Application of Evolutionary Computation to the Optimization of Biodiesel Mixtures Using a Nature-Inspired Adaptive Genetic Algorithm

Abstract

1. Introduction

1.1. Literature Review

- From 1990, at least a 40% reduction in greenhouse gas emissions

- Revision by 2023: 32% at least renewable energy apportion

- Energy efficiency improvement at least 32.5%.

- 1st Generation: Consumable Vegetable Oils

- 2nd Generation: Non-edible Oils and Animal Fats

- 3rd Generation: Microalgal Oils.

- Linear Regression

- Principal component analysis (PCA),

- Genetic Algorithms (GA),

- K-Nearest Neighbors (KNN)

- Random Forest Regression (RF),

- Artificial Neural Networks (ANNs) or simulated neural networks (SNNs),

- Support Vector Machines (SVMs).

- Fuzzy Multi-Criteria methodologies

1.2. Novel Contribution of the Research

- (a)

- implementing innovative modeling techniques, including specific evaluations to enhance modeling.

- (b)

- refining and defining the genetic algorithm.

- Reducing Experiment Costs

- Minimizing Experiment Duration

- Improving Cost and Density using Enhanced Evaluation Functions

- Developing Environmentally Sustainable Fuels

2. Modeling of Biofuel Mixture

- Min Ingredient Percentage% ≤ pi ≤ Max Ingredient Percentage%

- ci, where c1: diesel cost and c2: biodiesel cost

- di, where d1: diesel density and d2: biodiesel density

- wi, where weights: w1 + w2 = 100%

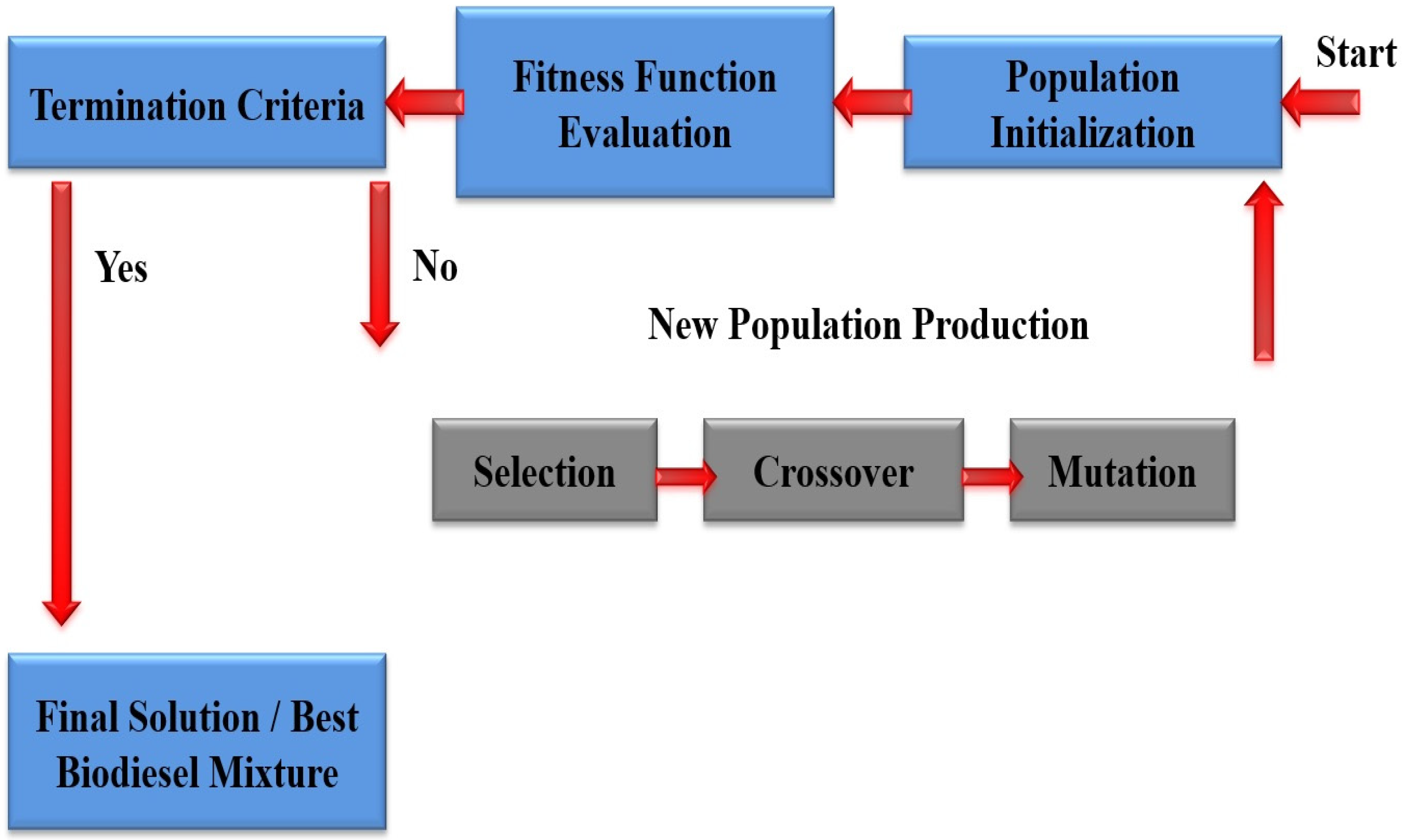

3. Algorithmic Framework

3.1. GA—Chromosome Representation

3.2. GA—Chromosome Representation

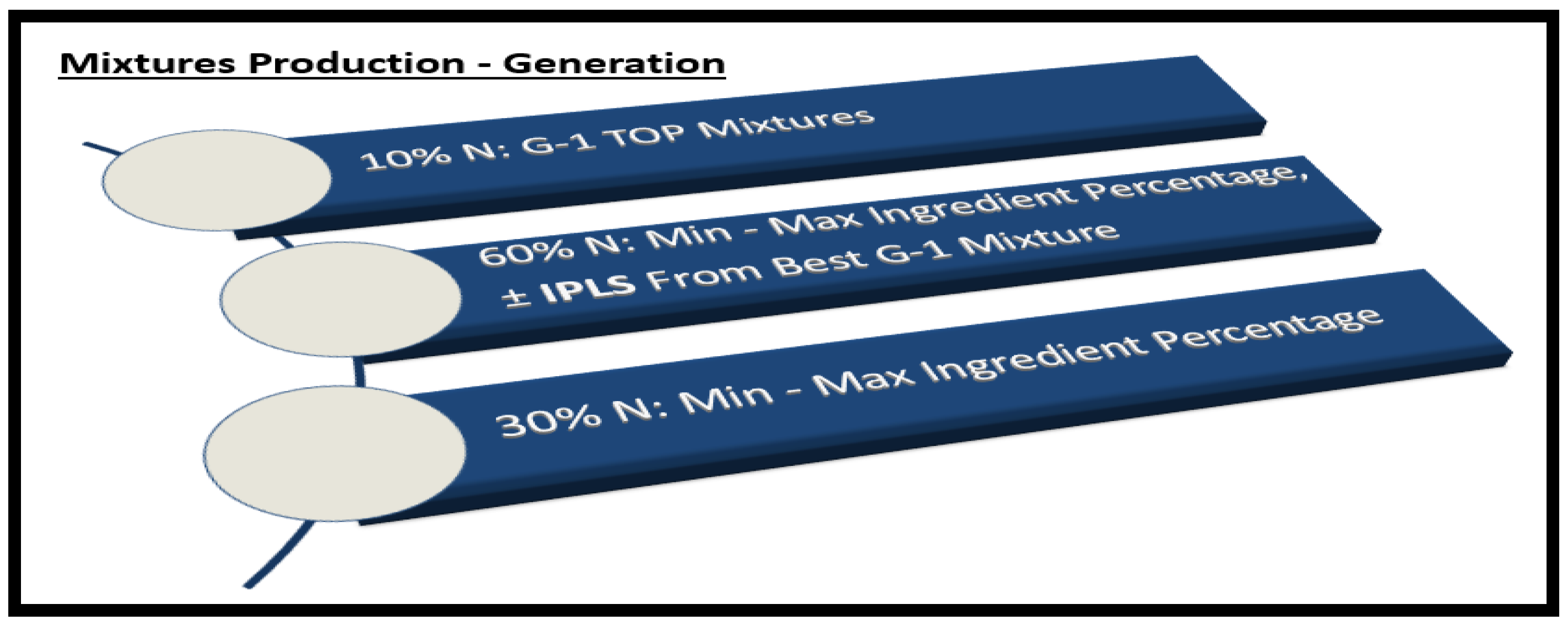

- Focusing on last-generation best solutions (10% N) and leveraging them in next-generation production.

