Evaluating the Economic Incentives of Biomass Removal on Site Preparation for Different Harvesting Systems in Australia

Abstract

:1. Introduction

1.1. Harvesting Systems and Biomass Availablity

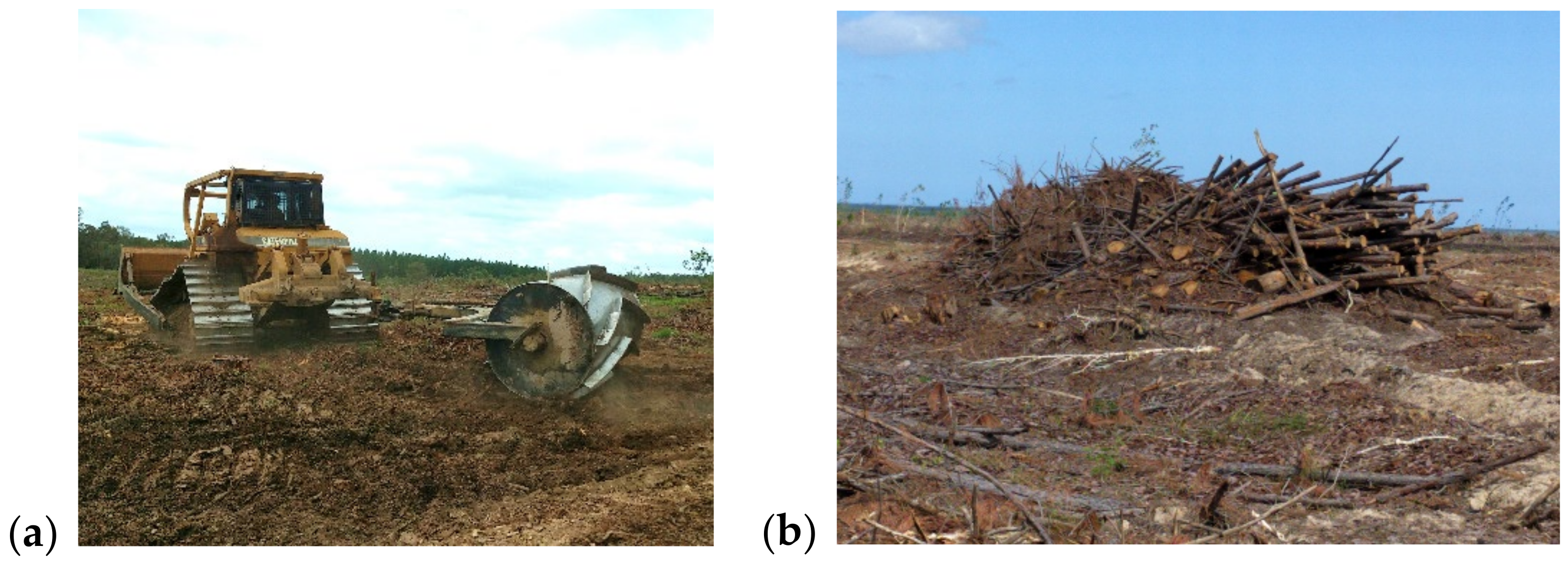

1.2. Site Preparation

2. Materials and Methods

2.1. Mathematical Model

2.2. Site Preparation Framework

2.3. Site Preparation Example

2.3.1. Regional Operations

2.3.2. Slash Assessment

3. Results

3.1. Cut to Length Site Preparation Costs

3.2. Whole-Tree System Site Preparation Costs

3.3. Model Break-Even Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bisson, J.; Han, H.-S. Quality of feedstock produced from sorted forest residues. Am. J. Biomass Bioenergy. 2016, 5, 81–97. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Kizha, A.R.; Mani, S. Economic analysis of forest residues supply chain options to produce enhanced quality feedstocks. Biofuels Bioprod. Biorefin. 2019, 13, 514–534. [Google Scholar] [CrossRef]

- Han, H.-S.; Lee, H.W.; Johnson, L.R. Economic feasibility of an integrated harvesting system for small-diameter trees in southwest Idaho. For. Prod. J. 2004, 54, 21–27. [Google Scholar]

- Kizha, A.R.; Han, H.-S.; Montgomery, T.; Hohl, A. Biomass power plant feedstock procurement: Modeling transportation cost zones and the potential for competition. Calif. Agric. 2015, 69, 184–190. [Google Scholar] [CrossRef]

- Parliament of Australia. Renewable Energy Targets; Australian Government: Canberra, Australia, 2010. [Google Scholar]

- CEFC. The Australian Bioenergy and Energy from Waste Market, Clean Energy Financial Corporation. November 2015. Available online: https://www.cefc.com.au/media/107567/the-australian-bioenergy-and-energy-from-waste-market-cefc-market-report.pdf (accessed on 12 December 2020).

