Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of the Quebracho Extract

2.3. Adhesive Preparation and Characterization

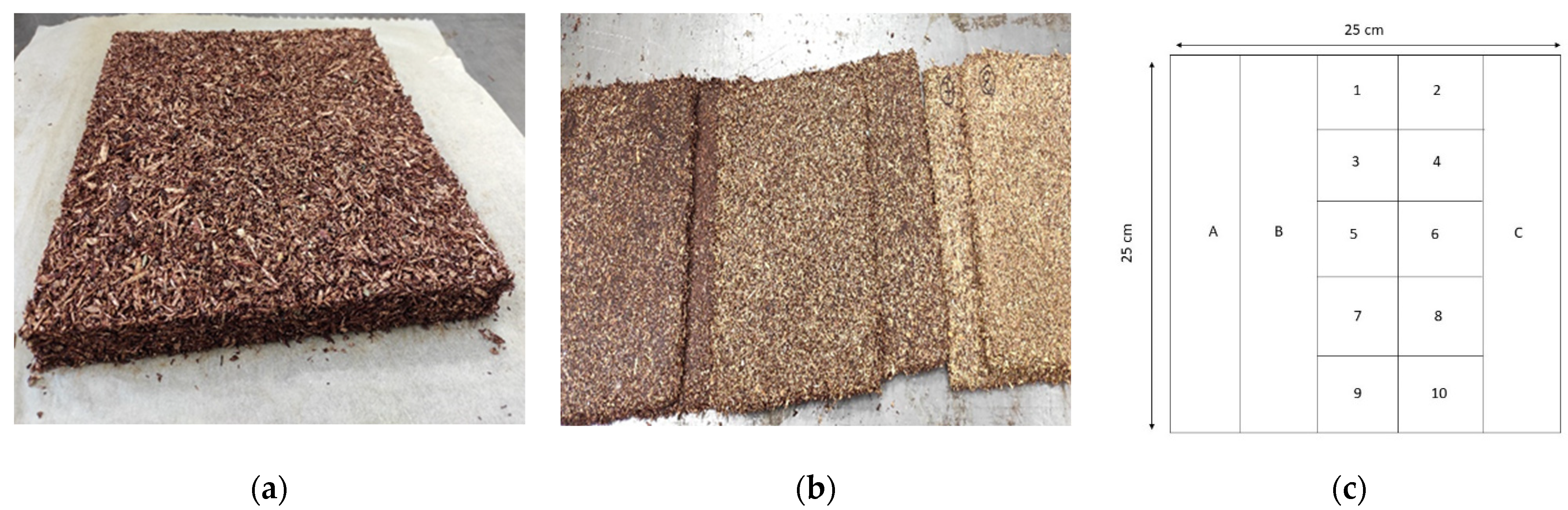

2.4. Particleboard Production

2.5. Particleboard Testing

2.6. Statistical Analysis

3. Results and Discussion

