Investigation of the Impact of Micro-Structuring on the Bonding Performance of Beechwood (Fagus Sylvatica L.)

Abstract

:1. Introduction

2. Material and Methods

2.1. Comparison of Five Different Surfacing Methods

2.1.1. Bonding Parameters and Test Specimens

2.1.2. Roughness

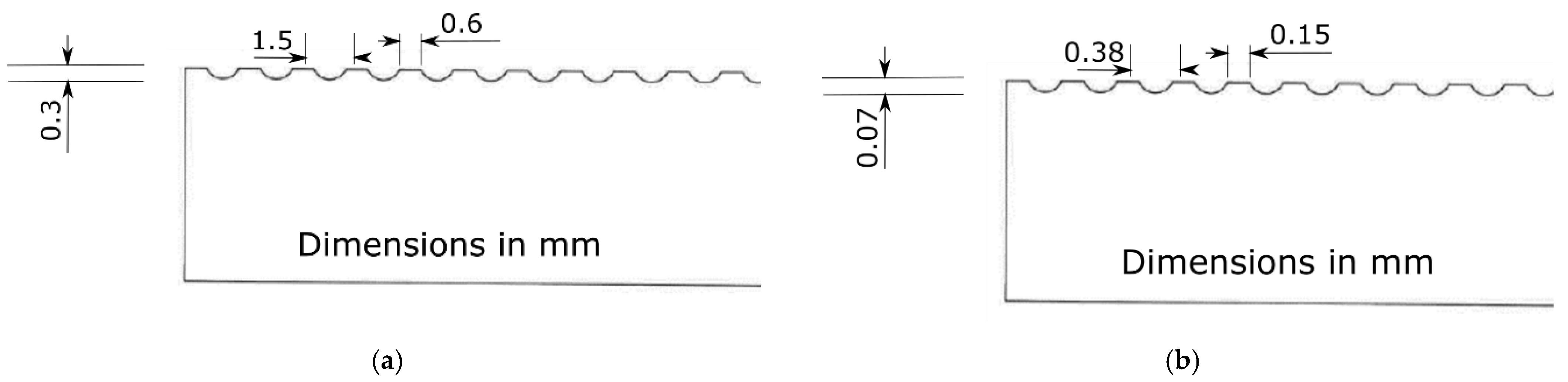

2.2. Analysis of Micro-Structuring Impact

2.2.1. Test Set-Up and Bonding Parameters

2.2.2. Tensile Shear Test

2.2.3. Delamination Test

- C1

- (627–662 kg/m3);

- C2

- (662–697 kg/m3);

- C3

- (697–732 kg/m3).

