Assessment of Bending Properties of Sawn and Glulam Blackwood in Portugal

Abstract

:1. Introduction

2. Materials and Methods

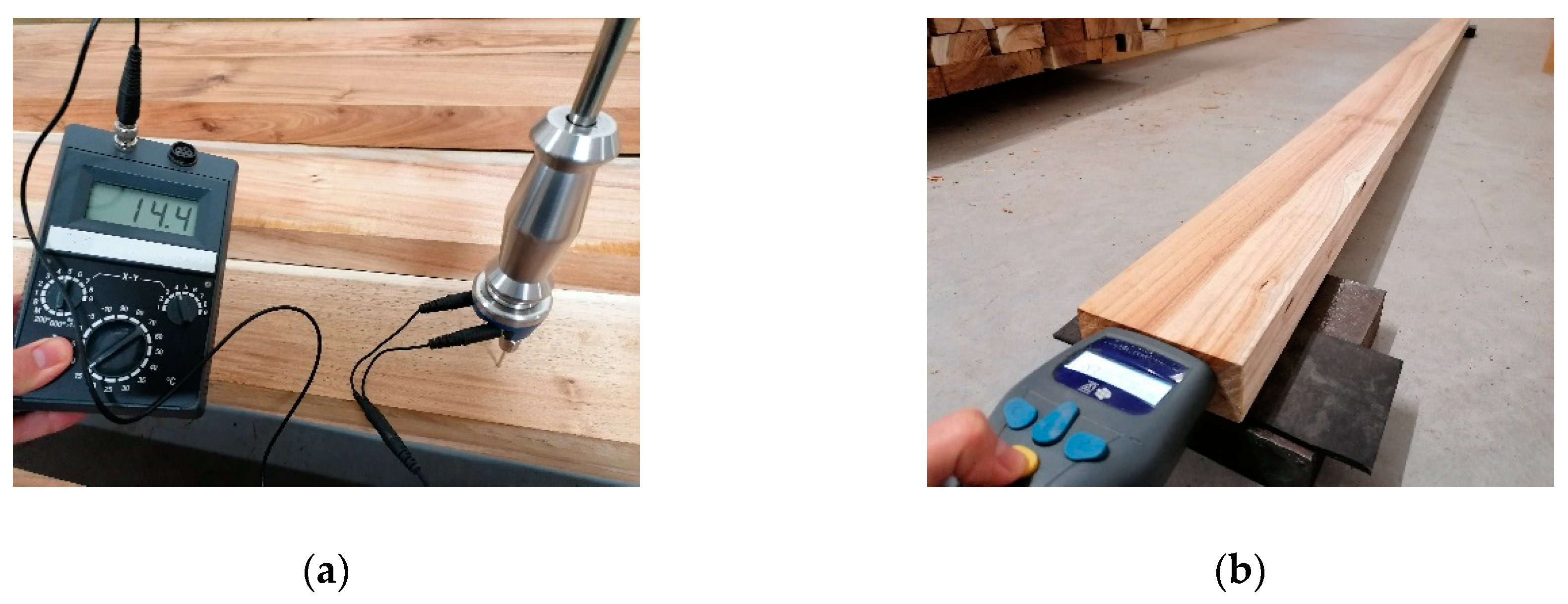

2.1. Portuguese Blackwood as Sawn wood: Raw-Material Characterization

2.2. Portuguese Blackwood Glulam Beams: Assembly and Mechanical Characterization

3. Results and Discussion

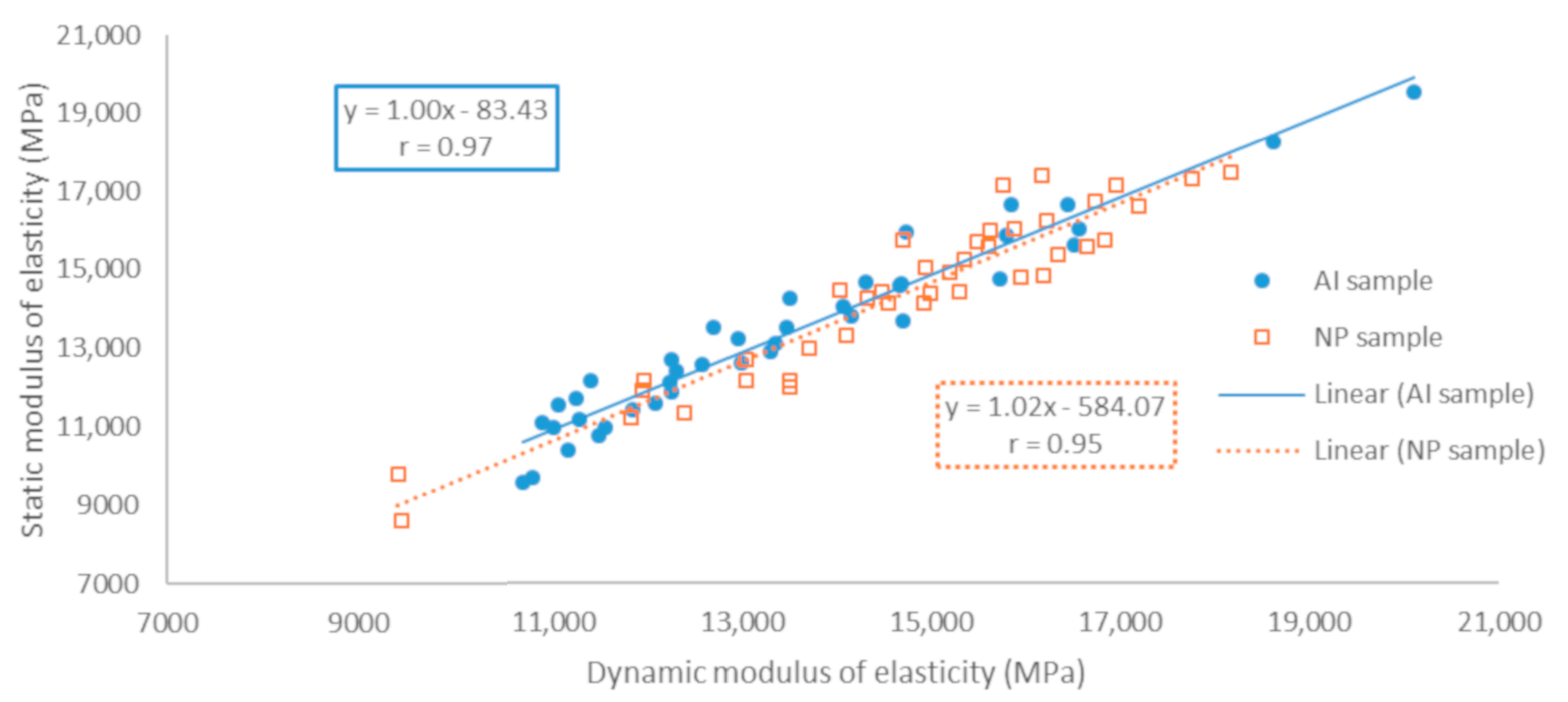

3.1. Portuguese Blackwood Sawn Wood

3.2. Portuguese Blackwood Glulam Beams

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ICNF—Instituto da Conservação da Natureza e das Florestas [Institute for Nature Conservation and Forests]. Importância Económica [Economic importance]. 2019. Available online: http://www2.icnf.pt/portal/florestas/fileiras/econ (accessed on 1 July 2019).

- ICNF—Instituto da Conservação da Natureza e das Florestas [Institute for Nature Conservation and Forests]. IFN6-6.º; Inventário Florestal Nacional [6th National Forest Inventory]: Lisbon, Portugal, 2019; p. 284. [Google Scholar]

- Knorz, M.; Schmidt, M.; Torno, S.; Van de Kuilen, J.W. Structural bonding of ash (Fraxinus excelsior L.): Resistance to delamination and performance in shearing tests. Eur. J. Wood Wood Prod. 2014, 72, 297–309. [Google Scholar] [CrossRef]

- Schlotzhauer, P.; Kovryga, A.; Emmerich, L.; Bollmus, S.; Van de Kuilen, J.W.; Militz, H. Analysis of Economic Feasibility of Ash and Maple Lamella Production for Glued Laminated Timber. Forests 2019, 10, 529. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, M.; Glos, P.; Wegener, G. Gluing of European beech wood for load bearing timber structures. Eur. J. Wood Wood Prod. 2010, 68, 43–57. [Google Scholar] [CrossRef]

- Ohnesorge, D.; Richter, K.; Becker, G. Influence of wood properties and bonding parameters on bond durability of European Beech (Fagus sylvatica L.) glulams. Ann. For. Sci. 2010, 67, 601. [Google Scholar] [CrossRef] [Green Version]

