Perception of the Harvester Operator’s Working Environment in Windthrow Stands

Abstract

1. Introduction

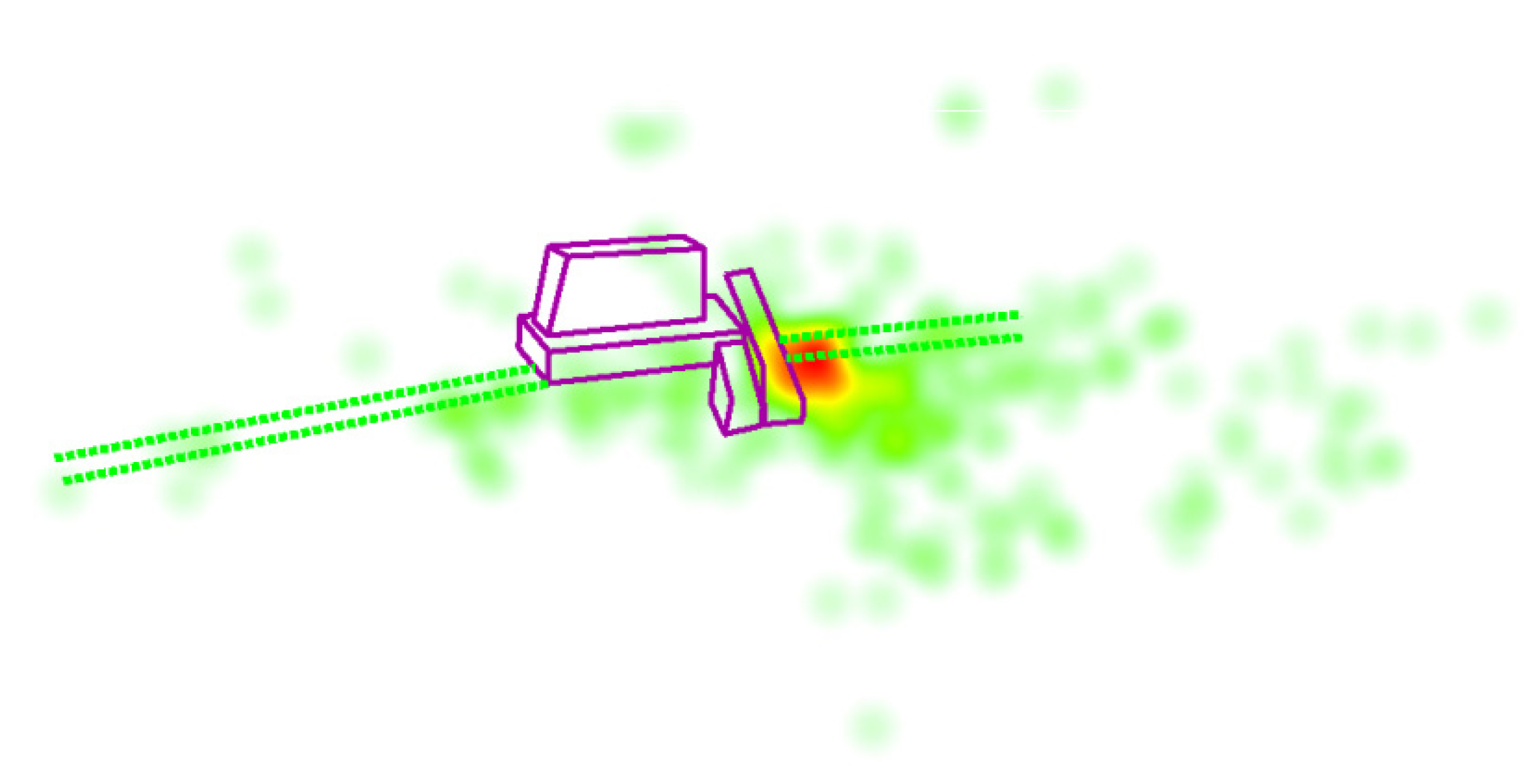

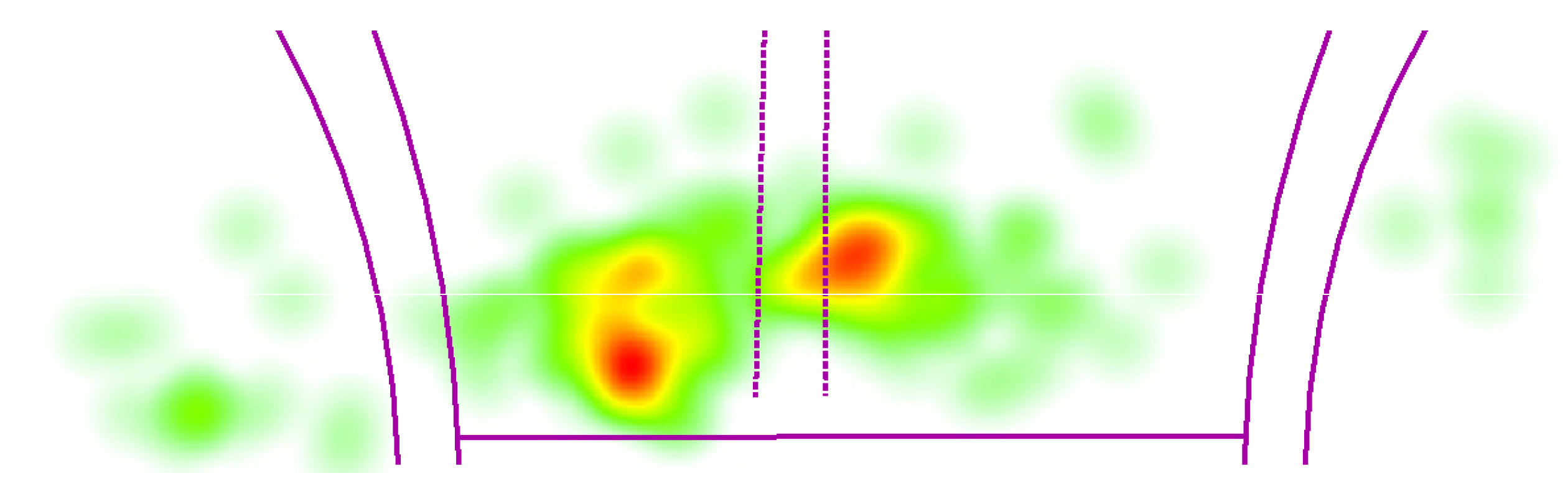

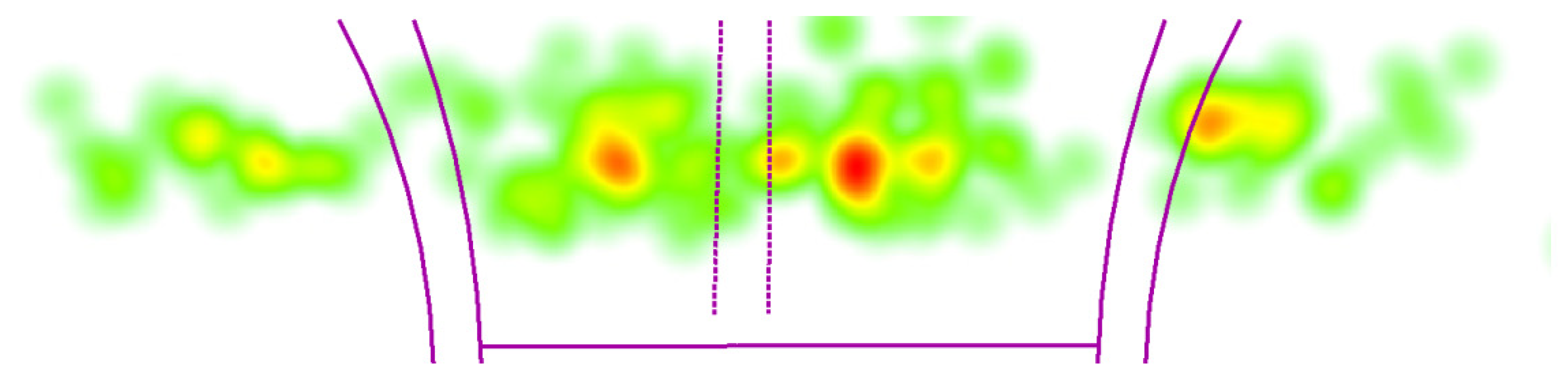

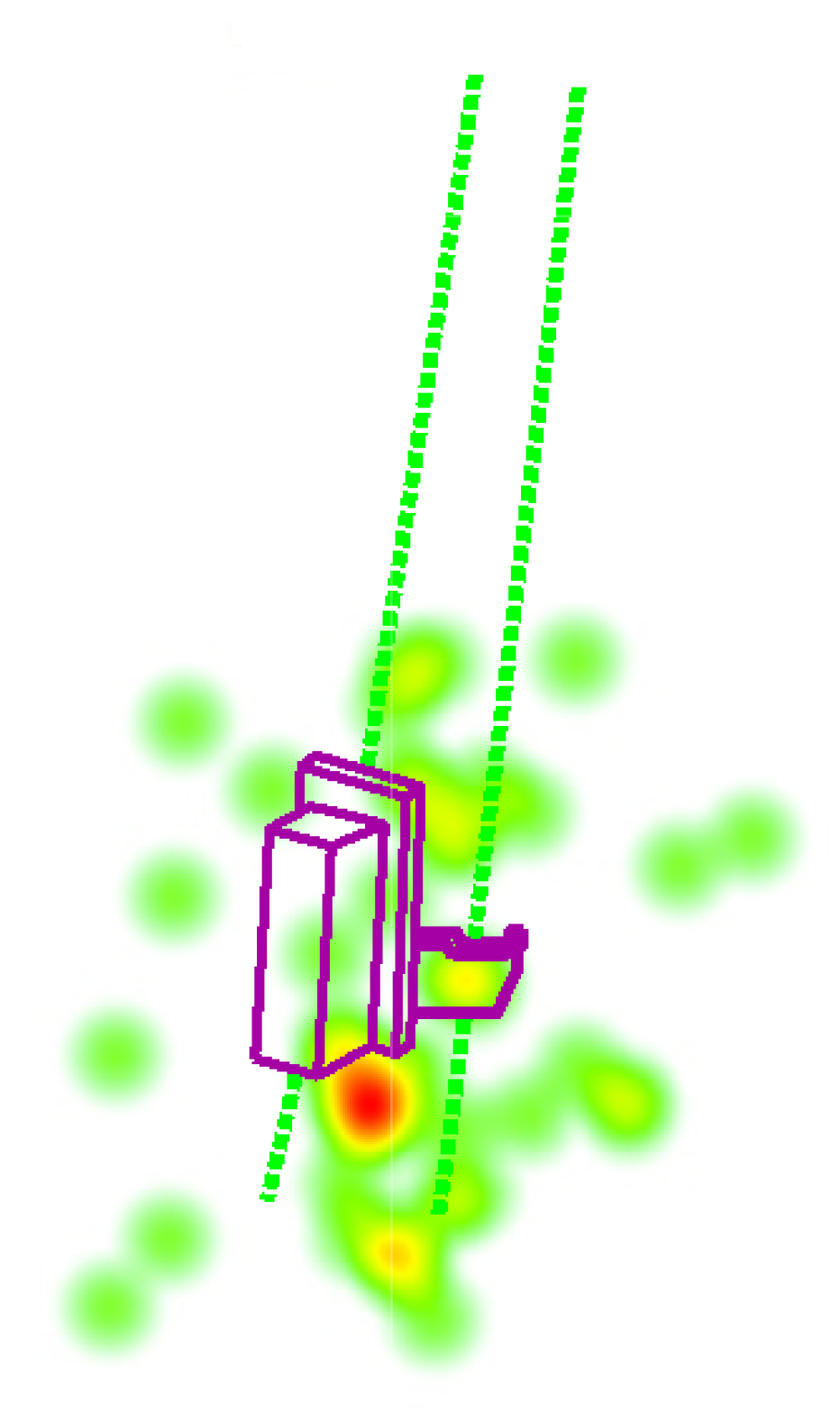

2. Materials and Methods

- S—indicator of variation of saccade durations [%]

- n—activity (p—processing, m—moving, c—cutting),

- m—stand category (s—standard stand, p—post-disaster stand),

- ax—sum of saccade durations during work with a tree [ms]

