Investigation of Feller-Buncher Performance Using Weibull Distribution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area and Data Collection

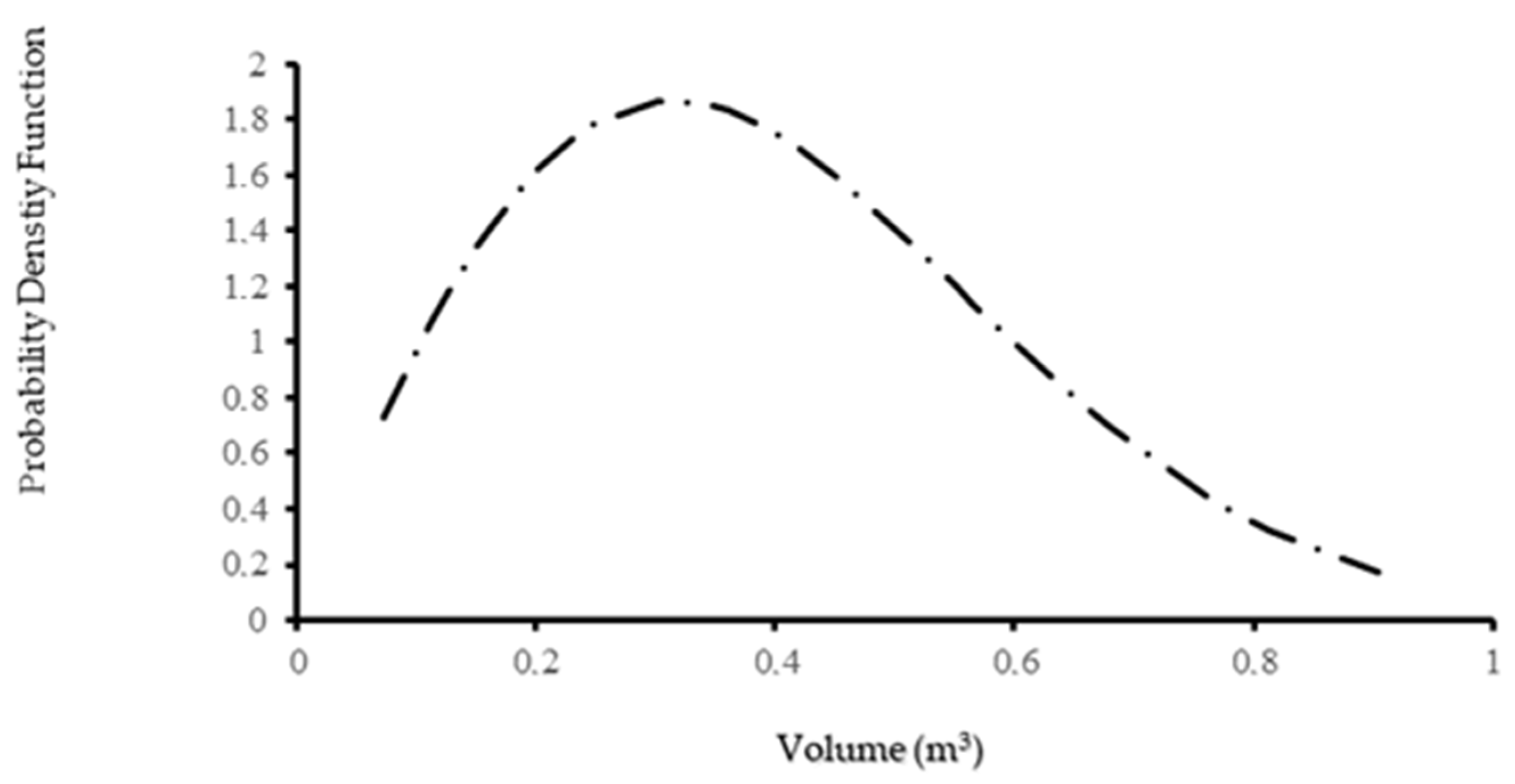

2.2. Data Analysis

2.2.1. Weibull Distribution Confirmations and the Approach Used in the Study

2.2.2. Estimation of Weibull Parameters

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akay, A.E.; Sessions, J. Identifying the Factors Influencing the Cost of Mechanized Harvesting Equipment. KSU J. Sci. Eng. 2004, 7, 65–72. [Google Scholar]

