Analysis of the Offering and Resale Prices on the Second-Hand Skidders Market

Abstract

1. Introduction

2. Materials and Methods

3. Results

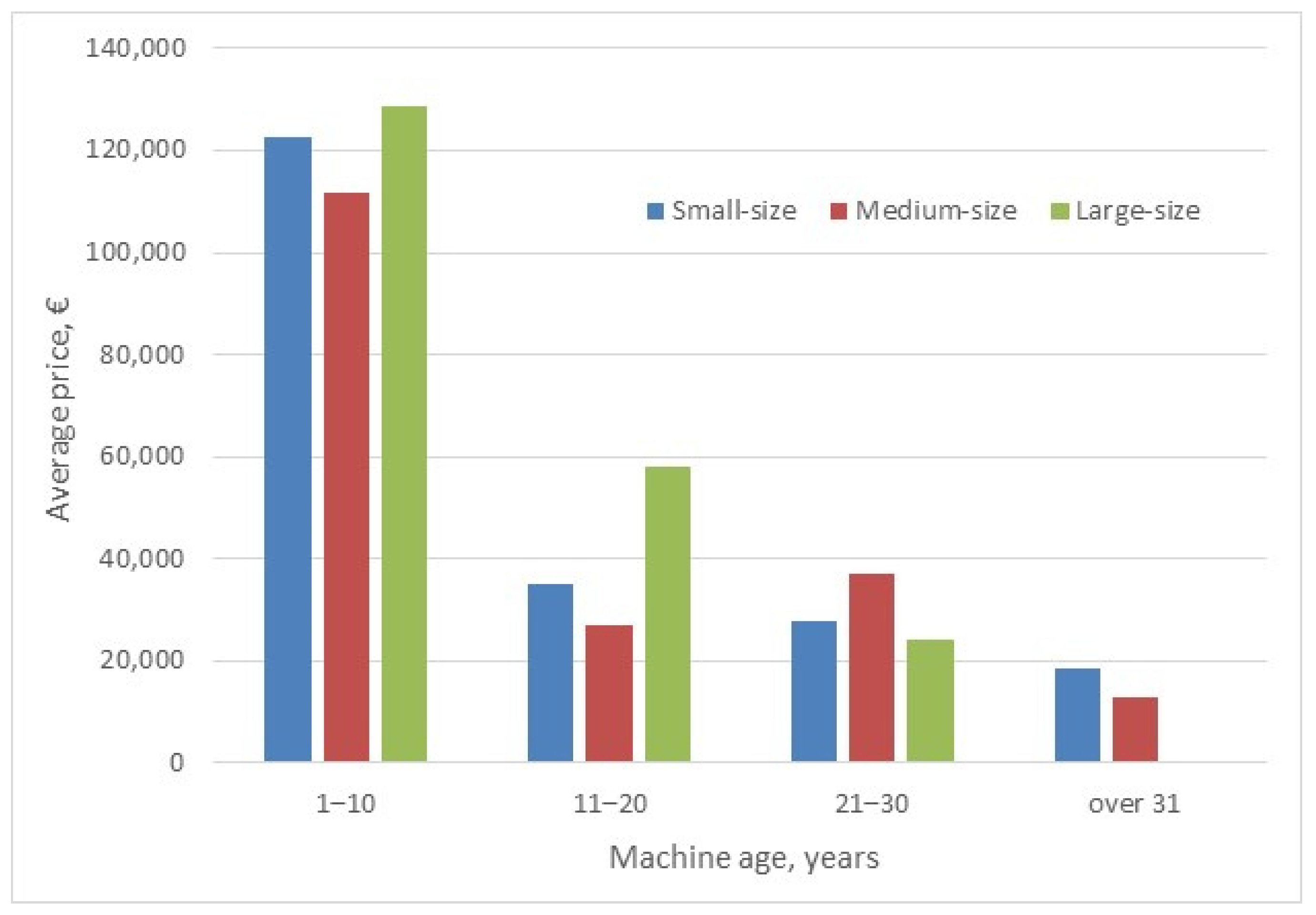

3.1. Skidder Size, Age and Brand

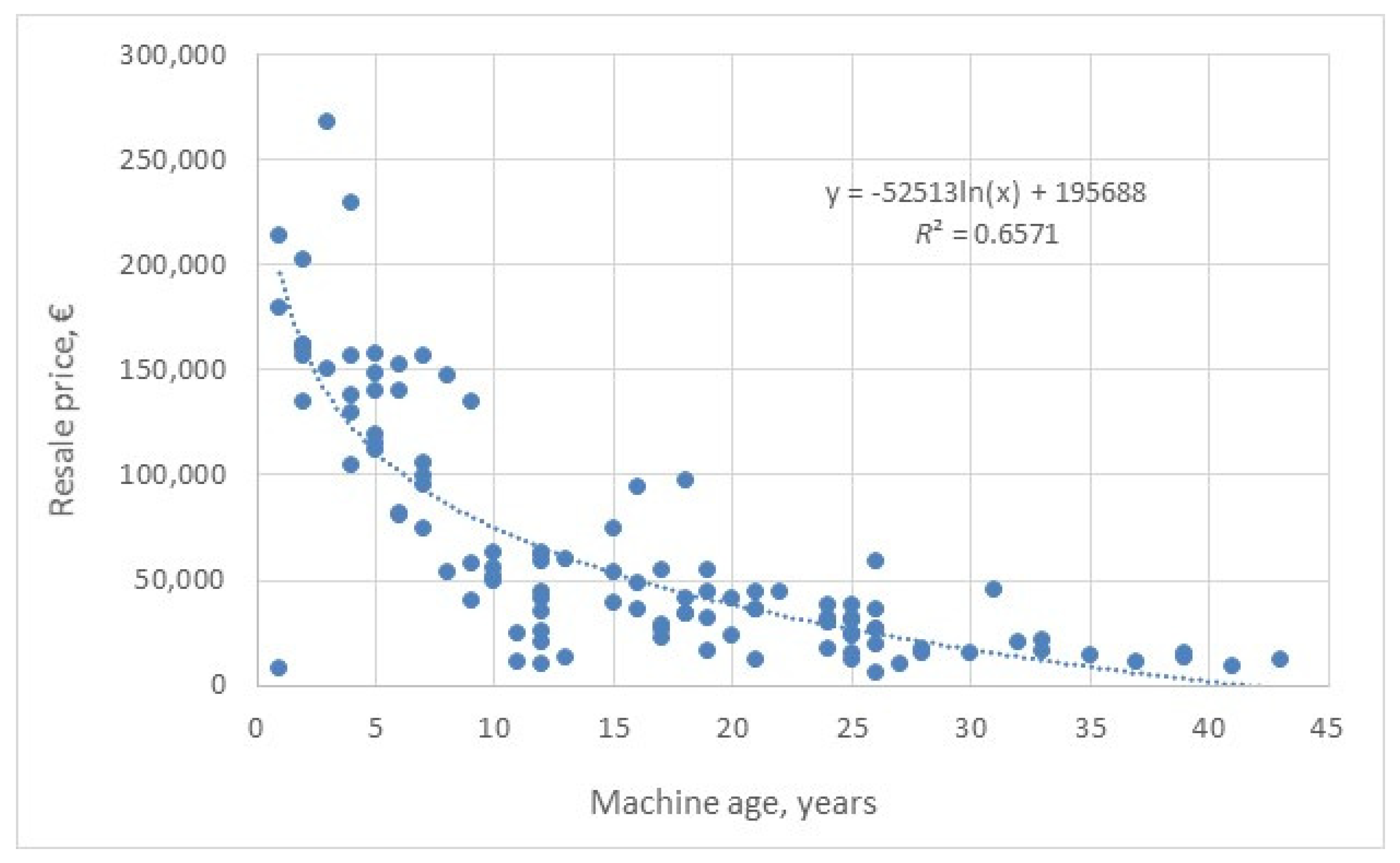

3.2. Total Work Hours, Annual Use and Resale Price

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grebner, D.L.; Bettinger, P.; Siry, J.P. Forest Harvesting Systems. In Introduction to Forestry and Natural Resources; Academic Press: Cambridge, MA, USA, 2013; pp. 287–302. [Google Scholar] [CrossRef]

- Heinrich, R.; Arzberger, U. Forest operations in the tropics, reduced impact logging. Encycl. For. Sci. 2004, 247–252. [Google Scholar] [CrossRef]

- Drushka, K.; Konttinen, H. Tracks in the Forest—The Evolution of Logging Machinery; Timberjack Group: Helsinky, Finland, 1997; 254p. [Google Scholar]

- Šušnjar, M.; Oršanić, M.; Pentek, T.; Poršinsky, T.; Šporčić, M. Recent challenges of forest engineering academic education. Croat. J. For. Eng. 2013, 34, 167–172. [Google Scholar]

- Blandon, P. Soviet Forest Industries, 1st ed.; Routledge: New York, NY, USA, 2019; 306p. [Google Scholar] [CrossRef]

- Borz, S.A. A review of the Romanian and international practices in skidding operations. In Proceedings of the 14th World Forestry Congress, Durban, South Africa, 7–11 September 2015; 11p. [Google Scholar]

