Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood Transportation Data

2.2. Wood Transportation Conditions

2.3. Fuel Consumption

2.4. Environmental Efficiency

2.5. Energy Conversion

2.6. Energy Efficiency

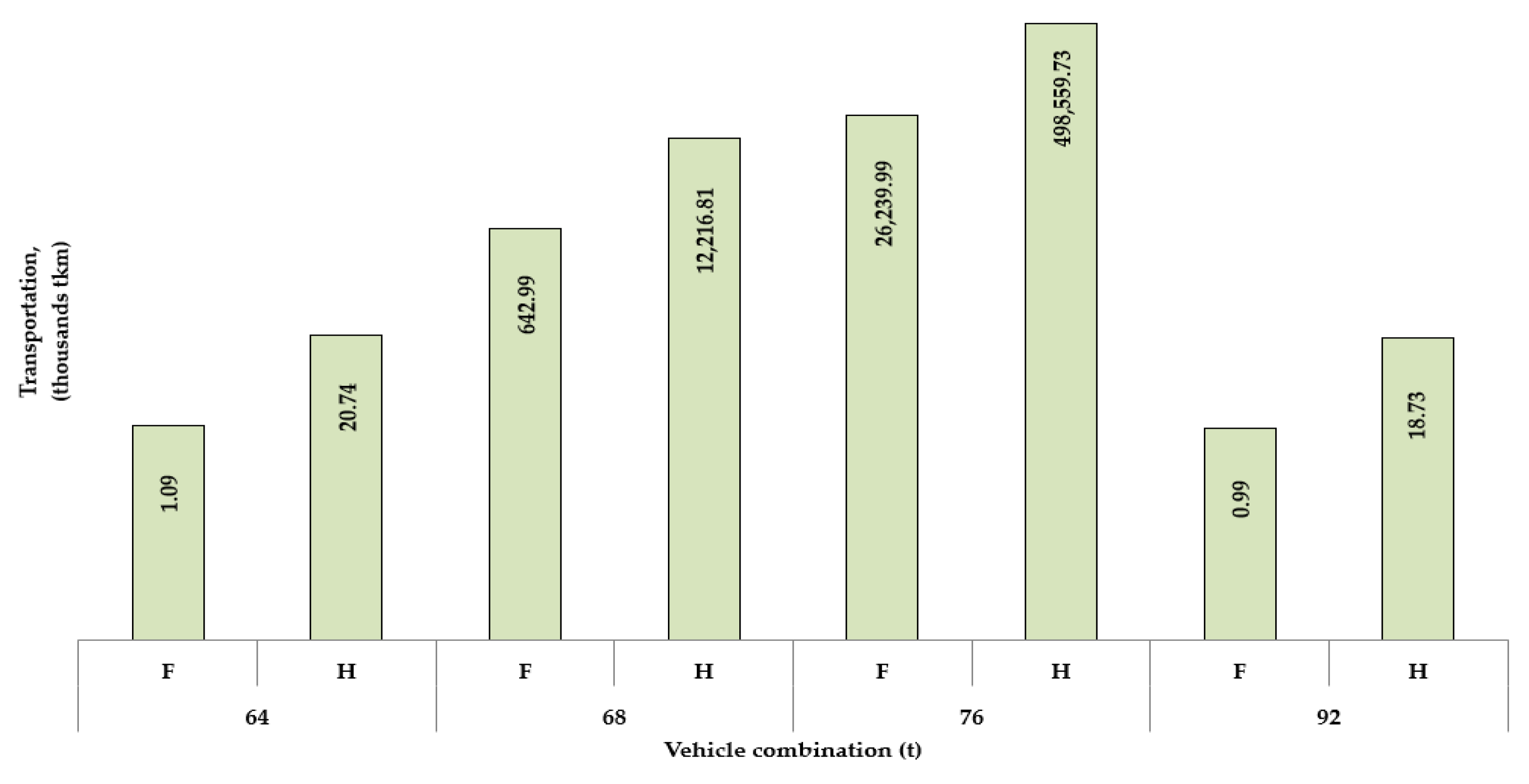

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EUR-Lex. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52011AE1389 (accessed on 2 March 2020).

