Some Methods for the Degradation-Fragility Degree Determination and for the Consolidation of Treatments with Paraloid B72 of Wood Panels from Icon-Type Heritage Objects

Abstract

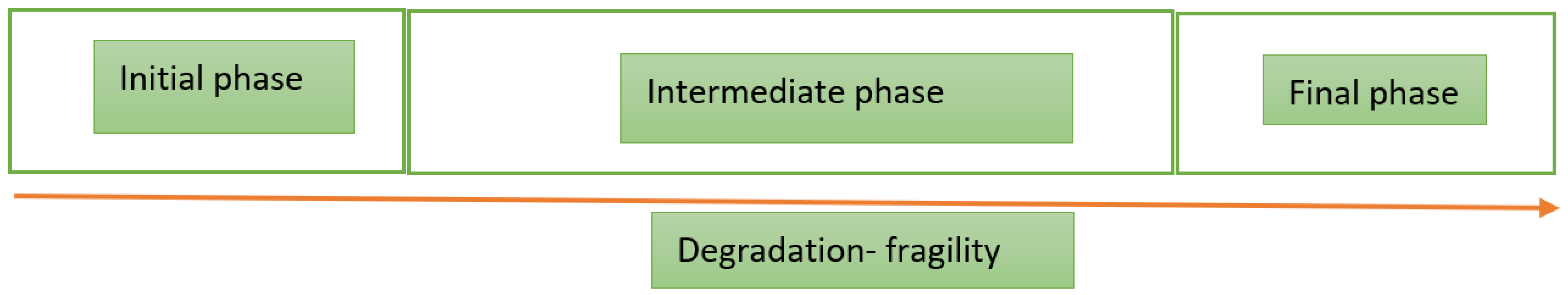

