Availability and Environmental Performance of Wood for a Second-Generation Biorefinery

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Region

2.2. Estimation of Potential Wood Supply

- 1.

- Plantation plans recorded by the Government (Dirección General Forestal, DGF) for the region since 1975 were gathered and classified for the species and purpose of interest. This information included registration number of the plantation plan, the species (pines and eucalypts), plantation date, intended product (solid, pulp, etc.), number of trees per hectare, effective planted area, and cadastral number (land registration number).

- 2.

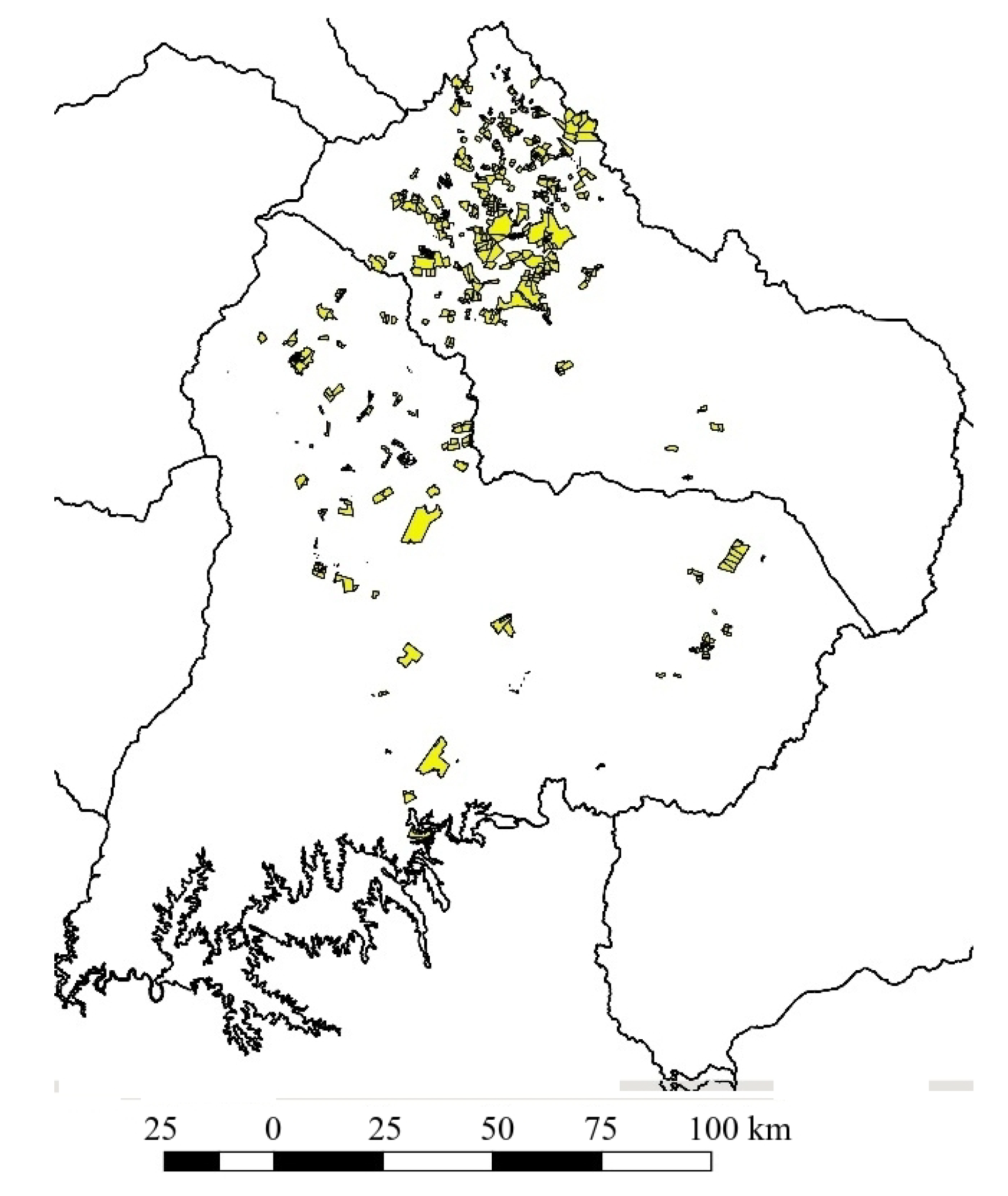

- Plantation plans were georeferenced through its corresponding cadastral number (land registration number) within the georeferenced national cadastral records [38] and checked with the geographical information system (GIS) of the National Forest Inventory for years 2010, 2011, and 2014 [39]. The GIS information was processed and analyzed with QGIS [40].

- 3.

- Based on biomass coefficients provided for Eucalyptus grandis in the northern region by previous work [41], we applied coefficients considering different tree fractions and stem portions usage: (a) a stem portion between 19 and 6 cm diameter only; (b) a stem portion smaller than 6 cm plus twigs, branches, leaves, and bark; (c) a stem portion smaller than 19 cm plus half of the biomass corresponding to twigs, branches, leaves, and bark. Coefficients applied are depicted in Table 6.

- 4.

- Considering the plantation date of each record, we assumed one commercial thinning at age 11 years and the clear cut at age 21 years (Table 4). We also assumed that the biomass formed at the first thinning was not exported and therefore was not computed. For year 11 and 21, the planted area for each record was multiplied by the estimated amount of dry matter per hectare considering tree fractions and stem portions usage listed in step 3. The maximum amount of forest biomass was calculated for a catchment area of 50 km radius located in the center of the most planted area.

