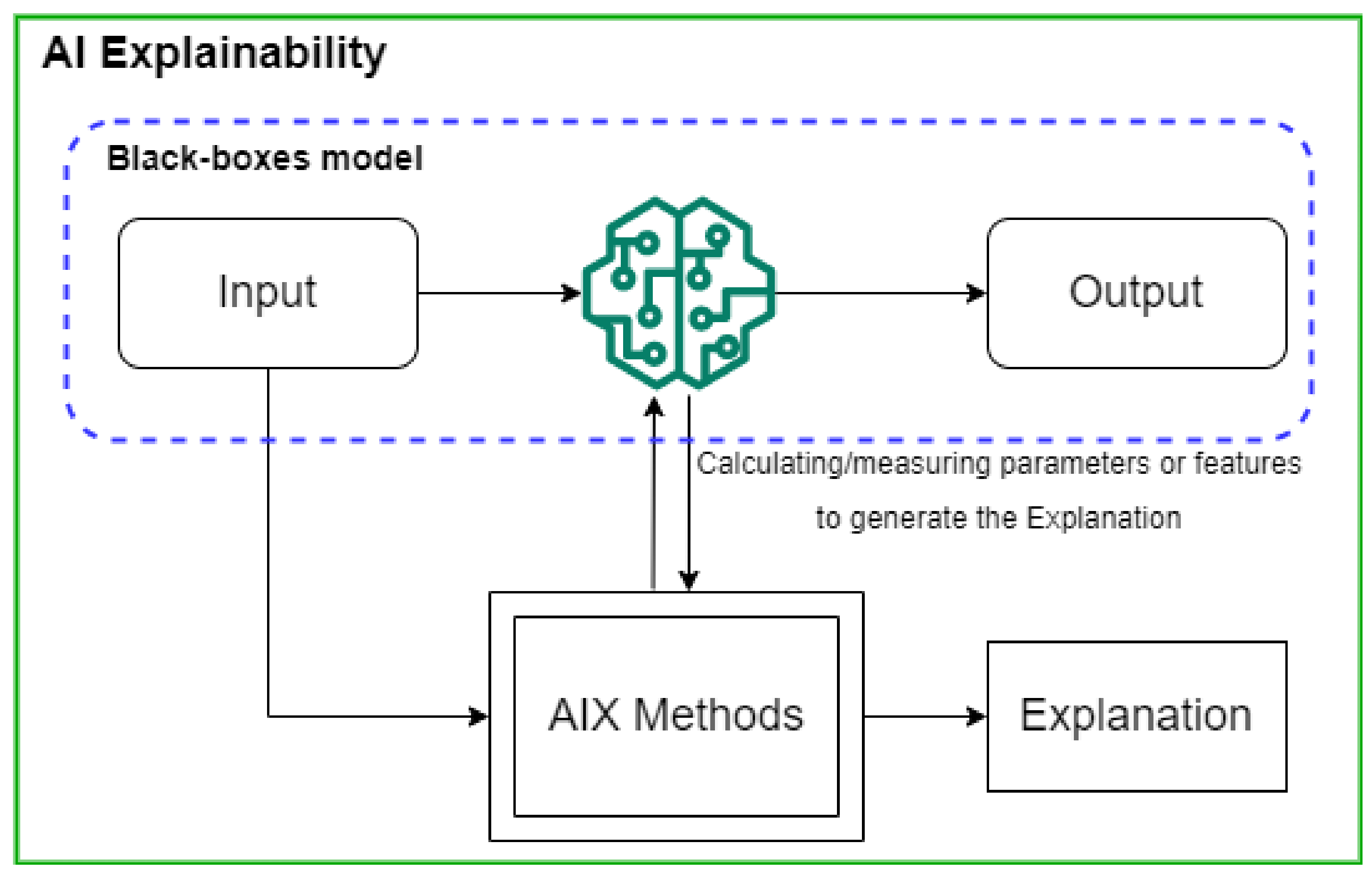

5.5. AI Explainability (AIX)

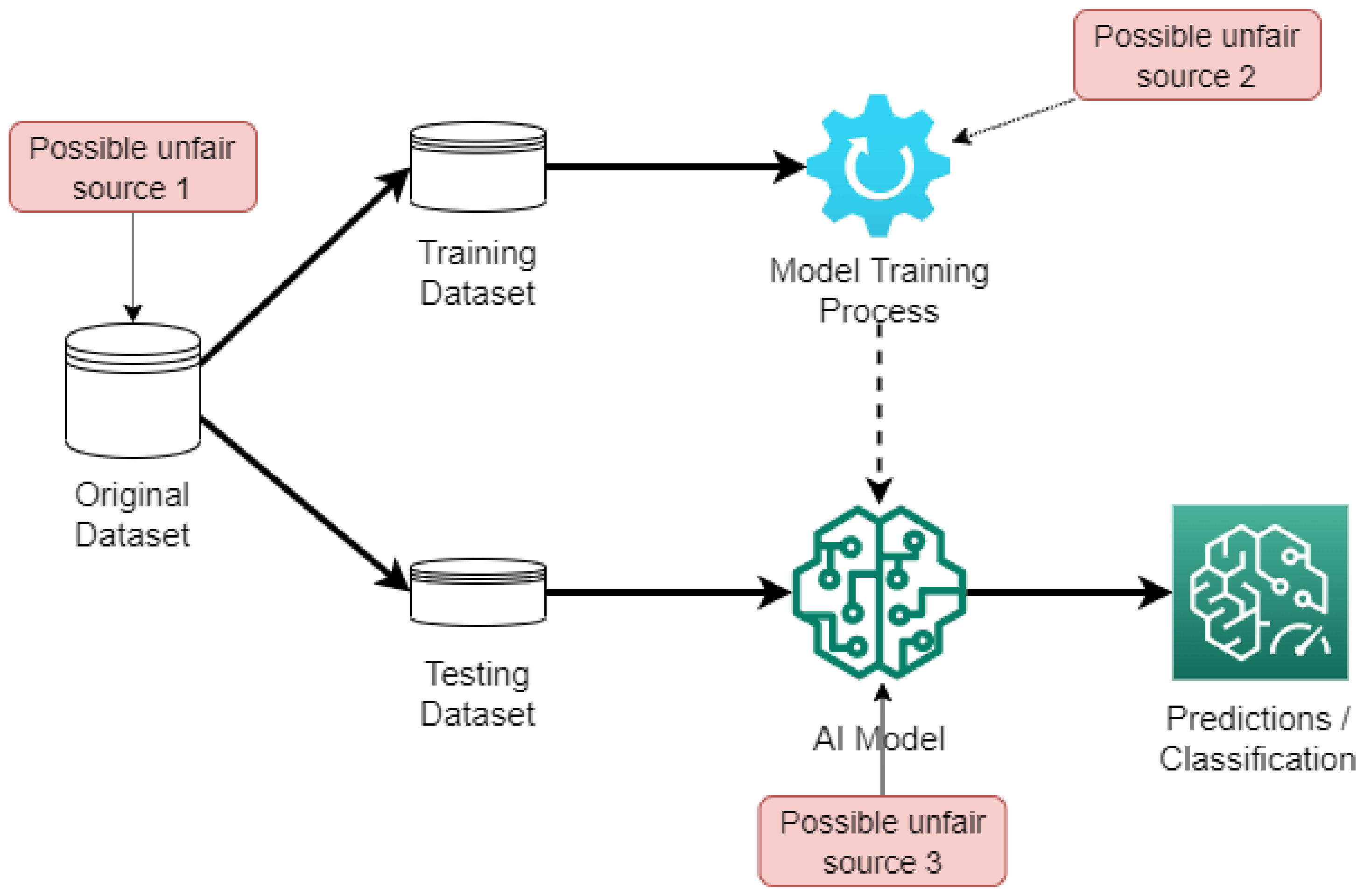

5.6. AI Fairness

5.7. Adversarial Robustness Toolbox (ART)

6. Future Thrust Areas in Additive Manufacturing

6.1. Big Data Analytics and IoT

6.2. Digital Twins

6.3. AI-Enabled Human-Centred AM

6.4. Federated Learning

6.5. Sustainability

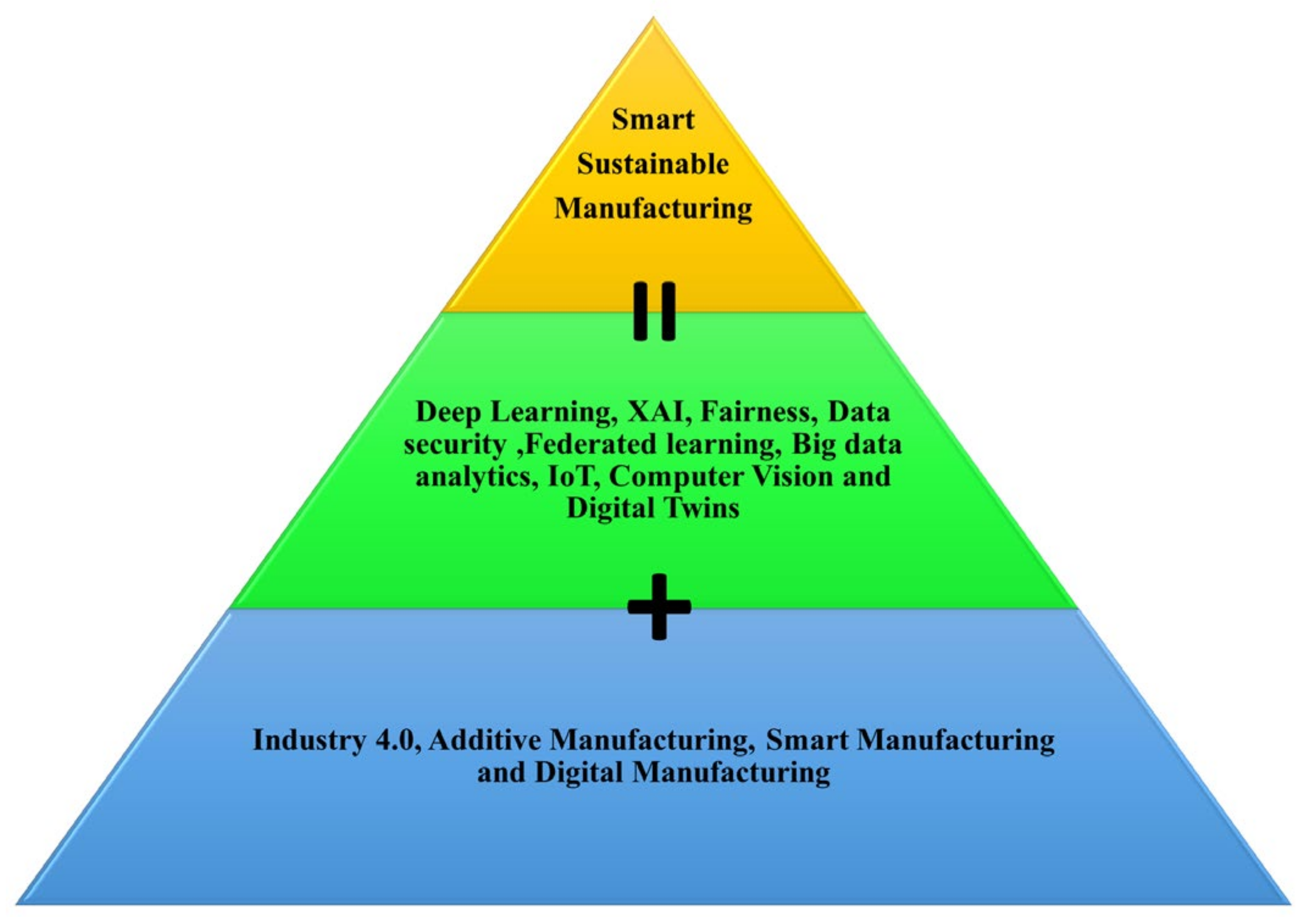

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef] [Green Version]

- Razvi, S.S.; Feng, S.; Narayanan, A.; Lee, Y.-T.T.; Witherell, P. A Review of Machine Learning Applications in Additive Manufacturing. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Jiang, J.; Weng, F.; Gao, S.; Stringer, J.; Xu, X.; Guo, P. A support interface method for easy part removal in directed energy deposition. Manuf. Lett. 2019, 20, 30–33. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, Y.; Pi, Y. Control of deposition height in WAAM using visual inspection of previous and current layers. J. Intell. Manuf. 2021, 32, 2209–2217. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep Learning in Neural Networks: An Overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yan, H.; Zhang, Y. A Deep Learning Method for Material Performance Recognition in Laser Additive Manufacturing. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 1735–1740. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.; Zhang, Z.; Rosen, D.W. Machine learning integrated design for additive manufacturing. J. Intell. Manuf. 2022, 33, 1073–1086. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 2017, 111, 1053–1070. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.; Lin, Y.; Tseng, T.-L.B. A review on quality control in additive manufacturing. Rapid Prototyp. J. 2018, 24, 645–669. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Shaikh, A.A. A Review on Machine Learning, Big Data Analytics, and Design for Additive Manufacturing for Aerospace Applications. J. Mater. Eng. Perform. 2022, 31, 6112–6130. [Google Scholar] [CrossRef]

- Charalampous, P.; Kostavelis, I.; Tzovaras, D. Non-destructive quality control methods in additive manufacturing: A survey. Rapid Prototyp. J. 2020, 26, 777–790. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.; Chai, S.; Kim, G.; Yong, H.; Bae, S.; Kwon, D. Review on Quality Control Methods in Metal Additive Manufacturing. Appl. Sci. 2021, 11, 1966. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef] [Green Version]

- Butt, J. Exploring the Interrelationship between Additive Manufacturing and Industry 4.0. Designs 2020, 4, 13. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Additive Manufacturing Applications in Industry 4.0: A Review. J. Ind. Integr. Manag. 2019, 4, 1930001. [Google Scholar] [CrossRef]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A review for advancements in standardization for additive manufacturing. Mater. Today Proc. 2022, 50, 1983–1990. [Google Scholar] [CrossRef]

- Taborda, L.L.L.; Maury, H.; Pacheco, J. Design for additive manufacturing: A comprehensive review of the tendencies and limitations of methodologies. Rapid Prototyp. J. 2021, 27, 918–966. [Google Scholar] [CrossRef]

