Stochastic Economic Analysis of Investment Projects in Forest Restoration Involving Containerized Tree Seedlings in Brazil

Abstract

:1. Introduction

2. Materials and Methods

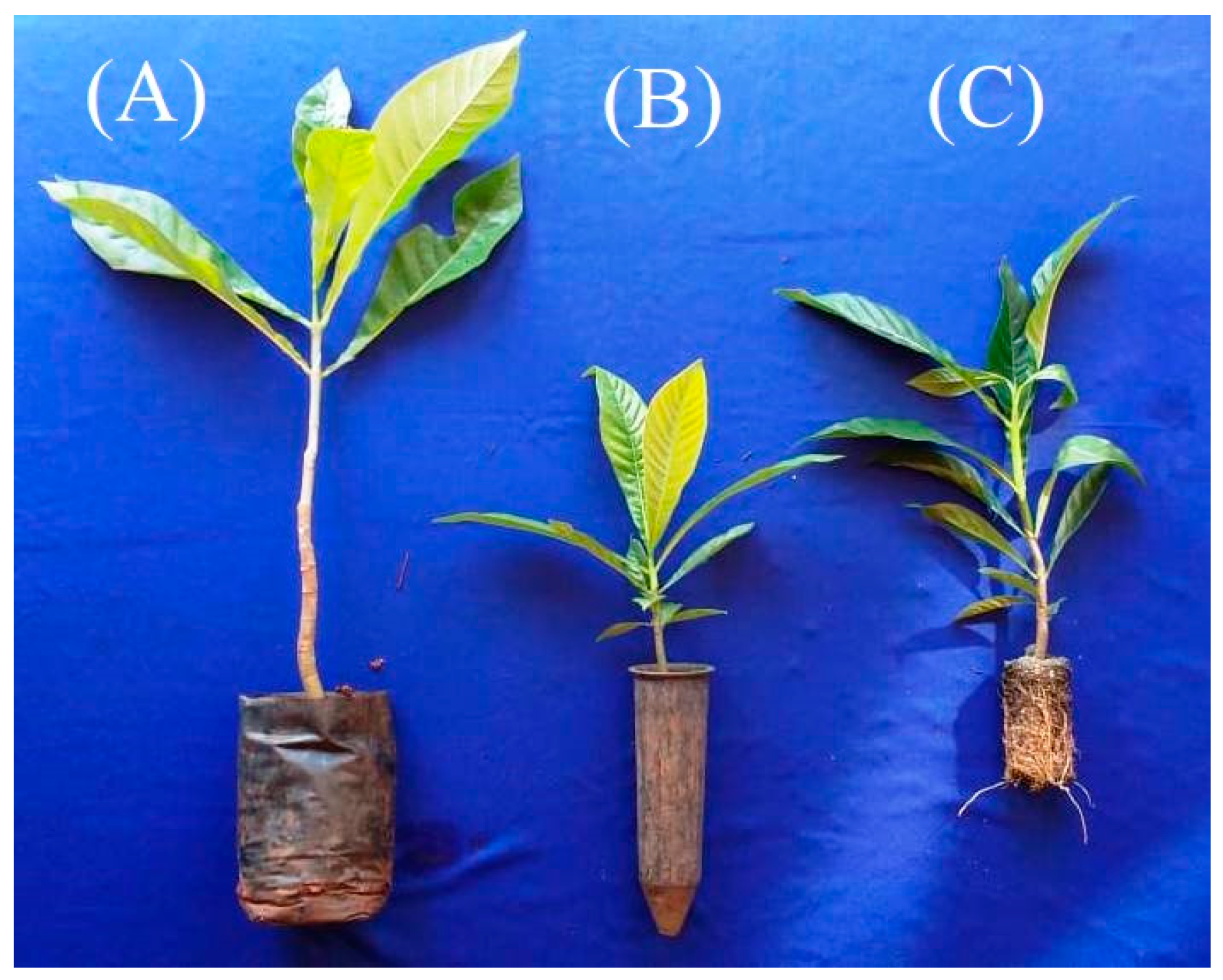

2.1. Site Description and Experimental Details

2.2. Economic Analysis of Forest Restoration Investment Projects

2.3. Opportunity Cost Rate Estimate

2.4. Equivalent Uniform Annual Cost (EUAC)

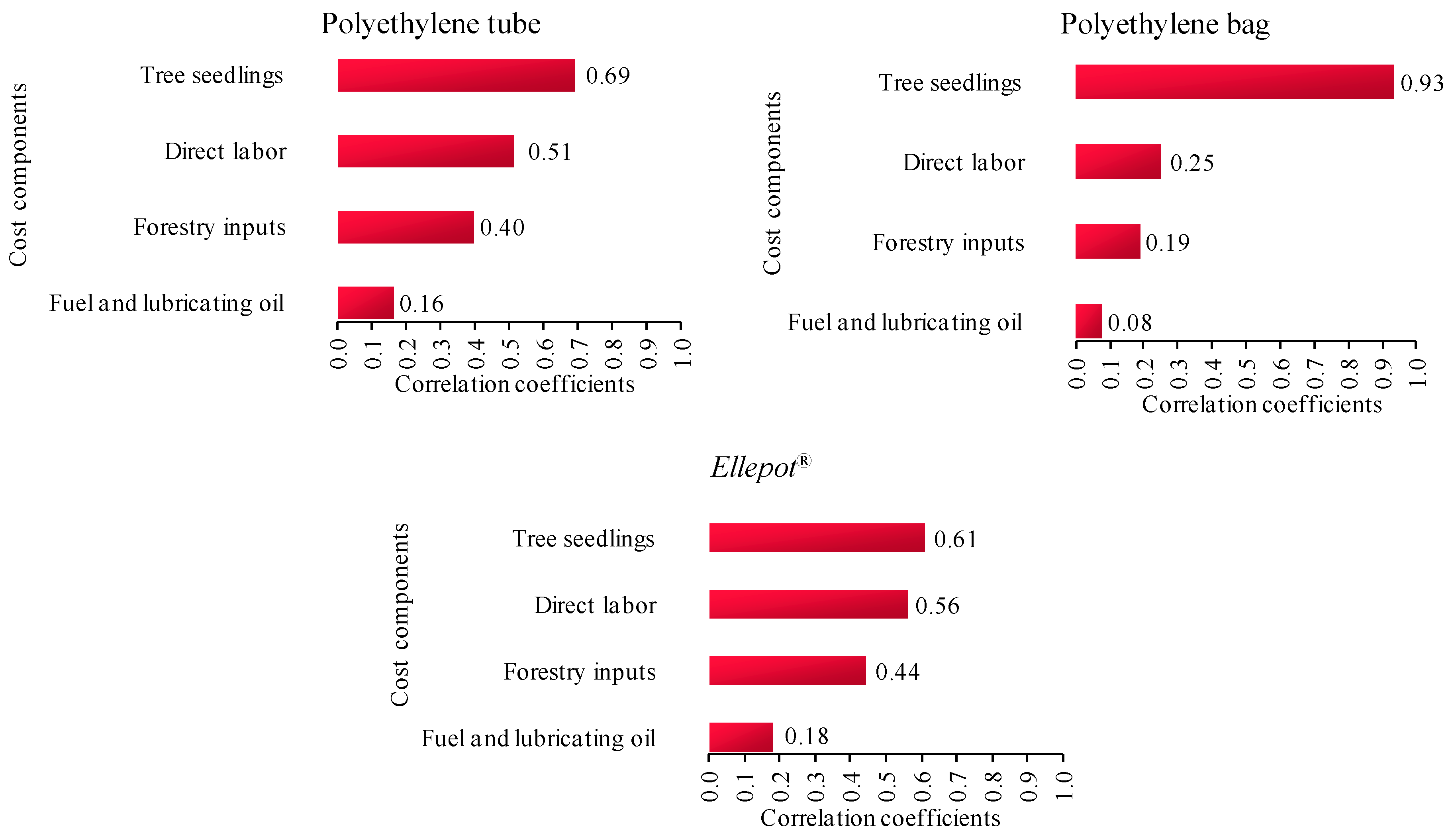

2.5. Stochastic Analysis

2.6. Seedling Survival Rate

3. Results

