Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space

Abstract

1. Introduction

1.1. Literature Review

1.2. Background and Related Work

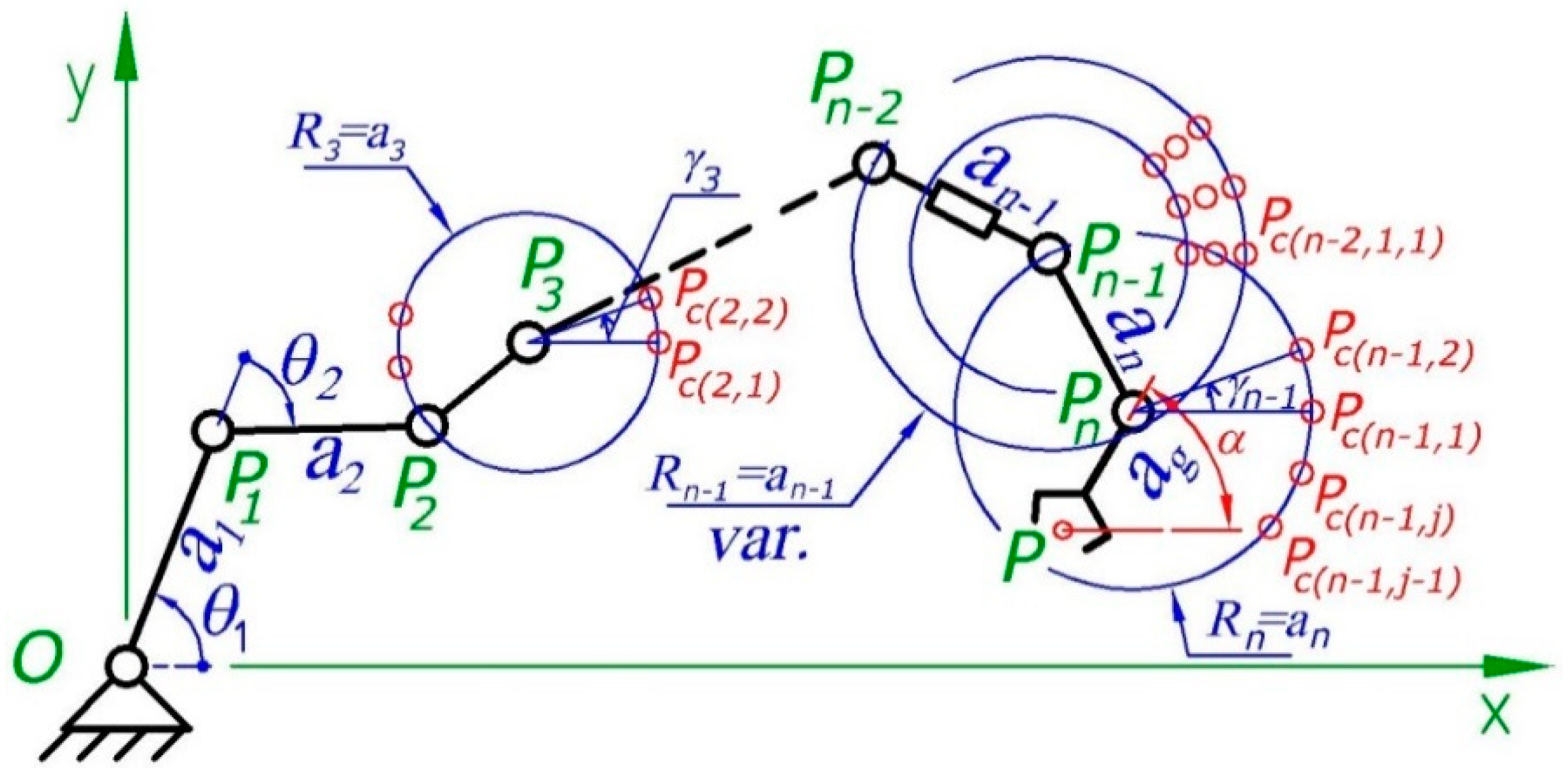

2. Definitions and Conditions for the Solution Types

- -

- Detect and classify multiple inverse kinematics solutions for a single position and orientation of the gripper;

- -

- Generate IK solutions for a planar trajectory in the workspace with or without changing the gripper orientation;

- -

- Generate the configuration space and regions of it corresponding to Definitions 1–3;

- -

- Generate the workspace and regions of it corresponding to Definitions 1–3.

