The Effect of Veneer Densification Temperature and Wood Species on the Plywood Properties Made from Alternate Layers of Densified and Non-Densified Veneers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Veneer Densification

2.2. Plywood Preparation

2.3. Density and Compression Ratio of the Plywood Samples

2.4. Bending Strength and Modulus of Elasticity of the Plywood Samples

2.5. Shear Strength of the Plywood Samples

2.6. Processing of Data

3. Results and Discussions

3.1. Thickness, Compression Ratio, and Density of the Plywood Samples

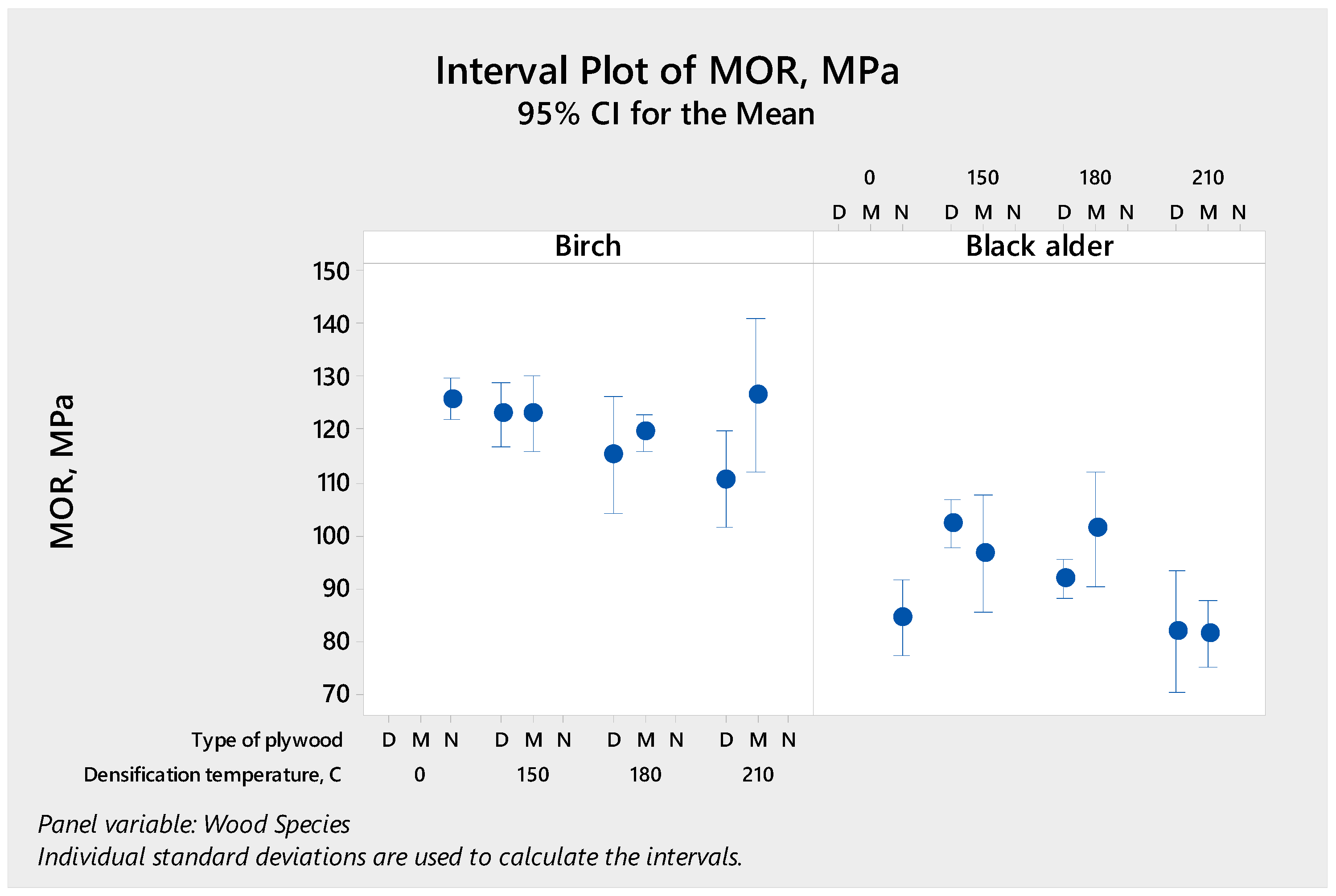

3.2. Bending Properties of the Plywod Samples

3.3. Shear Strength of the Plywood Samples

3.4. ANOVA Analysis and Response Optimization

4. Conclusions

- The bending strength and the modulus of elasticity along with overall shear strength presented higher values for birch plywood compared to black alder plywood. They increased with the increasing in density.

- The densification applied to birch veneers compared to black alder presented little improvement in terms of panel bending properties but quite significant enhancement of the bonding quality. The densification of black alder veneer did not provide any improvement in terms of shear strength quality of the plywood panels.

- The increase of veneer densification temperature resulted in a gradually decrease of MOR, MOE, and shear strength values for the plywood panels made of densified veneers and mixed panels of both species. The temperature of about 150 °C for veneer densification seemed to be enough to provide the best values for bending and bonding properties of such panels.

- All plywood panels in this study were manufactured using reduced glue consumption and they presented satisfactory properties performance for indoor applications. Apart of the plywood properties performance, such an approach can provide low emissions of toxic compounds and low costs for the finished product.