- EUR-Lex. A Policy Framework for Climate and Energy in the Period from 2020 to 2030. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014DC0015&from=EN (accessed on 2 March 2020).

- Korzhenevych, A.; Dehnen, N.; Bröcker, J.; Holtkamp, M.; Meier, H.; Gibson, G.; Varma, A.; Cox, V. Update of the Handbook on External Costs of Transport; European Commission, DG Mobility and Transport: Ispra, Italy, 2014. [Google Scholar]

- OECD. Moving Freight with Better Trucks: Improving Safety, Productivity and Sustainability. 2011. Available online: http://www.oecd-ilibrary.org/transport/ (accessed on 2 March 2013).

- García-Olivares, A.; Solé, J.; Samsó, R.; Ballabrera-Poy, J. Sustainable European Transport System in a 100% Renewable Economy. Sustainability 2020, 12, 5091. [Google Scholar] [CrossRef]

- Handler, R.M.; Shonnard, D.R.; Lautala, P.; Abbas, D.; Strivastava, A. Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. J. Clean. Prod. 2014, 76, 64–73. [Google Scholar] [CrossRef]

- Sonne, E. Greenhouse gas emissions from forestry operations: A lifecycle assessment. J. Environ. Qual. 2006, 35, 1439–1450. [Google Scholar] [CrossRef]

- Ghose, A.; Chinga-Carrasco, G. Environmental aspects of Norwegian production of pulp fibers and printing paper. J. Clean. Prod. 2013, 57, 293–301. [Google Scholar] [CrossRef]

- Ministry of Transport and Communications, Transport Emissions to Zero by 2045. Available online: https://valtioneuvosto.fi/en/article/-/asset_publisher/liikenteen-paastot-nollaan-vuoteen-2045-mennessa (accessed on 2 March 2020).

- Lipasto, Road Traffic Emissions and Energy Consumption in Finland, 2012. Available online: http://lipasto.vtt.fi/liisae/emissiondata.htm (accessed on 2 March 2020).

- Palander, T. The environmental emission efficiency of larger and heavier vehicles—A case study of road transportation in Finnish forest industry. J. Clean. Prod. 2017, 155, 57–62. [Google Scholar] [CrossRef]

- McKinnon, A. The economic and environmental benefits of increasing maximum truck weight: The British experience. Transp. Res. Part D Transp. Environ. 2005, 10, 77–95. [Google Scholar] [CrossRef]

- McKinnon, A.C.; Piecyk, M. Measurement of CO2 emissions from road freight transport: A Review of UK Experience. Energy Policy 2009, 37, 3733–3742. [Google Scholar] [CrossRef]

- Korhonen, J. Four ecosystem principles for an industrial ecosystem. J. Clean. Prod. 2001, 9, 253–259. [Google Scholar] [CrossRef]

- Korhonen, J. A material and energy flow model for co-production of heat and power. J. Clean. Prod. 2002, 10, 537–544. [Google Scholar] [CrossRef]

- Palander, T.; Kärhä, K. Characteristics of energy performance measures for 100% carbon-neutral wood procurement of forest industry. In New Trends in Nanotechnology, Material and Environmental Sciences; Zhu, J., Jin, A., Zhu, D., Eds.; AV AkademikerVerlag: Berlin, Germany, 2018; pp. 304–332. [Google Scholar]

- Palander, T.; Haavikko, H.; Kärhä, K. Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew. Sustain. Energy Rev. 2018, 96, 100–118. [Google Scholar] [CrossRef]

- Green and Vibrant Economy—The Climate Roadmap for the Forest Industry. Available online: https://www.metsateollisuus.fi/ilmastotiekartta/ (accessed on 2 March 2020).