- Thiffault, E.; Hannam, K.; Paré, D.; Titus, B.; Hazlett, P.; Maynard, D.; Brais, S. Effects of forest biomass harvesting on soil productivity in boreal and temperate forests—A review. Environ. Rev. 2011, 19, 278–309. [Google Scholar] [CrossRef]

- Watson, W.F.; Stokes, B.J.; Savelle, I.W. Site preparation savings through better utilization standards. In Forest Resources Management-the Influence of Policy and Law; The Congress Forestier International Forest Congress: Quebec, QC, Canada, 1984; pp. 389–392. Available online: https://www.fs.usda.gov/treesearch/pubs/7382 (accessed on 5 August 2020).

- Ghaffariyan, M. Remaining slash in different harvesting operation sites in Australian plantations. Silva Balcanica 2013, 14, 83–93. [Google Scholar]

- Ghaffariyan, M.; Apolit, R. Harvest residues assessment in pine plantations harvested by whole tree and cut-to-length harvesting methods (a case study in Queensland, Australia). Silva Balcanica 2015, 16, 113–122. [Google Scholar]

- Tuomasjukka, D.; Martire, S.; Lindner, M.; Athanassiadis, D.; Kühmaier, M.; Tumajer, J.; Vis, M.; Spinelli, R.; Dees, M.; Prinz, R.; et al. Sustainability impacts of increased forest biomass feedstock supply—A comparative assessment of technological solutions. Int. J. For. Eng. 2018, 29, 99–116. [Google Scholar] [CrossRef]

- Barrett, S.; Aust, W.; Bolding, C. Potential Impacts of Biomass Harvesting on Forest Resource Sustainability. In Proceedings of the 32nd Annual Council on Forest Engineering Meeting, Kings Beach, CA, USA, 15–18 June 2009; p. 6. [Google Scholar]

- Westbrook, M.D., Jr.; Greene, D.W.; Izlar, R.L. Utilizing Forest Biomass by adding a Chipper to a Tree-Length Southern Pine Harvesting Operation. South J. Appl. For. 2017, 31, 165–169. [Google Scholar] [CrossRef] [Green Version]

- Hall, J.P. Sustainable production of forest biomass for energy. For. Chron. 2007, 78, 391–396. [Google Scholar] [CrossRef] [Green Version]

- Cambero, C.; Taraneh, S. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Sutinen, R.; Gustavsson, N.; Hänninen, P.; Middleton, M.; Räisänen, M.L. Impact of mechanical site preparation on soil properties at clear-cut Norway spruce sites on mafic rocks of the Lapland Greenstone Belt. Soil Tillage Res. 2019, 86, 52–63. [Google Scholar] [CrossRef]

- Gan, J.; Smith, C.T. Co-benefits of utilizing logging residues for bioenergy production: The case for East Texas, USA. Biomass Bioenergy 2007, 31, 623–630. [Google Scholar] [CrossRef]

- Wrobel-Tobiszewska, A.; Boersma, M.; Sargison, J.; Adams, P.; Jarick, S. An economic analysis of biochar production using residues from Eucalypt plantations. Biomass Bioenergy 2015, 81, 177–182. [Google Scholar] [CrossRef]

- Ximenes, F.; Ramos, J.; Bi, H.; Cameron, N.; Sigh, B.; Blasi, M. Determining Biomass in Residues Following Harvesting in Pinus Radiata Forests in New South Wales. Australian Government RIRDC Publication No. 11/177. 2012. Available online: https://agrifutures.com.au/product/ (accessed on 5 August 2020).

- Bérubé, M.A. Conditions de Terrain Affectant la Qualité du Travail des Scarificateurs; FPInnovations: Pointe-Claire, QC, Canada, 2011; p. 8. [Google Scholar]

- Kizha, A.R.; Han, H.-S. Processing and sorting forest residues: Cost, productivity and managerial impacts. Biomass Bioenergy 2016, 93, 97–106. [Google Scholar] [CrossRef] [Green Version]

- Harrill, H. Costs and Productivity of Woody Biomass Harvesting in Integrated Stand Conversation and Residue Recovery Operations. Master’s Thesis, Humboldt State University, Arcata, CA, USA, 2015. Available online: http://humboldt-dspace.calstate.edu/bitstream/handle/2148/600/ThesisFinal.pdf?sequence=1 (accessed on 5 August 2020).

- Megalos, M.; Parajuli, R.; Lambert, C. NC State Extension—Managing Forests for Biomass Potential. North Carolina State University Extension Publication. 2020. Available online: https://content.ces.ncsu.edu/managing-forests-for-biomass-potential (accessed on 10 August 2020).

- Miller, D.E.; Straka, T.J.; Stokes, B.J.; Watson, W. Productivity and Cost of Conventional Understory Biomass Harvesting Systems—USFS Miscellaneous Publication. 1987. Available online: https://www.fs.usda.gov/treesearch/pubs/7324 (accessed on 10 August 2020).