3.1. Stochastic Analysis of the Total Cost

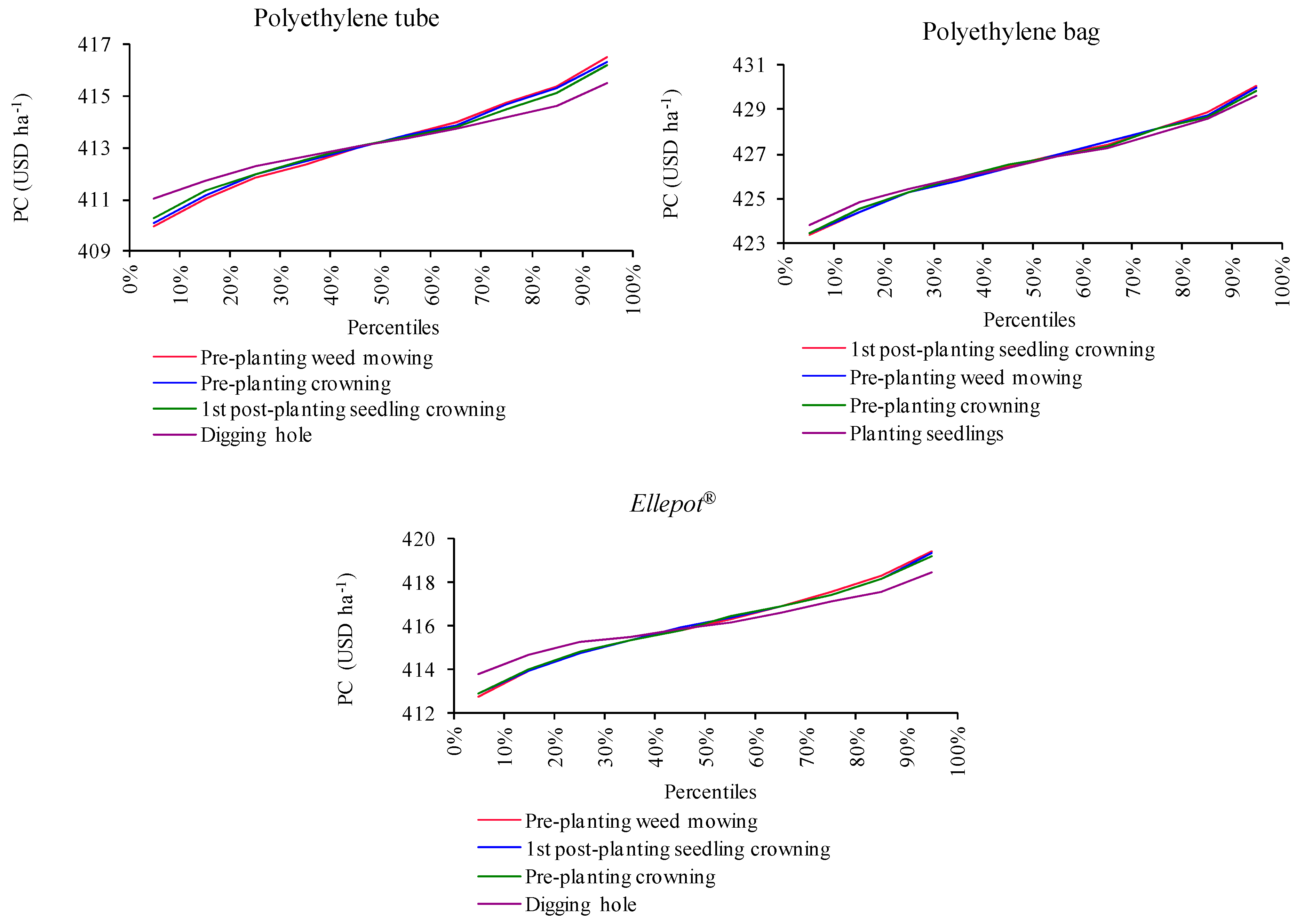

3.2. Stochastic Analysis of Production Costs

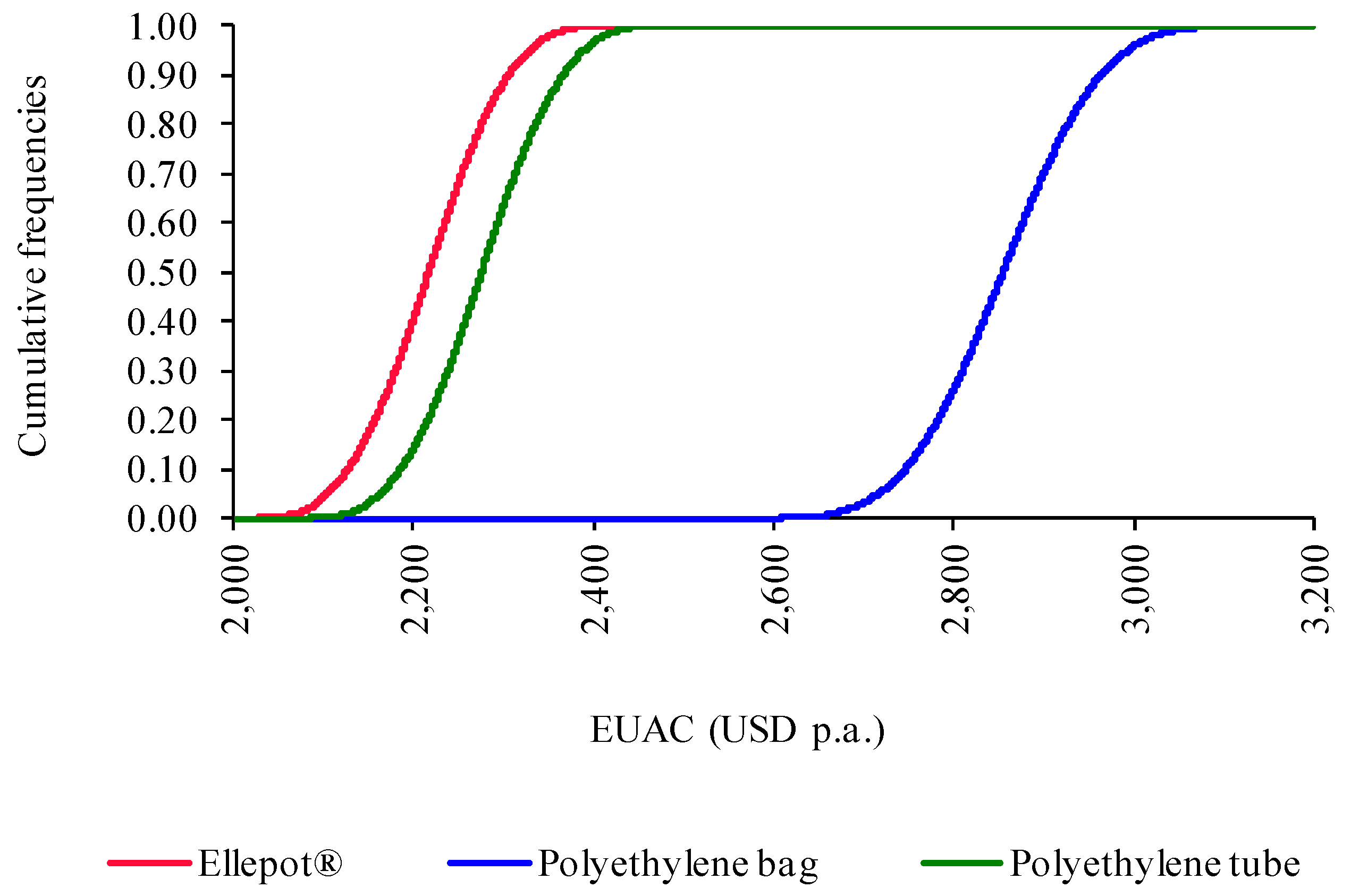

3.3. Stochastic Equivalent Uniform Annual Cost (EUAC)

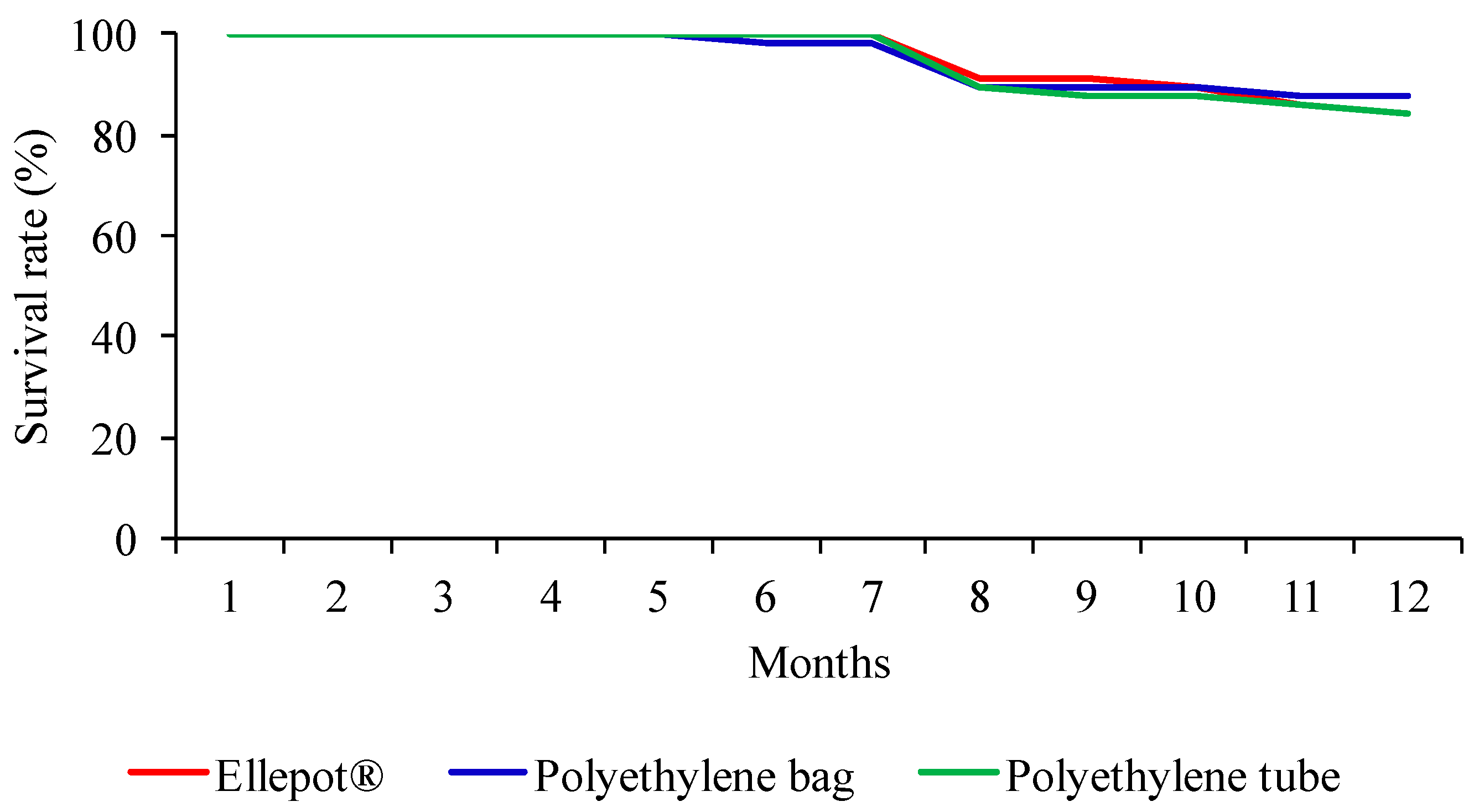

3.4. Seedling Survival Rate

4. Discussion

4.1. Stochastic Analysis of the Total Cost

4.2. Stochastic Analysis of Production Costs

4.3. Opportunity Cost of Forest Restoration Investment Projects

4.4. Stochastic Equivalent Uniform Annual Cost