- Boruszewski, P.J.; Borysiuk, P.; Maminski, M.L.; Grzeskiewicz, M. Gluability of thermally modified beech and birch wood. Wood Mater. Sci. Eng. 2011, 6, 185–189. [Google Scholar] [CrossRef]

- Martins, C. Avaliação Estrutural de Elementos de Madeira Lamelada Colada [Health Assessment of Glued Laminated Timber Elements]. Ph.D. Thesis, University of Coimbra, Coimbra, Portugal, October 2018. [Google Scholar]

- Martins, C.; Dias, A.M.P.G.; Cruz, H. Glulam made by poplar: Delamination and shear strength tests. In Proceedings of the 6th International Scientific Conference on Hardwood Processing—ISCHP 2017, Lahti, Finland, 5–28 September 2017; pp. 222–231. [Google Scholar]

- Monteiro, S.R.S.; Martins, C.E.J.; Dias, A.M.P.G.; Cruz, H. Mechanical Characterization of Clear Wood from Portuguese Poplar. Bioresources 2019, 14, 9677–9685. [Google Scholar]

- Monteiro, S.R.S.; Martins, C.E.J.; Dias, A.M.P.G.; Cruz, H. Mechanical performance of wood-based products fabricated with Portuguese Poplar. Eur. J. Wood Wood Prod. under revision.

- Martins, C.; Dias, A.M.P.G.; Cruz, H. Blue gum: Assessment of its potential for load bearing structures. In Proceedings of the 7th International Conference on Hardwood Processing—ISCHP 2019, Delft, The Netherlands, 28–30 August 2019. [Google Scholar]

- Knapic, S.; Tavares, F.; Pereira, H. Heartwood and sapwood variation in Acacia melanoxylon R. Br. trees in Portugal. Forestry 2006, 79, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Goes, E. A floresta portuguesa, sua importância e descrição das espécies de maior interesse [The Portuguese forest, its importance and description of the species of greatest interest]; Portucel: Lisbon, Portugal, 1991; p. 257. [Google Scholar]

- Leite, A.; Santos, C.; Saraiva, I.; Pinho, J.R. O planeamento florestal e as espécies invasoras [Forest planning and invasive species]. In Proceedings of the 1.° Encontro de Invasoras Lenhosas [1st Meeting of Invasive Ligneous], Gerês, Portugal, 16th to 18th November 1999; Sociedade Portuguesa de Ciências Florestais [Portuguese Society of Forest Sciences]: Lisboa, Portugal, 1999; pp. 45–50. [Google Scholar]

- Zwaan, J.G. The silviculture of blackwood (Acacia melanoxylon). S. Afr. For. J. 1982, 121, 39–43. [Google Scholar] [CrossRef]

- Nicholas, G.J.; Brown, I. Blackwood. A handbook for growers and users; New Zealand Forest Research Institute: Rotorua, New Zealand, 2002. [Google Scholar]

- Bradbury, G.J.; Beadle, C.L.; Potts, B.M. Genetic control in the survival, growth and form of Acacia melanoxylon. New For. 2010, 39, 139–156. [Google Scholar] [CrossRef]

- Santos, A.; Simões, R.; Tavares, M. Variation of some wood macroscopic properties along the stem of Acacia melanoxylon R. Br. Adult trees in Portugal. For. Syst. 2013, 22, 463–470. [Google Scholar] [CrossRef]

- Machado, J.S.; Louzada, J.L.; Santos, A.J.A.; Nunes, L.; Anjos, O.; Rodrigues, J.; Simões, R.M.S.; Pereira, H. Variation of wood density and mechanical properties of blackwood (Acacia melanoxylon R. Br.). Mater. Des. 2014, 56, 975–980. [Google Scholar] [CrossRef]

- Lourenço, A.; Baptista, I.; Gominho, J.; Pereira, H. The influence of heartwood on the pulping properties of Acacia melanoxylon wood. J. Wood Sci. 2008, 54, 464–469. [Google Scholar] [CrossRef] [Green Version]

- Anjos, O.; Santos, A.; Simões, A. Effect of Acacia melanoxylon fiber morphology on papermaking potential. Appita J. 2011, 64, 185–191. [Google Scholar]

- Santos, A.J.A.; Anjos, O.M.S.; Simões, R.M.S. Papermaking potential of Acacia dealbata and Acacia melanoxylon. Appita J. 2006, 59, 58–64. [Google Scholar]