- Puebla, K.; Arcaute, K.; Quintana, R.; Wicker, R.B. Effects of environmental conditions, aging, and build orientations on the mechanical properties of ASTM type I specimens manufactured via stereolithography. Rapid Prototyp. J. 2012, 18, 374–388. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Moroni, G.; Petrò, S.; Shao, H. On Standardization Efforts for Additive Manufacturing. In Proceedings of the 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 1–4 June 2020; Springer: Cham, Switzerland, 2020; pp. 156–172. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Rosen, D.W. Research supporting principles for design for additive manufacturing. Virtual Phys. Prototyp. 2014, 9, 225–232. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Minnema, J.; van Eijnatten, M.; Kouw, W.; Diblen, F.; Mendrik, A.; Wolff, J. CT image segmentation of bone for medical additive manufacturing using a convolutional neural network. Comput. Biol. Med. 2018, 103, 130–139. [Google Scholar] [CrossRef] [Green Version]

- Perone, C.S.; Cohen-Adad, J. Promises and limitations of deep learning for medical image segmentation. J. Med. Artif. Intell. 2019, 2, 1. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Additive manufacturing applications in orthopaedics: A review. J. Clin. Orthop. Trauma 2018, 9, 202–206. [Google Scholar] [CrossRef] [PubMed]

- Kamali, A.H.; Moradi, M.; Goodarzian, F.; Ghasemi, P. A discrete event simulation method for performance analysis of an additive manufacturing in the dental clinic. Int. J. Adv. Manuf. Technol. 2022, 118, 2949–2979. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Shang, X.; Li, Y.; Bao, Y.; Zhang, X.; Dong, X.; Wan, L.; Xiong, G.; Wang, F.-Y. PredNet and CompNet: Prediction and High-Precision Compensation of In-Plane Shape Deformation for Additive Manufacturing. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 462–467. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Guzzi, E.A.; Tibbitt, M.W. Additive Manufacturing of Precision Biomaterials. Adv. Mater. 2020, 32, e1901994. [Google Scholar] [CrossRef] [PubMed]

- Tuomi, J.; Paloheimo, K.-S.; Vehviläinen, J.; Björkstrand, R.; Salmi, M.; Huotilainen, E.; Kontio, R.; Rouse, S.; Gibson, I.; Mäkitie, A.A. A Novel Classification and Online Platform for Planning and Documentation of Medical Applications of Additive Manufacturing. Surg. Innov. 2014, 21, 553–559. [Google Scholar] [CrossRef]

- Shin, J.; Lee, Y.; Li, Z.; Hu, J.; Park, S.S.; Kim, K. Optimized 3D Bioprinting Technology Based on Machine Learning: A Review of Recent Trends and Advances. Micromachines 2022, 13, 363. [Google Scholar] [CrossRef]

- Jung, J.W.; Lee, J.-S.; Cho, D.-W. Computer-aided multiple-head 3D printing system for printing of heterogeneous organ/tissue constructs. Sci. Rep. 2016, 6, 21685. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delic, M.; Eyers, D.R. The effect of additive manufacturing adoption on supply chain flexibility and performance: An empirical analysis from the automotive industry. Int. J. Prod. Econ. 2020, 228, 107689. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.; Alves, M.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Shapiro, A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive Manufacturing for Aerospace Flight Applications. J. Spacecr. Rocket. 2016, 53, 952–959. [Google Scholar] [CrossRef]