2.3. Estimation of Soil Loss

2.4. Energy Return on Investment (EROI) and Carbon Footprint

2.4.1. Energy Return on Investment (EROI)

2.4.2. Carbon Footprint (CF)

| Inputs | Units | MJ Unit | Reference |

|---|---|---|---|

| Fuel | L | 38.6 | [57] |

| Herbicide | L | 327 | [58] |

| Machines | kg | 68.9 | [57] |

| Lubricant | L | 38.6 | [57] |

| Formicide | kg | 184.7 | [58] |

| Electricity | Kwh | 3.6 | |

| Liquefied petroleum gas | Kg | 30.33 | [59] |

| Gasoline | L | 39.61 | [59] |

| Glyphosate | Kg | 476 | [60] |

| N-fertilizer | Kg | 51.47 | [61] |

| P-fertilizer | Kg | 9.17 | [61] |

| K-fertilizer | Kg | 5.96 | [61] |

| Ammonium sulfate fertilizer | Kg | 1.12 | [59] |

| Urea | Kg | 75.63 | [59] |

| Insecticide | Kg | 325 | [61] |

| Eucalyptusglobulus | Kg | 19 | INIA’s data |

3. Results

3.1. Potential Wood Supply

Geographic Distribution and Availability

3.2. Soil Erosion by Water

3.3. EROI and CF

4. Discussion

4.1. Potential Wood Supply

4.2. Soil Erosion

4.3. EROI, Carbon Footprint, and Other Footprints

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CF | Carbon footprint |

| EROI | Energy return on investment |

| LCA | Life cycle assessment |

Appendix A

| Operations | Amount | Unit | Source |

|---|---|---|---|

| Nursery | |||

| Diesel oil | 497.3 | kg/tree | [60] |

| Liquid petroleum gas | 3.04 | MJ/tree | [60] |

| Gasoline (used as fuel) | 1.7 | m/tree | [60] |

| Electricity | 19.7 | Kwh/tree | [60] |

| Heavy fuel oil (used for heat) | 4.2 | L/plant/tree | [60] |

| Wood (for heat) | 2.8 | kg/tree | [60] |

| Carbaryl | 14.3 | kg AI/tree | [60] |

| Glyphosate | 8.0 | kg AI/tree | [60] |

| Granular mixed fertilizer (15–15–15) | 7.2 | kg | [60] |

| Ammonium sulfate fertilizer | 545.5 | kg | [60] |

| Urea fertilizer | 545.5 | kg | [60] |

| Surface water | 23.9 | L | [60] |

| Soil preparation | |||

| Ant control | |||

| Fipronil | 6 | Kg/ha | data from this research |

| Excentric and tractor (60 kW, 80 HP, 3683 kg) | 0.5 | d/ha | [60] |

| Excentric and tractor (54 kW, 75 HP, 3240 kg) | 0.5 | d/ha | [60] |

| Ripper (1 shaft every 5 m) and | data from this research | ||

| Tractor (54 kW, 75 HP, 3240 kg) | 0.5 | d/ha | [60] |

| Diammonium phosphate 18/46/0 | 110 | Kg/ha | data from this research |

| Oxufluorfen | 4.5 | L/ha | data from this research |

| Total fuel | 200 | L/ha | data from this research |

| CO emission | 544 | kg/ha | |

| NO emission | 11.3 | kg/ha | |

| Plantation | |||

| Diammonium phosphate 18/46/0 | 80.0 | Kg/ha | data from this research |

| Glyphosate | 12.6 | Kg/ha | data from this research |

| 7:6 m boom sprayer 670 kg | 0.03 | Kg/ha | data from this research |

| Tractor (37 kW, 50 HP, 2572 kg) | 0.129 | Kg/ha | [60] |

| Tractor (54 kW, 3240 kg) | 0.5 | Kg/ha | [60] |

| Fipronil | 2.5 | Kg/ha | data from this research |

| Tractor (54 kW, 3240 kg) | 0.97 | Kg/ha | [60] |

| Glyphosate | 13.24 | Kg/ha | data from this research |

| Fipronil | 12.0 | Kg/ha | data from this research |

| Tractor (54 kW, 3240 kg) | 0.97 | Kg/ha | [60] |

| Total fuel | 80.0 | kg/ha | data from this research |

| CO emission | 246 | kg/ha | [52] |

| NO emission | 5.08 | kg/ha | [52] |

| First thinning | |||

| Chainsaw 50 cc | 6 | trees/ha | data from this research |

| Harvested trees | 165 | trees/ha | data from this research |

| Harvest time | 27.5 | h | data from this research |

| 50:1 mixture of gasoline and 2-cycle engine oil | 12.8 | L/ha | data from this research |

