The Influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experiment Procedures

2.3. Measurement of Physical Properties

2.3.1. Density Profile Measurement

2.3.2. Color Changes

2.3.3. Change in Thickness

2.3.4. Compression Ratio

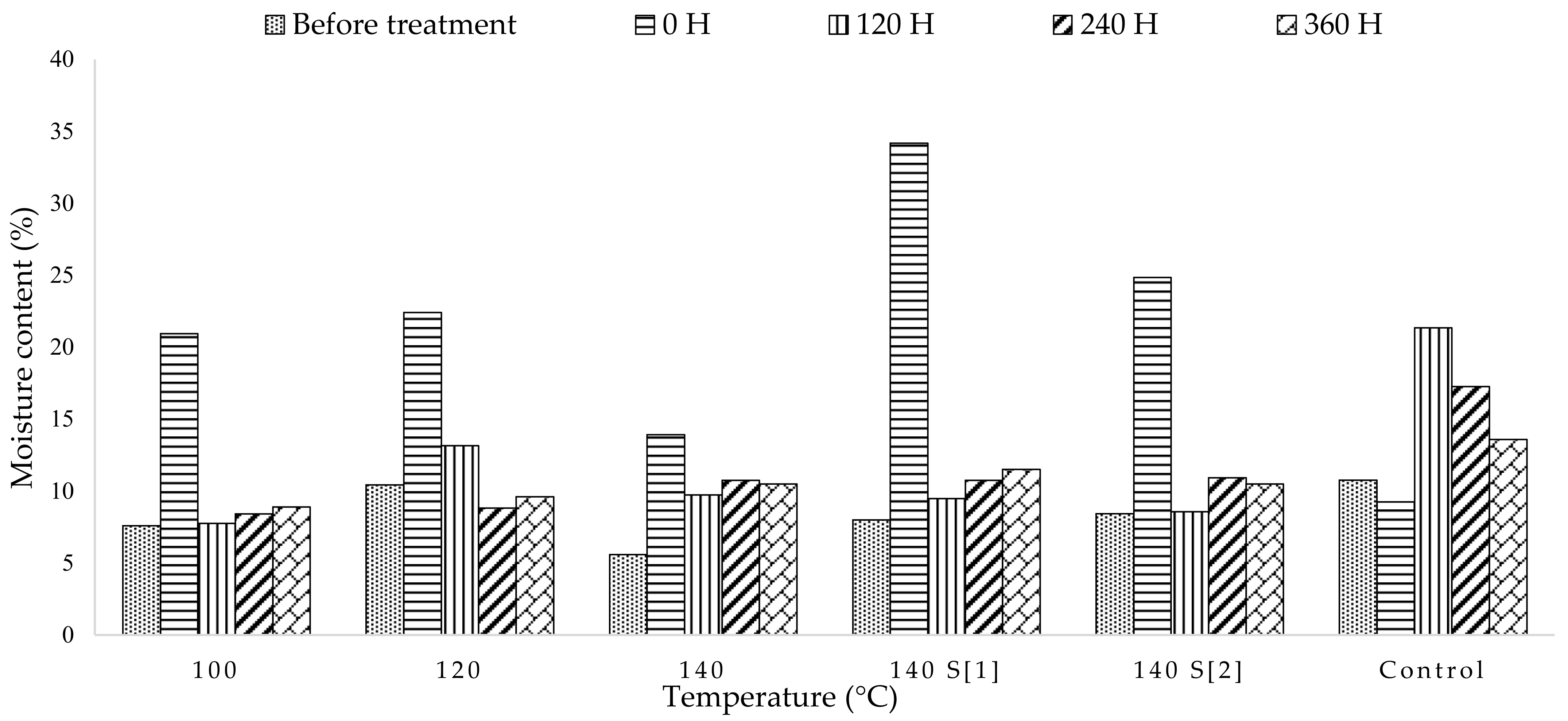

2.3.5. Equilibrium Moisture Content

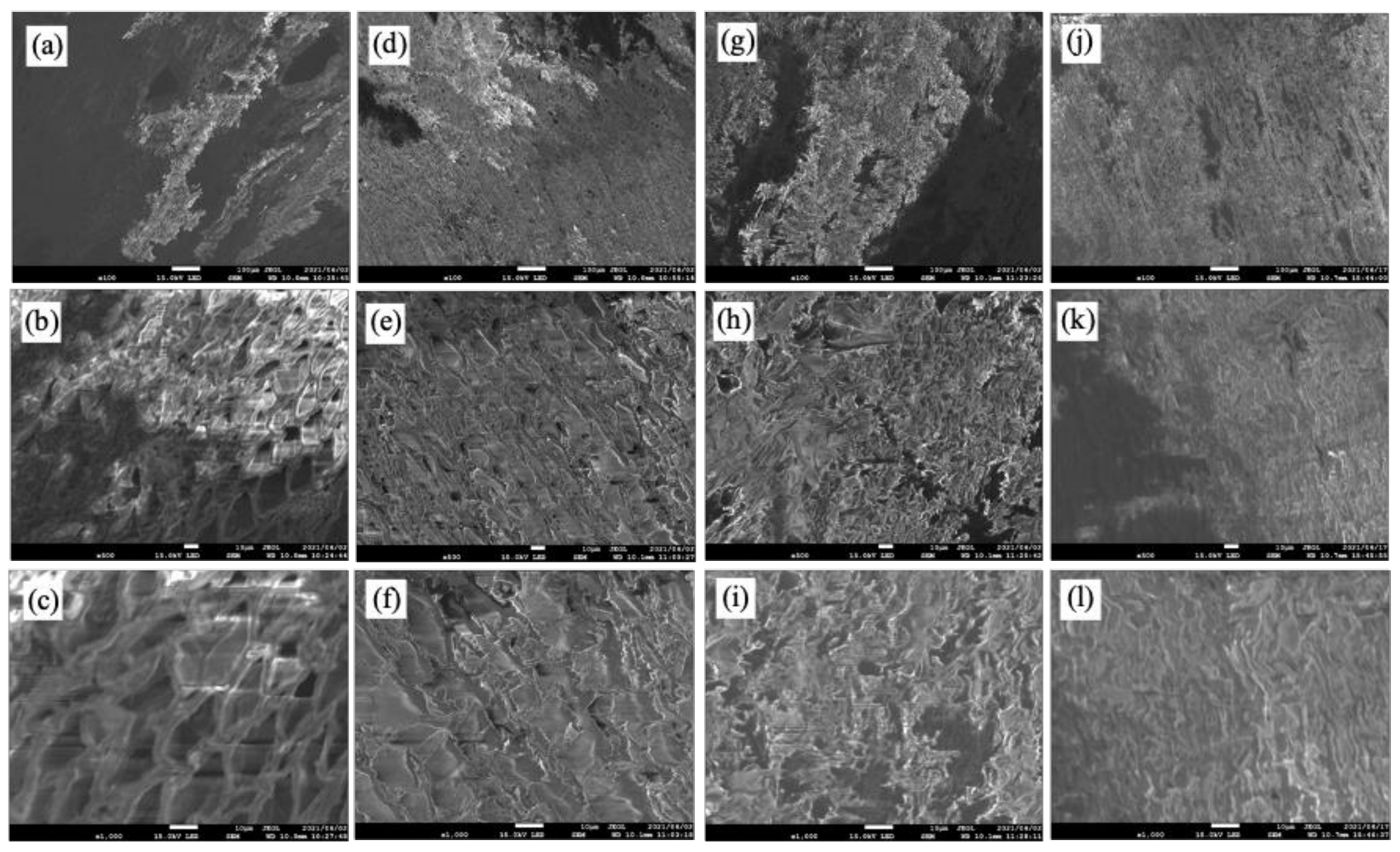

2.3.6. Scanning Electron Microscopy (SEM)

2.3.7. Statistical Analysis

3. Results and Discussion

3.1. Effect on the Density Profile

3.2. Color Changes

3.3. Change in Thickness

3.4. Compression Ratio

3.5. Equilibrium Moisture Content

3.6. Scanning Electron Microscopy (SEM)

4. Conclusions

- The Albizia falcataria board that has been densified to a density of 0.62 kg/L is denser than the control board that has not been densified to 0.29 kg/L.

- The treated specimens were darker than the control board. As the density of the wood increases, its chemical components, particularly hemicellulose, decompose, darkening the color of the wood.

- Board thickness can be modified to 50.95%, nearly twice its pre-treatment thickness. However, upon treatment and storage, the tangential surface of the board is not as flat as the control.

- The increased density and hemicellulose degradation decreased moisture, with treated specimens exhibiting a more stable EMC than the control board. These mechanical and physical properties increase as the moisture level declines.

- SEM analysis revealed that the treatment increased wood morphology. Notably, the observations demonstrated an improvement in mechanical properties. Although the interfacial bonding was not perfectly controlled, the results were better than the untreated board.

