Evaluation of Uniformity of Bamboo Bundle Veneer and Bamboo Bundle Laminated Veneer Lumber (BLVL)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

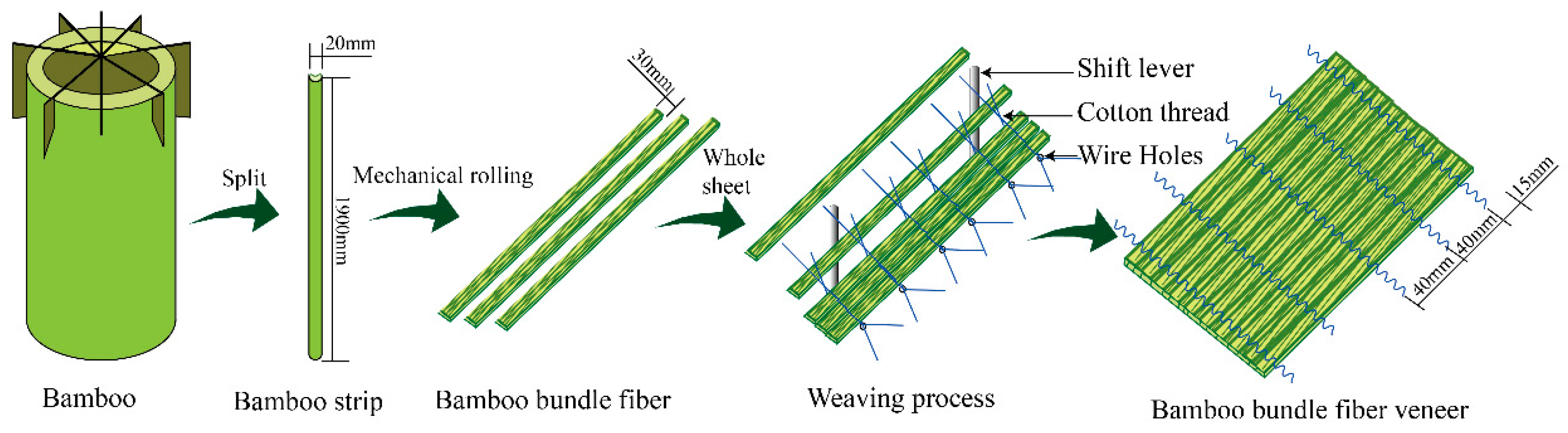

2.1.1. Bamboo Bundle Veneers

2.1.2. Bamboo Scrimber (BS) and Bamboo Bundle Laminated Veneer Lumber (BLVL)

2.2. Methods

2.2.1. Quality Evaluation Method of Bamboo Bundle Veneers

Light Transmittance Detection

Mechanical Stiffness Detection

2.2.2. Quality Stability Evaluation of BLVL and BS

3. Results

3.1. Quality Evaluation and Analysis of Bamboo Bundle Veneers

3.2. Influence of the Degree of Brooming and Glue on the Quality of Bamboo Bundle Veneers

3.3. Effect of Heat Treatment on the Quality of Bamboo Bundle Veneers

3.4. The Density and Mechanical Uniformity of Traditional BS and Novel BLVL

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yu, Y.; Zhu, R.; Wu, B.; Yu, A.; Hu, W. Fabrication, material properties, and application of bamboo scrimber. Wood Sci. Technol. 2015, 49, 83–98. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B 2014, 54, 48–53. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman, M.R.; Hamdan, S.; Sanaullah, K. Recent developments in bamboo fiber-based composites: A review. Polym. Bull. 2019, 76, 2655–2682. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Wei, Y.; Ji, X.; Duan, M.; Li, G. Flexural performance of bamboo scrimber beams strengthened with fiber-reinforced polymer. Constr. Build. Mater. 2017, 142, 66–82. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, B.; Yu, W. Research progress on new technology and new product development of bamboo scrimber. Int. Wood Ind. 2014, 7, 8–13. [Google Scholar]

- He, S.; Xu, J.; Wu, Z.; Yu, H.; Chen, Y.; Song, J. Effect of bamboo bundle knitting on enhancing properties of bamboo scrimber. Eur. J. Wood Wood Prod. 2018, 76, 1071–1078. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Li, H.; Chen, F.; Xian, Y.; Deng, J.; Wang, G.; Cheng, H. An empirical model for predicting the mechanical properties degradation of bamboo bundle laminated veneer lumber (blvl) by hygrothermal aging treatment. Eur. J. Wood Wood Prod. 2017, 75, 553–560. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, Z.; Wang, G.; Li, H.; Simth, L.M.; Shi, S.Q. The bending properties of bamboo bundle laminated veneer lumber (blvl) double beams. Constr. Build. Mater. 2016, 119, 145–151. [Google Scholar] [CrossRef]

- Wang, G.; Chen, F. Development of bamboo fiber-based composites. Adv. High Strength Nat. Fibre Compos. Constr. 2017, 235–255. [Google Scholar] [CrossRef]

- Yu, Z. Processing Technology of Laminated Bamboo-Bundle Veneer Lumber and Its Application Performance. Ph.D. Thesis, Chinese Academy of Sciences, Beijing, China, 2012. [Google Scholar]

- Zhang, D.; Ren, W.; Chen, F.; Deng, J.; Wang, G. Effect of Surface Veneer Joint on Properties of Bamboo Bundle Laminated Veneer Lumber. J. For. Res. 2014, 42, 83–85. [Google Scholar]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Shangguan, W. Effects of heat treatment on the properties of bamboo scrimber. J. Wood. Sci. 2016, 62, 1–9. [Google Scholar] [CrossRef]