3. Results

3.1. Comparison of Surfacing Methods

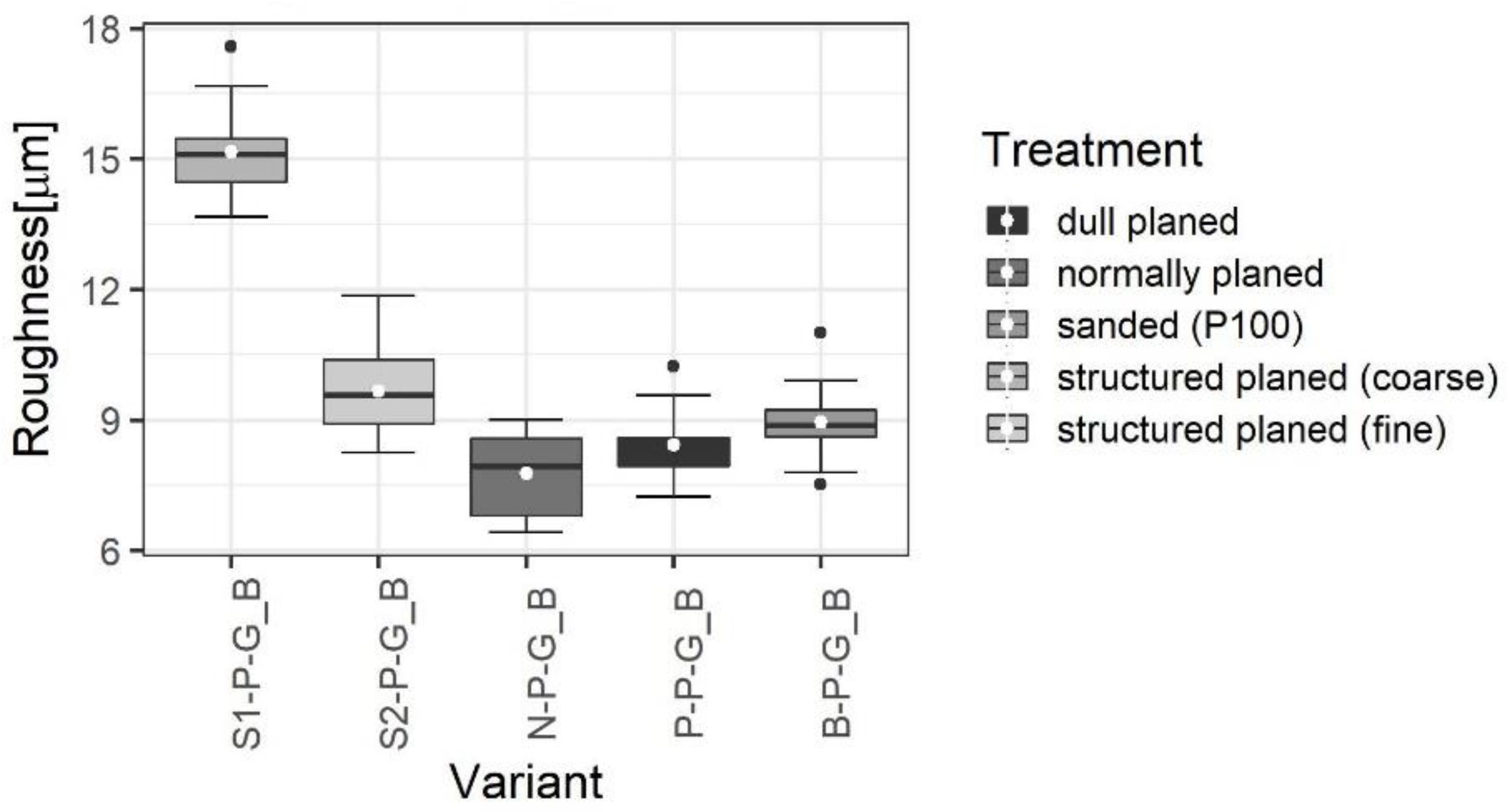

3.1.1. Roughness

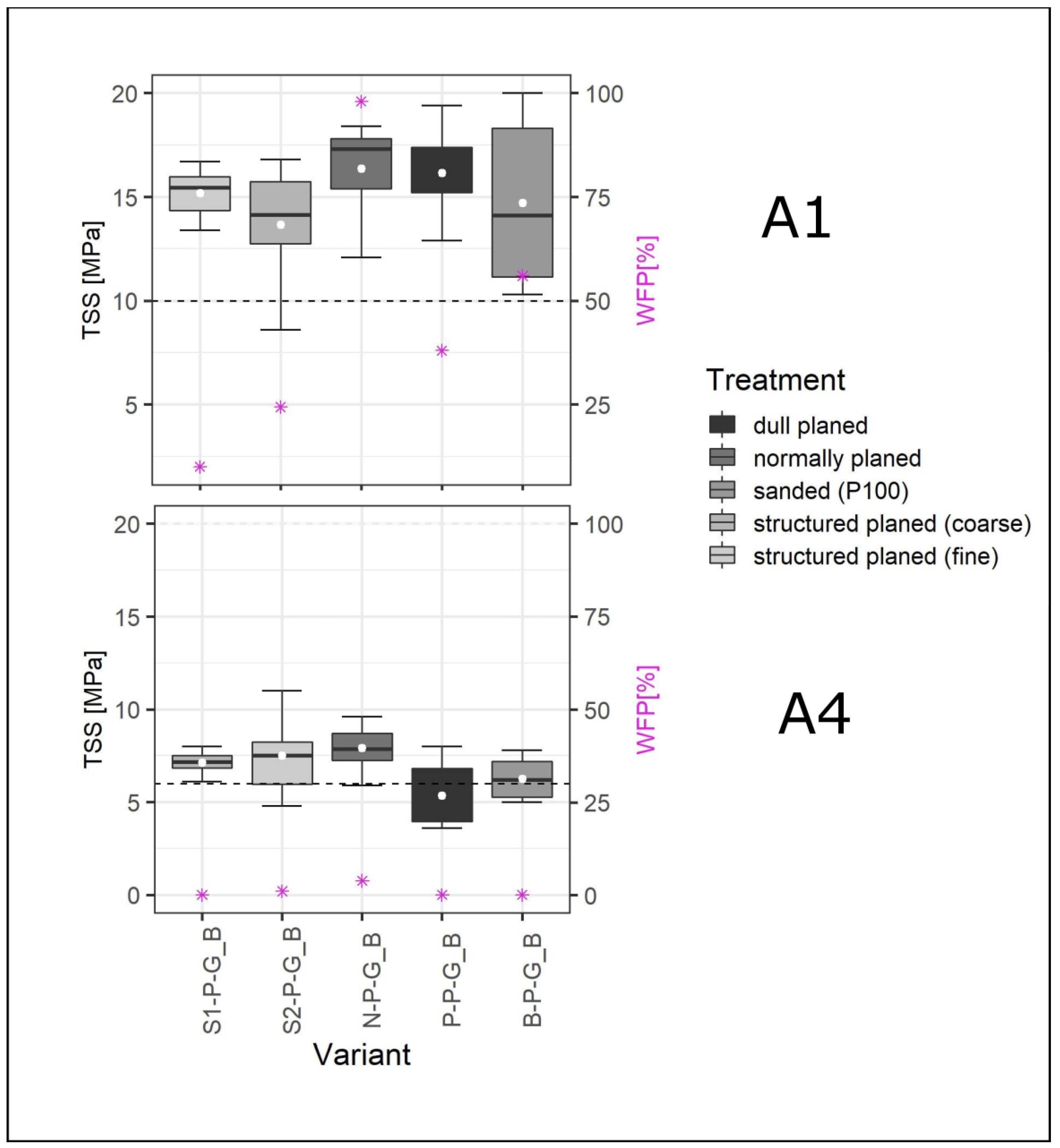

3.1.2. Tensile Shear Strength

3.2. Impact of Micro-Structuring

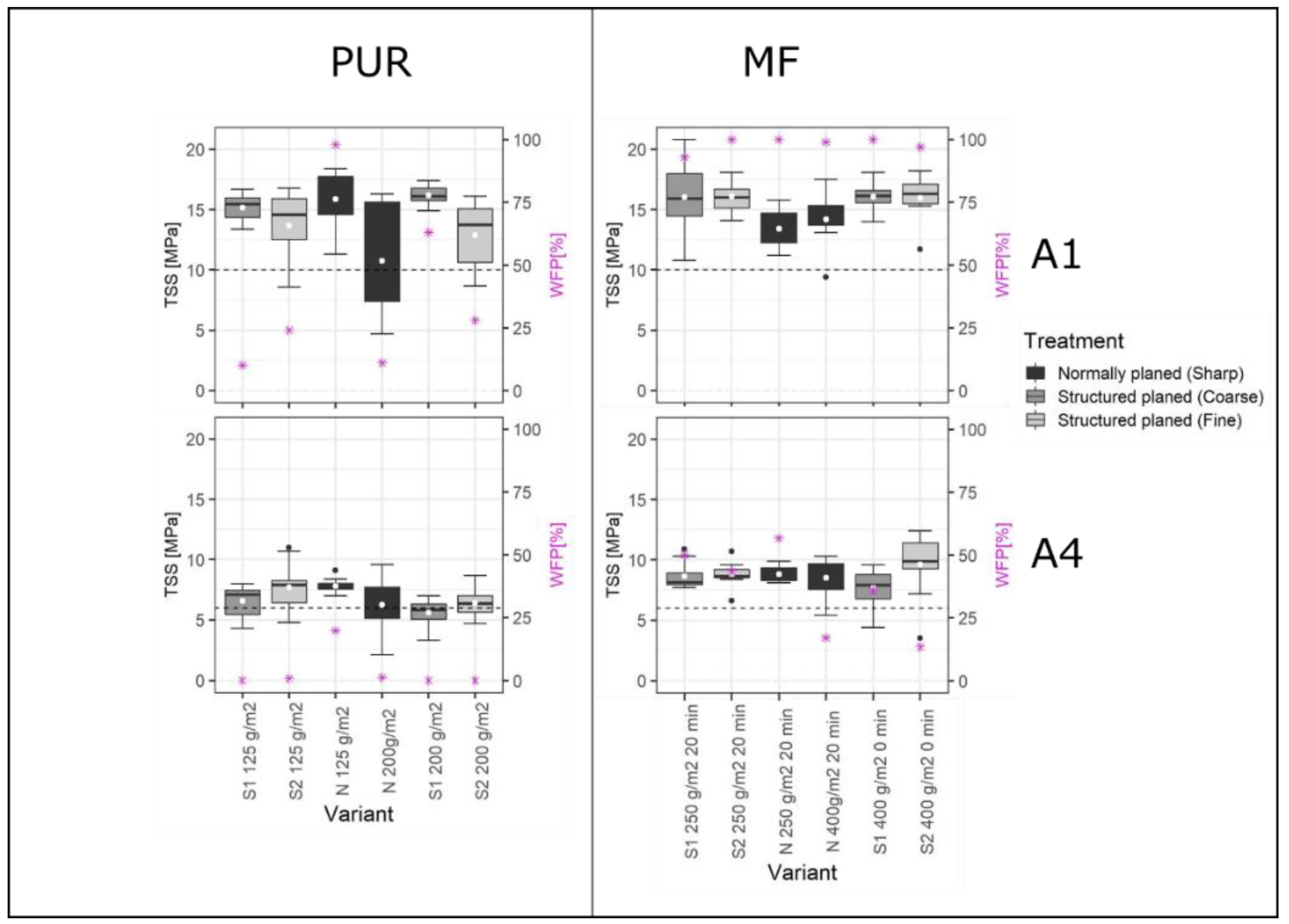

3.2.1. Tensile Shear Test Results

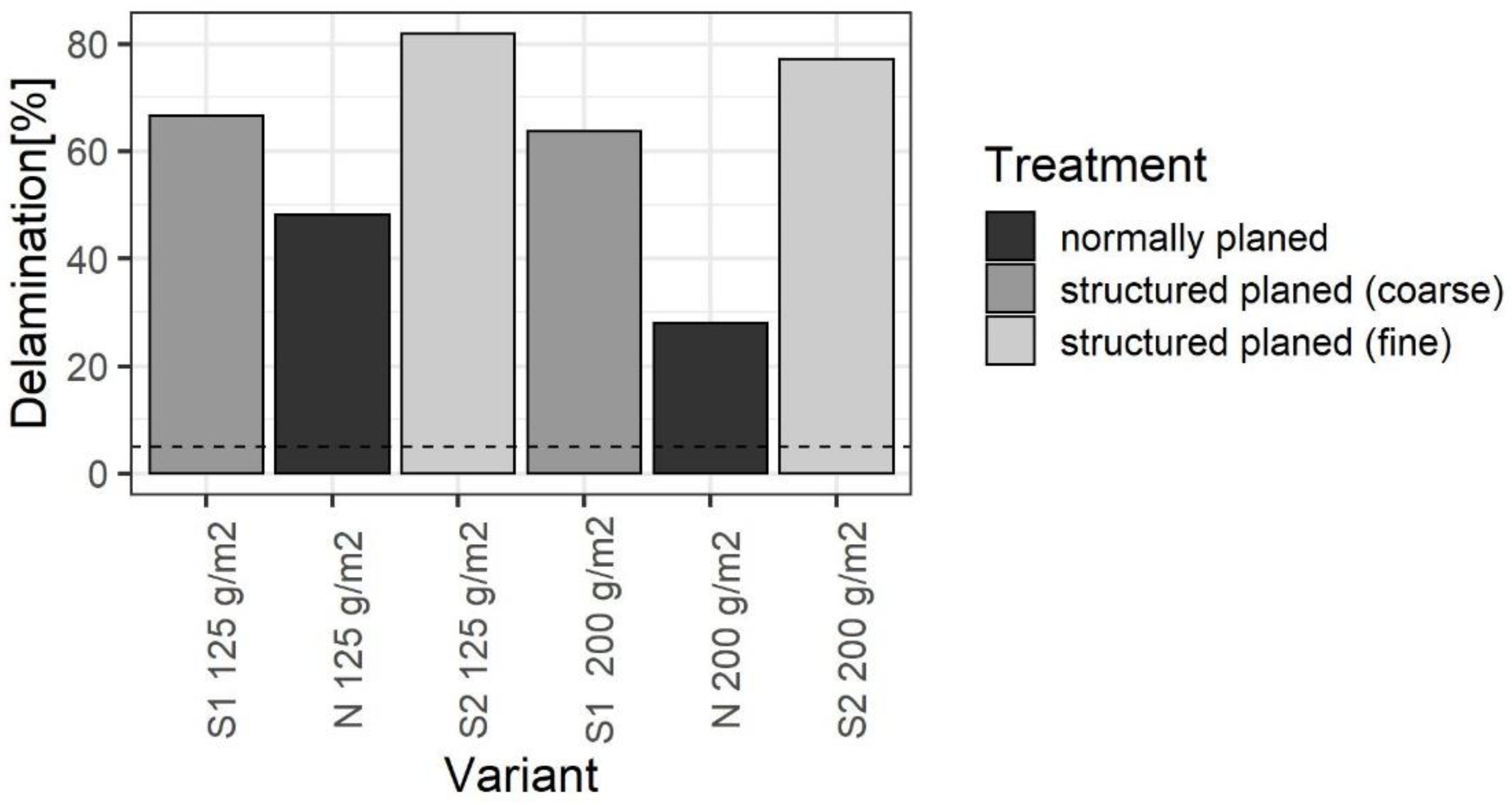

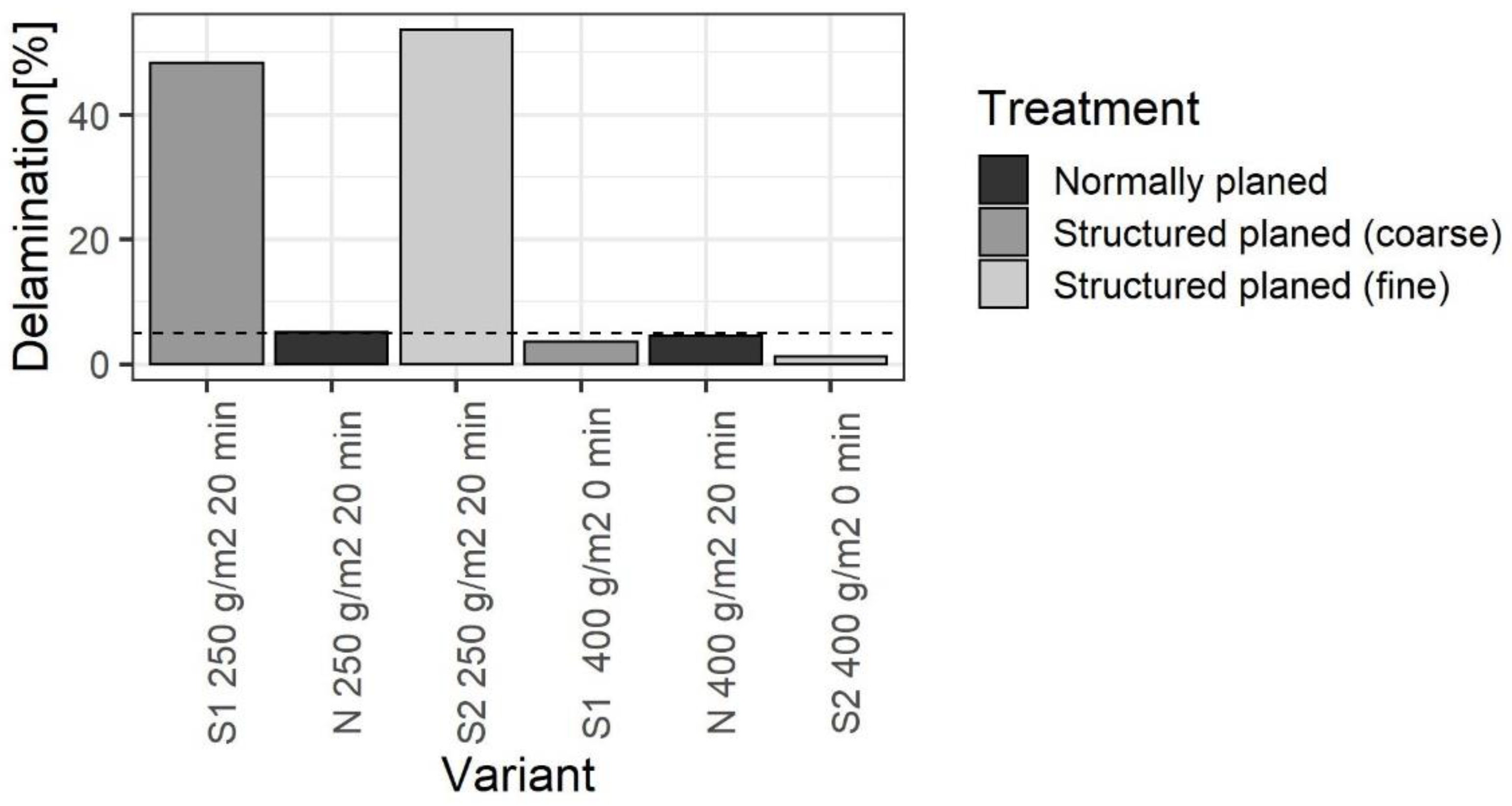

3.2.2. Delamination Results

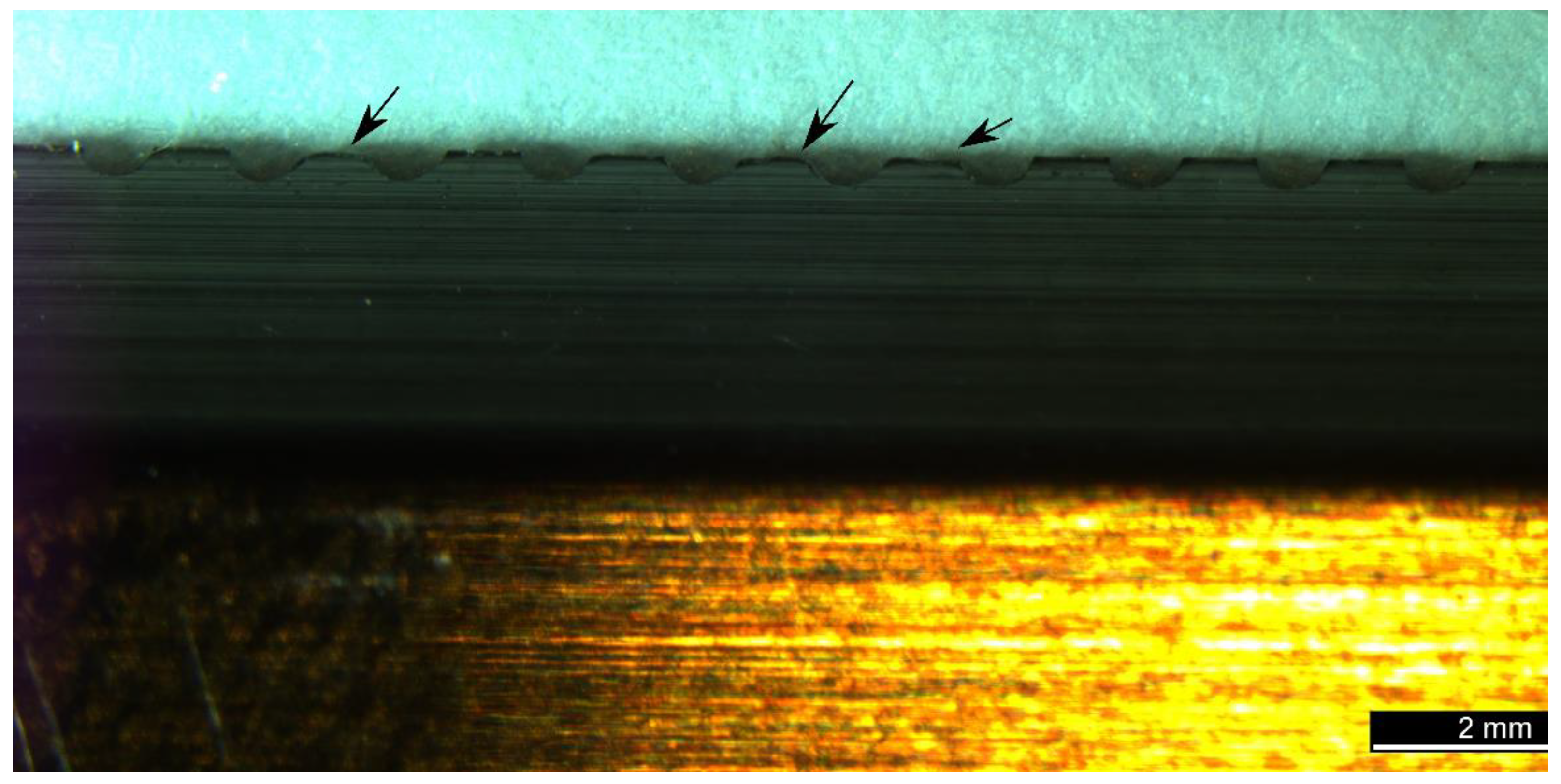

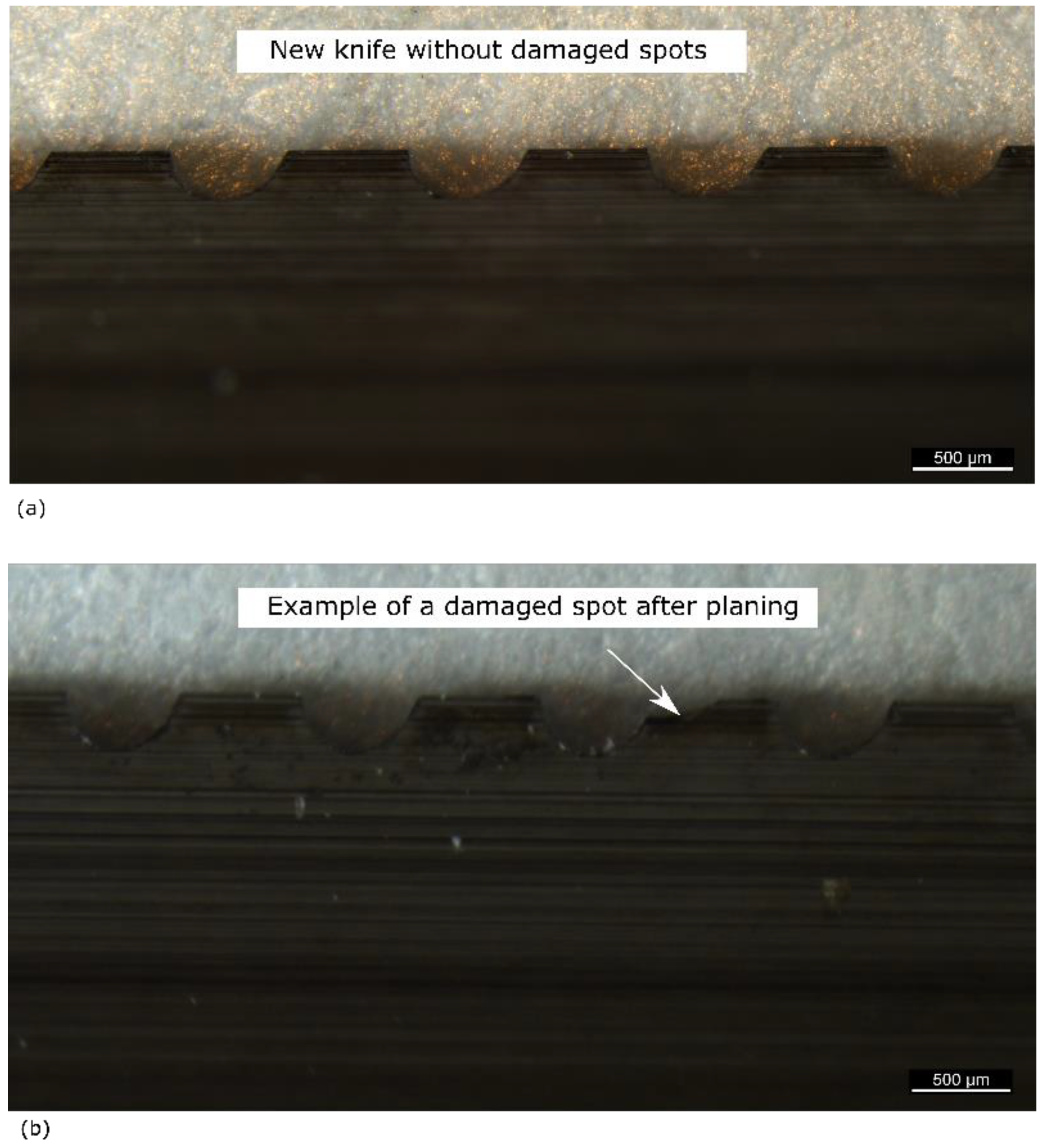

3.2.3. Tool Life

4. Discussion

4.1. Comparison of Five Surfacing Methods

4.1.1. Roughness

4.1.2. Tensile Shear Test

4.2. Impact of Structural Planing

4.2.1. Shear Test

4.2.2. Delamination

