The Harvest Operability Index (HOI): A Decision Support Tool for Mechanized Timber Harvesting in Mountainous Terrain

Abstract

:1. Introduction

2. Materials and Methods

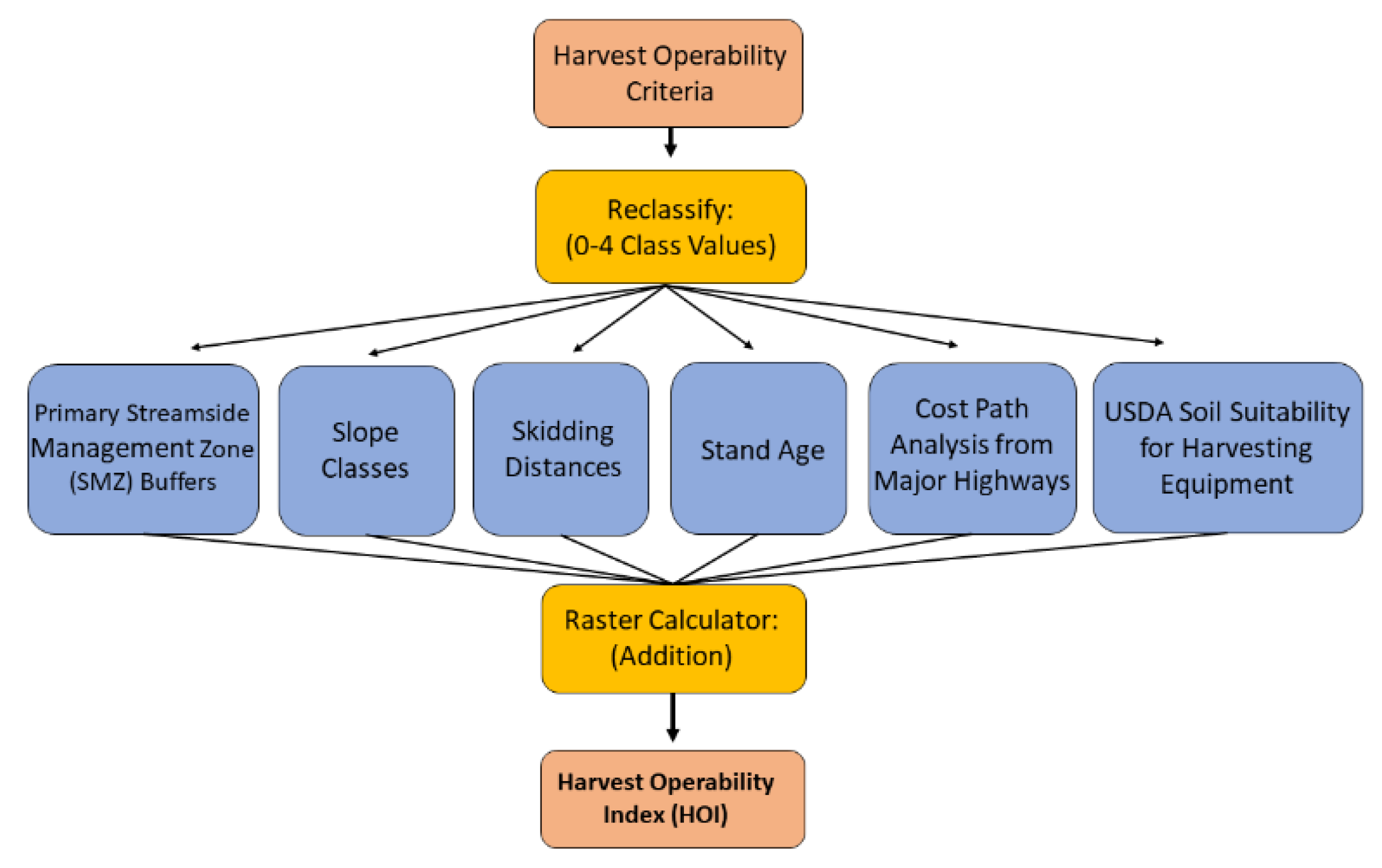

2.1. HOI Model Overview

2.2. Study Area

2.3. Data Sets Used in the Harvest Operability Index (HOI)

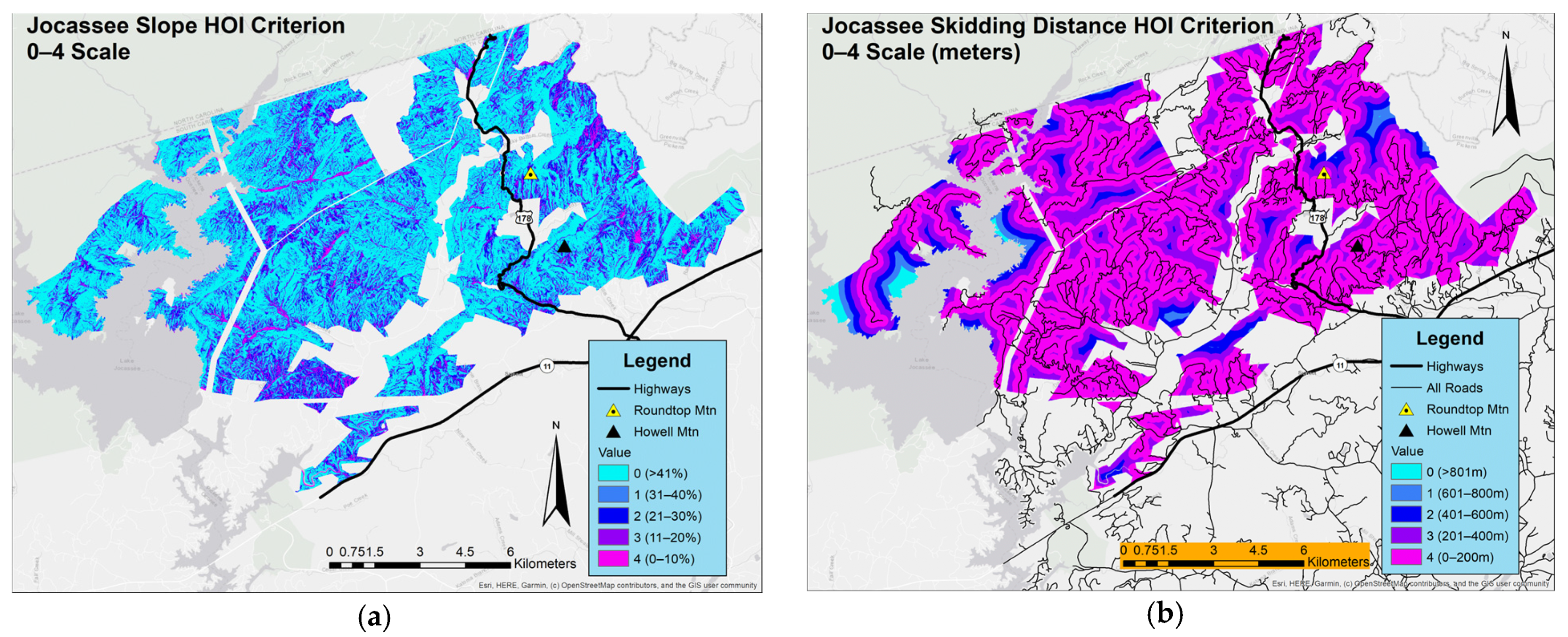

