Abstract

This study presents a decision support system for the financial analysis of an acorn chain used in food production. The application of these fruits, in fact, shows potential in human nutrition and valorization of rural and marginal areas. A multi-step production process is hypothesised with a different potential organizational structure of each phase and products to be sold. The net present value, pay-back period, safety margins, and internal rate of return are computed for the implemented scenario. The research was grounded on Italian-based data but can be easily transferred to other case studies. The results highlight potential economic suitability of the chain, although subject to a minimal value of prices and productivity. Future improvements and further integration of this study, such as the analysis of fluctuation’s risk of annual production or the need to investigate sensorial properties of acorns, are suggested and discussed.

1. Introduction

Acorns are the fruits of oaks (Quercus spp.) and tan oaks (Lithocarpus spp.), which are native to the Northern hemisphere. The Quercus genus includes about 600 species spread worldwide in a variety of habitats, including temperate deciduous forests, temperate and subtropical evergreen forests, subtropical and tropical savannahs, and subtropical woodlands.

Acorns are considered as non-wood forest products (NWFP); the Food and Agriculture Organization of the United Nations (FAO), defined NWFP as “goods derived from forests that are tangible and physical objects of biological origin other than wood” [1]. NWFP contribute to different classes of ecosystem services [2], such as provisioning and cultural services [3].

Acorns are used as feed for both domestic and wild animals [4]. In fact, traditionally, acorns are applied as feed for hogs and wild boars as these animals tolerate the tannin substances contained in these fruits, which are considered potentially toxic for other livestock [5].

Acorn components are being used for different industrial applications. Vinha et al. [6] investigated the potential use of acorn tissues for pharmaceutical products offering economic advantages and value-added by-products generated from agricultural wastes. Among industrial functions, acorns were examined for their properties for removing water turbidity. Antov et al. [7] demonstrated a promising application of the whole fruit of acorn and its cotyledons and coat as a potential source of natural coagulants. Similar conclusions were reported by Kuppusamy et al. [8]. Šćiban et al. [9] investigated further and demonstrated the effective coagulation capabilities of Quercus robur L., Quercus cerris L., and Quercus rubra L., and showed that their amounts depended on the pH value and initial turbidity. Aziz et al. [10] reported not only positive behaviour as emulsification for protein that is isolated from the waste of acorn fruit but also high suitability in inhibiting corrosion due to the extracted tannins [11], potential source of bioactive compounds [12] or production of activated carbons from acorn shells [13] that were demonstrated. Acorns components achieved encouraging results in the renewable resources and energies sector: for instance, Chao et al. [14] proved the technical and economic sustainability of acorn starch for bioethanol production. Li et al. [15] showed that bioplastics from acorn composites had superior mechanical and biodegradable properties compared to conventional thermoplastic plastics. Optimization of tannin extraction in industrial processes is extremely important for the application of these components in additional uses [11,14]. For example, Onem et al. [16] showed that the tanning properties of Quercus ithaburensis subsp. macrolepis (Kotschy) Hedge & Yalt. tannins isolated from acorns were satisfactory for the vegetable tanning process in leather production.

Besides the industrial possibilities, food is one of the most promising applications of acorns either as whole fruits or derivative products. García–Gómez et al. [4] described the consumption of acorns in the Iberian Peninsula right from prehistoric times through the 20th century until the 1960s. Similarly, Mason and Nesbitt [17] show evidence for its consumption in southeast Turkey. Bainbridge [18] reported on the widespread use of acorn as food in Europe, Asia, North Africa, the Middle East, and North America for thousands of years, based on archaeological records. Both García–Gómez et al. [4] and Izumi [19] revealed how acorns were important during food shortages and used as an alternative food source that saved people from starvation.

Consumption of acorns requires pre-treatment, such as drying, roasting, or boiling. They can be used in the form of nuts, flour, or cooking oil [20]. New acorn-based products such as acorn liquor, caramels, and beer are also produced on a small scale [4].

Manipulation and lowering the bitterness of the fruit is, however, the main aspect that must be considered because acorns seem to present toxicity due to tannins, in some mammalian species [21], including humans [18]. De-bittering of acorns can be carried out by either leaching, soaking, or boiling them in water [4,17]. Another technique to sweeten bitter acorns is the use of iron-rich red earth, wood ashes, or additional ingredients such as bicarbonate of soda [18].

The fruits of oaks and tan oaks present a positive phytochemical profile. Acorns provide health benefits such as antioxidant activity, decrease the risk of cardiovascular diseases, diabetes, cancer, hepatic fibrosis, or microbial infections [20,22,23,24].

The study of Gezici and Sekeroglu [25] focused on the positive neuroprotective and enzyme inhibitory effects of the ethanol and water extracts from the shell of acorns. Wang et al. [26] confirmed the neuroinflammatory benefits of acorns, suggesting how Chinese acorns can be served as a healthy product for preventing diseases such as Alzheimer’s. Dalar et al. [27] demonstrated the significant effects of acorn on regulating the levels of lipid peroxidation, antioxidant defence systems, and haematological parameters.

In recent years, a strong increase in the incidence of celiac disease patients has been registered worldwide. Celiac people benefit from gluten-free (GF) foods. Acorns presents interesting properties for preparing GF products [28]. Acorn flour showed good technological properties in GF baking [29] and was applied as a GF ingredient for muffin production [30].

Several authors have emphasized the cultural value of acorn products. For instance, in Sardinia (Italy), Pinna [31] described how the “laborious process of preparation of acorns for bread-making is said to have been a ceremony with religious connotations,” but it is now made exclusively as a tradition on the occasion of village festivities. Pignone and Laghetti [32] mentioned the use of acorn flour for bread and cake production in the Calabria and Sardinia regions, respectively, as a cultural specificity in the local tradition.

Despite the growing interest for using this fruit in different fields, scientific literature has paid less attention in investigating the financial aspect of acorn chains. Chao et al. [14] reported that the process of bioethanol production from acorn starch seems to be technically and economically sustainable. Molina Martínez et al. [33]—based on the weight gain value—defined acorn price related to swine production equal to 0.22 €/kg. The value of acorn was computed in a market opportunity approach quantifying the grazing lease price for livestock. The results indicate a price ranging from 0.2 €/kg for privately-owned dehesas to 0.01 €/kg in public forests [34]. Pemberton [35] indicated how acorns have an affirmed market in South Korea, for example, to produce a gelatine-like food. Pinna [31] highlighted how acorn bread is sold at a higher price than regular wheat flour bread in Sardinia.

Given these premises—particularly the lack of studies on the economics of acorn production—it is worth examining the economic feasibility of the entire process for acorn-based products. This study focuses on the use of acorn for food. The specific aim is to carry out a spreadsheet-based decision support system (DSS) to guide the user in the choice and quantification of parameters of process in each step of the chain and to assess the financial suitability of the obtained products. Data and technical analysis are grounded on an Italian case study.

