Effect of Moisture Content and Preservatives on the Discoloration of Oil Palm (Elaeis guineensis Jacq.) Lumber

Abstract

1. Introduction

2. Materials and Methods

Materials

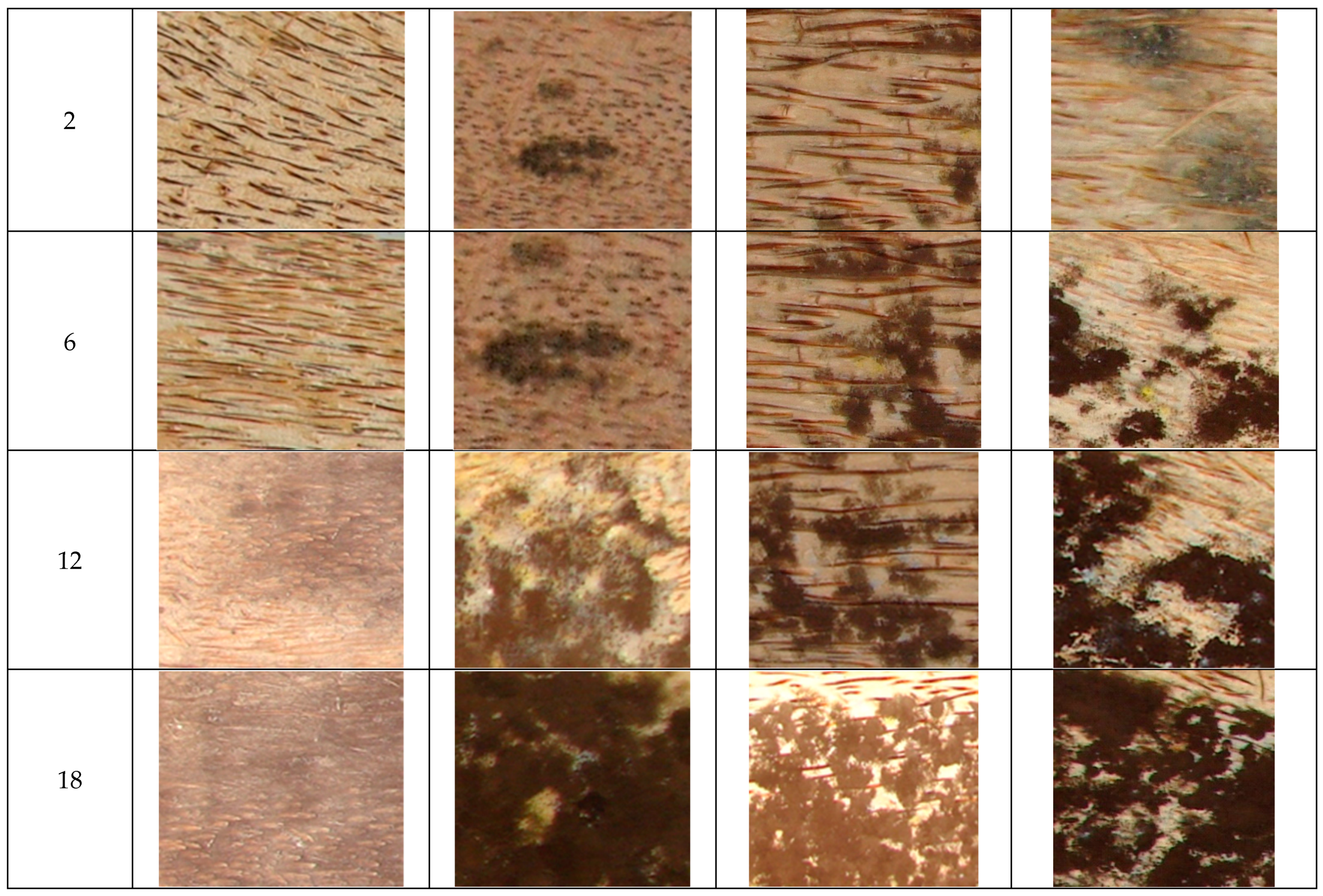

3. Results and Discussion

3.1. Physical Characteristics Identified in the Study

3.2. Moisture Content (MC)

3.3. Chemical Composition of Oil Palm Lumber

3.4. Mold as Occurred in Oil Palm Lumber Specimens

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yurnaliza, Y.; Jamilah, I.; Hartanto, A.; Lutfia, A. Screening of endophytic fungi from oil palm (Elaeis guineensis) in producing exopolysaccharides. Biodiversitas J. Biol. Divers. 2021, 22, 1467–1473. [Google Scholar] [CrossRef]

