Abstract

Considering the increasing need to produce energy from renewable sources, the interest towards Medium Rotation Coppices (MRC) plantations has increased. One of the main issues that require tackling for the comprehensive sustainability of these plantations is related to the development of sustainable harvesting systems. Indeed, as a consequence of the average tree diameters at a breast height (dbh) of about 15 cm, single-pass harvesting typical of short rotation coppice is not applicable. Therefore, these plantations are generally harvested with machinery specifically developed for forest operations, as for instance harvesters, feller-bunchers and forwarders. In the Mediterranean area, the availability of such machines is still limited to a few big forest enterprises. Indeed, the majority of forest contractors carry out their activities in the framework of small-scale forestry, without the financial possibility of purchasing expensive machineries. Thus, the present study had the objective to evaluate the performance of two small-scale harvesting systems in a 7-year-old poplar plantation in Central Italy. The difference between the two systems was the different machinery applied for wood extraction, i.e., a forestry-fitted farm tractor equipped with winch (WINCH) and a fork lift prototype, attached to a crawler tractor (CFL). Extraction via CFL system reached very high working performance with about 21.5 m3 SMH−1 (Scheduled Machine Hours, including delays), comparable to the productivities reported in the literature for forwarders working in similar plantations. Harvesting costs with CFL were 24.74 EUR m−3, of which 4.48 EUR m−3 was for felling with chainsaw, 4.61 EUR m−3 for extraction with CFL prototype and 15.64 EUR m−3 for wood chipping. WINCH showed unsatisfactory results instead, possessing a wood chip production cost of 41.95 EUR m−3, which is practically equivalent to the market price of wood chips.

1. Introduction

Enhancing the supply of renewable energy is fundamental in order to meet the expected increase in global energy demand in the following years, as well as fighting climate change through the reduction in pollutants [1,2,3,4].

In this framework, lignocellulosic biomass has been considered as a promising renewable and sustainable source of energy, considering its neutral or even negative carbon budget [5,6,7,8].

Moreover, in the frame of the growing development of the bioeconomy sector, the demand for lignocellulosic biomass has been increasing for different industrial purposes: for instance, building materials, wood pulp, wood-based panels and other biomaterials [9,10,11].

Fast growing woody plantations are of particular interest in this context, being able to supply the woody biomass that traditional agroforestry systems cannot provide [5,12]. Fast growing plantations consist of woody cultivation, characterised by a high planting density of fast-growing species, such as poplar (Populus spp.), willow (Salix spp.) and eucalyptus (Eucalyptus spp.) capable of sprouting from the stump after being cut and which can provide high biomass yield in short periods of time (usually less than 7 years).

According to the harvesting cycle and plantation scheme, it is possible to distinguish between Short Rotation Coppice (SRC), where plants are harvested at 2–3-year intervals reaching an average diameter of 5–8 cm at cut levels with a planting density of 6000–7000 plants ha−1; and Medium Rotation Coppice (MRC), with a harvesting cycle up to 5–7 years, a planting density of 1000–1500 plants ha−1 and trees with a diameter in the range of 15–20 cm at harvesting [13].

In recent years, there has been a growing interest in MRC cropping system. This is due to the higher biomass yield achievable by extending the harvesting age, along with a better biofuel quality given by a reduced bark/fiber ratio [13,14].

The length of the harvesting cycle influences the harvesting system, the level and type of mechanisation and its costs. In fact, harvesting is the part of the cropping cycle which shows the highest cost, and the amount of costs is largely affected by the level of mechanisation [9,15].

In SRC, it is possible to use a high productivity-modified forage harvester that performs cutting and chipping in a single pass. In MRC, due to the larger size of stems, it is instead necessary to use double passage biomass collection. Generally, these forms of plantations are harvested with machineries usually applied in forest utilisation, such as feller-bunchers, skidders and forwarders [16].

In MRC harvesting, partially to fully mechanised levels of mechanisation, they can be adopted for tree cutting and extraction to the landing area, with varying work productivity and related costs.

In semi-mechanised systems, felling is performed manually with a chainsaw while extraction is performed with forestry-fitted farm tractors, skidders or forwarders. In fully mechanised harvesting, in addition to dedicated logging machines, feller-bunchers (shear, disc saw or chainsaw head) are used [16].

To reach higher working performances, fully mechanised systems should be adopted, even if these systems rely on expensive machinery [17]. However, in the Mediterranean area, the availability of such machines is still limited to a few large forest enterprises. Thus, the growing demand from woody processing industry and bioenergy plants for good quality lignocellulosic biomass makes it crucial to look for alternative solutions that may guarantee high levels of productivity by using simple and inexpensive machinery, which is attractive to small-scale operators with limited capital availability [18].

