Decision Making under Conditions of Uncertainty and Risk in the Formation of Warehouse Stock of an Automotive Service Enterprise

Abstract

1. Introduction

2. Literature Review: Methods Used in the Spare Parts Supply System

3. Materials and Methods

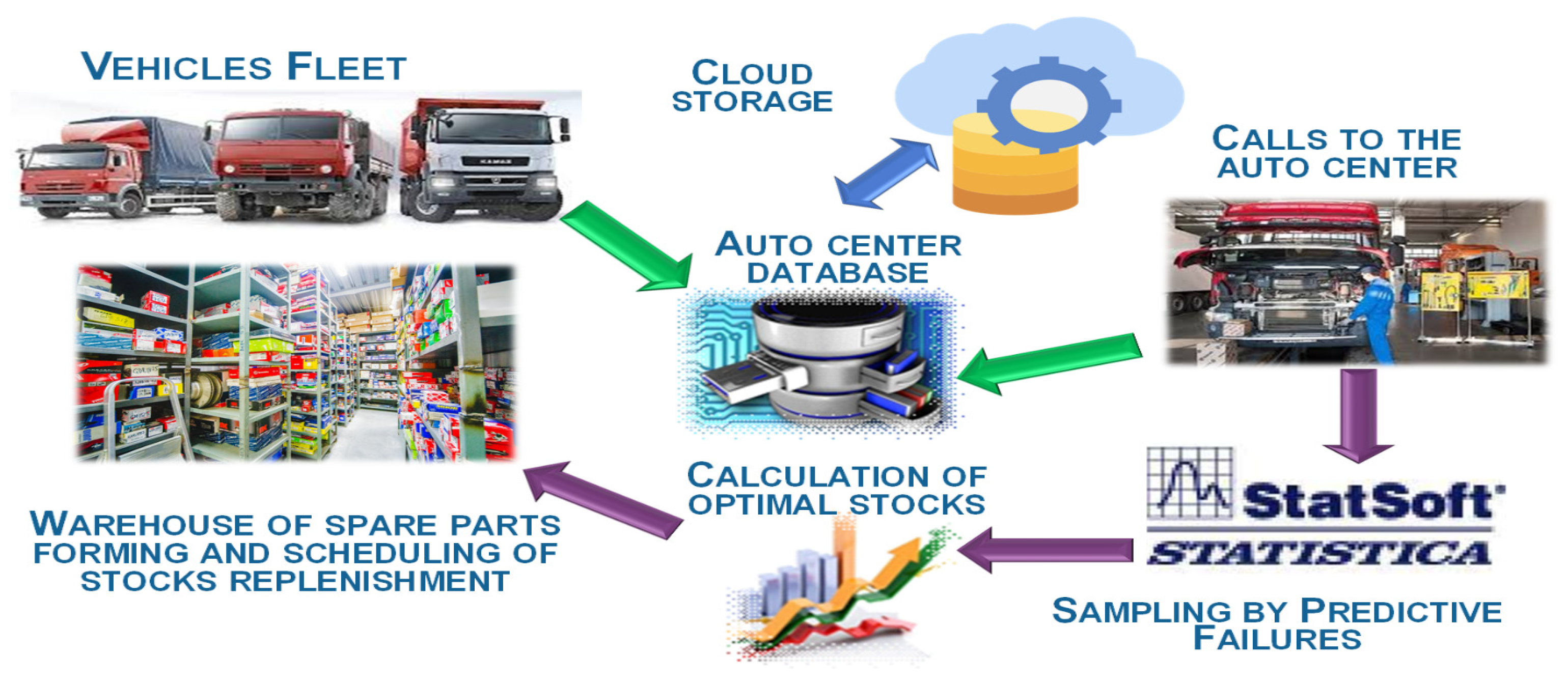

3.1. Spare Parts Management System

- A vehicle that can be in one of three states—serviceable, faulty, and planned to be handled;

- A service center that provides maintenance of vehicles using supplied spare parts.

- If the spare part belongs to the group of limited reliability, then it is necessary to plan its quantity so that it is available. However, here it is necessary to take into account the weight and size characteristics that affect the cost of storage. Therefore, most often the reaction of the system is in the form of a decision to ship spare parts from the warranty warehouse of the service center in the event of a vehicle failure at the stage of running in the warranty period due to a defect. When contacted during normal operation, the shipment of spare parts is carried out from the warehouse of the service center. If the required item is not in the warehouse of the service center, the regional warehouse is contacted.