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameters | Structural Planing | Planing |

|---|---|---|

| Machine | Weinig Powermat 400 | Hoffmann Thickness planer |

| Cutting and sanding materials | HSS | Carbide |

| Feed speed, Vf (m·min−1) | 7 | 7 |

| Number of cutting edges z | 1 | 1 |

| Cutting head speed n (rpm) | 8000 | 5000 |

| D (mm) | 125 | 125 |

| Feed fz (mm) | 0.88 | 1.4 |

| Cutting Speed Vc (m·s−1) | 52 | 33 |

| Tool marks length lm (mm) | 0.88 | 1.4 |

| Tool marks depth trth (µm) | 1.53 | 3.92 |

References

- Brändli, U.-B.; Abegg, M.; Leuch, B.A. Schweizerisches Landesforstinventar. In Ergebnisse der Vierten Erhebung 2009–2017; Eidgenössische Forschungsanstalt für Wald, Schnee und Landschaft WSL: Bern, Switzerland; Birmensdorf Bundesamt für Umwelt BAFU: Bern, Switzerland, 2020. [Google Scholar]

- Konnerth, J.; Kluge, M.; Schweizer, G.; Miljković, M.; Gindl-Altmutter, W. Survey of selected adhesive bonding properties of nine European softwood and hardwood species. Eur. J. Wood Wood Prod. 2016, 74, 809–819. [Google Scholar] [CrossRef] [Green Version]

- Lehmann, M.; Volkmer, T. Investigation of the bond quality of hardwoods with micro structured surfaces. In Proceedings of the 68th FPS International Convention, Quebec City, QC, Canada, 10–13 August 2014. [Google Scholar]