Thus, the objective of the present short communication was to carry out a preliminary evaluation of the performance of two small-scale harvesting systems in a 7-year poplar plantation in Central Italy. In addition to estimating the cost of the full harvesting systems (felling + extraction + wood chipping), a particular focus was placed on extraction operation, comparing the performance of a forestry-fitted farm tractor equipped with a winch (WINCH) and a fork lift prototype attached to a crawler tractor (CFL).

The research hypothesis behind the experimental design was as follows: in the common situation of poplar plantations in flat terrains with sufficient manoeuvre space, CFL performs similarly to machineries that are much more expensive, similarly to forwarders and grapple skidders. A lower productivity is instead expected for forestry-fitted farm tractors equipped with a winch.

The novel aspect of the study consists of investigating the performance of a prototype, which has never been evaluated in the current literature.

2. Materials and Methods

2.1. Study Area and Dendrometric Characteristic of the Plant

The study area was located in Monterotondo Municipality (Latium, Italy), and it consisted of an experimental poplar (clone AF-8) plant with an overall area of 0.42 ha (Coordinates in WGS84UTM33T 303994 E; 4663859 N). Terrain has a plain morphology and no roughness.

The plantation was 7 years old and the intervention carried out represented the first harvest; therefore, the plants showed a single-stem structure.

Planting density was 1666 N ha−1 (2 m on the row and 3 m between rows). Average diameter at breast height (dbh) was 13 cm, and the average height was 13.2 m, resulting in an average plant volume of 0.08 m3 according to the national allometric equations developed for poplar. Average wood density was derived by cutting 15 wood samples from different trees after felling, measuring their top diameter and base diameter with a caliper and length with a measure tape to determine volume, then weighing each sample with a precision scale. Derived fresh wood density was 0.869 Mg FM (fresh matter) m−3. A further 15 wood samples were taken from the same trees for wood moisture assessment via oven drying at 105 °C until constant weight. Average wood moisture was 54.05%; therefore, the dry wood density resulted in 0.399 Mg DM (dry matter) m−3. Therefore, the average whole tree weight was 0.070 Mg FM and 0.032 Mg DM. The resulting biomass yield was 108.132 m3 ha−1, corresponding to 93.975 Mg FM ha−1 and 43.178 Mg DM ha−1.

2.2. Experimental Design and Machineries Involved

The plantation consisted of 14 rows prior to starting the working time evaluations, and the two external rows were removed in order to avoid edge effects. The same applied to the first and the last plant of the remaining 12 rows. Randomly, 6 rows were subsequently extracted with a forestry-fitted farm tractor equipped with winch (WINCH) and 6 rows with the crawler fork lift prototype (CFL). The two experimental treatments differed for extraction system, while felling and chipping were carried out with the same machineries. The felling operation was performed by a single operator using a Stihl 201TX chainsaw (Waiblingen, Germany). Single trees were directionally felled perpendicularly to the rows’ direction. WINCH extraction was carried out with a 60 kW Landini tractor (Fabbrico, Italy) equipped with a Schwarz Tajfun kN 45 forest winch (Frangarto, Italy). The tractor did not enter directly into the stand, but it stood at the limit of the plantation winching trees outside the field, thus limiting the possibility of triggering substantial disturbance to soil and stumps. Considering that the dimension of the plantation winching distance ranged from 10 to 100 m, CFL extraction was performed with a Fiat 80C crawler tractor (Torino, Italy) equipped with the fork lift prototype. This consisted of a fork lift attached at the front loader of the tractor. The fork lift was equipped with a metal structure attached to a hydraulic piston in order to facilitate unloading harvested trees.