- Heinimann, H.R.; Stampfer, K.; Loschek, J.; Caminada, L. Perspectives on central European cable yarding systems. In Proceedings of the International Mountain Logging and 11th Pacific Northwest Skyline Symposium, Seattle, WA, USA, 10–12 December 2001; pp. 268–279. [Google Scholar]

- Spinelli, R.; Magagnotti, N. The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. For. Policy Econ. 2011, 13, 520–524. [Google Scholar] [CrossRef]

- Horvat, D.; Zečić, Ž.; Šušnjar, M. Morphological characteristics and productivity of skidder ECOTRAC 120 V. Croat. J. For. Eng. 2007, 28, 11–25. [Google Scholar]

- Russell, F.; Mortimer, D. A Review of Small-Scale Harvesting Systems in Use Worldwide and Their Potential Application in Irish Forestry; COFORD, National Council for Forest Research and Development: Dublin, Ireland, 2005; 48p. [Google Scholar]

- Picchio, R.; Neri, F.; Sirna, A.; Spinelli, R. Improved winching technique to reduce logging damage. Ecol. Eng. 2012, 47, 83–86. [Google Scholar] [CrossRef]

- Marenče, J.; Krč, J. Possibilities of using small tractors for forestry operations on private property. Croat. J. For. Eng. 2016, 37, 151–162. [Google Scholar]

- Kluender, R.; Lortz, D.; McCoy, W.; Stokes, B.; Klepac, K. Productivity of rubber-tired skidders in southern pine forests. For. Prod. J. 1997, 47, 53–58. [Google Scholar]

- Sabo, A.; Porsinsky, T. Skidding of fir roundwood by Timberjack 240C from selective forests of Gorski Kotar. Croat. J. For. Eng. 2005, 26, 13–27. [Google Scholar]

- Behjou, F.K. A techno-economic evaluation of skidding operation by Timber jack 450C and Clark Ranger 666BDS in Caspian forests. J. Food Agric. Environ. 2010, 8, 1020–1023. [Google Scholar]

- Borz, S.A.; Ignea, G.; Popa, B. Assessing timber skidding efficiency in a group shelterwood system applied to a fir-beech stand. Afr. J. Agric. Res. 2014, 9, 160–167. [Google Scholar] [CrossRef]

- Shegelman, I.R.; Budnik, P.V.; Baklagin, V.N. Simulation modeling of truck load of skidding tractors with a grapple for chokerless skidding. Croat. J. For. Eng. 2019, 40, 297–310. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Picchi, G. Annual use, economic life and residual value of cut-to-length harvesting machines. J. For. Econ. 2011, 17, 378–387. [Google Scholar] [CrossRef]

- Malinen, J.; Laitila, J.; Väätäinen, K.; Viitamäki, K. Variation in age, annual usage and resale price of cut-to-length machinery in different regions of Europe. Int. J. For. Eng. 2016, 27, 95–102. [Google Scholar] [CrossRef]

- Matthews, D.M. Cost Control in the Logging Industry; McGraw-Hill Book Co., Inc.: New York, NY, USA, 1942; 374p. [Google Scholar]

- Miyata, E.S. Determining Fixed and Operating Costs of Logging Equipment; General Technical Report Nr. NC-55; Northern Central Forest Experiment Station, US Forest Service: St. Paul, MN, USA, 1980; 16p.

- Ackerman, P.; Belbo, H.; Eliasson, L.; De Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Abbas, D.; Di Fulvio, F.; Marchi, E.; Spinelli, R.; Schmidt, M.; Bilek, T.; Han, H. A Proposal for an Integrated Methodological and Scientific Approach to Cost Used Forestry Machines. Croat. J. For. Eng. 2021, 42, 63–75. [Google Scholar] [CrossRef]

- Vondra, V.; Martinić, I.; Zdjelar, M. Procjena Uzroka Nerazvijenosti Privatnog Poduzetništva u Šumskom Gospodarstvu Hrvatske (Assessing the Causes of Underdevel-opment of Private Entrepreneurship in the Croatian Forestry); Research Study; Faculty of Forestry University of Zagreb: Zagreb, Croatia, 1997; 14p. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Visser, R.; O’Neal, B. A survey of the skidder fleet of Central, Eastern and Southern Europe. Eur. J. For. Res. 2021, 11. [Google Scholar] [CrossRef]

- Belenkji, J.; Andronov, A.; Martynov, B.; Khakhina, A. Trends of technical characteristics of wheeled skidding machinery. In Proceedings of the Conference Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2019; pp. 662–668. [Google Scholar] [CrossRef]