- Lindner, M.; Maroschek, M.; Netherer, S.; Kremer, A.; Barbati, A.; Garcia-Gonzalo, J.; Seidl, R.; Delzon, S.; Corona, P.; Kolström, M.; et al. Climate change impacts, adaptive capacity, and vulnerability of European forest ecosystems. For. Ecol. Manag. 2010, 259, 698–709. [Google Scholar] [CrossRef]

- Kläusler, O.; Hass, P.; Amen, C.; Schlegel, S.; Niemz, P. Improvement of tensile shear strength and wood failure percentage of 1C PUR bonded wooden joints at wet stage by means of DMF priming. Eur. J. Wood Wood Prod. 2014, 72, 343–354. [Google Scholar] [CrossRef]

- Gardner, D.J.; Blumentritt, M.; Wang, L.; Yildirim, N. Adhesion theories in wood adhesive bonding: A critical review. Rev. Adhes. Adhes. 2014, 2, 127–172. [Google Scholar] [CrossRef]

- Frihart, C.; Rowell, R. Wood Adhesion and Adhesives. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 255–320. [Google Scholar]

- Hass, P.F. Penetration Behavior of Adhesives into Solid Wood and Micromechanics of the Bondline. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2012. [Google Scholar]

- Trouy-triboulot, M.; Masson, D. Matériaux dérivés du bois. Tech. De L’ingénieur. 2017, 33, 1–23. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Adhesives with Wood Materials-Bond Formation and Performance. In Wood Handbook: Wood as an Engineering Material: Chapter 10. Centennial Ed. General Technical Report FPL; GTR-190; US Dept. of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 10–11. [Google Scholar]