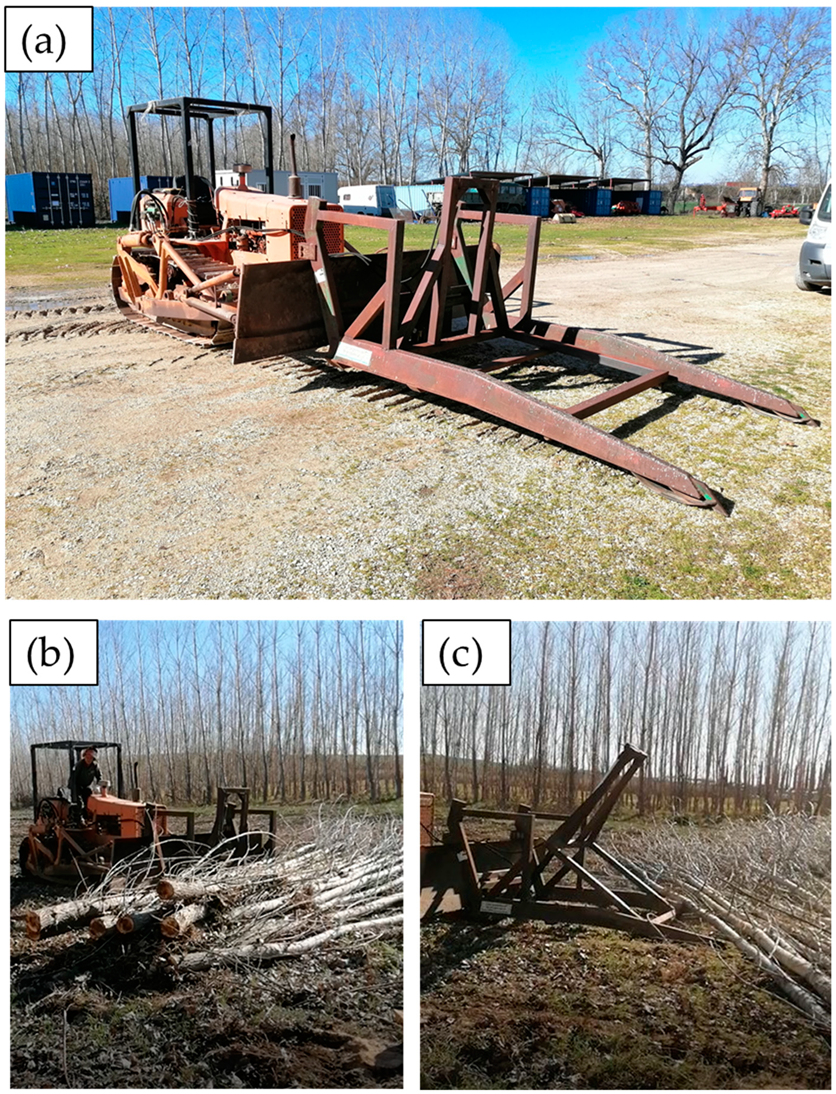

Extraction via CFL was carried out by felling half a row with the trees perpendicular to the row’s direction. The crawler tractor then moved towards the trees, loading them or simply pushing them outside the field. The extraction distance was, therefore, 50 m (half of the length of a row). A vision of CFL is provided in Figure 1.

Figure 1.

(a) Vision of CFL. (b) CFL while loading trees. (c) CFL while unloading trees.

Chipping operations were performed with a Farmi forest chipper CH260 (Iisalmi, Finland) powered by a 104 kW Landini tractor (Fabbrico, Italy), discharging the material into a trailer attached to the mentioned above 60 kW Landini tractor (Fabbrico, Italy).

2.3. Work Productivity and Costs Evaluation

The experimental field was subdivided into 12 blocks of 300 m2 each, corresponding to the various rows. Each block corresponded to about 45 trees. The dbh of all the plants in each block was measured and recorded, while a height-to-diameter equation was developed using 45 sample trees (felled and measured in height with a measuring tape). Each plant was subsequently identified with paint mark. Half of the blocks were randomly assigned to WINCH, while the others were assigned to CFL. The working cycles analysed for work productivity evaluation were as follows: 10 plants for felling, one block for extraction and the single tree for chipping. The time to carry out each working cycle was measured and recorded with a handheld chronometer with an accuracy of 1/100 min, separating work time from delay time [19]. Since delay time is typically erratic and there is a high possibility that a short-term study performed on small study areas can fail to represent the actual incidence of delay time in the long-term perspective, a 20% delay factor, revealed by long-term studies, was added to extraction and chipping working times [20], as suggested by several previous research studies on a similar topic [17,18,21]. This value for the delay factor was selected in order to represent the favorable work conditions constituted by a rational plantation in flat terrain, close to all maintenance and repair facilities [18,21].

A 40% delay factor was adopted for motor-manual felling via chainsaw, considering the need of recuperation as a consequence of the heavy physiological workload [22].

Knowing working times and the volume of the trees in each working cycle, it was possible to derive the net work productivity measured in m3 PMH−1 (productive machine hour, calculated not accounting for delay) and gross productivity measured in m3 SMH−1 (scheduled machine hour, calculated accounting for delay). The presence of statistically significant differences between the working productivity in extraction operation with WINCH and CFL was investigated by using an unpaired sample t-test, after checking for normality and homoscedasticity of the data, respectively, with Shapiro–Wilk and Levene’s tests.