- Pirker, J.; Mosnier, A.; Kraxner, F.; Havlík, P.; Obersteiner, M. What are the limits to oil palm expansion? Glob. Environ. Chang. 2016, 40, 73–81. [Google Scholar] [CrossRef]

- Mhd Ramle, S.F.; Sulaiman, O.; Hashim, R.; Arai, T.; Kosugi, A.; Abe, H.; Mori, Y. Characterization of Parenchyma and Vascular. Lignocellul. J. 2012, 1, 33–44. [Google Scholar]

- Sulaiman, O.; Salim, N.; Nordin, N.A.; Hashim, R.; Ibrahim, M.; Sato, M. The potential of oil palm trunk biomass as an alternative source for compressed wood. BioResources 2012, 7, 2688–2706. Available online: http://ncsu.edu/bioresources (accessed on 19 September 2022). ISSN: 1930-2126. [CrossRef]

- Gutbrod, P.; Reichert, S.; Gutbrod, K.; Hamai, A.; Bréhélin, C.; Ngando-Ebongue, G.; Dörmann, P. Fatty acid isoprenoid alcohol ester synthesis in fruits of the African Oil Palm (Elaeis guineensis). Phytochemistry 2021, 185, 112684. Available online: https://hal.archives-ouvertes.fr/hal-03141513/document (accessed on 29 July 2022). [CrossRef]

- Susila, W.R. Contribution of Oil Palm Industry To Economic Growth and Poverty Alleviation in Indonesia. J. Litbang Pertan. 2004, 23, 107–114. [Google Scholar]

- Alam, A.S.A.F.; Er, A.C.; Begum, H. Malaysian Oil Palm Industry: Prospect and Problem. J. Food Agric. Environ. 2015, 13, 143–148. [Google Scholar]

- Levin, J. Profitability and Sustainability in Palm Oil Production Analysis. In Analysis of Incremental Financial Costs and Benefits of RSPO Compliance; WWF Report; WWF-US, FMO, CDC: Westernieland, Netherlands, 2012. [Google Scholar]

- Mirande-Ney, C.; Tcherkez, G.; Balliau, T.; Zivy, M.; Gilard, F.; Cui, J.; Ghashghaie, J.; Lamade, E. Metabolic leaf responses to potassium availability in oil palm (Elaeis guineensis Jacq.) trees grown in the field. Environ. Exp. Bot. 2020, 175, 104062. [Google Scholar] [CrossRef]

- Hansen, S.B.; Padfield, R.; Syayuti, K.; Evers, S.; Zakariah, Z.; Mastura, S. Trends in global palm oil sustainability research. J. Clean. Prod. 2015, 100, 140–149. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. Evaluation of hybrid briquettes from corncob and oil palm trunk bark in a domestic cooking application for rural communities in Nigeria. J. Clean. Prod. 2020, 284, 124745. [Google Scholar] [CrossRef]

- Tomimura, Y. Chemical characteristics and utilization of oil palm trunks. Jpn. Agric. Res. Q. JARQ 1992, 25, 283–288. [Google Scholar]

- Zeng, N.; Hausmann, H. Wood Vault: Remove atmospheric CO2 with trees, store wood for carbon sequestration for now and as biomass, bioenergy and carbon reserve for the future. Carbon Balance Manag. 2022, 17, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Razman, M.R. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2021, 17, 33–65. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Abdul-Khalil, H.P.S.; Bhat, A.H.; Jawaid, M.; Amouzgar, P.; Ridzuan, P.; Said, M.R. Agro-Waste: Mechanical and Physical Properties of Resin Impregnated Oil Palm Trunk Core Lumber. Polym. Compos. 2010, 31, 638–644. [Google Scholar] [CrossRef]

- Okai, R.; Mitchual, S.J.; Mensah, P.; Dzakpasu, R.K. Characterization of Physical, Machining and Finishing Properties of Oil Palm Lumber: An Emerging Non-Timber Forest Product in Sub-Saharan Africa. Int. J. Emerg. Technol. Adv. Eng. 2015, 5, 289–296. [Google Scholar]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Wear, D.N.; Prestemon, J.; Foster, M.O. US Forest Products in the Global Economy. J. For. 2016, 114, 483–493. [Google Scholar] [CrossRef]

- Shamsudin, N.A.; Sahid, I.; Mokhtar, A.; Muhamad, H.; Ahmad, S. Life cycle inventory of oil palm lumber production: A gate-to-gate case study. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1940, p. 020042. [Google Scholar] [CrossRef]

- Mantau, U.; Saal, U.; Prins, K.; Steierer, F.; Lindner, M.; Verkerk, H.; Eggers, J.; Leek, N. EUwood-Real Potential for Changes in Growth and Use of EU Forest; Final Report; Hamburg/Germany, 2010; p. 160. Available online: https://franzjosefadrian.com/wp-content/uploads/2013/06/euwood_final_report.pdf (accessed on 19 September 2022).

