Environmental Impact of a Mass Timber Building—A Case Study

Abstract

:1. Introduction

2. Materials and Methods

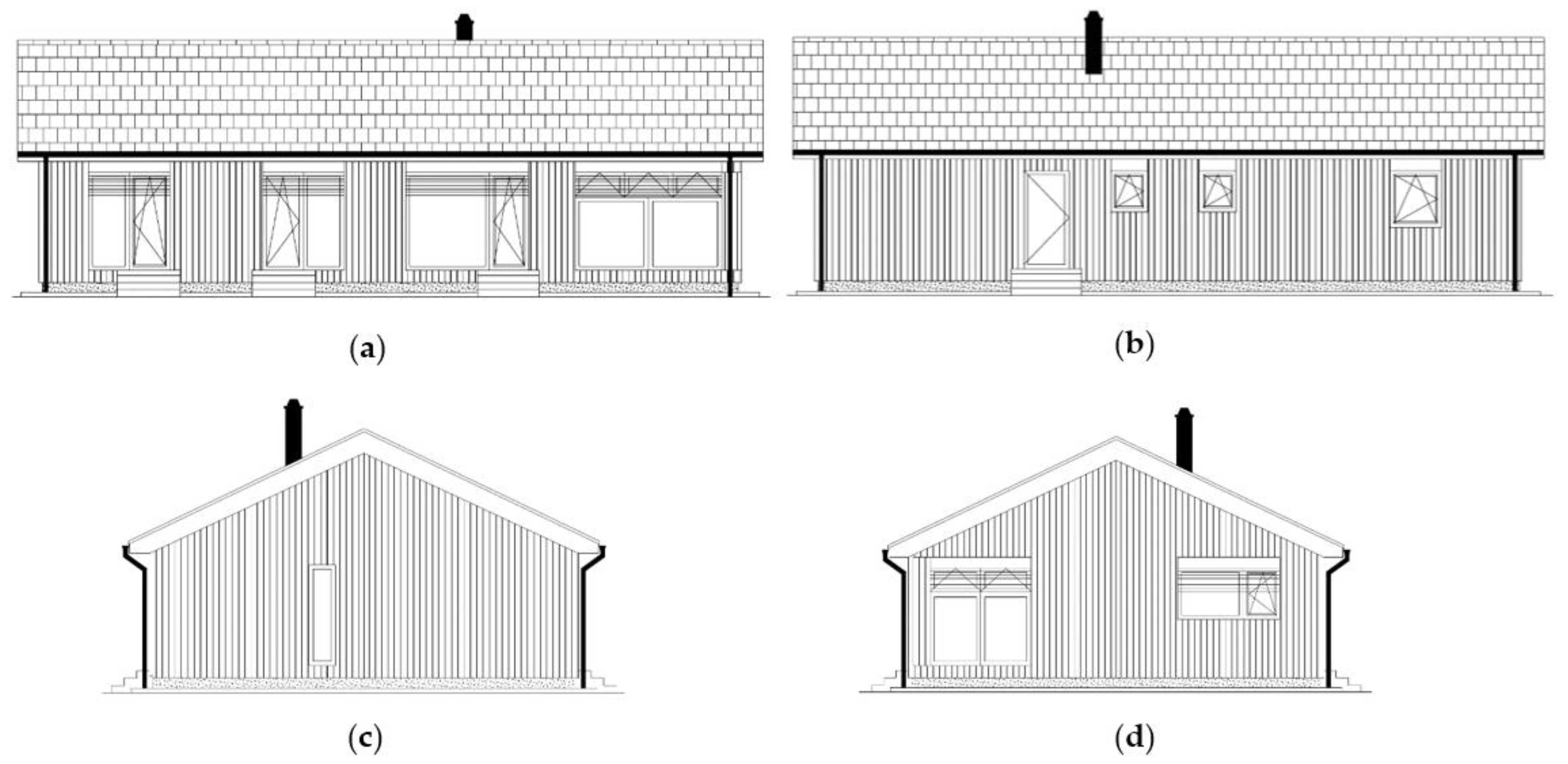

2.1. Reference Unit and System Boundaries Description

2.2. Data Quality Statements

3. Results

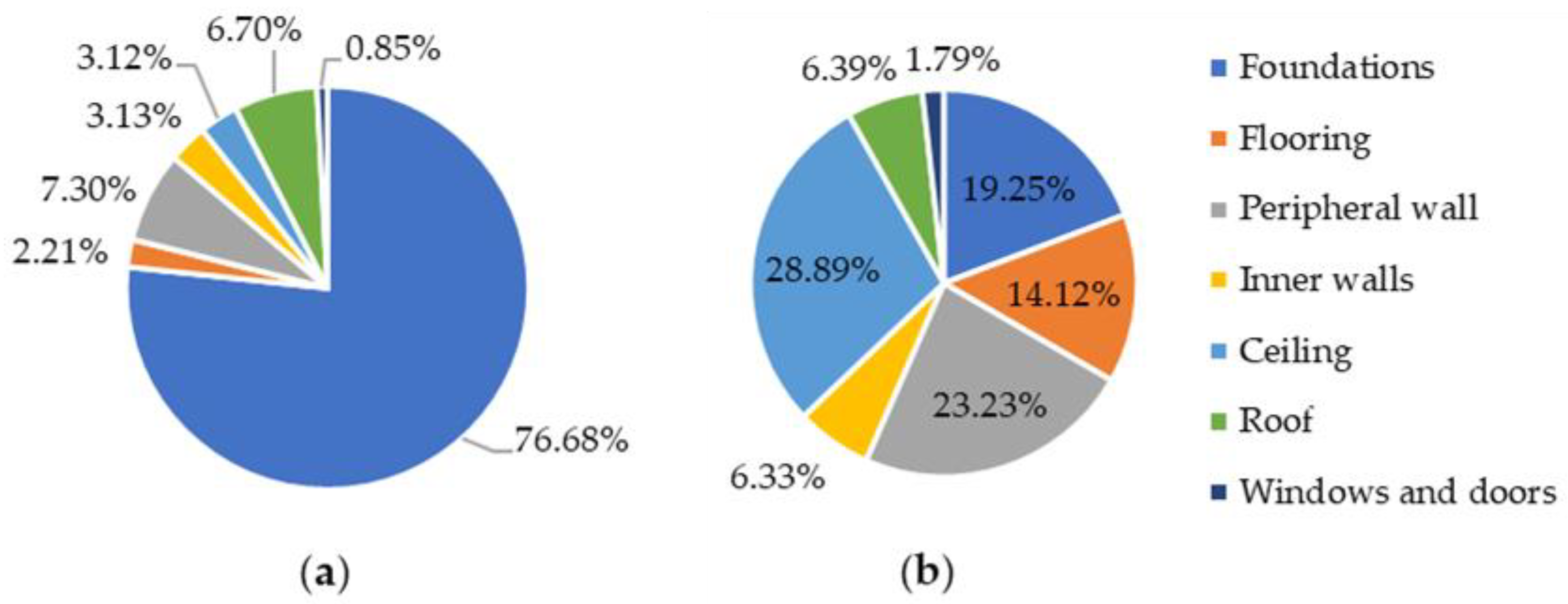

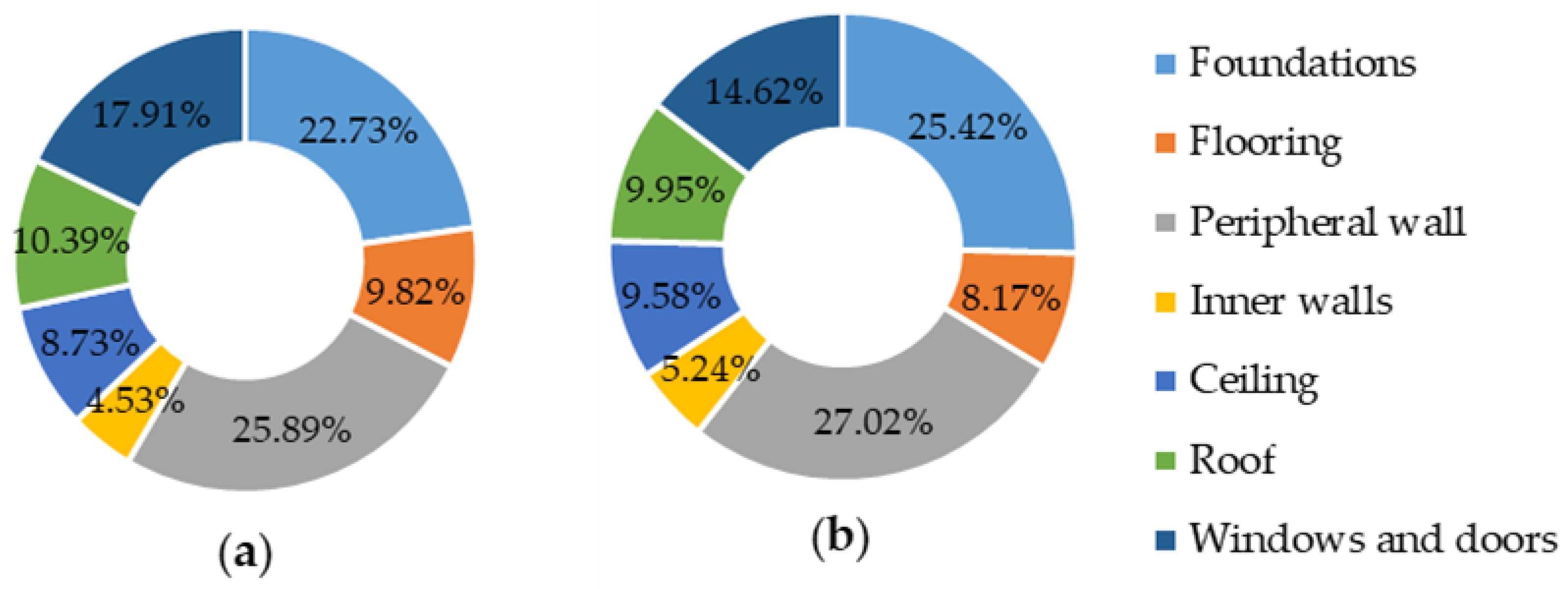

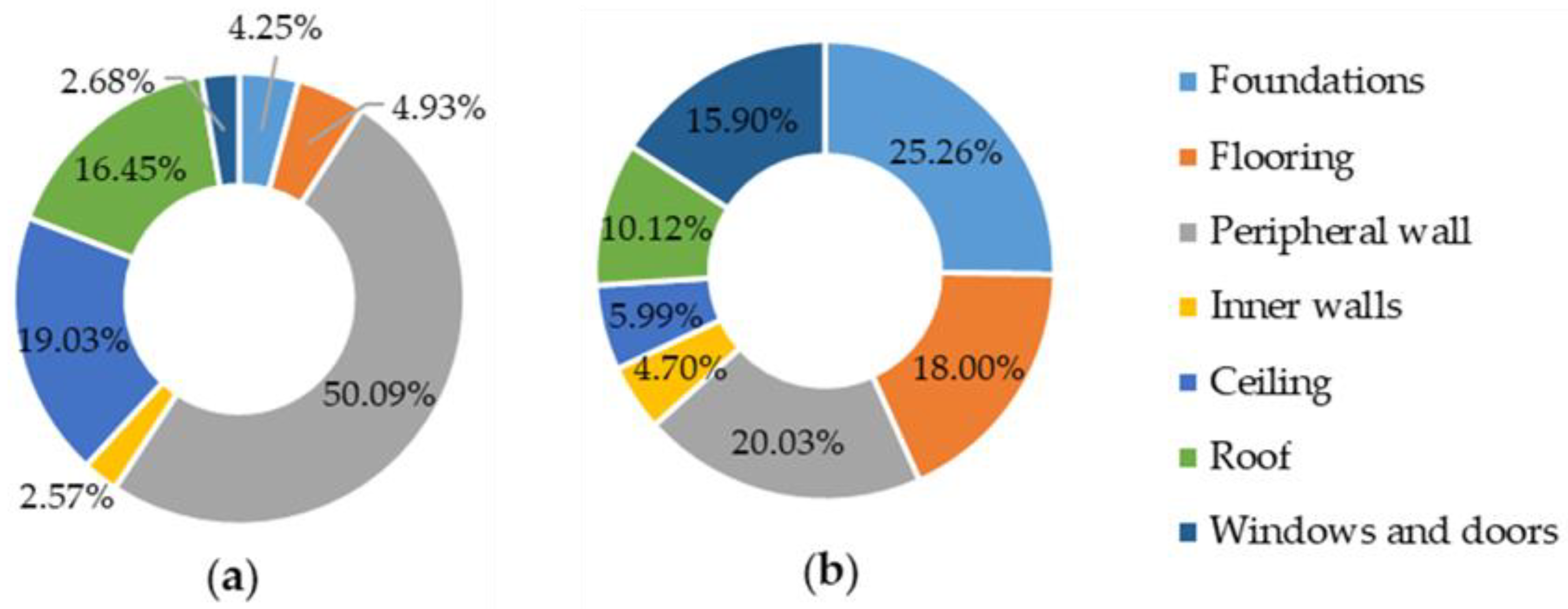

3.1. Weight and Volume Distribution

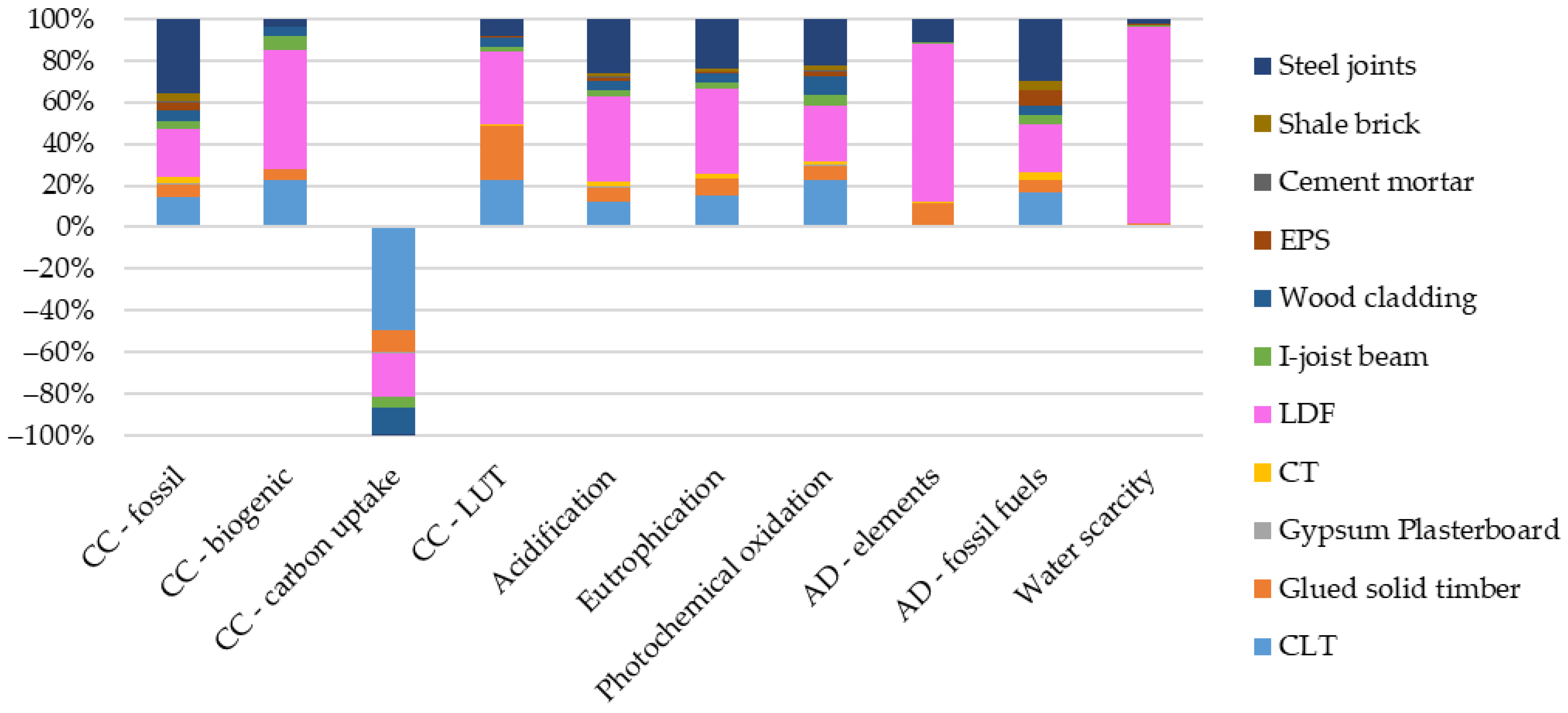

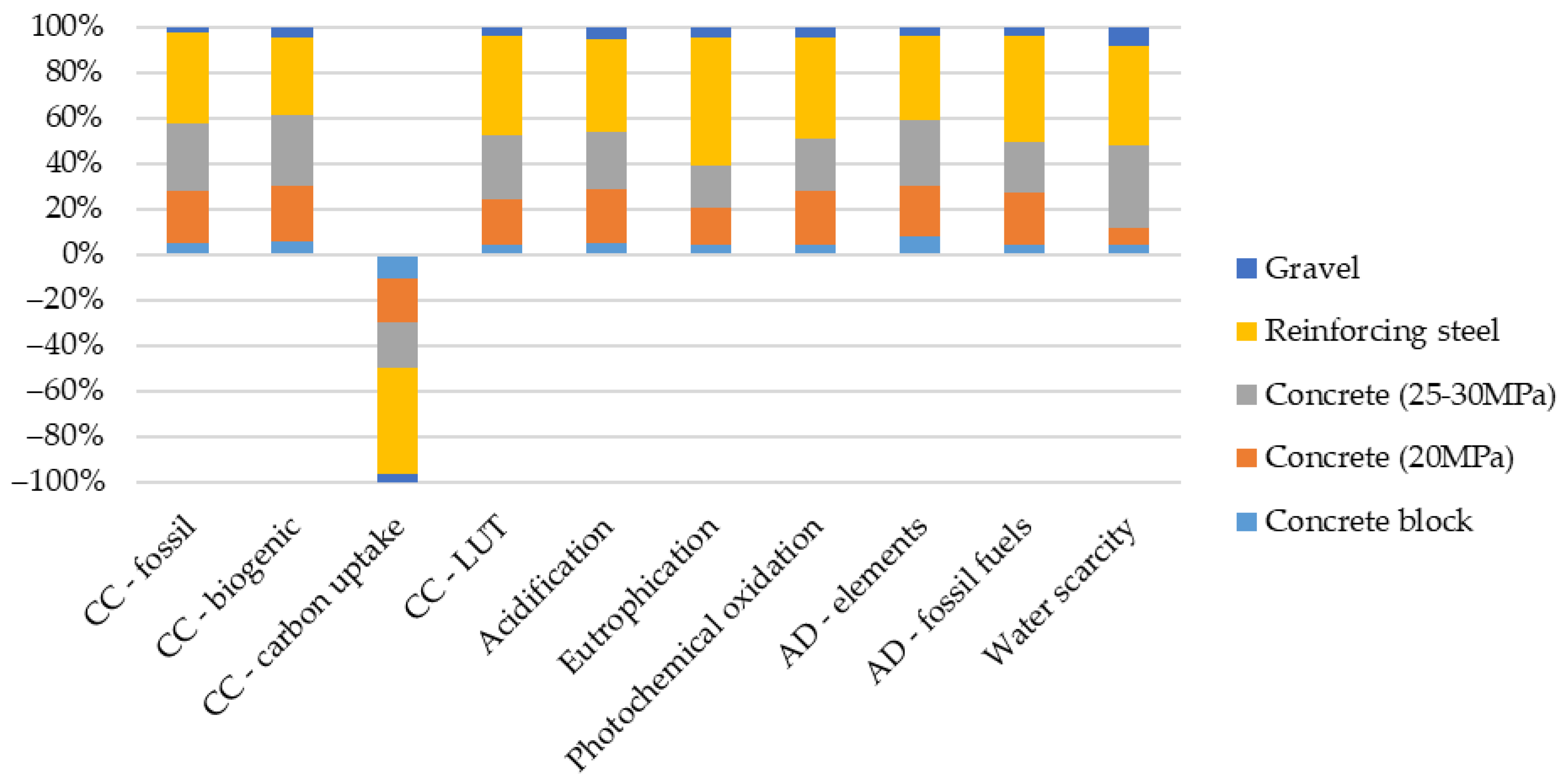

3.2. Holistic Life Cycle Impact Assessment

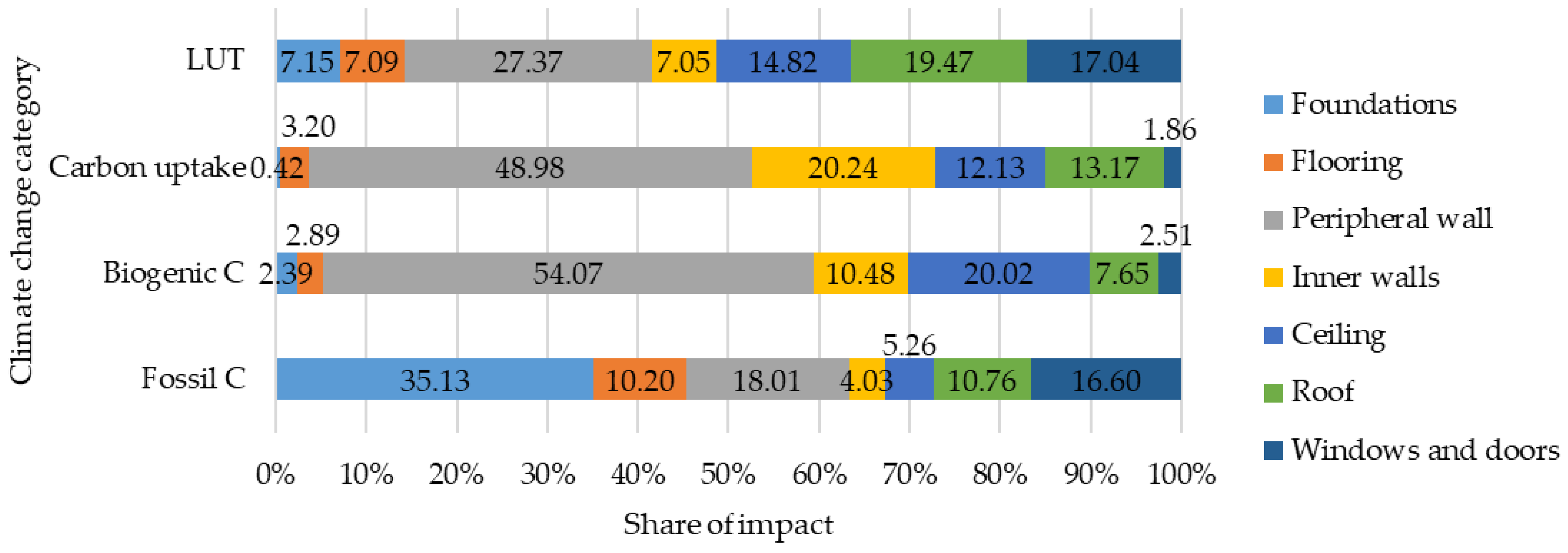

3.2.1. Impact on Climate Change

3.2.2. Impact on Acidification and Eutrophication

