Thermochemical and Mechanical Properties of Pine Wood Treated by In Situ Polymerization of Methyl Methacrylate (MMA)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Treatment by Methyl Methacrylate (MMA) Impregnation

2.3. Characterization of Physical and Mechanical Properties

2.4. Fourier Transform Infrared Spectroscopy (FT-IR)

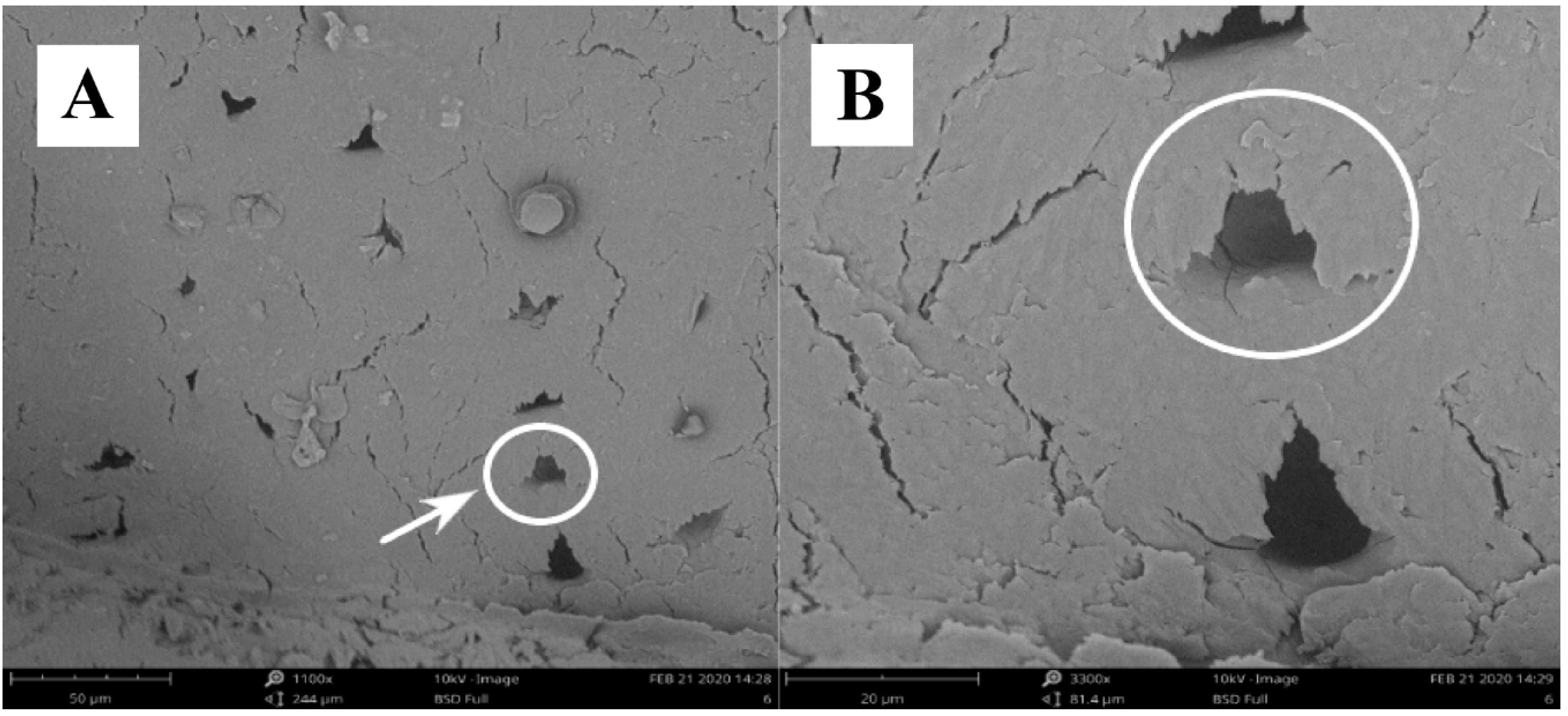

2.5. Scanning Electron Microscopy (SEM)

2.6. Thermogravimetric Analysis (TGA)

2.7. Statistical Analyses

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lasserre, J.P.; Mason, E.G.; Watt, M.S. Influence of initial planting spacing and genotype on microfibril angle, wood density, fibre properties and modulus of elasticity in Pinus radiata D. Don core wood. For. Ecol. Manag. 2009, 258, 1924–1931. [Google Scholar] [CrossRef]