- The frame ± I, which leads to a faster optimal solution convergence, implements the local search method.

- Mutation operator prevents the GA from a premature convergence in a semi-optimal solution of moderate-quality fuel.

3.3. GA—Chromosome Representation

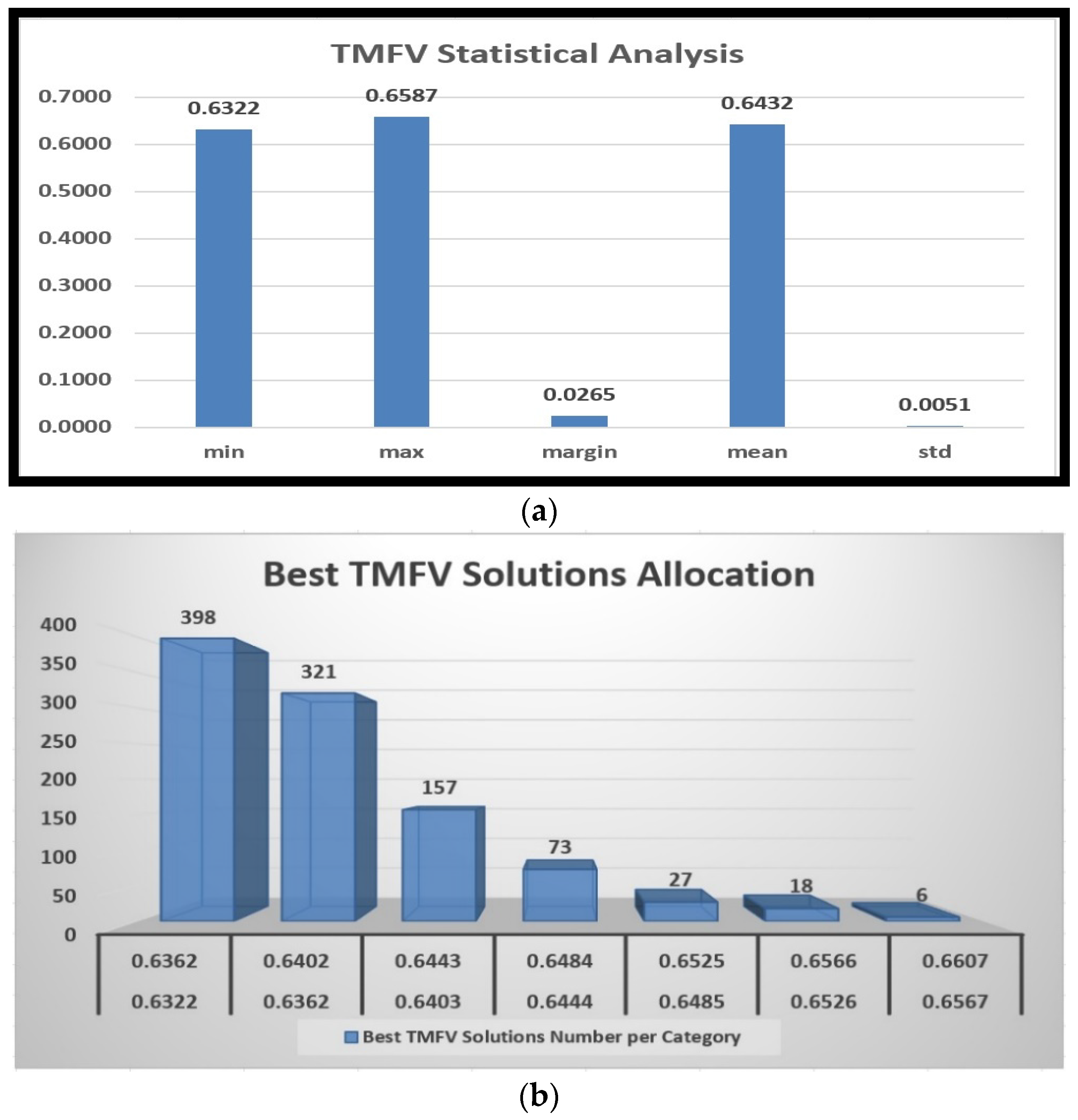

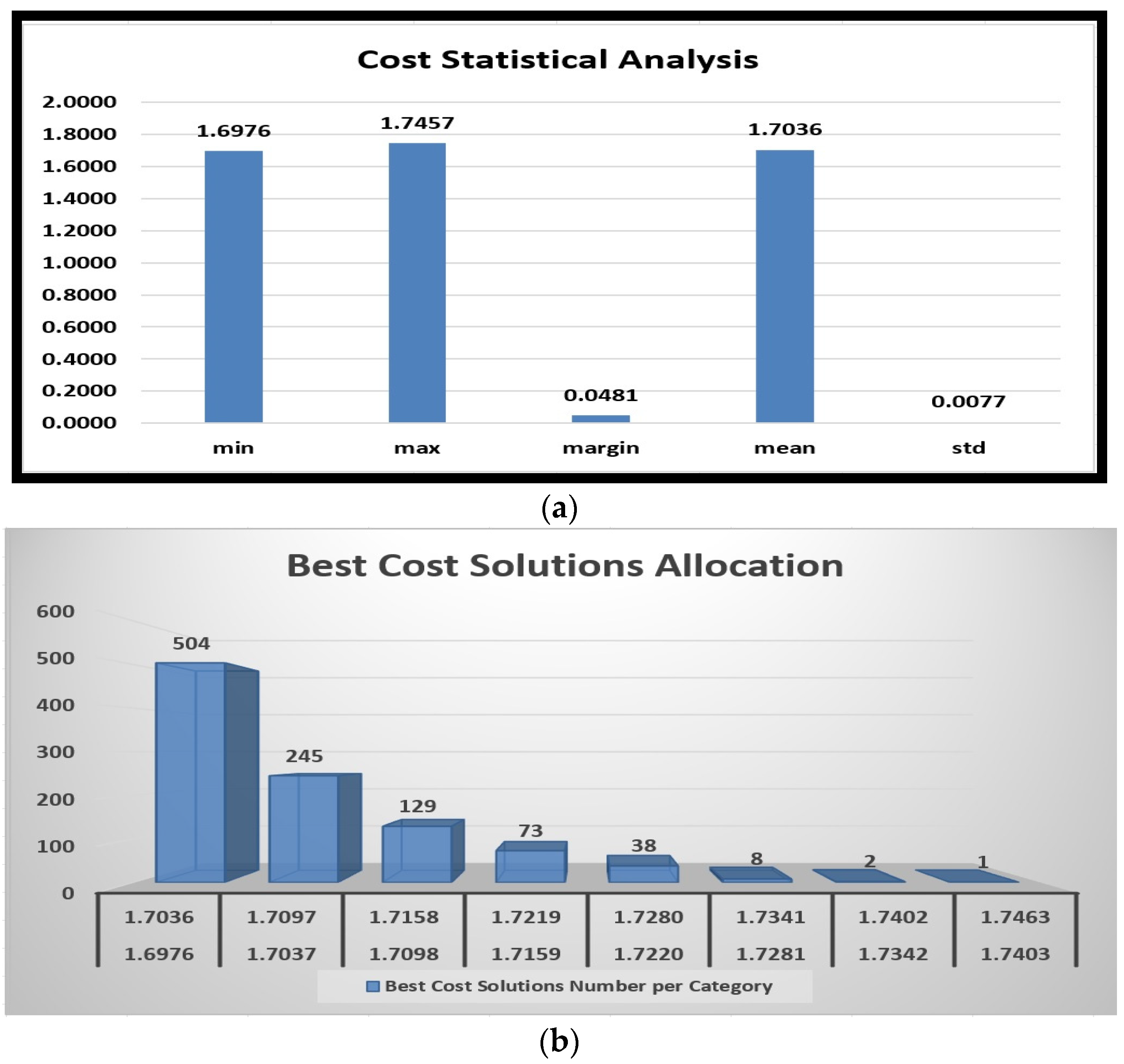

3.4. Experimental Results

- Diesel percentage: 74.95%

- Biodiesel percentage: 25.05%

- TMFV: 0.6322

- Mixture Cost: 1.6976 EUR/L

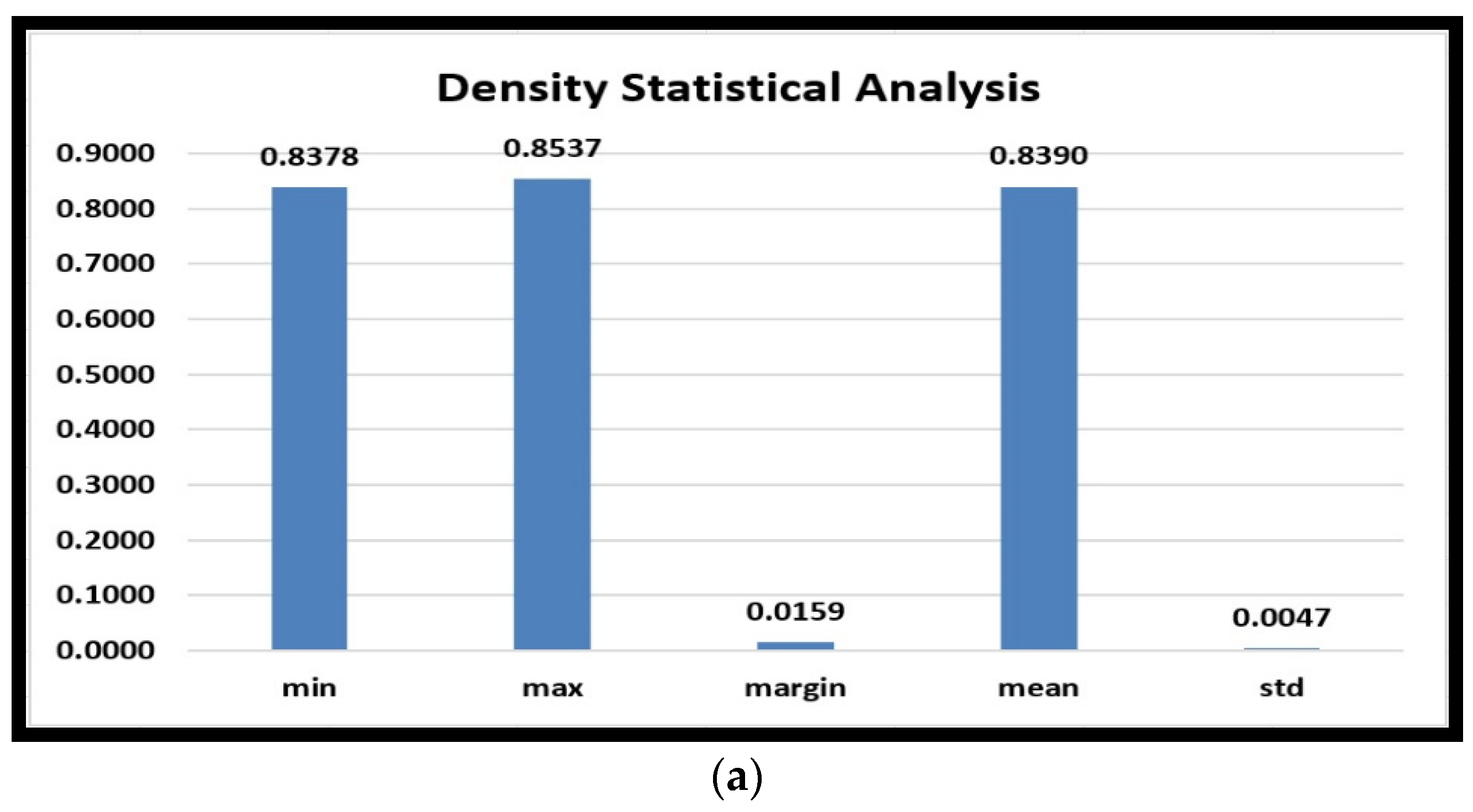

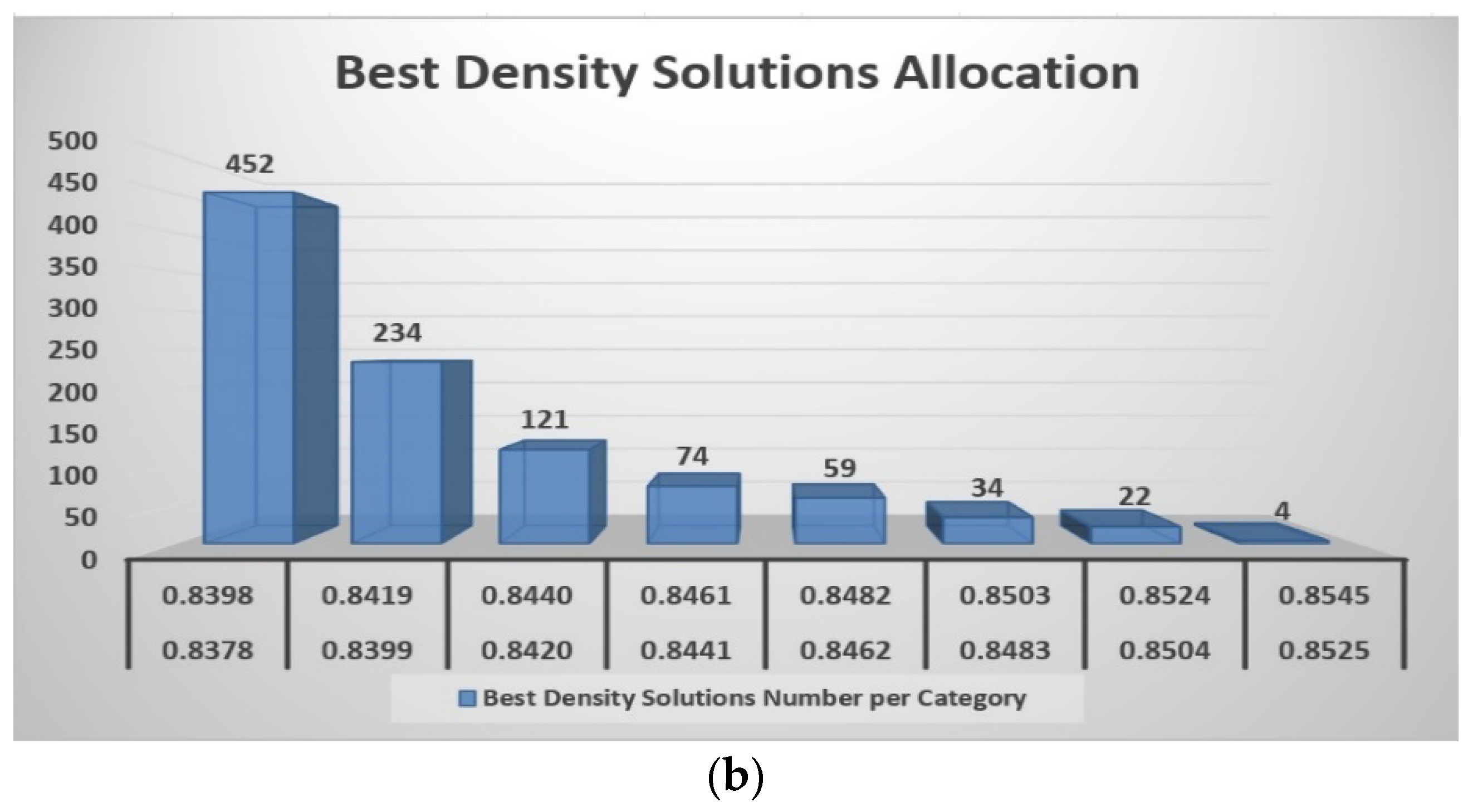

- Mixture Density: 0.8378 g/mL

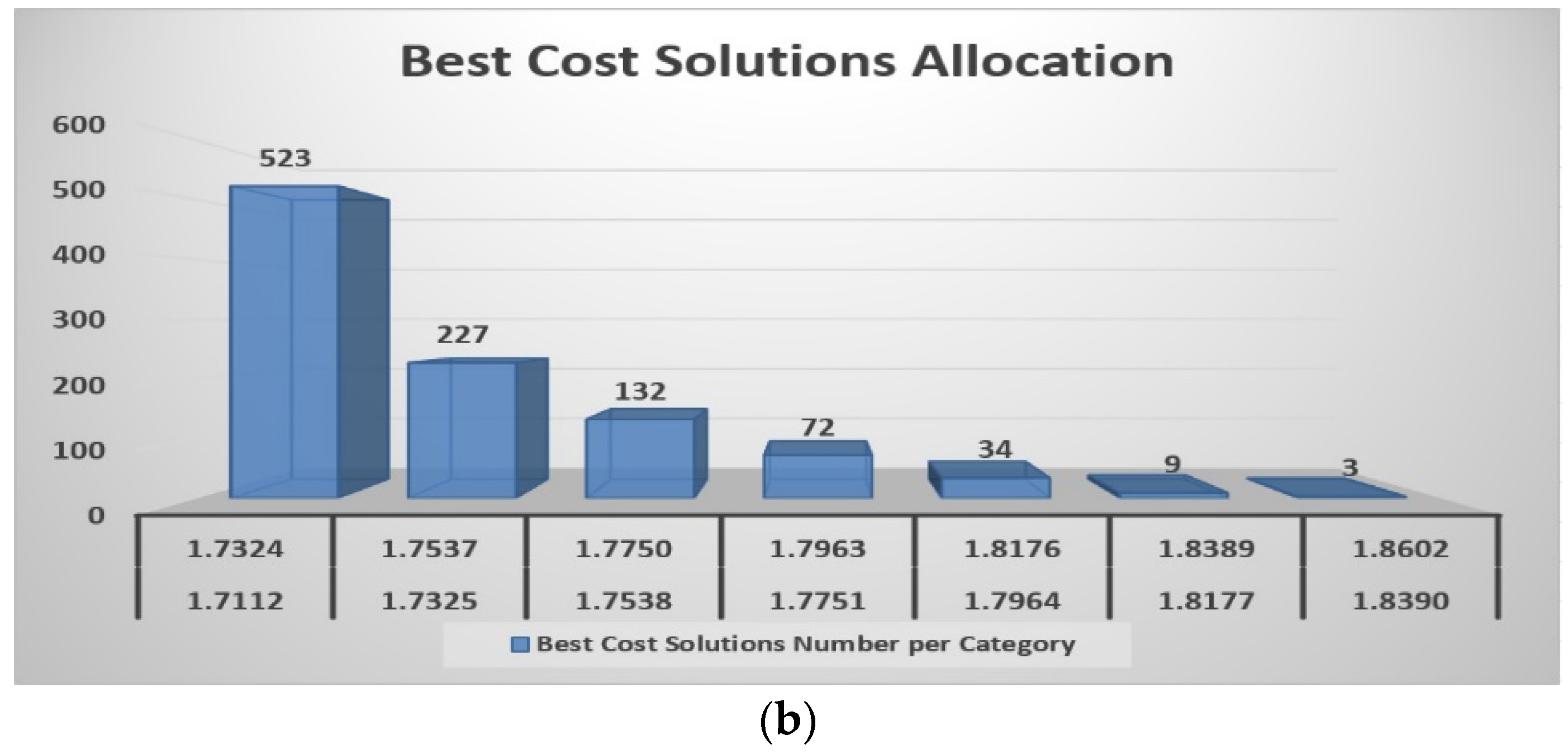

- Diesel percentage: 74.88%

- Biodiesel percentage: 25.12%

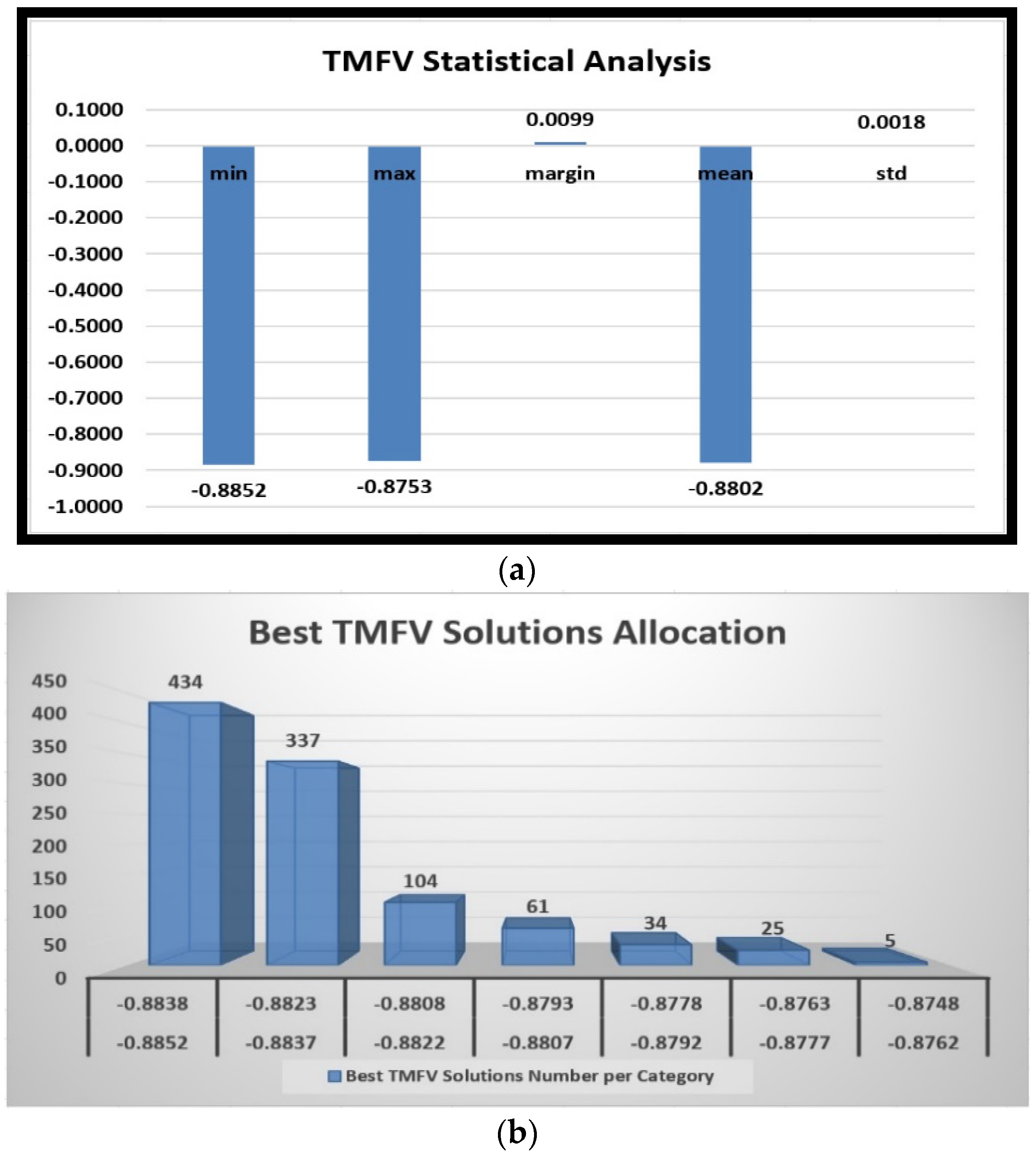

- TMFV: −0.8852

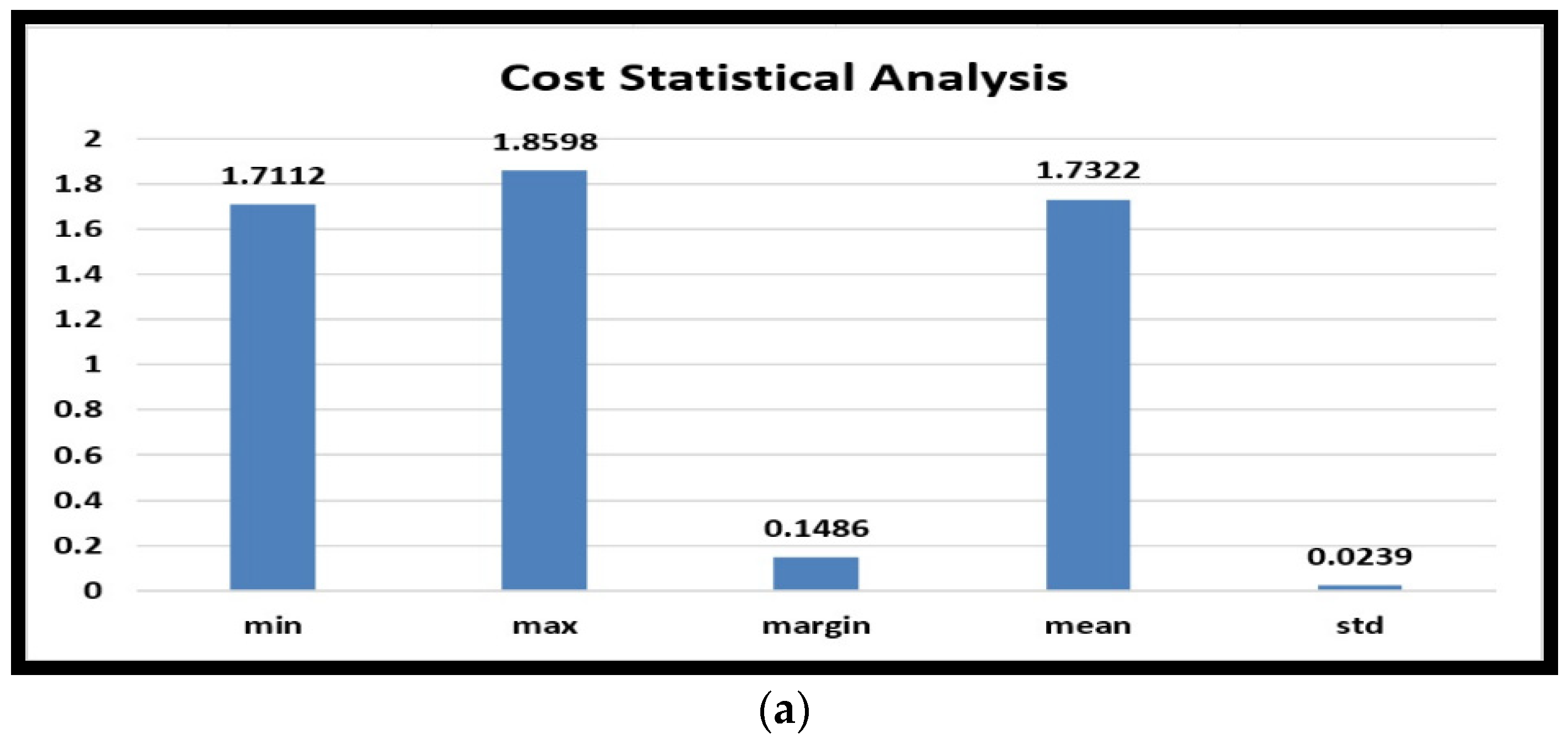

- Mixture Cost: 1.7112 EUR/L

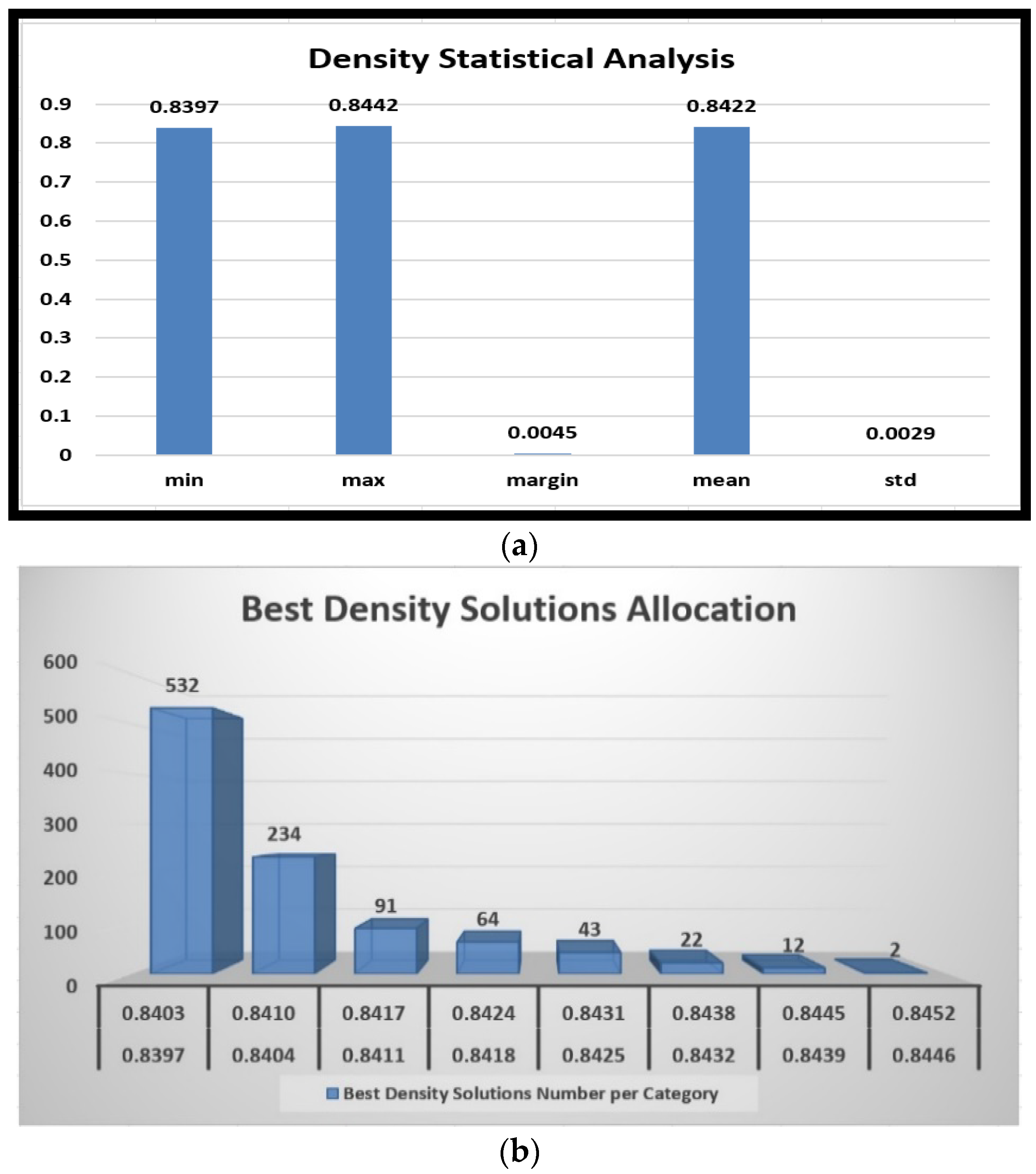

- Mixture Density: 0.8397 g/mL

4. Combustion of Mixtures

5. Concluding Remarks

- Optimal Blend in Group 1 (5 °C, w1 = 90%, w2 = 10%): Diesel content: 74.95%, Biodiesel content: 25.05%, OMPM: 0.6322, Blend Cost: 1.6976 EUR/L, Blend Density: 0.8378 g/mL.

- Optimal Blend in Group 2 (20 °C, w1 = 10%, w2 = 90%): Diesel content: 74.88%, Biodiesel content: 25.12%, OMPM: −0.8852, Blend Cost: 1.7112 EUR/L, Blend Density: 0.8397 g/mL.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Enerdata. Global Energy Trends—2022 Edition. In World Energy & Climate Statistics—Yearbook 2022; Enerdata: Paris, France, 2022. [Google Scholar]