2. Materials and Methods

2.1. Structure of Decision Support System (DSS)

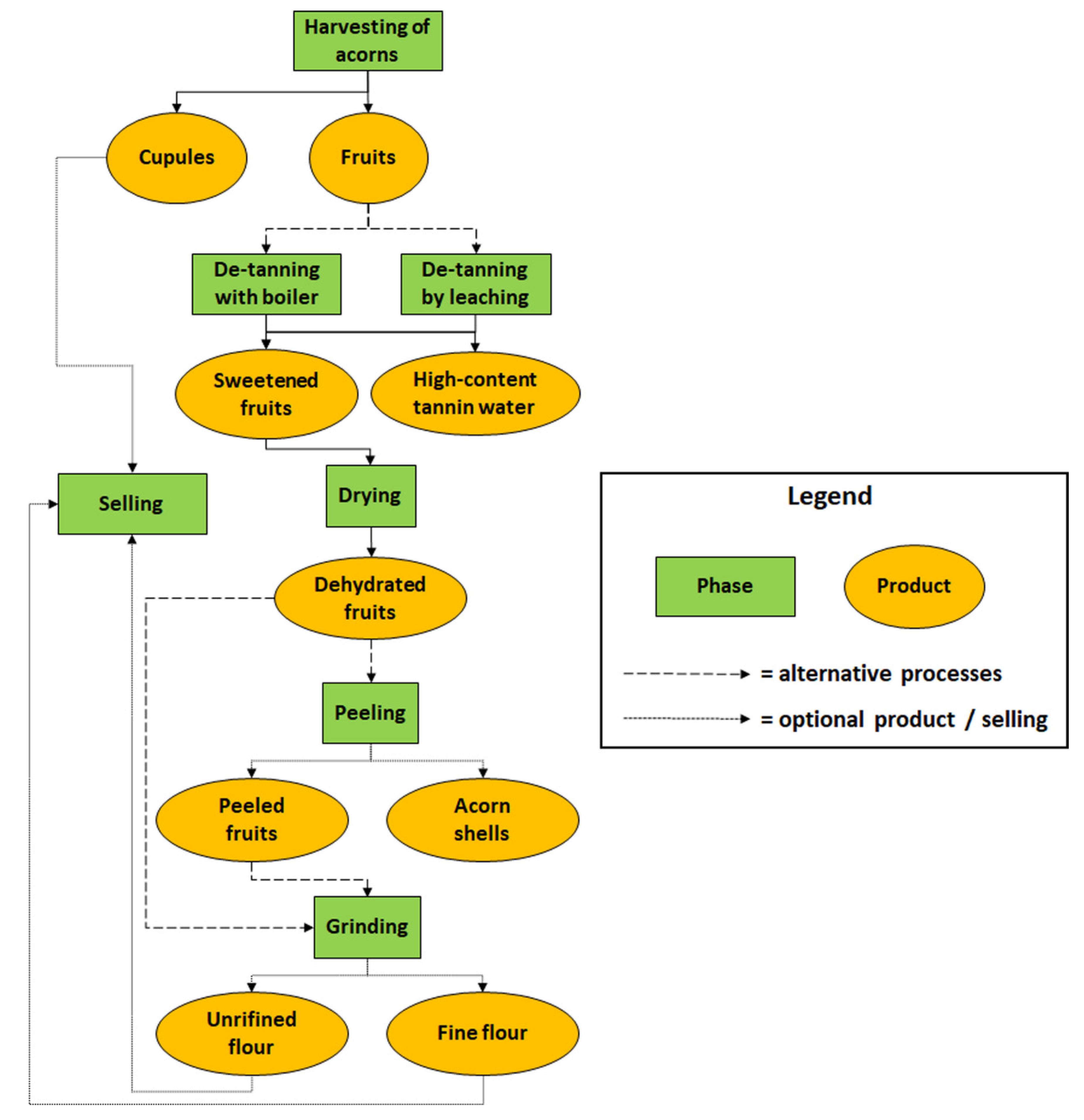

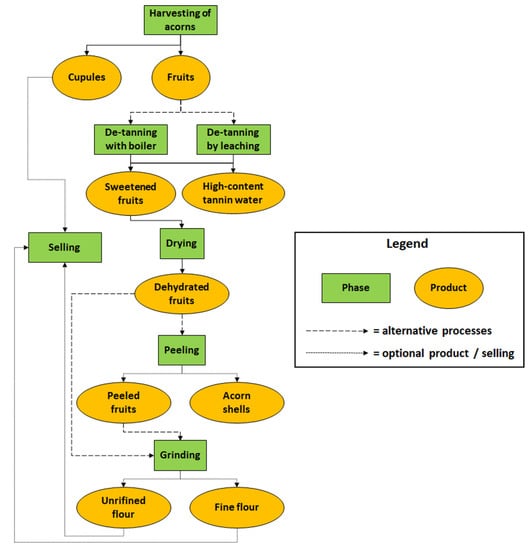

Among the different products available in the acorn-based food market and considering the in-depth literature review on the topic by Giovannoni [36], an acorn chain can be structured in several ways. The organization depends on the availability of workers and technologies as well as the manufacturer’s level of mechanization. In this study, the DSS (namely, Acorn1.0) was implemented based on a medium level of mechanization, as described in Figure 1, and to be adopted in medium-small farms that are potentially interested in the Italian market context. The considered fruits are acorns from Quercus spp.; the most common species present in Italy are Quercus cerris L., Quercus pubescens Willd, Quercus robur L., Quercus petraea (Matt.) Liebl. and Quercus ilex L. Despite a minimal variability among acorns from these species, the size and the mechanical properties of them make the applicability of the DSS suitable for all the fruits of national context.

Figure 1.

General framework of production process of acorn flour.

The model was implemented on a Calc spreadsheet application in OpenOffice. The DSS was structured in eight sheets and analysed in the following value chain steps: production, harvesting, de-tanning, drying, peeling, grinding and bagging, revenues, other costs, and financial analysis. The units of measure and base data (selling prices, unitary machinery and workers costs, efficiency of workers and machinery, cost of investments) are detailed and listed in Table 1 and Appendix A. Revenues and costs are computed on an annual basis.

Table 1.

Coefficients and unitary values applied in the DSS (Equations (1)–(14)).

2.1.1. Production

The model allows users to choose the typology of acorn production (per hectare or per tree). Subsequently, partitioning of acorn into fruit and cupules (or caps) is developed. The DSS permits selecting the final products that are to be sold. In this first version of the model, the analysis is grounded on potential selling of acorn flour and cupules (optional). Flour can be produced as both unrefined (ground with shell) or fine flour (ground without acorn shell).