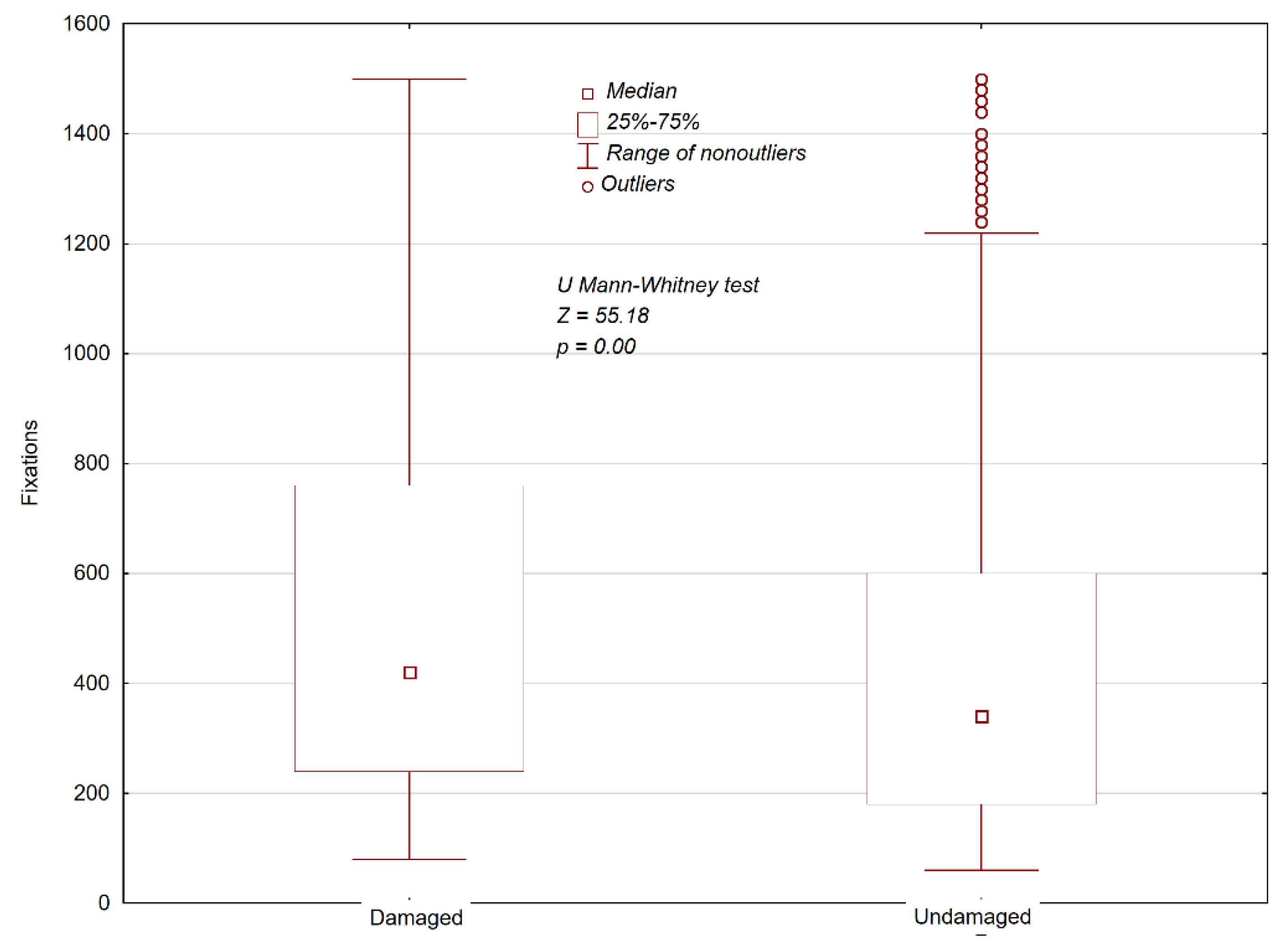

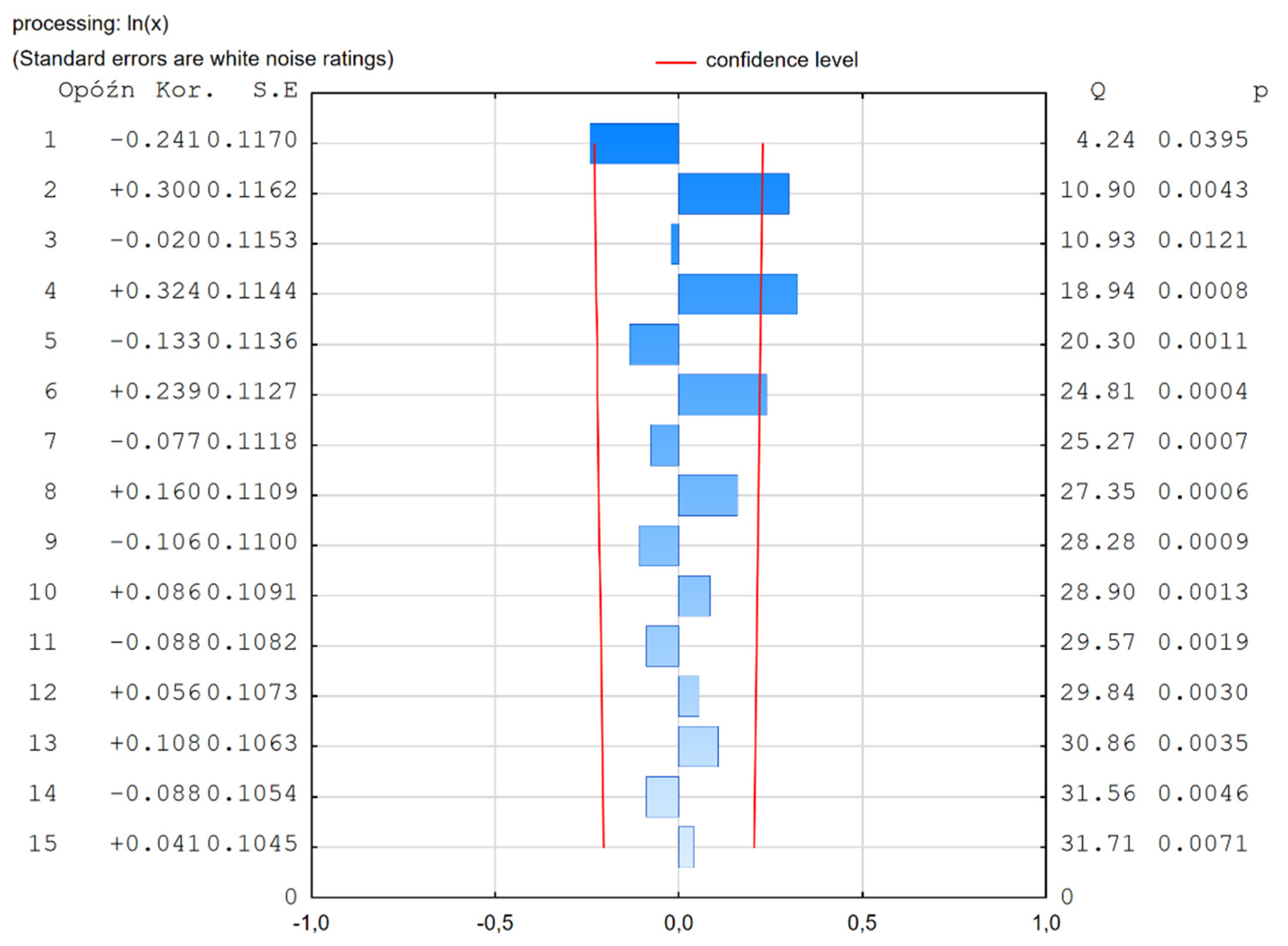

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pickett, S.T.A.; White, P.S. The Ecology of Natural Disturbance and Patch Dynamics; Academic Press: Cambridge, MA, USA, 1985. [Google Scholar]

- Ziemblińska, K.; Urbaniak, M.; Merbold, L.; Black, T.A.; Jagodziński, A.M.; Herbst, M.; Qiu, C.; Olejnik, J. The carbon balance of a Scots pine forest following severe wind throw: Comparison of reforestation techniques. Agr. Forest Meteorol. 2018, 260–261, 216–228. [Google Scholar] [CrossRef]

- Schelhaas, M.; Nabuurs, G.; Schuck, A. Natural disturbances in the European forests in the 19th and 20th centuries. Glob. Change Biol. 2003, 11, 1620–1633. [Google Scholar] [CrossRef]

- Don, A.; Bärwolff, M.; Kalbitz, K.; Andruschkewitsch, R.; Jungkunst, H.F.; Schulze, E.D. No rapid soil carbon loss after a windthrow event in the High Tatra. Forest Ecol. Manag. 2012, 276, 239–246. [Google Scholar] [CrossRef]

- Zajączkowski, J. Odporność Lasu na Szkodliwe Działanie Wiatru i Śniegu (Forest Resistance to the Harmful Effects of Wind and Snow); Wydawnictwo Świat: Warszawa, Poland, 1991. [Google Scholar]

- Gardiner, B.A.; Quine, C.P. Management of forests to reduce the risk of abiotic damage—A review with particular reference to the effects of strong winds. For. Ecol. Manag. 2000, 135, 261–277. [Google Scholar] [CrossRef]

- Panferov, O.; Doering, C.; Rauch, E.; Sogachev, A.; Ahrends, B. Feedbacks of windthrow for Norway spruce and scots pine stands under changing climate. Environ. Res. Lett. 2009, 4, 1–10. [Google Scholar] [CrossRef]

- Frank, D.; Reichstein, M.; Bahn, M.; Thonicke, K.; Frank, D.; Mahecha, M.D.; Smith, P.; Velde, M.; Babst, F.; Beer, C.; et al. Effects of climate extremes on the terrestrial carbon cycle: Concepts, processes and potential future impacts. Glob. Change Biol. 2015, 21, 2861–2880. [Google Scholar] [CrossRef]

- Leckebusch, G.C.; Koffi, B.; Ulbrich, U.; Pinto, J.G.; Spangehl, T.; Zachsarias, S. Analysis of frequency and intensity of European winter storm events from a multi-model perspective, at synoptic and regional scales. Clim. Res. 2006, 31, 59–74. [Google Scholar] [CrossRef]