- Schiller, G.J. Additive manufacturing for Aerospace. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Yakout, M.; Cadamuro, A.; Elbestawi, M.A.; Veldhuis, S.C. The selection of process parameters in additive manufacturing for aerospace alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2081–2098. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Drake, R.; Watts, C.; Martina, F. Defining Next-Generation Additive Manufacturing Applications for the Ministry of Defence (MoD). Procedia CIRP 2016, 55, 302–307. [Google Scholar] [CrossRef] [Green Version]

- Segonds, F. Design by Additive Manufacturing: An application in aeronautics and defence. Virtual Phys. Prototyp. 2018, 13, 237–245. [Google Scholar] [CrossRef] [Green Version]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Drake, R.; Watts, C.; Wilding, S. Additive manufacturing applications in Defence Support Services: Current practices and framework for implementation. Int. J. Syst. Assur. Eng. Manag. 2017, 9, 657–674. [Google Scholar] [CrossRef] [Green Version]

- Turkmen, K.G.H.S. Common FDM 3D Printing Defects. In Proceedings of the International Congress on 3D Printing (Additive Manufacturing) Technologies and Digital Industry, Antalya, Turkey, 19–21 April 2018. [Google Scholar]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Bochmann, L.; Bayley, C.; Helu, M.; Transchel, R.; Wegener, K.; Dornfeld, D. Understanding error generation in fused deposition modeling. Surf. Topogr. Metrol. Prop. 2015, 3, 014002. [Google Scholar] [CrossRef]

- Doubrovski, Z.; Verlinden, J.C.; Geraedts, J.M.P. Optimal Design for Additive Manufacturing: Opportunities and Challenges. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; Volume 54860, pp. 635–646. [Google Scholar] [CrossRef]

- Linder, W. Digital Photogrammetry; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

- Di Stefano, F.; Chiappini, S.; Gorreja, A.; Balestra, M.; Pierdicca, R. Mobile 3D scan LiDAR: A literature review. Geomat. Nat. Hazards Risk 2021, 12, 2387–2429. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Nagarkar, K.; DeGennaro, M.; Srihari, K.; Courtney, A.K.; Emick, F. A Study of the CT Scan Area of a Healthcare Provider. In Proceedings of the 2004 Winter Simulation Conference, Washington, DC, USA, 5–8 December 2004; Volume 2, pp. 939–945. [Google Scholar] [CrossRef]

- Yuan, L. Solidification Defects in Additive Manufactured Materials. JOM 2019, 71, 3221–3222. [Google Scholar] [CrossRef] [Green Version]

- Haghsefat, K.; Tingting, L. FDM 3D Printing Technology and Its Fundemental Properties. In Proceedings of the International Conference on Innovation and Research in Engineering Sciences, Tbilisi, Georgia, 30 June 2020. [Google Scholar]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Bishop, E.G.; Leigh, S.J. Using Large-Scale Additive Manufacturing (LSAM) as a Bridge Manufacturing Process in Response to Shortages in PPE during the COVID-19 Outbreak. Int. J. Bioprinting 2020, 6, 281. [Google Scholar] [CrossRef]

- Acevedo, R.; Sedlak, P.; Kolman, R.; Fredel, M. Residual stress analysis of additive manufacturing of metallic parts using ultrasonic waves: State of the art review. J. Mater. Res. Technol. 2020, 9, 9457–9477. [Google Scholar] [CrossRef]

- Geng, D.; Zhao, J. Analysis and Optimization of Warpage Deformation in 3D Printing Training Teaching—Taking Jilin University Engineering Training Center as an example. In Proceedings of the 2018 International Workshop on Education Reform and Social Sciences (ERSS 2018), Qingdao, China, 29–30 December 2019. [Google Scholar] [CrossRef] [Green Version]

- Kadam, V.; Kumar, S.; Bongale, A.; Wazarkar, S.; Kamat, P.; Patil, S. Enhancing Surface Fault Detection Using Machine Learning for 3D Printed Products. Appl. Syst. Innov. 2021, 4, 34. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. A multi-scale convolutional neural network for autonomous anomaly detection and classification in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2018, 24, 273–286. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Fischer, F.G.; Zimmermann, M.G.; Praetzsch, N.; Knaak, C. Monitoring of the powder bed quality in metal additive manufacturing using deep transfer learning. Mater. Des. 2022, 222, 111029. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; Debroy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Du, Y.; Mukherjee, T.; DebRoy, T. Physics-informed machine learning and mechanistic modeling of additive manufacturing to reduce defects. Appl. Mater. Today 2021, 24, 101123. [Google Scholar] [CrossRef]

- Zhang, B.; Seede, R.; Xue, L.; Atli, K.C.; Zhang, C.; Whitt, A.; Karaman, I.; Arroyave, R.; Elwany, A. An efficient framework for printability assessment in Laser Powder Bed Fusion metal additive manufacturing. Addit. Manuf. 2021, 46, 102018. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Y.; Oerlemans, A.; Lao, S.; Wu, S.; Lew, M.S. Deep learning for visual understanding: A review. Neurocomputing 2016, 187, 27–48. [Google Scholar] [CrossRef]

- Gu, J.; Wang, Z.; Kuen, J.; Ma, L.; Shahroudy, A.; Shuai, B.; Liu, T.; Wang, X.; Wang, G.; Cai, J.; et al. Recent advances in convolutional neural networks. Pattern Recognit. 2018, 77, 354–377. [Google Scholar] [CrossRef] [Green Version]

- O’Shea, K.; Nash, R. An Introduction to Convolutional Neural Networks. arXiv 2015, arXiv:1511.08458. [Google Scholar] [CrossRef]

- Shrestha, A.; Mahmood, A. Review of Deep Learning Algorithms and Architectures. IEEE Access 2019, 7, 53040–53065. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A Survey of Convolutional Neural Networks: Analysis, Applications, and Prospects. IEEE Trans. Neural Networks Learn. Syst. 2021, 33, 6999–7019. [Google Scholar] [CrossRef]

- Karoly, A.I.; Galambos, P.; Kuti, J.; Rudas, I.J. Deep Learning in Robotics: Survey on Model Structures and Training Strategies. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 266–279. [Google Scholar] [CrossRef]

- Saluja, A.; Xie, J.; Fayazbakhsh, K. A closed-loop in-process warping detection system for fused filament fabrication using convolutional neural networks. J. Manuf. Process. 2020, 58, 407–415. [Google Scholar] [CrossRef]

- Li, X.; Siahpour, S.; Lee, J.; Wang, Y.; Shi, J. Deep Learning-Based Intelligent Process Monitoring of Directed Energy Deposition in Additive Manufacturing with Thermal Images. Procedia Manuf. 2020, 48, 643–649. [Google Scholar] [CrossRef]

- Caggiano, A.; Zhang, J.; Alfieri, V.; Caiazzo, F.; Gao, R.; Teti, R. Machine learning-based image processing for on-line defect recognition in additive manufacturing. CIRP Ann. 2019, 68, 451–454. [Google Scholar] [CrossRef]

- Cui, W.; Zhang, Y.; Zhang, X.; Li, L.; Liou, F. Metal Additive Manufacturing Parts Inspection Using Convolutional Neural Network. Appl. Sci. 2020, 10, 545. [Google Scholar] [CrossRef] [Green Version]

- Jin, Z.; Zhang, Z.; Gu, G.X. Autonomous in-situ correction of fused deposition modeling printers using computer vision and deep learning. Manuf. Lett. 2019, 22, 11–15. [Google Scholar] [CrossRef]

- Snow, Z.; Diehl, B.; Reutzel, E.W.; Nassar, A. Toward in-situ flaw detection in laser powder bed fusion additive manufacturing through layerwise imagery and machine learning. J. Manuf. Syst. 2021, 59, 12–26. [Google Scholar] [CrossRef]

- Yuan, B.; Guss, G.M.; Wilson, A.C.; Hau--Riege, S.P.; DePond, P.J.; McMains, S.; Matthews, M.J.; Giera, B. Machine--Learning--Based Monitoring of Laser Powder Bed Fusion. Adv. Mater. Technol. 2018, 3, 1800136. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, Y.; Yeung, H.; Krishnamurty, S. Investigation of Deep Learning for Real-Time Melt Pool Classification in Additive Manufacturing. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 640–647. [Google Scholar] [CrossRef]