- Papapolymerou, G.; Karayannis, V.; Besios, A.; Riga, A.; Gougoulias, N.; Spiliotis, X. Scaling-up sustainable chlorella vulgaris microalgal biomass cultivation from laboratory to pilot-plant photobioreactor, towards biofuel. Glob. Nest J. 2019, 21, 37–42. [Google Scholar]

- Pokushko, M.; Stupina, A.; Medina-Bulo, I.; Ezhemanskaya, S.; Kuzmich, R.; Pokushko, R. Algorithm for Application of a Basic Model for the Data Envelopment Analysis Method in Technical Systems. Algorithms 2023, 16, 460. [Google Scholar] [CrossRef]

- Kokkinos, K.; Karayannis, V.; Samaras, N.; Moustakas, K. Multi-scenario analysis on hydrogen production development using PESTEL and FCM models. J. Clean. Prod. 2023, 419, 138251. [Google Scholar] [CrossRef]

- Vasiliadou, I.A.; Semizoglou, Z.A.; Karayannis, V.G.; Tsanaktsidis, C.G. Extraction Study of Lignite Coalbed Methane as a Potential Supplement to Natural Gas for Enhancing Energy Security of Western Macedonia Region in Greece. Appl. Sci. 2024, 14, 174. [Google Scholar] [CrossRef]

- Semwal, S.; Arora, A.K.; Badoni, R.P.; Tuli, D.K. Biodiesel production using heterogeneous catalysts. Bioresour. Technol. 2011, 102, 2151–2161. [Google Scholar] [CrossRef] [PubMed]