- Beniston, M.; Stephenson, D.B.; Christensen, O.B.; Ferro, C.A.T.; Frei, C.; Goyette, S.; Halsnaes, K.; Holt, T.; Jylha, K.; Koffi, B.; et al. Future extreme events in European climate: An exploration of regional climate model projections. Clim. Chang. 2007, 81, 71–95. [Google Scholar] [CrossRef]

- Lorz, C.; Fürst, C.; Galic, Z.; Matijasic, D.; Podrazky, V.; Potocic, N.; Simoncic, P.; Strauch, M.; Vacik, H.; Makeschin, F. GIS-based probability assessment of natural hazards in forested landscapes of Central and South-Eastern Europe. Environ. Manag. 2010, 46, 920–930. [Google Scholar] [CrossRef]

- Ikonen, V.P.; Kilpeläinen, A.; Zubizarreta-Gerendiain, A.; Strandman, H.; Asikainen, A.; Venäläinen, A.; Kaurola, J.; Kangas, J.; Peltola, H. Regional risks of wind damage in boreal forests under changing management and climate projections. Can. J. For. Res. 2017, 47, 1632–1645. [Google Scholar] [CrossRef]

- Bilici, E.; Andiç, G.V.; Akay, A.E.; Sessions, J. Productivity of a portable winch system used in salvage logging of storm-damaged timber. Croat. J. For. Eng. 2019, 40, 311–318. [Google Scholar] [CrossRef]

- Szewczyk, G.; Stańczykiewicz, A. Model szacowania pracochłonności pozyskiwania drewna w drzewostanach ze śniegołomami (A model for estimating labour requirements during timber harvesting in snowbreak stands). Leśne Pr. Badaw. 2012, 2, 167–173. [Google Scholar]

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber Harvesting Methods in Eastern European Countries: A Review. Croat. J. For. Eng. 2017, 2, 231–241. [Google Scholar]

- Frutig, F.; Fahrni, F.; Stettler, A.; Egger, A. Mechanisierte Holzernte in Hanglagen. Wald Und Holz 2007, 4, 47–52. [Google Scholar]

- Dvořák, J.; Bystrický, R.; Hošková, P.; Hrib, M.; Jarkovská, M.; Kováč, J.; Krilek, J.; Natov, P.; Natovová, L. The Use of Harvester Technology in Production Forests; Folia Forestalia Bohemica: Kostelec nad Černýmilesy, Czech Republic, 2011. [Google Scholar]

- Szewczyk, G.; Sowa, J.M.; Grzebieniowski, W.; Kormanek, M.; Kulak, D.; Stańczykiewicz, A. Sequencing of harvester work during standard cuttings and in areas with windbreaks. Silva. Fenn. 2014, 48, 1–16. [Google Scholar] [CrossRef]

- Szewczyk, G.; Sowa, J.M.; Michalec, K.; Gaj-Gielarowec, D.; Gielarowiec, K. Salvage condition assesment of timber volume in disturbed areas. Balt. For. 2017, 23, 619–625. [Google Scholar]

- Bort, U.; Mahler, G. Kranvollernter einsatz bei der sturmholz aufarbeitung. AFZ Wald 1990, 14–15, 366–368. [Google Scholar]

- Bort, U.; Mahler, G.; Pfeil, C. Sturmholz auf arbeitung mit Kranvollernten. AFZ Wald 1990, 25–26, 640–641. [Google Scholar]

- Brzózko, J. Pozyskiwanie drewna z obszarów poklęskowych—Czynniki ryzyka i sposoby zwiększania bezpieczeństwa pracy (Wood harvesting from calamity areas risk factors and methods of work safety increasing). Tech. Rol. Ogrod. Leśna 2009, 1, 10–12. [Google Scholar]

- Brzózko, J. Metoda Prognozowania Wydajności Maszynowego Pozyskiwania Drewna Poklęskowego na Podstawie cech Uszkodzonej Powierzchni Leśnej (The Method of Forecasting of Windthrown Wood Machine Harvesting Performance Based on the Characteristics of the Damaged Forest Area); Wydawnictwo SGGW: Warszawa, Poland, 2014. [Google Scholar]

- Brzózko, J.; Kaluga, T. Investigations on technological process of after-calamity site preparation to logging with the harvester. Ann. Wars. Univ. Life Sci. SGGW Agric. 2010, 56, 79–87. [Google Scholar]

- Heinimann, H.R. Forest operations engineering and management—The ways behind and ahead of a scientific discipline. Croat. J. For. Eng. 2007, 28, 107–121. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Labelle, E.R. The effect of new silvicultural trends on mental workload of harvester operators. Croat. J. For. Eng. 2020, 41, 177–190. [Google Scholar] [CrossRef]

- Grzywiński, W.; Hołota, R. Subjective assessment of the fatigue of forest workers based on japanese questionnaire. Acta Sci. Pol. 2006, 5, 27–37. [Google Scholar]

- Sullman, M.; Gellerstedt, S. The mental workloads of mechanized harvesting. N. Z. For. 1997, 11, 48. [Google Scholar]

- Berger, C. Mental stress on harvester operators. In Proceedings of the Austro2003: High Tech Forest Operations for Mountainous Terrain, Schlaegl, Austria, 5–9 October 2003. 10p. [Google Scholar]

- Stampfer, K. Stress and Strain Effects of Forest Work in Steep Terrain. In Proceedings of the IUFRO/FAO Seminar on Forest Operations in Himalayan Forests with Special Consideration of Ergonomic and Socio-Economic Problems, Thimphu, Bhutan, 20–23 October 1997; Heinimann, H.R., Sessions, J., Eds.; Kassel University Press: Kassel, Germany, 1998; pp. 113–119. Available online: http://www.uni-kassel.de/upress/online/inhalt/978-3-933146-12-0.inhalt.pdf (accessed on 30 January 2021).