- If the spare part belongs to the group of rarely failed parts, an order to the manufacturer for urgent delivery of the required items is made.

- Losses from storage of unclaimed spare parts, which are adjusted daily after the planned period of the customer’s call, taking into account the daily cost of storing a storage unit;

- Losses from the costs of urgent delivery, which are calculated when the flow of spare parts from the automobile manufacturer to the service center;

- Losses associated with the cost of fines for shortages are calculated for the planned period for those requests, the deadline for which exceeds the declared standard, taking into account the costs of downtime of service posts and personnel, as well as lost profits for customers during the vehicle commercial operation.

- —surplus in warehouses for each i-th position of spare parts.

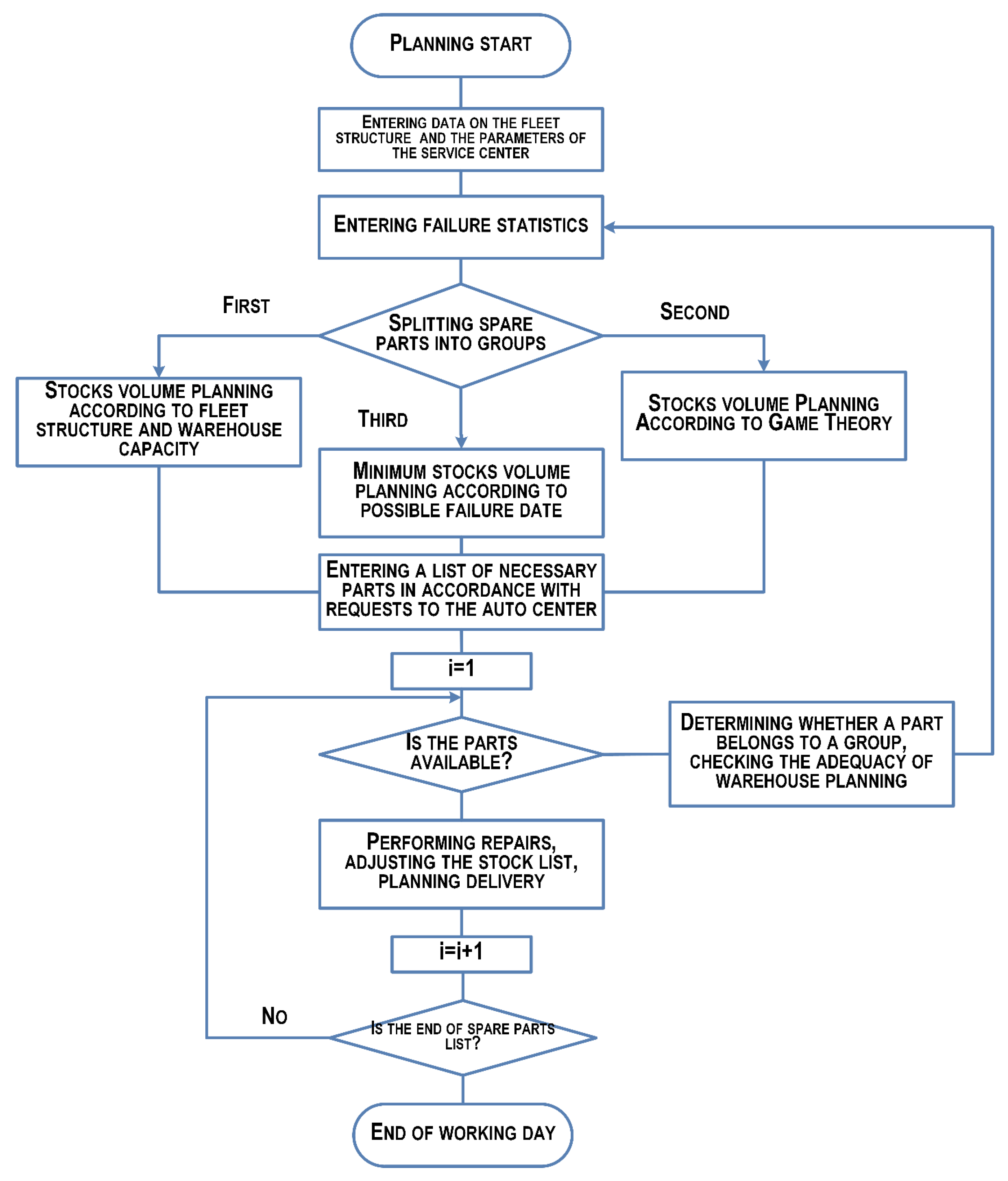

3.2. Game Methods When Deciding on the Volume of Stored Spare Parts

3.2.1. Decision Making under Risk

- Formation of strategies of the sides (Table 1). Production strategies or service market requirements are determined by the number of spare parts of a certain type required during the change nj.

- 2.

- Calculation of the consequences from a random combination of sides’ strategies. In real conditions, the combination of strategies Ai and Pj is random, but each combination of strategies corresponds to certain consequences bij.

- 3.

- Determining the gain for all possible combinations of strategies in this example of Ai and Pj (in this case 25).

- 4.