- Tavares, F.; Louzada, J.L.; Pereira, H. Variation in wood density and ring width in Acacia melanoxylon at four sites in Portugal. Eur. J. For. Res. 2014, 133, 31–39. [Google Scholar] [CrossRef]

- Medhurst, J.L.; Pinkard, E.A.; Beadle, C.L.; Worledge, D. Growthand stem form responses of plantation-grown Acacia melanoxylon (R. Br.) to form pruning and nurse-crop thinning. For. Ecol. Manag. 2003, 179, 183–193. [Google Scholar] [CrossRef]

- Jennings, S.M.; Hichey, J.E.; Candy, S.G. Comparison of regeneration success of alternative silvicultural treatments in blackwood swamps. Tasforests 2000, 12, 55–68. [Google Scholar]

- Dias, A.M.P.G.; Machado, J.S.; Santos, P. Uso de produtos de madeira de alto desempenho em aplicações estruturais [Use of high performance wood products in structural applications]. In Proceedings of the 5.as Jornadas Portuguesas de Engenharia de Estruturas [5th Portuguese Structural Engineering Days], Lisbon, Portugal, 26—28 November 2014. [Google Scholar]

- Hodoušek, M.; Dias, A.M.P.G.; Martins, C.; Marques, A.; Böhm, M. Comparison of non-destructive methods based on natural frequency for determining the modulus of elasticity of Cupressus lusitanica and Populus x Canadensis. BioResources 2017, 12, 270–282. [Google Scholar] [CrossRef] [Green Version]

- Martins, M. Caracterização do Eucalipto globulus para aplicação estrutural [Eucalyptus globulus characterization for structural applications]. Master’s Thesis, University of Coimbra, Coimbra, Portugal, July 2015. [Google Scholar]

- EU. Moisture Content of A Piece of Sawn Timber-Part. 2: Estimation by Electrical Resistance Method; EN 13183-2; CEN: Brussels, Belgium, 2002. [Google Scholar]

- Martins, C.; Dias, A.M.P.G.; Cruz, H. Using non-destructive testing to predict the mechanical properties of glued laminated poplar. P I Civil. Eng-Str B 2019, 172, 661–670. [Google Scholar] [CrossRef]

- EU. Timber Structures-Structural Timber and Glued Laminated Timber-Determination of Some Physical and Mechanical Properties; EN 408; CEN: Brussels, Belgium, 2012. [Google Scholar]

- EU. Structural Timber and Glued Laminated Timber-Determination of Characteristic Values of Mechanical Properties and Density; EN 384; CEN: Brussels, Belgium, 2010. [Google Scholar]

- EU. Timber Structures-Glued Laminated Timber and Glued Solid Timber–Requirements; EN 14080; CEN: Brussels, Belgium, 2013. [Google Scholar]

- Martins, C.; Dias, A.M.P.G.; Martins, H.; Jorge, L. Non destructive testing of Portuguese Chestnut beams. In Proceedings of the 4th International Conference on Hardwood Processing–ISCHP 2013, Florence, Italy, 7–9 October 2013. [Google Scholar]

- Vega, A.; Arriaga, F.; Guaita, M.; Baño, V. Proposal for visual grading criteria of structural timber of sweet chestnut from Spain. Eur. J. Wood Wood Prod. 2013, 71, 529–532. [Google Scholar] [CrossRef]

- Cibecchini, D.; Cavalli, A.; Goli, G.; Togniof, M. Beech sawn timber for structural use: A case study for mechanical characterization and optimization. the Italian visual strength grading rule. J. For. Sci. 2016, 62, 521–528. [Google Scholar] [CrossRef] [Green Version]

- Castro, G.; Paganini, F. Mixed glued laminated timber of poplar and Eucalyptus grandis clones. Holz als Roh-und Werkstoff. 2003, 61, 291–298. [Google Scholar] [CrossRef]

| Edyn-b MPa | Eglobal-b MPa | fm MPa | w % | ρ kg/m3 | ρ12%1 kg/m3 | Eglobal-b-12%1 MPa | fm-adj2 MPa | |

