Characterizing Mode I Fracture Behaviors of Wood Using Compact Tension in Selected System Crack Propagation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood Materials

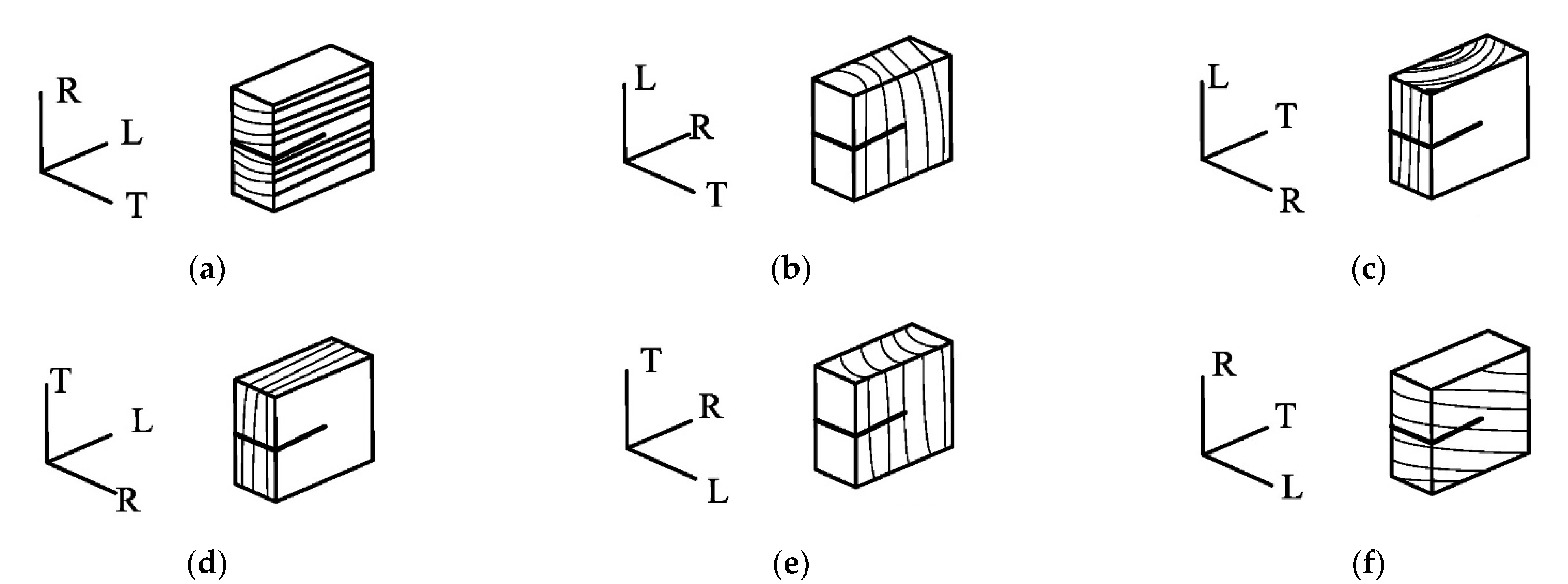

2.2. Specimens Preparation

2.3. Experimental Design

2.4. Calculating Method of Fractal Dimentions

2.5. Statistical Analysis

3. Results and Discussion

3.1. Density and Moisture Content

3.2. Fracture Characteristics

3.3. Failure Modes and Fractal Dimensions

4. Conclusions

- (1)

- Wood species had significant effects on characteristic values, maximum fracture load, critical stress intensity factor and fracture energy, at 5% significance level. Beech got greater characteristic values than the others, followed by ash, okoume, and poplar in descending order.

- (2)

- The fracture behavior of CT wood blocks subjected to compact tension load in the RL crack propagation system could be characterized by combining linear and exponential equations in the initial stage and evolution stage, respectively, with determination coefficient greater than 0.98.

- (3)

- Linear positive proportional relationships were found between critical stress intensity factor and fracture energy versus fractal dimensions of cracks in front and left views of wood samples in RL crack propagation system when subjected to compact tension load. While the relationships between critical stress intensity factor and fracture energy versus fractal dimensions of fracture surfaces were negative.