- Warman, R.D. Global wood production from natural forests has peaked. Biodivers. Conserv. 2014, 23, 1063–1078. [Google Scholar] [CrossRef]

- Whiteman, A.; Brown, C. Modelling global forest products supply and demand: Recent results from FAO and their potential implications for New Zealand. N. Z. J. For. 2000, 44, 6–9. [Google Scholar]

- Bowyer, J.L.; Stockmann, V.E. Agricultural Residues. An Exciting Bio-Based Raw Material for the Global Panel Industry. 2017. Available online: https://www.researchgate.net/publication/279546173. (accessed on 29 July 2022).

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.R.; Almutairi, Z.; Jawaid, M. Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Iswanto, A.H.; Sucipto, T.; Azhar, I.; Coto, Z.; Febrianto, F. Physical and mechanical properties of oil palm stem (Elaeis guineensis Jacq.) From Aek Pancur garden in North Sumatra (in Indonesian). Jurnal Ilmu dan Teknologi Hasil Hutan 2010, 3, 1–7. [Google Scholar]

- Rafidah, J.; Asma, W.; Puad, E.; Mahanim, S.M.A.; Shaharuddin, H. Toward Zero Waste Production of Value-Added Products from Waste Oil Palm Trunk (WOPT); Forest Research Institute Malaysia (FRIM): Kuala Lumpur, Malaysia, 2012. [Google Scholar] [CrossRef]

- Ilango, P.; Arulpari, M.; Medona, M.; Abirami, T. Chlorhexidine: A miracle chemical. Int. J. Curr. Res. Rev. 2013, 5, 26–34. [Google Scholar]

- Rahman, M.A.; Fuad, A. Biodeterioration of Wood By Fungi; Forestry and Wood Technology Discipline Khulna University Khulna: Khulna, Bangladesh, 2002; pp. 20–38. Available online: https://d1wqtxts1xzle7.cloudfront.net/63734494/Biodeterioration_of_Wood_by_Fungi_-_MS_Project_Thesis_xii__65_pages_as_pdf20200624-8910-1x5imij-libre.pdf?1593109007=&response-content-disposition=inline%3B+filename%3DBIODETERIORATION_OF_WOOD_BY_FUNGI_Forest.pdf&Expires=1666191875&Signature=e3jt1VTmSDZzZ6~fJ7efn9NjzoGWG0FWciMEd1pXKUfGuCMMLNlbR97AiNVoCN8sa0R7oXlXghLWbuLhSAyoMLzxfERm9nUxAU7zme4r9eoQfOoSTqM~U4NltMUKQFlbMetqsCiWoWBAcMBP1wfc0HoGkvfG1MzlclGBTRIEdZ8hV61DPVC2gkZHOnSdQ~zk8wCVz3PeB7EqQ4EUXOnIa8okumQRbH9cTRboVt12StImA7lZAuG28FlpCE9HvD6A9fPeDE~sYT~mzX6wmrVFJxEFTFeG8Myw2WdbvmbWNkX4ofhfPHHwLp9eTJuXS2qJFgsl7W~pNLs98Yspl0Gjqg__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 29 July 2022).

- Rees, R.W.; Flood, J.; Hasan, Y.; Potter, U.; Cooper, R.M. Basal stem rot of oil palm (Elaeis guineensis); mode of root infection and lower stem invasion by Ganoderma boninense. Plant Pathol. 2009, 58, 982–989. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Methods for Evaluating Properties of Wood-Base Fibre and Particle Panel Materials; ASTM standard D1037-06a; ASTM: Philadelphia, PA, USA, 1999. [Google Scholar]

- Omar, R.; Idris, A.; Yunus, R.; Khalid, K.; Isma, M.A. Characterization of empty fruit bunch for microwave-assisted pyrolysis. Fuel 2011, 90, 1536–1544. [Google Scholar] [CrossRef]