- Roschat, W.; Kacha, M.; Yoosuk, B.; Sudyoadsuk, T.; Promarak, V. Biodiesel production based on heterogeneous process catalyzed by solid waste coral fragment. Fuel 2012, 98, 194–202. [Google Scholar] [CrossRef]

- Lee, S.; Posarac, D.; Ellis, N. An experimental investigation of biodiesel synthesis from waste canola oil using supercritical methanol. Fuel 2012, 91, 229–237. [Google Scholar] [CrossRef]

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Kamm, B.; Kamm, M. Principles of biorefineries. Appl. Microbiol. Biotechnol. 2004, 64, 37–45. [Google Scholar] [CrossRef]

- Tyson, K.S.; Bozell, J.; Wallace, R.; Petersen, E.; Moens, L. Biomass oil analysis: Research needs and recommendations. NREL/Tech. Rep. 2004. [Google Scholar] [CrossRef][Green Version]

- Bezergianni, S.; Kalogeras, K.; Pilavachi, P.A. On maximizing biodiesel mixing ratio based on final product specifications. Comput. Chem. Eng. 2011, 35, 936–942. [Google Scholar] [CrossRef]

- Gerpen, J.V.; Shanks, B.; Pruszko, R.; Clements, D.; Knothe, G. Biodiesel Production Technology NREL/SR-510-36244; National Renewable Energy Laboratory: Golden, CO, USA, 2004.

- Balat, M.; Balat, H. Progress in biodiesel processing. Appl. Energy 2010, 87, 1815–1835. [Google Scholar] [CrossRef]