| Lubricant | 22.5 | Kg/ha | data from this research |

| Grapo EcoLog 574 F 20,000 kg | 1.6 | kg/ha | data from this research |

| Truck | 30 | m/round trips | data from this research |

| Load and distance | 287 | t*km | data from this research |

| Total fuel | 15.6 | kg/ha | data from this research |

| CO emission | 42.5 | kg/ha | [52] |

| NO emission | 0.9 | kg/ha | [52] |

| 2nd thinning | |||

| Feller Tigercat 720 | 1.7 | kg/ha | data from this research |

| Harvester:Forwarder (1:2) | data from this research | ||

| X 2 forwarders mass | 50.7 | kg/ha | data from this research |

| Grapo EcoLog 574 F | 27.3 | kg/ha | data from this research |

| Truck Volvo 400 | 106.7 | kg/ha | data from this research |

| Load and distance | 3126.0 | t*km | data from this research |

| Total fuel | 527.3 | kg/ha | data from this research |

| CO emission | 1433.7 | kg/ha | [52] |

| NO emission | 29.7 | kg/ha | [52] |

| Harvest | |||

| Feller Tigercat 720 | 8.48 | kg/ha | data from this research |

| Performance | 150.0 | m/h | data from this research |

| Time of work | 5.3 | h/ha | |

| Harvester:Forwarder (1:2) | |||

| Harvester Tiger Cat 845 | 33.3 | kg/ha | data from this research |

| Performance | 49 | m/h | data from this research |

| Time of work | 11.9 | h/ha | data from this research |

| Forwader PONSSE Buffalo | 10.49 | kg/ha | data from this research |

| Time of work | 16 | h/ha | data from this research |

| Performance | 37.6 | m/hr | data from this research |

| Grapo EcoLog 574 F | 132.8 | kg/ha | data from this research |

| Truck | 30 | Ton/round trip | data from this research |

| Harvested mass | 303.74 | ton | biomass yield from INIA’s model |

| Load and distance | 15187 | t*km | data from this research |

| Total fuel | 3259.7 | kg/ha | data from this research |

| CO emission | 8862.4 | kg/ha | [52] |

| NO emission | 183.4 | kg/ha | [52] |

References

- Brundtland, G.H. Our Common Future; United Nations: New York, NY, USA, 1987; p. 300. [Google Scholar]

- Elkington, J. Partnerships from Cannibals with Forks: The Triple Bottom Line of 21st-Century Business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Environmental Impact Assessment of Agricultural Production Systems Using the Life Cycle Assessment Methodology: I. Theoretical Concept of a LCA Method Tailored to Crop Production. Eur. J. Agron. 2004, 20, 247–264. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A Safe Operating Space for Humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Chen, S.S.; Zhang, S.; Ok, Y.S.; Matsagar, B.M.; Wu, K.C.-W.; Tsang, D.C.W. Advances in Lignin Valorization towards Bio-Based Chemicals and Fuels: Lignin Biorefinery. Bioresour. Technol. 2019, 291, 121878. [Google Scholar] [CrossRef] [PubMed]

- De, D.; Naga Sai, M.S.; Aniya, V.; Satyavathi, B. Strategic Biorefinery Platform for Green Valorization of Agro-Industrial Residues: A Sustainable Approach towards Biodegradable Plastics. J. Clean. Prod. 2021, 290, 125184. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Cardona Alzate, C.A. The Potential Use of Lignin as a Platform Product in Biorefineries: A Review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Zhao, Y.; Shakeel, U.; Saif Ur Rehman, M.; Li, H.; Xu, X.; Xu, J. Lignin-Carbohydrate Complexes (LCCs) and Its Role in Biorefinery. J. Clean. Prod. 2020, 253, 120076. [Google Scholar] [CrossRef]

- Meena, M.; Shubham, S.; Paritosh, K.; Pareek, N.; Vivekanand, V. Production of Biofuels from Biomass: Predicting the Energy Employing Artificial Intelligence Modelling. Bioresour. Technol. 2021, 340, 125642. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Raj, T.; Mohanta, C.S.; Semwal, S.; Satlewal, A.; Gupta, R.P.; Puri, S.K.; Ramakumar, S.S.V.; Kumar, R. 2G Waste Lignin to Fuel and High Value-Added Chemicals: Approaches, Challenges and Future Outlook for Sustainable Development. Chemosphere 2021, 268, 129326. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A Systematic Review of Sustainable Supply Chain Management in Global Supply Chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Lo, S.L.Y.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-Economic Analysis for Biomass Supply Chain: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2021, 135, 110164. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Lambert, J.G.; Balogh, S.B. EROI of Different Fuels and the Implications for Society. Energy Policy 2014, 64, 141–152. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Hall, C.A.S.; Wang, J.; Feng, L.; Poisson, A. Energy Return on Investment (EROI) of China’s Conventional Fossil Fuels: Historical and Future Trends. Energy 2013, 54, 352–364. [Google Scholar] [CrossRef]

- Macedo, I.; Terra, J.A.; Siri-Prieto, G.; Velazco, J.I.; Carrasco-Letelier, L. Rice-Pasture Agroecosystem Intensification Affects Energy Use Efficiency. J. Clean. Prod. 2021, 278, 123771. [Google Scholar] [CrossRef]

- Townsend, J.M.; Hall, C.A.S.; Volk, T.A.; Murphy, D.; Ofezu, G.; Powers, B.; Quaye, A.; Serapiglia, M. Energy Return on Investment (EROI), Liquid Fuel Production, and Consequences for Wildlife. In Peak Oil, Economic Growth, and Wildlife Conservation; Gates, J.E., Trauger, D.L., Czech, B., Eds.; Springer: New York, NY, USA, 2014; pp. 29–61. ISBN 978-1-4939-1953-6. [Google Scholar]

- Howes, T. The EU’s new renewable energy directive (2009/28/EC). The new climate policies of the European. Union Intern. Legis. Clim. Dipl. 2010, 15, 3. [Google Scholar]

- Beretta-Blanco, A.; Carrasco-Letelier, L. USLE/RUSLE K-Factors Allocated through a Linear Mixed Model for Uruguayan Soils. Cienc. E Investig. Agrar. 2017, 44, 100–112. [Google Scholar] [CrossRef] [Green Version]

- Carrasco-Letelier, L.; Beretta-Blanco, A. Soil Erosion by Water Estimated for 99 Uruguayan Basins. Cienc. E Investig. Agrar. 2017, 44, 184–194. [Google Scholar]

- Beretta-Blanco, A.; Pérez, O.; Carrasco-Letelier, L. Soil Quality Decrease over 13 Years of Agricultural Production. Nutr. Cycl. Agroecosystems 2019, 114, 45–55. [Google Scholar] [CrossRef]

- Simoes, A. Uruguay (URY) Exports, Imports, and Trade Partners. The Observatory of Economic Complexity (OEC). Available online: https://oec.world/en/profile/country/ury (accessed on 1 November 2021).