- Palander, T.; Väätäinen, J. Impacts of inter-enterprise collaboration and backhauling on wood procurement in Finland. Scand. J. For. Res. 2005, 20, 177–183. [Google Scholar] [CrossRef]

- Palander, T.; Säynäjärvi, T.; Högnäs, T. New organizing models of timber truck transportation. Metsätieteen Aikakauskirja 2006, 1, 5–22. (In Finnish) [Google Scholar]

- Palander, T.; Vainikka, M.; Yletyinen, A. Potential mechanisms for co-operation between transportation entrepreneurs and customers: A case study of regional entrepreneurship in Finland. Croat. J. For. Eng. 2012, 33, 89–103. [Google Scholar]

- Stora Enso, Progress Book, Part of Stora Enso’s Annual Report 2017, 2018. Available online: https://www.storaenso.com/download-centre/ (accessed on 2 March 2020).

- Haavikko, H.; Kärhä, K.; Hourula, M.; Palander, T. Attitudes of small and medium-sized enterprises towards energy efficiency in wood procurement: A case study of Stora Enso in Finland. Croat. J. For. Eng. 2019, 40, 107–123. [Google Scholar]

- Palander, T.; Kärhä, K. Improving energy efficiency in a synchronized road-transportation system by using a TFMC (Transportation Fleet-Management Control) in Finland. Energies 2019, 12, 670. [Google Scholar] [CrossRef] [Green Version]

- Holzleitner, F.; Kanzian, C.; Stampfer, K. Analyzing time and fuel consumption in road transport of round wood with an onboard fleet manager. Eur. J. For. Res. 2011, 130, 293–301. [Google Scholar] [CrossRef]

- Svenson, G.; Fjeld, D. The impact of road geometry, surface roughness and truck weight on operating speed of logging trucks. Scand. J. For. Res. 2017, 32, 515–527. [Google Scholar] [CrossRef]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, L.; Kusiak, W. Fuel consumption and exhaust emissions in the process of mechanized wood extraction and transport. Eur. J. For. Res. 2017, 136, 153–160. [Google Scholar] [CrossRef] [Green Version]

- Palander, T. Environmental benefits from improving transportation efficiency in wood procurement systems. Transp. Res. Part D Transp. Environ. 2016, 44, 211–218. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M. Trends of energy efficiency in Finnish road freight transport 1995–2009 and forecast to 2016. Energy Policy 2010, 38, 7676–7686. [Google Scholar] [CrossRef]

- Hämäläinen, E.; Hilmola, O.P. Energy efficiency at the paper mill—Dilemma of improvement. Energy Effic. 2017, 10, 809–821. [Google Scholar] [CrossRef]

- Höök, C.; Asmoarp, V.; Edlund, B.; Bergström, D. A Method of Finding HCT Roundwood Corridors for Reduction of GHG Emissions and Fuel Costs in Sweden. Forest 2020, 11, 220. [Google Scholar] [CrossRef] [Green Version]

- Joelsson, J.M.; Gustavsson, L. CO2 emission and oil use reduction through black liquor gasification and energy efficiency in pulp and paper industry. Resour. Conserv. Recycl. 2008, 52, 747–763. [Google Scholar] [CrossRef]

- Kilponen, L.; Ahtila, P.; Parpala, J.; Pihko, M. Improvement of pulp mill energy efficiency in an integrated pulp and paper mill. In Proceedings of the 2001 ACEEE Summer Study on Energy Efficiency in Industry, Tarrytown, NY, USA, 24–27 July 2001; pp. 363–374. [Google Scholar]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K. Comparison of energy efficiency indicators of road transportation for modeling environmental sustainability in “Green” Circular Industry. Sustainability 2020, 12, 2740. [Google Scholar] [CrossRef] [Green Version]

- Taha, H.A. Operations Research: An Introduction, 10th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Palander, T. Local factors and time-variable parameters in tactical planning models: A tool for adaptive timber procurement planning. Scand. J. For. Res. 1995, 10, 370–382. [Google Scholar] [CrossRef]

- Palander, T. Tactical Models of Wood-Procurement Teams for Geographically Decentralized Group Decision-Making. Ph.D. Thesis, University of Eastern Finland, Joensuu, Finland, 1998. Available online: https://www.researchgate.net/publication/44364975_Tactical_models_of_wood-procurement_teams_for_geographically_decentralized_group_decision-making_Teijo_Palander (accessed on 22 October 2020).