- Hiesl, P.; Benjamin, J. Applicability of international harvesting equipment productivity studies in Maine, USA: A literature review. Forests 2013, 4, 898–921. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Long, C.; Mcneel, J. Production and cost analysis of a feller-buncher and grapple skidder in central Appalachian hardwood forests. For. Prod. J. 2004, 54, 159–167. [Google Scholar]

- Spinelli, R.; Hartsough, B.R.; Magagnoti, N. Productivity standards for harvesters and processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- Hiesl, P. Productivity Standards for Whole-Tree and Cut-To-Length Harvesting Systems in Maine. Master’s Thesis, The University of Main, Orono, ME, USA, 2013; 150p. [Google Scholar]

- Akay, A.E.; Özkan, D.; Bilici, E. Assessing Productivity and Work Safety of a Mechanized Logging Operation. In Proceedings of the International Forestry Symposium (IFS 2016), Kastamonu, Turkey, 7–11 December 2016. [Google Scholar]

- Bilici, E.; Akay, A.E.; Abbas, D. Assessing the effects of Site Factors on the Productivity of a Feller Buncher: A Time and Motion Analysis. J. For. Res. 2019, 30, 1471–1478. [Google Scholar] [CrossRef]

- Visser, R.; Spinelli, R. Determining the shape of the productivity function for mechanized felling and felling-processing. J. For. Res. 2012, 17, 397–402. [Google Scholar] [CrossRef]

- Enez, K.; Aricak, B. Evaluation of technical and working conditions of tree harvesting machine. KSU J. Eng. Sci. 2012, 108–114. [Google Scholar]

- Klepac, J. Performance of a Tracked Feller-Buncher with a Shear Head Operating in Small-Diameter Pine. In Proceedings of the 2013 Council on Forest Engineering Annual Meeting, Missoula, MT, USA, 7–10 July 2013. [Google Scholar]

- Schweier, J.; Spinelli, R.; Magagnotti, N.; Becker, G. Mechanized coppice harvesting with new small scale feller bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass Bioenergy 2015, 72, 85–94. [Google Scholar] [CrossRef]

- Bilici, E.; Akay, A.E.; Abbas, D. An evaluation of a fully mechanized forest harvesting operation in Bursa, Turkey. In Proceedings of the ISFOR—International Symposium on New Horizons in Forestry, Isparta, Turkey, 18–20 October 2017; pp. 220–224. [Google Scholar]

- Joseph, P.; Hennessey, J.P., Jr. Some aspects of wind power statistics. J. Appl. Meteorol. 1977, 16, 119–128. [Google Scholar]

- Kahriman, A.; Yavuz, H. The Probability Density Functions to Diameter Distributions for Scots Pine Oriental Beech and Mixed Stands. Artvin Çoruh Univ. Fac. For. J. 2011, 12, 109–125. [Google Scholar]

- Bolat, F.; Ercanli, İ. Modeling Diameter Distributions by Using Weibull Function in Forests Located Kestel-Bursa. Kast. Univ. J. For. Fac. 2017, 17, 107–115. [Google Scholar]

- Harish Kumar, N.S.; Choudhary, R.P.; Murthy, C.S.N. Reliability analysis of dumper in lime stone mine based on Weibull distribution. In Proceedings of the 91st the IRES International Conference, Chicago, IL, USA, 3–5 August 2017. [Google Scholar]

- Bala, R.J.; Govinda, R.M.; Murthy, C.S.N. Reliability analysis and failure rate evaluation of load haul dump machines using Weibull distribution analysis. Math. Model. Eng. Probl. 2018, 5, 116–122. [Google Scholar] [CrossRef]

- Napiórkowskia, J.; Gonerab, J. Analysis of failures and reliability model of farm tractors. Agric. Eng. 2020, 24, 89–101. [Google Scholar]

- Hawkins, K.; Hotvedt, J.; Cao, Q.; Jackson, B. Using the Weibull distribution to model harvesting machine productivity. For. Prod. J. 1988, 38, 59–65. [Google Scholar]