- Cambero, C.; Sowlati, T.; Marinescu, M.; Roser, D. Strategic optimization of forest residues to bioenergy and biofuel supply chain. Int. J. Energy Res. 2014, 39, 439–452. [Google Scholar] [CrossRef]

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Acuna, M. Timber and biomass transport optimization: A review of planning issues, solution techniques and decision support tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Berry, M.; Sessions, J. The Economics of Biomass Logistics and Conversion Facility Mobility: An Oregon Case Study. Appl. Eng. Agric. 2018, 34, 57–72. [Google Scholar] [CrossRef] [Green Version]

- Adebayo, A.B.; Han, H.-S.; Johnson, L. Productivity and cost of cut-to-length and whole-tree harvesting in a mixed-conifer stand. For. Prod. J. 2007, 57, 59–69. [Google Scholar]

- Magnus, L.; Ersson, B.T.; Hjältén, J.; Nordfjell, T.; Oliet, J.; Willoughby, I. Site Preparation Techniques for Forest Restoration. In Restoration of Boreal and Temperate Forests; CRC Press: Boca Raton, FL, USA, 2016; pp. 85–102. [Google Scholar]

| Notation | |

|---|---|

| i | Harvesting method (1 = WT, 2 = CTL) |

| Ai | Area (ha) |

| Ti | Tonnage of product (logs) delivered (t ha−1) |

| TBi | Tonnage of biomass product extracted (t ha−1) |

| Ri | Revenue for logs (USD t−1) |

| RBi | Revenue for biomass (USD t−1) |

| HCi | Harvest cost (USD t−1) |

| HCBi | Harvest cost of biomass (USD t−1) |

| SPBGi | Site preparation costs with biomass collection for general plantation area (USD ha−1) |

| SPBRi | Site preparation costs with biomass collection for roadside consolidated area (USD ha−1) |

| SPi | Site preparation cost without collection of biomass (USD ha−1) |

| Ii, IBi, ICi | Binary variables (can only choose one harvest method) |

| Slash Level | Frequency | Area | Treatment | Long-Term Impact | High Cost (USD ha−1) | Low Cost (USD ha−1) |

|---|---|---|---|---|---|---|

| High (t ha−1) | % | GPA: | USD | USD | ||

| Roadside: | ||||||

| Notes: | ||||||

| Medium (t ha−1) | % | GPA: | USD | USD | ||

| Roadside: | ||||||

| Notes: | ||||||

| Low (t ha−1) | % | GPA: | USD | USD | ||

| Roadside: | ||||||

| Notes: |

| Slash Level | Frequency | Area | Treatment | Cost (USD ha−1) |

|---|---|---|---|---|

| High (>35 t ha−1) | 75% | GPA: | Windrow | 675 |

| Roadside: | None | |||

| Notes: | Too heavy to CR | |||

| Medium–low (<35 t ha−1) | 25% | GPA | Full chopper roll (CR) | 225 |

| Roadside: | None | |||

| Notes: | Light enough for CR only |

| Costs of Site Prep (USD ha−1) | |||||

|---|---|---|---|---|---|

| Slash Level | Frequency | Area | Treatment | Full Treatment | No Pile |

| High—no burn (>25 t ha−1) | 25% | GPA: | CR full area | 503 | 300 |

| Roadside: | Lane clear (none) | ||||

| Notes: | Full CR and clear planting row | ||||

| High—burn (>25 t ha−1) | GPA: | CR full area | 375 | 300 | |

| Roadside: | Pile and burn (none) | ||||

| Notes: | Burning is cheap but carries a risk | ||||

| Medium (15–25 t ha−1) | 50% | GPA: | CR at tree line | 387 | 225 |

| Roadside: | Lane clear (none) | ||||

| Notes: | Targeted CR, clear planting row | ||||

| Low (<15 t ha−1) | 25% | GPA: | CR at tree line | 312 | 150 |

| Roadside: | Lane clear (none) | ||||

| Notes: | Limited CR, clear planting row | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berry, M.; Sessions, J. Evaluating the Economic Incentives of Biomass Removal on Site Preparation for Different Harvesting Systems in Australia. Forests 2020, 11, 1370. https://doi.org/10.3390/f11121370

Berry M, Sessions J. Evaluating the Economic Incentives of Biomass Removal on Site Preparation for Different Harvesting Systems in Australia. Forests. 2020; 11(12):1370. https://doi.org/10.3390/f11121370

Chicago/Turabian StyleBerry, Michael, and John Sessions. 2020. "Evaluating the Economic Incentives of Biomass Removal on Site Preparation for Different Harvesting Systems in Australia" Forests 11, no. 12: 1370. https://doi.org/10.3390/f11121370

APA StyleBerry, M., & Sessions, J. (2020). Evaluating the Economic Incentives of Biomass Removal on Site Preparation for Different Harvesting Systems in Australia. Forests, 11(12), 1370. https://doi.org/10.3390/f11121370