- Carlsson, D.; Rönngvist, M. Backhauling in Forest Transportation—Models, Methods and Practical Usage. Can. J. For. Res. 2007, 37, 2612–2623. [Google Scholar] [CrossRef]

- Hu, J.; Wang, S. Total-factor energy efficiency of regions in China. Energy Policy 2006, 34, 3206–3217. [Google Scholar] [CrossRef]

- Chang, Y.-T. Environmental efficiency of ports: A data envelopment analysis approach. Marit. Policy Manag. 2013, 40, 467–478. [Google Scholar] [CrossRef]

- Chang, Y.-T.; Zhang, N.; Danao, D.; Zhang, N. Environmental efficiency analysis of transportation system in China: A non-radial DEA approach. Energy Policy 2013, 58, 277–283. [Google Scholar] [CrossRef]

- Ministry of Transport and Communications. Better Competitiveness through New Masses and Dimensions for Heavy Goods Vehicles. 2013. Available online: http://www.lvm.fi/tiedote/4150413/better-competitiveness-through-new-masses-and-dimensions-for-heavy-goods-vehicles (accessed on 2 March 2020).

- Palander, T.S. A model to estimate benefits from log drying for supply chains in wood procurement. In Proceedings of the 2nd World Symposium on Logistics in Forest Sector, IUFRO and Wood Logistics Network, Växjö, Sweden, 12–15 August 2001; Available online: https://www.researchgate.net/profile/Teijo_Palander/publications?sorting=newest&page=2 (accessed on 2 March 2020).

- Inkinen, T.; Hämäläinen, E. Reviewing Truck Logistics: Solutions for Achieving Low Emission Road Freight Transport. Sustainability 2020, 12, 6714. [Google Scholar] [CrossRef]

- European Modular Systems. 2013. Available online: http://www.modularsystem.eu/ (accessed on 2 March 2020).

- DieselNet, Emission Standards. 2014. Available online: https://www.dieselnet.com/standards/eu/hd.php (accessed on 2 March 2020).

- Park, Y.S.; Lim, S.H.; Egilmez, G.; Szmerekovsky, J. Environmental efficiency assessment of U.S. transport sector: A slack-based data envelopment analysis approach. Transp. Res. Part D Transp. Environ. 2018, 61, 152–164. [Google Scholar] [CrossRef] [Green Version]

- Seppänen, R.; Kervinen, M.; Parkkila, I.; Karkela, L.; Meriläinen, P. MAOL-Tables; Otavan kirjapaino Oy: Helsinki, Finland, 2012; p. 167. (In Finnish) [Google Scholar]

- Neste, Pro Diesel Summer Quality, Tuotetiedote. 2017. Available online: https://www.neste.fi/static/datasheet_pdf/150425_fi.pdf (accessed on 2 March 2020). (In Finnish).

- Neste, Pro Diesel Winter Quality, Tuotetiedote. 2017. Available online: https://www.neste.fi/static/datasheet_pdf/150445_fi.pdf (accessed on 2 March 2020). (In Finnish).

- Teboil, Diesel Summer Quality, Tuotetiedote. 2018. Available online: https://www.teboil.fi/globalassets/tuotetiedotteet/diesel-kl.pdf (accessed on 2 March 2020). (In Finnish).

- Teboil, Diesel Winter Quality, Tuotetiedote. 2018. Available online: https://www.teboil.fi/globalassets/tuotetiedotteet/diesel--29_-38.pdf (accessed on 2 March 2020). (In Finnish).