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prevedello, J.A.; Winck, G.R.; Weber, M.M.; Nichols, E.; Sinervo, B. Impacts of forestation and deforestation on local temperature across the globe. PLoS ONE 2019, 14, e0213368. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vargas Zeppetello, L.R.; Parsons, L.A.; Spector, J.T.; Naylor, R.L.; Battisti, D.S.; Masuda, Y.J.; Wolff, N.H. Large scale tropical deforestation drives extreme warming. Environ. Res. Lett. 2020, 15, 084012. [Google Scholar] [CrossRef]

- Luwesi, C.N.; Obando, J.A.; Shisanya, C.A. The Impact of a Warming Micro-Climate on Muooni Farmers of Kenya. Agriculture 2017, 7, 20. [Google Scholar] [CrossRef] [Green Version]

- Tan, B.T.; Fam, P.S.; Firdaus, R.B.R.; Tan, M.L.; Gunaratne, M.S. Impact of Climate Change on Rice Yield in Malaysia: A Panel Data Analysis. Agriculture 2021, 11, 569. [Google Scholar] [CrossRef]

- Ribeiro, M.C.; Metzger, J.P.; Martensen, A.C.; Ponzoni, F.J.; Hirota, M.M. The Brazilian Atlantic Forest: How much is left, and how is the remaining forest distributed? Implications for conservation. Biol. Conserv. 2009, 142, 1141–1153. [Google Scholar] [CrossRef]

- Fiore, N.V.; Ferreira, C.C.; Dzedzej, M.; Massi, K.G. Monitoring of a Seedling Planting Restoration in a Permanent Preservation Area of the Southeast Atlantic Forest Biome, Brazil. Forests 2019, 10, 768. [Google Scholar] [CrossRef] [Green Version]

- INDC Intended Nationally Determined Contribution. Available online: https://www4.unfccc.int/sites/submissions/indc/Submission%20Pages/submissions.aspx (accessed on 5 November 2020).