- Pérez-Cisnerosa, E.S.; Mena-Espinoa, X.; Rodríguez-Lópezc, V.; Sales-Cruzb, M.; Viveros-Garcíaa, T.; Lobo-Oehmichen, R. An integrated reactive distillation process for biodiesel production. Comput. Chem. Eng. 2016, 35, 936–942. [Google Scholar] [CrossRef]

- Burton, R. Biodiesel Standards and Testing Methods. In Alternative Fuels Consortium; Central Carolina Community College: Sanford, NC, USA, 2008. [Google Scholar]

- Gomez, L.D.; Steele-King, C.G.; McQueen-Mason, S.J. Sustainable liquid biofuels from biomass: The writing’s on the walls. New Phytol. 2008, 178, 473–485. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Review on biodiesel production processes and sustainable raw materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef]

- Kavallari, A.; Smeets, E.; Tabeau, A. Land use changes from EU biofuel use: A sensitivity analysis. Oper. Res. 2014, 14, 261–281. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M. Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renew. Energy 2008, 33, 2623–2630. [Google Scholar] [CrossRef]

- Tsanaktsidis, C.G.; Vasiliadis, V.; Itziou, A.; Petrakis, L.A.; Moisiadis, S.A. Application of factor analysis for the study of physicochemical properties in different blends of diesel fuel with biodiesel. Int. J. Soft Comput. Eng. 2013, 3, 42–46. [Google Scholar]