- Gomolka, Z.; Kordos, D.; Zeslawska, E. The application of flexible areas of interest to pilot mobile eye tracking. Sensors 2020, 20, 986. [Google Scholar] [CrossRef]

- Olsen, A. The Tobii I-VT fixation filter algorithm description. Tobii Technol. 2012, 21, 1–21. Available online: https://www.tobiipro.com/siteassets/tobii-pro/learn-and-support/analyze/how-do-we-classify-eye-movements/tobii-pro-i-vt-fixation-filter.pdf (accessed on 17 April 2020).

- Box, G.E.P.; Jenkins, G.M.; Reinsel, G.C. Time Series Analysis: Forecasting and Control; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Giefing, D.F. Badania nad opracowaniem proekologicznych procesów pozyskiwania drewna. In Model Optymalnych dla Środowiska Procesów Pozyskiwania Drewna; IBL: Warszawa, Poland, 1995; pp. 52–59. [Google Scholar]

- Paschalis, P. Kryteria zrównoważonej gospodarki leśnej w użytkowaniu lasu (Sustainable forest management criteria in forest utilisation). Prz. Tech. Rol. Leśnej 1997, 62, 22–29. [Google Scholar]

- Skoupý, A. Sophisticated model for nature-friendly timber haulage evaluation. In Technology and Ergonomics in the Service of Modern Forestry; Starzyk, J., Ed.; Publishing House of the University of Agriculture: Krakow, Poland, 2011; pp. 241–251. ISBN 978-83-60633-51-9. [Google Scholar]

- Kühmaier, M.; Stampfer, K. Development of a multi-criteria decision support tool for energy wood supply management. Croat. J. For. Eng. 2012, 33, 181–198. [Google Scholar]

- Häggström, C.; Englund, M.; Lindroos, O. Examining the gaze behaviors of harwester operators: Aneye-tracking study. Int. J. For. Eng. 2015, 2, 96–113. [Google Scholar] [CrossRef]

- Land, M.; Mennie, N.; Rusted, J. The roles of vision and eye movements in the control of activities of daily living. Perception 1999, 28, 1311–1328. [Google Scholar] [CrossRef]

- Rayner, K. Eyemovements in reading and information processing: 20 years of research. Psychol. Bull. 1998, 124, 372–422. [Google Scholar] [CrossRef] [PubMed]

- Duchowski, A. Eye tracking methodology. In Theory and Practice; Springer: London, UK, 2007. [Google Scholar]

- Szewczyk, G.; Spinelli, R.; Maganotti, N.; Tylek, P.; Sowa, J.M.; Rudy, P.; Gaj-Gielarowiec, D. The mental workload of harvester operators working in steep terrain conditions. Silva. Fenn. 2020, 54, 1–18. [Google Scholar] [CrossRef]

- Schütz, A.C.; Braun, D.I.; Gegenfurtner, K.R. Eye movements and perception: A selective review. J. Vis. 2011, 11, 1–30. [Google Scholar] [CrossRef] [PubMed]

- Hayhoe, M.M.; Rothkopf, C.A. Vision in the natural world. Wiley Interdisciplinary Reviews: Cognitive Sci. 2011, 2, 158–166. [Google Scholar] [CrossRef] [PubMed]

- Aştefănoaei, C.; Creangă, D.; Pretegiani, E.; Optican, L.M.; Rufa, A. Dynamical complexity analysis of saccadic eye movements in two different psychological conditions. Rom. Rep. Phys. 2014, 66, 1038–1055. [Google Scholar] [PubMed]

- Calvo, M.G.; Lang, P.J. Gaze patterns when looking at emotional pictures: Motivationally biased attention. Motiv. Emotion. 2004, 28, 221–243. [Google Scholar] [CrossRef]

- Patalano, A.L.; Juhasz, B.J.; Dicke, J. The relationship between decisiveness and eye movement patterns in a decision making informational search task. J. Behav. Decis. Making. 2010, 23, 353–368. [Google Scholar]

- Przybyło, J.; Kańtoch, E.; Augustyniak, P. Eyetracking-based assessment of affect-related decay of human performance in visual tasks. Future Gener. Com. Sys. 2018. [Google Scholar] [CrossRef]

- Holmqvist, K.; Nyström, M.; Andersson, R.; Dewhurst, R.; Jarodzka, H.; Van de Weijer, J. Eyetracking: A Comprehensive Guide to Methods and Measures; Oxford University Press: New York, NY, USA, 2011. [Google Scholar]

- Ballard, D.H.; Hayhoe, M.M.; Li, F.; Whitehead, S.D.; Frisby, J.; Taylor, J.; Fisher, R. Hand-eye coordination durings equential tasks. Philos. T. Roy. Soc. B 1992, 337, 331–339. [Google Scholar]

- Molnar, F. About the Role of Visual Exploration in Aesthetics. In Advances in Intrinsic Motivation and Aesthetics; Day, H., Ed.; Plenum Press: New York, NY, USA, 1981. [Google Scholar]

- Rayner, K.; Castelhano, M.S. Eye Movements during Reading, Scene Perception, Visual Search, and While Looking at Print Advertisements; Pieters, R., Wedel, M., Eds.; Erlbaum: Mahwah, NJ, USA, 2007. [Google Scholar]

- Steinman, R.M. Gaze control in natural conditions. In The Visual Neuroscience; Werner, J.S., Chalupa, L.M., Eds.; The MIT Press: Cambridge, MA, USA, 2003; Volume 2. [Google Scholar]