Machine costs were estimated by applying the Harmonized European Costing Model developed within EU COST Action FP0902 [23]. Costing assumptions were obtained from previously conducted interviews from local forest enterprises. Calculated scheduled machine hour (SMH) costs and component for cost calculations are provided in Table 1.

Table 1.

Components of cost calculations for the machines. SMH refers to scheduled machine hour, inclusive of delays.

3. Results and Discussion

The obtained values of working productivity for felling operations, including delays, are provided in Table 2. The results were only slightly lower than the findings of Spinelli et al. 2011, i.e., 6.3 m3 SMH−1 [24], and Tavankar et al. 2020, i.e., 7.101 m3 SMH−1 [25], notwithstanding the smaller dbh of the trees in the present study (average dbh 13 cm vs. 32–38 cm). Tree size is generally positively related to work productivity, i.e., the higher the average tree volume, the higher the productivity [16,26,27], but the application of entire tree harvesting system, therefore avoiding delimbing and bucking, allowed obtaining comparable values of productivity [28].

Table 2.

Productivity SMH (including delays) of felling operation.

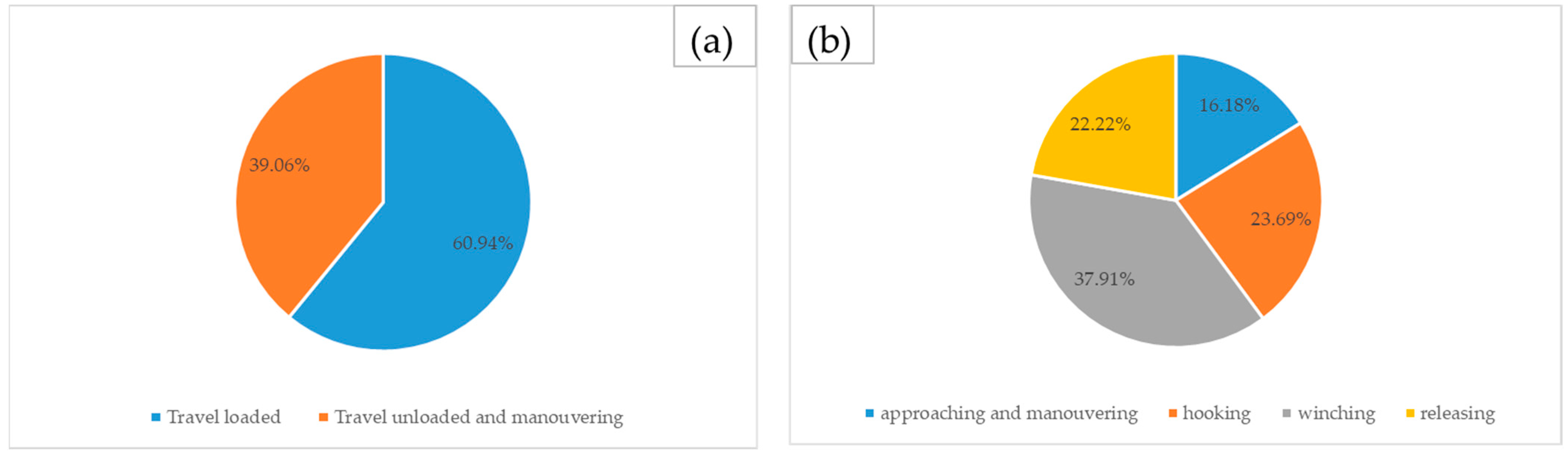

The share of working times (without considering delays) for the two different investigated extraction systems is provided in Figure 2. As it is possible to notice, for CFL, there were only two working phases: travel loaded (including loading and unloading of trees), which accounted for more than 60% of total net time; and travel unloaded, which corresponded to about 40%. Regarding WINCH, the share of working times is more complex, referring to four different phases, of which the one that accounted for the major percentage of working times was winching.

Figure 2.

Share of working time without considering delays for CFL (a) and WINCH (b).

The results of working performance for the two investigated extraction systems are reported in Table 3. As it is possible to notice, CFL performed much better than WINCH. A forestry-fitted farm tractor equipped with a winch revealed, therefore, to not be a valid option for extracting timber from this kind of stand, characterised by low tree dimensions, showing unsatisfactory productivity. Winching is, however, a suitable solution for poplar plants but only dealing with plantations dedicated to high value timber, where the average tree dimension is substantially higher [25]. Furthermore, the application of machineries specifically dedicated to forest operations is recommended, replacing forestry-fitted farm tractors with skidders. A cable skidder in a poplar plantation for high-value timber production in Northern Italy achieved a productivity of 28.846 m3 h−1 [25], while grapple skidder productivity was 20.7 Mg FM SMH−1 in a plantation with an average dbh of 15 cm and mean height of 16.5 m [18].