- Shi, K.; Oladejo, J.M.; Yan, J.; Wu, T. Investigation on the interactions among lignocellulosic constituents and minerals of biomass and their influences on co-firing. Energy 2019, 179, 129–137. [Google Scholar] [CrossRef]

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization; Van Nostrand Reinhold: New York, NY, USA, 1991; Volume 115. [Google Scholar]

- Bahanawan, A.; Kusumah, S.S.; Darmawan, T.; Ismadi; Masruchin, N.; Sudarmanto; Jayadi; Pramasari, D.A.; Triwibowo, D.; Kusumaningrum, W.B.; et al. Moisture Content, Color Quantification and Starch Content of Oil Palm Trunk (Elaeis guineensis Jack.). Earth Environ. Sci. 2019, 374, 012041. [Google Scholar] [CrossRef]

- Sulaiman, N.S.; Hashim, R.; Amini MH, M.; Sulaiman, O.; Hiziroglu, S. Evaluation of the properties of particleboard made using oil palm starch modified with epichlorohydrin. BioResources 2013, 8, 283–301. [Google Scholar] [CrossRef]

- Salleh, K.M.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Nadhari, W.N.A.W.; Karim, N.A.; Jumhuri, N.; Ang, L.Z.P. Evaluation of properties of starch-based adhesives and particleboard manufactured from them. J. Adhes. Sci. Technol. 2014, 29, 319–336. [Google Scholar] [CrossRef]

- H`ng, P.; Wong, L.; Chin, K.L.; Tor, E.; Tan, S.; Tey, B.T.; Maminski, M. Oil palm (Elaeis guineensis) trunk as a resource of starch and other sugars. J. Appl. Sci. 2011, 11, 3053–3057. [Google Scholar] [CrossRef]

- Loh, Y.F.; Paridah, T.; Hoong, Y.B.; Bakar, E.S.; Anis, M.; Hamdan, H. Resistance of phenolic-treated oil palm stem plywood against subterranean termites and white rot decay. Int. Biodeterior. Biodegrad. 2011, 65, 14–17. [Google Scholar] [CrossRef]

- Rosli, F.; Ghazali, C.M.R.; Abdullah, M.M.A.B.; Hussin, K. A review: Characteristics of oil palm trunk (OPT) and quality improvement of palm trunk plywood by resin impregnation. BioResources 2016, 11, 5565–5580. [Google Scholar] [CrossRef]

- Dungani, R.; Jawaid, M.; Khalil, H.A.; Jasni, J.; Aprilia, S.; Hakeem, K.R.; Islam, M.N. A review on quality enhancement of oil palm trunk waste by resin impregnation: Future materials. BioResources 2013, 8, 3136–3156. Available online: http://ncsu.edu/bioresources (accessed on 19 September 2022). ISSN: 1930-2126. [CrossRef]

- Abram, N.K.; Xofis, P.; Tzanopoulos, J.; MacMillan, D.C.; Ancrenaz, M.; Chung, R.; Ambu, L. Synergies for improving oil palm production and forest conservation in floodplain landscapes. PLoS ONE 2014, 9, e95388. [Google Scholar] [CrossRef]

- Loh, Y.F.; Paridah, T.; Hoong, Y.B.; Yoong, A.C.C. Effects of treatment with low molecular weight phenol formaldehyde resin on the surface characteristics of oil palm (Elaeis guineensis) stem veneer. Mater. Des. 2011, 32, 2277–2283. [Google Scholar] [CrossRef]

- Klímek, P.; Wimmer, R.; Meinlschmidt, P.; Kúdela, J. Utilizing Miscanthus stalks as raw material for particleboards. Ind. Crop. Prod. 2018, 111, 270–276. [Google Scholar] [CrossRef]

- Nuryawan, A.; Sutiawan, J.; Rahmawaty; Masruchin, N.; Bekhta, P. Panel Products Made of Oil Palm Trunk: A Review of Potency, Environmental Aspect, and Comparison with Wood-Based Composites. Polymers 2022, 14, 1758. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Mai, C. Weathering of uncoated and coated wood treated with methylated 1, 3-dimethylol-4, 5-dihydroxyethyleneurea (mDMDHEU). Holz als Roh-und Werkst. 2008, 66, 455–464. [Google Scholar] [CrossRef]

- Bakar, E.S.; Hamzah, N.N.; Ashaari, Z.; Hua, L.S. Assessment of oil palm wood quality improvement through integrated treatment process as function of sawing pattern and slab thickness. J. Oil Palm Res. 2017, 29, 366–372. [Google Scholar] [CrossRef][Green Version]