- Tokuda, S. Using saccadic eye movements to measure mental workload. J. Vision. 2008, 8, 86. [Google Scholar] [CrossRef]

- Rosner, J. Ergonomia (Ergonomics); Państwowe Wydawnictwo Ekonomiczne: Warszawa, Poland, 1985. [Google Scholar]

- Grandjean, E. Physiologische arbeitsgestaltung. Zeitschrift für Präventivmedizin 1958, 3, 253–260. [Google Scholar] [CrossRef]

- Traschütz, A.; Zinke, W.; Wegener, D. Speed change detection in foveal and peripheral vision. Vis. Res. 2012, 72, 1–13. [Google Scholar] [CrossRef] [PubMed]

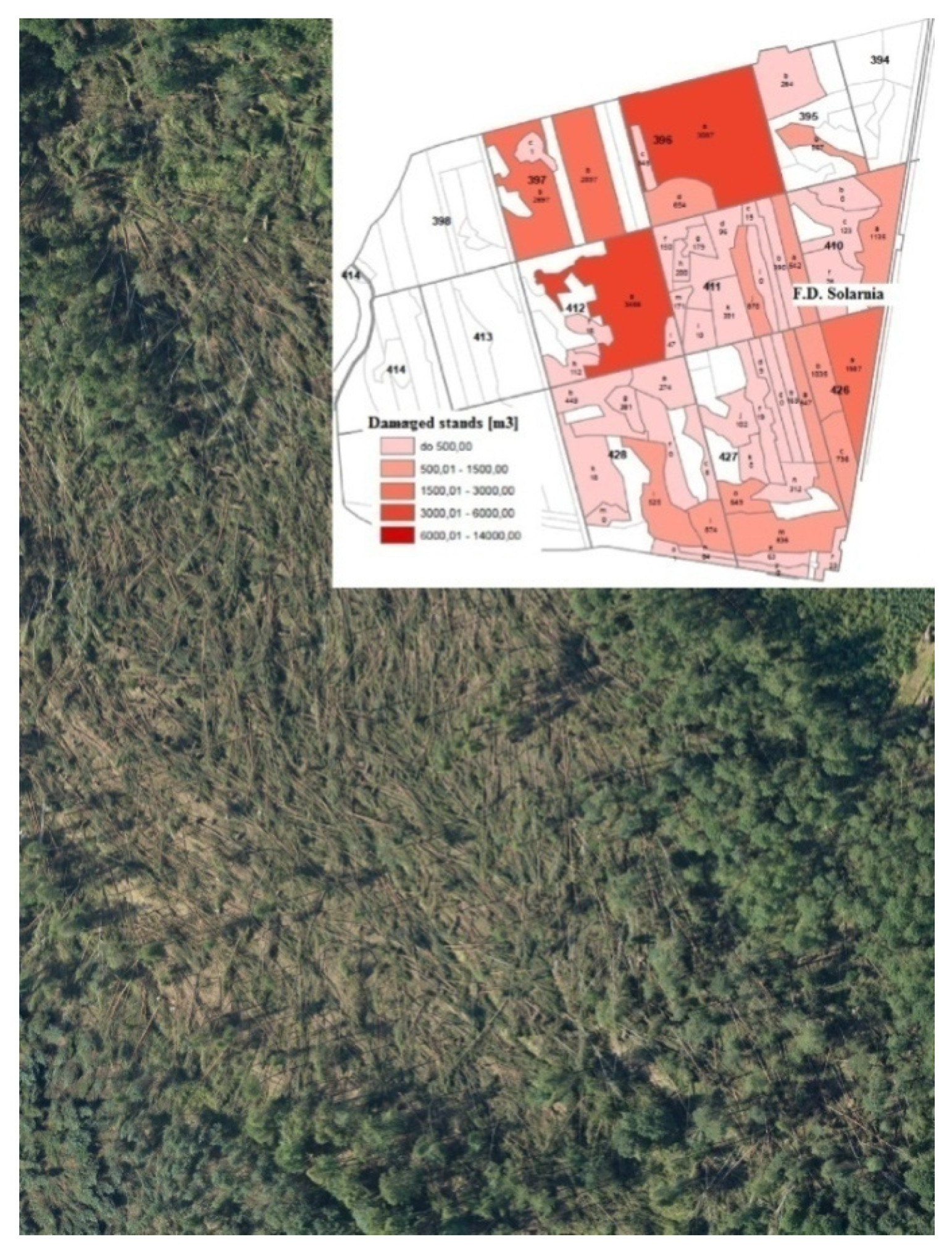

| Location | Compartment | Area [ha] | Site Type | Species Composition | Age [Years] | DBH [cm] | Height [m] | Merchantable Timber [m3·ha−1] | Disaster [%] |

|---|---|---|---|---|---|---|---|---|---|

| Solarnia F.R. | 411d | 3.65 | Humid mixed forest | Pine 40% Pine 30% Alder 30% | 22 28 28 | 10 15 12 | 9 15 12 | 32 42 28 | 50 |

| Solarnia F.R. | 410c | 3.15 | Humid mixed forest | Pine 60% Pine 20% Pine 20% | 33 33 33 | 17 17 16 | 15 16 15 | 77 12 19 | 50 |

| Parameter | Value |

|---|---|

| Weight [t] | 11.55 |

| Dimensions: length/width/height [m] | 5.91/2.45/3.62 |

| Crane: type/range [m] | John Deere 140H/7.9m |

| Cutting head | Waratah H412 |

| Engine power (kW/KM) | 140/190.35 |

| Eye-tracker | |

|---|---|

| Sampling frequency | 50–100 Hz (in respect to eye-trackers the sampling frequency means the number of identified locations of fixation points per one second. This frequency determines the quality of results and the accuracy of measurements taken) |