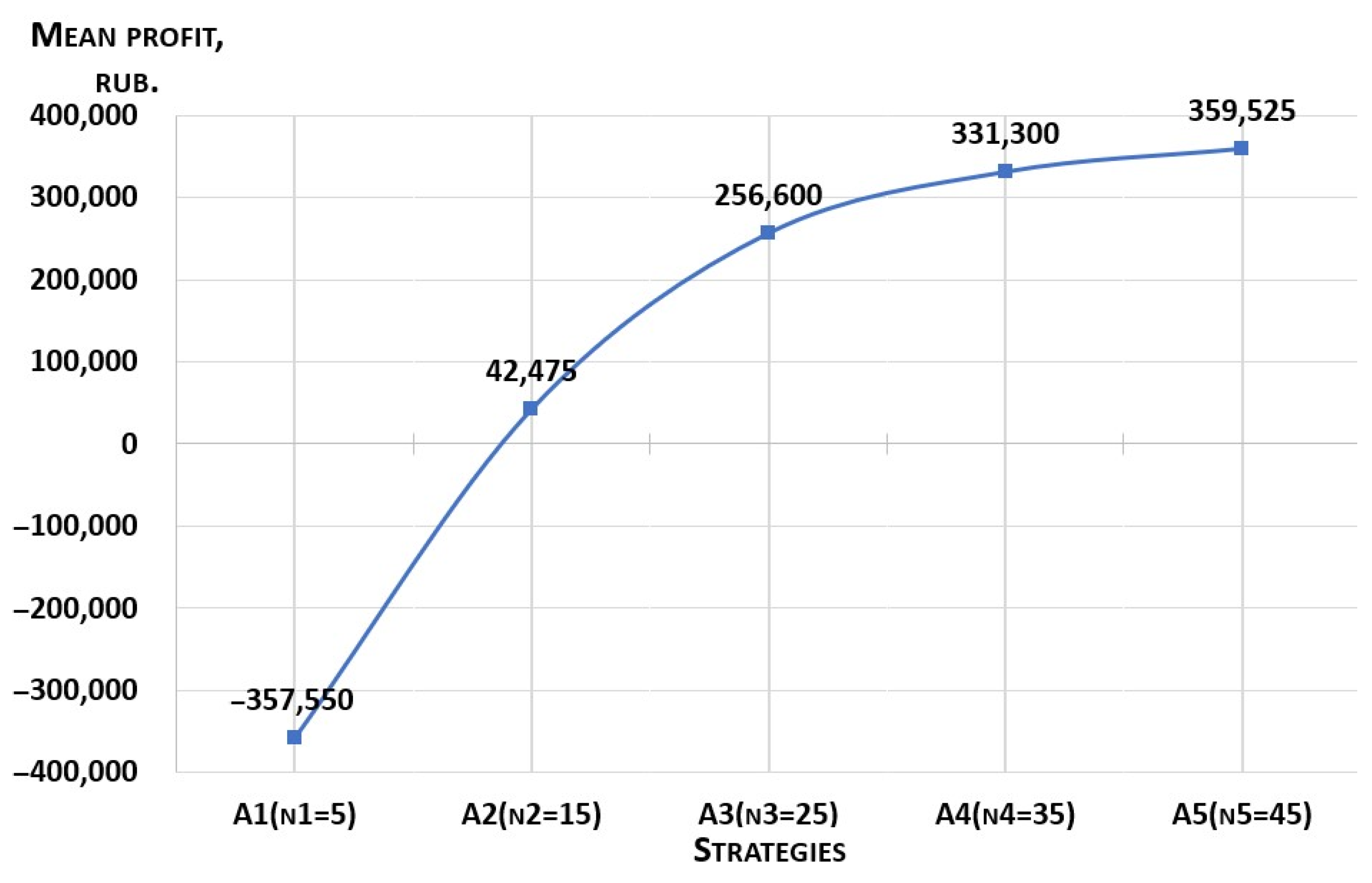

- Choice of the rational strategy of production organizers Ai 0. The simplest solution arises when a strategy Ai is found, each gain of which, for any state Πj, is not less than the gain for any other strategy. In the general case, with known probabilities of each state Πj, a strategy Ai is chosen, in which the mathematical expectation of the profit of the production organizers will be maximum. To do this, calculate the weighted average gain for each row of the payment matrix for the i-th strategy:

- 5.

- From the profit matrix, we choose the optimal strategy that provides the maximum profit (bi) max.

- 6.

- The results obtained for the change in gain depending on the stock of aggregates in the warehouse (strategies A) are shown graphically.

- 7.

- Determine the economic effect of using the optimal strategy.

- qi—the probability of this need.

- 8.

- We analyze the obtained solutions. Conclusions are given on the basis of the data obtained in Table 4 and the calculation of economic efficiency from the application of the optimal strategy.

3.2.2. Decision Making under Uncertainty

- Reduction of unknown probabilities qj to known ones, which means transition to the problem of decision making is under risk. The simplest way is Laplace’s principle of insufficient reason, according to which none of the j-th states of nature Pj is given preference and equal probability is assigned to them, which means q1 =q2 =q3 =… qj = 1/j for all states.

- If there is no information about the probability of states Pj, then events can be ranked based on previously accumulated experience, which means they are arranged in decreasing (or increasing) order of probabilities, for example, using an expert method. In this case, the ranks are translated into places and the probabilities are determined using the following formula.

- 3.

- After determining the probabilities qj, the calculation is carried out according to the decision-making method under risk conditions.

- 4.

- The minimax criterion KII (Savage) provides the choice of such a strategy in which the risk value will be minimal in the most unfavorable production conditions:

- 5.