- (4)

- The fractal dimension of cracks in front view of CT samples could be a better indicator used to predict critical stress intensity factor and fracture energy of CT blocks subjected to compact tension load with correlation coefficients greater than 0.95.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, G.; Sun, J.; Huang, C.; Ren, H.; Zhao, R. Research progress on mechanical properties of tenon-mortise joints in traditional Chinese wood structures. J. Forest Eng. 2020, 5, 29–37. [Google Scholar] [CrossRef]

- Fu, W.; Guan, H.; Zhang, X. Verification and further study on method of measuring contact force between mortise and tenon joint. BioResources 2021, 16, 263–276. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Y.; Zhang, Z. Study on small-diameter wood scrimber and furniture design. J. Forest Eng. 2019, 4, 155–159. [Google Scholar] [CrossRef]

- Xi, X.; Yang, Y.; Zhang, Z. Pull-out force and finite element analysis of T-type components of Vitex negundo L. scrimber with different node forms. J. Forest Eng. 2020, 5, 182–187. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, C.; Wu, D.; Chen, Z.; Zhu, N.; Gui, C.; Zhang, M.; Umemura, K.; Yong, Q. Utilization of enzymatic hydrolysate from corn stover as a precursor to synthesize an eco-friendly plywood adhesive. Ind. Crop. Prod. 2020, 152, 112501. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Wu, Z. Fabrication of coatings with structural color on a wood surface. Coatings 2020, 10, 32. [Google Scholar] [CrossRef] [Green Version]

- Yin, Q.; Liu, H. Drying stress and strain of wood: A review. Appl. Sci. 2021, 11, 5023. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Yang, F.; Wang, Y.; Wang, J.; Zhang, J. A strong multi-layered transparent wood with natural wood color and texture. J. Mater. Sci. 2021, 56, 8000–8013. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.; Han, J.; Wu, Z.; Zhang, J. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Yu, M.; Zhou, T. Experimental study on three-dimensional shape mapping of complex furniture. EURASIP J. Image Video Process. 2018, 9, 89. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Influence of the PVC of glass fiber powder on the properties of a thermochromic waterborne coating for Chinese Fir boards. Coatings 2020, 10, 588. [Google Scholar] [CrossRef]

- Sang, R.; Manley, A.J.; Wu, Z.; Feng, X. Digital 3D texture: UV-curable inkjet printing on board surface. Coatings 2020, 10, 1144. [Google Scholar] [CrossRef]

- Fu, W.; Guan, H.; Kei, S. Effects of moisture content and grain direction on the elastic properties of beech wood based on experiment and finite element method. Forests 2021, 12, 610. [Google Scholar] [CrossRef]

- Cai, C.; Zhou, F.; Cai, J. Bound water content and pore size distribution of thermally modified wood studied by NMR. Forests 2020, 11, 1279. [Google Scholar] [CrossRef]

- Nairn, J.A.; Aimene, Y.E. A re-evaluation of mixed-mode cohesive zone modeling based on strength concepts instead of traction laws. Eng. Fract. Mech. 2021, 248, 107704. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, A.; Liu, Y.; Sheng, B. Numerical simulation analysis of parallel strand bamboo type I fracture using extended finite element method. J. Forest Eng. 2020, 5, 49–56. [Google Scholar] [CrossRef]

- Tu, J.; Zhao, D.; Zhao, J. Experimental study for determining method of cracking load of wooden beams with LT crack. J. Forest Eng. 2020, 5, 149–154. [Google Scholar] [CrossRef]

- Atkins, A. Toughness and cutting: A new way of simultaneously determining ductile fracture toughness and strength. Eng. Fract. Mech. 2005, 72, 849–860. [Google Scholar] [CrossRef]

- Sinn, G.; Chuchała, D.; Orlowski, K.A.; Taube, P. Cutting model parameters from frame sawing of natural and impregnated Scots pine (Pinus sylvestris L.). Eur. J. Wood Prod. 2020, 78, 777–784. [Google Scholar] [CrossRef]

- Reiterer, A. The influence of temperature on the mode I fracture behavior of wood. J. Mater. Sci. Lett. 2001, 20, 1905–1907. [Google Scholar] [CrossRef]