- Narayanan, B.N.; Beigh, K.; Loughnane, G.; Powar, N.U. Support vector machine and convolutional neural network based approaches for defect detection in fused filament fabrication. In Applications of Machine Learning; SPIE: Bellingham, WA, USA, 2019; p. 36. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, G.S.; Ye, D.; Zhu, K.; Fuh, J.Y. Extraction and evaluation of melt pool, plume and spatter information for powder-bed fusion AM process monitoring. Mater. Des. 2018, 156, 458–469. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of Recurrent Neural Network (RNN) and Long Short-Term Memory (LSTM) Network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef] [Green Version]

- Fu, R.; Zhang, Z.; Li, L. Using LSTM and GRU neural network methods for traffic flow prediction. In Proceedings of the 31st Youth Academic Annual Conference of Chinese Association of Automation (YAC 2016), Wuhan, China, 11–13 November 2016; pp. 324–328. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Zhang, Y.; Fuh, J.; Bi, G. Thermal field prediction for laser scanning paths in laser aided additive manufacturing by physics-based machine learning. Comput. Methods Appl. Mech. Eng. 2020, 362, 112734. [Google Scholar] [CrossRef]

- Mozaffar, M.; Liao, S.; Lin, H.; Ehmann, K.; Cao, J. Geometry-agnostic data-driven thermal modeling of additive manufacturing processes using graph neural networks. Addit. Manuf. 2021, 48, 102449. [Google Scholar] [CrossRef]

- Inyang-Udoh, U.; Mishra, S. A Physics-Guided Neural Network Dynamical Model for Droplet-Based Additive Manufacturing. IEEE Trans. Control Syst. Technol. 2022, 30, 1863–1875. [Google Scholar] [CrossRef]

- Mozaffar, M.; Paul, A.; Al-Bahrani, R.; Wolff, S.; Choudhary, A.; Agrawal, A.; Ehmann, K.; Cao, J. Data-driven prediction of the high-dimensional thermal history in directed energy deposition processes via recurrent neural networks. Manuf. Lett. 2018, 18, 35–39. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Wu, D. Prediction of melt pool temperature in directed energy deposition using machine learning. Addit. Manuf. 2021, 37, 101692. [Google Scholar] [CrossRef]

- Nalajam, P.K.; Varadarajan, R. A Hybrid Deep Learning Model for Layer-Wise Melt Pool Temperature Forecasting in Wire-Arc Additive Manufacturing Process. IEEE Access 2021, 9, 100652–100664. [Google Scholar] [CrossRef]

- Hu, F.; Qin, J.; Li, Y.; Liu, Y.; Sun, X. Deep Fusion for Energy Consumption Prediction in Additive Manufacturing. Procedia CIRP 2021, 104, 1878–1883. [Google Scholar] [CrossRef]

- Tian, Q.; Guo, S.; Melder, E.; Bian, L.; Guo, W. Deep Learning-Based Data Fusion Method for In Situ Porosity Detection in Laser-Based Additive Manufacturing. J. Manuf. Sci. Eng. 2021, 143, 041011. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Wang, W. Research on condition monitoring of FDM equipment based on LSTM. In Proceedings of the 2021 IEEE International Conference on Advances in Electrical Engineering and Computer Applications (AEECA), Dalian, China, 27–28 August 2021; pp. 612–615. [Google Scholar] [CrossRef]

- Yarahmadi, A.M.; Breuß, M.; Hartmann, C. Long Short-Term Memory Neural Network for Temperature Prediction in Laser Powder Bed Additive Manufacturing. In Proceedings of SAI Intelligent Systems Conference; Springer: Cham, Switzerland, 2023; pp. 119–132. [Google Scholar] [CrossRef]

- Tan, Y.; Jin, B.; Nettekoven, A.; Chen, Y.; Yue, Y.; Topcu, U.; Sangiovanni-Vincentelli, A. An Encoder-Decoder Based Approach for Anomaly Detection with Application in Additive Manufacturing. In Proceedings of the 2019 18th IEEE International Conference On Machine Learning And Applications (ICMLA), Boca Raton, FL, USA, 16–19 December 2019; pp. 1008–1015. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Wang, Z.; Tian, L.; Lauria, S.; Liu, X. Melt pool segmentation for additive manufacturing: A generative adversarial network approach. Comput. Electr. Eng. 2021, 92, 107183. [Google Scholar] [CrossRef]

- Hertlein, N.; Buskohl, P.R.; Gillman, A.; Vemaganti, K.; Anand, S. Generative adversarial network for early-stage design flexibility in topology optimization for additive manufacturing. J. Manuf. Syst. 2021, 59, 675–685. [Google Scholar] [CrossRef]

- Gobert, C.; Arrieta, E.; Belmontes, A.; Wicker, R.B.; Medina, F.; McWilliams, B. Conditional generative adversarial networks for in-situ layerwise additive manufacturing data. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019; University of Texas at Austin: Austin, TX, USA, 2019; pp. 192–201. [Google Scholar]

- Sharpe, C.; Seepersad, C.C. Topology Design with Conditional Generative Adversarial Networks. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019; American Society of Mechanical Engineers: Houston, TX, USA, 2019. [Google Scholar] [CrossRef]

- Siegkas, P. Generating 3D porous structures using machine learning and additive manufacturing. Mater. Des. 2022, 220, 110858. [Google Scholar] [CrossRef]

- Ramlatchan, A.; Li, Y. Image Synthesis Using Conditional GANs for Selective Laser Melting Additive Manufacturing. In Proceedings of the 2022 International Joint Conference on Neural Networks (IJCNN), Padua, Italy, 18–23 July 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Cannizzaro, D.; Varrella, A.G.; Paradiso, S.; Sampieri, R.; Chen, Y.; Macii, A.; Patti, E.; Di Cataldo, S. In-Situ Defect Detection of Metal Additive Manufacturing: An Integrated Framework. IEEE Trans. Emerg. Top. Comput. 2021, 10, 74–86. [Google Scholar] [CrossRef]

- Shi, Z.; Mandal, S.; Harimkar, S.; Liu, C. Surface Morphology Analysis Using Convolutional Autoencoder in Additive Manufacturing with Laser Engineered Net Shaping. Procedia Manuf. 2021, 53, 16–23. [Google Scholar] [CrossRef]

- Shi, Z.; Al Mamun, A.; Kan, C.; Tian, W.; Liu, C. An LSTM-autoencoder based online side channel monitoring approach for cyber-physical attack detection in additive manufacturing. J. Intell. Manuf. 2022, 1–17. [Google Scholar] [CrossRef]

- Salakhutdinov, R.; Mnih, A.; Hinton, G. Restricted Boltzmann machines for collaborative filter-ing. In Proceedings of the 24th International Conference on Machine Learning—ICML ’07, Corvalis, OR, USA, 20–24 June 2007; IEEE: New York, NY, USA, 2007; pp. 791–798. [Google Scholar] [CrossRef]

- Hua, Y.; Guo, J.; Zhao, H. Deep Belief Networks and deep learning. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Ye, D.; Hong, G.S.; Zhang, Y.; Zhu, K.; Fuh, J.Y.H. Defect detection in selective laser melting technology by acoustic signals with deep belief networks. Int. J. Adv. Manuf. Technol. 2018, 96, 2791–2801. [Google Scholar] [CrossRef]

- Ye, D.; Fuh, J.Y.H.; Zhang, Y.; Hong, G.S.; Zhu, K. In situ monitoring of selective laser melting using plume and spatter signatures by deep belief networks. ISA Trans. 2018, 81, 96–104. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Wang, G.; Xiong, G.; Zhao, M.; Li, G.; Li, R. Deep learning based online metallic surface defect detection method for wire and arc additive manufacturing. Robot. Comput. Manuf. 2023, 80, 102470. [Google Scholar] [CrossRef]

- Chen, Y.W.; Shiu, J.M. An implementation of YOLO-family algorithms in classifying the product quality for the acrylonitrile butadiene styrene metallization. Int. J. Adv. Manuf. Technol. 2022, 119, 8257–8269. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Cheung, C.F. CenterNet-based defect detection for additive manufacturing. Expert Syst. Appl. 2022, 188, 116000. [Google Scholar] [CrossRef]

- Petsiuk, A.; Singh, H.; Dadhwal, H.; Pearce, J.M. Synthetic-to-real Composite Semantic Seg-mentation in Additive Manufacturing. arXiv 2022, arXiv:2210.07466. [Google Scholar] [CrossRef]

- Wong, V.W.H.; Ferguson, M.; Law, K.H.; Lee, Y.-T.T.; Witherell, P. Automatic Volumetric Segmentation of Additive Manufacturing Defects with 3D U-Net. Janaury 2021. Available online: http://arxiv.org/abs/2101.08993 (accessed on 30 October 2022).