3.2.3. Impact on Photochemical Oxidation

3.2.4. Impact on Water Scarcity

3.2.5. Impact on Abiotic Depletion

3.2.6. Specification of the Most and the Least Contributing Construction Components

3.3. Sensitivity Analysis

4. Discussion

5. Conclusions

- The majority of the overall construction weight was located in foundations accounting for 76.68%. CLT panels constituted only 4.62% of the total construction weight. The biggest component by volume represented ceiling (28.89%) due to rather large ceiling thickness due to the insulation layer of 400 mm followed by the peripheral wall (23.23%) with the relatively large openings for windows and entrance door.

- Foundations and peripheral wall were identified as the worst components of the construction in terms of several impact categories. The impact contribution of foundations was mainly caused by concrete and reinforcing steel. LDF was marked as the main environmental impact contributor of the peripheral wall component causing the majority of the impact on the depletion of elements and water scarcity.

- The considered construction composition carbon balance was 57.08 kg CO2 eq/m2 of GIA. Sensitivity analysis showed that substitution of CLT by MHM panel led to carbon-negative embodied emissions of the construction (−38.82 kg CO2 eq/m2 of GIA).

- CLT panels were found to be one of the least negative impact contributing construction material. On the other hand, the study showed LDF to contribute the most to the environmental impact of the construction. Moreover, a properly chosen composition of construction materials might result in carbon negative embodied emissions of a building as it was in the case of MHM panels. Future studies might be focused on the application of bark-based panel insulation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Framework Convention on Climate Change, The Paris Agreement. 2015. Available online: https://unfccc.int/files/essential_background/convention/application/pdf/english_paris_agreement.pdf (accessed on 22 October 2021).

- European Commission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 22 October 2021).

- World Green Building Council. Bringing Embodied Carbon Upfront. 2019. Available online: https://www.worldgbc.org/sites/default/files/WorldGBC_Bringing_Embodied_Carbon_Upfront.pdf (accessed on 21 October 2021).

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- American Wood Council. National Design Specification (NDS) for Wood Construction, 2017. ANSI/AWC NDS-2017; American Wood Council: Leesburg, VA, USA, 2017; Available online: https://www.awc.org/pdf/codes-standards/publications/nds/AWC-NDS2018-ViewOnly-171117.pdf (accessed on 20 October 2021).