- Tuomaala, M.; Ahtila, P.; Haikonen, T.; Kalenoja, H.; Kallionpää, E.; Rantala, J.; Tuominen, P.; Shemeikka, J.; Rämä, M.; Sipilä, K.; et al. Energy efficiency measurements and potentials. Sci. Technol. 2012, 1, 1–340. (In Finnish) [Google Scholar]

- Nurmi, J. Heating values of the above ground biomass of small-sized trees. Acta For. Fenn. 1993, 236, 1–30. (In Finnish) [Google Scholar] [CrossRef] [Green Version]

| Emission Type | Emissions (t) | Share of Road Transport (%) |

|---|---|---|

| CO | 2572 | 6.9 |

| HC | 303 | 8.1 |

| NOX | 11,130 | 36.6 |

| PM | 185 | 23.4 |

| CH4 | 52 | 14.0 |

| N2O | 91 | 33.3 |

| CO2 | 3,526,890 | 32.4 |

| CO2eq. | 3,555,265 | 32.4 |

| Parameter | Measurement Unit | Vehicle Combination | |||

|---|---|---|---|---|---|

| 64 t | 68 t | 76 t | 92 t | ||

| Share of measured loads | % | 1 | 14 | 84 | 1 |

| Transportation distance—average | km | 83 | 72 | 76 | 165 |

| Transportation distance—range | km | 1–294 | 1–439 | 1–626 | 14–303 |

| Transportation distance—standard deviation | km | 59 | 53 | 52 | 61 |

| Transportation distance—median | km | 75 | 60 | 65 | 146 |

| Load size—average | t | 42 | 43 | 50 | 65 |

| Load size—range | t | 1–71 1 | 1–98 1 | 1–113 1 | 48–69 1 |

| Load size—standard deviation | t | 8 | 14 | 8 | 3 |

| Load size—median | t | 43 | 47 | 52 | 65 |

| Fuel consumption—average | L × 100 km−1 | 58 | 59 | 62 | 73 |

| Fuel consumption—range | L × 100 km−1 | 35–66 | 37–73 | 39–76 | 42–91 |

| Parameter | Measurement Unit | Region A | Region B | Region C | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 64 t | 68 t | 76 t | 92 t | 64 t | 68 t | 76 t | 92 t | 64 t | 68 t | 76 t | 92 t | ||

| Number of loads | - | 625 | 7550 | 72,159 | 158 | 392 | 4763 | 46,890 | 196 | 13 | 2036 | 48,264 | 259 |

| Average load size | t | 46 | 46 | 50 | 66 | 40 | 46 | 50 | 64 | 52 | 48 | 49 | 65 |

| Fuel consumption as loaded | L × 100 km−1 | 59 | 60 | 61 | 73 | 58 | 60 | 61 | 72 | 62 | 61 | 61 | 73 |

| Fuel consumption of loaded trip | kWh | 768 | 545 | 568 | 1099 | 811 | 559 | 568 | 1574 | 437 | 444 | 561 | 1142 |

| Fuel consumption of empty trip | kWh | 709 | 503 | 525 | 1014 | 748 | 516 | 525 | 1453 | 403 | 410 | 518 | 1054 |

| Energy content of the loads | kWh | 41,634 | 44,084 | 45,255 | 73,793 | 29,815 | 34,288 | 39,931 | 61,334 | 55,371 | 51,112 | 49,568 | 76,136 |

| Empty driving distance | km | 101 | 70 | 72 | 116 | 108 | 72 | 72 | 169 | 54 | 56 | 71 | 121 |

| Loaded driving distance | km | 109 | 76 | 78 | 126 | 117 | 78 | 78 | 183 | 59 | 61 | 77 | 131 |

| Number of plants | - | 11 | 11 | 11 | 11 | 6 | 6 | 6 | 6 | 4 | 4 | 4 | 4 |

| Highways with speed >60 km × h−1 | km | 1468 | 1468 | 1468 | 1468 | 737 | 737 | 737 | 737 | 501 | 501 | 501 | 501 |