2.4. Slope HOI Criterion Methodology

2.5. Skidding Distance HOI Criterion Methodology

2.6. Cost Distance to Highways HOI Criterion Methodology

2.7. Stand Age HOI Criterion Methodology

2.8. SMZ HOI Criterion Methodology

2.9. Soil Suitability HOI Criterion Methodology

2.10. HOI Model Validation

3. Results

3.1. HOI Criteria Class Value Results

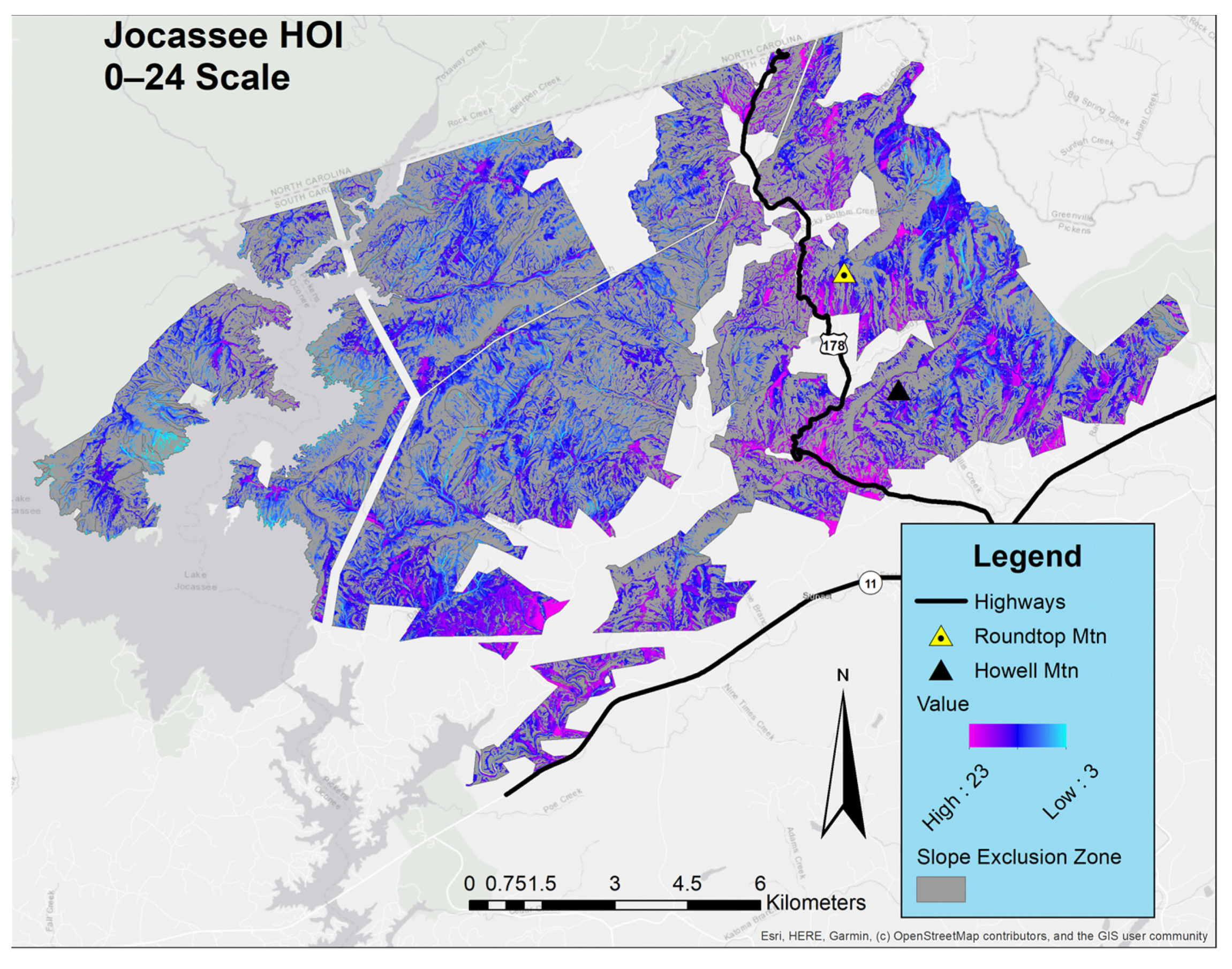

3.2. HOI Model Results

3.3. HOI Model Validation Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lindroos, O.; La Hera, P.; Häggström, C. Drivers of Advances in Mechanized Timber Harvesting—A Selective Review of Technological Innovation. Croat. J. For. Eng. 2017, 38, 243–258. [Google Scholar]