- Bonifacino, S.; Resquín, F.; Lopretti, M.; Buxedas, L.; Vázquez, S.; González, M.; Sapolinski, A.; Hirigoyen, A.; Doldán, J.; Rachid, C.; et al. Bioethanol Production Using High Density Eucalyptus Crops in Uruguay. Heliyon 2021, 7, e06031. [Google Scholar] [CrossRef]

- Duque, A.; Doménech, P.; álvarez, C.; Ballesteros, M.; Manzanares, P. Study of the Bioprocess Conditions to Produce Bioethanol from Barley Straw Pretreated by Combined Soda and Enzyme-Catalyzed Extrusion. Renew. Energy 2020, 158, 263–270. [Google Scholar] [CrossRef]

- Ferrari, M.D.; Guigou, M.; Lareo, C. Energy Consumption Evaluation of Fuel Bioethanol Production from Sweet Potato. Bioresour. Technol. 2013, 136, 377–384. [Google Scholar] [CrossRef]

- DIEA Agricultural Statistic Yearbook 2018 (Anuario Estadístico Agropecuario 2018); Ministerio de Agricultura, Ganadería y Pesca, Editorial Hemisferio Sur (In Spanish): Montevideo, Uruguay, 2018.

- Boscana, M.; Boragno, L.; Arriaga, E. Estadísticas Forestales 2021: Extracción, Producción, Consumo, Mano de Obra, Comercio Exterior; División Evaluación e Información, Dirección General Forestal, Ministerio de Ganadería Agricultura y Pesca: Montevideo, Uruguay, 2021; p. 69. [Google Scholar]

- Carrasco-Letelier, L.; Vázquez, D.; D’Ottone, F.; Resquin, F.; Scoz, R.; Vilaró, F.; Rodríguez, G.; Terra, J. Revista INIA; Instituto de Investigación Agropecuaria: Montevideo, Uruguay, 2013; pp. 40–46. [Google Scholar]

- BABET-REAL5 Consortium BABET-REAL5. Available online: https://www.babet-real5.eu/https://www.babet-real5.eu/ (accessed on 18 August 2021).

- Royo Pallares, O.; Berretta, E.J.; Maraschin, G.E. Chapter 5: The South American Campos Ecosystem. In Grasslands of the World; Plant Production and Protection Series; FAO (Food and Agriculture Organization of the United Nations): Rome, Italy, 2005; pp. 171–220. ISBN 92-5-105337-5. [Google Scholar]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Küppen-Geiger Climate Classification Updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Castaño, J.P.G.; Ceroni, A.; Furest, M.; Aunchayna, J.; Bidegain, R. Caracterización Agroclimática Del Uruguay 1980–2009; Serie Técnica INIA; Serie Técnica N° 193; Instituto de Investigación Agropecuaria: Montevideo, Uruguay, 2011. [Google Scholar]

- Gardi, C.; Angelini, M.; Barceló, S.; Comerma, J.; Cruz Gaistardo, C.; Encina Rojas, A.; Jones, A.; Krasilnikov, P.; Mendonça Santos Brefin, M.L.; Montanarella, L.; et al. Atlas de Suelos de América Latina y El Caribe; Comisión Europea, Oficina de Publicaciones de la Unión Europea: Luxembourg, 2014. [Google Scholar]

- Altamirano, A.; Da Silva, H.; Durán, A.; Echevarría, A.; Panario, D.; Puentes, R. Carta de Reconocimiento de Suelos del Uruguay; Tomo I: Clasificación de Suelos; Dirección de Suelos y Fertilizantes, Ministerio de Agricultura y Pesca: Montevideo, Uruguay, 1976. [Google Scholar]

- Durán, A.; Califra, A.; Molfino, J.; Lynn, W. Keys to Soil Taxonomy for Uruguay; US Department of Agriculture, Natural Resources Conservation Service: Washington, DC, USA, 2006.

- MAP/DSF Carta de Reconocimiento de Suelos Del Uruguay. Descripciones, Datos Físicos y Químicos de Los Suelos Dominantes; Tomo III Apéndice- Parte I y Parte II; Dirección de Suelos y Fertilizantes, Ministerio de Agricultura y Pesca: Montevideo, Uruguay, 1976. [Google Scholar]

- Durán, A.; García-Préchac, F. Suelos Del Uruguay. Origen, Clasificación, Manejo y Conservación; Hemisferio Sur: Montevideo, Uruguay, 2007; Volume II. [Google Scholar]

- Lima, M.A.; Gomez, L.D.; Steele-King, C.G.; Simister, R.; Bernardinelli, O.D.; Carvalho, M.A.; Rezende, C.A.; Labate, C.A.; deAzevedo, E.R.; McQueen-Mason, S.J.; et al. Evaluating the Composition and Processing Potential of Novel Sources of Brazilian Biomass for Sustainable Biorenewables Production. Biotechnol. Biofuels 2014, 7, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dirección Nacional de Catastro Visualizador de geoCatastro. Available online: http://visor.catastro.gub.uy/visordnc/ (accessed on 23 August 2021).

- Dirección General Forestal Resultados de La Cartografía Forestal Nacíonal 2018; Ministerio de Agricultura, Ganadería y Pesca: Montevideo, Uruguay, 2018; p. 22.

- QGIS Geographic Information System. Open Source Geospatial Foundation Project. 2021. Available online: https://qgis.org/es/site/ (accessed on 1 November 2021).

- PROBIO Mejoramiento en la Calidad de la Información Vinculada con la Utilización de la Biomasa Forestal; MVOTMA, INIA: Tacuarembó, Uruguay, 2015; p. 34.