- Knorz, M.; Neuhaeuser, E.; Torno, S.; van de Kuilen, J.W. Influence of surface preparation methods on moisture-related performance of structural hardwood-adhesive bonds. Int. J. Adhes. Adhes. 2015, 57, 40–48. [Google Scholar] [CrossRef]

- Luedtke, J.; Amen, C.; van Ofen, A.; Lehringer, C. 1C-PUR-bonded hardwoods for engineered wood products: Influence of selected processing parameters. Eur. J. Wood Wood Prod. 2015, 73, 167–178. [Google Scholar] [CrossRef]

- Murmanis, L.; River, B.; Stewart, H. Surface and subsurface characteristics related to abrasive-planing conditions. Wood Fiber Sci. 1986, 18, 107–117. [Google Scholar]

- Kläusler, O.; Rehm, K.; Elstermann, F.; Niemz, P. Influence of wood machining on tensile shear strength and wood failure percentage of onecomponent polyurethane bonded wooden joints after wetting. Int. Wood Prod. J. 2014, 5, 18–26. [Google Scholar] [CrossRef]

- Kiliç, M. Effects of machining methods on the surface roughness values of Pinus nigra arnold wood. BioResources 2015, 10, 5596–5606. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.P.; Anderson, C.R.; Warnes, J.M.; Matsumura, J. The effect of planing on the microscopic structure of Pinus radiata wood cells in relation to penetration of PVA glue. Holz Roh-Und Werkst. 2002, 60, 333–341. [Google Scholar] [CrossRef]

- Cool, J.; Hernández, R.E. Evaluation of four surfacing methods on black spruce wood in relation to gluing performance. J. Wood Sci. 2013, 59, 185–194. [Google Scholar] [CrossRef]

- De Moura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci. 2005, 37, 355–366. [Google Scholar]

- Stewart, H.A. Some Surfacing Defects and Problems Related to Wood Moisture-Content. Wood Fiber 1980, 12, 175–182. [Google Scholar]

- Jokerst, R.; Stewart, H. Knife-Versus Abrasive-Planed Wood: Quality of Adhesive Bonds. Wood Fiber Sci. 1976, 8, 107–113. [Google Scholar]

- Murmanis, L.; River, B.H.; Stewart, H. Microscopy of abrasive-planed and knife-planed surfaces in wood-adhesive bonds. Wood Fiber Sci. 1983, 15, 102–115. Available online: http://wfs.swst.org/index.php/wfs/article/view/1181 (accessed on 20 October 2020).

- De Moura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for three surfacing methods on sugar maple wood. For. Prod. J. 2006, 56, 130–136. [Google Scholar]

- de Moura, L.F.; Cool, J.; Hernandez, R.E. Anatomical Evaluation of Wood Surfaces Produced By Oblique Cutting and Face Milling. IAWA J. 2010, 64, 1225–1228. [Google Scholar] [CrossRef]

- Bustos, A.C.; Moya, L.C.; Lisperguer, M.J.; Viveros, M.E. Effect of knife wear on the gluability of planed surfaces of radiata pine. Wood Fiber Sci. 2010, 42, 185–191. [Google Scholar]

- Sandak, J.; Negri, M. Wood surface roughness—What is it ? BOKU Univ. Nat. Sources Appl. Life Sci. 2005, 1–10. Available online: https://www.researchgate.net/publication/267805159 (accessed on 20 October 2020).

- Sinn, G.; Sandak, J.; Ramananantoandro, T. Properties of wood surfaces-Characterisation and measurement. A review. COST Action E35 2004-2008: Wood machining-Micromechanics and fracture. Holzforschung 2009, 63, 196–203. [Google Scholar] [CrossRef]

- Follrich, J.; Teischinger, A.; Gindl, W.; Müller, U. Tensile strength of softwood butt end joints. Part 1: Effect of grain angle on adhesive bond strength. Wood Mater. Sci. Eng. 2007, 2, 83–89. [Google Scholar] [CrossRef]

- Schmidt, M.; Glos, P.; Wegener, G. Verklebung von Buchenholz für tragende Holzbauteile. Eur. J. Wood Wood Prod. 2010, 68, 43–57. [Google Scholar] [CrossRef]

- Kipfer, H.U. Neue Entwicklungen beschichteter Holzoberflächen im Aussenbereich. SAH-Fortbildungskurs 2010, 42, 179–183. [Google Scholar]

- Ohnesorge, D.; Richter, K.; Becker, G. Influence of wood properties and bonding parameters on bond durability of European Beech (Fagus sylvatica L.) glulams. Ann. For. Sci. 2010, 67, 601. [Google Scholar] [CrossRef] [Green Version]

- Föhn, M.; Mathis, T. Scherzugfestigkeit von Verklebten Laubhölzern mit Mikrostrukturierten Oberflächen’, Biel; BUAS: Breda, The Netherlands, 2013. [Google Scholar]

- Hass, P.; Müller, C.; Clauss, S.; Niemz, P. Influence of growth ring angle, adhesive system and viscosity on the shear strength of adhesive bonds. Wood Mater. Sci. Eng. 2009, 4, 140–146. [Google Scholar] [CrossRef]

- SN EN 302-1:2013; Klebstoffe für tragende Holzbauteile-Prüfverfahren-Teil 1: Bestimmung der Längszugscherfestigkeit. Schweizerische Normen-Vereinigung Norme: Winterthur, Switzerland, 2013.

- SN EN 205:2016; Klebstoffe-Holzklebstoffe für nicht tragende Anwendungen-Bestimmung der Klebfestigkeit von Längsklebungen im Zugversuch Adhésifs-Colles pour bois à usages non structuraux-Détermination de la résistance au cisaillement en traction des joints à reco. Schweizerische Normen-Vereinigung (SNV): Winterthur, Switzerland, 2016.