- Burnes, T.A.; Blanchette, R.A.; Farrell, R.L. Bacterial biodegradation of extractives and patterns of bordered pit membrane attack in pine wood. Appl. Environ. Microbiol. 2000, 66, 5201–5205. [Google Scholar] [CrossRef]

- Sandoval Torres, S.; Jomaa, W.; Puiggali, J.R.; Avramidis, S. Multiphysics modeling of vacuum drying of wood. Appl. Math. Model. 2011, 35(10), 5006–5016. [Google Scholar] [CrossRef]

- Zak, B. A Field Guide to Texas Critters: Common Household and Garden Pests; Taylor Trade Publishing: Abingdon, UK, 1988. [Google Scholar]

- Yamada, H.; Tanaka, R.; Sulaiman, O.; Hashim, R.; Hamid, Z.; Yahya, M.; Kosugi, A.; Arai, T.; Murata, Y.; Nirasawa, S.; et al. Old oil palm trunk: A promising source of sugars for bioethanol production. Biomass Bioenergy 2010, 34, 1608–1613. [Google Scholar] [CrossRef]

- Zahari, M.A.K.M.; Zakaria, M.R.; Ariffin, H.; Mokhtar, M.N.; Salihon, J.; Shirai, Y.; Hassan, M.A. Renewable sugars from oil palm frond juice as an alternative novel fermentation feedstock for value-added products. Bioresour. Technol. 2012, 110, 566–571. [Google Scholar] [CrossRef]

- Oramahi, H.A.; Yoshimura, T.; Diba, F.; Setyawati, D.; Nurhaida. Antifungal and Antitermitic activities of wood vinegar from Oil palm trunk. J. Wood Sci. 2018, 64, 311–317. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Anane-Fenin, K.; Akwada, D.R. Regeneration, cultivation, and sustenance of bamboo. In Bamboo; Springer: Cham, Switzerland, 2017; pp. 39–86. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Wong, R. Green possibilities in a green industrial sector: The lumber industry. Phys. Sci. Rev. 2020, 5. [Google Scholar] [CrossRef]

- Geburtig, A.; Wachtendorf, V. Determination of the spectral sensitivity and temperature dependence of polypropylene crack formation caused by UV-irradiation. Polym. Degrad. Stab. 2010, 95, 2118–2123. [Google Scholar] [CrossRef]

- Hon, D.N.-S.; Shiraishi, N. (Eds.) Weathering and photochemistry of wood. In Wood and Cellulose Chemistry; Marcel Dekker: New York, NY, USA, 2001; pp. 512–546. [Google Scholar]

- Gobakken, L.R.; Lebow, P.K. Modelling mould growth on coated modified and unmodified wood substrates exposed outdoors. Wood Sci. Technol. 2009, 44, 315–333. [Google Scholar] [CrossRef]

- Lim, S.C.; Khoo, K. Characteristics of oil palm trunk and its potential utilization. Malays. For. 1986, 49, 3–22. [Google Scholar]

- Schmidt, O. Wood and Tree Fungi. In Biology, Damage, Protection, and Use; Springer: Berlin, Germany, 2006; pp. 119–133. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mensah, P.; Danso, H.; Mitchual, S.J.; Donkoh, M.B. Effect of Moisture Content and Preservatives on the Discoloration of Oil Palm (Elaeis guineensis Jacq.) Lumber. Forests 2022, 13, 1799. https://doi.org/10.3390/f13111799

Mensah P, Danso H, Mitchual SJ, Donkoh MB. Effect of Moisture Content and Preservatives on the Discoloration of Oil Palm (Elaeis guineensis Jacq.) Lumber. Forests. 2022; 13(11):1799. https://doi.org/10.3390/f13111799

Chicago/Turabian StyleMensah, Prosper, Humphrey Danso, Stephen Jobson Mitchual, and Mark Bright Donkoh. 2022. "Effect of Moisture Content and Preservatives on the Discoloration of Oil Palm (Elaeis guineensis Jacq.) Lumber" Forests 13, no. 11: 1799. https://doi.org/10.3390/f13111799

APA StyleMensah, P., Danso, H., Mitchual, S. J., & Donkoh, M. B. (2022). Effect of Moisture Content and Preservatives on the Discoloration of Oil Palm (Elaeis guineensis Jacq.) Lumber. Forests, 13(11), 1799. https://doi.org/10.3390/f13111799