- García-Préchac, F. Guía Para la Toma de Decisiones en Conservación de Suelos: 3a. Aproximación; Serie Técnica INIA; INIA Uruguay: Montevideo, Uruguay, 1992. [Google Scholar]

- García-Préchac, F.; Hill, M.; Clericí, C. Erosión: Modelo de Estimación de Erosión de Suelos En Uruguay y Región Sur de La Cuenca Del Plata (software); Departamento de Suelos y Aguas, Facultad de Agronomía, Universidad de la República, Ministerio de Ganadería Agricultura y Pesca-Banco Mundial; Montevideo, Uruguay. 2013. Available online: https://www.gub.uy/ministerio-ganaderia-agricultura-pesca/politicas-y-gestion/actualizacion-tecnica-del-modelo-para-cuantificacion-perdida-suelo-erosion (accessed on 1 November 2021).

- García-Préchac, F.; Durán, A. Propuesta de Estimación Del Impacto de La Erosión Sobre La Productividad Del Suelo En Uruguay. Agrociencia Urug. 1998, 2, 26–36. [Google Scholar]

- Foster, G.R.; McCool, D.K.; Renard, K.G.; Moldenhauer, W.C. Conversion of the Universal Soil Loss Equation to SI Metric Units. J. Soil Water Conserv. 1981, 36, 355–359. [Google Scholar]

- DGRNR, (Dirección General de Recursos Naturales Renovables) Modelo Digital de Terreno de La República Oriental Del Uruguay: Resolución Del Modelo 30 × 30 Metros (Online) [Digital Terrain Model of the Eastern Republic of Uruguay: Model Resolution of 30 × 30 Meters]. 2014. Available online: https://www.gub.uy/ministerio-ganaderia-agricultura-pesca/tramites-y-servicios/servicios/modelo-digital-terreno/ (accessed on 23 August 2021).

- DGRNR, (Dirección General de Recursos Naturales Renovables) Cartografía Digital de Grupos de Suelos CONEAT (Comisión Nacional de Estudio Agroeconómico de La Tierra) de La República Oriental Del Uruguay (Online). Available online: http://web.renare.gub.uy/js/visores/coneat/ (accessed on 23 August 2021).

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What Is the Minimum EROI That a Sustainable Society Must Have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Powers, R.; Schoenberg, W. Peak Oil, EROI, Investments and the Economy in an Uncertain Future. In Biofuels, Solar and Wind as Renewable Energy Systems; Pimentel, D., Ed.; Springer: Dordrecht, The Netherlands, 2008; pp. 109–132. ISBN 978-1-4020-8653-3. [Google Scholar]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A Review of Life Cycle Assessment (LCA) on Some Food Products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Romanelli, T.L.; Milan, M. Energy Performance of a Production System of Eucalyptus. Rev. Bras. Eng. Agríc. E Ambient. 2010, 14, 896–903. [Google Scholar] [CrossRef]

- Berg, S. Some Aspects of LCA in the Analysis of Forestry Operations. J. Clean. Prod. 1997, 5, 211–217. [Google Scholar] [CrossRef]

- Berg, S.; Karjalainen, T. Comparison of Greenhouse Gas Emissions from Forest Operations in Finland and Sweden. For. Int. J. For. Res. 2003, 76, 271–284. [Google Scholar] [CrossRef]

- Berg, S.; Lindholm, E.-L. Energy Use and Environmental Impacts of Forest Operations in Sweden. J. Clean. Prod. 2005, 13, 33–42. [Google Scholar] [CrossRef]

- Green Delta OpenLCA; Green Delta: Berlin, Germany, 2020.

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. In Proceedings of the IPCC Fifth Assessment Synthesis Report-Climate Change 2014 Synthesis Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Ulbanere, R.; Ferreira, W. Energetic Balance Analysis for Corn Production in Sao Paulo State-Southeast Brazil; Analise Do Balanco Energetico Para a Producao de Milho No Estado de Sao Paulo. Energ. Na Agric. 1989, 4, 35–42. [Google Scholar]

- Pimentel, D. Handbook of Energy Utilization in Agriculture; CRC press: Boca Raton, FL, USA, 1980. [Google Scholar]

- Nagy, C.N. Energy Coefficients for Agriculture Inputs in Western Canada; Centre for Studies in Agriculture, Law and the Environment, University of Saskatchewan: Saskatoon, SK, USA, 1999. [Google Scholar]

- Heller, M.C.; Keoleian, G.A.; Volk, T.A. Life Cycle Assessment of a Willow Bioenergy Cropping System. Biomass Bioenergy 2003, 25, 147–165. [Google Scholar] [CrossRef]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, Economic, and Energetic Costs and Benefits of Biodiesel and Ethanol Biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 11206–11210. [Google Scholar] [CrossRef] [Green Version]

- García-Prechac, F.; Durán, A. Estimating Soil Productivity Loss Due to Erosion in Uruguay in Terms of Beef and Wool Production on Natural Pastures. In Proceedings of the Sustaining the Global Farm; Stott, D.E., Mohtar, R.H., Steinhardt, G.C., Eds.; Purdue University and the USDA-ARS National Soil Erosion Research Laboratory: West Lafayette, IN, USA, 2001; pp. 040–045. [Google Scholar]

- Hernández, J.; del Pino, A.; Salvo, L.; Arrarte, G. Nutrient Export and Harvest Residue Decomposition Patterns of a Eucalyptus dunnii Maiden Plantation in Temperate Climate of Uruguay. For. Ecol. Manag. 2009, 258, 92–99. [Google Scholar] [CrossRef]

- Hernández, J.; del Pino, A.; Hitta, M.; Lorenzo, M. Management of Forest Harvest Residues Affects Soil Nutrient Availability during Reforestation of Eucalyptus grandis. Nutr. Cycl. Agroecosystems 2016, 105, 141–155. [Google Scholar] [CrossRef]

- Bentancor, L.; Hernández, J.; del Pino, A.; Califra, á.; Resquín, F.; González-Barrios, P. Evaluation of the Biomass Production, Energy Yield and Nutrient Removal of Eucalyptus dunnii Maiden Grown in Short Rotation Coppice under Two Initial Planting Densities and Harvest Systems. Biomass Bioenergy 2019, 122, 165–174. [Google Scholar] [CrossRef]