- In further studies it would be desirable to evaluate some of the other properties of such samples including thickness swelling and water absorption would help better understanding behavior of these panels. Also some data on surface quality evaluation of non-densified and densified veneer sheets could help to optimize overall adhesive consumption.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bekhta, P.; Salca, E.A.; Lunguleasa, A. Some properties of plywood panels manufactured from combinations of thermally densified and non-densified veneers of different thickness in one structure. J. Build. Eng. 2020, 29, 101116. [Google Scholar] [CrossRef]

- Daoui, A.; Descamps, C.; Marchal, R.; Zerizer, A. Influence of veneer quality on beech LVL mechanical properties. Maderas Cienc Tecnol. 2011, 13, 69–83. [Google Scholar] [CrossRef] [Green Version]

- Del Menezzi, C.; Mendes, L.; de Souza, M.; Bortoletto, G. Effect of Nondestructive Evaluation of Veneers on the Properties of Laminated Veneer Lumber (LVL) from a Tropical Species. Forests 2013, 4, 270–278. [Google Scholar] [CrossRef] [Green Version]

- de Melo, R.R.; Del Menezzi, C.H.S. Influence of veneer thickness on the properties of LVL from Parica (Schizolobium amazonicum) plantation trees. Eur. J. Wood Wood Prod. 2014, 72, 191–198. [Google Scholar] [CrossRef]

- Pałubicki, B.; Marchal, R.; Butaud, J.-C.; Denaud, L.-E.; Bléron, L.; Collet, R.; Kowaluk, G. A method of lathe checks measurement; SMOF device and its software. Eur. J. Wood Wood Prod. 2010, 68, 151–159. [Google Scholar] [CrossRef] [Green Version]

- DeVallance, D.B.; Funck, J.W.; Reeb, J.E. Douglas-Fir plywood gluebond quality as influenced by veneer roughness, lathe checks, and annual ring characteristics. Forest Prod. J. 2007, 57, 21–28. [Google Scholar]

- Wang, B.J.; Ellis, S.; Dai, C. Veneer surface roughness and compressibility pertaining to plywood/LVL manufacturing. Part II. Optimum panel densification. Wood Fiber Sci. 2006, 38, 727–735. [Google Scholar]

- Seborg, R.M.; Millet, M.; Stamm, A.J. Heat-stabilized compressed wood. Staypack. Mech. Eng. 1945, 67, 25–31. [Google Scholar]

