Surface Detection of Solid Wood Defects Based on SSD Improved with ResNet

Abstract

:1. Introduction

2. Materials and Methods

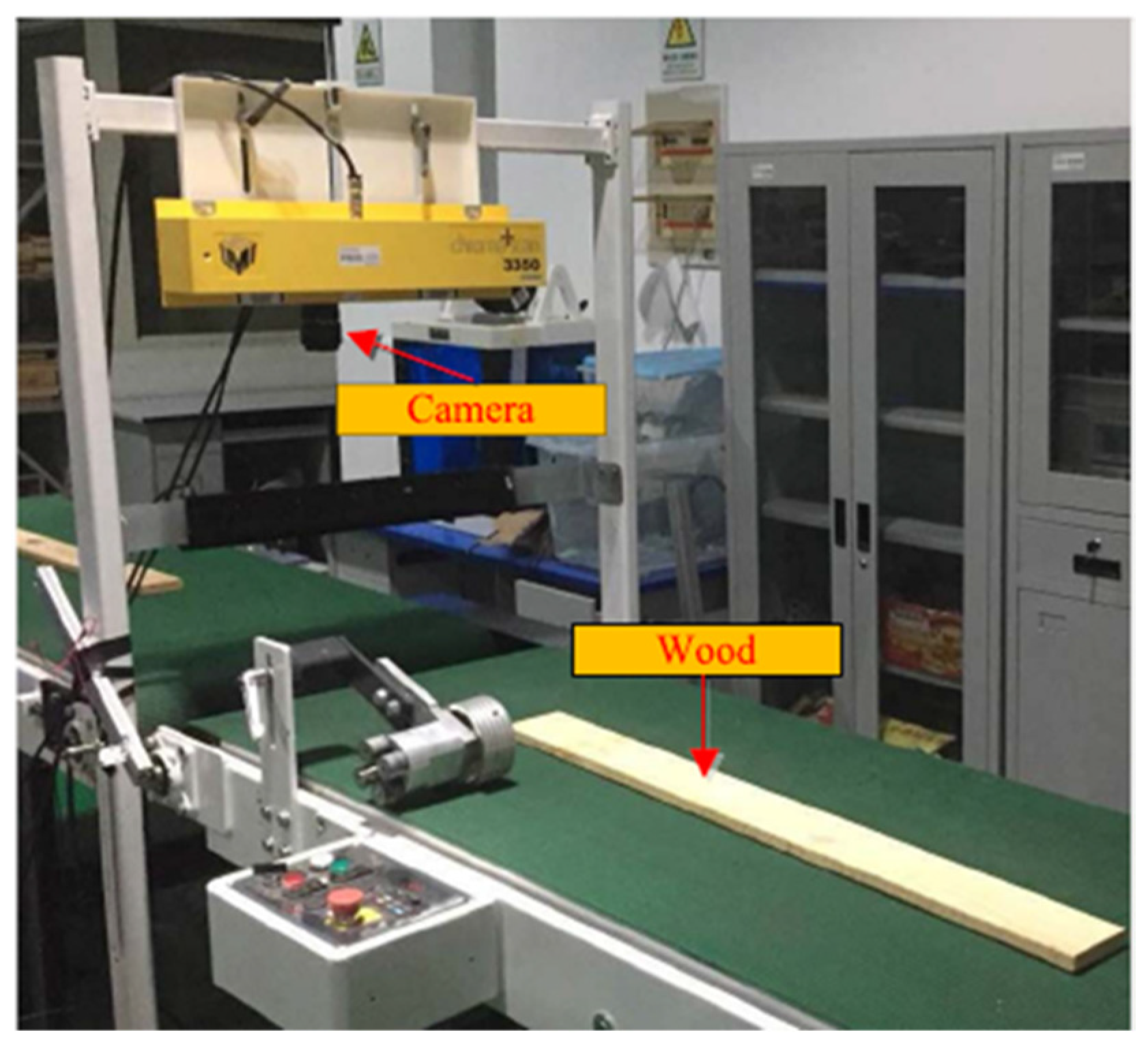

2.1. Image Acquisition and Environment Configuration

2.2. Establishment of Database

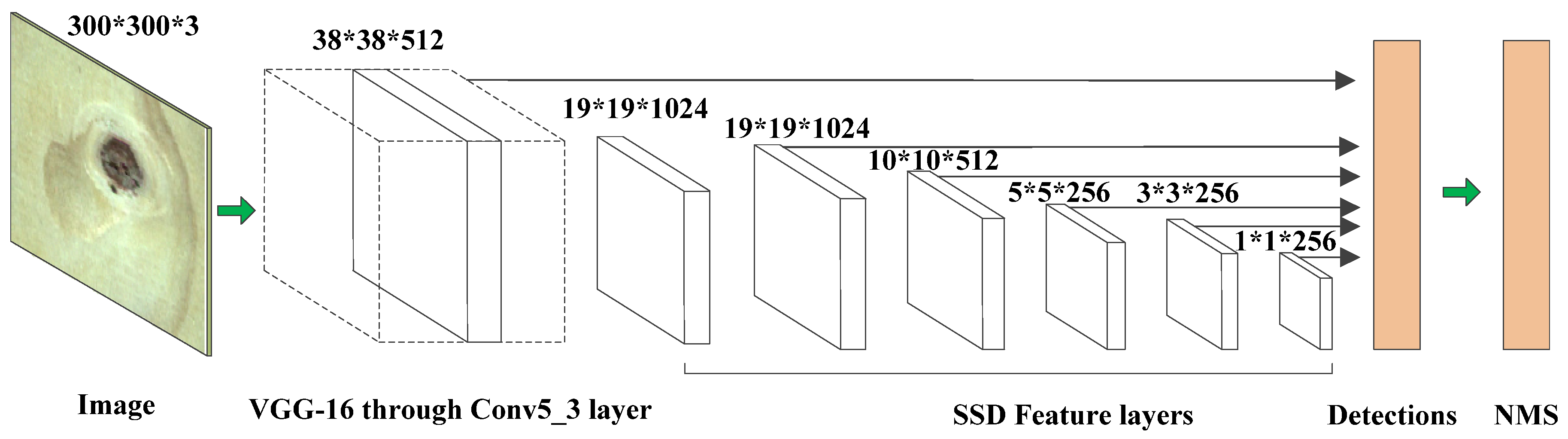

2.3. SSD Model

2.4. General Procedure of SSD Algorithm

2.5. Loss Function

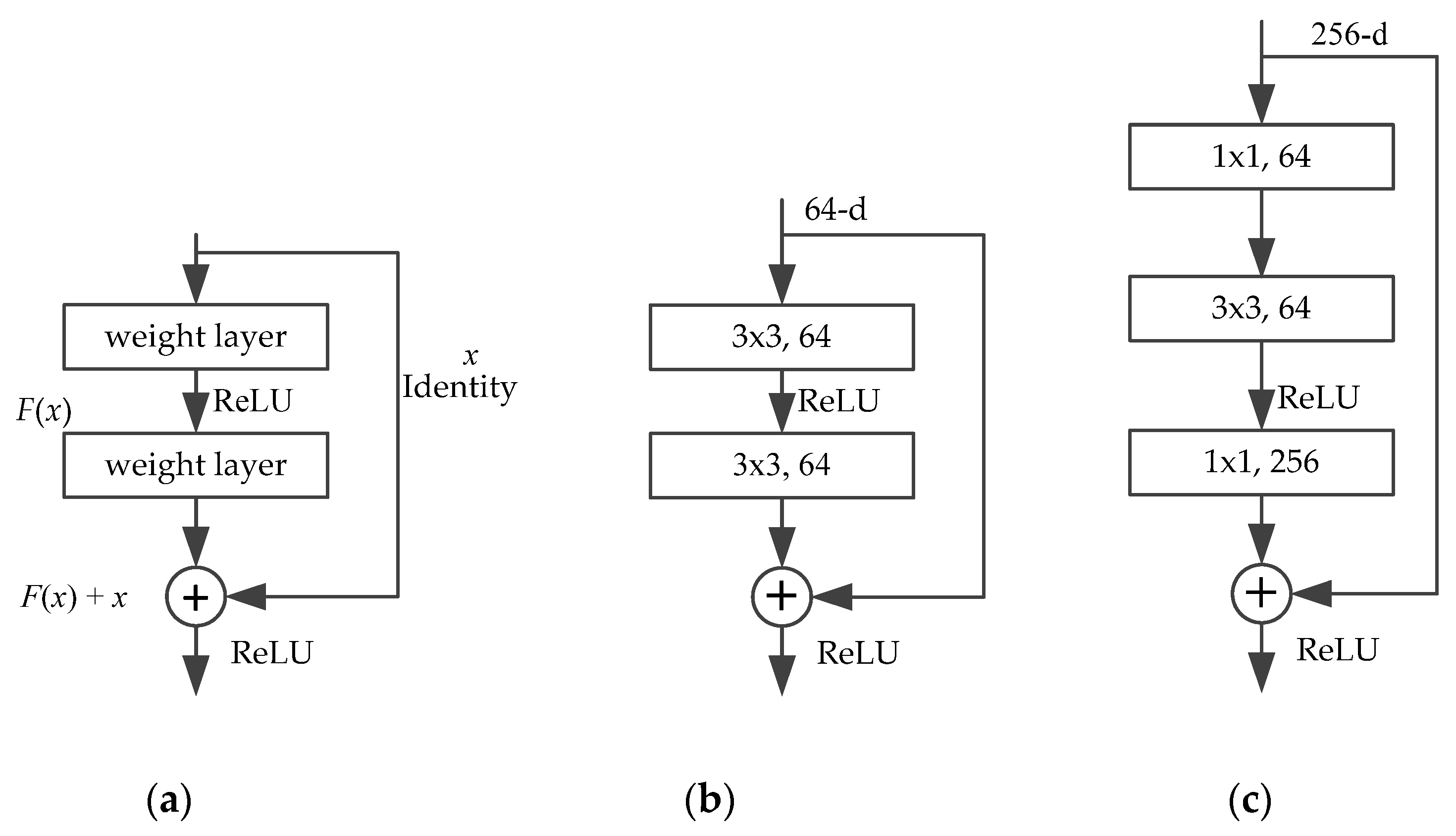

2.6. Deep Residual Network

3. Results