- Gagnon, S.; Bilek, E.M.; Podesto, L.; Crespell, P. Chapter 1: CLT Introduction to cross-laminated timber. In CLT Handbook: Cross-Laminated Timber; Karacabeyli, E., Brad, D., Eds.; FPInnovations: Pointe-Claire, QC, Canada, 2013; pp. 1–45. Available online: https://www.fpl.fs.fed.us/documnts/pdf2013/fpl_2013_gagnon001.pdf (accessed on 20 October 2021).

- Santi, S.; Pierobon, F.; Corradini, G.; Cavalli, R.; Zanetti, M. Massive wood material for sustainable building design: The Massiv–Holz–Mauer wall system. J. Wood Sci. 2016, 62, 416–428. [Google Scholar] [CrossRef] [Green Version]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA-based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- ISO. EN ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. EN ISO 14044:2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. EN 15978:2011 Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- ISO. ISO 21931-1:2010 Sustainability in Building Construction—Framework for Methods of Assessment of the Environmental Performance of Construction Works—Part 1: Buildings; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A Comparative Cradle-to-Gate Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.-S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef] [Green Version]

- Environmental Product Declaration. CLT (Cross Laminated Timber). The Norwegian EPD Foundation. 2020. Available online: https://www.epd-norge.no/getfile.php/1316508-1607949248/EPDer/Byggevarer/Heltreprodukter/NEPD-2587-1314_CLT--Cross-Laminated-Timber-.pdf (accessed on 20 October 2021).

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life-Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Consortium for Research on Renewable Industrial Materials. CORRIM REPORT—Life Cycle Assessment of Cross Laminated Timbers Produced in Oregon. 2018. Available online: https://corrim.org/wp-content/uploads/2019/02/Life-Cycle-Assessment-of-Oregon-Cross-Laminated-Timber.pdf (accessed on 20 October 2021).

- Balasbaneh, A.T.; Sher, W. Comparative sustainability evaluation of two engineered wood-based construction materials: Life cycle analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- Leskovar, V.Ž.; Žigart, M.; Premrov, M.; Lukman, R.K. Comparative assessment of shape-related cross-laminated timber building typologies focusing on environmental performance. J. Clean. Prod. 2019, 216, 482–494. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Inardex, Ltd. Available online: https://inardex.sk/rodinne-domy/katalog/prizemne-domy-podorysy/001-s/001-s-magnolia/ (accessed on 13 September 2021).

- STN 73 0540-2+Z1+Z2 (2019). Thermal Protection of Buildings. In Thermal Performance of Buildings and Components—Part 2: Functional Requirements; Slovak Technical Standards: Bratislava, Slovakia, 2012.

- EN 15804+A1 (2013). Sustainability of Construction Works. In Environmental Product Declarations. Core Rules for the Product Category of Construction Products; European Committee for Standardization: Bruxelles, Belgium, 2012.

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro; PRé Consultants: Amersfoort, The Netherlands, 2013; p. 80. Available online: https://www.pre-sustainability.com/download/SimaPro8IntroductionToLCA.pdf (accessed on 7 July 2021).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- IPCC Climate Change 2013: The Physical Science Basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. (Eds.) Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; p. 1535. Available online: https://www.ipcc.ch/site/assets/uploads/2018/02/WG1AR5_all_final.pdf (accessed on 10 November 2021).

- PRé Consultants. SimaPro Database Manual—Methods Library; PRé Consultants: Amersfoort, The Netherlands, 2021; p. 98. Available online: https://simapro.com/wp-content/uploads/2021/07/DatabaseManualMethods920.pdf (accessed on 10 November 2021).

- Cabeza, L.F.; Boquera, L.; Chàfer, M.; Vérez, D. Embodied energy and embodied carbon of structural building materials: Worldwide progress and barriers through literature map analysis. Energy Build. 2021, 231, 110612. [Google Scholar] [CrossRef]

- Ondová, M.; Eštoková, A.; Fabianová, M. Reducing the carbon footprint in the foundations structures of masonry family houses. Sel. Sci. Pap. J. Civil. Eng. 2020, 15, 55–62. [Google Scholar] [CrossRef]

- Vanova, R.; Vlcko, M.; Stefko, J. Life Cycle Impact Assessment of Load-Bearing Straw Bale Residential Building. Materials 2021, 14, 3064. [Google Scholar] [CrossRef] [PubMed]

- Ata-Ali, N.; Penandés-Plà, V.; Martínez-Muñoz, D.; Yepes, V. Recycled versus non-recycled insulation alternatives: LCA analysis for different climatic conditions in Spain. Resour. Conserv. Recycl. 2021, 175, 105838. [Google Scholar] [CrossRef]