3.1. Industrial Quebracho Extract Chemical Analysis

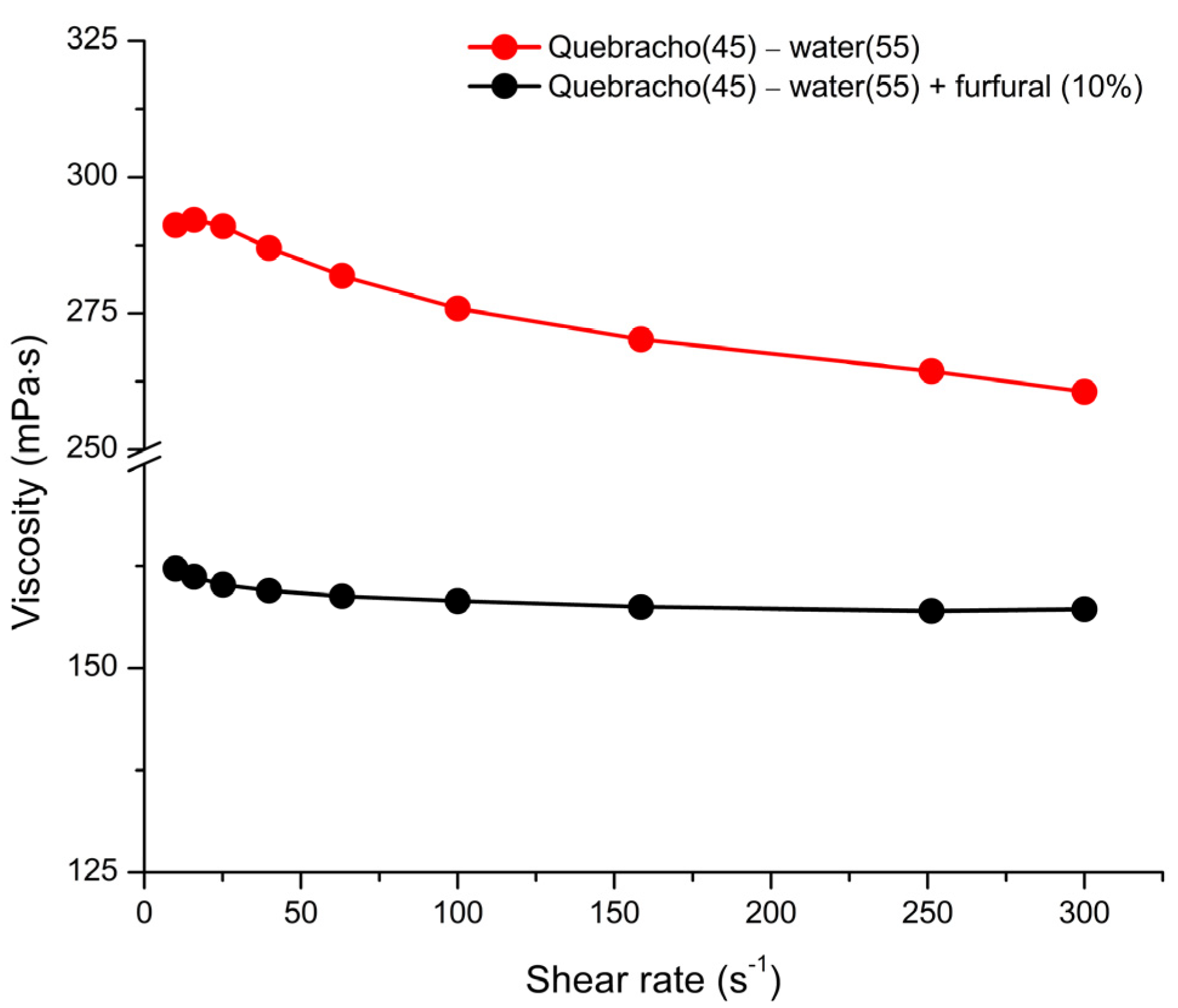

3.2. Adhesive Characterization

3.3. Particleboard Characterization

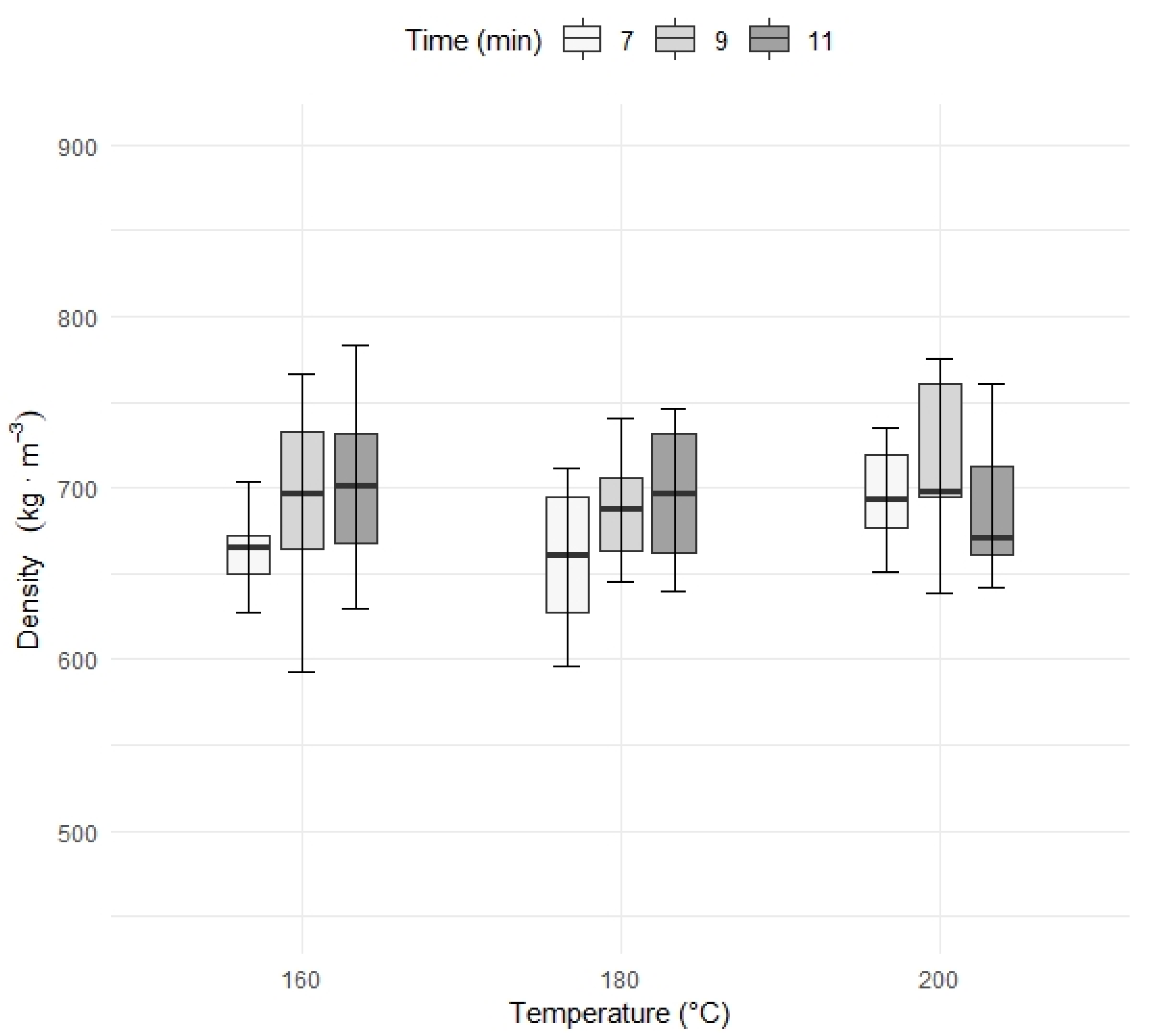

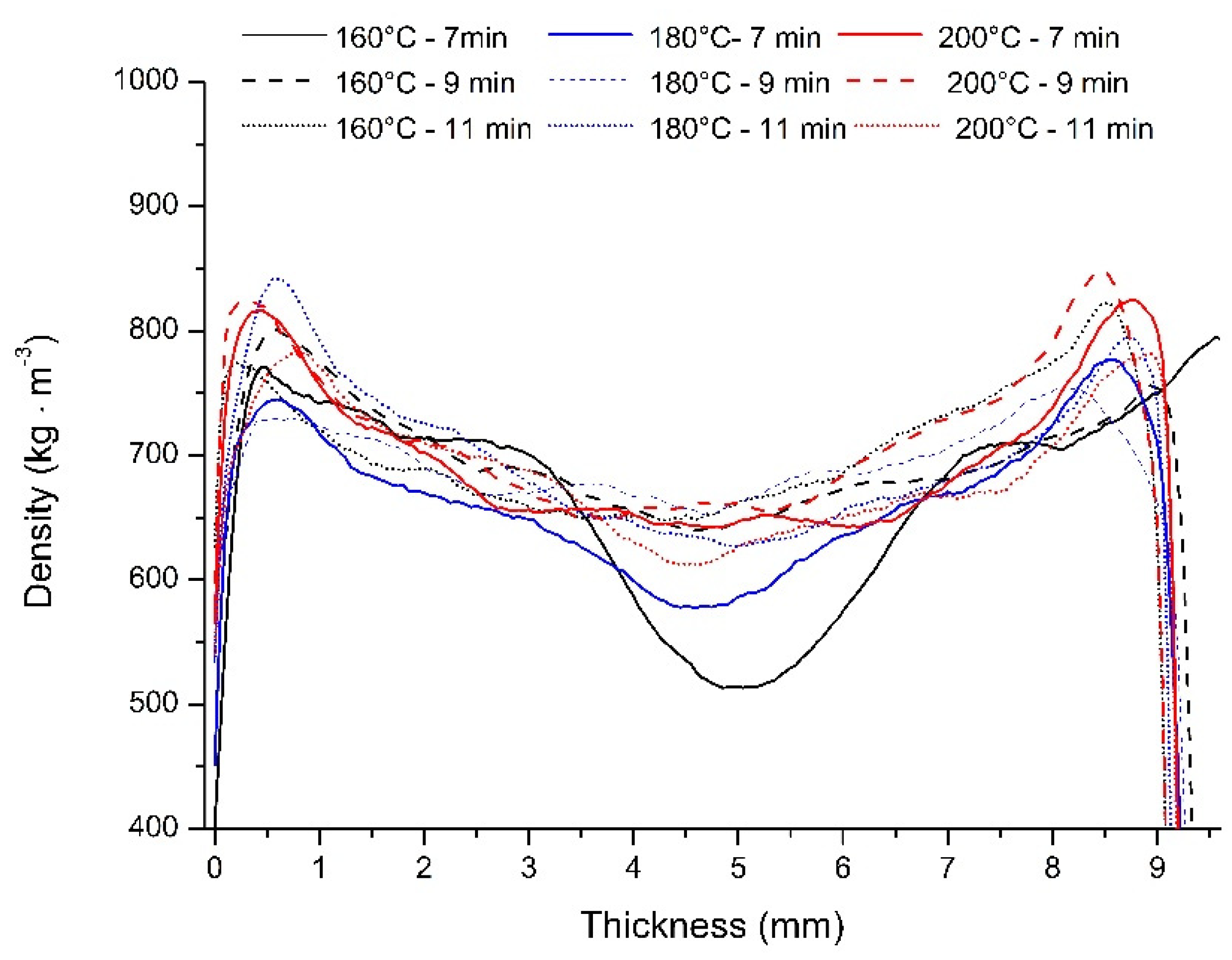

3.3.1. Density Profile

3.3.2. Mechanical Properties