- Conrad, J.L.; Greene, W.D.; Hiesl, P. A Review of Changes in US Logging Businesses 1980s–Present. J. For. 2018, 116, 291–303. [Google Scholar] [CrossRef]

- Conrad, J.L.; Greene, W.D.; Hiesl, P. The Evolution of Logging Businesses in Georgia 1987–2017 and South Carolina 2012–2017. For. Sci. 2018, 64, 671–681. [Google Scholar] [CrossRef]

- Allen, C.D.; Savage, M.; Falk, D.A.; Suckling, K.F.; Swetnam, T.W.; Schulke, T.; Stacey, P.B.; Morgan, P.; Hoffman, M.; Klingel, J.T. Ecological Restoration of Southwestern Ponderosa Pine Ecosystems: A Broad Perspective. Ecol. Appl. 2002, 12, 1418–1433. [Google Scholar] [CrossRef]

- United States Forest Service, United States Department of Agriculture. Increasing the Pace of Restoration and Job Creation on Our National Forests. Available online: https://www.fs.usda.gov/sites/default/files/legacy_files/media/types/publication/field_pdf/increasing-pace-restoration-job-creation-2012.pdf (accessed on 5 December 2021).

- Heinimann, H.R. Ground-based Harvesting Technologies for Steep Slopes. In Proceedings of the International Mountain Logging and 10th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 28 March–1 April 1991; Sessions, J., Chung, W., Eds.; Department of Forest Engineering, Oregon State University: Corvallis, OR, USA; pp. 1–19. [Google Scholar]

- Adams, J.D.; Visser, R.M.; Prisley, S.P. Modeling steep terrain harvesting risks using GIS. In Proceedings of the Austro2003: High Tech Forest Operations for Mountainous Terrain, Schlaegal, Austria, 5–9 October 2003; pp. 1–13. [Google Scholar]

- Pellegrini, M. Support Tools for Planning and Management of a Forest Road Network. Ph.D. Thesis, Universita Degli Studi di Padova, Padua, Italy, 2012. Available online: http://paduaresearch.cab.unipd.it/4454/ (accessed on 3 March 2021).

- Mreže, P.; Cesta, Š.; Planskoj, S.U.; Anbarda, J. Evaluation of Forest Road Network and Determining Timber Extraction System Using GIS: A Case Study in Anbardag Planning Unit. Sumarski 2017, 383, 163–171. [Google Scholar]

- Diniz, C.C.C.; Nakajima, N.Y.; Robert, R.C.G.; Dolácio, C.J.F.; da Silva, F.A.; Balensiefer, D.F. Performance of grapple skidder in different ground inclinations. Floresta 2019, 49, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Lotfalian, M.; Fallah, A.; Moafi, M.; Nobakht, A. Determining the maximum allowable cross slope of skid trails for rubber-tired skidder Timberjack 450C. Ann. Biol. Res. 2012, 3, 3805–3810. [Google Scholar]

- Đuka, A.; Poršinsky, T.; Pentek, T.; Pandur, Z.; Vusić, D.; Papa, I. Mobility range of a cable skidder for timber extraction on sloped terrain. Forests 2018, 9, 526. [Google Scholar] [CrossRef] [Green Version]

- Haynes, H.; Visser, R. Productivity Improvements through Professional Training in Appalachian Cable Logging Operations. In Proceedings of the International Mountain Logging 11th Pacific Northwest Skyline Symposium, Seattle, WA, USA, 10–12 December 2001; pp. 48–55. [Google Scholar]

- Holzfeind, T.; Kanzian, C.; Stampfer, K.; Holzleitner, F. Assessing cable tensile forces and machine tilt of winch-assisted forwarders on steep terrain under real working conditions. Croat. J. For. Eng. 2019, 40, 281–296. [Google Scholar] [CrossRef] [Green Version]

- Kolka, R.; Smidt, M. Effects of forest road amelioration techniques on soil bulk density, surface runoff, sediment transport, soil moisture and seedling growth. For. Ecol. Manag. 2004, 202, 313–323. [Google Scholar] [CrossRef]