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

| Component | Material | Specification of the Chosen Database |

|---|---|---|

| Foundations | Concrete | Concrete block {RoW}|market for concrete block|APOS, S |

| Concrete, 20 MPa {RoW}|market for concrete, 20 MPa|APOS, S | ||

| Concrete, 25–30 MPa {RoW}|market for concrete, 25–30 MPa|APOS, S | ||

| Steel | Reinforcing steel {GLO}|market for|APOS, S | |

| Gravel | Gravel, crushed {RoW}|market for gravel, crushed|APOS, S | |

| Flooring | Waterproof layer | Bitumen seal, Alu80 {RER}|production|APOS, S |

| Insulation | Polystyrene foam slab {GLO}|market for|APOS, S | |

| Mortar | Adhesive mortar {RoW}|production|APOS, S | |

| Cement mortar {RoW}|market for cement mortar|APOS, S | ||

| Wood floor | Three and five-layered board {RER}|market for three and five-layered board|APOS, S | |

| Tiling | Ceramic tile {GLO}|market for|APOS, S | |

| Peripheral wall | Timber | Cross-laminated timber {RER}|market for cross-laminated timber|APOS, S |

| Glued solid timber {RER}|market for glued solid timber|APOS, S | ||

| Joist, engineered wood {GLO}|market for|APOS, S | ||

| Insulation | Fibreboard, soft {RoW}|market for fibreboard, soft|APOS, S | |

| Polystyrene foam slab for perimeter insulation {GLO}|market for|APOS, S | ||

| Inner sheating | Gypsum plasterboard {GLO}|market for|APOS, S | |

| Mortar | Cement mortar {RoW}|market for cement mortar|APOS, S | |

| Steel joints | Steel, chromium steel 18/8 {GLO}|market for|APOS, S | |

| Inner tiling | Ceramic tile {GLO}|market for|APOS, S | |

| Plinth tiling | Shale brick {GLO}|market for|APOS, S | |

| Outer sheating | Wood cladding, softwood {GLO}|market for|APOS, S | |

| Inner walls | Timber | Cross-laminated timber {RER}|market for cross-laminated timber|APOS, S |

| Glued solid timber {RER}|market for glued solid timber|APOS, S | ||

| Sheating | Gypsum plasterboard {GLO}|market for|APOS, S | |

| Tiling | Ceramic tile {GLO}|market for|APOS, S | |

| Steel joints | Steel, chromium steel 18/8 {GLO}|market for|APOS, S | |

| Mortar | Cement mortar {RoW}|market for cement mortar|APOS, S | |

| Ceiling | Timber | Glued solid timber {RER}|market for glued solid timber|APOS, S |

| Sheating | Gypsum plasterboard {GLO}|market for|APOS, S | |

| Oriented strand board {RER}|market for oriented strand board|APOS, S | ||

| Insulation | glass wool mat, uncoated, Saint-Gobain ISOVER SA {CH}|market for glass wool mat, uncoated, Saint-Gobain ISOVER SA|APOS, U | |

| Cellulose fibre {RoW}|market for cellulose fibre|APOS, S | ||

| Steel joints | Steel, chromium steel 18/8 {GLO}|market for|APOS, S | |

| Roof | Timber | Glued solid timber {RER}| market for glued solid timber|APOS, S |

| Wood cladding, softwood {GLO}|market for|APOS, S | ||

| Insulation | Stone wool, packed {GLO}|market for stone wool, packed|APOS, S | |

| glass wool mat, uncoated, Saint-Gobain ISOVER SA {CH}|market for glass wool mat, uncoated, Saint-Gobain ISOVER SA|APOS, U | ||

| Steel joints | Steel, chromium steel 18/8 {GLO}|market for|APOS, S | |

| Roof tiles | Roof tile {GLO}|market for|APOS, S | |

| Water drainage system | Aluminum, primary, cast alloy slab from continuous casting {GLO}|market for|APOS, S | |

| Chimney | Autoclaved aerated concrete block {RoW}|market for autoclaved aerated concrete block|APOS, S | |

| Refractory, fireclay, packed {GLO}|market for|APOS, U | ||

| Windows and doors | Window frame | Window frame, aluminium, U = 1.6 W/m2K {GLO}|market for|APOS, S |

| Glazing | Glazing, triple, U < 0.5 W/m2K {GLO}|market for|APOS, S | |

| Outer door | Door, outer, wood-aluminium {GLO}|market for|APOS, S | |

| Inner door | Door, inner, wood {GLO}|market for|APOS, S |

| Impact Category | Unit | Impact Per Whole Structure | Impact Per 1 m2 of GIA |

|---|---|---|---|

| CC—fossil | kg CO2 eq | 76,279.05 | 513.66 |

| CC—biogenic 1 | kg CO2 eq | 19,861.54 | 133.75 |

| CC—carbon uptake 2 | kg CO2 eq | −87,955.40 | −592.29 |

| CC—LUT 3 | kg CO2 eq | 291.41 | 1.96 |

| Acidification | kg SO2 eq | 408.76 | 2.75 |

| Eutrophication | kg PO4− eq | 130.84 | 0.88 |

| Photochemical oxidation | kg NMVOC | 346.11 | 2.33 |

| AD—elements | kg Sb eq | 3.31 | 0.02 |

| AD—fossil fuels | MJ | 837,548.89 | 5640.06 |

| Water scarcity | m3 eq | 99,137.69 | 667.59 |

| Impact Category | Rank (No. 1 Refer to the Highest Contribution) | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| CC—fossil | Found. | PW | W/D | Roof | Flooring | Ceiling | IW |