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, T.; Liu, Y.; Xu, C.Y.; Zhou, X.L.; Hu, Z.K.; Fan, J.N. A Fully Convolutional Neural Network for Wood Defect Location and Identification. IEEE Access 2019, 7, 123453–123462. [Google Scholar] [CrossRef]

- He, T.; Liu, Y.; Yu, Y.B.; Zhao, Q.; Hu, Z.K. Application of deep convolutional neural network on feature extraction and detection of wood defects. Measurement 2020, 152, 107357. [Google Scholar] [CrossRef]

- Shi, J.H.; Li, Z.Y.; Zhu, T.T.; Wang, D.Y.; Ni, C. Defect Detection of Industry Wood Veneer Based on NAS and Multi-Channel Mask R-CNN. Sensors 2020, 20, 4398. [Google Scholar] [CrossRef] [PubMed]

- Sandak, J.; Orlowski, K.A.; Sandak, A.; Chuchala, D.; Taube, P. On-Line Measurement of Wood Surface Smoothness. Drv. Ind. Znan. Čas. Pitanja Drv. Tehnol. 2020, 71, 193–200. [Google Scholar] [CrossRef]

- Tondon, A.; Singh, M.; Sandhu, B.S.; Singh, B. Importance of Voxel Size in Defect Localization Using Gamma-Ray Scattering. Nucl. Sci. Eng. 2019, 193, 1265–1275. [Google Scholar] [CrossRef]