- Malik, S.; Darolia, P.J.; Garg, S.K.; Sharma, V.K. Densities and excess molar volumes of mixtures containing diesel, biodiesel and alkanols at temperatures from 288.15 to 313.15 K. Chin. J. Chem. Eng. 2021, 34, 198–207. [Google Scholar] [CrossRef]

- Tsanaktsidis, C.G.; Spinthiropoulos, K.G.; Guliyev, F.; Dimitriou, D.; Euthaltsidou, K.; Tzilantonis, G.T. Relation between quality and production cost for pure biodiesel bases on the mixes of raw materials. IOP Conf. Ser. Earth Environ. Sci. 2016, 40, 012048. [Google Scholar] [CrossRef]

- Deya, P.; Raya, S.; Newarb, A. Defining a waste vegetable oil-biodiesel based diesel substitute blend fuel by response surface optimization of density and calorific value. Fuel 2021, 283, 118978. [Google Scholar] [CrossRef]

- Valdez, F.; Castillo, O.; Melin, P. Bio-inspired algorithms and its applications for optimization in fuzzy clustering. Algorithms 2021, 14, 122. [Google Scholar] [CrossRef]

- Kyriklidis, C.; Dounias, G. Evolutionary computation for resource leveling optimization in project management. In Integrated Computer-Aided Engineering; IOS Press: Amsterdam, The Netherland, 2016; Volume 23, pp. 173–184. [Google Scholar]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 1959, 3, 210–229. [Google Scholar] [CrossRef]