| CC—biogenic | PW | Ceiling | IW | Roof | Flooring | W/D | Found. |

| CC—carbon uptake | PW | IW | Roof | Ceiling | Flooring | W/D | Found. |

| CC—LUT | PW | Roof | W/D | Ceiling | Found. | Flooring | IW |

| Acidification | PW | Found. | W/D | Roof | Flooring | Ceiling | IW |

| Eutrophication | PW | Found. | W/D | Roof | Ceiling | Flooring | IW |

| Photochemical oxidation | Found. | PW | W/D | Flooring | Roof | Ceiling | IW |

| AD—elements | PW | Ceiling | Roof | Flooring | Found. | W/D | IW |

| AD—fossil fuels | Found. | PW | Flooring | W/D | Roof | Ceiling | IW |

| Water scarcity | PW | Ceiling | Found. | Flooring | W/D | Roof | IW |

| Impact Category | Foundations | Flooring | Peripheral Wall | Inner Walls | Ceiling | Roof | Windows and Doors |

|---|---|---|---|---|---|---|---|

| CC—fossil | −1.05% | −1.05% | 1.83% | 12.08% | −1.05% | −1.05% | −1.05% |

| CC—biogenic | −8.67% | −8.67% | −0.31% | 30.91% | −8.67% | −8.67% | −8.67% |

| CC—carbon uptake | −16.16% | −16.16% | 1.05% | 22.02% | −16.16% | −16.16% | −16.16% |

| CC—LUT | −5.23% | −5.23% | 4.79% | 30.03% | −5.23% | −5.23% | −5.23% |

| Acidification | −1.81% | −1.81% | 1.77% | 17.69% | −1.81% | −1.81% | −1.81% |

| Eutrophication | −2.42% | −2.42% | 2.18% | 19.99% | −2.42% | −2.42% | −2.42% |

| Photochemical oxidation | −3.07% | −3.07% | 3.70% | 22.94% | −3.07% | −3.07% | −3.07% |

| AD—elements | −1.19% | −1.19% | 0.10% | 19.97% | −1.19% | −1.19% | −1.19% |

| AD—fossil fuels | −0.91% | −0.91% | 1.23% | 9.33% | −0.91% | −0.91% | −0.91% |

| Water scarcity | 0.32% | 0.32% | 0.00% | −12.17% | 0.32% | 0.32% | 0.32% |

| Impact Category | Foundations | Flooring | Peripheral Wall | Inner Walls | Ceiling | Roof | Windows and Doors |

|---|---|---|---|---|---|---|---|

| CC—fossil | 4.21% | 4.21% | −19.16% | 4.21% | 4.21% | 4.21% | 4.21% |

| CC—biogenic | 44.87% | 44.87% | −38.12% | 44.87% | 44.87% | 44.87% | 44.87% |

| CC—carbon uptake | 11.42% | 11.42% | −11.89% | 11.42% | 11.42% | 11.42% | 11.42% |

| CC—LUT | 10.43% | 10.43% | −27.67% | 10.43% | 10.43% | 10.43% | 10.43% |

| Acidification | 11.70% | 11.70% | −33.49% | 11.70% | 11.70% | 11.70% | 11.70% |

| Eutrophication | 12.28% | 12.28% | −33.18% | 12.28% | 12.28% | 12.28% | 12.28% |

| Photochemical oxidation | 6.59% | 6.59% | −21.76% | 6.59% | 6.59% | 6.59% | 6.59% |

| AD—elements | 61.44% | 61.44% | −61.22% | 61.44% | 61.44% | 61.44% | 61.44% |

| AD—fossil fuels | 4.75% | 4.75% | −18.95% | 4.75% | 4.75% | 4.75% | 4.75% |

| Water scarcity | 130.26% | 130.26% | −85.76% | 130.26% | 130.26% | 130.26% | 130.26% |

| Impact Category | Original Impact | Change in Impact after Substituting CLT by MHM Panel | Change in Impact after Substituting LDF by Stone Wool |

|---|---|---|---|

| CC—fossil | 100.00% | 1.06% | −4.04% |

| CC—biogenic | 100.00% | 9.49% | −30.97% |

| CC—carbon uptake | 100.00% | 19.27% | −10.25% |

| CC—LUT | 100.00% | 5.52% | −9.44% |

| Acidification | 100.00% | 1.84% | −10.48% |

| Eutrophication | 100.00% | 2.47% | −10.94% |

| Photochemical oxidation | 100.00% | 3.17% | −6.19% |

| AD—elements | 100.00% | 1.21% | −38.06% |

| AD—fossil fuels | 100.00% | 0.92% | −4.53% |

| Water scarcity | 100.00% | −0.32% | −56.57% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanova, R.; Stompf, P.; Stefko, J.; Stefkova, J. Environmental Impact of a Mass Timber Building—A Case Study. Forests 2021, 12, 1571. https://doi.org/10.3390/f12111571

Vanova R, Stompf P, Stefko J, Stefkova J. Environmental Impact of a Mass Timber Building—A Case Study. Forests. 2021; 12(11):1571. https://doi.org/10.3390/f12111571

Chicago/Turabian StyleVanova, Rozalia, Patrik Stompf, Jozef Stefko, and Jaroslava Stefkova. 2021. "Environmental Impact of a Mass Timber Building—A Case Study" Forests 12, no. 11: 1571. https://doi.org/10.3390/f12111571

APA StyleVanova, R., Stompf, P., Stefko, J., & Stefkova, J. (2021). Environmental Impact of a Mass Timber Building—A Case Study. Forests, 12(11), 1571. https://doi.org/10.3390/f12111571