Total amount of acorns (A) is quantified according to Equation (1).

where PU.M and TU.M are acorn productivity per unit of measures (trees or hectares) and the total amount of units, respectively; φ is the loss of products due to both acorns infected by pathogens or acorn cupules that remained on branches.

A = PU.M · TU.M · (1 − φ)

The relative production of fruits (F) and cupules (C) are defined as:

where σ is the weight of fruit (%) on total production (A).

F = A · σ

C = A − F

The partitioning (percentage) of fruits delivered to unrefined (u) and fine (f) flour can be selected in this section.

2.1.2. Harvesting, De-Tanning, Drying

Acorn harvesting can be done by manual hand picking as they fall from the tree to the ground or with a manual electric shaker (similar to the equipment applied for harvesting other fruits such as olives). The process is developed by one worker with a shaker plus other potential workers aiding in the collection phase. Separation of fruits and cupules is performed in this phase.

The sweeting of acorns is hypothesized through de-tanning developed by boiling or leaching. The former option is provided by one worker working with an electric boiling pan, while the latter involves one worker plus the use of tubs where acorns are maintained covered by water (changed periodically) for a few days.

The process of grinding acorns into flour can be done with fresh or dehydrated fruits. Flour from dehydrated fruits can be, however, better preserved because of low moisture content (about 18%) [20]. Therefore, a drying operation is hypothesized; this is carried out with one worker and a single electric machinery considered more efficient with respect to dehydration in ventilated open spaces.

The cost for each operation mentioned above is quantified as:

where γα is the total cost for α phase, ηα,τ is the efficiency in α phase with τ typology of operation/machinery (hand picking, manual harvesting with shaker, de-tanning with boiler or leaching, drying), w is the number of involved workers, μ are the unitary costs for workers (w) and machinery (m), respectively, Q is the purchase cost for τ machinery and π is the unitary cost of machinery maintenance. In other words, the component (Qτ · π) indicates maintenance costs (inclusive of ordinary and extraordinary maintenance) of machinery synthetically based on purchase cost [37].

γα = F/ηα,τ · [(w · μw + μm) + (Qτ · πτ)]

2.1.3. Peeling

Peeling is the propaedeutic phase to grinding; it is developed for only the number of acorns used for production of fine flour. Despite peeling being usually manually implemented for small productions, the DSS considers semi-automated peeling with an electric peeler. Similar to the previous phases, the cost of operation is:

where δ is the loss in weight (percentage) due to dehydration.

γα = F · f · (1 − δ)/ηα,τ · [(w · μw + μm) + (Qτ · π)]

2.1.4. Grinding & Bagging

The last phases of the production process are grinding of both whole and peeled acorn and bagging of the unrefined and fine flour. In this step, a medium-small electric grinder loaded by one worker is applied. The grinder allows for semi-automated bagging. The cost of operation is given as:

where the component [F · (1 − δ) · ω/χ] · λ represents the total cost for bags, with ω as the yield of flour from fruit (%), χ is the capacity of bags, and λ is the unitary cost of a bag.

γα = F · (1 − δ)/ηα,τ · [(w · μw + μm) + (Qτ · π)] + [F · (1 − δ) · ω/χ ] · λ

2.1.5. Revenues

Total revenues are quantified according to Equation (7) as follows:

where θ, ϕ, and β are the unitary prices for unrefined flour, fine flour, and cupules, respectively.

R = F · (1 − δ) · ω · (u · θ + f · ϕ) + C · β

Selling of caps is affirmed in some areas, for instance, as in Greece [38], mainly for the leather tanning industry. Acorn caps were also exported for decorative purposes in mass quantities [38]. There are no recent examples recorded for the use of caps in Italy, despite the fact that potential application can be feasible (e.g., bioenergy production). Thus, the selling of these products is maintained as optional in the DSS.

2.1.6. Other Costs and Financial Analysis

The model quantifies additional costs—namely, cost for space, administrative and marketing expenses, and interests. The cost for space (rooms where machinery is located) is based on rental expenditure for workshops (ε) and occupied surface (s), according to Equation (8):

W = s · ε

Administrative and marketing costs (M) are synthetically hypothesised, grounded on revenues (Equation (9)); interests (I) are based on anticipated capital (Q) (Equation (10)).

where m is a coefficient ranging from 5% to 10% according to the complexity in bureaucracy and advertising activities [37].

where r is the interest rate.

M = R · m

I = ΣQτ · r

Total annual costs (E) are computed as:

E = Σ γα + W + M + I

Financial performance of the acorn chain is finally quantified using five different indicators:

- net present value (NPV), the amount of projected cash flows, discounted to the present (Equation (12));

- pay-back period (PBP), the number of years to start recovering investments;

- internal rate of return (IRR), the value of interest rate that makes NPV = 0, defines the efficiency of the investment;

- break even (BE) on prices and productivity, the values that make NPV = 0 and allow for safety margin quantification in respect of current prices and productivity; and

- Safety margin (SM) on both price of flour (ϕ) and quantity (P) of produced acorns (Equations (13) and (14)).

3. Results

The appraisal of the acorn chain was based on scenario analysis. In fact, the production process could be affected by uncertainty due to potential variability in applied machineries, selling price of acorn products, and annual productivity. Therefore, output is based on sensitivity analysis founded on modification of acorn yield and the price of flour.

The coefficients and unitary values of Equations (1)–(14) are reported in Table 1. They are based on in-depth scientific and grey literature review reported in the Introduction or analysis of technical manuals and websites, as summarized in Appendix A.