- DIN EN ISO 4287:2010; Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Terms, Definitions and Surface Texture Parameters. DIN: Berlin, Germany, 2010.

- Lehringer, C.; Gabriel, J. Review of Recent Research Activities on One-Component PUR-Adhesives for Engineered Wood Products. In Materials and Joints in Timber Structures; Springer: Dordrecht, The Netherlands, 2014; Volume 9, pp. 405–420. [Google Scholar]

- Hernández, R.E.; Cool, J. Einfluss von Fräsparametern auf die Oberflächenqualität von Papierbirke, die mit Zwei Fräsverfahren Quer zur Faser Bearbeitet Wurde. Holz Roh-Und Werkst. 2008, 66, 147–154. [Google Scholar] [CrossRef]

- Ammann, S.; Schlegel, S.; Beyer, M.; Aehlig, K.; Lehmann, M.; Jung, H.; Niemz, P. Quality assessment of glued ash wood for construction engineering. Eur. J. Wood Wood Prod. 2016, 74, 67–74. [Google Scholar] [CrossRef]

- Hass, P.; Kläusler, O.; Schlegel, S.; Niemz, P. Effects of mechanical and chemical surface preparation on adhesively bonded wooden joints. Int. J. Adhes. Adhes. 2014, 51, 95–102. [Google Scholar] [CrossRef]

- Knorz, M.; Schmidt, M.; Torno, S.; van de Kuilen, J.W. Structural bonding of ash (Fraxinus excelsior L.): Resistance to delamination and performance in shearing tests. Eur. J. Wood Wood Prod. 2014, 72, 297–309. [Google Scholar] [CrossRef]

- Sogutlu, C. Determination of the Effect of Surface Roughness on the Bonding Strength of Wooden Materials. BioResources 2017, 12, 1417–1429. [Google Scholar] [CrossRef]

- Clerc, G.; Lehmann, M.; Gabriel, J.; Salzgeber, D.; Pichelin, F.; Strahm, T.; Niemz, P. Improvement of ash (Fraxinus excelsior L.) bonding quality with one-component polyurethane adhesive and hydrophilic primer for load-bearing application. Int. J. Adhes. Adhes. 2018, 85, 303–307. [Google Scholar] [CrossRef]

| Surface Preparation | Cutting Tool | Description | Code |

|---|---|---|---|

| Planing | Sharp knives | Planing (normal) | N |

| Planing | Dull knives | Planing (dull) | P |

| Planing | Knives with coarse structure | Micro-structuring (coarse) | S1 |

| Planing | Knives with fine structure | Micro-structuring (fine) | S2 |

| Abrasive Planing | P100 abrasive band | Sanding | B |

| Adhesive | OAT (min) | CAT (min) | Press Time (min) | Pressure (N/mm2) | Grammage (g/m2) | Max OAT (min) | Application Tool |

|---|---|---|---|---|---|---|---|

| 1C PUR | 4 | 0 | 75 | 0.8 | 125 | 30 | Wooden spatula |

| Adhesive | OAT (min) | CAT (min) | Press Time (min) | Pressure (N/mm2) | Grammages (g/m2) | Max OAT (min) | Application Tool |

|---|---|---|---|---|---|---|---|

| MF | 4 | 20; 0 a | 120 | 0.8 | 250; 400 | 35 | Wooden spatula |

| 1C PUR | 4 | 0 | 75 | 0.8 | 125; 200 | 10 | Wooden spatula |

| Adhesive | OAT (min) | CAT (min) | Press Time (min) | Press Force (N/mm2) | Grammage (g/m2) | Surfacing Methods | Application Tool |

|---|---|---|---|---|---|---|---|

| 1C PUR | 4 | 0 | 75 | 0.9 | 125 | Micro-structured (coarse and fine) | Wooden spatula |

| 4 | 0 | 75 | 0.9 | 200 | Micro-structured (coarse and fine) | Wooden spatula | |

| 4 | 0 | 75 | 0.9 | 125 | Normally planed | Wooden spatula | |

| 4 | 0 | 75 | 0.9 | 200 | Normally planed | Wooden spatula | |

| MF | 4 | 0 | 120 | 1 | 250 | Micro-structured (coarse and fine) | Wooden spatula |

| 4 | 0 | 120 | 1 | 400 | Micro-structured (coarse and fine) | Wooden spatula | |

| 4 | 20 | 120 | 1 | 250 | Normally planed | Wooden spatula | |

| 4 | 20 | 120 | 1 | 400 | Normally planed | Wooden spatula |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bamokina Moanda, D.; Lehmann, M.; Niemz, P. Investigation of the Impact of Micro-Structuring on the Bonding Performance of Beechwood (Fagus Sylvatica L.). Forests 2022, 13, 113. https://doi.org/10.3390/f13010113

Bamokina Moanda D, Lehmann M, Niemz P. Investigation of the Impact of Micro-Structuring on the Bonding Performance of Beechwood (Fagus Sylvatica L.). Forests. 2022; 13(1):113. https://doi.org/10.3390/f13010113

Chicago/Turabian StyleBamokina Moanda, Destin, Martin Lehmann, and Peter Niemz. 2022. "Investigation of the Impact of Micro-Structuring on the Bonding Performance of Beechwood (Fagus Sylvatica L.)" Forests 13, no. 1: 113. https://doi.org/10.3390/f13010113

APA StyleBamokina Moanda, D., Lehmann, M., & Niemz, P. (2022). Investigation of the Impact of Micro-Structuring on the Bonding Performance of Beechwood (Fagus Sylvatica L.). Forests, 13(1), 113. https://doi.org/10.3390/f13010113