- The ANOVA showed that the high-temperature and -pressure treatment had no significant effect on the EMC of compressed wood (p > 0.05) but had a significant effect on the mass, density, and thickness changes of the wood (p < 0.05), compared to the control board.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bergman, R.; Puettmann, M.; Taylor, A.; Skog, K.E. The carbon impacts of wood products. For. Prod. J. 2014, 64, 220–231. [Google Scholar] [CrossRef]

- Adi, D.S.; Risanto, L.; Damayanti, R.; Rullyati, S.; Dewi, L.M.; Susanti, R.; Dwianto, W.; Hermiati, E.; Watanabe, T. Exploration of Unutilized Fast Growing Wood Species from Secondary Forest in Central Kalimantan: Study on the Fiber Characteristic and Wood Density. Procedia Environ. Sci. 2014, 20, 321–327. [Google Scholar] [CrossRef] [Green Version]

- Siregar, U.J.; Rachmi, A.; Massijaya, M.Y.; Ishibashi, N.; Ando, K. Economic analysis of sengon (Paraserianthes falcataria) community forest plantation, a fast growing species in East Java, Indonesia. For. Policy Econ. 2007, 9, 822–829. [Google Scholar] [CrossRef]

- Darmawan, W.; Nandika, D.; Rahayu, I.; Fournier, M.; Marchal, R. Determination of juvenile and mature transition ring for fast growing sengon and jabon wood. J. Indian Acad. Wood Sci. 2013, 10, 39–47. [Google Scholar] [CrossRef]

- Hartati, S.; Sudarmonowati, E.; Fatriasari, W.; Hermiati, E.; Dwianto, W.; Kaida, R.; Baba, K.; Hayashi, T. Wood Characteristic of Superior Sengon Collection and Prospect of Wood Properties Improvement through Genetic Engineering. J. Indones. Wood Res. Soc. 2010, 1, 103–105. [Google Scholar]

- Inoue, M. Compressed Wood. First Int. Wood Sci. Semin. JSPS 1996. [Google Scholar]

- Tomme, F.; Girardet, F.; Gfeller, B.; Navi, P. Densified Wood: Innovative Products with Highly Enhanced Character. In Proceedings of the Proceeding 5th World Conference on Timber Engineering, Montreux, Switzerland, August 17–20 1998; Volume 2, pp. 640–647. [Google Scholar]

- Nandika, D.; Darmawan, W.; Arinana, A. Quality Improvement of Sengon Wood Through Compregnation Process. J. Teknol. Ind. Pertan. 2015, 25, 125–135. [Google Scholar]

- Subyakto, I.; Hata, T.; Kajimoto, T.; Ishihara, S. Fire Endurance of Surface Densified Wood of Albizzia falcata Treated with Fire Retardant. Wood Res. 1995, 82, 1–7. [Google Scholar]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Blomberg, J.; Persson, B.; Blomberg, A. Effects of semi-isostatic densification of wood on the variation in strength properties with density. Wood Sci. Technol. 2005, 39, 339–350. [Google Scholar] [CrossRef]

- Pelİt, H.; Korkmaz, M.; Budakçi, M.; Esen, R. The Effects of Densification and Heat Treatment on Thermal Conductivity of Fir Wood. J. Sci. Technol. 2017, 7, 117–122. [Google Scholar]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Homan, W.J.; Jorissen, A.J.M. Wood modification developments. Heron 2004, 49, 361–386. [Google Scholar]

- Kollmann, F.F.P.; Kuenzi, E.W.; Stamm, A.J. Principles of Wood Science and Technology: II Wood Based Materials; Springer Verlag: Berlin/Heidelberg, Germany, 1975; ISBN 9783642879333. [Google Scholar]

- Seborg, R.; Stamm, A. The Compression of Wood; United States Department of Agriculture Forest Service Forest Products Laboratory: Madison, WI, USA, 1941. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies-A review. IForest 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Kutnar, A.; Šernek, M. Densification of wood. Zb. Gozdarstva Lesar. 2007, 82, 53–62. [Google Scholar]

- Dwianto, W.; Morooka, T.; Norimoto, M.; Kitajima, T. Stress relaxation of sugi (cryptomeria japonica d.don) wood in radial compression under high temperature steam. Holzforschung 1999, 53, 541–546. [Google Scholar] [CrossRef]