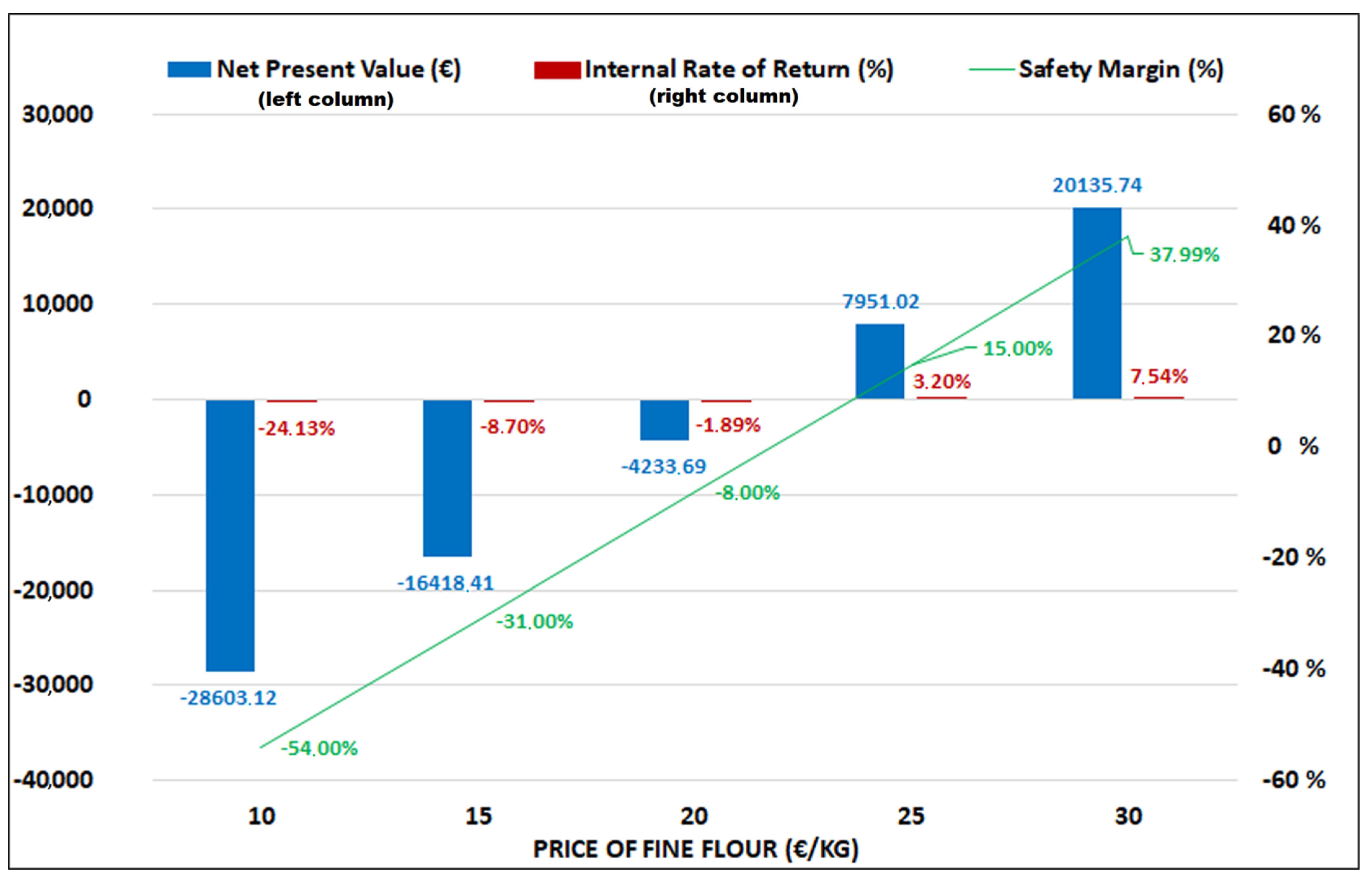

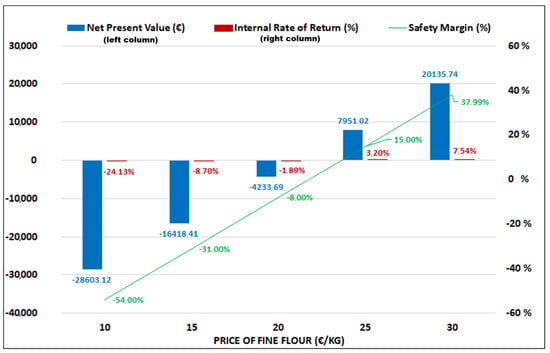

The financial efficiency based on variation of fine flour price (with other values remaining constant) is described in Figure 2.

Figure 2.

Financial parameters of acorn chain (sensitivity analysis on flour price).

Market analysis reveals a potential range of acorn flour price from 8 to 39 €/kg (Appendix A). Setting a sensitivity analysis within 10–30 €/kg, NPV varies from −28,603.12 € to 20,135.74 €. The BE price of flour is 21.74 €/kg. Above this value, interesting results can be obtained for financial indexes; for example, with a price of 30 €/kg, production obtains an IRR of 7.54% and an SM on price of 37.99%. The PBP is 12 and 9 years, for prices equal to 25 and 30 €/kg, respectively.