Table 3.

Work productivity SMH (including delays) for the two investigated extraction systems. “***” indicates statistically significant differences at p > 0.001 between the mean values of the treatments.

On the other hand, CFL showed very interesting results, with performances that are in line with those of much more expensive extraction machineries, thus confirming the research hypothesis. Magagnotti et al. reported a productivity of 24 m3 h−1 SMH for a forwarder working in very similar conditions to the ones of the present study, with the same planting density and average tree dimensions [21]. In another similar plantation, a second-hand forwarder reached a productivity value ranging from 7.8 to 11.2 Mg FM SMH−1 [17], which is, therefore, even lower than what was revealed for CFL. However, in this last case, the landing was located at a distance between 400 and 700 m from the harvesting site [17], obviously leading to increased working time in comparison to the situation in the present trial, where there was not a proper landing but the trees were unloaded just outside the plantation.

Work productivity for the chipping operation is shown in Table 4. The results were in line with those reported in the current literature for the wood chipper of limited dimension, such as the tested Farmi Forest CH260 [29].

Table 4.

Work productivity SMH (including delays) for chipping operation.

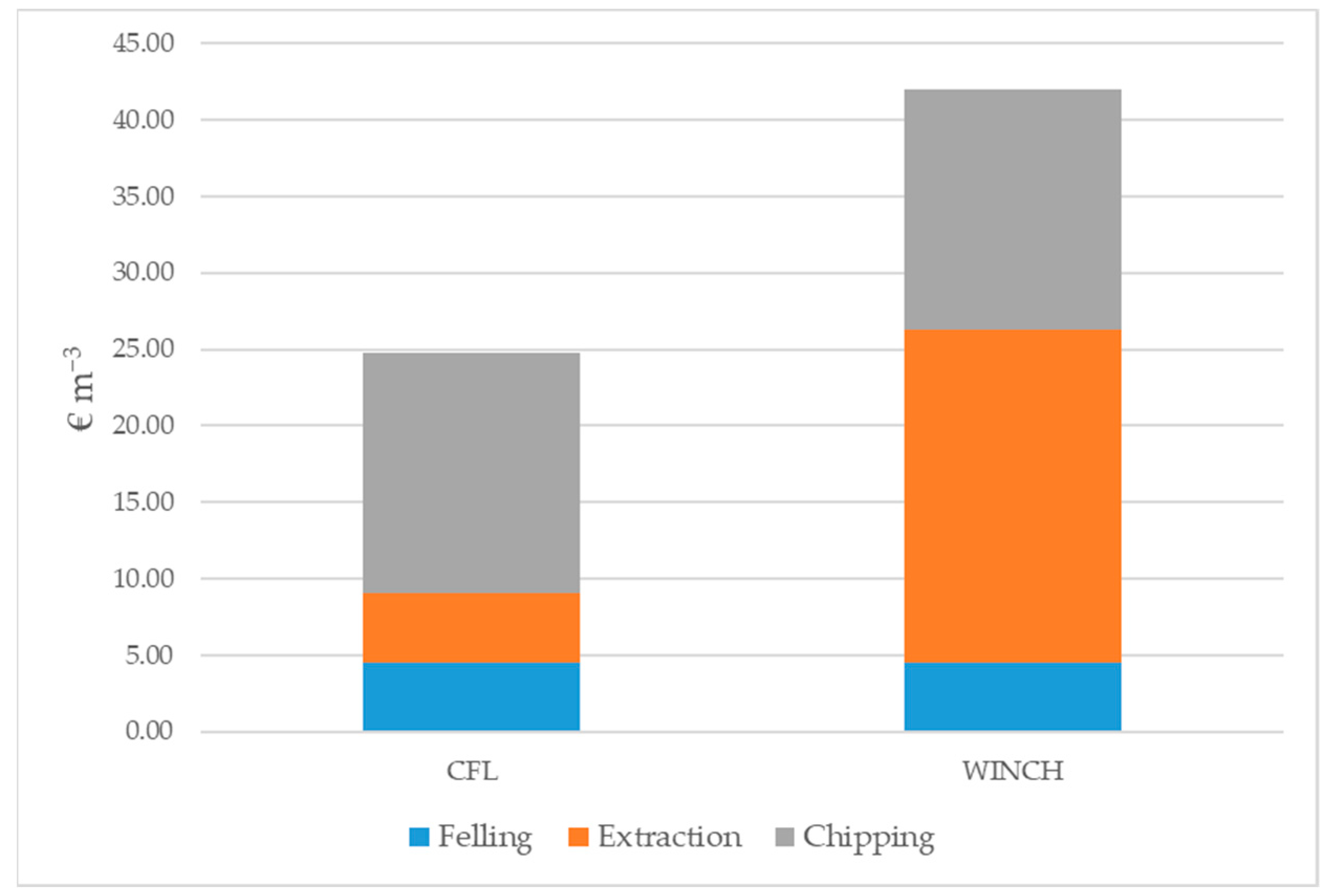

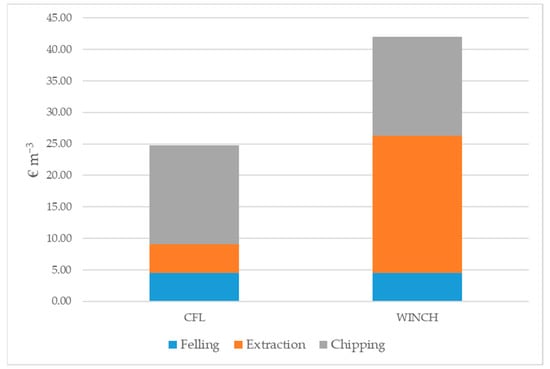

The results of cost analysis for producing wood chips with the investigated harvesting systems are provided in Figure 3. The substantial difference in extraction productivity between the two systems led to a much lower cost for CFL in comparison to WINCH. Cost for extraction with CFL was indeed 4.61 EUR m−3, while in WINCH, the cost was 21.83 EUR m−3.

Figure 3.

Costs of the two investigated harvesting systems.

The combined cost for felling and extraction in CFL was 9.10 EUR m−3 (10.46 EUR MG FM−1 and 22.77 EUR Mg DM−1), in line with 9.1–9.4 EUR m−3 reported for a system based on the harvester and forwarder [21] and slightly lower than the value of 8.0 EUR Mg FM−1 revealed for a system based on the feller buncher and grapple skidder [18]. In CFL, harvesting the chipping operation had the highest cost; therefore, a possible improvement of the system could be the adoption of a larger wood chipper that is able to guarantee higher performance [30]. A shift to mechanised felling with the application of a feller-buncher could also be as well a suitable option to further reduce harvesting costs.

The application of the WINCH harvesting system was, instead, not economically sustainable as the cost of wood chips production was very close to the market value of wood chips in the zone, i.e., 50.00 EUR Mg FM−1 [31,32,33].