- Lekounougou, S.; Kocaefe, D. Effect of thermal modification temperature on the mechanical properties, dimensional stability, and biological durability of black spruce (Picea mariana). Wood Mater. Sci. Eng. 2014, 9, 59–66. [Google Scholar] [CrossRef]

- Bayani, S.; Taghiyari, H.R.; Papadopoulos, A.N. Physical and mechanical properties of thermally-modified beech wood impregnated with silver nano-suspension and their relationship with the crystallinity of cellulose. Polymers 2019, 11, 1538. [Google Scholar] [CrossRef] [Green Version]

- Susilawati, D.; Kanowski, P.; Setyowati, A.B.; Resosudarmo, I.A.P.; Race, D. Compliance of smallholder timber value chains in East Java with Indonesia’s timber legality verification system. For. Policy Econ. 2019, 102, 41–50. [Google Scholar] [CrossRef]

- JIS Z 2101; Methods Of Test For Woods. Japanese Standards Association: Tokyo, Japan, 2009.

- Kollmann, F.; Schneider, A. On the sorption behaviour of heat stabilized wood. Holz Roh-Werkst. 1963, 21, 77–85. [Google Scholar] [CrossRef]

- Yuhe, C.; Muehl, J.H. Factors of affecting the spring back of compressed Paulownia wood. J. For. Res. 1999, 10, 168–172. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M. Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 2017, 12, 40–54. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. A spectrocolorimetric and chemical study on color modification of heat-treated wood during artificial weathering. Appl. Surf. Sci. 2012, 258, 5360–5369. [Google Scholar] [CrossRef]

- Fang, C.H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Gong, M.; Lamason, C.; Li, L. Interactive effect of surface densification and post-heat-treatment on aspen wood. J. Mater. Process. Technol. 2010, 210, 293–296. [Google Scholar] [CrossRef]

- Navi, P.; Girardet, F. Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 2000, 54, 287–293. [Google Scholar] [CrossRef]

- Gong, M.; Nakatani, M.; Yang, Y.; Afzal, M. Maximum compression ratios of softwoods produced in eastern Canada. In Proceedings of the Proceedings of the 9th World Conference on Timber Engineering, Portland, OR, USA, 6–10 August 2006. [Google Scholar]

- Altgen, M.; Hofmann, T.; Militz, H. Wood moisture content during the thermal modification process affects the improvement in hygroscopicity of Scots pine sapwood. Wood Sci. Technol. 2016, 50, 1181–1195. [Google Scholar] [CrossRef]

- Simpson, W.; TenWolde, A. Wood Handbook, Wood as an Engineering Material: Physical Properties and Moisture Relations of Wood. In Forest Service; FPL-GTR-113: Madison, WI, USA, 1999. [Google Scholar]

- Hernández, R.E.; Passarini, L.; Koubaa, A. Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci. Technol. 2014, 48, 1281–1301. [Google Scholar] [CrossRef]

- Scheffe, H. The Analysis of Variance; Wiley: New York, NY, USA, 1959. [Google Scholar]

- Fox, R.A.; Steel, R.G.D.; Torrie, J.H. Principles and Procedures of Statistics with Special Reference to the Biological Sciences. Inc. Stat. 1961, 11, 170. [Google Scholar] [CrossRef]

- Julian, T.C.; Fukuda, H. The effect of wood modification under high temperature and pressure on its physical and mechanical properties. AIP Conf. Proc. 2021, 2447, 030011. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Froidevaux, J.; Navi, P.; Popescu, C.-M. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy. J. Mol. Struct. 2013, 1033, 176–186. [Google Scholar] [CrossRef]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Wikberg, H.; Maunu, S.L. Characterisation of thermally modified hard- And softwoods by13C CPMAS NMR. Carbohydr. Polym. 2004, 58, 461–466. [Google Scholar] [CrossRef]

- Severo, D.; Calonego, F.W.; Sansígolo, C.A. Physical and chemical changes in juvenile and mature woods of Pinus elliottii var. elliottii by thermal modification. Eur. J. Wood Wood Prod. 2012, 70, 741–747. [Google Scholar] [CrossRef]

- Woodrow, R.J.; Grace, J.K. Termite control from the perspective of the termite: A 21st century approach. ACS Symp. Ser. 2008, 982, 256–271. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef] [Green Version]

- Tenorio, C.; Moya, R. Thermogravimetric characteristics, its relation with extractives and chemical properties and combustion characteristics of ten fast-growth species in Costa Rica. Thermochim. Acta 2013, 563, 12–21. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Zhu, S.; Li, H. Effects of high-pressure treatment on poplar wood: Density profile, mechanical properties, strength potential index, and microstructure. BioResources 2017, 12, 6283–6297. [Google Scholar] [CrossRef] [Green Version]