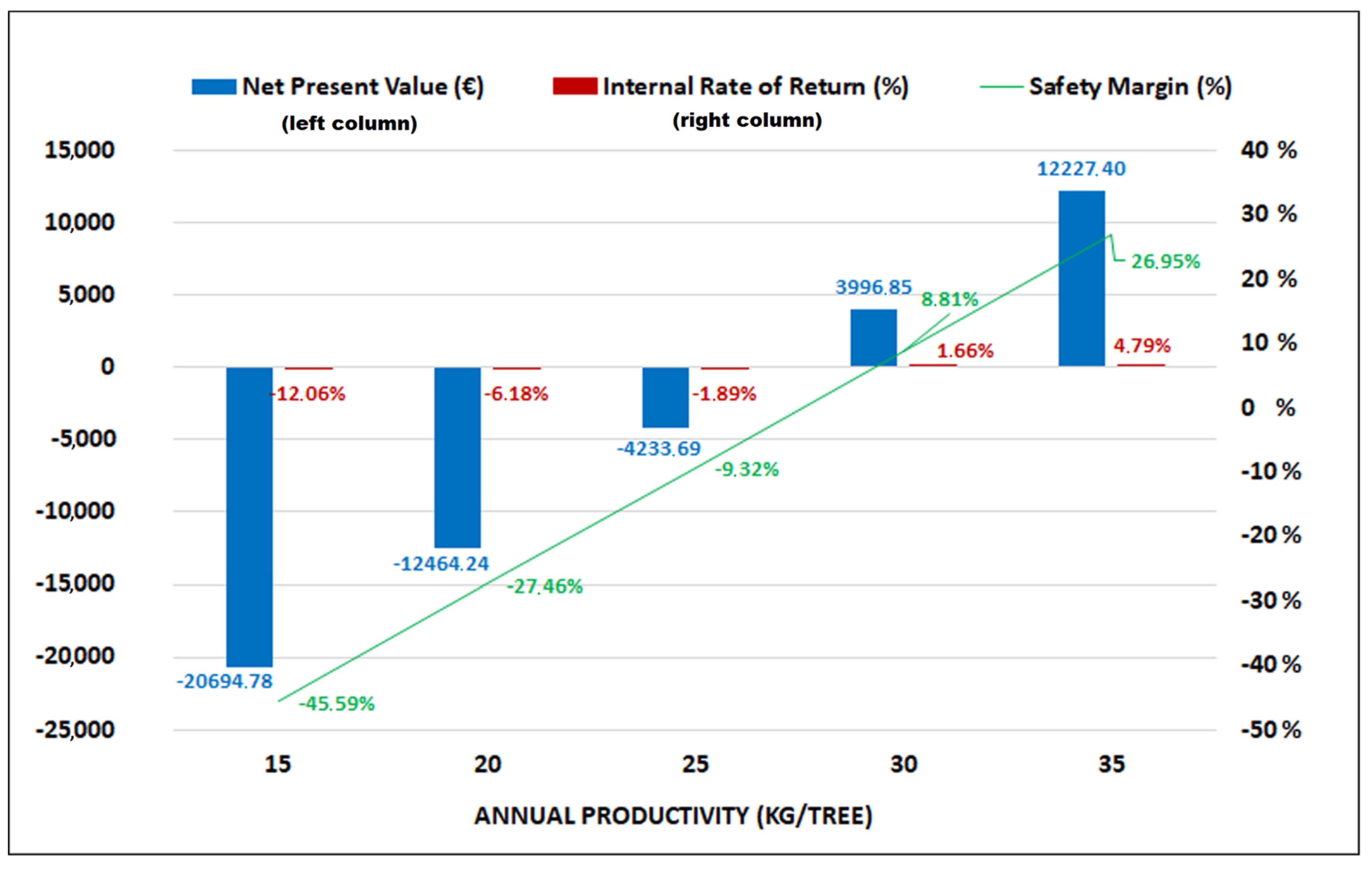

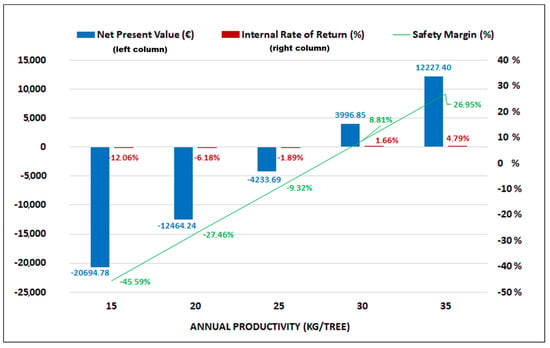

The potential marked annual variability in acorn production—due to natural mast-seeding—suggests how financial analysis of chain should consider a risk analysis based on this variable. Figure 3 reports trends of financial indexes considering variability of oak production.

Figure 3.

Financial parameters of acorn chain (sensitivity analysis on annual productivity).

With an annual productivity from 15 to 35 kg/tree NPV ranges from −20,694.78 € to 12,227.40 €. The BE on productivity is 27.57 kg/tree. Maximum hypothesised productivity (35 kg/tree) leads to an IRR of 4.79% and SM on production of 26.95%. The PBP is equal to 14 and 11 years with a productivity of 30 and 35 kg/tree, respectively.

A potential trade-off in the process can be evaluated considering a different partitioning in unrefined and fine flour and by including or not selling of caps. With selling of caps, the optimal partitioning of flour is 95.23% (fine) and 4.77% (unrefined); excluding caps selling, the percentages are modified into 98.14% (fine) and 1.86% (unrefined).

4. Discussion

Output from Acorn1.0 reports a potential financial efficiency of an acorn chain for food production. For example, both BE for price of flour and for productivity are slightly higher than the average values presented in Table 1 showing a certain economic margin in chain efficiency. However, based on the hypothesised production process and base data, more efficiency is reached for the medium high value of flour price and acorn productivity. Fine flour, which is the main product, requires attention (versus of unrefined flour) notwithstanding higher production costs due to an additional phase of peeling. Sale of cupules as by-products does not seem to be relevant in the acorn chain. This marginality is expressed by a low difference in the optimal partitioning of fine and unrefined flour in the case of selling cupules (about 3%).

One of the main strengths of this fruit is the diffusion of oaks along the temperate and semi-arid areas of the boreal hemisphere. Therefore, the quantity of available acorns is not a problem for the supply of forest chain based on this NWFP. The spatial and temporal changeability of tree production depends on many factors: site conditions, species, tree density, crown diameter, climatic variability, natural mast-seeding, age, size, genetic variability, management regime, and phytosanitary condition [33]. However, the variability can be overcome by supply planning; the planning is also facilitated thanks to diffusion of oaks as well as a small dimension of the chain based on acorns, in particular during a preliminary phase of their implementation [4]. Considering these aspects, the risk related to insufficient supply can be considered lower for acorns with respect to timber or other specific NWFP species. The potential causes of loss and reduction in germination could be depicted during droughts, abandonment of traditional harvesting practices, overgrazing, fires, and insect attacks [33,39]. Future studies will be needed to identify silvicultural treatments to maximize acorn production for different species. The convenience of different silvicultural treatments or forest management for acorn production must also be evaluated economically.

Additional methods can be proposed for quantifying acorn availability in a food production chain. Currently, different methods are reported in the scientific literature to compute acorn production and potentially support management plans. Cañellas et al. [40] examined the effect of pruning on holm oak acorn productivity in southwest Spain; the differences among five Quercus species were defined for multiple years by Greenberg et al. [41] in the southern Appalachian oaks. Touzot et al. [42] assessed temporal dynamicity in acorn production based on the low-cost “ground plot” method and compared it with the traditional trap acorn collection method. Airborne hyperspectral imaging based on canopy reflectance was applied by Yao et al. [43] to estimate acorn yield from the values of individual trees, demonstrating best contribution to the estimation model in comparison to ground sampling.

This study shows potential supply-side feasibility for the acorn-based forest chain in food production in Italy. Further investigations must focus on potential demand from the perspective of both dimensions; that is, quantity and economics (willingness to pay). The demand for acorn products should also examine the sensorial properties of traditional prepared (flour, cake, oil etc.), e.g., by means of laboratory tests. The analysis of sensorial properties can be accompanied by the valuation of people’s perception from a cultural point of view that acorns are traditionally considered as a poor man’s fruit, mainly addressed as feed for animals.

Presently, a few studies have focused on the above-mentioned sensorial properties: for instance, Korus et al. [44] examined the effect of substituting a percentage of corn flour with acorn flour. The results were positive but lower scores were obtained by acorn-based biscuits (i.e., control sample) for colour, smell, consistency, and taste; other studies [45,46] seem to have confirmed this trend. These studies can represent a starting point for additional valuations.

As reported in the literature review, currently many qualitative examples of acorn utilization from nutritional, medical, and technological viewpoints are presented; however quantitative data about commercial viability, market needs, and market size of acorn products in the world or a nation are lacking. Therefore, additional technical and economic analysis of acorn chain should be coupled with investigation about current market and/or its potentiality, in order to set efficient business plans and complete assessment of investments in “acorn as food” sector.

Future analysis must include technical and economic investigation of potential chains of by-products such as acorn shells from peeling (e.g., for bioenergy production) or highly tannins-rich water from leaching (e.g., for the leather industry). Pilot studies are required to practically calibrate the base data and processes in the DSS. Another interesting future development will be the quantification of environmental sustainability through a life cycle assessment (LCA) for acorn flour and compare it with traditional flour and chestnut flour.