- Brancalion, P.H.S.; Meli, P.; Tymus, J.R.C.; Lenti, F.E.B.; Benini, R.M.; Silva, A.P.M.; Isernhagen, I.; Holl, K.D. What makes ecosystem restoration expensive? A systematic cost assessment of projects in Brazil. Biol. Conserv. 2019, 240, 108274. [Google Scholar] [CrossRef]

- da Silva, A.M.; Bortoleto, L.A.; Castelli, K.R.; e Silva, R.A.; Mendes, P.B. Prospecting the potential of ecosystem restoration: A proposed framework and a case study. Ecol. Eng. 2017, 108, 505–513. [Google Scholar] [CrossRef] [Green Version]

- de Oliveira, R.E.; Engel, V.L. A restauração florestal na Mata Atlântica: Três décadas em revisão. Rev. Ciência Tecnol. Ambiente 2017, 5, 40–48. [Google Scholar] [CrossRef]

- Suganuma, M.S.; Durigan, G. Indicators of restoration success in riparian tropical forests using multiple reference ecosystems. Restor. Ecol. 2015, 23, 238–251. [Google Scholar] [CrossRef]

- Lone, R.A.; Jabeen, S.; Sarlach, H.S.; Tamta, N.; Kaur, J. Effect of Different Size of Container on Growth and Quality of Seedlings of Gmelina arborea Roxb. Indian For. 2020, 146, 1046–1052. [Google Scholar]

- Silva, R.B.; Gabira, M.M.; Prado, D.Z.; Uesugi, G.; Simões, D.; Silva, M.R. Influence of Mean Leaf Angles and Irrigation Volumes on Water Capture, Leaching, and Growth of Tropical Tree Seedlings. Forests 2020, 11, 1198. [Google Scholar] [CrossRef]

- Mangueira, J.R.S.A.; Holl, K.D.; Rodrigues, R.R. Enrichment planting to restore degraded tropical forest fragments in Brazil. Ecosyst. People 2019, 15, 3–10. [Google Scholar] [CrossRef]

- Meli, P.; Isernhagen, I.; Brancalion, P.H.S.; Isernhagen, E.C.C.; Behling, M.; Rodrigues, R.R. Optimizing seeding density of fast-growing native trees for restoring the Brazilian Atlantic Forest. Restor. Ecol. 2018, 26, 212–219. [Google Scholar] [CrossRef]

- Molin, P.G.; Chazdon, R.; de Ferraz, S.F.B.; Brancalion, P.H.S. A landscape approach for cost-effective large-scale forest restoration. J. Appl. Ecol. 2018, 55, 2767–2778. [Google Scholar] [CrossRef]

- Brancalion, P.H.S.; Guillemot, J.; César, R.G.; Andrade, H.S.; Mendes, A.; Sorrini, T.B.; Piccolo, M.D.C.; Peluci, M.C.; Moreno, V.D.S.; Colletta, G.; et al. The cost of restoring carbon stocks in Brazil’s Atlantic Forest. Land Degrad. Dev. 2021, 32, 830–841. [Google Scholar] [CrossRef]

- Crouzeilles, R.; Beyer, H.L.; Monteiro, L.M.; Feltran-Barbieri, R.; Pessôa, A.C.M.; Barros, F.S.M.; Lindenmayer, D.B.; Lino, E.D.S.M.; Grelle, C.E.V.; Chazdon, R.L.; et al. Achieving cost-effective landscape-scale forest restoration through targeted natural regeneration. Conserv. Lett. 2020, 13, e12709. [Google Scholar] [CrossRef]

- Lemos, C.M.G.; Andrade, P.R.; Rodrigues, R.R.; Hissa, L.; Aguiar, A.P.D. Combining regional to local restoration goals in the Brazilian Atlantic forest. Reg. Environ. Chang. 2021, 21, 68. [Google Scholar] [CrossRef]

- Pukkala, T. Optimizing continuous cover management of boreal forest when timber prices and tree growth are stochastic. For. Ecosyst. 2015, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; de Gonçalves, J.L.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Rogozhin, A.; Gallaher, M.; Helfand, G.; McManus, W. Using indirect cost multipliers to estimate the total cost of adding new technology in the automobile industry. Int. J. Prod. Econ. 2010, 124, 360–368. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Kizha, A.R.; Mani, S. Economic analysis of forest residues supply chain options to produce enhanced-quality feedstocks. Biofuels Bioprod. Biorefining 2019, 13, 514–534. [Google Scholar] [CrossRef]

- Cuthbert, J.R. Partitioning transaction vectors into pure investments. Eng. Econ. 2018, 63, 143–152. [Google Scholar] [CrossRef]