- Zeytinoğlu, F.Ç. Comparison of statistical estimation methods for the scale and shape parameters of the Weibull distribution. Istanb. Commer. Univ. J. Soc. Sci. 2009, 8, 73–78. [Google Scholar]

- Carta, J.A.; Ramirez, P.; Velazquez, S. A review of wind speed probability distributions used in wind energy analysis: Case studies in the Canary Islands. Renewable and Sustainable. Energy Rev. 2009, 13, 933–955. [Google Scholar]

- Chellali, F.; Khellaf, A.; Belouchrani, A.; Khanniche, R. A comparison between wind speed distributions derived from the maximum entropy principle and Weibull distribution. Case of study; six regions of Algeria. Renew. Sustain. Energy Rev. 2012, 16, 379–385. [Google Scholar] [CrossRef]

- Wang, J.; Hu, J.; Ma, K. Wind speed probability distribution estimation and wind energy assessment. Renew. Sustain. Energy Rev. 2016, 60, 881–899. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar]

- Stout, J.C.; Rutherfurd, I.; Grove, J.; Webb, J.A.; Kitchingman, A.; Tonkin, Z. Using the Weibull distribution to improve the description of riverine wood loads. Earth Surf. Process. Landf. 2016, 42, 647–656. [Google Scholar] [CrossRef]

- Zhang, T.; Xie, M. Failure data analysis with extended Weibull distribution. Commun. Stat. Simul. Comput. 2007, 36, 579–592. [Google Scholar] [CrossRef]

- Genc, A.; Erisoglu, M.; Pekgor, A.; Oturanc, K.; Hepbasli, A.; Ulgen, K. Estimation of wind power potential using Weibull distribution. Energy Sources 2005, 27, 809–822. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, J.; Jiang, H.; Shi, X. Intelligent optimized wind resource assessment and wind turbines selection in Huitengxile of Inner Mongolia, China. Appl. Energy 2013, 109, 239–253. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Chi, D. Wind energy potential assessment for the site of Inner Mongolia in China. Renew. Sustain. Energy Rev. 2013, 21, 215–228. [Google Scholar] [CrossRef]

- Chang, T.P. Performance comparison of six numerical methods in estimating Weibull parameters for wind energy application. Appl. Energy 2011, 88, 272–282. [Google Scholar] [CrossRef]

- Alam, M.; Acuna, M.; Brown, M. Self-Levelling Feller-Buncher Productivity Based on Lidar-Derived Slope. Croat. J. For. Eng. 2013, 34, 273–281. [Google Scholar]

- Mohammadi, K.; Alavi, O.; Mostafaeipour, A.; Goudarzi, N.; Jalilvand, M. Assessing different parameters estimation methods of Weibull distribution to compute wind power density. Energy Convers. Manag. 2016, 108, 322–335. [Google Scholar] [CrossRef]

| Components | Description |

|---|---|

| Moving | Vehicle begins to move and chooses the tree |

| Felling | Positioning of the cutting head around the standing tree and felling with the chainsaw starts |

| Stacking | Stacking the logs |

| Other activities | The time spent on other activities (e.g., removing of obstacles, etc.). |

| Delays | Non-productive time including mechanical, operational, and personal delays |

| Min | Max | Std | Median | |

|---|---|---|---|---|

| Length (m) | 10.00 | 20.00 | 2.94 | 15.00 |

| Diameter (cm) | 9.60 | 24.00 | 4.51 | 17.60 |

| Volume (m3) | 0.07 | 0.90 | 0.22 | 0.34 |

| Total time (s) | 12.30 | 39.30 | 6.36 | 23.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilici, E. Investigation of Feller-Buncher Performance Using Weibull Distribution. Forests 2021, 12, 284. https://doi.org/10.3390/f12030284

Bilici E. Investigation of Feller-Buncher Performance Using Weibull Distribution. Forests. 2021; 12(3):284. https://doi.org/10.3390/f12030284

Chicago/Turabian StyleBilici, Ebru. 2021. "Investigation of Feller-Buncher Performance Using Weibull Distribution" Forests 12, no. 3: 284. https://doi.org/10.3390/f12030284