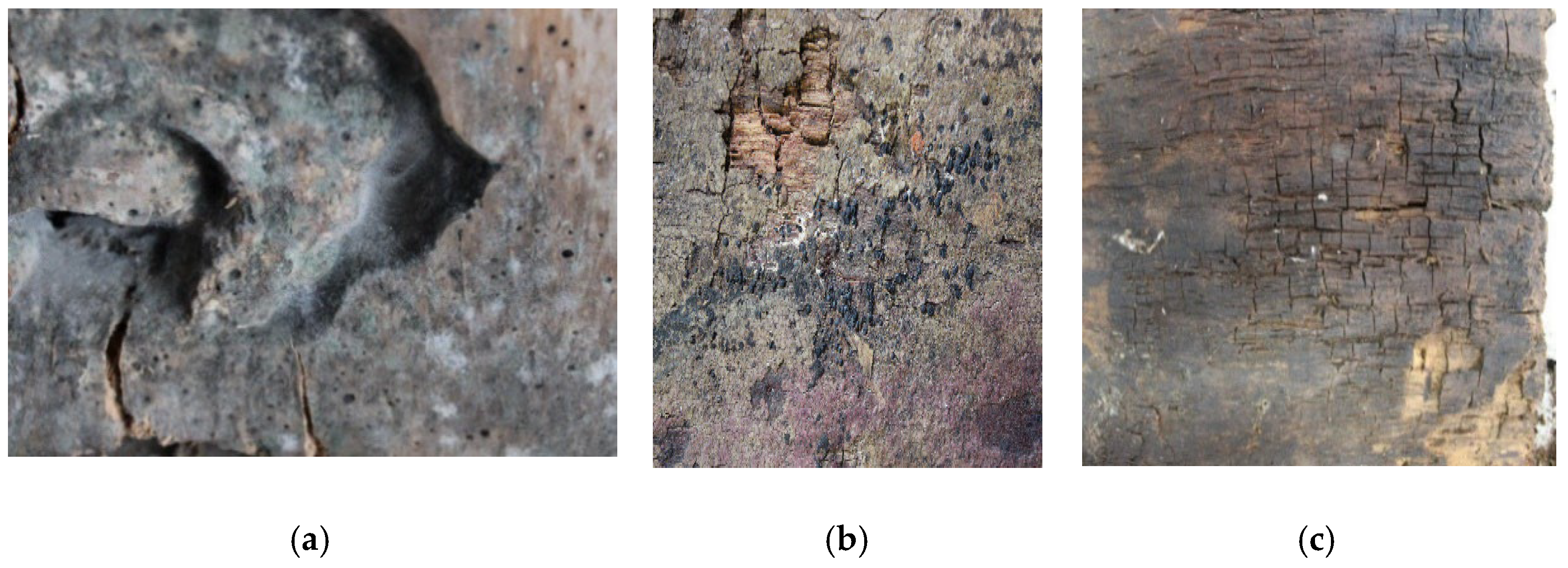

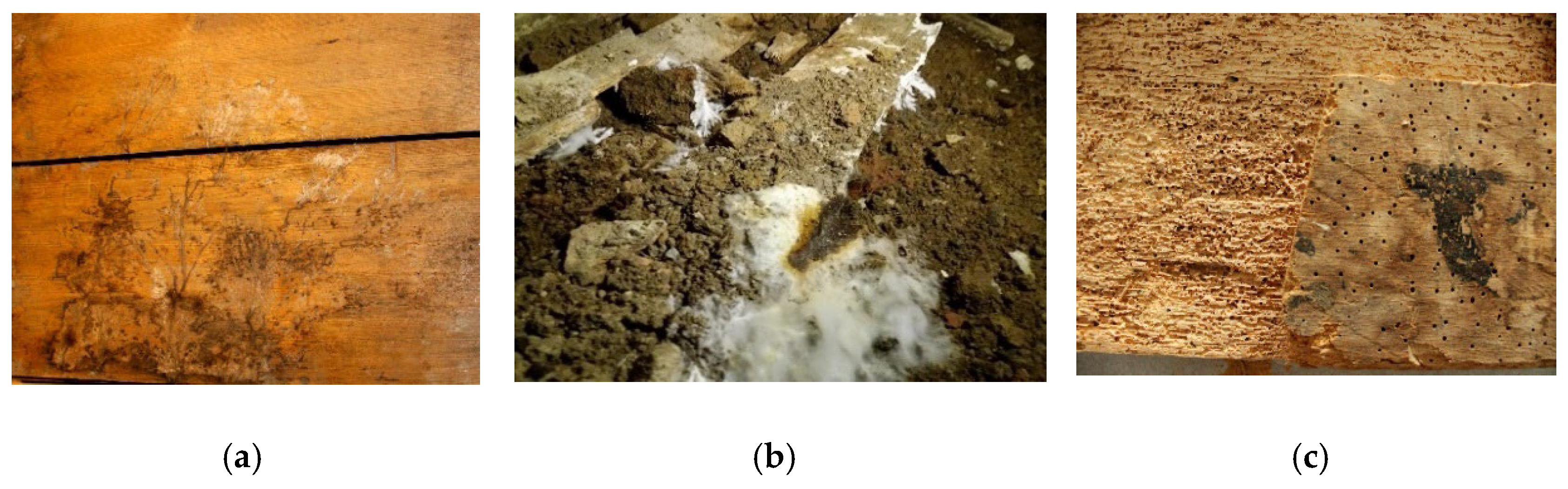

:1. Introduction

2. Materials and Methods

- Determining the comparative density of healthy wood and degraded wood;