- Wang, R.; Cheung, C.; Wang, C. Unsupervised Defect Segmentation with Self-Attention in Ad-ditive Manufacturing. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Y.; Liu, C.; Shi, W. An Adaptive Reinforcement Learning-Based Scheduling Approach with Combination Rules for Mixed-Line Job Shop Production. Math. Probl. Eng. 2022, 2022, 1672166. [Google Scholar] [CrossRef]

- Abualkishik, A.Z.; Almajed, R. Deep Neural Network-based Fusion and Natural Language Processing in Additive Manufacturing for Customer Satisfaction. Fusion Pract. Appl. 2021, 3, 70–90. [Google Scholar] [CrossRef]

- Guo, D.; Ling, S.; Li, H.; Ao, D.; Zhang, T.; Rong, Y.; Huang, G.Q. A framework for personalized production based on digital twin, blockchain and addi-tive manufacturing in the context of Industry 4.0. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE), Hong Kong, China, 20–21 August 2020; pp. 1181–1186. [Google Scholar] [CrossRef]

- Rana, M.M.; Dahotre, N. IoT-Based Cyber-Physical Additive Manufacturing Systems: A Secure Communication Architecture, Research Challenges and Directions. In Proceedings of the 2021 6th International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 20–22 January 2021; pp. 216–219. [Google Scholar] [CrossRef]

- Kurt, M.N.; Ogundijo, O.; Li, C.; Wang, X. Online Cyber-Attack Detection in Smart Grid: A Reinforcement Learning Approach. IEEE Trans. Smart Grid 2019, 10, 5174–5185. [Google Scholar] [CrossRef] [Green Version]

- Frustaci, M.; Pace, P.; Aloi, G.; Fortino, G. Evaluating Critical Security Issues of the IoT World: Present and Future Challenges. IEEE Internet Things J. 2018, 5, 2483–2495. [Google Scholar] [CrossRef]

- Pearce, H.; Yanamandra, K.; Gupta, N.; Karri, R. FLAW3D: A Trojan-Based Cyber Attack on the Physical Outcomes of Additive Manufacturing. IEEE/ASME Trans. Mechatron. 2022, 3, 1–10. [Google Scholar] [CrossRef]

- Jakubovitz, D.; Giryes, R.; Rodrigues, M.R.D. Generalization Error in Deep Learning. In Compressed Sensing and Its Applications; Birkhäuser: Cham, Switzerland, 2019; pp. 153–193. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Bengio, S.; Hardt, M.; Recht, B.; Vinyals, O. Understanding deep learning (still) re-quires rethinking generalization. Commun. ACM 2021, 64, 107–115. [Google Scholar] [CrossRef]

- Justus, D.; Brennan, J.; Bonner, S.; McGough, A.S. Predicting the Computational Cost of Deep Learning Models. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 3873–3882. [Google Scholar] [CrossRef] [Green Version]

- Jouppi, N.P.; Young, C.; Patil, N.; Patterson, D.; Agrawal, G.; Bajwa, R.; Yoon, D.H. In-Datacenter Performance Analysis of a Tensor Processing Unit. In Proceedings of the 44th Annual International Symposium on Computer Architecture, Toronto, Canada, 24–28 June 2017; pp. 1–12. [Google Scholar] [CrossRef] [Green Version]

- Cai, H.; Gan, C.; Wang, T.; Zhang, Z.; Han, S. Once-for-All: Train One Network and Specialize It for Efficient Deployment. 2019; pp. 1–15. Available online: http://arxiv.org/abs/1908.09791 (accessed on 25 October 2022).

- Long, M.; Zhu, H.; Wang, J.; Jordan, M.I. Deep transfer learning with joint adaptation networks. In Proceedings of the 34th International Conference on Machine Learning ICML, Sydney, Australia, 6–11 August 2017; Volume 5, pp. 3470–3479. [Google Scholar]

- Kumar, M.; Moser, B.A.; Fischer, L.; Freudenthaler, B. Information Theoretic Evaluation of Privacy-Leakage, Interpretability, and Transferability for Trustworthy AI. arXiv 2022. Available online: http://arxiv.org/abs/2106.06046 (accessed on 27 October 2022).

- Ribeiro, M.T.; Singh, S.; Guestrin, C. ‘Why Should I Trust You?’: Explaining the Predictions of Any Classifier. arXiv 2016. Available online: http://arxiv.org/abs/1602.04938 (accessed on 25 October 2022).

- Zhou, P.; Finley, B.; Lee, L.-H.; Liao, Y.; Xie, H.; Hui, P. Towards User-Centered Metrics for Trustworthy AI in Immersive Cyberspace. arXiv 2022. Available online: https://arxiv.org/abs/2203.03718v1 (accessed on 25 October 2022).

- Markus, A.F.; Kors, J.A.; Rijnbeek, P.R. The role of explainability in creating trustworthy artificial intelligence for health care: A comprehensive survey of the terminology, design choices, and evaluation strategies. J. Biomed. Inform. 2021, 113, 103655. [Google Scholar] [CrossRef]

- Floridi, L. Establishing the rules for building trustworthy AI. Nat. Mach. Intell. 2019, 1, 261–262. [Google Scholar] [CrossRef]

- Brundage, M.; Avin, S.; Wang, J.; Belfield, H.; Krueger, G.; Hadfield, G.; Anderljung, M. Toward Trustworthy AI Development: Mechanisms for Supporting Verifiable Claims. arXiv 2020, arXiv:2004.07213. Available online: http://arxiv.org/abs/2004.07213 (accessed on 26 October 2022).

- Trusted AI—LFAI & Data. 11 May 2022. Available online: https://lfaidata.foundation/projects/trusted-ai/ (accessed on 26 October 2022).

- Thiebes, S.; Lins, S.; Sunyaev, A. Trustworthy artificial intelligence. Electron. Mark. 2021, 31, 447–464. [Google Scholar] [CrossRef]

- Baker-Brunnbauer, J. TAII Framework for Trustworthy AI Systems. ROBONOMICS J. Autom. Econ. 2021, 2, 17. [Google Scholar]

- Antoniadi, A.; Du, Y.; Guendouz, Y.; Wei, L.; Mazo, C.; Becker, B.; Mooney, C. Current Challenges and Future Opportunities for XAI in Machine Learning-Based Clinical Decision Support Systems: A Systematic Review. Appl. Sci. 2021, 11, 5088. [Google Scholar] [CrossRef]

- KServe. KSERVE, 11 May 2022. Available online: https://github.com/kserve/kserve (accessed on 25 October 2022).

- AI Explainability 360 (v0.2.1). Trusted-AI, 11 May 2022. Available online: https://github.com/Trusted-AI/AIX360 (accessed on 25 October 2022).

- AI Fairness 360 (AIF360). Trusted-AI, 11 May 2022. Available online: https://github.com/Trusted-AI/AIF360 (accessed on 25 October 2022).

- Adversarial Robustness Toolbox (ART) v1.10. Trusted-AI, 11 May 2022. Available online: https://github.com/Trusted-AI/adversarial-robustness-toolbox (accessed on 17 November 2022).

- Kaur, D.; Uslu, S.; Durresi, A.; Badve, S.; Dundar, M. Trustworthy Explainability Acceptance: A New Metric to Measure the Trustworthiness of Interpretable AI Medical Diagnostic Systems. In Conference on Complex, Intelligent, and Software Intensive Systems; Springer: Cham, Switzerland, 2021; pp. 35–46. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. October 2017, vol. 30. Available online: https://proceedings.neurips.cc/paper/2017/hash/8a20a8621978632d76c43dfd28b67767-Abstract.html (accessed on 17 November 2022).

- Selvaraju, R.R.; Cogswell, M.; Das, A.; Vedantam, R.; Parikh, D.; Batra, D. Grad-CAM: Visual Explanations from Deep Networks via Gradient-Based Localization. Robonomics J. Autom. Econ. 2022, 31, 336–359. [Google Scholar] [CrossRef]

- Gurumoorthy, K.S.; Dhurandhar, A.; Cecchi, G.; Aggarwal, C. Efficient Data Representation by Selecting Prototypes with Importance Weights. arXiv 2019. Available online: http://arxiv.org/abs/1707.01212 (accessed on 17 November 2022).