In summary, CFL was revealed to be a very interesting solution in harvesting medium rotation poplar plantations in the framework of small-scale forestry. The obtained productivity and costs are in line with those reported in the literature for other harvesting systems, based on much more expensive machineries such as forwarders. It is, however, worth highlighting some limitations of CFL system. Firstly, the crawler tractor equipped with the fork lift prototype allows only unidirectional movement. Thus, it is applicable in fields where there is enough space to accumulate trees in the headland that do not constitute a real landing site, a situation of which is, however, common in poplar plantations. If the trees have to be accumulated on a dedicated site outside the plantation, CFL is not applicable. Furthermore, a lower wood chip quality in comparison to the one obtained from material extracted via forwarding is expected. This is related to the fact that trees are extracted touching the terrain, with the possibility of ground particles remaining attached to the stems resulting in increased ash content during combustion. This aspect has to be, however, evaluated in further dedicated studies.

4. Conclusions

Medium rotation coppices represent an interesting source of renewable energy and good quality lignocellulosic biomass for other industrial purposes. However, this kind of plantation requires particular attention to be paid to harvesting operations. Indeed, as a consequence of the dimension reached from the trees, single-pass harvesting typical of short rotation coppice is not a suitable option. Currently, these stands are harvested by relying on machineries specifically developed for forest operations such as harvesters, feller-bunchers and forwarders. In the context of Mediterranean forestry, particularly in Central and Southern Italy, the availability of such machines is still limited. Indeed, the major part of forest contractors operates in the framework of small-scale forestry and do not possess financial ability of purchasing expensive machineries. Taking this into account, the present study aimed to evaluate the performance of two small-scale harvesting systems in a 7-year poplar plantation. The investigated harvesting systems were based on motor-manual felling with a chainsaw and chipping via a stationary chipper. The difference between the systems consisted of the different machineries used for extraction operations, which were a forestry-fitted farm tractor equipped with a winch (WINCH) and a fork lift prototype attached to a crawler tractor (CFL).