3. Materials and Methods

- -

- The reviewed configuration is not an IK solution.

- -

- There is only one solution, classified according to definitions 1, 2 and 3; for example: .

- -

- There are two solutions, classified according to definitions 1, 2 and 3; for example: and .

4. Results

4.1. Example 1

4.2. Example 2

Octants and Types of Solutions in the Configuration Space

5. Discussion

5.1. Discussion of Definitions

5.2. Discussion of Example 1

5.3. Discussion of Example 2

5.4. Advantages of the Algorithm

- -

- Finds a set of points in the configuration space that can reach a given point in the workspace and sorts them by type. This can be used to determine the service coefficient and the robot’s mobility factor.

- -

- Transforms trajectories from the workspace into a corresponding set of points with possible solutions in the configuration space. This gives completeness to the solutions, unlike some numerical methods known so far, which find only one solution, one that is affected by the initial configuration;

- -

- Can be used to define regions from the workspace and configuration space with different types of solutions. Once created, a region map for a particular robot (environment with obstacle), can be used repeatedly by motion planning algorithms with different initial and target configurations.

- -

- Finds an IK solution even in singular configurations. Numerical methods based on the Jacobian matrix do not deal with this problem.

- -

- The algorithm is applicable to planar robots with a serial structure.

- -

- The resulting regions are useful for planning the placement of objects in the workspace of the robot.

5.5. Disadvantages of the Algorithm

- -

- It is not applicable (or difficult to apply) to real-time tasks.

- -

- In order to obtain a detailed and correct map for robots with more degrees of freedom or for complex obstacles in the workspace area, it is necessary to increase the number of checked points and algorithm cycles.

- -

- The algorithm is only suitable for robots with a serial structure. It is not applicable to parallel robots and closed structure robots.

- -

- The even distribution of survey points on circles requires multiple reachability checks for points that are sometimes clearly unreachable. We believe that this process can be optimized in the future.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Nomenclature

| IK | Inverse kinematics |

| DOF | Degrees of freedom |

| CAD | Computer aided design |

| 3D | Three dimensional |

| J | Jacobian matrix |

| Point, center of joint i | |

| Workspace | |

| Configuration | |

| Area, only reachable with a left (right) hand configuration | |

| Area, reachable with both left and right-hand configurations | |

| Distance between points | |

| Relative singularity configuration | |

| Link length | |

| Gripper length | |

| Area, reachable with a left-hand configuration | |

| Area, reachable with a right-hand configuration | |

| Greek Symbols | |

| Joint angle | |

| Orientation angle of the gripper | |

| Subscripts | |

| Link and joint identifiers | |

| Left-hand relative configuration | |

| Right-hand relative configuration | |

| Relative singularity configuration of type | |

References

- Denavit, J.; Hartenberg, R. A kinematic notationfor lower-pair mechanisms based on matrices. ASME J. Appl. Mech. 1951, 22, 215–221. [Google Scholar] [CrossRef]

- Kucuk, S.; Bingul, Z. Robot Kinematics: Forward and Inverse Kinematics. In Industrial-Robotics-Theory-Modelling-Control; Cubero, S., Ed.; IntechOpen: Berlin, Germany, 2006. [Google Scholar]

- Venkata Neeraj Kumar, R.; Sreenivasulu, R. Inverse Kinematics (IK) Solution of a Robotic Manipulator using PYTHON. J. Mechatron. Robot. 2019, 3, 542–551. [Google Scholar] [CrossRef]