- Samek, W.; Montavon, G.; Lapuschkin, S.; Anders, C.J.; Muller, K.-R. Explaining Deep Neural Networks and Beyond: A Review of Methods and Applications. Proc. IEEE 2021, 109, 247–278. [Google Scholar] [CrossRef]

- Ahmed, I.; Jeon, G.; Piccialli, F. From Artificial Intelligence to Explainable Artificial Intelligence in Industry 4.0: A Survey on What, How, and Where. IEEE Trans. Ind. Inform. 2022, 18, 5031–5042. [Google Scholar] [CrossRef]

- Tolan, S.; Miron, M.; Gómez, E.; Castillo, C. Why Machine Learning May Lead to Unfairness: Evidence from Risk Assessment for Juvenile Justice in Catalonia. In Proceedings of the ICAIL ’19: Seventeenth International Conference on Artificial Intelligence and Law, Association for Computing Machinery, Montreal, QC, Canada, 17–21 June 2019; pp. 83–92. [Google Scholar] [CrossRef]

- Dastin, J. Amazon Scraps Secret AI Recruiting Tool that Showed Bias against Women *. In Ethics of Data and Analytics; Auerbach Publications: Boca Raton, FL, USA, 2022. [Google Scholar]

- Manzini, T.; Lim, Y.C.; Tsvetkov, Y.; Black, A.W. Black Is to Criminal as Caucasian Is to Police: Detecting and Removing Multiclass Bias in Word Embeddings. arXiv 2019. Available online: http://arxiv.org/abs/1904.04047 (accessed on 17 November 2022).

- Yang, K.; Qinami, K.; Fei-Fei, L.; Deng, J.; Russakovsky, O. Towards fairer datasets: Filtering and balancing the distribution of the people subtree in the ImageNet hierarchy. In Proceedings of the 2020 Conference on Fairness, Accountability, and Transparency, Association for Computing Machinery, Barcelona, Spain, 27–30 January 2020; pp. 547–558. [Google Scholar] [CrossRef]

- Lokhande, V.S.; Akash, A.K.; Ravi, S.N.; Singh, V. FairALM: Augmented Lagrangian Method for Training Fair Models with Little Regret. In European Conference on Computer Vision; Springer: Cham, Switzerland, 2020; pp. 365–381. [Google Scholar] [CrossRef]

- Maheshwari, G.; Perrot, M. FairGrad: Fairness Aware Gradient Descent. arXiv 2022. Available online: http://arxiv.org/abs/2206.10923 (accessed on 17 November 2022).

- Zhao, B.; Xiao, X.; Gan, G.; Zhang, B.; Xia, S.-T. Maintaining Discrimination and Fairness in Class Incremental Learning. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 13–19 June 2020; pp. 13208–13217. Available online: https://openaccess.thecvf.com/content_CVPR_2020/html/Zhao_Maintaining_Discrimination_and_Fairness_in_Class_Incremental_Learning_CVPR_2020_paper.html (accessed on 17 November 2022).

- Chen, P.-Y.; Zhang, H.; Sharma, Y.; Yi, J.; Hsieh, C.-J. ZOO: Zeroth Order Optimization Based Black-box Attacks to Deep Neural Networks without Training Substitute Models. In Proceedings of the 10th ACM Workshop on Artificial Intelligence and Security, Dallas, TX, USA, 2–6 April 2017; Association for Computing Machinery: New York, NY, USA; pp. 15–26. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.-Y.; Sharma, Y.; Zhang, H.; Yi, J.; Hsieh, C.-J. EAD: Elastic-Net Attacks to Deep Neural Networks via Adversarial Examples. In Proceedings of the AAAI Conference on Artificial Intelligence; AAAI Press: Palo Alto, CA, USA; New Orleans, LA, USA, 2018; Volume 32. [Google Scholar] [CrossRef]

- Newaz, A.I.; Haque, N.I.; Sikder, A.K.; Rahman, M.A.; Uluagac, A.S. Adversarial Attacks to Machine Learning-Based Smart Healthcare Systems. In Proceedings of the GLOBECOM 2020–2020 IEEE Global Communications Conference, Taipei, Taiwan, 7–11 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Lin, J.; Xu, L.; Liu, Y.; Zhang, X. Composite Backdoor Attack for Deep Neural Network by Mix-ing Existing Benign Features. In Proceedings of the 2020 ACM SIGSAC Conference on Computer and Communications Security, Virtual, 9–13 November 2020; Association for Computing Machinery: New York, NY, USA, 2020; pp. 113–131. [Google Scholar] [CrossRef]

- Cheng, S.; Liu, Y.; Ma, S.; Zhang, X. Deep Feature Space Trojan Attack of Neural Networks by Controlled Detoxification. In Proceedings of the AAAI Conference on Artificial Intelligence, Virtually, 2–9 May 2021; AAAI Press: Palo Alto, CA, USA, 2021; Volume 35, pp. 1148–1156. [Google Scholar] [CrossRef]

- Xivuri, K.; Twinomurinzi, H. A Systematic Review of Fairness in Artificial Intelligence Algorithms. In Conference on e-Business, e-Services and e-Society; Springer: Cham, Switzerland, 2021; pp. 271–284. [Google Scholar] [CrossRef]

- John-Mathews, J.-M.; Cardon, D.; Balagué, C. From Reality to World. A Critical Perspective on AI Fairness. J. Bus. Ethics 2022, 178, 945–959. [Google Scholar] [CrossRef]

- Janssen, M.; Brous, P.; Estevez, E.; Barbosa, L.S.; Janowski, T. Data governance: Organizing data for trustworthy Artificial Intelligence. Gov. Inf. Q. 2020, 37, 101493. [Google Scholar] [CrossRef]

- Silva, S.H.; Najafirad, P. Opportunities and Challenges in Deep Learning Adversarial Robustness: A Survey. arXiv 2020. Available online: http://arxiv.org/abs/2007.00753 (accessed on 17 November 2022).

- Raj, A.; Bresler, Y.; Li, B. Improving Robustness of Deep-Learning-Based Image Reconstruction. In Proceedings of the 37th International Conference on Machine Learning, Virtual Event, 12–18 July 2020; pp. 7932–7942. Available online: https://proceedings.mlr.press/v119/raj20a.html (accessed on 17 November 2022).

- Goswami, G.; Ratha, N.; Agarwal, A.; Singh, R.; Vatsa, M. Unravelling Robustness of Deep Learning Based Face Recognition Against Adversarial Attacks. In Proceedings of the AAAI Conference on Artificial Intelligence, New Orleans, LA, USA, 2–7 February 2018; Volume 32. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Sun, Y.; Ma, X.; Wang, D.; Sun, J.; Cheng, P. RobOT: Robustness-Oriented Testing for Deep Learning Systems. In Proceedings of the 2021 IEEE/ACM 43rd International Conference on Software Engineering (ICSE), Madrid, Spain, 22–30 May 2021; pp. 300–311. [Google Scholar] [CrossRef]

- Carlini, N.; Wagner, D. Towards Evaluating the Robustness of Neural Networks. In Proceedings of the 2017 IEEE Symposium on Security and Privacy (SP), San Jose, CA, USA, 22–26 May 2017; pp. 39–57. [Google Scholar] [CrossRef] [Green Version]

- Tramèr, F.; Kurakin, A.; Papernot, N.; Goodfellow, I.; Boneh, D.; McDaniel, P. Ensemble Adversarial Training: Attacks and Defenses. arXiv 2017, arXiv:1705.07204. [Google Scholar] [CrossRef]

- Hajjaji, Y.; Boulila, W.; Farah, I.R.; Romdhani, I.; Hussain, A. Big data and IoT-based applications in smart environments: A systematic review. Comput. Sci. Rev. 2020, 39, 100318. [Google Scholar] [CrossRef]

- Bi, K.; Lin, D.; Liao, Y.; Wu, C.-H.; Parandoush, P. Additive manufacturing embraces big data. Prog. Addit. Manuf. 2021, 6, 181–197. [Google Scholar] [CrossRef]

- Francis, J.; Bian, L. Deep Learning for Distortion Prediction in Laser-Based Additive Manufacturing using Big Data. Manuf. Lett. 2019, 20, 10–14. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial Internet of Things (IIOT). In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 129–164. [Google Scholar] [CrossRef]

- Amanullah, M.A.; Habeeb, R.A.A.; Nasaruddin, F.H.; Gani, A.; Ahmed, E.; Nainar, A.S.M.; Akim, N.M.; Imran, M. Deep learning and big data technologies for IoT security. Comput. Commun. 2020, 151, 495–517. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Tuegel, E.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef] [Green Version]

- DebRoy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Juarez, M.G.J.; Botti, V.J.; Giret, A.S. Digital Twins: Review and Challenges. J. Comput. Inf. Sci. Eng. 2021, 21, 030802. [Google Scholar] [CrossRef]

- Groshev, M.; Guimaraes, C.; Martin-Perez, J.; de la Oliva, A. Toward Intelligent Cyber-Physical Systems: Digital Twin Meets Artificial Intelligence. IEEE Commun. Mag. 2021, 59, 14–20. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital twin-driven supervised machine learning for the development of artificial intelligence applications in manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Tian, W.; Kan, C. When AI meets additive manufacturing: Challenges and emerging opportunities for human-centered products development. J. Manuf. Syst. 2022, 64, 648–656. [Google Scholar] [CrossRef]