- Li, S.L.; Li, D.J.; Yuan, W.Q. Wood Defect Classification Based on Two-Dimensional Histogram Constituted by LBP and Local Binary Differential Excitation Pattern. IEEE Access 2019, 7, 145829–145842. [Google Scholar] [CrossRef]

- Ji, X.; Guo, H.; Hu, M. Features Extraction and Classification of Wood Defect Based on Hu Invariant Moment and Wavelet Moment and BP Neural Network. In Proceedings of the 12th International Symposium on Visual Information Communication and Interaction, New York, NY, USA, 20–22 September 2019. [Google Scholar]

- Bandara, S.; Rajeev, P.; Gad, E.; Sriskantharajah, B.; Flatley, I. Damage detection of in service timber poles using Hilbert-Huang transform. NDT E Int. 2019, 107, 15. [Google Scholar] [CrossRef]

- Li, B.; Wu, Y.; Guo, F.X.; Qi, J. Real-Time Detection Method for Surface Defects of Stamping Parts Based on Template Matching. In Proceedings of the 2018 4th International Conference on Environmental Science and Material Application, Xi’an, China, 15–16 December 2018; Iop Publishing Ltd.: Bristol, UK, 2019; Volume 252. [Google Scholar]

- Ruz, G.; Estevez, P.; Perez, C. A Neurofuzzy Color Image Segmentation Method for Wood Surface Defect Detection. For. Prod. J. 2005, 55, 52–58. [Google Scholar]

- Li, C.; Zhang, Y.Z.; Tu, W.J.; Jun, C.; Liang, H.; Yu, H.L. Soft measurement of wood defects based on LDA feature fusion and compressed sensor images. J. For. Res. 2017, 28, 1285–1292. [Google Scholar] [CrossRef]

- Gao, M.; Qi, D.; Mu, H.; Chen, J. A Transfer Residual Neural Network Based on ResNet-34 for Detection of Wood Knot Defects. Forests 2021, 12, 212. [Google Scholar] [CrossRef]

- Tu, Y.X.; Ling, Z.G.; Guo, S.Y.; Wen, H. An Accurate and Real-Time Surface Defects Detection Method for Sawn Lumber. IEEE Trans. Instrum. Meas. 2021, 70, 11. [Google Scholar] [CrossRef]

- Urbonas, A.; Raudonis, V.; Maskeliunas, R.; Damasevicius, R. Automated Identification of Wood Veneer Surface Defects Using Faster Region-Based Convolutional Neural Network with Data Augmentation and Transfer Learning. Appl. Sci. 2019, 9, 4898. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.Z.; Xu, C.; Li, C.; Yu, H.L.; Cao, J. Wood defect detection method with PCA feature fusion and compressed sensing. J. For. Res. 2015, 26, 745–751. [Google Scholar] [CrossRef]

- Xie, Y.H.; Wang, J.C. Study on the identification of the wood surface defects based on texture features. Optik 2015, 126, 2231–2235. [Google Scholar]

- Peng, Z.; Yue, L.; Xiao, N. Simultaneous Wood Defect and Species Detection with 3D Laser Scanning Scheme. Int. J. Opt. 2016, 2016, 7049523. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Wang, P.J.A. Extraction and Detection of Surface Defects in Particleboards by Tracking Moving Targets. Algorithms 2018, 12, 6. [Google Scholar] [CrossRef] [Green Version]

- Pahlberg, T.; Thurley, M.; Popovic, D.; Hagman, O. Crack detection in oak flooring lamellae using ultrasound-excited thermography. Infrared Phys. Technol. 2018, 88, 57–69. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Zheng, X.; Yao, J.; Xiao, J.; Yan, L. 3D Surface Defects Recognition of Lumber and Straw-Based Panels Based on Structure Laser Sensor Scanning Technology. INMATEH-Agric. Eng. 2019, 57, 225–232. [Google Scholar]

- Badrinarayanan, V.; Kendall, A.; Cipolla, R. SegNet: A Deep Convolutional Encoder-Decoder Architecture for Image Segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 2481–2495. [Google Scholar] [CrossRef]