- Mantanis, G.I. Chemical modification of wood by acetylation or furfurylation: A review of the present scaled-up technologies. Bioresources 2017, 12, 4478–4489. [Google Scholar] [CrossRef] [Green Version]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies-a review. iForest Biogeosciences For. 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. Bioresources 2009, 4, 370–404. [Google Scholar]

- Ding, W.; Koubaa, A.; Chaala, A. Dimensional stability of methyl methacrylate hardened hybrid poplar wood. Bioresources 2012, 7, 0504–0520. [Google Scholar]

- Koubaa, A.; Ding, W.D.; Chaala, A.; Bouafif, H. Surface properties of methyl methacrylate hardened hybrid poplar wood. J. Appl. Polym. Sci. 2012, 123, 1428–1436. [Google Scholar] [CrossRef]

- Dong, X.; Sun, T.; Liu, Y.; Li, C.; Li, Y. Structure and properties of polymer-impregnated wood prepared by in-situ polymerization of reactive monomers. BioResources 2015, 10, 7854–7864. [Google Scholar] [CrossRef] [Green Version]

- Rowell, R.M.; Ellis, W.D. Determination of dimensional stabilization of wood using the water-soak method. Wood Fiber Sci. 2007, 10, 104–111. [Google Scholar]

- Hadi, Y.S.; Massijaya, M.Y.; Zaini, L.H.; Abdillah, I.B.; Arsyad, W.O.M. Resistance of methylmethacrylate-impregnated wood to subterranean termite attack. J. Korean Wood Sci. Technol. 2018, 46, 748–755. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Massijaya, M.Y.; Zaini, L.H.; Pari, R. Physical and mechanical properties of methyl methacrylate-Impregnated wood from three fast-growing tropical tree species. J. Korean Wood Sci. Technol. 2019, 47, 324–335. [Google Scholar] [CrossRef]

- ASTM D 2395: Standard Test Methods for Density and Density (Relative Density) of Wood and Wood-Based Materials. Available online: https://www.astm.org/Standards/D2395.htm (accessed on 2 February 2020).

- ASTM D 143: Standard Test Methods for Small Clear Specimens of Timber. Available online: https://www.astm.org/Standards/D143.htm (accessed on 2 February 2020).

- Phuong, L.X.; Shida, S.; Saito, Y. Effects of heat treatment on brittleness of Styrax tonkinens is wood. J. Wood Sci. 2007, 53, 181–186. [Google Scholar] [CrossRef]

- Esteban, L.G.; Simón, C.; Fernández, F.G.; de Palacios, P.; Martín-Sampedro, R.; Eugenio, M.E.; Hosseinpourpia, R. Juvenile and mature wood of Abiespinsapo boissier: Sorption and thermodynamic properties. Wood Sci. Technol. 2015, 49, 725–738. [Google Scholar] [CrossRef]

- Gallio, E.; Zanatta, P.; Ribes, D.D.; Lazarotto, M.; Gatto, D.A.; Beltrame, R. Fourier transform infrared spectroscopy in treated woods deteriorated by a white rot fungus. Maderas. Ciencia y Tecnología 2018, 20, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wang, F.; Keer, L. Influence of surface modification on the microstructure and thermo-mechanical properties of bamboo fibers. Materials 2015, 8, 6597–6608. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tomak, E.D.; Topaloglu, E.; Gumuskaya, E. An FT-IR study of the changes in chemical composition of bamboo degraded by brown-rot fungi. Int. Biodeterior. Biodegrad. 2013, 85, 131–138. [Google Scholar] [CrossRef]

- Darwish, S.S.; El Hadidi, N.M.N.; Mansour, M. The effect of fungal decay on Ficussy comorus wood. Int. J. Conserv. Sci. 2013, 4, 271–282. [Google Scholar]

- Tommasini, F.J.; Ferreira, L.D.C.; Tienne, L.G.P.; Aguiar, V.D.O.; da Silva, M.H.P.; Rocha, L.F.D.M.; Marques, M.D.F.V. Poly (methyl methacrylate)-sic nanocomposites prepared through in situ polymerization. Mater. Res. 2018, 21, 6. [Google Scholar] [CrossRef]