- The criterion of pessimism–optimism (Hurwitz) is focused on the choice as an intermediate between the two considered strategies:

3.2.3. Feedback in the Spare Parts Supply Chain

- For parts with a high probability of failure—stock planning according to the structure of the fleet and the capacity of the warehouse;

- For parts with an average probability of failure—planning for a moderate stock in accordance with game theory;

- For parts with a low probability of failure—planning the minimum stock according to the date of possible failure.

4. Results

Analysis of the Needs of Service Centers for Spare Parts

- A group of spare parts with a high probability of failure means limiting reliability; thus, it is necessary to make a decision on the volumes of expedient storage, limited by the weight and size characteristics of spare parts;

- For spare parts with medium turnover and failure probability, include moderate inventory and implement game theory methods;

- The planning of the third group of stocks is carried out on demand or the creation of stocks in a small amount.

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Makarova, I.; Khabibullin, R.; Belyaev, A.; Belyaev, E. Dealer-service center competitiveness increase using modern management methods. Transp. Probl. 2012, 7, 53–59. [Google Scholar]

- Ivančić, V. Improving the decision making process trought the pareto principle application. Ekon. Misao Praksa 2014, 23, 633–656. [Google Scholar]

- Dobbs, I. Externality, efficiency and the pareto principle. Int. Rev. Law Econ. 1981, 1, 167–181. [Google Scholar] [CrossRef]

- Li, J. Distributed Multi-level Inventory Algorithms for Automotive Maintenance Spare Parts Based on Centralized Control Model. Jordan J. Mech. Ind. Eng. 2020, 14, 89–99. [Google Scholar]

- Milicevic, R.M.; Sokolovic, V.S.; Milenkov, M.A. Repairable spare parts flow in a multi-echelon inventory system. Vojnoteh. Glas. 2016, 64, 110–129. [Google Scholar] [CrossRef]

- In 2022, Truck Accidents in Russia Occurred More Often than Others. Available online: https://iz.ru/1490483/2023-03-29/v-2022-godu-dtp-s-gruzovikami-v-rossii-proiskhodili-chashche-ostalnykh (accessed on 5 August 2023).