A typical characteristic of oak that is reflected in acorns is the strong variability (also at tree level) in size and organoleptic variables [6]. Therefore, further investigations must consider the impact of that changeability from the perspective of both supply and (particularly) demand.

The structure of Acorn1.0 is currently based on the hypothesis that acorn chain is implemented by owner (either private or public) of trees or forests. Therefore any harvesting permission or license are needed. However, harvesting rights is an important issue in NWFP [47] and future analysis can concentrate on property rights and on how they affect the costs.

In addition to provisioning ecosystem services, the use of acorns for food production can also revitalize cultural ecosystem services of forests, as these fruits are applied in traditional and ethnical uses in Italy alongside the Lazio, Basilicata, Tuscany, and Sardinia regions [32]. In the national context, neither ecosystem disservices [48] nor negative trade-offs are currently registered for using acorns as food. As examples, Campbell [48] developed a survey based on the Theory of Planned Behaviour to analyse attractors for wildlife potentially dangerous for people—specifically bears—in a region of Canada. Acorns were depicted as attractors; in Italy this ecosystem disservices is not registered. Additional investigations are needed to study potential impact on natural regeneration. Negative trade-offs can emerge in the production of other NWFP. For example, the recreational function of picking mushrooms or the function to produce berries can compete with the traditional objective to provide wood but for acorns the problem seems not to be relevant.

5. Conclusions

This study has developed the first comprehensive financial analysis of acorns chain for food production. The evaluation centred on an open-source DSS allowing for the depiction of different financial indexes and flexibility in the choice of the production process and variables. The results, based on the hypothesis that the sale of acorn flour (and caps) shows potential feasibility in the innovative market but only under specific conditions: base prices and supply of fruit seem to have a major role in economic suitability. Additional variables can be investigated through sensitivity analysis in future studies. The output of this preliminary research highlights how acorns can be considered as a by-product in the Italian rural sector, primarily to support the main production of medium-small farms.

A strength of our method is that the DSS (available as supplementary material) can be applied by public and private stakeholders using data relating to unit costs and wages of labour in the territory of interest. More advantageous results are likely to be achieved in less developed countries as lower labour costs favour labour-intensive activities. However, to avoid problems related, for example, to phytosanitary aspect, losses of local genetic biodiversity and pollution due to emissions, short chains based on local peculiarities should be implemented. Due to limited information on acorn value chain the proposed tool was set as a prototype.

Traditional and historical use of acorns across different countries shows potential enhancement of not only provisioning but also cultural value for forest ecosystem services. Considering the improvements suggested in the Discussion section, the DSS can be a valid tool to test the viability of acorns flour at both the local and rural levels.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/f12060784/s1, Table S1: Acorn1.0 Decision Support System.

Author Contributions

Conceptualization, S.S. and M.C.; methodology, S.S., T.C. and C.B.; software, T.C.; writing—original draft preparation and editing, S.S.; review, S.S., T.C., C.B., M.C., R.F. and I.B.; supervision, S.S.; project administration, S.S. and I.B.; funding acquisition, S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the article processing charge (APC) were funded by Regione Puglia—Sezione Gestione Sostenibile e Tutela delle Risorse Forestali [Apulia Region—Section of Sustainable Management and Protection of Forest Resources], grant number Cap.121027/2019, DDS 390/2019.

Conflicts of Interest

The authors declare that there is no conflict of interest. The funders had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Additional web resources used to define the production process for acorns chain (last accessed 30 January 2021):

(1) Analysis of workers’ productivity and costs:

(2) Cost and productivity analysis of machinery:

- Laboratory rent: https://wwwt.agenziaentrate.gov.it/geopoi_omi/index.php

(3) Acorn products and selling prices:

- Cupules: https://plecocavescanada.ca/products/acorn-caps-tannin; https://www.internationaloaksociety.org/sites/default/files//files/IO/IOS%20Journal%20%2325/04-ios%20journal%2325-maroulis.pdf; https://www.internationaloaksociety.org/sites/default/files//files/IO/IOS%20Journal%20%2325/04-ios%20journal%2325-maroulis.pdf; https://www.internationaloaksociety.org/sites/default/files//files/IO/IOS%20Journal%20%2325/04-ios%20journal%2325-maroulis.pdf

- Flour: https://www.oakmeal.com/store/p16//acornflour.html; https://www.casailgobbo.com/product/farina-di-ghianda-1-kg/; https://www.wempla.com/shop/en/product/organic-acorn-flour; https://highorganic.eu/product/acorn-flour-1000g/; https://highorganic.eu/product/acorn-flour-500g/; https://shop.pacgourmet.com/products/acorn-flour-powder?variant=34412560711838.

- Potential additional products (starch, coffee substitute, pasta, biscuits, liquor): https://www.oakmeal.com/store/p14/NUT-AC.html; https://www.oakmeal.com/store/p8/Acorn_Cookies_300g.html; https://www.oakmeal.com/store/p11/ACORN_PASTA%2C_tagiatellia_style_400g.html; https://www.casailgobbo.com/product/biscotti-farina-di-ghianda/; https://www.amazon.com/ROM-AMERICA-Pound-Starch-Powder/dp/B01NBEO4Z6/ref=pd_lpo_325_img_0/151-3606405-7451540?_encoding=UTF8&pd_rd_i=B01NBEO4Z6&pd_rd_r=e5a3feb6-76f7-464c-ab0d-ce3df7b19a10&pd_rd_w=kk8WJ&pd_rd_wg=TKSac&pf_rd_p=7b36d496-f366-4631-94d3-61b87b52511b&pf_rd_r=3F6RE1J98C4C3P8GDY6W&psc=1&refRID=3F6RE1J98C4C3P8GDY6W; https://healthembassy.co.uk/en/natural-coffee/15-acorn-coffee.html#/28-weight-100g; https://healthembassy.co.uk/en/natural-coffee/15-acorn-coffee.html#/29-weight-200g; https://www.amazon.co.uk/Acorn-Coffee-BIO-100-NATURY/dp/B07Z3KW7FF/ref=sr_1_1?dchild=1&keywords=DARY+NATURY+acorn&qid=1603370118&s=grocery&sr=1-1; https://www.amazon.co.uk/Acorn-Coffee-SACHETS-BIO-70/dp/B082QZ18FQ/ref=sr_1_3?dchild=1&keywords=DARY+NATURY+acorn&qid=1603369746&s=grocery&sr=1-3; https://www.amazon.co.uk/Coffee-Acorn-Ginseng-BIO-100/dp/B08D998HLW/ref=sr_1_2?dchild=1&keywords=DARY+NATURY+acorn&qid=1603370118&s=grocery&sr=1-2; https://www.drinksco.it/liquori-e-creme/licor-de-bellota-beso-extremeno; https://www.cashgolosinas.com/it/spiriti/1156-liquor-de-bellota-extremadura.html.