- Kollmann, H.T.; Abueidda, D.W.; Koric, S.; Guleryuz, E.; Sobh, N.A. Deep learning for topology optimization of 2D metamaterials. Mater. Des. 2020, 196, 109098. [Google Scholar] [CrossRef]

- Tang, Y.; Dong, G.; Xiong, Y.; Wang, Q. Data-driven Design of Customized Porous Lattice Sole Fabricated by Additive Manufacturing. Procedia Manuf. 2021, 53, 318–326. [Google Scholar] [CrossRef]

- Yang, H.; Rao, P.; Simpson, T.; Lu, Y.; Witherell, P.; Nassar, A.R.; Reutzel, E.; Kumara, S. Six-Sigma Quality Management of Additive Manufacturing. Proc. IEEE 2021, 109, 347–376. [Google Scholar] [CrossRef] [PubMed]

- Colosimo, B.M.; Huang, Q.; Dasgupta, T.; Tsung, F. Opportunities and challenges of quality engineering for additive manufacturing. J. Qual. Technol. 2018, 50, 233–252. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Fan, Y.; Tse, M.; Lin, K.-Y. A review of applications in federated learning. Comput. Ind. Eng. 2020, 149, 106854. [Google Scholar] [CrossRef]

- Yin, X.; Zhu, Y.; Hu, J. A Comprehensive Survey of Privacy-preserving Federated Learning. ACM Comput. Surv. 2021, 54, 1–36. [Google Scholar] [CrossRef]

- Kanagavelu, R.; Li, Z.; Samsudin, J.; Hussain, S.; Yang, F.; Yang, Y.; Goh, R.S.M.; Cheah, M. Federated Learning for Advanced Manufacturing Based on Industrial IoT Data Analytics. In Implementing Industry; Springer: Cham, Switzerland, 2021; pp. 143–176. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, Z.; He, K.; Lai, S.; Xia, J.; Fan, L. Efficient and flexible management for industrial Internet of Things: A federated learning approach. Comput. Networks 2021, 192, 108122. [Google Scholar] [CrossRef]

- Zellinger, W.; Wieser, V.; Kumar, M.; Brunner, D.; Shepeleva, N.; Gálvez, R.; Langer, J.; Fischer, L.; Moser, B. Beyond federated learning: On confidentiality-critical machine learning applications in industry. Procedia Comput. Sci. 2019, 180, 734–743. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, H.; Fang, Z.; Wang, Z. Industrial Internet Federated Learning Driven by IoT Equipment ID and Blockchain. Wirel. Commun. Mob. Comput. 2021, 2021, 7705843. [Google Scholar] [CrossRef]

- Mehta, M.; Shao, C. Federated learning-based semantic segmentation for pixel-wise defect detection in additive manufacturing. J. Manuf. Syst. 2022, 64, 197–210. [Google Scholar] [CrossRef]

- KAggour, K.S.; Kumar, V.S.; Cuddihy, P.; Williams, J.W.; Gupta, V.; Dial, L.; Hanlon, T.; Gambone, J.; Vinciquerra, J. Federated Multimodal Big Data Storage & Analytics Platform for Additive Manufacturing. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 1729–1738. [Google Scholar] [CrossRef]

- Hao, M.; Li, H.; Luo, X.; Xu, G.; Yang, H.; Liu, S. Efficient and Privacy-Enhanced Federated Learning for Industrial Artificial Intelligence. IEEE Trans. Ind. Inform. 2019, 16, 6532–6542. [Google Scholar] [CrossRef]

- Qu, Y.; Pokhrel, S.R.; Garg, S.; Gao, L.; Xiang, Y. A Blockchained Federated Learning Framework for Cognitive Computing in Industry 4.0 Networks. IEEE Trans. Ind. Inform. 2021, 17, 2964–2973. [Google Scholar] [CrossRef]

- Rieke, N.; Hancox, J.; Li, W.; Milletarì, F.; Roth, H.R.; Albarqouni, S.; Bakas, S.; Galtier, M.N.; Landman, B.A.; Maier-Hein, K.; et al. The future of digital health with federated learning. NPJ Digit. Med. 2020, 3, 119. [Google Scholar] [CrossRef] [PubMed]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: The circular economy of materials and environmental perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Niaki, M.K.; Torabi, S.A.; Nonino, F. Why manufacturers adopt additive manufacturing technologies: The role of sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Dwivedi, G.; Srivastava, S.K.; Srivastava, R.K. Analysis of barriers to implement additive manufacturing technology in the Indian automotive sector. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 972–991. [Google Scholar] [CrossRef]

- Rogers, H.; Baricz, N.; Pawar, K.S. 3D printing services: Classification, supply chain implications and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 886–907. [Google Scholar] [CrossRef]

- Fruggiero, F.; Lambiase, A.; Bonito, R.; Fera, M. The load of sustainability for Additive Manufacturing processes. Procedia Manuf. 2019, 41, 375–382. [Google Scholar] [CrossRef]

- Delgadillo, R.R.; Medini, K.; Wuest, T. A DMAIC Framework to Improve Quality and Sustainability in Additive Manufacturing—A Case Study. Sustainability 2022, 14, 581. [Google Scholar] [CrossRef]

- Ribeiro, I.; Matos, F.; Jacinto, C.; Salman, H.; Cardeal, G.; Carvalho, H.; Godina, R.; Peças, P. Framework for Life Cycle Sustainability Assessment of Additive Manufacturing. Sustainability 2020, 12, 929. [Google Scholar] [CrossRef] [Green Version]

- Taddese, G.; Durieux, S.; Duc, E. Sustainability performance indicators for additive manufacturing: A literature review based on product life cycle studies. Int. J. Adv. Manuf. Technol. 2020, 107, 3109–3134. [Google Scholar] [CrossRef]

- Agnusdei, L.; Del Prete, A. Additive manufacturing for sustainability: A systematic literature review. Sustain. Futur. 2022, 4, 100098. [Google Scholar] [CrossRef]

| Sector | Application | Modalities | Use | Material | Process | Deep Learning Model | References |

| Medical | Orthopedics | Anatomic models | Implant | Stainless steel, Titanium | Classification, Segmentation | CNN, U NET | [28,29,30] |

| Dental | Crowns Fixtures | Titanium, MFH | Shape deformation in AM part | PredNet and CompNet | [31,32,33] | ||

| Pharma | NA | Drug delivery | Polymer | Optimization | LSTM | [34,35] | |

| Bioprinting | Extrusion-based, Inkjet | Tissue engineering | Bio ink | Classification | [36,37] | ||

| Automotive | Production flexibility | Custom parts | Metal, Polymer | Optimization, Quality control | CNN, | [38,39] | |

| Aerospace | Electron beam melting, Selective laser melting, and laser deposition, | Microtrusses, Multifunctional Structures | Multi materials, Metals, Titanium, Ceramics | Parameter optimization, Segmentation | LSTM, CNN | [40,41,42] | |

| Defense | Defense Support Service | Delocalized manufacturing | NA | Computer vision | Deep learning | [43,44,45] |

| Technique | Description | Quality | Drawback | Reference |

|---|---|---|---|---|

| Photogrammetry | Based on images collected from various angles surrounding an object and then “stitched” together using software applications | Low | The method requires a studio setup because it involves a complex camera system that can be challenging to set up and is not easily portable. | [50] |

| Light-based 3D scanning | A structured–light 3D scanner produces a light pattern of parallel stripes on an object’s surface. This projection is then recorded by the scanner’s camera and converted into a digital duplicate. | High | For small objects. | [51] |

| CT scanning | CT scanning involves numerous X-ray projections into an object, producing images merged to generate a computerized 3D model. | High | CT scanning is exceptional in providing data on the exterior and inside components. | [52] |

| Anomaly | Cause | Affect | References |

| Cracking | Small cavities, stress buildup, and uneven heating or cooling | Failure of a printed part. | [53] |

| Porosity | Inadequate printing procedure or material | Cavities in the printed component | [53] |

| Material Shrinkage | Property of the material used. | Lead to the generation of residual stress, which can induce cracks in the material. | [54] |

| Poor surface finish | Technique and materials used in printing | More time in post-processing | [55] |

| Stringing | Printing technique and material used | Extra material attached to the part needs post-processing | [56] |

| Residual Stress | The print is rapidly heated or cooled. | The excessive tensile strength can result in the creation of cracks or flaws such as warpage. | [57] |

| Wrapping | Incorrect cooling of the printed component or because of the materials’ processing | The component swells upward, causing a change in form. | [58] |

| Blistering | Lower layers need to be adequately cooled. | Because of the weights of the top layers, the lowest layer swells outward. | [59] |

| Recoater Hopping | As a result of the recoater blade impacting a component | Lead to an inhomogeneous spreading of material | [60] |