- Mburu, F.; Dumarçay, S.; Bocquet, J.F.; Petrissans, M.; Gérardin, P. Effect of chemical modifications caused by heat treatment on mechanical properties of Grevillea robusta wood. Polym. Degrad. Stab. 2008, 93, 401–405. [Google Scholar] [CrossRef]

- Iskandar; Budiarso, E.; Wardhani, I.; Sulistyobudi, A. Comparison of Densified Sengon and Mahang Boards At 43% Densification Target, 150 °C Temperature, and 6.0 Minute Pressing Time. Russ. J. Agric. Socio-Econ. Sci. 2019, 91, 341–348. [Google Scholar] [CrossRef]

- Welzbacher, C.; Wehsener, J.; Rapp, A.; Haller, P. Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale–Dimensional stability and durability aspects. Holz Als Roh-Werkst. 2008, 66, 39–49. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; De Gruyter: Berlin, Germany, 1989. [Google Scholar]

- Tabarsa, T.; Chui, Y.H. Effects of hot-pressing on properties of white spruce. For. Prod. J. 1997, 47, 71–76. [Google Scholar]

- Nemoto, A. Farm Tree Planting and the Wood Industry in Indonesia: A Study of Falcataria Plantations and the Falcataria Product Market in Java. Policy Trend Rep. 2002, 42–51. [Google Scholar]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Boluk, Y. Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 2008, 3, 517–537. [Google Scholar] [CrossRef]

- Bourgois, P.J.; Janin, G.; Guyonnet, R. Color measurement. A method of studying and optimizing the chemical transformations of thermolytic wood. Holzforschung 1991, 45, 377–382. [Google Scholar] [CrossRef]

- Morita, S.; Yamazumi, Y. Coloring of wood by high pressure steam. Coloring degree and appearance of defects depending on treatment condition. Wood Ind. 1987, 42, 266–272. [Google Scholar]

- Effect of Compaction in the Radial Direction with High Temperature on the Physical and Mechanical Properties of Agatis (Agathis lorantifolia Salisb.) and Sengon (Paraserianthes falcataria L. Nielsen) Wood; IPB University: Bogor Regency, Indonesia, 2000.

- Gao, Z.; Huang, R.; Lu, J.; Chen, Z.; Guo, F.; Zhan, T. Sandwich compression of wood: Control of creating density gradient on lumber thickness and properties of compressed wood. Wood Sci. Technol. 2016, 50, 833–844. [Google Scholar] [CrossRef]

- Kitamori, A.; Jung, K.-H.; Mori, T.; Komatsu, K. Mechanical Properties of Compressed Wood in Accordance with the Compression Ratio. Mokuzai Gakkaishi 2010, 56, 67–78. [Google Scholar] [CrossRef] [Green Version]

- Rautkari, L.; Laine, K.; Kutnar, A.; Medved, S.; Hughes, M. Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J. Mater. Sci. 2013, 48, 2370–2375. [Google Scholar] [CrossRef]

- Akyildiz, M.; Ates, S. Effect of heat treatment on equilibrium moisture content (EMC) of some wood species in Turkey. Agric. Biol. Sci. 2008, 4, 660–665. [Google Scholar]

- Yu, Y.; Li, A.; Yan, K.; Ramaswamy, H.S.; Zhu, S.; Li, H. High-pressure densification and hydrophobic coating for enhancing the mechanical properties and dimensional stability of soft poplar wood boards. J. Wood Sci. 2020, 66, 45. [Google Scholar] [CrossRef]

- Nikolov, S.; Encev, E. Effect of heat treatment on the sorption dynamics of Beech wood. Nauc. Tr. Lesoteh. Inst. Sofija 1967, 14, 71–77. [Google Scholar]

- D’Jakonov, K.; Konepleva, T. Moisture absorption by Scots Pine wood after heat treatment. Arhangelsk 1967, 112–114. [Google Scholar]

- Hill, C. Wood Modification: Chemical, Thermal, and Other Processes; John Wiley & Sons, Ltd.: Chichester, UK, 2006. [Google Scholar]

- Hartono, R.; Sucipto, T. Quality improvement of laminated board made from oil palm trunk at various outer layer using phenol formaldehyde adhesive. IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012049. [Google Scholar] [CrossRef]