- Page-Dumroese, D.S.; Jurgensen, M.F.; Tiarks, A.E.; Ponder, F.; Sanchez, F.G.; Fleming, R.L.; Kranabetter, J.M.; Powers, R.F.; Stone, D.M.; Elioff, J.D.; et al. Soil physical property changes at the North American Long-Term Soil Productivity study sites: 1 and 5 years after compaction. Can. J. For. Res. 2006, 36, 551–564. [Google Scholar] [CrossRef]

- Wang, J.; Ledoux, C.B.; Edwards, P.; Jones, M. Soil bulk density changes caused by mechanized harvesting: A case study in central Appalachia. For. Prod. J. 2005, 55, 37–40. [Google Scholar]

- Martin, C.W.; Hornbeck, J.W. Logging in New England need not cause sedimentation of streams. North. J. Appl. For. 1994, 11, 17–23. [Google Scholar] [CrossRef]

- Reisinger, T.W.; Simmons, G.L.; Pope, P.E. The impact of timber harvesting on soil properties and seedling growth in the south. South J. Appl. For. 1988, 12, 58–67. [Google Scholar] [CrossRef]

- Wang, J.; LeDoux, C.; Vanderberg, M.; Li, Y. Effects of Soil Compaction on Residual Stand Growth in Central Appalachian Hardwood Forest: A Preliminary Case Study. In Proceedings of the 29th Council of Forest Engineering Conference, Coeur d’Alene, ID, USA, 30 July–2 August 2006; pp. 333–341. [Google Scholar]

- Zenner, E.K.; Fauskee, J.T.; Berger, A.L.; Puettmann, K.J. Impacts of skidding traffic intensity on soil disturbance, soil recovery, and aspen regeneration in North Central Minnesota. North. J. Appl. For. 2007, 24, 177–183. [Google Scholar] [CrossRef] [Green Version]

- Shaffer, R.M.; Haney, H.L.; Worrell, E.G.; Aust, W.M. Forestry BMP implementation costs for Virginia. For. Prod. J. 1998, 48, 27–29. [Google Scholar]

- Kilgore, M.A.; Blinn, C.R. Encouraging the application of sustainable timber harvesting practices: A review of policy tool use and effectiveness in the eastern United States. Water Air Soil Pollut. Focus 2004, 4, 203–216. [Google Scholar] [CrossRef]

- Sawyers, C.; Aust, W.M.; Bolding, M.C.; Lakel, W.A., III. Effectiveness and costs of Overland Skid Trail BMPS. In Proceedings of the 16th Biennial Southern Silvicultural Resource Conference, Charleston, SC, USA, 15–17 February 2011; pp. 283–289. [Google Scholar]

- Jodlowski, K.; Kalinowski, M. Current possibilities of mechanized logging in mountain areas. Leśne Prace Badawcze 2018, 79, 365–375. [Google Scholar] [CrossRef] [Green Version]

- Adebayo, A.B.; Han, H.; Johnson, L. Productivity and cost of cut-to-length and whole-tree harvesting in mixed-conifer stand in northern Idaho. In Proceedings of the 29th Council on Forest Engineering Conference, Couer d’Alene, ID, USA, 22 July–2 August 2006; pp. 127–136. [Google Scholar]

- Jirousek, R.; Klvac, R.; SkoupY, A. Productivity and costs of the mechanized cut-to-length wood harvesting system in clear-felling operations. J. For. Sci. 2007, 53, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Hiesl, P.; Benjamin, J.G. Harvesting Equipment Cycle Time and Productivity Guide for Logging Operations in Maine; Miscellaneous Publication 762; Maine Agricultural and Forest Experiment Station: Orono, ME, USA, 2013; pp. 1–67. ISSN 1070-1508. [Google Scholar]

- Petković, V.; Marčeta, D.; Ljubojević, D.; Kuburić, J. Determination of Average Skidding Distance Using GIS. Nova Mehanizacija Šumarstva 2017, 38, 33–42. [Google Scholar]