- Amirkhanova, L.; Tereshin, O. Development of a method for forecasting the volume of purchases of spare parts for the body center of a car service enterprise. News Ural. State Univ. Econ. 2010, 1, 37–42. Available online: https://cyberleninka.ru/article/n/razrabotka-metodiki-prognozirovaniya-obemov-zakupok-zapasnyh-chastey-dlya-kuzovnogo-tsentra-avtoservisnogo-predpriyatiya (accessed on 5 August 2023).

- Mitrofanovs, V.; Boiko, I.; Geriņš, Ē. Management of Parts and Components for Units and Assemblies in Mechanical Engineering Industry and Its Impact on the Environment. Agron. Res. 2019, 17, 1138–1145. [Google Scholar]

- Kim, B.; Nadzhi, S.Z.; Kuznetsov, S. Methodology for calculating the required number of reserve elements to ensure the required machinery fleets’ serviceability. In Networked Control Systems for Connected and Automated Vehicles; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Bauer, V.I.; Mukhortov, A.A.; Kozin, E.S.; Bazanov, A.V. Providing special vehicles with spare parts in the oil-and-gas sector. In Proceedings of the International Conference Actual Issues of Mechanical Engineering 2017 (AIME 2017), Tomsk, Russia, 27–29 July 2017. [Google Scholar] [CrossRef]

- Subochev, A.; Sichko, A.; Volkov, M. Increasing the level of providing service enterprises with spare parts and materials. Mech. Agric. Conserv. Resour. 2020, 66, 63–67. [Google Scholar]

- Jiang, S.; Xu, F.; Fan, S.Q.; Jiang, Y.; Zhang, Y.; Chen, Y.J. Researches on Spare Parts Management of Truck Assembly Shop. Adv. Mater. Res. 2011, 403–408, 1262–1265. [Google Scholar] [CrossRef]

- Mehdizadeh, M. Integrating ABC analysis and rough set theory to control the inventories of distributor in the supply chain of auto spare parts. Comput. Ind. Eng. 2020, 139, 105637. [Google Scholar] [CrossRef]

- Wang, X. Optimization of ABC Classification Method for Automobile Spare Parts based on DEA. IOP Conf. Ser. Earth Environ. Sci. 2019, 252, 022005. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, C.; Zhang, Z. Deep Learning Algorithms for Automotive Spare Parts Demand Forecasting. In Proceedings of the 2021 International Conference on Computer Information Science and Artificial Intelligence (CISAI), Kunming, China, 19 September 2021. [Google Scholar] [CrossRef]

- Fan, L.; Liu, X.; Mao, W.; Yang, K.; Song, Z. Spare Parts Demand Forecasting Method Based on Intermittent Feature Adaptation. Entropy 2023, 25, 764. [Google Scholar] [CrossRef] [PubMed]

- Shafi, I.; Sohail, A.; Ahmad, J.; Espinosa, J.C.M.; Lopez, L.A.D.; Thompson, E.B.; Ashraf, I. Spare Parts Forecasting and Lumpiness Classification Using Neural Network Model and Its Impact on Aviation Safety. Appl. Sci. 2023, 13, 5475. [Google Scholar] [CrossRef]

- Kim, J.D.; Kim, T.H.; Han, S.W. Demand Forecasting of Spare Parts Using Artificial Intelligence: A Case Study of KX Tanks. Mathematics 2023, 11, 501. [Google Scholar] [CrossRef]

- Jacyna, M.; Semenov, I. Models of vehicle service system supply under information uncertainty. Eksploat. Niezawodn. Maint. Reliab. 2020, 22, 694–704. [Google Scholar] [CrossRef]

- Basu, R.J.; Abdulrahman, M.; Yuvaraj, M. Improving agility and resilience of automotive spares supply chain: The additive manufacturing enabled truck model. Socio-Econ. Plan. Sci. 2023, 85, 101401. [Google Scholar] [CrossRef]

- KAMAZ Uses Additive Technologies. Available online: https://www.vestikamaza.ru/posts/na_kamaze_primenyayut_additivnye_tehnologii/ (accessed on 25 June 2023).