References

- FAO. FRA 2015—Terms and Definition. Forest Resources Assessment Working Paper 180; FAO: Rome, Italy, 2015; p. 12. [Google Scholar]

- Millennium Ecosystem Assessment. Ecosystem and Human Well-Being: Biodiversity Synthesis; Island Press: Washington, DC, USA, 2005; p. 86. [Google Scholar]

- Weiss, G.; Emery, M.R.; Corradini, G.; Živojinović, I. New Values of Non-Wood Forest Products. Forests 2020, 11, 165. [Google Scholar] [CrossRef]

- García-Gómez, E.; Pérez-Badia, R.; Pereira, J.; Puri, R.K. The Consumption of Acorns (from Quercus spp.) in the Central West of the Iberian Peninsula in the 20th Century. Econ. Bot. 2017, 71, 256–268. [Google Scholar] [CrossRef]

- Cappai, M.G.; Wolf, P.; Pinna, W.; Kamphues, J. Pigs use endogenous proline to cope with acorn (Quercus pubescens Willd.) combined diets high in hydrolysable tannins. Livest. Sci. 2013, 155, 316–322. [Google Scholar] [CrossRef]

- Vinha, A.F.; Costa, A.S.G.; Barreira, J.C.M.; Pacheco, R.; Oliveira, M.B.P.P. Chemical and antioxidant profiles of acorn tissues from Quercus spp.: Potential as new industrial raw materials. Ind. Crop. Prod. 2016, 94, 143–151. [Google Scholar] [CrossRef]

- Antov, M.J.; Šćiban, M.B.; Prodanović, J.M.; Kukić, D.V.; Vasić, V.M.; Đorđević, T.R.; Milošević, M.M. Common oak (Quercus robur) acorn as a source of natural coagulants for water turbidity removal. Ind. Crop. Prod. 2018, 117, 340–346. [Google Scholar] [CrossRef]

- Kuppusamy, S.; Venkateswarlu, K.; Thavamani, P.; Lee, Y.B.; Naidu, R.; Megharaj, M. Quercus robur acorn peel as a novel coagulating adsorbent for cationic dye removal from aquatic ecosystems. Ecol. Eng. 2017, 101, 3–8. [Google Scholar] [CrossRef]

- Šćiban, M.; Klašnja, M.; Antov, M.; Škrbić, B. Removal of water turbidity by natural-coagulants obtained from chestnut and acorn. Bioresour. Technol. 2009, 100, 6639–6643. [Google Scholar] [CrossRef]

- Aziz, A.; Khan, N.M.; Ali, F.; Khan, Z.U.; Ahmad, S.; Jan, A.K.; Rehman, N.; Muhammad, N. Effect of protein and oil volume concentrations on emulsifying properties of acorn protein isolate. Food Chem. 2020, 324, 126894. [Google Scholar] [CrossRef]

- Luo, X.; Bai, R.; Zhen, D.; Yang, Z.; Huang, D.; Mao, H.; Li, X.; Zou, H.; Xiang, Y.; Liu, K.; et al. Response surface optimization of the enzyme-based ultrasound-assisted extraction of acorn tannins and their properties. Ind. Crop. Prod. 2019, 129, 405–413. [Google Scholar] [CrossRef]

- Górnaś, P.; Rudzińska, M.; Grygier, A.; Ying, Q.; Mišina, I.; Urvaka, E.; Rungis, D. Sustainable valorization of oak acorns as a potential source of oil rich in bioactive compounds. Process. Saf. Environ. Prot. 2019, 128, 244–250. [Google Scholar] [CrossRef]

- Şahin, Ö.; Saka, C. Preparation and characterization of activated carbon from acorn shell by physical activation with H2O–CO2 in two-step pretreatment. Bioresour. Technol. 2013, 136, 163–168. [Google Scholar] [CrossRef] [PubMed]

- Chao, B.; Liu, R.; Zhang, X.; Zhang, X.; Tan, T. Tannin extraction pretreatment and very high gravity fermentation of acorn starch for bioethanol production. Bioresour. Technol. 2017, 241, 900–907. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wang, C.; Zhuang, X.; Hu, Y.; Chu, F. Renewable Resource-Based Composites of Acorn Powder and Polylactide Bio-Plastic: Preparation and Properties Evaluation. J. Polym. Environ. 2011, 19, 301–311. [Google Scholar] [CrossRef]

- Onem, E.; Gulumser, G.; Akay, S.; Yesil-Celiktas, O. Optimization of tannin isolation from acorn and application in leather processing. Ind. Crop. Prod. 2014, 53, 16–22. [Google Scholar] [CrossRef]

- Mason, S.; Nesbitt, M. Acorn as Food in Southeast Turkey: Implication for Prehistoric Subsistence in Southwest Asia. In From Foragers to Farmers: Papers in Honour of Gordon C. Hillman; Fairbairn, A.S., Weiss, E., Eds.; Oxbow Books: Oxford, UK, 2009; pp. 71–85. [Google Scholar]

- Bainbridge, D.A. Acorns as Food. History, Use, Recipes, and Bibliography; Alliant International University: San Diego, CA, USA, 2001. [Google Scholar]

- Izumi, K. Spatial Distribution of Local Forest Products at the End of the 19th Century: A Case Study of Former Villages in Iwate Prefecture. Forests 2020, 11, 1044. [Google Scholar] [CrossRef]

- Vinha, A.F.; Barreira, J.C.M.; Costa, A.S.; Oliveira, M.B.P.P. A New Age for Quercus spp. Fruits: Review on Nutritional and Phytochemical Composition and Related Biological Activities of Acorns. Compr. Rev. Food Sci. Food Saf. 2016, 15, 947–981. [Google Scholar] [CrossRef] [PubMed]

- Martinson, K.; Hovda, L.; Murphy, M.; Weicherding, P. Plants Poisonous or Harmful to Horses in the North. Central Unites States; University of Minnesota Extension: St. Paul, MN, USA, 2007. [Google Scholar]

- Dogan, A.; Celik, I.; Kaya, M.S. Antidiabetic properties of lyophilized extract of acorn (Quercus brantii Lindl.) on experimentally STZ-induced diabetic rats. J. Ethnopharmacol. 2015, 176, 243–251. [Google Scholar] [CrossRef]