3.3.3. Thickness Swelling

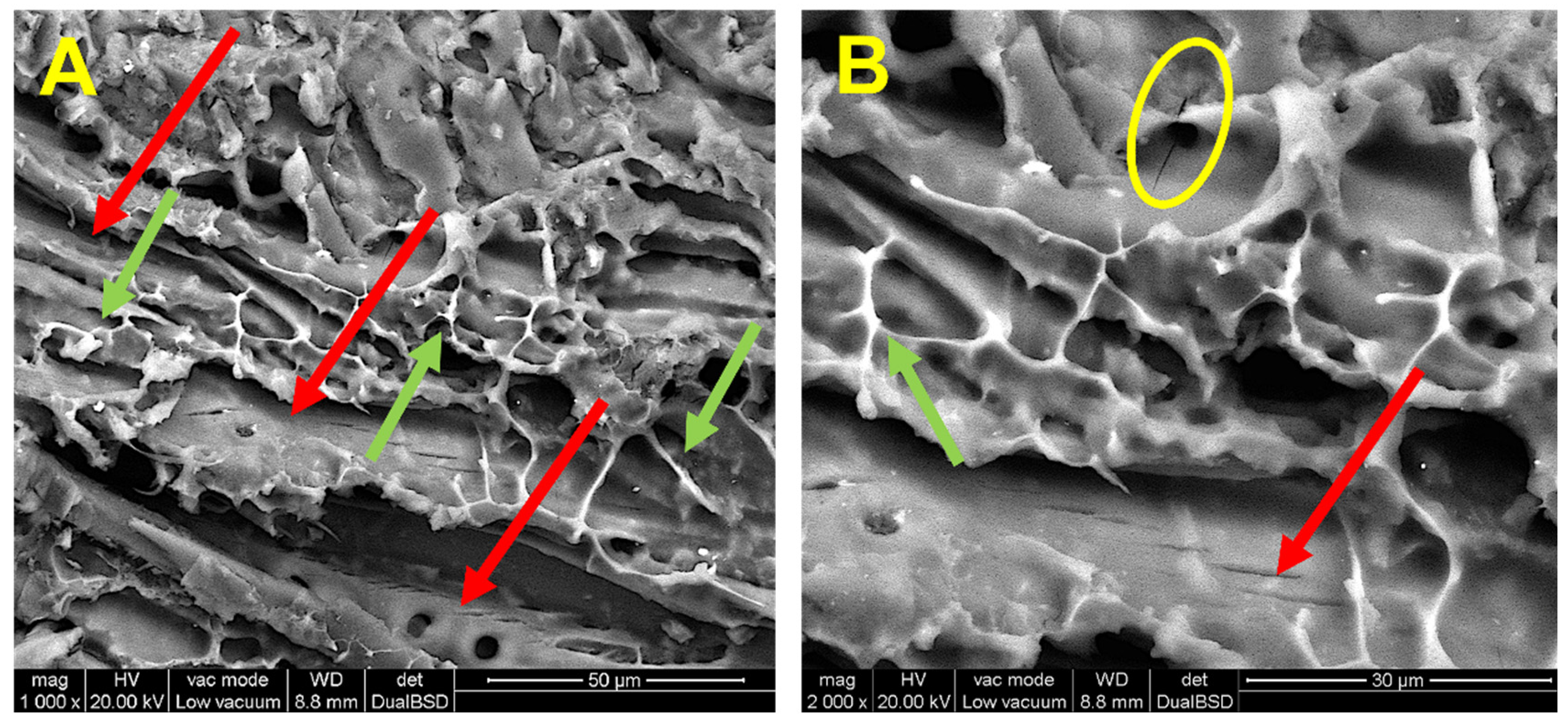

3.3.4. SEM Analysis

3.4. Optimization of Pressing Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Carvalho Araújo, C.K.; Salvador, R.; Piekarski, C.M.; Sokulski, C.C.; de Francisco, A.C.; de Carvalho Araujo Camargo, S.K. Circular economy practices on wood panels: A bibliographic analysis. Sustainability 2019, 11, 1057. [Google Scholar] [CrossRef] [Green Version]

- FAOSTAT—Food and Agriculture Organization of the United Nations. 2017. Available online: http://www.fao.org/faostat/en/#country (accessed on 30 June 2022).