The obtained results revealed the unsuitability of the WINCH system in the study context. On the other hand, CFL reached very satisfactory working performance, comparable to those reported in the literature for harvesting systems based on much more expensive machines. Therefore, CFL represents a very interesting harvesting system for these plantations; in this case, there is no need to shift the trees to a landing site, but it is possible to accumulate the trees in the headland before chipping.

Author Contributions

F.L.: Conceptualisation, methodology, formal analysis, investigation, writing—original draft, and writing—review and editing. W.S.: Conceptualisation, methodology, formal analysis, investigation, writing—original draft, and writing—review and editing. V.A.: Conceptualisation, methodology, investigation, writing—original draft, and writing—review and editing. N.P.: Formal analysis. P.M.: Methodology. L.P.: Supervision and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

The work was performed in the framework of the European project “BeCool” (grant agreement No. 744821). The BeCool project is financed by the EU H2020 programme.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge Cesare Cervellini, Franco Bernardini, Gino Branetti, Sandu Lazar and Alberto Sestili for helpful collaboration during the harvesting operations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Union Renewable Energy Directive 2018/2001/EU. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001&from=EN (accessed on 10 February 2020).

- European Commission Communication from The Commission to The European Parliament, The Council, The European Economic And Social Committee and The Committee of The Regions Energy Roadmap 2050. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:5 (accessed on 10 February 2020).

- Reinhardt, J.; Hilgert, P.; Von Cossel, M. A review of industrial crop yield performances on unfavorable soil types. Agronomy 2021, 11, 2382. [Google Scholar] [CrossRef]

- Reinhardt, J.; Hilgert, P.; Von Cossel, M. Yield performance of dedicated industrial crops on low-temperature characterized marginal agricultural land in Europe—A review. Biofuels Bioprod. Biorefining 2022, 16, 609–622. [Google Scholar] [CrossRef]

- Rodrigues, A.M.; Costa, M.M.G.; Nunes, L.J.R. Short rotation woody coppices for biomass production: An integrated analysis of the potential as an energy alternative. Curr. Sustain. Energy Rep. 2021, 8, 70–89. [Google Scholar] [CrossRef]

- Fuertes, A.; Oliveira, N.; Cañellas, I.; Sixto, H.; Rodríguez-Soalleiro, R. An economic overview of Populus spp. in Short Rotation Coppice systems under Mediterranean conditions: An assessment tool for decision-making. Renew. Sustain. Energy Rev. 2021, 151, 111577. [Google Scholar] [CrossRef]

- Sperandio, G.; Suardi, A.; Acampora, A.; Civitarese, V. Environmental Sustainability of Heat Produced by Poplar Short-Rotation Coppice (SRC) Woody Biomass. Forests 2021, 12, 878. [Google Scholar] [CrossRef]

- Perdomo, E.A.; Schwarzbauer, A.; Fürtner, D.; Hesser, F. Life Cycle Assessment of Agricultural Wood Production—Methodological Options: A Literature Review. Bioenergy Res. 2021, 14, 492–509. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; DeSouza, D.; Hallen, K.; Stanton, B.; Espinoza, J.; Himes, A.; Shuren, R.; Stonex, R.; Summers, B.; et al. An assessment of the harvesting and fuel performance of a single-pass cut-and-chip harvester in commercial-scale short-rotation poplar crops as influenced by crop and weather conditions. Biomass Bioenergy 2021, 149, 106075. [Google Scholar] [CrossRef]

- Fortier, J.; Truax, B.; Gagnon, D.; Lambert, F. Thinning and Gap Harvest Effects on Soil, Tree and Stand Characteristics in Hybrid Poplar Bioenergy Buffers on Farmland. Forests 2022, 13, 194. [Google Scholar] [CrossRef]

- Olba-Zięty, E.; Stolarski, M.J.; Krzyżaniak, M. Economic Evaluation of the Production of Perennial Crops for Energy Purposes—A Review. Energies 2021, 14, 7147. [Google Scholar] [CrossRef]

- Alesso, S.P.; Tapias, R.; Alaejos, J.; Fernández, M. Biomass Yield and Economic, Energy and Carbon Balances of Ulmus pumila L., Robinia pseudoacacia L. and Populus × euroamericana (Dode) Guinier Short-Rotation Coppices on Degraded Lands under Mediterranean Climate. Forests 2021, 12, 1337. [Google Scholar] [CrossRef]