- Orgeldinger, C.; Seynstahl, A.; Rosnitschek, T.; Tremmel, S. Surface Properties and Tribological Behavior of Additively Manufactured Components: A Systematic Review. Lubricants 2023, 11, 257. [Google Scholar] [CrossRef]

- Delic, M.; Eyers, D.R. The effect of additive manufacturing adoption on supply chain flexibility and performance: An empirical analysis from the automotive industry. Int. J. Prod. Econ. 2020, 228, 107689. [Google Scholar] [CrossRef]

- Farhadi, M.; Shahrokhi, M.; Rahmati, S.H.A. Developing a supplier selection model based on Markov chain and probability tree for a k-out-of-N system with different quality of spare parts. Reliab. Eng. Syst. Saf. 2022, 222, 108387. [Google Scholar] [CrossRef]

- Makarova, I.; Shubenkova, K.; Buyvol, P.; Mukhametdinov, E. A software module for multi-criteria suppliers’ selection with respect to the spare parts logistics. Transp. Probl. 2020, 15, 105–116. [Google Scholar]

- Zheng, M.; Ye, H.; Wang, D.; Pan, E. Joint Optimization of Condition-Based Maintenance and Spare Parts Orders for Multi-Unit Systems with Dual Sourcing. Reliab. Eng. Syst. Saf. 2021, 210, 107512. [Google Scholar] [CrossRef]

- Ishak, A.; Wijaya, T. Rubber Spare Parts Supplier Selection Model Using Artificial Neural Network: Multi-Layer Perceptron. In Proceedings of the 2019 1st International Conference on Engineering and Management in Industrial System (ICOEMIS 2019), Malang, Indonesia, 8–9 August 2019. [Google Scholar] [CrossRef][Green Version]

- Yang, K.; Yang, T.; Yao, Y.; Fan, S.-D. A transfer learning-based convolutional neural network and its novel application in ship spare-parts classification. J. Clean. Prod. 2021, 326, 129358. [Google Scholar] [CrossRef]

- Makarova, I.; Khabibullin, R.; Belyaev, E.; Gabsalikhova, L.; Mukhametdinov, E. Improving the Logistical processes in corporate service system. Transp. Probl. 2016, 11, 5–18. [Google Scholar] [CrossRef]

- Makarova, I.; Pashkevich, A.; Buyvol, P.; Mukhametdinov, E. Risk analysis in the appointment of the trucks’ warranty period operation. Adv. Intell. Syst. Comput. 2019, 854, 293–302. [Google Scholar]

- Yuksel, H.B.; Bolat, S.; Bozkurt, H.; Yucekaya, A. The Implementation of Smart Contract via Blockchain Technology in Supply Chain Management: A Case Study from The Automotive Industry in Turkey. In Proceedings of the 2021 International Conference on Artificial Intelligence and Blockchain Technology (AIBT), Beijing, China, 25–27 June 2021. [Google Scholar]

- Blockchain in the Automotive Industry. Available online: https://vc.ru/crypto/59207-blokcheyn-v-avtomobilnoy-industrii (accessed on 25 June 2023).

- Chang, S.L.; Piraveenan, M.; Pattison, P.; Prokopenko, M. Game theoretical modeling of infectious disease dynamics and intervention methods: A review. J. Biol. Dyn. 2020, 14, 57–89. [Google Scholar] [CrossRef] [PubMed]

- Smirnov, N.; Liu, Y.; Validi, A.; Morales-Alvarez, W.; Olaverri-Monreal, C. A Game Theory-Based Approach for Modeling Autonomous Vehicle Behavior in Congested Urban Lane-Changing Scenarios. Sensors 2021, 21, 1523. [Google Scholar] [CrossRef]