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Frihart, C.R. Wood adhesives: Past, present, and future. For. Prod. J. 2015, 65, 4–8. [Google Scholar] [CrossRef]

- Carvalho, L.H.; Magalhães, F.D.; Ferra, J.M. Formaldehyde emissions from wood-based panels—Testing methods and industrial perspectives. In Formaldehyde: Chemistry, Applications and Role in Polymerization; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2012. [Google Scholar]

- Dunky, M. Adhesives in the wood industry. In Handbook of Adhesive Technology, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 223–262. ISBN 9781498736473. [Google Scholar]

- Vnučec, D.; Kutnar, A.; Goršek, A. Soy-based adhesives for wood-bonding–a review. J. Adhes. Sci. Technol. 2017, 31, 910–931. [Google Scholar] [CrossRef]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-based adhesives and evaluation for wood composites application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.H.; Jahan, S.A.; Lee, J.T. Exposure to formaldehyde and its potential human health Hazards. J. Environ. Sci. Health Part C Environ. Carcinog. Ecotoxicol. Rev. 2011, 29, 277–299. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A. Ionic liquids as enhancers of urea-glyoxal panel adhesives as substitutes for urea–formaldehyde resins. Eur. J. Wood Wood Prod. 2017, 75, 481–483. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Forest Products Annual Market Review 2018–2019; United Nations Publication: Herndon, VA, USA, 2019. [Google Scholar]

- Ningsi, D.W.; Suhasman; Saad, S. Characteristic of Chitosan Adhesive from Shell Shrimp Litopenaeus vannamei and Their Application for Producing Particleboard. IOP Conf. Ser. Mater. Sci. Eng. 2019, 593, 012015. [Google Scholar] [CrossRef]

- Sulaiman, N.S.; Hashim, R.; Amini, M.H.M.; Sulaiman, O.; Hiziroglu, S. Evaluation of the properties of particleboard made using oil palm starch modified with epichlorohydrin. BioResources 2013, 8, 283–301. [Google Scholar] [CrossRef]

- Bacigalupe, A.; Escobar, M.M. Soy Protein Adhesives for Particleboard Production—A Review. J. Polym. Environ. 2021, 29, 2033–2045. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Li, X.; Luo, J.; Gao, Q.; Li, J. A high-performance bio-adhesive derived from soy protein isolate and condensed tannins. RSC Adv. 2017, 7, 21226–21233. [Google Scholar] [CrossRef] [Green Version]

- Lei, H.; Du, G.; Wu, Z.; Xi, X.; Dong, Z. Cross-linked soy-based wood adhesives for plywood. Int. J. Adhes. Adhes. 2014, 50, 199–203. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Li, K. A new method of making particleboard with a formaldehyde-free soy-based adhesive. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1447–1453. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhong, Z.; Wang, D.; Ratto, J.A.; Sheng, K.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef]

- Gu, K.; Huang, J.; Li, K. Preparation and evaluation of particleboard bonded with a soy flour-based adhesive with a new curing agent. J. Adhes. Sci. Technol. 2013, 27, 2053–2064. [Google Scholar] [CrossRef]

- Gu, K.; Li, K. Preparation and evaluation of particleboard with a soy flour- polyethylenimine-maleic anhydride adhesive. J. Am. Oil Chem. Soc. 2011, 88, 673–679. [Google Scholar] [CrossRef]

- Margarida Martins, M.; Carvalheiro, F.; Gírio, F. An overview of lignin pathways of valorization: From isolation to refining and conversion into value-added products. Biomass Convers. Biorefinery 2022, 1–25. [Google Scholar] [CrossRef]

- Gillet, S.; Aguedo, M.; Petitjean, L.; Morais, A.R.C.; Da Costa Lopes, A.M.; Łukasik, R.M.; Anastas, P.T. Lignin transformations for high value applications: Towards targeted modifications using green chemistry. Green Chem. 2017, 19, 4200–4233. [Google Scholar] [CrossRef]

- Chen, X.; Pizzi, A.; Zhang, B.; Zhou, X.; Fredon, E.; Gerardin, C.; Du, G. Particleboard bio-adhesive by glyoxalated lignin and oxidized dialdehyde starch crosslinked by urea. Wood Sci. Technol. 2022, 56, 63–85. [Google Scholar] [CrossRef]

- El Mansouri, N.E.; Pizzi, A.; Salvadó, J. Lignin-based wood panel adhesives without formaldehyde. Holz als Roh Werkst. 2007, 65, 65–70. [Google Scholar] [CrossRef]

- Paul, G.B.; Timar, M.C.; Zeleniuc, O.; Lunguleasa, A.; Coșereanu, C. Mechanical properties and formaldehyde release of particleboard made with lignin-based adhesives. Appl. Sci. 2021, 11, 8720. [Google Scholar] [CrossRef]