- Detemple, J.; Kitapbayev, Y. The Value of Green Energy: Optimal Investment in Mutually Exclusive Projects and Operating Leverage. Rev. Financ. Stud. 2020, 33, 3307–3347. [Google Scholar] [CrossRef]

- Rodas, J.M.C.; Castanho, R.A.; Fernández, J.C.; Gómez, J.M.N. Sustainable valuation of land for development. Adding value with urban planning progress. A Spanish case study. Land Use Policy 2020, 92, 104456. [Google Scholar] [CrossRef]

- Perold, A.F. The Capital Asset Pricing Model. J. Econ. Perspect. 2004, 18, 3–24. [Google Scholar] [CrossRef]

- Dachraoui, H.; Smida, M.; Sebri, M. Role of capital flight as a driver of sovereign bond spreads in Latin American countries. Int. Econ. 2020, 162, 15–33. [Google Scholar] [CrossRef]

- Department of the Treasury T-Bonds. Available online: https://www.treasury.gov/resource-center/data-chart-center/interest-rates/Pages/TextView.aspx?data=yieldAll (accessed on 20 July 2020).

- Bolsa do Brasil. Cotações Históricas. Available online: http://www.b3.com.br/pt_br/market-data-e-indices/servicos-de-dados/market-data/historico/mercado-a-vista/cotacoes-historicas (accessed on 19 July 2020).

- S&P Down Jones S&P Global Timber & Forestry Index. Available online: https://www.spglobal.com/spdji/en/indices/equity/sp-global-timber-and-forestry-index/#overview (accessed on 20 July 2020).

- J.P Morgan Emerging Markets Bond Index + Risco Brasil (EMBI + RB). Available online: https://www.jpmorgan.com.br/pt/disclosures (accessed on 20 January 2021).

- Damodaran, A. Country Default Spreads and Risk Premiums. Available online: http://pages.stern.nyu.edu/~adamodar/New_Home_Page/datafile/ctryprem.html (accessed on 28 January 2021).

- Moody’s Rating Country Default Spreads. Available online: https://www.moodys.com/credit-ratings/Brazil-Government-of-credit-rating-114650 (accessed on 20 January 2021).

- Schwarz, G. Estimating the Dimension of a Model. Ann. Stat. 1978, 6, 461–464. [Google Scholar] [CrossRef]

- Ronquist, F.; Teslenko, M.; van der Mark, P.; Ayres, D.L.; Darling, A.; Höhna, S.; Larget, B.; Liu, L.; Suchard, M.A.; Huelsenbeck, J.P. MrBayes 3.2: Efficient Bayesian phylogenetic inference and model choice across a large model space. Syst. Biol. 2012, 61, 539–542. [Google Scholar] [CrossRef] [Green Version]

- Palisade Corporation @Risk Versão 8.0 Ithaca. Available online: https://www.palisade-br.com (accessed on 15 May 2020).

- Matsumoto, M.; Nishimura, T. Mersenne twister: A 623-dimensionally equidistributed uniform pseudo-random number generator. ACM Trans. Model. Comput. Simul. 1998, 8, 3–30. [Google Scholar] [CrossRef] [Green Version]

- Croux, C.; Dehon, C. Influence functions of the Spearman and Kendall correlation measures. Stat. Methods Appl. 2010, 19, 497–515. [Google Scholar] [CrossRef] [Green Version]

- Dellinger, J.B. Correlation, Spearman. In The Sage Encyclopedia of Communication Research Methods; Allen, M., Ed.; Sage Publications: Thousand Oaks, CA, USA, 2017; pp. 273–275. [Google Scholar]

- Sun, Q.; Dumroese, R.K.; Liu, Y. Container volume and subirrigation schedule influence Quercus variabilis seedling growth and nutrient status in the nursery and field. Scand. J. For. Res. 2018, 33, 560–567. [Google Scholar] [CrossRef]

- Hüller, A.; Coelho, G.C.; Meneghello, G.E.; Peske, S.T. Evaluation of direct seeding and seedling planting of two neotropical tree species with the use of natural inputs. Rev. Árvore 2017, 41. [Google Scholar] [CrossRef] [Green Version]

- Raupp, P.P.; Ferreira, M.C.; Alves, M.; Campos-Filho, E.M.; Sartorelli, P.A.R.; Consolaro, H.N.; Vieira, D.L.M. Direct seeding reduces the costs of tree planting for forest and savanna restoration. Ecol. Eng. 2020, 148, 105788. [Google Scholar] [CrossRef]