- Pecora, G.; Todaro, L.; Moretti, N. Optimization of Timber Harvesting System Using GIS-Based System. In Proceedings of the Second International Congress of Silviculture, Florence, Italy, 26–29 November 2014; pp. 892–895. [Google Scholar]

- Davis, C.J. Evaluating Terrain for Harvesting Equipment Selection. Int. J. For. Eng. 1990, 2, 9–16. [Google Scholar] [CrossRef]

- Becker, R.M.; Keefe, R.F.; Anderson, N.M.; Eitel, J.U.H. Use of lidar-derived landscape parameters to characterize alternative harvest system options in the Inland Northwest. Int. J. For. Eng. 2018, 29, 179–191. [Google Scholar] [CrossRef]

- Picchio, R.; Pignatti, G.; Id, E.M.; Latterini, F.; Benanchi, M.; Foderi, C.; Venanzi, R.; Verani, S. The Application of Two Approaches Using GIS Technology Implementation in Forest Road Network Planning in an Italian Mountain Setting. Forests 2018, 9, 277. [Google Scholar] [CrossRef] [Green Version]

- Picchio, R.; Latterini, F.; Mederski, P.S.; Tocci, D.; Venanzi, R.; Stefanoni, W.; Pari, L. Applications of GIS-Based Software to Improve the Sustainability of a Forwarding Operation in Central Italy. Sustainability 2020, 12, 5716. [Google Scholar] [CrossRef]

- Dodson, E.M.; Chung, W.; Mills, K.; Nall, R.; Sessions, J.; Zartman, G. Planning to determine low-volume road standards, long-term needs, and environmental risks and trade-offs. Transp. Res. Rec. 2007, 1, 11–19. [Google Scholar] [CrossRef]

- Simon, S.A. Ecological Zones in the Southern Blue Ridge: 4th Approximation; Report; Ecological Modeling and Fire Ecology Inc.: Asheville, NC, USA, 2015. [Google Scholar]

- Abella, S.R.; Shelburne, V.B.; MacDonald, N.W. Multifactor classification of forest landscape ecosystems of Jocassee Gorges, southern Appalachian Mountains, South Carolina. Can. J. For. Res. 2003, 33, 1933–1946. [Google Scholar] [CrossRef]

- Boyle, M.F.; Abella, S.R.; Shelburne, V.B. An ecosystem classification approach to assessing forest change in the southern Appalachian Mountains. For. Ecol. Manag. 2014, 323, 85–97. [Google Scholar] [CrossRef]

- ESRI. ArcGIS Desktop: Release 10.7; Environmental Systems Research Institute: Redlands, CA, USA, 2011. [Google Scholar]

- South Carolina LiDAR Data. Available online: https://www.dnr.sc.gov/GIS/lidar.html (accessed on 2 April 2021).

- Spinelli, R.; Hartsough, B.R.; Magagnotti, N. Productivity standards for harvesters and processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- TIGER/Line® Shapefiles. Available online: https://www.census.gov/cgi-bin/geo/shapefiles/index.php (accessed on 20 February 2021).

- Long, C.; Wang, J. Production and Cost Analysis of a Feller-Buncher in Central Appalachian Hardwood Forest. In Proceedings of the 25th Council on Forest Engineering, Auburn, AL, USA, 16–20 June 2002; pp. 1–5. [Google Scholar]

- Behjou, F.K.; Majnounian, B.; Namiranian, M.; Dvořák, J. Time study and skidding capacity of the wheeled skidder Timberjack 450C in Caspian forests. J. For. Sci. 2008, 54, 183–188. [Google Scholar] [CrossRef] [Green Version]

- ArcGIS Desktop Distance Tool Concepts: How Cost Distance Tools Work. Available online: https://desktop.arcgis.com/en/arcmap/10.3/tools/spatial-analyst-toolbox/how-the-cost-distance-tools-work.htm (accessed on 16 February 2021).

- Rongzu, Q.; Mikkonen, E. GIS-based Decision Support System for Wood Logistics. For. Stud. China 2004, 6, 29–33. [Google Scholar]

- Gingrich, S.F. Management of Young and Intermediate Stands of Upland Hardwoods; Resreach Paper NE-195; USDA Forest Service, Northeastern Forest Experiment Station: Upper Darby, PA, USA, 1971.