- Russell, S.; Norvig, P. Artificial Intelligence—A Modern Approach, 3rd ed.; Hirsch, M., Ed.; Pearson Education Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Xing, Y.; Zheng, Z.; Sun, Y.; Alikhani, M.A. A Review on Machine Learning Application in Biodiesel Production Studies. Int. J. Chem. Eng. 2021, 2021, 2154258. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Artificial neural networks in renewable energy systems applications: A review. Renew. Sustain. Energy Rev. 2001, 5, 373–401. [Google Scholar] [CrossRef]

- Baños, R.; Manzano-Agugliaro, F.; Montoya, F.G.; Gil, C.; Alcayde, A.; Gómez, J. Optimization methods applied to renewable and sustainable energy: A review. Renew. Sustain. Energy Rev. 2011, 15, 1753–1766. [Google Scholar] [CrossRef]

- Liao, M.; Yao, Y. Applications of artificial intelligence-based modeling for bioenergy systems: A review. GCB Bioenergy 2021, 13, 774–802. [Google Scholar] [CrossRef]

- Kokkinos, K.; Karayannis, V. Supportiveness of low-carbon energy technology policy using fuzzy multicriteria decision-making methodologies. Mathematics 2020, 8, 1178. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Yang, X.; Ling, Y. Optimal reactive power dispatch using water wave optimization algorithm. Oper. Res. 2020, 20, 2537–2553. [Google Scholar] [CrossRef]

- Mohd Ali, J.; Hussain, M.A.; Tade, M.O.; Zhang, J. Artificial Intelligence techniques applied as estimator in chemical process systems-a literature survey. Expert. Syst. Appl. 2015, 42, 5915–5931. [Google Scholar] [CrossRef]

- Liu, Z.; Baghban, A. Application of LSSVM for biodiesel production using supercritical ethanol solvent. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1869–1874. [Google Scholar] [CrossRef]

- Mohadesi, M.; Rezaei, A. Biodiesel Conversion Modeling under Several Conditions Using Computational Intelligence Methods. Environ. Prog. Sustain. Energy 2018, 37, 562–568. [Google Scholar] [CrossRef]

- Kokkinos, K.; Karayannis, V.; Moustakas, K. Optimizing Microalgal Biomass Feedstock Selection for Nanocatalytic Conversion Into Biofuel Clean Energy, Using Fuzzy Multi-Criteria Decision Making Processes. Front. Energy Res. 2021, 8, 622210. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic Algorithms. Sci. Am. 1992, 267, 66–72. [Google Scholar] [CrossRef]

- Fuladi, S.K.; Kim, C.-S. Dynamic Events in the Flexible Job-Shop Scheduling Problem: Rescheduling with a Hybrid Metaheuristic Algorithm. Algorithms 2024, 17, 142. [Google Scholar] [CrossRef]

- Kyriklidis, C.; Kyriklidis, M.-E.; Loizou, E.; Stimoniaris, A.; Tsanaktsidis, C.G. Optimal Bio Marine Fuel production evolutionary Computation: Genetic algorithm approach for raw materials mixtures. Fuel 2022, 323, 124232. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAOSTAT). Available online: https://www.fao.org/faostat/en/#data/PP (accessed on 1 February 2024).

- Hellenic Statistical Authority, Greece (HSA). Available online: https://www.statistics.gr/ (accessed on 1 February 2024).

| Abbreviation | Concept Definition |

|---|---|

| Min (Max) Ingredient Percentage | Minimum (Maximum) Ingredient Percentage value. |

| InPer | Ingredient Percentage. |

| IPLS | Ingredient Percentage Local Search (in%). |

| I1 | Ingredient Percentage Local Search Bound created by minimum ingredient percentage. |

| I2 | Ingredient percentage Local Search Bound created by maximum ingredient percentage. |