- Papoti, V.T.; Kizaki, N.; Skaltsi, A.; Karayannakidis, P.D.; Papageorgiou, M. The phytochemical rich potential of acorn (Quercus aegilops) products and by products. Food Sci. Biotechnol. 2018, 27, 819–828. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Su, G.; Yue, J.; Sun, Y.; Cao, J.; Zhang, X.; Zhao, Y. The antioxidant and anti-hepatic fibrosis activities of acorns (Quercus liaotungensis) and their natural galloyl triterpenes. J. Funct. Foods 2018, 46, 567–578. [Google Scholar] [CrossRef]

- Gezici, S.; Sekeroglu, N. Neuroprotective potential and phytochemical composition of acorn fruits. Ind. Crop. Prod. 2019, 128, 13–17. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, Y.; Huang, Y.; Wang, Z.; Xu, J.; He, X. Jasmonates from Chinese acorns (Quercus serrata var. brevipetiolata) exert pronounced anti-neuroinflammatory activities. Bioorganic Chem. 2020, 103, 104143. [Google Scholar] [CrossRef]

- Dalar, A.; Dogan, A.; Sukru Bengu, A.; Mukemre, M.; Celik, I. Screening in vivo antioxidant and haematological properties of sumac and acorn bioactive rich extracts. Ind. Crop. Prod. 2018, 124, 20–27. [Google Scholar] [CrossRef]

- Silva, S.; Costa, E.M.; Borges, A.; Carvalho, A.P.; Monteiro, M.J.; Pintado, M.M.E. Nutritional characterization of acorn flour (a traditional component of the Mediterranean gastronomical folklore). Food Meas. 2016, 10, 584–588. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Gouvinhas, I.; Nunes, M.C.; Alcides Peres, J.; Raymundo, A.; Barros, A.I.R.N.A. Acorn Flour as a Source of Bioactive Compounds in Gluten-Free Bread. Molecules 2020, 25, 3568. [Google Scholar] [CrossRef] [PubMed]

- Masmoudi, M.; Besbes, S.; Bouaziz, M.A.; Khlifi, M.; Yahyaoui, D.; Attia, H. Optimization of acorn (Quercus suber L.) muffin formulations: Effect of using hydrocolloids by a mixture design approach. Food Chem. 2020, 328, 127082. [Google Scholar] [CrossRef] [PubMed]

- Pinna, C. Acorn bread: A traditional food of the past in Sardinia (Italy). J. Cult. Herit. 2013, 14, S71–S74. [Google Scholar]

- Pignone, D.; Laghetti, G. On sweet acorn (Quercus spp.) cake tradition in Italian cultural and ethnic islands. Genet. Resour. Crop. Evol. 2010, 57, 1261–1266. [Google Scholar] [CrossRef]

- Molina Martínez, J.R.; Herrera Machuca, M.; Zamora Díaz, R.; Rodríguez y Silva, F.; González-Cabán, A. Economic losses to Iberian swine production from forest fires. For. Policy Econ. 2011, 13, 614–621. [Google Scholar] [CrossRef]

- Ovando, P.; Campos, P.; Oviedo, J.L.; Caparrós, A. Ecosystem accounting for measuring total income in private and public agroforestry farms. For. Policy Econ. 2016, 71, 43–51. [Google Scholar] [CrossRef]

- Pemberton, R.W.; Lee, N.S. Wild food plants in South Korea; market presence, new crops, and exports to the United States. Econ. Bot. 1996, 50, 57–70. [Google Scholar] [CrossRef]

- Giovannoni, M. Ghiande e Uso Alimentare Umano-Storia e Tecniche; Compagnia delle Foreste: Arezzo, Italy, 2019; p. 90. ISBN 978-8898850358. (In Italian) [Google Scholar]

- Bernetti, I.; Romano, S. Economia delle Risorse Forestali–Volume II; Liguori Editore: Naples, Italy, 2007; pp. 340–355. (In Italian) [Google Scholar]

- International Oak Society. International Oaks-The Journal of the International Oak Society; International Oak Society Publisher: Saint-Jory-de-Chalais, France, 2014; Issue No. 25, ISSN 1941-20612014. [Google Scholar]

- Branco, M.; Branco, C.; Merouani, H.; Almeida, M.H. Germination success, survival and seedling vigour of Quercus suber acorns in relation to insect damage. For. Ecol. Manag. 2002, 166, 159–164. [Google Scholar] [CrossRef]

- Cañellas, I.; Roig, S.; Poblaciones, M.; Gea-Izquierdo, G.; Olea, Æ.L. An approach to acorn production in Iberian dehesas. Agroforest Syst. 2007, 70, 3–9. [Google Scholar] [CrossRef]

- Greenberg, C.H. Individual variation in acorn production by five species of southern Appalachian oaks. For. Ecol. Manag. 2000, 132, 199–210. [Google Scholar] [CrossRef]

- Touzot, L.; Bel-Venner, M.C.; Gamelon, M.; Focardi, S.; Boulanger, V.; Débias, F.; Delzon, S.; Saïd, S.; Schermer, E.; Baubet, E.; et al. The ground plot counting method: A valid and reliable assessment tool for quantifying seed production in temperate oak forests? For. Ecol. Manag. 2018, 430, 143–149. [Google Scholar] [CrossRef]

- Yao, Z.; Sakai, K.; Ye, X.; Akita, T.; Iwabuchi, Y.; Hoshino, Y. Airborne hyperspectral imaging for estimating acorn yield based on the PLS B-matrix calibration technique. Ecol. Inform. 2008, 3, 237–244. [Google Scholar] [CrossRef]

- Korus, A.; Gumul, D.; Krystyjan, M.; Juszczak, L.; Korus, J. Evaluation of the quality, nutritional value and antioxidant activity of gluten-free biscuits made from corn-acorn flour or corn-hemp flour composites. Eur. Food Res. Technol. 2017, 243, 1429–1438. [Google Scholar] [CrossRef]

- Molavi, H.; Keramat, J.; Raisee, B. Evaluation of the cake quality made from acorn-wheat flour blends as a functional food. J. Food Biosence Technol. 2015, 5, 53–60. [Google Scholar]

- Pasqualone, A.; Makhlouf, F.Z.; Barkat, M.; Difonzo, G.; Summo, C.; Squeo, G.; Caponio, F. Effect of acorn flour on the physico-chemical and sensory properties of biscuits. Heliyon 2019, 5, e02242. [Google Scholar] [CrossRef] [PubMed]

- Prokofieva, I.; Górriz-Mifsud, E.; Bonet, J.A.; Martínez de Aragón, J. Viability of Introducing Payments for the Collection of Wild Forest Mushrooms in Catalonia (North-East Spain). Small-Scale For. 2017, 16, 147–167. [Google Scholar] [CrossRef]

- Campbell, J.M. The effect of education in reducing bear attractants on cottage properties: Manitoba’s “Bear Smart” program. For. Policy Econ. 2012, 19, 56–65. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).