| Local roads with speed ≤60 km × h−1 | km | 1407 | 1407 | 1407 | 1407 | 784 | 784 | 784 | 784 | 1051 | 1051 | 1051 | 1051 |

| Stage | Year | CO | HC | NOx | PM |

|---|---|---|---|---|---|

| EURO IV | 2005 | 1.5 | 0.46 | 3.5 | 0.02 |

| EURO V | 2008 | 1.5 | 0.46 | 2.0 | 0.02 |

| EURO VI | 2013 | 1.5 | 0.13 | 0.4 | 0.01 |

| Emissions (g × tkm−1) | 64 t 1 | 76 t 1 | 92 t 1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F 2 | H 2 | AR 2 | F 2 | H 2 | AR 2 | F 2 | H 2 | AR 2 | |

| CO2 | 38.251 | 34.965 | 35.1293 | 34.092 | 31.233 | 31.376 | 28.329 | 27.080 | 27.143 |

| SO2 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| NOx | 0.0099 | 0.0082 | 0.0083 | 0.0080 | 0.0063 | 0.0064 | 0.0067 | 0.0055 | 0.0055 |

| CO | 0.0052 | 0.0038 | 0.0039 | 0.0042 | 0.0030 | 0.0031 | 0.0035 | 0.0026 | 0.0027 |

| PM | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| HC | 0.0008 | 0.0006 | 0.0006 | 0.0007 | 0.0005 | 0.0005 | 0.0006 | 0.0004 | 0.0004 |

| N2O | 0.0009 | 0.0014 | 0.0014 | 0.0007 | 0.0011 | 0.0011 | 0.0006 | 0.0010 | 0.0010 |

| CH4 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Fuel (L × tkm−1) | 0.016 | 0.014 | 0.015 | 0.014 | 0.013 | 0.013 | 0.012 | 0.011 | 0.011 |

| 64 t 1 | 68 t 1 | 76 t 1 | 92 t 1 | ||||

|---|---|---|---|---|---|---|---|

| L | EE 2 | L | EE 2 | L | EE 2 | L | EE 2 |

| 34 | 0.72 | 29 | 0.60 | 42 | 0.83 | 62 | 1.05 |

| 38 | 0.80 | 36 | 0.74 | 46 | 0.91 | 64 | 1.08 |

| 42 | 0.88 | 43 | 0.89 | 50 | 1.00 | 65 | 1.10 |

| 46 | 0.96 | 50 | 1.04 | 54 | 1.08 | 66 | 1.13 |

| 50 | 1.04 | 57 | 1.18 | 58 | 1.16 | 68 | 1.16 |

| Energy Type | Moisture Content (%) | Energy Content 1 (kWh × tkm−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 64 t | 68 t | 76 t | 92 t | ||||||

| I 2 | E 2 | I 2 | E 2 | I 2 | E 2 | I 2 | E 2 | ||

| FC | - | 139 | 139 | 138 | 138 | 123 | 123 | 111 | 111 |

| WE | 55 | 1304 | 88 | 1335 | 90 | 1553 | 105 | 2018 | 136 |

| WE | 35 | 1884 | 137 | 1929 | 140 | 2243 | 163 | 2915 | 212 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K.; Borz, S.A. Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry. Forests 2020, 11, 1194. https://doi.org/10.3390/f11111194

Palander T, Haavikko H, Kortelainen E, Kärhä K, Borz SA. Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry. Forests. 2020; 11(11):1194. https://doi.org/10.3390/f11111194

Chicago/Turabian StylePalander, Teijo, Hanna Haavikko, Emma Kortelainen, Kalle Kärhä, and Stelian Alexandru Borz. 2020. "Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry" Forests 11, no. 11: 1194. https://doi.org/10.3390/f11111194

APA StylePalander, T., Haavikko, H., Kortelainen, E., Kärhä, K., & Borz, S. A. (2020). Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry. Forests, 11(11), 1194. https://doi.org/10.3390/f11111194