|---|---|---|---|---|---|---|---|---|

| Mean | 14,104 | 14,038 | 68.6 | 11.5 | 646 | 647 | 13,908 | 65.2 |

| Minimum | 9420 | 8399 | 26.8 | 9.1 | 492 | 493 | 8618 | 25.7 |

| Maximum | 20,054 | 20,520 | 130.1 | 16.8 | 803 | 808 | 19,552 | 123.8 |

| COV: % | 15.5 | 16.1 | 30.2 | 14.4 | 14 | 14 | 16.3 | 30.4 |

| Char.val. | - | - | - | - | - | 518 | 10,402 | 36.9 |

| Edyn-b MPa | Eglobal-b MPa | fm MPa | w % | ρ kg/m3 | ρ12%1 kg/m3 | Eglobal-b-12%1 MPa | fm-adj2 MPa | |

|---|---|---|---|---|---|---|---|---|

| Mean | 13,452b | 13,648 | 65.0 | 11.0 | 590 | 593b | 13,351b | 61.0a |

| Minimum | 10,726 | 9954 | 27.7 | 9.1 | 492 | 493 | 9609 | 25.9 |

| Maximum | 20,054 | 20,520 | 130.1 | 15.4 | 772 | 779 | 19,552 | 121.9 |

| COV: % | 16.4 | 17.6 | 28.1 | 15.1 | 11 | 11 | 17.1 | 28.0 |

| Char.val. | - | - | - | - | - | 513 | 10,396 | 34.5 |

| Edyn-b MPa | Eglobal-b MPa | fm MPa | w % | ρ kg/m3 | ρ12%1 kg/m3 | Eglobal-b-12%1 MPa | fm-adj2 MPa | |

|---|---|---|---|---|---|---|---|---|

| Mean | 14,757a | 14,429 | 72.3 | 12.1 | 702 | 701a | 14,466a | 69.3a |

| Minimum | 9420 | 8399 | 26.8 | 9.2 | 535 | 538 | 8618 | 25.7 |

| Maximum | 18,137 | 17,660 | 129.1 | 16.8 | 803 | 808 | 17,514 | 123.8 |

| COV: % | 13.5 | 14.4 | 31.2 | 12.2 | 10 | 10 | 14.8 | 31.2 |

| Char.val. | - | - | - | - | - | 581 | 11,193 | 42.7 |

| ETSM MPa | Edyn MPa | fm MPa | Elocal1 MPa | Eglobal1 MPa | w % | ρ kg/m3 | ρ12%2 kg/m3 | Elocal-12%2 MPa | Eglobal-12%2 MPa | fm-adj3 MPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | 15,048 | 14,129 | 88.8 | 17,569 | 14,377 | 13.1 | 671 | 679 | 17,764 | 14,533 | 83.9 |

| Minimum | 12,802 | 12,807 | 69.3 | 13,852 | 12,086 | 11.5 | 599 | 600 | 14,074 | 12,280 | 65.5 |

| Maximum | 17,261 | 15,896 | 102.3 | 21,231 | 16,197 | 13.8 | 744 | 746 | 21,571 | 16,456 | 96.7 |

| COV: % | 9.5 | 9.8 | 12.2 | 14.4 | 9.5 | 5.9 | 10 | 9 | 14.8 | 9.8 | 12.2 |

| Char.val. | - | - | 73.5 | - | 12,532 | - | 601 | 606 | - | 12,632 | 69.4 |

| Species | Eglobal-12%/ρ12% | fm-adj/ρ12% | Reference |

|---|---|---|---|

| Blackwood | 21.8 | 0.13 | - |

| Blue gum | 23.1 | 0.12 | [12] |

| E. grandis ‘330′ | 24.0 | 0.13 | [38] |

| E. grandis ‘329′ | 21.0 | 0.10 | [38] |

| P. alba, P. nigra and P. x canadensis | 25.7 | 0.12 | [31] |

| P. x euramericana, ‘Neva’ | 25.0 | 0.11 | [38] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, C.; Monteiro, S.; Knapic, S.; Dias, A. Assessment of Bending Properties of Sawn and Glulam Blackwood in Portugal. Forests 2020, 11, 418. https://doi.org/10.3390/f11040418

Martins C, Monteiro S, Knapic S, Dias A. Assessment of Bending Properties of Sawn and Glulam Blackwood in Portugal. Forests. 2020; 11(4):418. https://doi.org/10.3390/f11040418

Chicago/Turabian StyleMartins, Carlos, Sandra Monteiro, Sofia Knapic, and Alfredo Dias. 2020. "Assessment of Bending Properties of Sawn and Glulam Blackwood in Portugal" Forests 11, no. 4: 418. https://doi.org/10.3390/f11040418