- Sadooghi, S.E.; Taleai, M.; Abolhasani, S. Simulation of urban growth scenarios using integration of multi-criteria analysis and game theory. Land Use Policy 2022, 120, 106267. [Google Scholar] [CrossRef]

| Production (P) | Warehouse Organizers (A) | |||

|---|---|---|---|---|

| Strategies Notation Pj | Need Spare Parts for Repairs, nj | The Probability of This Need, qj | Strategy Designation, Ai | There Are Serviceable Spare Parts in Stock, ni |

| P1 | n1 | q 1 | A1 | n1 |

| P2 | n2 | q2 | A2 | n2 |

| P3 | … | … | A3 | … |

| P4 | … | … | A4 | … |

| P5 | n5 | q 5 | A5 | n5 |

| Situations | Winning in Conventional Units | |

|---|---|---|

| Penalties | Profit | |

| Storage in the warehouse of one unit of actually unclaimed spare part | b1 | - |

| Satisfying the need for one spare part | - | b2 |

| Lack of a spare part necessary to fulfill the requirement in the warehouse | b3 | - |

| Number of Spare Parts Needed and Gain by Strategy | Minimum Win by Strategies (Line Minimums) | |||||||

|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | ||||

| n1 | n2 | … | … | … | ||||

| Available number of aggregates and strategy payoff | Ai | ni | b11 | b12 | … | … | b1j | |

| A1 | n1 | b21 | b22 | … | … | b2j | ||

| A2 | n2 | b31 | b32 | … | … | b3j | ||

| A3 | … | … | … | … | … | … | ||

| A4 | … | … | … | … | … | … | ||

| A5 | … | bi1 | bi2 | … | … | bij | ||

| Max win (column maxima) | β1 | β2 | β3 | β4 | β5 | |||

| Ai (ni) | Pj (nj) | Average Profit with Strategy | ||||

|---|---|---|---|---|---|---|

| P1 (n1 = 0) | P2 (n2 = 1) | P3 (n3 = 2) | P4 (n4 = 3) | P5 (n5 = 4) | ||

| A1 (n1 = 0) | q1 b11 | q2 b12 | … | … | q5 b1j | b1 |

| A2 (n2 = 1) | q1 b21 | q2 b22 | … | … | q5 b2j | b2 |

| A3 (n3 = 2) | q1 b31 | q2 b32 | … | … | q5 b3j | b3 |

| A4 (n4 = 3) | q1 b41 | q2 b42 | … | … | q5 b4j | b4 |

| A5 (n5 = 4) | q1 b51 | q2 b52 | … | … | q5 b5j | b5 |

| State probabilities, qi | q1 | q2 | q3 | q4 | q5 | — |

| Ai | Pj | |||||

|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | Maximum Risk at Ai (Row Maximums) | |

| A1 | r11 | r12 | … | … | r1j | |

| A2 | r21 | r22 | … | … | r2j | |

| A3 | r31 | r32 | … | … | r3j | |

| A4 | … | … | … | … | … | |

| A5 | … | … | … | … | … | |

| (βi)max | β1 | β2 | β3 | β4 | β5 | |

| Components and Assemblies of the Vehicle | * Absolute Value, ** Reduced Value | Mileage, Thousand km | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0–10 | 10–20 | 20–30 | 30–40 | 40–50 | 50–60 | 60–70 | 70–85 | ||

| Engine | * | 152 | 125 | 112 | 86 | 75 | 52 | 26 | 22 |

| ** | 0.23 | 0.17 | 0.16 | 0.15 | 0.10 | 0.20 | 0.09 | 0.07 | |

| Transmission | * | 90 | 68 | 52 | 47 | 21 | 19 | 14 | 9 |

| ** | 0.28 | 0.18 | 0.15 | 0.136 | 0.13 | 0.118 | 0.10 | 0.07 | |

| Electrical equipment and appliances | * | 136 | 122 | 100 | 89 | 56 | 38 | 24 | 15 |

| ** | 0.23 | 0.21 | 0.20 | 0.17 | 0.14 | 0.13 | 0.9 | 0.06 | |

| Clutch | * | 62 | 42 | 29 | 25 | 19 | 15 | 12 | 9 |

| ** | 0.29 | 0.20 | 0.189 | 0.16 | 0.14 | 0.13 | 0.12 | 0.07 | |

| Node Name, Unit | Total Number of Failures | % of Failures from the Number of Vehicles Sailed |