- Resquin, F.; Navarro-Cerrillo, R.M.; Carrasco-Letelier, L.; Casnati, C.R. Influence of Contrasting Stocking Densities on the Dynamics of Above-Ground Biomass and Wood Density of Eucalyptus benthamii, Eucalyptus dunnii, and Eucalyptusgrandis for Bioenergy in Uruguay. For. Ecol. Manag. 2019, 438, 63–74. [Google Scholar] [CrossRef]

- Resquin, F.; Navarro-Cerrillo, R.M.; Carrasco-Letelier, L.; Casnati, C.R.; Bentancor, L. Evaluation of the Nutrient Content in Biomass of Eucalyptus Species from Short Rotation Plantations in Uruguay. Biomass Bioenergy 2020, 134, 105502. [Google Scholar] [CrossRef]

- Resquin, F.; Navarro-Cerrillo, R.M.; Carrasco-Letelier, L.; Rachid-Casnati, C. Influence of Age and Planting Density on the Energy Content of Eucalyptus Benthamii, Eucalyptus Dunnii and Eucalyptus Grandis Planted in Uruguay. New For. 2020, 51, 631–655. [Google Scholar] [CrossRef]

- Resquin, F.; Navarro-Cerrillo, R.M.; Rachid-Casnati, C.; Hirigoyen, A.; Carrasco-Letelier, L.; Duque-Lazo, J. Allometry, Growth and Survival of Three Eucalyptus Species (Eucalyptus benthamii Maiden and Cambage, E. dunnii Maiden and E. grandis Hill Ex Maiden) in High-Density Plantations in Uruguay. Forests 2018, 9, 745. [Google Scholar] [CrossRef] [Green Version]

- UPM Pulp Direct 3/2017 - UPM Fray Bentos Has Been Serving Customers for 10 Years. Available online: https://www.upm.com/about-us/for-media/releases/2017/11/pulp-direct-32017---upm-fray-bentos-has-been-serving-customers-for-10-years/ (accessed on 23 August 2021).

- Stora Enso Montes Del Plata Mill. Available online: https://www.storaenso.com/en/about-stora-enso/stora-enso-locations/montes-del-plata-mil (accessed on 23 August 2021).

- UPM UPM Top Management Met with Uruguay’s President Dr. Tabaré Vázquez. Available online: https://www.upm.com/about-us/for-media/releases/2019/02/upm-top-management-met-with-uruguays-president-dr.-tabare-vazquez/ (accessed on 23 August 2021).

- da Silva, P.H.M.; Marco, M.; Alvares, C.A.; Lee, D.; de Moraes, M.L.T.; de Paula, R.C. Selection of Eucalyptus grandis Families across Contrasting Environmental Conditions. Crop Breed. Appl. Biotechnol. 2019, 19, 47–54. [Google Scholar] [CrossRef]

- Clericí, C.; García-Préchac, F. Aplicaciones Del Modelo USLE/RUSLE Para Estimar Pérdidas de Suelo Por Erosión En Uruguay y La Región Sur de La Cuenca Del Río de La Plata. Agrociencia 2001, V, 92–103. [Google Scholar]

- Murphy, D.J.; Hall, C.A.S.; Powers, B. New Perspectives on the Energy Return on (Energy) Investment (EROI) of Corn Ethanol. Environ. Dev. Sustain. 2011, 13, 179–202. [Google Scholar] [CrossRef]

- Weißbach, D.; Ruprecht, G.; Huke, A.; Czerski, K.; Gottlieb, S.; Hussein, A. Energy Intensities, EROIs (Energy Returned on Invested), and Energy Payback Times of Electricity Generating Power Plants. Energy 2013, 52, 210–221. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Life Cycle Assessment of Various Cropping Systems Utilized for Producing Biofuels: Bioethanol and Biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Pimentel, D.; Patzek, T. Ethanol Production Using Corn, Switchgrass and Wood; Biodiesel Production Using Soybean. In Biofuels, Solar and Wind as Renewable Energy Systems: Benefits and Risks; Pimentel, D., Ed.; Springer: Dordrecht, The Netherlands, 2008; pp. 373–394. ISBN 978-1-4020-8654-0. [Google Scholar]

- Chiriboga, G.; De La Rosa, A.; Molina, C.; Velarde, S.; Carvajal C, G. Energy Return on Investment (EROI) and Life Cycle Analysis (LCA) of Biofuels in Ecuador. Heliyon 2020, 6, e04213. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Dale, B.E.; Pimentel, D. Seeking to Understand the Reasons for Different Energy Return on Investment (EROI) Estimates for Biofuels. Sustainability 2011, 3, 2413–2432. [Google Scholar] [CrossRef] [Green Version]

- McCallum, D. Carbon Footprint of New Zealand. Laminated Veneer Lumber SCION – Next Generation Biomaterials; 2010. Available online: http://www.nelsonpine.co.nz/wp-content/uploads/Carbon-Footprint-of-NZ-LVL-Dec10-FINAL.pdf (accessed on 1 November 2021).

- Martínez-Alonso, C.; Berdasco, L.; González, L.; Martínez, S. Huella de Carbono de Un Producto de Madera de Castaño (Proyecto Piloto En Asturias). Prog. For. 2012, 29, 35–39. [Google Scholar]

- Symons, K.; Dowdell, D.; Butler, J.; Vickers, J.; Wakelin, S.; Rawlinson, D. Timber, Carbon and the Environment; NZ Wood Design Guides; Wood Processors and Manufacturers Association. 2020. Available online: https://www.wpma.org.nz/uploads/1/3/2/8/132870817/ch-2.1-trees-carbon-and-the-environment.pdf (accessed on 1 November 2021).