- Santangelo, E.; Scarfone, A.; Del Giudice, A.; Acampora, A.; Alfano, V.; Suardi, A.; Pari, L. Harvesting systems for poplar short rotation coppice. Ind. Crops Prod. 2015, 75, 85–92. [Google Scholar] [CrossRef]

- Saulino, L.; Allevato, E.; Rossi, S.; Minotta, G.; Fiorentino, N.; Saracino, A. Lengthening single-stem rotation improves biomass yield and water use efficiency in black poplar genotype multi-stem rotation coppice plantations. Biomass Bioenergy 2021, 154, 106256. [Google Scholar] [CrossRef]

- Stanton, B.J.; Bourque, A.; Coleman, M.; Eisenbies, M.; Emerson, R.M.; Espinoza, J.; Gantz, C.; Himes, A.; Rodstrom, A.; Shuren, R.; et al. The practice and economics of hybrid poplar biomass production for biofuels and bioproducts in the Pacific Northwest. Bioenergy Res. 2021, 14, 543–560. [Google Scholar] [CrossRef]

- Sperandio, G.; Acampora, A.; Del Giudice, A.; Civitarese, V. Models for the Evaluation of Productivity and Costs of Mechanized Felling on Poplar Short Rotation Coppice in Italy. Forests 2021, 12, 954. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Lombardini, C.; Mihelič, M. A Low-Investment Option for the Integrated Semi-mechanized Harvesting of Small-Scale, Short-Rotation Poplar Plantations. Small-Scale For. 2021, 20, 59–72. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Lombardini, C. Low-Investment Fully Mechanized Harvesting of Short-Rotation Poplar (populus spp.) Plantations. Forests 2020, 11, 502. [Google Scholar] [CrossRef]

- Bjorheden, R.; Thompson, M.A. An international nomenclature for forest work study. In Proceedings of the IUFRO 1995, 20th World Congress, Tampere, Finland, 6–15 August 1995; pp. 190–215. [Google Scholar]

- Spinelli, R.; Visser, R. Analyzing and Estimating Delays in Harvester Operations. Int. J. For. Eng. 2008, 19, 36–41. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R.; Kärhä, K.; Mederski, P.S. Multi-tree cut-to-length harvesting of short-rotation poplar plantations. Eur. J. For. Res. 2021, 140, 345–354. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N. Comparison of two harvesting systems for the production of forest biomass from the thinning of Picea abies plantations. Scand. J. For. Res. 2010, 25, 69–77. [Google Scholar] [CrossRef]

- Ackerman, P.; Belbo, H.; Eliasson, L.; de Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Sperandio, G.; Cielo, P.; Verani, S.; Zanuttini, R. Cost and productivity of harvesting high-value hybrid poplar plantations in Italy. For. Prod. J. 2011, 61, 64–70. [Google Scholar] [CrossRef]

- Tavankar, F.; Nikooy, M.; Latterini, F.; Venanzi, R.; Bianchini, L.; Picchio, R. The Effects of Soil Moisture on Harvesting Operations in Populus spp. Plantations: Specific Focus on Costs, Energy Balance and GHG Emissions. Sustainability 2021, 13, 4863. [Google Scholar] [CrossRef]

- Marčeta, D.; Petković, V.; Ljubojević, D.; Potočnik, I. Harvesting system suitability as decision support in selection cutting forest management in northwest Bosnia and Herzegovina. Croat. J. For. Eng. 2020, 41, 251–265. [Google Scholar] [CrossRef]

- Francesco, L.; Stefanoni, W.; Venanzi, R.; Tocci, D.; Picchio, R. GIS-AHP approach in forest logging planning to apply sustain-able forest operations. Forests 2022, 13, 484. [Google Scholar]

- Carbone, F.; Picchio, R. Operative Machinery Costs Analysis within Forest Management Implementation Frame. In Timber Buildings and Sustainability; IntechOpen: London, UK, 2019; p. 32. [Google Scholar]

- Spinelli, R.; Eliasson, L.; Magagnotti, N. Determining the repair and maintenance cost of wood chippers. Biomass Bioenergy 2019, 122, 202–210. [Google Scholar] [CrossRef]

- Laitila, J.; Prinz, R.; Sikanen, L. Selection of a chipper technology for small-scale operations—A Finnish case. J. For. Sci. 2019, 65, 121–133. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef] [Green Version]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. [Google Scholar] [CrossRef] [Green Version]

- Latterini, F.; Stefanoni, W.; Suardi, A.; Alfano, V.; Bergonzoli, S.; Palmieri, N.; Pari, L. A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs. Energies 2020, 13, 3385. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).