- Aristri, M.A.; Lubis, M.A.R.; Yadav, S.M.; Antov, P.; Papadopoulos, A.N.; Pizzi, A.; Fatriasari, W.; Ismayati, M.; Iswanto, A.H. Recent developments in lignin- and tannin-based non-isocyanate polyurethane resins for wood adhesives—A review. Appl. Sci. 2021, 11, 4242. [Google Scholar] [CrossRef]

- Glasser, W.G. About Making Lignin Great Again—Some Lessons From the Past. Front. Chem. 2019, 7, 565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ang, A.F.; Ashaari, Z.; Lee, S.H.; Md Tahir, P.; Halis, R. Lignin-based copolymer adhesives for composite wood panels—A review. Int. J. Adhes. Adhes. 2019, 95, 102408. [Google Scholar] [CrossRef]

- Olivares, M.; Guzmán, J.A.; Natho, A.; Saavedra, A. Kraft lignin utilization in adhesives. Wood Sci. Technol. 1988, 22, 157–165. [Google Scholar] [CrossRef]

- Cheng, S.; Yuan, Z.; Leitch, M.; Anderson, M.; Xu, C.C. Highly efficient de-polymerization of organosolv lignin using a catalytic hydrothermal process and production of phenolic resins/adhesives with the depolymerized lignin as a substitute for phenol at a high substitution ratio. Ind. Crops Prod. 2013, 44, 315–322. [Google Scholar] [CrossRef]

- Hernes, P.J.; Hedges, J.I. Tannin signatures of barks, needles, leaves, cones, and wood at the molecular level. Geochim. Cosmochim. Acta 2004, 68, 1293–1307. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Efhamisisi, D.; Pizzi, A. Tannins as a sustainable raw material for green chemistry: A review. Ind. Crops Prod. 2018, 126, 316–332. [Google Scholar] [CrossRef]

- Pizzi, A. Tannins: Prospectives and actual industrial applications. Biomolecules 2019, 9, 344. [Google Scholar] [CrossRef] [Green Version]

- Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Fatriasari, W.; Sari, R.K.; Antov, P.; Gajtanska, M.; Papadopoulos, A.N.; Pizzi, A. Bio-based polyurethane resins derived from tannin: Source, synthesis, characterisation, and application. Forests 2021, 12, 1516. [Google Scholar] [CrossRef]

- Bisanda, E.T.N.; Ogola, W.O.; Tesha, J.V. Characterisation of tannin resin blends for particle board applications. Cem. Concr. Compos. 2003, 25, 593–598. [Google Scholar] [CrossRef]

- Cesprini, E.; Šket, P.; Causin, V.; Zanetti, M.; Tondi, G. Development of Quebracho (Schinopsis balansae) Tannin-Based Thermoset Resins. Polymers 2021, 13, 4412. [Google Scholar] [CrossRef]

- Tondi, G. Tannin-Based copolymer resins: Synthesis and characterization by solid state 13C NMR and FT-IR spectroscopy. Polymers 2017, 9, 223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pizzi, A. Advanced Wood Adhesives Technology; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Engozogho Anris, S.P.; Bikoro Bi Athomo, A.; Safou-Tchiama, R.; Leroyer, L.; Vidal, M.; Charrier, B. Development of green adhesives for fiberboard manufacturing, using okoume bark tannins and hexamine–characterization by 1H NMR, TMA, TGA and DSC analysis. J. Adhes. Sci. Technol. 2021, 35, 436–449. [Google Scholar] [CrossRef]

- Valenzuela, J.; Von Leyser, E.; Pizzi, A.; Westermeyer, C.; Gorrini, B. Industrial production of pine tannin-bonded particleboard and MDF. Eur. J. Wood Wood Prod. 2012, 70, 735–740. [Google Scholar] [CrossRef]

- Ballerini, A.; Despres, A.; Pizzi, A. Non-toxic, zero emission tannin-glyoxal adhesives for wood panels. Holz als Roh Werkst. 2005, 63, 477–478. [Google Scholar] [CrossRef]

- Luckeneder, P.; Gavino, J.; Kuchernig, R.; Petutschnigg, A.; Tondi, G. Sustainable phenolic fractions as basis for furfuryl alcohol-based co-polymers and their use as wood adhesives. Polymers 2016, 8, 396. [Google Scholar] [CrossRef]

- Jorda, J.; Cesprini, E.; Barbu, M.-C.; Tondi, G.; Zanetti, M.; Král, P. Quebracho Tannin Bio-Based Adhesives for Plywood. Polymers 2022, 14, 2257. [Google Scholar] [CrossRef]