- Doldán, J. Evaluación de Parámetros de Calidad de Eucalyptus globulus y Eucalyptus maidenii de Plantaciones Uruguayas Para Pulpa de Celulosa; LATU: Montevideo, Uruguay, 2006; p. 8. [Google Scholar]

- Grahmann, K.; Rubio Dellepiane, V.; Terra, J.A.; Quincke, J.A. Long-term observations in contrasting crop-pasture rotations over half a century: Statistical analysis of chemical soil properties and implications for soil sampling frequency. Agric. Ecosyst. Environ. 2020, 287, 106710. [Google Scholar] [CrossRef]

- Bustamante-Silveira, M.; Siri-Prieto, G.; Carrasco-Letelier, L. Water footprints of bioethanol cropping systems in Uruguay. Agric. Water Manag. 2021, 252, 106870. [Google Scholar] [CrossRef]

- Myllyviita, T.; Sironen, S.; Saikku, L.; Holma, A.; Leskinen, P.; Palme, U. Assessing Biodiversity Impacts in Life Cycle Assessment Framework - Comparing Approaches Based on Species Richness and Ecosystem Indicators in the Case of Finnish Boreal Forests. J. Clean. Prod. 2019, 236, 117641. [Google Scholar] [CrossRef]

- Cravino, A.; Brazeiro, A. Grassland Afforestation in South America: Local Scale Impacts of Eucalyptus Plantations on Uruguayan Mammals. For. Ecol. Manag. 2021, 484, 118937. [Google Scholar] [CrossRef]

- Ferreira, V.; Boyero, L.; Calvo, C.; Correa, F.; Figueroa, R.; Gonçalves, J.F.; Goyenola, G.; Graça, M.A.S.; Hepp, L.U.; Kariuki, S.; et al. A Global Assessment of the Effects of Eucalyptus Plantations on Stream Ecosystem Functioning. Ecosystems 2019, 22, 629–642. [Google Scholar] [CrossRef]

- Farley, K.A. Effects of Afforestation on Water Yield: A Global Synthesis with Implications for Policy. Glob. Change Biol. 2005, 11, 1565–1576. [Google Scholar] [CrossRef]

- Silveira, L.; Gamazo, P.; Alonso, J.; Martínez, L. Effects of Afforestation on Groundwater Recharge and Water Budgets in the Western Region of Uruguay. Hydrol. Process. 2016, 30, 3596–3608. [Google Scholar] [CrossRef]

- Gerber, P.J.; Mottet, A.; Opio, C.I.; Falcucci, A.; Teillard, F. Environmental Impacts of Beef Production: Review of Challenges and Perspectives for Durability. Meat Sci. 2015, 109, 2–12. [Google Scholar] [CrossRef]

- Côté, S.; Beauregard, R.; Margni, M.; Bélanger, L. Using Naturalness for Assessing the Impact of Forestry and Protection on the Quality of Ecosystems in Life Cycle Assessment. Sustainability 2021, 13, 8859. [Google Scholar] [CrossRef]

- Auer, V.; Rauch, P. Wood Supply Chain Risks and Risk Mitigation Strategies: A Systematic Review Focusing on the Northern Hemisphere. Biomass Bioenergy 2021, 148, 106001. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Wachowicz, J. Comparative Analysis of Carbon, Ecological, and Water Footprints of Polypropylene-Based Composites Filled with Cotton, Jute and Kenaf Fibers. Materials 2020, 13, 3541. [Google Scholar] [CrossRef]

- Clift, R. Metrics for supply chain sustainability. In Technological Choices for Sustainability; Sikdar, S.K., Glavič, P., Jain, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 239–253. ISBN 978-3-662-10270-1. [Google Scholar]

- Giannakis, M.; Papadopoulos, T. Supply Chain Sustainability: A Risk Management Approach. Int. J. Prod. Econ. 2016, 171, 455–470. [Google Scholar] [CrossRef]

- Beretta-Blanco, A.; Carrasco-Letelier, L. Relevant Factors in the Eutrophication of the Uruguay River and the Río Negro. Sci. Total Environ. 2021, 761, 143299. [Google Scholar] [CrossRef] [PubMed]

| Species | Department | Total Planted Area | |

|---|---|---|---|

| Rivera | Tacuarembó | ||

| Pinus taeda Pinus elliotii | 74.107 | 62.158 | 136.265 |

| Eucalyptus grandis Eucalyptus saligna | 45.038 | 23.441 | 68.479 |

| Climatic Variable | Mean | Minimum | Maximum |

|---|---|---|---|

| Rainfall (mm) | 1400 | 1200 | 1600 |

| Temperature (°C) | 17.7 | 12.9 | 22.6 |

| Accumulated days with frosts | 30 | 20 | 40 |

| Radiation (h d yr) | 7 | ||

| Annual air relative humidity (%) | 74 | 70 | 78 |

| Potential evapotranspiration (mm month) | 1100 | 1000 | 1200 |

| Residues Fraction | Mineral | Lignin | Cellulose | Xylan |

|---|---|---|---|---|

| Wood | 0.4 | 29.7 | 49.0 | 14.8 |

| Bark | 10.3 | 20.6 | 47.0 | 11.4 |

| Leaves | 4.7 | 34.3 | 48.0 | 8.0 |

| Planting | Thinnings | Harvest | ||

|---|---|---|---|---|

| 1st | 2nd | |||

| Age (years) | 1 | 6 | 11 | 21 |

| Trees per hectare before thinning | 800 | 665 | 500 | 187 |

| Harvested trees (tree ha) | 165 | 250 | 187 | |

| MAI (m ha yr) | 24 | 29 | 28 | |

| Total harvested biomass (m ha) | 23.3 | 94.4 | 583 | |

| Logs sawmill (m ha) >19 cm | 11 | 65 | 545 | |

| Logs biorefinery (m ha) 6–19 cm | 29 | 32 | ||

| Tips (m ha) <6 cm | 0.4 | 6.0 | ||

| Operation | Year | Description |

|---|---|---|

| Ant control | 0–1.5 | 2–4 times |

| Soil preparation | 0 | Plantation rows, minimum slope, subsoil ripping, 1 or 2 offset disk passes, mounding |