- Donrado, N.; De Moura, M.F.S.F. Effect of temperature on the fracture toughness of wood under mode I quasi-static loading. Constr. Build. Mater. 2019, 223, 863–869. [Google Scholar] [CrossRef]

- Yoshihara, H.; Kacamura, T. Influence of the measurement methods on the mode I fracture toughness of woods. J. Soc. Mater. Sci. Jpn. 2007, 56, 311–315. [Google Scholar] [CrossRef]

- Reiterer, A.; Tschegg, S. The influence of moisture content on the mode I fracture behavior of sprucewood. J. Mater. Sci. 2002, 37, 4487–4491. [Google Scholar] [CrossRef]

- Tukiainen, P.; Hughes, M. The effect of temperature and moisture content on the fracture behaviour of spruce and birch. Hulzforschung 2015, 70, 369–376. [Google Scholar] [CrossRef]

- Phan, N.C.; Chaplain, M.; Morel, S.; Coureau, J.L. Influence of moisture content on mode I fracture process of Pinus pinaster: Evolution of micro-cracking and crack-bridging energies highlighted by bilinear softening in cohesive zone model. Wood Sci. Technol. 2017, 51, 1051–1066. [Google Scholar] [CrossRef]

- Bertolin, C.; Karvan, P.; Rosa, A.D.; Razavi, J.M.; Berto, F. Relation between fracture characteristics and moisture content along longitudinal direction in a naturally drying Scots pine. Theor. Appl. Fract. Mech. 2021, 112, 102911. [Google Scholar] [CrossRef]

- Yang, L.; Liu, H. Effect of a combination of moderate-temperature heat treatment and subsequent wax impregnation on wood hygroscopicity, dimensional stability, and mechanical properties. Forests 2020, 11, 920. [Google Scholar] [CrossRef]

- Reiterer, A.; Stanzl-Tshegg, S.E.; Tschegg, E.K. Mode I fracture and acoustic emission of softwood and hardwood. Wood Sci. Technol. 2000, 34, 417–430. [Google Scholar] [CrossRef]

- Liu, X.; Lv, M.; Liu, M.; Lv, J.F. Repeated humidity cycling’s effect on physical properties of three kinds of wood-based panels. BioResources 2019, 14, 9444–9453. [Google Scholar] [CrossRef]

- Frühmann, K.; Reiterer, A.; Tschegg, E.K.; Stanzl-Tshegg, S.S. Fracture characteristics of wood under mode I, mode II and mode III loading. Philos. Mag. A 2002, 82, 3289–3298. [Google Scholar] [CrossRef]

- Zboňák, A.; Niemz, P.; Dierner, M. Estimate of fracture toughness of spruce wood. Wood Res.-Slovak. 2002, 47, 27–36. [Google Scholar]

- Kretschmann, D.E. Mechanical Properties of Wood. In Wood handbook-Wood as an Engineering Material, General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; 508p, ISBN 978-0898750829. [Google Scholar]

- Ohuchi, T.; Hermawan, A.; Fujimoto, N. Basic studies on fracture toughness of sugi and acoustic emission. J.-Fac. Agric. Kyushu Univ. 2011, 56, 99–102. [Google Scholar] [CrossRef]

- ASTM E1820-05. Standard Test Method for Measurement of Fracture Toughness; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Wu, Y.; Shao, Z.P.; Wang, F. Study on wood fracture parallel to the grains based on fractal geometry. Int. J. Fract. 2012, 176, 163–169. [Google Scholar] [CrossRef]

- Zhang, C.; Liao, H.; Chun, Y. Fractal analysis on damage characteristics of wood of ancient building under fatigue vibration. Chin. J. Appl. Mech. 2018, 35, 292–297. [Google Scholar] [CrossRef]

- ASTM D 2395-93. Standard Test Methods for Specific Gravity of Wood and Wood—Based Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D 4442-92. Test Methods for Direct Moisture Content Measurement of Wood and Wood—Base Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Konukcu, A.C.; Quin, F.; Zhang, J. Effect of growth rings on fracture toughness of wood. Eur. J. Wood Wood Prod. 2021. [Google Scholar] [CrossRef]

- Schachner, H.; Reiterer, A.; Stanzl-Tschegg, S.E. Orthotropic fracture toughness of wood. J. Mater. Sci. Lett. 2000, 19, 1783–1785. [Google Scholar] [CrossRef]