| Cameras | 4 |

| Scene camera FOV | 82° horizontally, 52° vertically |

| Scene camera parameters | h.264; 1920 × 1080 pixels; @25 fps |

| Field of view | 160° |

| Diagonal of scene camera FOV | 90°; 16:9 |

| Sound recording | Yes |

| Weight | 45 g |

| Battery | 120 min. |

| Recording Station | |

| Connection | HDMI, Micro USB, 3.5 mm Jack |

| Frequency | 2.4 GHz & 5 GHz band |

| Dimensions | 130 × 85 × 27 mm |

| Weight | 312 g |

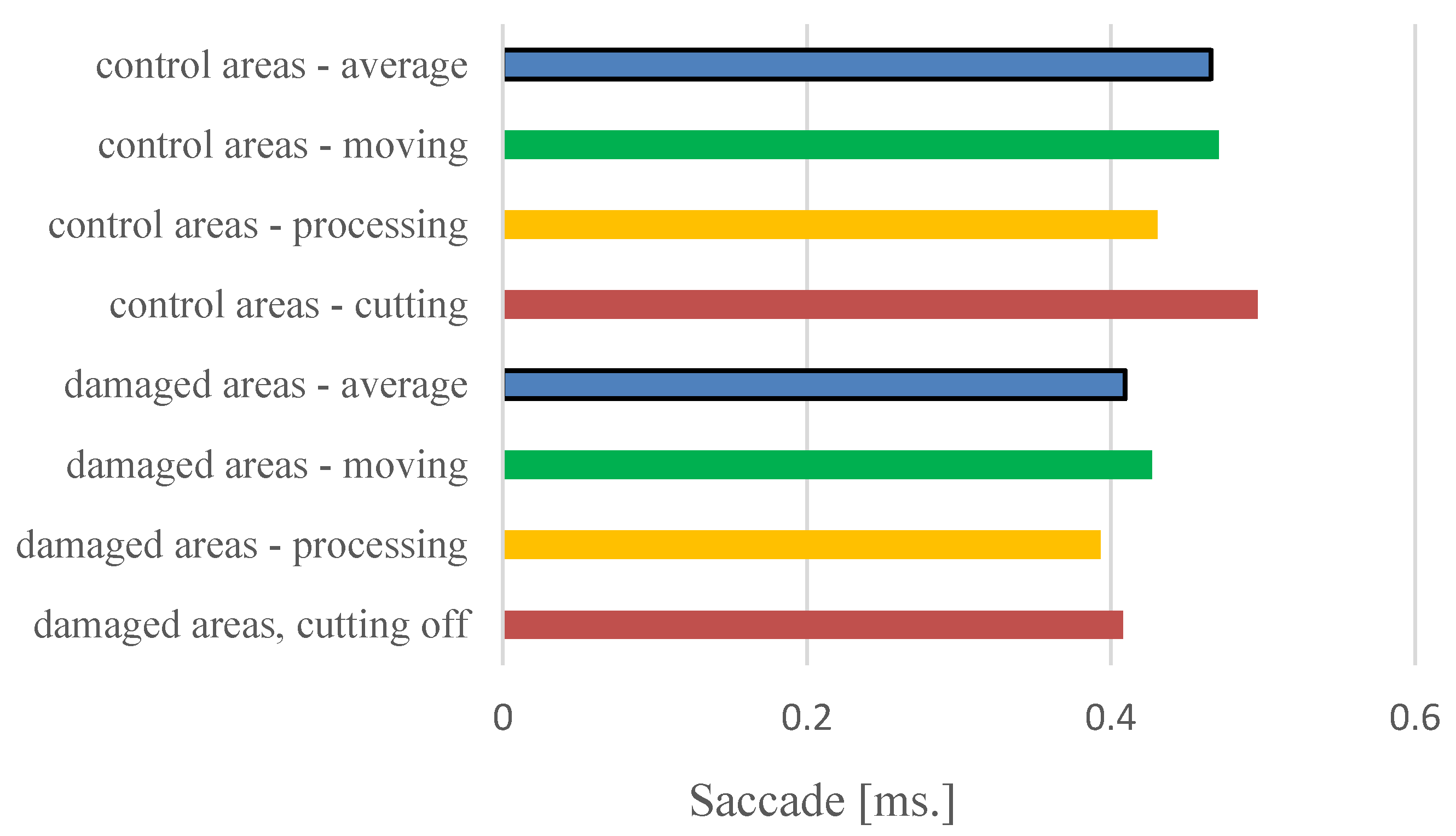

| Operation | Z | p |

|---|---|---|

| Total of all operations | −1.839 | 0.049 |

| Cutting/Cutting off | −2.143 | 0.030 |

| Processing | −0.510 | 0.610 |

| Moving | 0.714 | 0.470 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczyk, G.; Spinelli, R.; Magagnotti, N.; Mitka, B.; Tylek, P.; Kulak, D.; Adamski, K. Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests 2021, 12, 168. https://doi.org/10.3390/f12020168

Szewczyk G, Spinelli R, Magagnotti N, Mitka B, Tylek P, Kulak D, Adamski K. Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests. 2021; 12(2):168. https://doi.org/10.3390/f12020168

Chicago/Turabian StyleSzewczyk, Grzegorz, Raffaele Spinelli, Natascia Magagnotti, Bartosz Mitka, Paweł Tylek, Dariusz Kulak, and Kamil Adamski. 2021. "Perception of the Harvester Operator’s Working Environment in Windthrow Stands" Forests 12, no. 2: 168. https://doi.org/10.3390/f12020168

APA StyleSzewczyk, G., Spinelli, R., Magagnotti, N., Mitka, B., Tylek, P., Kulak, D., & Adamski, K. (2021). Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests, 12(2), 168. https://doi.org/10.3390/f12020168