- Ayush, G. A Geometric Approach to Inverse Kinematics of a 3 DOF Robotic Arm. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 3524–3530. [Google Scholar]

- Tokarz, K.; Kieltyka, S. Geometric approach to inverse kinematics for arm manipulator. In Proceedings of the 14th WSEAS International Conference on Systems: Part of the 14th WSEAS CSCC Multi Conference—Volume II, Corfu, Greece, 22–24 July 2010. [Google Scholar]

- Wang, P.; Zhou, Y.; Yan, N. An Inverse Solution Algorithm for Industrial Robot. J. Phys. Conf. Ser. 2022, 2173, 012085. [Google Scholar] [CrossRef]

- Manseur, R.; Doty, K.L. A Fast Algorithm for Inverse Kinematic Analysis of Robot Manipulators. Int. J. Robot. Res. 1988, 7, 52–63. [Google Scholar] [CrossRef]

- Gan, J.Q.; Oyama, E.; Rosales, E.M.; Hu, H. A complete analytical solution to the inverse kinematics of the Pioneer 2 robotic arm. Robotica 2005, 23, 123–129. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L. Kinematic Model and Redundant Space Analysis of 4-DOF Redundant Robot. Mathematics 2022, 10, 574. [Google Scholar] [CrossRef]

- Ghosal, A. Resolution of redundancy in robots and in a human arm. Mech. Mach. Theory 2018, 125, 126–136. [Google Scholar] [CrossRef]

- Xie, S.; Sun, L.; Wang, Z.; Chen, G. A speedup method for solving the inverse kinematics problem of robotic manipulators. Int. J. Adv. Robot. Syst. 2022. [Google Scholar] [CrossRef]

- Heidari, O.; Gracia, A.P. Inverse Kinematics Using a Converging Paths Algorithm. Adv. Robot Kinemat. 2020, 2020, 15. [Google Scholar] [CrossRef]

- Alavandar, S.; Nigam, M.J. Inverse Kinematics Solution of 3DOF Planar Robot using ANFIS. Int. J. Comput. Commun. Control 2008, 3, 150–155. [Google Scholar]

- Jamali, A.; Khan, R.; Rahman, M.M. A new geometrical approach to solve inverse kinematics of hyper redundant robots with variable link length. In Proceedings of the 4th International Conference on Mechatronics (ICOM), Kuala Lumpur, Malaysia, 17–19 May 2011. [Google Scholar] [CrossRef]

- Al-Mashhadany, Y.I. Inverse Kinematics Problem (IKP) of 6-DOF Manipulator by Locally Recurrent Neural Networks (LRNNs). In Proceedings of the International Conference on Management and Service Science, Wuhan, China, 24–26 August 2010. [Google Scholar] [CrossRef]

- Semwal, V.B.; Gupta, Y. Performance Analysis of Data-Driven Techniques for Solving Inverse Kinematics Problems. Intell. Syst. Appl. 2021, 294, 85–99. [Google Scholar] [CrossRef]

- Köker, R.; Çakar, T.; Sari, Y. A neural-network committee machine approach to the inverse kinematics problem solution of robotic manipulators. Eng. Comput. 2014, 30, 641–649. [Google Scholar] [CrossRef]

- Kenwright, B. Inverse Kinematics—Cyclic Coordinate Descent (CCD). J. Graph. Tools 2012, 16, 177–217. [Google Scholar] [CrossRef]

- Chen, Y.; Luo, X.; Han, B.; Jia, Y.; Liang, G.; Wang, X. A General Approach Based on Newton’s Method and Cyclic Coordinate Descent Method for Solving the Inverse Kinematics. Appl. Sci. 2019, 9, 5461. [Google Scholar] [CrossRef]

- Song, W.; Hu, G. A Fast Inverse Kinematics Algorithm for Joint Animation. Procedia Eng. 2011, 24, 350–354. [Google Scholar] [CrossRef][Green Version]

- Müller-Cajar, R.; Mukundan, R. Triangulation: A New Algorithm for Inverse Kinematics. Proc. Image Vis. Comput. 2007, 181–186. Available online: https://ir.canterbury.ac.nz/bitstream/handle/10092/743/12607089_ivcnz07.pdf;sequence=1 (accessed on 18 September 2022).