- Morsing, N. Densification of Wood. The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to the Grain. Ph.D. Thesis, Building Materials Laboratory, Technical University of Denmark, Lyngby, Denmark, 1997. [Google Scholar]

- Navi, P.; Sandberg, D. Thermo-Hydro-Mechanical Wood Processing. Lausanne; EPFL Press: Lausanne, Switzerland, 2012. [Google Scholar]

- Bekhta, P.; Hiziroglu, S.; Shepelyuk, O. Properties of plywood manufactured from compressed veneer as building material. Mater. Des. 2009, 30, 947–953. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A.; Sernek, M. Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci. Technol. 2009, 43, 57–68. [Google Scholar] [CrossRef]

- Arruda, L.M.; Menezzi, H.S.C. Properties of a laminated wood composite produced with thermomechanically treated veneers. Adv. Mater. Sci. Eng. 2016, 9. [Google Scholar] [CrossRef] [Green Version]

- Bekhta, P.; Niemz, P.; Sedliacik, J. Effect of pre-pressing of veneer on the glueability and properties of veneer-based products. Eur. J. Wood Wood Prod. 2012, 70, 99–106. [Google Scholar] [CrossRef]

- Bekhta, P.; Salca, E.A. Influence of veneer densification on the shear strength and temperature behavior inside the plywood during hot press. Constr. Build. Mater. 2018, 162, 20–26. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliacik, J.; Jones, D. Effect of short-term thermomechanical densification of wood veneers on the properties of birch plywood. Eur. J. Wood Wood Prod. 2018, 76, 549–562. [Google Scholar] [CrossRef]

- Candan, Z.; Hiziroglu, S.; Mcdonald, A.G. Surface quality of thermally compressed Douglas fir veneer. Mater. Des. 2010, 31, 3574–3577. [Google Scholar] [CrossRef]

- Diouf, P.N.; Stevanovic, T.; Cloutier, A.; Fang, C.-H.; Blanchet, P.; Koubaa, A.; Mariotti, N. Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl. Surf. Sci. 2011, 257, 3558–3564. [Google Scholar] [CrossRef]

- Li, W.; Wang, C.; Zhang, Y.; Jia, C.; Gao, C.; Jin, J. The influence of hot compression on the surface characteristics of poplar veneer. BioRes 2014, 9, 2808–2823. [Google Scholar] [CrossRef] [Green Version]

- EN 323. Wood-Based Panels—Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 310. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standartiztion: Brussels, Belgium, 1993. [Google Scholar]

- EN 314-1. Plywood—Bonding Quality—Part 1: Test Methods; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- EN 314-2. Plywood—Bonding Quality—Part 2: Requirements; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 315. Plywood. Tolerances for Dimensions; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- Bekhta, P.; Sedliacik, J.; Bekhta, N. Effects of selected parameters on the bonding quality and temperature evolution inside plywood during pressing. Polymers 2020, 12, 1035. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Sedliacik, J. Environmetally-friendly high-density polyethylene-bonded plywood panels. Polymers 2019, 11, 1166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bekhta, P.; Marutzky, R. Reduction of glue consumption in the plywood production by using previously compressed veneer. Holz Roh Werkst 2007, 65, 87–88. [Google Scholar] [CrossRef]

| Wood Species | Type of Plywood per Species | Codification: Densification Temperature and Plywood Symbol | Glue Spread, g/m2 | Pressure, MPa | Temperature, °C | Pressing Time, s | |

|---|---|---|---|---|---|---|---|

| Variable | Constant Schedule | ||||||

| 1.8 | 130 | 270 + 60 | |||||

| Black alder/ Birch | Plywood made of non-densified veneers | 0 | N | 80 |  | ||

| Plywood made of densified veneers and densification temperature | 150 180 210 | D | 60 | ||||

| Plywood made of densified and non-densified veneers and densification temperature | 150 180 210 | M | 70 | ||||

| Densification Temperature and Type of Plywood | 0 N | 150 D | 180 D | 210 D | 150 M | 180 M | 210 M | |