- Guo, X.P.; Nie, R.C.; Cao, J.D.; Zhou, D.M.; Qian, W.H. Fully Convolutional Network-Based Multifocus Image Fusion. Neural Comput. 2018, 30, 1775–1800. [Google Scholar] [CrossRef]

- Nian, R.; He, B.; Lendasse, A. 3D object recognition based on a geometrical topology model and extreme learning machine. Neural Comput. Appl. 2013, 22, 427–433. [Google Scholar] [CrossRef]

- Huang, G.B.J.C.C. What are Extreme Learning Machines? Filling the Gap between Frank Rosenblatt’s Dream and John von Neumann’s Puzzle. Cogn. Comput. 2015, 7, 263–278. [Google Scholar] [CrossRef]

- Chau, V.H.; Vo, A.T.; Le, B.T. A Gravitational-Double Layer Extreme Learning Machine and Its Application in Powerlifting Analysis. IEEE Access 2019, 7, 143990–143998. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C.J.S. SSD: Single Shot MultiBox Detector. In Proceedings of the Computer Vision—ECCV 2016, 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Simonyan, K.; Zisserman, A.J.C.S. Very Deep Convolutional Networks for Large-Scale Image Recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- Jia, S.; Deng, L.; Shen, L.L. An Effective Collaborative Representation Algorithm for Hyperspectral Image Classification. In Proceedings of the 2014 IEEE International Conference on Multimedia and Expo (ICME), Chengdu, China, 14–18 July 2014. [Google Scholar]

- He, K.M.; Zhang, X.Y.; Ren, S.Q.; Sun, J. Identity Mappings in Deep Residual Networks. In Proceedings of the Computer Vision—ECCV 2016, 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Springer: Cham, Switzerland, 2016; Volume 9908, pp. 630–645. [Google Scholar]

| Hardware and Software | Name |

|---|---|

| System | Windows 10 |

| CPU | Intel Xeon W-2155@3.30 GHz |

| Main panel | Dell 0X8DXD Core i7 |

| Graphics card | Nvidia GeForce GTX 1080 Ti |

| Environment language | Python3.6/C++ |

| Environment configuration | PyCharm + Visual Studio 2015 |

| Deep learning framework | TensorFlow1.8.0 |

| Wood Defect | ResNet + SSD Algorithm | SSD Algorithm | ||

|---|---|---|---|---|

| Accuracy of Training Set | Accuracy of Test Set | Accuracy of Training Set | Accuracy of Test Set | |

| Live knot | 0.984 | 0.970 | 0.962 | 0.917 |

| Dead knot | 0.962 | 0.924 | 0.936 | 0.884 |

| Decay | 0.922 | 0.875 | 0.884 | 0.804 |

| Mildew | 0.912 | 0.860 | 0.801 | 0.700 |

| Crackle | 0.992 | 0.967 | 0.995 | 0.956 |

| Pinhole | 0.838 | 0.786 | 0.625 | 0.455 |

| Average accuracy | 0.935 | 0.897 | 0.867 | 0.786 |

| Average detection time | 90 ms | 116 ms | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Wang, H.; Jiang, D.; Hu, Z. Surface Detection of Solid Wood Defects Based on SSD Improved with ResNet. Forests 2021, 12, 1419. https://doi.org/10.3390/f12101419

Yang Y, Wang H, Jiang D, Hu Z. Surface Detection of Solid Wood Defects Based on SSD Improved with ResNet. Forests. 2021; 12(10):1419. https://doi.org/10.3390/f12101419

Chicago/Turabian StyleYang, Yutu, Honghong Wang, Dong Jiang, and Zhongkang Hu. 2021. "Surface Detection of Solid Wood Defects Based on SSD Improved with ResNet" Forests 12, no. 10: 1419. https://doi.org/10.3390/f12101419

APA StyleYang, Y., Wang, H., Jiang, D., & Hu, Z. (2021). Surface Detection of Solid Wood Defects Based on SSD Improved with ResNet. Forests, 12(10), 1419. https://doi.org/10.3390/f12101419