- Biswas, M.; Libera, J.A.; Darling, S.B. Kinetics for the sequential infiltration synthesis of alumina in poly (methyl methacrylate): An infrared spectroscopic study. J. Phys. Chem. C 2015, 119, 14585–14592. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, S.; Agnihotry, S.A. Synthesis and characterization of in situ prepared poly (methyl methacrylate) nanocomposites. Bull. Mater. Sci. 2009, 30, 31–35. [Google Scholar] [CrossRef]

- Dinwoodie, J.M. Timber: Its Nature and Behavior, 2nd ed.; E & FN Spon: New York, NY, USA, 2000; p. 270. [Google Scholar]

- Darmawan, W.; Nandika, D.; Sari, R.K.; Sitompul, A.; Rahayu, I.; Gardner, D. Juvenile and mature wood characteristics of short and long rotation teak in Java. IAWA J. 2015, 36, 428–442. [Google Scholar] [CrossRef]

- Ding, W.D.; Koubaa, A.; Chaala, A.; Belem, T.; Krause, C. Relationship between wood porosity, wood density and methyl methacrylate impregnation rate. Wood Mater. Sci. Eng. 2008, 3, 62–70. [Google Scholar] [CrossRef]

- Mattos, B.D.; de Cademartori, P.H.G.; Magalhães, W.L.E.; Lazzarotto, M.; Gatto, D.A. Thermal tools in the evaluation of decayed and weathered wood polymer composites prepared by in situ polymerization. J. Therm. Anal. Calorim. 2015, 12, 1263–1271. [Google Scholar] [CrossRef] [Green Version]

- Hadi, Y.S.; Rahayu, I.S.; Danu, S. Physical and mechanical properties of methyl methacrylate impregnated jabon wood. J. Indian Acad. Wood Sci. 2013, 10, 77–80. [Google Scholar] [CrossRef]

- Ding, W.; Koubaa, A.; Chaala, A. Mechanical properties of MMA-hardened hybrid poplar wood. Ind. Crops Prod. 2013, 46, 304–310. [Google Scholar] [CrossRef]

- Ghorbani, M.; Shahmirzadi, A.N.; Amininasab, S.M. Physical and morphological properties of combined treated wood polymer composites by maleic anhydride and methyl methacrylate. J. Wood Chem. Technol. 2017, 37, 443–450. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.Y.; Chui, Y.H.; Wan, H. Effect of impregnation and in-situ polymerization of methacrylates on hardness of sugar maple wood. J. Appl. Polym. Sci. 2006, 99, 1674–1683. [Google Scholar] [CrossRef]

- Li, Y.F.; Gong, D.W.; Dong, X.Y.; Liu, Z.B. Mechanical properties of wood-polymer composite prepared by in-situ polymerization of methyl methacryalte and styrene. Appl. Mech. Mater. 2012, 166, 2938–2941. [Google Scholar] [CrossRef]

- Islam, M.S.; Hamdan, S.; Hassan, A. The chemical modification of tropical wood polymer composites. J. Compas. Mater. 2014, 48, 783–789. [Google Scholar] [CrossRef]

- Simón, C.; Esteban, L.G.; de Palacios, P.; Fernández, F.G.; Martín-Sampedro, R.; Eugenio, M.E. Thermodynamic analysis of water vapour sorption behaviour of juvenile and mature wood of Abiesalba Mill. J. Mater. Sci. 2015, 50, 7282–7292. [Google Scholar] [CrossRef]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Gałka, P.; Kowalonek, J.; Kaczmarek, H. Thermogravimetric analysis of thermal stability of poly (methyl methacrylate) films modified with photoinitiators. J. Anal. Calorim. 2014, 115, 1387–1394. [Google Scholar] [CrossRef] [Green Version]

- Georgieva, M.; Harata, M.; Miloshev, G. The nuclear actin-related protein Act3p/Arp4 influences yeast cell shape and bulk chromatin organization. J. Cell. Biochem. 2008, 104, 59. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Fu, Q.; Wang, Q. Effects of chemical modification on the mechanical properties of wood. Eur. J. Wood Wood Prod. 2013, 71, 401–416. [Google Scholar] [CrossRef]