- Lundbäck, M.; Häggström, C.; Nordfell, T. Worldwide trends in the methods and systems for harvesting, extraction and transportation of roundwood. In Proceedings of the 6th International Forest Engineering Conference, Rotorua, New Zealand, 16–19 April 2018. [Google Scholar]

- Harrill, H.; Visser, R. A Survey of NZ Ground-Based Harvesting Systems; HTN12; Forest Growers Research: Rotorua, New Zealand, 2019; 8p. [Google Scholar]

- Arlinger, J.; Björheden, R.; Brunberg, T.; Lundström, H.; Möller, J.J. Size matters. Improving operations by analyzing the effects of machine size. In Proceedings of the Nordic Baltic Conference OSCAR14 SOLUTIONS for Sustainable Forestry Operations, NOVA Park Conference, Knivsta, Sweden, 25–27 June 2014; Volume 830, pp. 54–55. [Google Scholar]

- Nordfell, T.; Öhman, E.; Lindroos, O.; Ager, B. The technical development of forwarders in Sweden between 1962 and 2012 and of sales between 1975 and 2017. Int. J. For. Eng. 2019, 30, 1–13. [Google Scholar] [CrossRef]

| Specialised Website, Name | Internet Address |

|---|---|

| Mascus | http://www.mascus.co.uk/ (accessed on 7 April 2020) |

| Machine Finder | http://www.machinefinder.com/ (accessed on 10 April 2020) |

| Machinery Zone | http://www.machineryzone.eu/ (accessed on 10 April 2020) |

| Ritchie Bros. Auctioneers | https://www.rbauction.com/ (accessed on 4 May 2020) |

| Agriaffaires | http://www.agriaffaires.co.uk/ (accessed on 16 April 2020) |

| Njuškalo | http://www.njuskalo.hr/ (accessed on 29 April 2020) |

| My Little Salesman | http://www.mylittlesalesman.com/ (accessed on 7 May 2020) |

| Agropijaca | http://www.agropijaca.com/ (accessed on 29 April 2020) |

| Technik Boerse | http://technikboerse.com/ (accessed on 11 May 2020) |

| Market Book | http://www.marketbook.ca/ (accessed on 7 May 2020) |

| Size Class | Skidders, N | Machine Age in Years, % | Leading Brands | |||

|---|---|---|---|---|---|---|

| <10 | 11–20 | 21–30 | >30 | |||

| Small (<110 kW) | 57 | 12 | 28 | 44 | 16 | Timberjack (33%) |

| Medium (110–130 kW) | 20 | 35 | 30 | 30 | 5 | John Deere (40%), Caterpillar (30%) |

| Large (>130 kW) | 44 | 70 | 25 | 5 | - | Caterpillar (36%), HSM (18%) |

| Total | 121 | 37 | 27 | 27 | 8 | |

| Total Use, Machine Hours | Machine Age, Years | Annual Use, Machine Hours/Year | Resale Price, EUR | |

|---|---|---|---|---|

| Mean | 8494 | 16.0 | 863 | 64,725 |

| Std. Dev. | 5219 | 10.2 | 589 | 57,231 |

| Min | 100 | 1.0 | 9 | 5710 |

| Max | 20,243 | 43.0 | 2826 | 267,631 |

| Median | 8091 | 15.0 | 822 | 41,299 |

| Mode | 11,000 | 12.0 | 692 | 35,540 |

| IQR | 7090 | 17.0 | 791 | 74,556 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šporčić, M.; Šušnjar, M.; Pandur, Z.; Bačić, M.; Mijoč, D.; Landekić, M. Analysis of the Offering and Resale Prices on the Second-Hand Skidders Market. Forests 2021, 12, 729. https://doi.org/10.3390/f12060729

Šporčić M, Šušnjar M, Pandur Z, Bačić M, Mijoč D, Landekić M. Analysis of the Offering and Resale Prices on the Second-Hand Skidders Market. Forests. 2021; 12(6):729. https://doi.org/10.3390/f12060729

Chicago/Turabian StyleŠporčić, Mario, Marijan Šušnjar, Zdravko Pandur, Marin Bačić, David Mijoč, and Matija Landekić. 2021. "Analysis of the Offering and Resale Prices on the Second-Hand Skidders Market" Forests 12, no. 6: 729. https://doi.org/10.3390/f12060729

APA StyleŠporčić, M., Šušnjar, M., Pandur, Z., Bačić, M., Mijoč, D., & Landekić, M. (2021). Analysis of the Offering and Resale Prices on the Second-Hand Skidders Market. Forests, 12(6), 729. https://doi.org/10.3390/f12060729