- Li, Y.M.; Gornish, E.S. General attributes and practice of ecological restoration in Arizona and California, U.S.A., revealed by restoration stakeholder surveys. Restor. Ecol. 2020, 28, 1296–1307. [Google Scholar] [CrossRef]

- Pérez, D.R.; González, F.; Ceballos, C.; Oneto, M.E.; Aronson, J. Direct seeding and outplantings in drylands of Argentinean Patagonia: Estimated costs, and prospects for large-scale restoration and rehabilitation. Restor. Ecol. 2019, 27, 1105–1116. [Google Scholar] [CrossRef]

- Muriuki, J.K.; Kuria, A.W.; Muthuri, C.W.; Mukuralinda, A.; Simons, A.J.; Jamnadass, R.H. Testing Biodegradable Seedling Containers as an Alternative for Polythene Tubes in Tropical Small-Scale Tree Nurseries. Small-Scale For. 2014, 13, 127–142. [Google Scholar] [CrossRef]

- Stanturf, J.A. Forest landscape restoration: Building on the past for future success. Restor. Ecol. 2021, 29, e13349. [Google Scholar] [CrossRef]

- Verdone, M.; Seidl, A. Time, space, place, and the Bonn Challenge global forest restoration target. Restor. Ecol. 2017, 25, 903–911. [Google Scholar] [CrossRef]

- Taleghani, S.T.; Sorin, M.; Gaboury, S. Thermo-economic analysis of heat-driven ejector system for cooling smelting process exhaust gas. Energy 2021, 220, 119661. [Google Scholar] [CrossRef]

- Miyajima, R.H.; Tonin, R.P.; Fenner, P.T.; Simões, D. Análise quantitativa do risco técnico-econômico de um trator florestal skidder. BIOFIX Sci. J. 2017, 2, 12–15. [Google Scholar] [CrossRef] [Green Version]

- Grossnickle, S.C. Why seedlings survive: Influence of plant attributes. New For. 2012, 43, 711–738. [Google Scholar] [CrossRef]

- Stowe, D.C.; Lamhamedi, M.S.; Carles, S.; Fecteau, B.; Margolis, H.A.; Renaud, M.; Bernier, P.Y. Managing irrigation to reduce nutrient leaching in containerized white spruce seedling production. New For. 2010, 40, 185–204. [Google Scholar] [CrossRef]

| Species | Average Height (±Standard Deviation; cm) | ||

|---|---|---|---|

| Polyethylene Bag | Polyethylene Tube | Ellepot® | |

| Citharexylum myrianthum Cham. | 37.4 ± 3.3 | 27.7 ± 2.9 | 26.3 ± 2.1 |

| Copaifera langsdorffii Desf. | 69.2 ± 5.8 | 19.3 ± 1.5 | 18.0 ± 3.0 |

| Enterolobium contortisiliquum (Vell.) Morong | 55.6 ± 5.6 | 17.3 ± 1.2 | 18.5 ± 3.8 |

| Eugenia brasiliensis Lam. | 34.5 ± 2.3 | 9.6 ± 0.6 | 22.0 ± 2.8 |

| Genipa americana L. | 22.0 ± 3.2 | 22.4 ± 1.6 | 16.7 ± 2.4 |

| Guazuma ulmifolia Lam. | 41.3 ± 2.6 | 28.4 ± 1.0 | 33.7 ± 4.2 |

| Heliocarpus popayanensis Kunth | 44.5 ± 5.3 | 12.7 ± 3.8 | 14.0 ± 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, D.; Gil, J.F.S.; da Silva, R.B.G.; Munis, R.A.; da Silva, M.R. Stochastic Economic Analysis of Investment Projects in Forest Restoration Involving Containerized Tree Seedlings in Brazil. Forests 2021, 12, 1381. https://doi.org/10.3390/f12101381

Simões D, Gil JFS, da Silva RBG, Munis RA, da Silva MR. Stochastic Economic Analysis of Investment Projects in Forest Restoration Involving Containerized Tree Seedlings in Brazil. Forests. 2021; 12(10):1381. https://doi.org/10.3390/f12101381

Chicago/Turabian StyleSimões, Danilo, Jean Fernando Silva Gil, Richardson Barbosa Gomes da Silva, Rafaele Almeida Munis, and Magali Ribeiro da Silva. 2021. "Stochastic Economic Analysis of Investment Projects in Forest Restoration Involving Containerized Tree Seedlings in Brazil" Forests 12, no. 10: 1381. https://doi.org/10.3390/f12101381