- Kabbour, M.; Luque, R. Furfural as a Platform Chemical: From Production to Applications; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780444643070. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of Total Phenols and Other Oxidation Substrates and Antioxidants by Means of Folin-Ciocalteu Reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Seppepere, T.; Hernandez-Ramos, F.; Labidi, J.; Oostingh, G.J.; Bogner, B.; Petutschnigg, A.; Tondi, G. Purification of industrial tannin extract through simple solid-liquid extractions. Ind. Crop. Prod. 2019, 139, 111502. [Google Scholar] [CrossRef]

- De Iseppi, A.; Marangon, M.; Lomolino, G.; Crapisi, A.; Curioni, A. Red and white wine lees as a novel source of emulsifiers and foaming agents. LWT 2021, 152, 112273. [Google Scholar] [CrossRef]

- Hafiz, N.L.M.; Tahir, P.M.D.; Hua, L.S.; Abidin, Z.Z.; Sabaruddin, F.A.; Yunus, N.M.; Abdullah, U.H.; Abdul Khalil, H.P.S. Curing and thermal properties of co-polymerized tannin phenol-formaldehyde resin for bonding wood veneers. J. Mater. Res. Technol. 2020, 9, 6994–7001. [Google Scholar] [CrossRef]

- SIST EN 323:1996; Wood-Based Panels—Determination of Density. British Standards: London, UK, 1993.

- BS EN 319:1993; Particleboards and Fiberboards—Determination of Tensile Strength Perpendicular to the Plane of Board. British Standards: London, UK, 1993.

- BS EN 310:1993; Wood-based panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. British Standards: London, UK, 1993; pp. 1–14.

- BS EN 317:1993; Particleboards and Fiberboards—Determination of Swelling in Thickness after Immersion in Water. British Standards: London, UK, 1993.

- RStudio. Integrated Development Environment for R; RStudio PBC: Boston, MA, USA, 2012. [Google Scholar]

- Cesprini, E.; De Iseppi, A.; Giovando, S.; Tarabra, E.; Zanetti, M.; Primož, Š.; Matteo, M.; Tondi, G. Wood Science and Technology Chemical characterization of cherry (Prunus avium) tannins in comparison with commercial mimosa and chestnut tannin extracts. Wood Sci. Technol. 2022, 56, 1455–1473. [Google Scholar] [CrossRef]

- Watrelot, A.A.; Norton, E.L. Chemistry and reactivity of tannins in vitis spp.: A review. Molecules 2020, 25, 2110. [Google Scholar] [CrossRef] [PubMed]

- Garro Galvez, J.M.; Riedl, B.; Conner, A.H. Analytical studies on tara tannins. Holzforschung 1997, 51, 235–243. [Google Scholar] [CrossRef]

- Bianchi, S.; Kroslakova, I.; Janzon, R.; Mayer, I.; Saake, B.; Pichelin, F. Characterization of condensed tannins and carbohydrates in hot water bark extracts of European softwood species. Phytochemistry 2015, 120, 53–61. [Google Scholar] [CrossRef]

- Navarrete, P.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Pasch, H.; Rode, K.; Delmotte, L.; Rigolet, S. Low formaldehyde emitting biobased wood adhesives manufactured from mixtures of tannin and glyoxylated lignin. J. Adhes. Sci. Technol. 2012, 26, 1667–1684. [Google Scholar] [CrossRef]

- Hauptt, R.A.; Sellers, T. Characterizations of Phenol-Formaldehyde Resol Resins. Ind. Eng. Chem. Res. 1994, 33, 693–697. [Google Scholar] [CrossRef]

- Wong, E.D.; Zhang, M.; Wang, Q.; Kawai, S. Formation of the density profile and its effects on the properties of particleboard. Wood Sci. Technol. 1999, 33, 327–340. [Google Scholar] [CrossRef]

- EN 312:2010; Particleboards—Specifications. British Standards: London, UK, 2010.

- de Palacios, P.; Fernández, F.G.; García-Iruela, A.; González-Rodrigo, B.; Esteban, L.G. Study of the influence of the physical properties of particleboard type P2 on the internal bond of panels using artificial neural networks. Comput. Electron. Agric. 2018, 155, 142–149. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Febrianto, F.; Hadi, Y.S.; Ruhendi, S.; Hermawan, D. The Effect of Pressing Temperature and Time on the Quality of Particle Board Made from Jatropha Fruit Hulls Treated in Acidic Condition. MAKARA J. Technol. Ser. 2014, 17, 8. [Google Scholar] [CrossRef] [Green Version]

- Ferrández-García, C.E.; Ferrández-García, A.; Ferrández-Villena, M.; Hidalgo-Cordero, J.F.; García-Ortuño, T.; Ferrández-García, M.T. Physical and mechanical properties of particleboard made from palm tree prunings. Forests 2018, 9, 755. [Google Scholar] [CrossRef] [Green Version]