- Gao, X.; Li, Q.; Cheng, W.; Han, G.; Xuan, L. Optimization of high temperature and pressurized steam modified wood fibers for high-density polyethylene matrix composites using the orthogonal design method. Materials 2016, 9, 847. [Google Scholar] [CrossRef] [Green Version]

- Bao, M.; Huang, X.; Zhang, Y.; Yu, W.; Yu, Y. Effect of density on the hygroscopicity and surface characteristics of hybrid poplar compreg. J. Wood Sci. 2016, 62, 441–451. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S.A.; Morén, T.; Hagman, O.; Cloutier, A.; Fang, C.H.; Elustondo, D. Anatomical properties and process parameters affecting blister/blow formation in densified European aspen and downy birch sapwood boards by thermo-hygro-mechanical compression. J. Mater. Sci. 2013, 48, 8571–8579. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood (Populus tomentosa). J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

| Dependent Variable | SS | MS | F Ratio | p Value |

|---|---|---|---|---|

| Mass (g) | 41,106.233 a | 8221.247 | 6.371 | 0.001 |

| Density (kg/L) | 0.435 b | 0.087 | 3.130 | 0.026 |

| Thickness (mm) | 146.507 c | 29.301 | 3.511 | 0.016 |

| EMC (%) | 90.005 d | 18.001 | 0.409 | 0.837 |

| Category | Mass (g) | Density (kg/L) | Thickness (mm) | EMC (%) |

|---|---|---|---|---|

| 100 | 452.058 abc | 0.558 ab | 8.052 ab | 10.718 a |

| 120 | 391.034 ab | 0.57 ab | 7.178 a | 12.884 a |

| 140 | 441.212 ab | 0.606 b | 7.504 a | 10.1 a |

| 140 S[1] | 490.298 c | 0.618 b | 7.972 ab | 14.784 a |

| 140 S[2] | 455.898 bc | 0.568 ab | 7.994 ab | 12.65 a |

| Control | 385.304 a | 0.266 a | 13.61 b | 14.432 a |

| Category | Density (kg/L) | SR-D(%) | DC(%) | ||

|---|---|---|---|---|---|

| Do | Da | Ds | |||

| 100 °C | 0.29 | 0.75 | 0.58 | 36.96 | 100.00 |

| 120 °C | 0.26 | 0.84 | 0.59 | 43.10 | 126.92 |

| 140 °C | 0.29 | 0.85 | 0.62 | 41.07 | 113.79 |

| 140 °C S[1] | 0.32 | 0.78 | 0.67 | 23.91 | 109.38 |

| 140 °C S[2] | 0.29 | 0.71 | 0.62 | 21.43 | 113.79 |

| Control | 0.26 | - | - | - | - |

| Category | Thickness (mm) | SR-T (%) | TC (%) | ||

|---|---|---|---|---|---|

| To | Ta | Ts | |||

| 100 °C | 13.5 | 6.53 | 6.88 | 5.02 | −49.04 |

| 120 °C | 13.41 | 4.36 | 6.02 | 18.34 | −55.11 |

| 140 °C | 13.23 | 5.04 | 6.61 | 19.17 | −50.04 |

| 140 °C S[1] | 13.24 | 6.74 | 6.6 | −2.15 | −50.15 |

| 140 °C S[2] | 13.29 | 6.9 | 6.59 | −4.85 | −50.41 |

| Control | 13.52 | - | - | - | |

| Category | Density (kg/L) | CR (%) | |

|---|---|---|---|

| Before | After | ||

| 100 °C | 0.29 | 0.58 | 103.63 |

| 120 °C | 0.26 | 0.59 | 104.11 |

| 140 °C | 0.29 | 0.62 | 103.78 |

| 140 °C S[1] | 0.32 | 0.67 | 103.79 |

| 140 °C S[2] | 0.29 | 0.62 | 103.79 |

| Control | 0.26 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Julian, T.C.; Fukuda, H.; Novianto, D. The Influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board. Forests 2022, 13, 239. https://doi.org/10.3390/f13020239

Julian TC, Fukuda H, Novianto D. The Influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board. Forests. 2022; 13(2):239. https://doi.org/10.3390/f13020239

Chicago/Turabian StyleJulian, Treza Chandra, Hiroatsu Fukuda, and Didit Novianto. 2022. "The Influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board" Forests 13, no. 2: 239. https://doi.org/10.3390/f13020239

APA StyleJulian, T. C., Fukuda, H., & Novianto, D. (2022). The Influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board. Forests, 13(2), 239. https://doi.org/10.3390/f13020239