- Yoshihara, H.; Usuki, A. Mode I critical stress intensity factor of wood and medium-density fiberboard measured by compact tension test. Holzforschung 2011, 65, 729–735. [Google Scholar] [CrossRef]

- Valentin, G.; Adjanohoun, G. Applicability of classical isotropic fracture mechanics specimens to wood crack propagation studies. Mater. Struct. 1992, 25, 3–13. [Google Scholar] [CrossRef]

- Tukiainen, P.; Hughes, M. The effect of elevated temperature and high moisture content on the fracture behavior of thermally modified spruce. J. Mater. Sci. 2016, 51, 1437–1444. [Google Scholar] [CrossRef]

| Wood Species | Beech | Ash | Okoume | Poplar |

|---|---|---|---|---|

| MC (%) | 9.22 (2.7) | 9.69 (2.4) | 9.40 (2.0) | 8.64 (2.5) |

| Density (g/cm3) | 0.68 (5.5) | 0.74 (2.5) | 4.76 (2.8) | 0.45 (9.2) |

| Wood Species | Maximum Fracture Load (N) | Critical Stress Intensity Factor | Maximum Stress (MPa) | Fracture Energy (J/mm2) |

|---|---|---|---|---|

| Ash | 133.5 (18.3) B | 0.649 B | 0.854 B | 0.148 (17.9) B |

| Beech | 164.3 (14.5) A | 0.798 A | 1.050 A | 0.218 (11.9) A |

| Okoume | 87.3 (12.8) C | 0.424 C | 0.559 C | 0.086 (18.7) C |

| Poplar | 73.5 (23.9) C | 0.357 C | 0.470 C | 0.064 (20.6) D |

| Wood Species | yL | RL2 | yE | RE2 |

|---|---|---|---|---|

| Ash | 2.7401x − 0.03437 | 0.997 | 4.82586 × 0.00521x + 0.01468 | 0.9916 |

| Beech | 2.8437x − 0.06339 | 0.998 | 13.8640 × 0.00378x + 0.00108 | 0.9828 |

| Okoume | 1.88874x − 0.07901 | 0.981 | 5.57933 × 0.00109x + 0.00112 | 0.9960 |

| Poplar | 1.42949x − 0.01307 | 0.997 | 3.96315 × 0.00219x − 0.01301 | 0.9905 |

| Wood Species | Fractal Dimension | ||

|---|---|---|---|

| Front | Left | Surface | |

| Beech | 1.3893 (8.2) | 1.3142 (9.2) | 1.7268 (20.6) |

| Ash | 1.3321 (14.5) | 1.3133 (11.3) | 1.8202 (17.8) |

| Okoume | 1.2950 (7.6) | 1.2766 (6.4) | 1.8064 (15.3) |

| Poplar | 1.2738 (6.8) | 1.2605 (7.5) | 1.8234 (16.2) |

| Fracture Characteristics | Fractal Dimension of Crack | Linear Regression | ||

|---|---|---|---|---|

| a | b | R2 | ||

| Critical stress intensity factor | Front | −4.82059 | 4.05886 | 0.95708 |

| Left | −8.86452 | 7.29028 | 0.88654 | |

| Surface | 7.52128 | −3.90728 | 0.42762 | |

| Fracture energy | Front | −1.6631 | 1.35448 | 0.99116 |

| Left | −2.7936 | 2.26337 | 0.81466 | |

| Surface | 2.72567 | −1.45434 | 0.62554 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Liu, Y.; Li, S. Characterizing Mode I Fracture Behaviors of Wood Using Compact Tension in Selected System Crack Propagation. Forests 2021, 12, 1369. https://doi.org/10.3390/f12101369

Hu W, Liu Y, Li S. Characterizing Mode I Fracture Behaviors of Wood Using Compact Tension in Selected System Crack Propagation. Forests. 2021; 12(10):1369. https://doi.org/10.3390/f12101369

Chicago/Turabian StyleHu, Wengang, Yan Liu, and Shuang Li. 2021. "Characterizing Mode I Fracture Behaviors of Wood Using Compact Tension in Selected System Crack Propagation" Forests 12, no. 10: 1369. https://doi.org/10.3390/f12101369