- Panchanand, J.; Biswal, B.B. Inverse Kinematic Solution of 5R Manipulator Using ANN and ANFIS. Int. J. Robot. Autom. IJRA 2015, 4, 109–123. [Google Scholar]

- Takehiko, O.; Hajime, K. Solution for Ill-Posed Inverse Kinematics of Robot Arm by Network Inversion. J. Robot. 2010, 2010. [Google Scholar] [CrossRef]

- Pan, J.; Manocha, D. Efficient Configuration Space Construction and Optimization for Motion Planning. Engineering 2015, 1, 46–57. [Google Scholar] [CrossRef]

- Ardila, F.; Bastidas, H.; Ceballos, C.; Guo, J. The configuration space of a robotic arm in a tunnel. SIAM J. Discret. Math. 2017, 31, 2675–2702. [Google Scholar] [CrossRef][Green Version]

- Verghese, M.; Das, N.; Zhi, Y.; Yip, M. Configuration Space Decomposition for Scalable Proxy Collision Checking in Robot Planning and Control. IEEE Robot. Autom. Lett. 2020, 7, 3811–3818. [Google Scholar] [CrossRef]

- Varadhan, G.; Kim, Y.J.; Krishna, S.; Manocha, D. Topology preserving approximation of free configuration space. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 3041–3048. [Google Scholar] [CrossRef]

- XieRui, Y.; Zhou, Z.; Yang, Y. Improved Distorted Configuration Space Path Planning and Its Application to Robot Manipulators. Sensors 2020, 20, 6060. [Google Scholar] [CrossRef]

- Uk, M.; Sajjad Ali Shah, F.B.; Soyaslan, M.; Eldogan, O. Modeling, control, and simulation of a SCARA PRR-type robot manipulator. Sci. Iran. 2020, 27, 330–340. [Google Scholar] [CrossRef]

- Chavdarov, I.; Nikolov, V.; Naydenov, B.; Boiadjiev, G. Design and Control of an Educational Redundant 3D Printed Robot. In Proceedings of the International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split, Croatia, 19–21 September 2019. [Google Scholar] [CrossRef]

- Miteva, L.; Chavdarov, I.; Yovchev, K. Trajectory Planning for Redundant Robotic Manipulators with Constrained Joint Space. In Proceedings of the International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Hvar, Croatia, 23–25 September 2020. [Google Scholar] [CrossRef]

- Miteva, L.; Yovchev, K.; Chavdarov, I. Preliminary Study on Motion Planning with Obstacle Avoidance for Hard Constrained Redundant Robotic Manipulators. In Proceedings of the International Conference on Computer Systems and Technologies ’21 (CompSysTech ’21), Ruse, Bulgaria, 18–19 June 2021. [Google Scholar] [CrossRef]

| Solution Type | RR | LR | RL | LL | ||||

|---|---|---|---|---|---|---|---|---|

| Octants Coordinates | I | II | III | IV | V | VI | VII | VIII |

| + | - | - | + | + | - | - | + | |

| + | + | - | - | + | + | - | - | |

| + | + | + | + | - | - | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chavdarov, I.; Naydenov, B. Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space. Algorithms 2022, 15, 469. https://doi.org/10.3390/a15120469

Chavdarov I, Naydenov B. Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space. Algorithms. 2022; 15(12):469. https://doi.org/10.3390/a15120469

Chicago/Turabian StyleChavdarov, Ivan, and Bozhidar Naydenov. 2022. "Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space" Algorithms 15, no. 12: 469. https://doi.org/10.3390/a15120469

APA StyleChavdarov, I., & Naydenov, B. (2022). Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space. Algorithms, 15(12), 469. https://doi.org/10.3390/a15120469