| Plantation | 0 | 800–1200 trees per hectare, manual or mechanized, clones or seeds |

| Fertilization | 0 | On the plantation, prescription according to soil characteristics (i.e., 45 g per plant) |

| Weed controls | 0–2 | Postemergent previous plantation, pre-emergence on the plantation and postemergence one or two times up to canopy closure |

| Thinnings | 2–11 | 2–3 thinnings depending on site quality and company purposes |

| Prunings | 2–11 | 2–3 prunings depending on site quality and company purposes up to 6.5 or 9 m |

| Preharvest | 16–19 | Ant’s control |

| Harvest | 16–21 | Cut-to-length systems mainly, but full-tree systems can occur depending on topography and density |

| Wood and Fractions | Biomass (tDM yr) | |

|---|---|---|

| Commercial Thinning | Clearcut | |

| Total biomass considering wood under <19 cm diameter | 47.5 | 45.9 |

| Debarked wood between 6 and 19 cm diameter plus 50 % of branches | 35.0 | 21.2 |

| Debarked wood between 6 and 19 cm diameter | 31.7 | 17.8 |

| Tips (wood < 6 cm diameter) | 0.7 | 1.3 |

| Options | Branches and Leaves | Bark | Diameter of Logs | ||

|---|---|---|---|---|---|

| >20 cm | 19–6 cm | <6 cm | |||

| Current Scenario | Field | Field | Sawmill and plywood mill | Pulp mill | Field |

| Scenario I | Field | Field | Sawmill and plywood mill | Pulp mill | Biofuel plant |

| Scenario II | Field | Field | Sawmill and plywood mill | Biofuel plant | Field |

| Scenario III | 50% Field 50% Biofuel plant | Field | Sawmill and plywood mill | Biofuel plant | Field |

| Total Biomass | Solid Wood | Current Scenario | Scenario I | Scenario II | Scenario III | |

|---|---|---|---|---|---|---|

| Fuel | 58,673 | 54,903 | 57,928 | 57,970 | 57,928 | 58,301 |

| Electricity | 57 | 57 | 57 | 57 | 57 | 57 |

| Pesticides | 16,086 | 16,086 | 16,086 | 16,086 | 16,086 | 16,086 |

| Fertilizers | 1912 | 1912 | 1912 | 1912 | 1912 | 1912 |

| Agricultural machinery | 63,675 | 61,592 | 62,675 | 62,800 | 62,675 | 63,175 |

| Total energy input | 140,403 | 134,549 | 138,658 | 138,824 | 138,658 | 139,530 |

| Total energy output | 6,936,229 | 6,147,279 | 6,751,118 | 6,814,472 | 6,751,118 | 6,209,395 |

| EROI yr | 2.35 | 2.18 | 2.32 | 2.34 | 2.32 | 2.12 |

| EROI 21 yr | 49.4 | 45.7 | 48.7 | 49.1 | 48.7 | 44.5 |

| Total | Solid | Current | Scenario | Mean | Minimum | Maximum | |||

|---|---|---|---|---|---|---|---|---|---|

| Biomass | Wood | Scenario | I | II | III | ||||

| Tree nursery | 0.0024 | 0.0027 | 0.0025 (0.2 %) | 0.0024 | 0.0025 | 0.0024 | 0.0025 | 0.0024 | 0.0027 |

| Soil preparation | 0.0783 | 0.0884 | 0.0805 (6.6 %) | 0.0797 | 0.0805 | 0.0794 | 0.0811 | 0.0794 | 0.0884 |

| Plantation | 0.0553 | 0.0624 | 0.0568 (4.7%) | 0.0563 | 0.0568 | 0.0560 | 0.0573 | 0.0560 | 0.0624 |

| First thinning | 0.0263 | 0.0140 | 0.0128 (1.3%) | 0.0127 | 0.1277 | 0.0197 | 0.0547 | 0.0127 | 0.1277 |

| Second thinning | 0.1663 | 0.1293 | 0.1702 (13.2%) | 0.1694 | 0.1703 | 0.1683 | 0.1623 | 0.1293 | 0.1702 |

| Harvest | 0.8895 | 0.9387 | 0.9049 (74.0%) | 0.9058 | 0.9049 | 0.8973 | 0.9069 | 0.8973 | 0.9387 |

| Total | 1.2181 | 1.2354 | 1.2276 | 1.2263 | 1.2276 | 1.2231 | 1.2264 | 1.2231 | 1.2354 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rachid-Casnati, C.; Resquin, F.; Carrasco-Letelier, L. Availability and Environmental Performance of Wood for a Second-Generation Biorefinery. Forests 2021, 12, 1609. https://doi.org/10.3390/f12111609

Rachid-Casnati C, Resquin F, Carrasco-Letelier L. Availability and Environmental Performance of Wood for a Second-Generation Biorefinery. Forests. 2021; 12(11):1609. https://doi.org/10.3390/f12111609

Chicago/Turabian StyleRachid-Casnati, Cecilia, Fernando Resquin, and Leonidas Carrasco-Letelier. 2021. "Availability and Environmental Performance of Wood for a Second-Generation Biorefinery" Forests 12, no. 11: 1609. https://doi.org/10.3390/f12111609

APA StyleRachid-Casnati, C., Resquin, F., & Carrasco-Letelier, L. (2021). Availability and Environmental Performance of Wood for a Second-Generation Biorefinery. Forests, 12(11), 1609. https://doi.org/10.3390/f12111609