|---|---|---|

| Electrical equipment | 580 | 38.6 |

| Engine | 650 | 43.3 |

| Transmission | 320 | 21.3 |

| Clutch | 213 | 14.2 |

| Production (P) | Warehouse Organizers (A) | |||

|---|---|---|---|---|

| Strategies Notation, Pj | Average Required Number of Starters for Repair, nj | The Probability of This Need, qj | Strategy Designation, Ai | There Are Serviceable Starters in Stock, ni |

| P1 | 5 (0–9) | 0.1 | A 1 | 5 |

| P2 | 15 (10–19) | 0.4 | A 2 | 15 |

| P3 | 25 (20–29) | 0.3 | A 3 | 25 |

| P4 | 35 (30–39) | 0.1 | A 4 | 35 |

| P5 | 45 (40–50) | 0.1 | A 5 | 45 |

| Situations | Winning in RUB | |

|---|---|---|

| Lesion | Profit | |

| Storage in the warehouse of one actually unclaimed starter | −1825 | - |

| Satisfying the need for one starter | - | 18,250 |

| Starter to fulfill the requirement in the warehouse | −26,400 | - |

| Required Number of Starters and Winnings by Strategies | |||||||

|---|---|---|---|---|---|---|---|

| Pj | P1 | P2 | P3 | P4 | P5 | ||

| nj | 5 | 15 | 25 | 35 | 45 | ||

| Number of starters available and winnings by strategy | Ai | ni | |||||

| A1 | 5 | 91,250 | −172,750 | −436,750 | −700,750 | −964,750 | |

| A2 | 15 | 73,000 | 273,750 | 9750 | −254,250 | −518,250 | |

| A3 | 25 | 54,750 | 255,500 | 456,250 | 192,250 | −71,750 | |

| A4 | 35 | 36,500 | 237,250 | 438,000 | 638,750 | 374,750 | |

| A5 | 45 | 18,250 | 219,000 | 419,750 | 620,500 | 821,250 | |

| Ai (ni) | Pj (nj) | Average Profit with Strategy | ||||

|---|---|---|---|---|---|---|

| P1 (n1 = 5) | P2 (n2 = 15) | P3 (n3 = 25) | P4 (n4 = 35) | P5 (n5 = 45) | ||

| A1 (n1 = 5) | 9125 | −69,100 | −131,025 | −70,075 | −96,475 | −357,550 |

| A2 (n2 = 15) | 7300 | 109,500 | 2925 | −25,425 | −51,825 | 42,475 |

| A3 (n3 = 25) | 5475 | 102,200 | 136,875 | 19,225 | −7175 | 256,600 |

| A4 (n4 = 35) | 3650 | 94,900 | 131,400 | 63,875 | 37,475 | 331,300 |

| A5 (n5 = 45) | 1825 | 87,600 | 125,925 | 62,050 | 82,125 | 359,525 |

| State probabilities, qi | 0.1 | 0.4 | 0.3 | 0.1 | 0.1 | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makarova, I.; Buyvol, P.; Gabsalikhova, L.; Belyaev, E.; Mukhametdinov, E. Decision Making under Conditions of Uncertainty and Risk in the Formation of Warehouse Stock of an Automotive Service Enterprise. Algorithms 2023, 16, 388. https://doi.org/10.3390/a16080388

Makarova I, Buyvol P, Gabsalikhova L, Belyaev E, Mukhametdinov E. Decision Making under Conditions of Uncertainty and Risk in the Formation of Warehouse Stock of an Automotive Service Enterprise. Algorithms. 2023; 16(8):388. https://doi.org/10.3390/a16080388

Chicago/Turabian StyleMakarova, Irina, Polina Buyvol, Larisa Gabsalikhova, Eduard Belyaev, and Eduard Mukhametdinov. 2023. "Decision Making under Conditions of Uncertainty and Risk in the Formation of Warehouse Stock of an Automotive Service Enterprise" Algorithms 16, no. 8: 388. https://doi.org/10.3390/a16080388

APA StyleMakarova, I., Buyvol, P., Gabsalikhova, L., Belyaev, E., & Mukhametdinov, E. (2023). Decision Making under Conditions of Uncertainty and Risk in the Formation of Warehouse Stock of an Automotive Service Enterprise. Algorithms, 16(8), 388. https://doi.org/10.3390/a16080388