- Maloney, T. Moder Particleboard and Dry-Process Fiberboard Manufacturing; Miller Freeman: San Francisco, CA, USA, 1993. [Google Scholar]

- Oktay, S.; Kızılcan, N.; Bengü, B. Development of bio-based cornstarch—Mimosa tannin—Sugar adhesive for interior particleboard production. Ind. Crops Prod. 2021, 170, 113689. [Google Scholar] [CrossRef]

- Alamsyah, E.M.; Sutrisno; Nuryawan, A.; Widyorini, R. Identifying best parameters of particleboard bonded with dextrin-based adhesives. Open Agric. 2020, 5, 345–351. [Google Scholar] [CrossRef]

- Santos, J.; Antorrena, G.; Freire, M.S.; Pizzi, A.; González-Álvarez, J. Environmentally friendly wood adhesives based on chestnut (Castanea sativa) shell tannins. Eur. J. Wood Wood Prod. 2017, 75, 89–100. [Google Scholar] [CrossRef]

- Zhao, Z.; Umemura, K. Investigation of a New Natural Particleboard Adhesive Composed of Tannin and Sucrose. 2. Effect of Pressing Temperature and Time on Board Properties, and Characterization of Adhesive. BioResources 2015, 10, 2444–2460. [Google Scholar] [CrossRef] [Green Version]

- Ghahri, S.; Pizzi, A. Improving soy-based adhesives for wood particleboard by tannins addition. Wood Sci. Technol. 2018, 52, 261–279. [Google Scholar] [CrossRef]

- Mahieu, A.; Vivet, A.; Poilane, C.; Leblanc, N. Performance of particleboards based on annual plant byproducts bound with bio-adhesives. Int. J. Adhes. Adhes. 2021, 107, 102847. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from recycled wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

| Extract | TPC (μg GAE/mg) | TCT (μg CE/mg) | PS (mg/L) |

|---|---|---|---|

| Quebracho | 646 ± 18 | 304 ± 65 | 552 ± 103 |

| Temperature (°C) | Time (min) | Density (kg∙m−3) | Thickness (mm) | ||

|---|---|---|---|---|---|

| Mean | SD | Mean | SD | ||

| 160 | 7 | 663 | 21 | 10.1 | 0.19 |

| 9 | 692 | 55 | 9.6 | 0.09 | |

| 11 | 701 | 46 | 9.3 | 0.08 | |

| 180 | 7 | 659 | 40 | 9.4 | 0.10 |

| 9 | 687 | 29 | 9.6 | 0.13 | |

| 11 | 698 | 40 | 9.3 | 0.05 | |

| 200 | 7 | 696 | 37 | 9.4 | 0.07 |

| 9 | 713 | 52 | 9.3 | 0.07 | |

| 11 | 685 | 39 | 9.5 | 0.10 | |

| Samples | IB | MOE | MOR | T-Swelling | ||

|---|---|---|---|---|---|---|

| Temperature (°C) | Pressing Time (min) | Adhesive Amount (%) | (MPa) | (MPa) | (MPa) | (%) |

| 140 | 11 | 15 | 0.16 | 1453 | 4.8 | 82 |

| 160 | 13 | 15 | 0.35 | 1560 | 5.5 | 77 |

| 160 | 11 | 10 | 0.31 | 1083 | 5.5 | 82 |

| 160 | 11 | 15 | 0.37 | 1417 | 4.9 | 80 |

| 160 | 9 | 15 | 0.32 | 1542 | 5.3 | 90 |

| 160 | 7 | 15 | 0.03 | 1417 | 4.5 | n.a. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cesprini, E.; Causin, V.; De Iseppi, A.; Zanetti, M.; Marangon, M.; Barbu, M.C.; Tondi, G. Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards. Forests 2022, 13, 1781. https://doi.org/10.3390/f13111781

Cesprini E, Causin V, De Iseppi A, Zanetti M, Marangon M, Barbu MC, Tondi G. Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards. Forests. 2022; 13(11):1781. https://doi.org/10.3390/f13111781

Chicago/Turabian StyleCesprini, Emanuele, Valerio Causin, Alberto De Iseppi, Michela Zanetti, Matteo Marangon, Marius Catalin Barbu, and Gianluca Tondi. 2022. "Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards" Forests 13, no. 11: 1781. https://doi.org/10.3390/f13111781

APA StyleCesprini, E., Causin, V., De Iseppi, A., Zanetti, M., Marangon, M., Barbu, M. C., & Tondi, G. (2022). Renewable Tannin-Based Adhesive from Quebracho Extract and Furfural for Particleboards. Forests, 13(11), 1781. https://doi.org/10.3390/f13111781