|---|---|---|---|---|---|---|---|---|

| Black alder | Thickness, mm | 6.98 (0.18) * | 6.84 (0.11) | 6.74 (0.05) | 6.48 (0.20) | 6.80 (0.06) | 6.79 (0.02) | 6.50 (0.14) |

| Compression ratio, % | 11.1 | 5.0 | 3.7 | 0.3 | 8.8 | 7.5 | 7.7 | |

| Density, kg/m3 | 607.4 (23.2) | 608.9 (28.5) | 619.9 (2.1) | 637.3 (19.1) | 607.1 (23.8) | 615.0 (21.1) | 623.8 (14.5) | |

| Birch | Thickness, mm | 7.03 (0.05) | 6.96 (0.04) | 6.76 (0.13) | 6.72 (0.13) | 7.06 (0.15) | 6.86 (0.12) | 6.83 (0.07) |

| Compression ratio, % | 10.4 | 3.3 | 3.4 | 1.2 | 5.4 | 6.5 | 5.4 | |

| Density, kg/m3 | 747.0 (20.5) | 807.9 (6.4) | 809.3 (13.8) | 828.2 (7.1) | 766.8 (4.7) | 769.8 (31.1) | 805.3 (27.4) | |

| One-Way ANOVA Response | Source | Degrees of Freedom (DF) | Adjusted Sums of Squares (Adj SS) | Adjusted Means Squares (Adj MS) | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Bending strength (MOR), MPa | A | 1 | 30,315 | 30,314.7 | 199.16 | 0.000 |

| B | 3 | 2538 | 846.1 | 5.56 | 0.001 | |

| A*B | 3 | 2361 | 787.0 | 5.17 | 0.002 | |

| Modulus of elasticity (MOE), MPa | A | 1 | 363,249,244 | 363,249,244 | 213.91 | 0.000 |

| B | 3 | 11,208,650 | 3,736,217 | 2.20 | 0.091 | |

| A*B | 3 | 16,538,180 | 5,512,727 | 3.25 | 0.024 | |

| Shear strength (SS), MPa | A | 1 | 0.427 | 0.4272 | 1.05 | 0.306 |

| B | 3 | 7.929 | 2.6431 | 6.52 | 0.000 | |

| A*B | 3 | 10.358 | 3.4526 | 8.52 | 0.000 |

| Solution | Densification Temperature, °C | Wood Species | Type of Plywood | Properties | Composite Desirability | |

|---|---|---|---|---|---|---|

| 1 | 154.286 | Birch | M | MOE, Mpa Fit | 12,830.8 | 0.765479 |

| MOR, Mpa Fit | 127.384 | |||||

| Shear strength, Mpa Fit | 2.97644 | 0.569985 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salca, E.-A.; Bekhta, P.; Seblii, Y. The Effect of Veneer Densification Temperature and Wood Species on the Plywood Properties Made from Alternate Layers of Densified and Non-Densified Veneers. Forests 2020, 11, 700. https://doi.org/10.3390/f11060700

Salca E-A, Bekhta P, Seblii Y. The Effect of Veneer Densification Temperature and Wood Species on the Plywood Properties Made from Alternate Layers of Densified and Non-Densified Veneers. Forests. 2020; 11(6):700. https://doi.org/10.3390/f11060700

Chicago/Turabian StyleSalca, Emilia-Adela, Pavlo Bekhta, and Yaroslav Seblii. 2020. "The Effect of Veneer Densification Temperature and Wood Species on the Plywood Properties Made from Alternate Layers of Densified and Non-Densified Veneers" Forests 11, no. 6: 700. https://doi.org/10.3390/f11060700

APA StyleSalca, E. -A., Bekhta, P., & Seblii, Y. (2020). The Effect of Veneer Densification Temperature and Wood Species on the Plywood Properties Made from Alternate Layers of Densified and Non-Densified Veneers. Forests, 11(6), 700. https://doi.org/10.3390/f11060700