| Recoater Streaking | It happened because the recoater blade damaged itself or because it dragged a contaminant across the powder bed. | Poor surface quality | [61] |

| Super-Elevation | When a section bends or coils upward through the powder layer, this occurs. | The effect of leftover thermal stresses or swelling. | [60] |

| Incomplete Spreading | When not enough powder is consistently taken from the powder dispenser, this error happens. | As a result, there is a lack of powder, the severity of which is greatest near the powder collector. | [62] |

| Lack of fusion | This flaw is a result of improper laser power, scanning speed, laser spot radius, layer thickness, hatch spacing, and alloy choice, among other factors. | Insufficient overlaps of successive melt pools, Lead o part rejection | [63,64,65] |

| Balling | Molten pools break in the separated island | Lead to a discontinuous melting track | [66,67] |

| Type of CNN | AM Process | Activation | Loss | Optimizer | Accuracy | References |

|---|---|---|---|---|---|---|

| CNN | Leaky-Relu and SoftMax | Cross entropy | Adam | 99.3% | [74] | |

| Alex Net | Powder bed fusion | SoftMax and Relu | - | Momentum-based Stochastic Gradient Descent | 97% | [60] |

| CNN | Direct energy deposition | SoftMax and Relu | Cross entropy | Adam | 80 | [75] |

| CNN | Selective laser melting | SoftMax and Relu | Cross entropy | Gradient descent | 99.4 | [76] |

| CNN | Metal AM | SoftMax and Relu | Cross entropy | Adam | 92.1% | [77] |

| ResNet 50 | FDM | 98 | [78] | |||

| CNN | PBF | SoftMax and Relu | [79] | |||

| CNN | LASER PBF | ReLU and sigmoid | Standard mean squared error and cross-entropy | Adam | 93.1 | [80] |

| CNN | PBF (melt pool classification) | Reply | 9.84 | [81] | ||

| CNN | Fused filament fabrication | SoftMax and Relu | 99.5 | [82] | ||

| CNN | PBF (Melt pool, plume and splatter) | SoftMax and Relu | Mini batch gradient descent | 92.7 | [83] |

| Model | AM Procedure | Problem | Outcome | References |

| RNN +DNN | Laser-based | Laser scanning patterns and the thermal history distributions correlated, and finding a relationship is complex. | The created RNN-DNN model can forecast thermal fields for any geometry using various scanning methodologies. The agreement between the numerical simulation results and the RNN-DNN forecasts was more significant than 95%. | [86] |

| RGNN GNN | DED | Specific model generalizability has remained a barrier across a wide range of geometries. | Deep learning architecture provides a feasible substitute for costly computational mechanics or experimental techniques by successfully forecasting long thermal histories for unknown geometries during the training phase. | [87] |

| Conv-RNN | Inkjet AM | Height data from the input–output relationship. | The model was empirically validated and shown to outperform a trained MLP with significantly fewer data. | [88] |

| RNN, GRU | DED | High-dimensional thermal history in DED processes is forecast with changes in geometry such as build dimensions, toolpath approach, laser power, and scan speed. | The model can predict the temperature history of each given point of the DED based on a test-set database and with minimum training. | [89] |

| LSTM | DED | To determine the temperature of the molten pool, analytical and numerical methods have been developed; however, since the real-time melt pool temperature distribution is not taken into account, the accuracy of these methods is rather low. | Developed a machine learning-based data-driven predictive algorithm to accurately estimate the melt pool temperature during DED. | [90] |

| CNN, LSTM | DED | Forecasting melt pool temperature is layer-by-layer. | By combining CNN and LSTM networks, geographical and temporal information may be retrieved from melt pool temperature data. | [91] |

| CNN, LSTM | SLS | Several factors determine the energy consumption of AM systems. These aspects include traits with multiple dimensions and structures, making them difficult to examine. | A data fusion strategy is offered for estimating energy consumption. | [92] |

| PyroNet, IRNet, LSTM | Laser-based Additive Manufacturing | Intends to advance awareness of the fundamental connection between the LBAM method and porosity. | DL-based data fusion method that takes advantage of the measured melt pool’s thermal history as well as two newly built deep learning neural networks to estimate porosity in LBAM sections. | [93] |

| LSTM | FDM | It is investigated how equipment operating conditions affect the quality of the generated products using standard data features from the printer’s sensor signals (vibration, current, etc.). | An intelligent monitoring system has been designed in terms of working conditions and product quality. | [94] |

| LSTM | PBF | During the printing process to avoid an uneven and harsh temperature distribution across the printing plate | Anticipate temperature gradient distributions during the printing process | [95] |

| Model | AM Procedure | Problem | Solution | Ref |

| GAN | DED | Melt pool segmentation | The melt pool’s morphology is examined by segmenting the collected thermal images. | [97] |

| GAN | NA | Topology optimization | A deep learning-based system has been successfully built to generate designs with little compliance suited for additive manufacturing. | [98] |

| CGAN | PBF | Monitoring in-situ layer-wise images for unseen conditional inputs | Using the turbine blade data collection, a CGAN was trained and used to produce new in-situ layerwise images for unseen conditional inputs. | [99] |

| GAN | NA | Topology design, concept generation | Discusses avenues for further developments that would enable the engineering design community to further leverage generative machine learning techniques to their full potential. | [100] |

| GAN, a bag of features | Mimicking–biomimicking porous structures. | Within the same resolution, created structures demonstrated consistency in compressive properties; however, reducing resolution considerably affects resultant properties. The structures developed have the potential to be scaled and employed with various materials and additive manufacturing techniques. | [101] | |

| CGAN | SLM | The difficulty is gathering enough data to characterize the internal microstructures to evaluate their physical attributes, as the laser passes at high speeds over powder grains at a micrometer scale. | The fake data can be generated using generative models with the same qualities as the experimental photographs could be generated. | [102] |

| GAN | PBF | Limited defect monitoring data, difficulties acquiring and integrating AM process data during fabrication | Generative adversarial network (GAN)-based off-axis camera mounted on top of the machine to detect faults in real-time and automatically provide synthetic images for dataset augmentation | [103] |

| Autoencoder | Laser Engineered Net Shaping | Surface profiles are often highly nonlinear; (2) a significant number of outliers and missing regions may occur in the observed surface profile. | A technique based on convolutional autoencoders is used to extract useful features from surface profiles. | [104] |

| fused filament fabrication (FFF) | Monitoring and effectively detecting cyber-physical threats has become a significant hurdle to the widespread use of AM technology. | To detect unexpected process/product changes caused by cyber-physical attacks, a data-driven feature extraction strategy based on the LSTM-autoencoder is developed. | [105] |

| Model | AM | Problem | Solution | Ref |

|---|---|---|---|---|

| DBN | SLM | Due to the addition of several phases during defect identification using conventional classification algorithms, the system becomes fairly complex. | The DBN technique might achieve a high defect identification rate among five melted states without signal preprocessing. It is implemented without feature extraction and signal preprocessing using a streamlined classification structure. | [108] |

| DBN | SLM | Melted state recognition during the SLM process. | [109] |

| Reference | Necessary Criteria, Mechanisms, or Frameworks of TAI |

|---|---|

| Floridi [133] | Criteria of TAI |

Floridi [133]

| |

| M. Brundage et al. [134] | Mechanism of TAI |

M. Brundage et al. [134]

| |

| Trusted AI Project [135] | Framework of TAI |

Trusted AI Project [135]

| |

| Thiebes et al. [136] | Criteria of TAI |

Thiebes et al. [136]

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pratap, A.; Sardana, N.; Utomo, S.; Ayeelyan, J.; Karthikeyan, P.; Hsiung, P.-A. A Synergic Approach of Deep Learning towards Digital Additive Manufacturing: A Review. Algorithms 2022, 15, 466. https://doi.org/10.3390/a15120466

Pratap A, Sardana N, Utomo S, Ayeelyan J, Karthikeyan P, Hsiung P-A. A Synergic Approach of Deep Learning towards Digital Additive Manufacturing: A Review. Algorithms. 2022; 15(12):466. https://doi.org/10.3390/a15120466

Chicago/Turabian StylePratap, Ayush, Neha Sardana, Sapdo Utomo, John Ayeelyan, P. Karthikeyan, and Pao-Ann Hsiung. 2022. "A Synergic Approach of Deep Learning towards Digital Additive Manufacturing: A Review" Algorithms 15, no. 12: 466. https://doi.org/10.3390/a15120466

APA StylePratap, A., Sardana, N., Utomo, S., Ayeelyan, J., Karthikeyan, P., & Hsiung, P.-A. (2022). A Synergic Approach of Deep Learning towards Digital Additive Manufacturing: A Review. Algorithms, 15(12), 466. https://doi.org/10.3390/a15120466