| Max IPLS | Maximum IPLS value. |

| Min IPLS | Minimum IPLS value. |

| Experiment Temperatures | w1/w2 (Set 1) | w1/w2 (Set 2) |

|---|---|---|

| 5 °C, 10 °C, 15 °C, 20 °C and 25 °C | 50%/50% | 50%/50% |

| 60%/40% | 40%/60% | |

| 70%/30% | 30%/70% | |

| 80%/20% | 20%/80% | |

| 90%/10% | 10%/90% |

| Fuel’s Temperature | Min% | Max% | Cost EUR/L | Density g/mL |

|---|---|---|---|---|

| Diesel 5 °C | 1 | 99 | 2.0000 | 0.8191 |

| Biodiesel 5 °C | 1 | 30 | 0.8091 | 0.8915 |

| Diesel 10 °C | 1 | 99 | 2.0000 | 0.8206 |

| Biodiesel 10 °C | 1 | 30 | 0.8091 | 0.8848 |

| Diesel 15 °C | 1 | 99 | 2.0000 | 0.8220 |

| Biodiesel 15 °C | 1 | 30 | 0.8091 | 0.8823 |

| Diesel 20 °C | 1 | 99 | 2.0000 | 0.8234 |

| Biodiesel 20 °C | 1 | 30 | 0.8091 | 0.8819 |

| Diesel 25 °C | 1 | 99 | 2.0000 | 0.8249 |

| Biodiesel 25 °C | 1 | 30 | 0.8091 | 0.8808 |

| Fuel’s Temp. | w1/w2 | Diesel% | Biodiesel% | TMFV | Cost | Density |

|---|---|---|---|---|---|---|

| 5 °C | w1: 50%, w2: 50% | 75.00% | 25.00% | −0.0771 | 1.6988 | 0.8340 |

| w1: 60%, w2: 40% | 75.00% | 25.00% | 0.1104 | 1.6985 | 0.8351 | |

| w1: 70%, w2: 30% | 74.98% | 25.02% | 0.2856 | 1.6978 | 0.8359 | |

| w1: 80%, w2: 20% | 74.97% | 25.03% | 0.4878 | 1.6978 | 0.8364 | |

| w1: 90%, w2: 10% | 74.95% | 25.05% | 0.6322 | 1.6976 | 0.8378 | |

| 10 °C | w1: 50%, w2: 50% | 75.01% | 24.99% | −0.0727 | 1.7377 | 0.8349 |

| w1: 60%, w2: 40% | 74.99% | 25.01% | 0.1134 | 1.7211 | 0.8355 | |

| w1: 70%, w2: 30% | 74.97% | 25.03% | 0.2987 | 1.7200 | 0.8363 | |

| w1: 80%, w2: 20% | 74.95% | 25.05% | 0.4881 | 1.6993 | 0.8376 | |

| w1: 90%, w2: 10% | 74.93% | 25.07% | 0.6781 | 1.6987 | 0.8379 | |

| 15 °C | w1: 50%, w2: 50% | 75.00% | 25.00% | −0.0715 | 1.7379 | 0.8356 |

| w1: 60%, w2: 40% | 74.98% | 25.02% | 0.1154 | 1.7216 | 0.8359 | |

| w1: 70%, w2: 30% | 74.96% | 25.04% | 0.2996 | 1.7222 | 0.8368 | |

| w1: 80%, w2: 20% | 74.95% | 25.05% | 0.4897 | 1.7077 | 0.8379 | |

| w1: 90%, w2: 10% | 74.93% | 25.07% | 0.6792 | 1.6991 | 0.8382 | |

| 20 °C | w1: 50%, w2: 50% | 75.01% | 24.99% | −0.0704 | 1.7382 | 0.8367 |

| w1: 60%, w2: 40% | 74.98% | 25.02% | 0.1155 | 1.7245 | 0.8371 | |

| w1: 70%, w2: 30% | 74.97% | 25.03% | 0.3011 | 1.7233 | 0.8377 | |

| w1: 80%, w2: 20% | 74.92% | 25.08% | 0.4954 | 1.7188 | 0.8385 | |

| w1: 90%, w2: 10% | 74.91% | 25.09% | 0.6808 | 1.6995 | 0.8389 | |

| 25 °C | w1: 50%, w2: 50% | 75.02% | 24.98% | −0.0681 | 1.7386 | 0.8371 |

| w1: 60%, w2: 40% | 75.01% | 24.99% | 0.1176 | 1.7248 | 0.8373 | |

| w1: 70%, w2: 30% | 74.95% | 25.05% | 0.3225 | 1.7254 | 0.8379 | |

| w1: 80%, w2: 20% | 74.91% | 25.09% | 0.5238 | 1.7195 | 0.8388 | |

| w1: 90%, w2: 10% | 74.89% | 25.11% | 0.7007 | 1.6999 | 0.8395 |

| Fuel’s Temp. | w1/w2 | Diesel% | Biodiesel% | TMFV | Cost | Density |

|---|---|---|---|---|---|---|

| 5 °C | w1: 50%, w2: 50% | 75.00% | 25.00% | −0.0771 | 1.6988 | 0.8340 |

| w1: 40%, w2: 60% | 74.99% | 25.01% | −0.2267 | 1.6986 | 0.8355 | |

| w1: 30%, w2: 70% | 74.98% | 25.02% | −0.4167 | 1.6984 | 0.8358 | |

| w1: 20%, w2: 80% | 74.96% | 25.04% | −0.6378 | 1.6980 | 0.8366 | |

| w1: 10%, w2: 90% | 74.95% | 25.05% | −0.8451 | 1.6979 | 0.8379 | |

| 10 °C | w1: 50%, w2: 50% | 75.01% | 24.99% | −0.0727 | 1.7379 | 0.8349 |

| w1: 40%, w2: 60% | 74.99% | 25.01% | −0.2588 | 1.7222 | 0.8357 | |

| w1: 30%, w2: 70% | 74.96% | 25.04% | −0.4506 | 1.7234 | 0.8364 | |

| w1: 20%, w2: 80% | 74.96% | 25.04% | −0.6428 | 1.7056 | 0.8378 | |

| w1: 10%, w2: 90% | 74.93% | 25.07% | −0.8322 | 1.6993 | 0.8381 | |

| 15 °C | w1: 50%, w2: 50% | 75.00% | 25.00% | −0.0715 | 1.7379 | 0.8356 |

| w1: 40%, w2: 60% | 74.98% | 25.02% | −0.2684 | 1.7256 | 0.8361 | |

| w1: 30%, w2: 70% | 74.97% | 25.03% | −0.4754 | 1.7237 | 0.8369 | |

| w1: 20%, w2: 80% | 74.94% | 25.06% | −0.6682 | 1.7087 | 0.8380 | |

| w1: 10%, w2: 90% | 74.92% | 25.08% | −0.8481 | 1.7023 | 0.8384 | |

| 20 °C | w1: 50%, w2: 50% | 75.01% | 24.99% | −0.0704 | 1.7384 | 0.8367 |

| w1: 40%, w2: 60% | 74.99% | 25.01% | −0.2791 | 1.7268 | 0.8373 | |

| w1: 30%, w2: 70% | 74.96% | 25.04% | −0.4984 | 1.7245 | 0.8379 | |

| w1: 20%, w2: 80% | 74.93% | 25.07% | −0.6709 | 1.7198 | 0.8386 | |

| w1: 10%, w2: 90% | 74.91% | 25.09% | −0.8687 | 1.7067 | 0.8390 | |

| 25 °C | w1: 50%, w2: 50% | 75.02% | 24.98% | −0.0681 | 1.7386 | 0.8371 |

| w1: 40%, w2: 60% | 75.00% | 25.00% | −0.2981 | 1.7269 | 0.8375 | |

| w1: 30%, w2: 70% | 74.96% | 25.04% | −0.5603 | 1.7258 | 0.8382 | |

| w1: 20%, w2: 80% | 74.92% | 25.08% | −0.6991 | 1.7212 | 0.8389 | |

| w1: 10%, w2: 90% | 74.88% | 25.12% | −0.8852 | 1.7112 | 0.8397 |

| D–B (%) | Gaseous Pollutants | ||||||

|---|---|---|---|---|---|---|---|

| O2 | CO2 | CO | NOX | C.P. | E.A. | ||

| 1 | 100–0 | 3.9 | 12.6 | 130 | 69 | 94.9 | 22.9 |

| 2 | 95–5 | 3.9 | 12.5 | 132 | 69 | 94.8 | 23.3 |

| 3 | 90–10 | 4.0 | 12.6 | 133 | 69 | 94.9 | 23.7 |

| 4 | 85–15 | 4.1 | 12.5 | 135 | 70 | 94.9 | 24.2 |

| 5 | 80–20 | 4.1 | 12.7 | 137 | 70 | 94.9 | 24.2 |

| 6 | 75–25 | 4.2 | 12.7 | 139 | 71 | 95.0 | 24.5 |

| 7 | 70–30 | 4.2 | 12.6 | 142 | 71 | 95.2 | 24.9 |

| 8 | 65–35 | 4.3 | 12.6 | 147 | 71 | 95.1 | 25.5 |

| 9 | 60–40 | 4.3 | 12.6 | 152 | 72 | 95.2 | 26.2 |

| 10 | 55–45 | 4.5 | 12.7 | 158 | 72 | 95.3 | 26.8 |

| 11 | 50–50 | 4.5 | 12.7 | 162 | 73 | 95.4 | 27.4 |

| 12 | 45–55 | 4.5 | 12.7 | 165 | 73 | 95.3 | 27.4 |

| 13 | 40–60 | 4.4 | 12.6 | 168 | 71 | 95.4 | 27.2 |

| 14 | 35–65 | 4.4 | 12.6 | 170 | 70 | 95.4 | 27.0 |

| 15 | 30–70 | 4.5 | 12.7 | 172 | 69 | 95.4 | 26.8 |

| 16 | 25–75 | 4.5 | 12.6 | 174 | 68 | 95.0 | 26.6 |

| 17 | 20–80 | 4.5 | 12.5 | 179 | 68 | 95.1 | 26.4 |

| 18 | 15–85 | 4.5 | 12.5 | 184 | 69 | 95.2 | 26.0 |

| 19 | 10–90 | 4.6 | 12.5 | 194 | 69 | 95.1 | 25.7 |

| 20 | 5–95 | 4.6 | 12.6 | 204 | 69 | 95.0 | 25.4 |

| 21 | 0–100 | 4.6 | 12.6 | 216 | 68 | 95.2 | 25.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasileiadis, V.; Kyriklidis, C.; Karayannis, V.; Tsanaktsidis, C. Application of Evolutionary Computation to the Optimization of Biodiesel Mixtures Using a Nature-Inspired Adaptive Genetic Algorithm. Algorithms 2024, 17, 181. https://doi.org/10.3390/a17050181

Vasileiadis V, Kyriklidis C, Karayannis V, Tsanaktsidis C. Application of Evolutionary Computation to the Optimization of Biodiesel Mixtures Using a Nature-Inspired Adaptive Genetic Algorithm. Algorithms. 2024; 17(5):181. https://doi.org/10.3390/a17050181

Chicago/Turabian StyleVasileiadis, Vasileios, Christos Kyriklidis, Vayos Karayannis, and Constantinos Tsanaktsidis. 2024. "Application of Evolutionary Computation to the Optimization of Biodiesel Mixtures Using a Nature-Inspired Adaptive Genetic Algorithm" Algorithms 17, no. 5: 181. https://doi.org/10.3390/a17050181

APA StyleVasileiadis, V., Kyriklidis, C., Karayannis, V., & Tsanaktsidis, C. (2024). Application of Evolutionary Computation to the Optimization of Biodiesel Mixtures Using a Nature-Inspired Adaptive Genetic Algorithm. Algorithms, 17(5), 181. https://doi.org/10.3390/a17050181