- Zhu, Y.; Mo, X.; Gu, D.; Guan, M. Preparation and performance evaluation of bamboo bundles. For. J. Eng. 2007, 21, 41–43. [Google Scholar]

- Wu, B.; Yu, Y.; Qi, J.; Yu, W. Effects of bamboo bundles treated with fine fluffing and carbonized trentment on the properties of bamboo scrimber. J. Nanjing For. Univ. (Nat. Sci. Ed.). 2014, 38, 115–120. [Google Scholar]

- Qi, J.; Xie, J.; Yu, W.; Chen, S. Effects of characteristic inhomogeneity of bamboo culm nodes on mechanical properties of bamboo fiber reinforced composite. J. For. Res. 2015, 26, 1057–1060. [Google Scholar] [CrossRef]

- Lee, C.H.; Yang, T.H.; Cheng, Y.W.; Lee, C.J. Effects of thermal modification on the surface and chemical properties of moso bamboo. Constr. Build. Mater. 2018, 178, 59–71. [Google Scholar] [CrossRef]

- Li, T.; Cheng, D.; Walinder, M.; Zhou, D. Wettability of oil heat-treated bamboo and bonding strength of laminated bamboo board. Ind. Crop. Prod. 2015, 69, 15–20. [Google Scholar] [CrossRef]

- Kwon, J.H.; Shin, R.H.; Ayrilmis, N.; Han, T.H. Properties of solid wood and laminated wood lumber manufactured by cold pressing and heat treatment. Mater. Des. 2014, 62, 375–381. [Google Scholar] [CrossRef]

- Xu, M.; Cui, Z.; Chen, Z.; Xiang, J. Experimental study on compressive and tensile properties of a bamboo scrimber at elevated temperatures. Constr. Build. Mater. 2017, 151, 732–741. [Google Scholar] [CrossRef]

- Qin, L.; Yu, W.; Yu, Y. Research on properties of reconstituted bamboo lumber made by thermo-treated bamboo bundle curtains. For. Prod. J. 2012, 62, 545–550. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo I: Fundamental properties of bamboo zephyr board. J. Wood. Sci. 2000, 46, 68–74. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. J. Wood. Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Rao, W. Research of the Wood-bamboo Composite Scrimber. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2003. (In Chinese). [Google Scholar]

- Gu, D. The Key Process and Property Research of Wood-Bamboo Scrimber. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2008. (In Chinese). [Google Scholar]

- Chung, M.J.; Wang, S.Y. Mechanical properties of oriented bamboo scrimber boards made of Phyllostachys pubescens (moso bamboo) from Taiwan and China as a function of density. Holzforschung 2018, 72, 151–158. [Google Scholar]

- Möller, R.; Mild, G. Protection of Moso bamboo (Phyllostachys pubescens) materials against fungal decay and discolouration by treatment with wood preservatives. Eur. J. Wood Wood Prod. 2019, 77, 139–145. [Google Scholar]

- Hakkou, M.; Pétrissans, M.; Zoulalian, A.; Gérardin, P. Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym. Degrad. Stab. 2015, 89, 1–5. [Google Scholar] [CrossRef]

- Windeisen, E.; Strobel, C.; Wegener, G. Chemical changes during the production of thermo-treated beech wood. Wood Sci. Technol. 2007, 41, 523–536. [Google Scholar] [CrossRef]

- Yildiz, S.; Tomak, E.D.; Yildiz, U.C.; Ustaomer, D. Effect of artificial weathering on the properties of heat treated wood. Polym. Degrad. Stab. 2013, 98, 1419–1427. [Google Scholar] [CrossRef]

| Types | Average Density (g/cm3) | Maximum Density on the Left (g/cm3) | Maximum Density on the Right (g/cm3) | Minimum Density (g/cm3) | MOR (MPa) | MOE (GPa) |

|---|---|---|---|---|---|---|

| BS | 1.02 (12.36) | 1.04 (10.16) | 1.01 (19.53) | 0.66 (9.90) | 104.57 (26.68) | 12.57 (39.71) |

| BLVL | 0.98 (3.89) | 1.00 (3.64) | 1.03 (2.73) | 0.81 (2.71) | 121.31 (7.90) | 15.83 (10.79) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Wei, X.; Smith, L.M.; Wang, G.; Chen, F. Evaluation of Uniformity of Bamboo Bundle Veneer and Bamboo Bundle Laminated Veneer Lumber (BLVL). Forests 2019, 10, 921. https://doi.org/10.3390/f10100921

Zhou H, Wei X, Smith LM, Wang G, Chen F. Evaluation of Uniformity of Bamboo Bundle Veneer and Bamboo Bundle Laminated Veneer Lumber (BLVL). Forests. 2019; 10(10):921. https://doi.org/10.3390/f10100921

Chicago/Turabian StyleZhou, Haiying, Xin Wei, Lee M. Smith, Ge Wang, and Fuming Chen. 2019. "Evaluation of Uniformity of Bamboo Bundle Veneer and Bamboo Bundle Laminated Veneer Lumber (BLVL)" Forests 10, no. 10: 921. https://doi.org/10.3390/f10100921

APA StyleZhou, H., Wei, X., Smith, L. M., Wang, G., & Chen, F. (2019). Evaluation of Uniformity of Bamboo Bundle Veneer and Bamboo Bundle Laminated Veneer Lumber (BLVL). Forests, 10(10), 921. https://doi.org/10.3390/f10100921