- United States Geologic Service. National Hydrography Dataset. Available online: https://www.usgs.gov/core-science-systems/ngp/national-hydrography/national-hydrography-dataset?qt-science_support_page_related_con=0#qt-science_support_page_related_con (accessed on 2 February 2020).

- Fishing Information from SCDNR-Trout Fishing Guide. Available online: https://www.dnr.sc.gov/fishing.html (accessed on 16 February 2021).

- South Carolina Forestry Commission. South Carolina’s Statewide Forest Resource Assessment and Strategy: Conditions, Trends, Threats, Benefits, and Issues; South Carolina Statewide Forest Resource Assessment Strategy: Columbia, SC, USA, 2010.

- Soil Survey Staff Natural Resources Conservation Service. United States Department of Agriculture, Web Soil Survey. Available online: https://websoilsurvey.nrcs.usda.gov/ (accessed on 2 April 2020).

- Soil Survey Staff Natural Resources Conservation Service, United States Department of Agriculture. Geospatial Data Gateway. Available online: https://datagateway.nrcs.usda.gov/GDGHome_DirectDownLoad.aspx (accessed on 9 April 2021).

- Addington, R.N.; Tavernia, B.G.; Caggiano, M.D.; Thompson, M.P.; Lawhon, J.D.; Sanderson, J.S. Identifying opportunities for the use of broadcast prescribed fire on Colorado’s Front Range. For. Ecol. Manag. 2020, 458, 1–12. [Google Scholar] [CrossRef]

- Hogland, J.; Anderson, N.; Chung, W. New geospatial approaches for efficiently mapping forest biomass logistics at high resolution over large areas. ISPRS Int. J. Geo-Inf. 2018, 7, 156. [Google Scholar] [CrossRef] [Green Version]

- Hiers, J.K.; Laine, S.C.; Bachant, J.J.; Furman, J.H.; Greene, W.W.; Compton, V. Simple Spatial Modeling Tool for Prioritizing Prescribed Burning Activities at the Landscape Scale. Conserv. Biol. 2003, 17, 1571–1578. [Google Scholar] [CrossRef]

- Abdi, E.; Majnounian, B.; Darvishsefat, A.; Mashayekhi, Z.; Sessions, J. A GIS-MCE based model for forest road planning. J. For. Sci. 2009, 55, 171–176. [Google Scholar] [CrossRef] [Green Version]

- Mahan, C.G.; Young, J.A.; Forder, M. Prioritizing Forest Communities and Areas for the Use of Prescribed Fire at Shenandoah National Park; Natural Resource Technical Report: NPS/SHEN/NRTR-2012/625; US National Park Service: Fort Collins, CO, USA, 2012.

- Memarbashi, E.; Azadi, H.; Barati, A.A.; Mohajeri, F.; Van Passel, S.; Witlox, F. Land-use suitability in Northeast Iran: Application of AHP-GIS hybrid model. ISPRS Int. J. Geo-Inf. 2017, 6, 396. [Google Scholar] [CrossRef] [Green Version]

- Aguirre-Salado, C.A.; Miranda-Aragón, L.; Pompa-García, M.; Reyes-Hernández, H.; Soubervielle-Montalvo, C.; Flores-Cano, J.A.; Méndez-Cortés, H. Improving identification of areas for ecological restoration for conservation by integrating USLE and MCDA in a gis-environment: A pilot study in a priority region northern Mexico. Int. J. Geo-Inf. 2017, 6, 262. [Google Scholar] [CrossRef] [Green Version]