| Groups | WPG (%) | ρ (g·cm−3) | MC (%) |

|---|---|---|---|

| MT | - | 0.577 (0.048) b | 14.40 (0.09) a |

| JV | - | 0.536 (0.030) b | 14.20 (0.17) a |

| MT + MMA | 73.59 (1.15) b | 0.984 (0.040) a | 5.76 (0.40) b |

| JV + MMA | 113.97 (1.01) a | 0.978 (0.045) a | 5.31 (0.62) b |

| Groups | Hardness(MPa) | Static Bending (MPa) | ||

|---|---|---|---|---|

| MOE | MOR | BT (%) | ||

| MT | 34.72 (0.08) b | 11,409.0 (1.404.2) b | 76.91 (1.10) bc | 3.15 (1.13) a |

| JV | 31.96 (0.06) b | 8,024.9 (1.016.9) c | 66.94 (1.03) c | 7.81 (1.25) b |

| MT + MMA | 56.67 (1.63) a | 13,326.0 (1.200.2) a | 127.94 (1.12) a | 11.81 (1.25) c |

| JV + MMA | 66.67 (0.42) a | 9040.1 (1.753.0) c | 83.66 (1.03) b | 20.93 (1.35) d |

| Wood | |||

| Wavenumber (cm−1) | Molecular Vibrations | Wood Compounds | Reference |

| 1740 | Stretching of C=O bonds of the carboxylic groups | hemicellulose/lignin | [5,16,17] |

| 1645 | Stretching at the C=O conjugated bonds of the alkyl ketones of the carbonyl groups | lignin | [16] |

| 1510 | Stretching of C=C bonds on aromatic ring | lignin | [17] |

| 1460 | Deformation on C–H bonds of aromatic ring | lignin | [18] |

| 1370 | Deformation on C–H bonds | cellulose/hemicellulose | [17] |

| 1260 | Stretching on C–O bonds in xylans | hemicellulose | [18] |

| 1030 | Stretching on C–O bonds and deformation on C–H bonds of guayacil units | cellulose/hemicellulose/lignin | [18] |

| 870 | Stretching on C–OH bonds | cellulose | [16] |

| Methyl Methacrylate (MMA) | |||

| Wavenumber (cm−1) | Vibration/Functional Groups | Reference | |

| 1725 | Stretching on C=O bonds of carbonyl groups | [19,20] | |

| 1440 | Asymmetric stretching on C–H bonds | [21] | |

| 1305 | Symmetric stretching on C–H bonds | ||

| 1160 | Stretching on C–O–R bonds of ester | [20,21] | |

| 1010/940/820 | Stretching on C–C bonds | [21] | |

| Groups | Region I | Region II | ||

|---|---|---|---|---|

| TONset (°C) | TENDset (°C) | TONset (°C) | TENDset (°C) | |

| MT | 30 | 105 | 320 | 386 |

| JV | 30 | 105 | 288 | 365 |

| MT + MMA | 30 | 105 | 349 | 465 |

| JV + MMA | 30 | 126 | 352 | 470 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta, A.P.; Labidi, J.; Schulz, H.R.; Gallio, E.; Barbosa, K.T.; Beltrame, R.; de Avila Delucis, R.; Gatto, D.A. Thermochemical and Mechanical Properties of Pine Wood Treated by In Situ Polymerization of Methyl Methacrylate (MMA). Forests 2020, 11, 768. https://doi.org/10.3390/f11070768

Acosta AP, Labidi J, Schulz HR, Gallio E, Barbosa KT, Beltrame R, de Avila Delucis R, Gatto DA. Thermochemical and Mechanical Properties of Pine Wood Treated by In Situ Polymerization of Methyl Methacrylate (MMA). Forests. 2020; 11(7):768. https://doi.org/10.3390/f11070768

Chicago/Turabian StyleAcosta, Andrey Pereira, Jalel Labidi, Henrique Römer Schulz, Ezequiel Gallio, Kelvin Techera Barbosa, Rafael Beltrame, Rafael de Avila Delucis, and Darci Alberto Gatto. 2020. "Thermochemical and Mechanical Properties of Pine Wood Treated by In Situ Polymerization of Methyl Methacrylate (MMA)" Forests 11, no. 7: 768. https://doi.org/10.3390/f11070768

APA StyleAcosta, A. P., Labidi, J., Schulz, H. R., Gallio, E., Barbosa, K. T., Beltrame, R., de Avila Delucis, R., & Gatto, D. A. (2020). Thermochemical and Mechanical Properties of Pine Wood Treated by In Situ Polymerization of Methyl Methacrylate (MMA). Forests, 11(7), 768. https://doi.org/10.3390/f11070768