- Griselda, V.; Prieto-ampar, A.; Pinedo-alvarez, A. GIS-Based Multicriteria Evaluation of Land Suitability for Grasslands Conservation in Chihuahua, Mexico. Sustainability 2020, 12, 1–19. [Google Scholar]

| Data Criteria | Rescale by Function HOI Value | Operability Classes |

|---|---|---|

| 0 1–1.5 | 0: Slope Exclusion Zone 1: Very Poor Operability | |

| Rescale by Function HOI | 1.6–2.0 | 2: Poor Operability |

| 2.1–3.0 | 3: Moderate Operability | |

| 3.1–4.0 | 4: High Operability | |

| 4.1–5.0 | 5: Very High Operability |

| Data Layer | Type | Source |

|---|---|---|

| Roads (Pickens Co., SC) | ShapeFile | US Census TIGER/Line® |

| Access Roads | ShapeFile | Jocassee Gorges Staff |

| Forest Stands | ShapeFile | Jocassee Gorges Staff |

| Stream/Lake Waterbodies | ShapeFile | USGS NHD |

| Soil Map Units | ShapeFile | NRCS SSURGO |

| Digital Elevation Model (Pickens, Oconee Co., SC) | Raster | SCDNR |

| Slope (Percent) | Skidding Distance (Meters) | Cost Distance to Major Highways (Meters) | Stand Age (Years) | Soil Suitability for Harvesting Equipment | SMZ Buffers | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Distance from Trout Stream/Lake Primary SMZ (Meters) | Distance From non-Trout Stream/Lake Primary SMZ (Meters) | ||||||||||||

| CV | CV | CV | CV | CV | CV | CV | |||||||

| 0–10% | 4 | 0–200 | 4 | 0–10,000 | 4 | >61 | 4 | Well Suited | 4 | >24.384 | 4 | >12.192 | 4 |

| 11–20% | 3 | 201–400 | 3 | 10,001–20,000 | 3 | 41–60 | 3 | ||||||

| 21–30% | 2 | 401–600 | 2 | 20,001–30,000 | 2 | 21–40 | 2 | Moderately Suited | 2 | ||||

| 31–40% | 1 | 601–800 | 1 | 30,001–40,000 | 1 | 10–20 | 1 | ||||||

| >41% | 0 | >801 | 0 | >40,001 | 0 | Open Area, 9 | 0 | Poorly Suited | 0 | 0–24.384 | 0 | 0–12.192 | 0 |

| CV: Class Value | |||||||||||||

| HOI Value | Slope Exclusion Zone (0) | Very Poor Operability (1) | Poor Operability (2) | Moderate Operability (3) | Good Operability (4) | Very Good Operability (5) |

|---|---|---|---|---|---|---|

| Area (ha) | 7824 | 95 | 118 | 1257 | 2442 | 1381 |

| Percent (%) | 60% | <1% | <1% | 9% | 18% | 10% |

| Clearcut Area | Size (ha) | Mean Rescale by Function HOI Score (0–5) |

|---|---|---|

| 1 | 4.90 | 3.83 |

| 2 | 5.40 | 3.70 |

| 3 | 0.32 | 3.89 |

| 4 | 0.45 | 4.64 |

| 5 | 0.33 | 4.00 |

| 6 | 0.70 | 4.27 |

| 7 | 0.20 | 4.35 |

| 8 | 0.66 | 3.54 |

| 9 | 0.18 | 3.73 |

| 10 | 2.35 | 3.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phelps, K.; Hiesl, P.; Hagan, D.; Hotaling Hagan, A. The Harvest Operability Index (HOI): A Decision Support Tool for Mechanized Timber Harvesting in Mountainous Terrain. Forests 2021, 12, 1307. https://doi.org/10.3390/f12101307

Phelps K, Hiesl P, Hagan D, Hotaling Hagan A. The Harvest Operability Index (HOI): A Decision Support Tool for Mechanized Timber Harvesting in Mountainous Terrain. Forests. 2021; 12(10):1307. https://doi.org/10.3390/f12101307

Chicago/Turabian StylePhelps, Keith, Patrick Hiesl, Donald Hagan, and Althea Hotaling Hagan. 2021. "The Harvest Operability Index (HOI): A Decision Support Tool for Mechanized Timber Harvesting in Mountainous Terrain" Forests 12, no. 10: 1307. https://doi.org/10.3390/f12101307