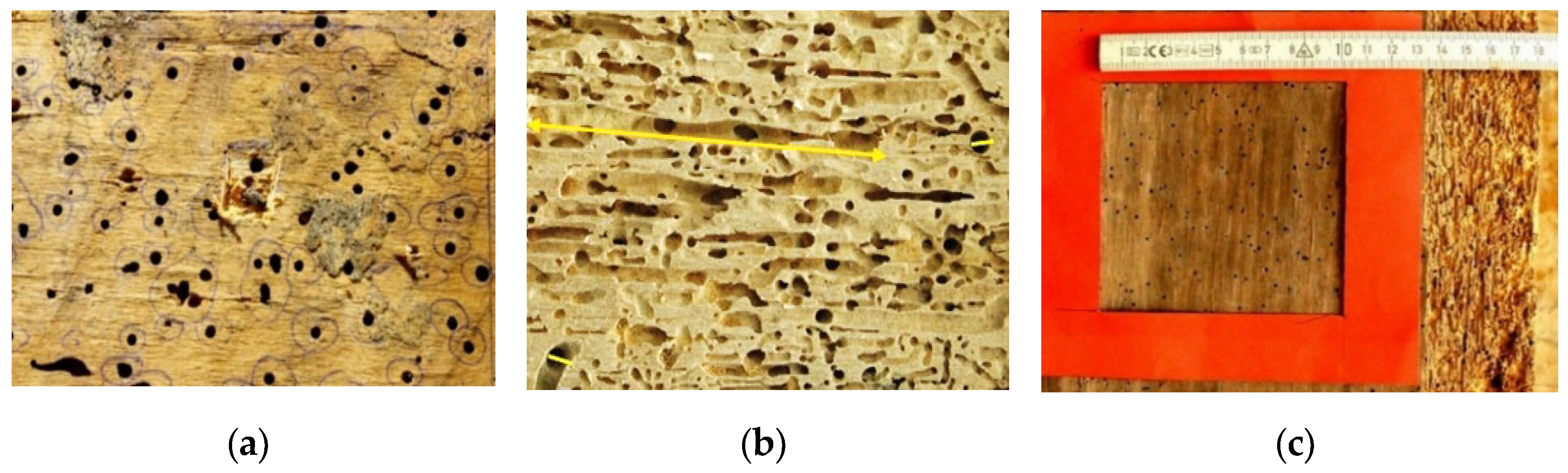

- Determination of excessive wood porosity caused by insect holes and galleries;

- Determination of Brinell hardness and comparison of the values obtained for healthy wood with degraded wood;

- Determination of hardness by means of the wood-pricking device, Mark 10, as a minimally destructive and alternative method.

2.1. Determination of the Degree of Fragility by the Method of Comparative Densities

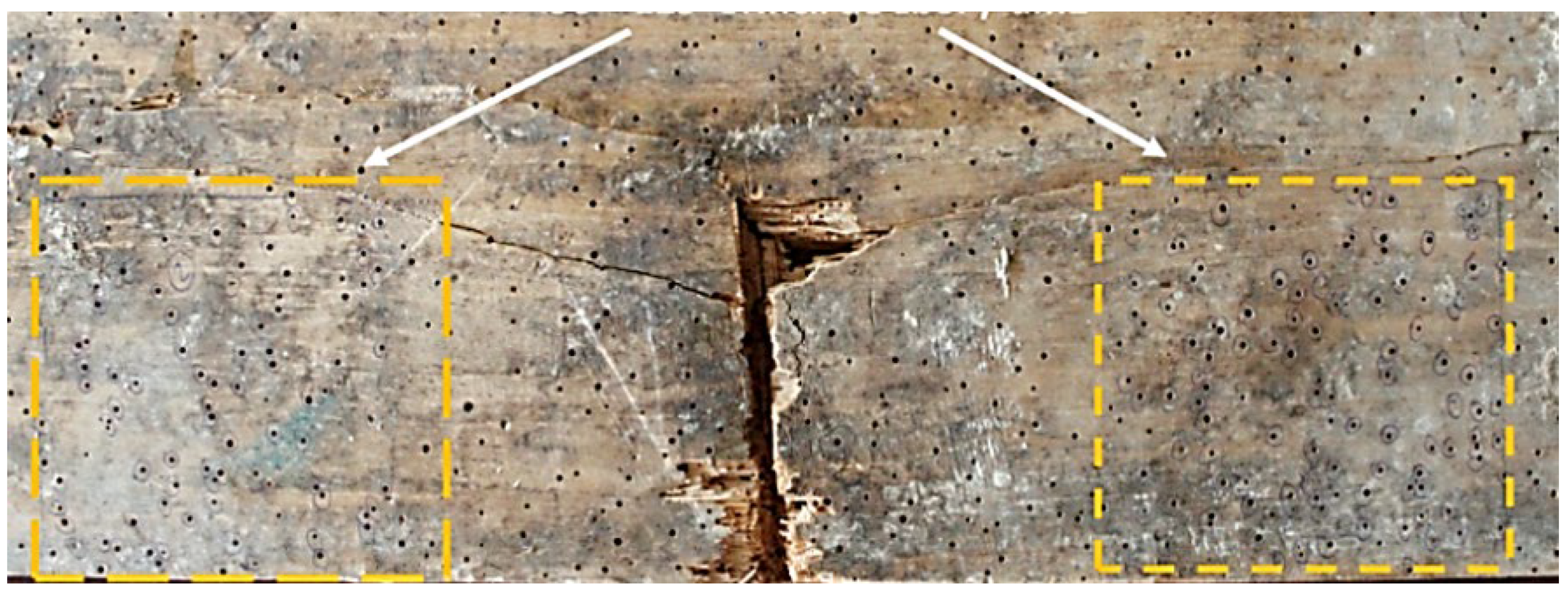

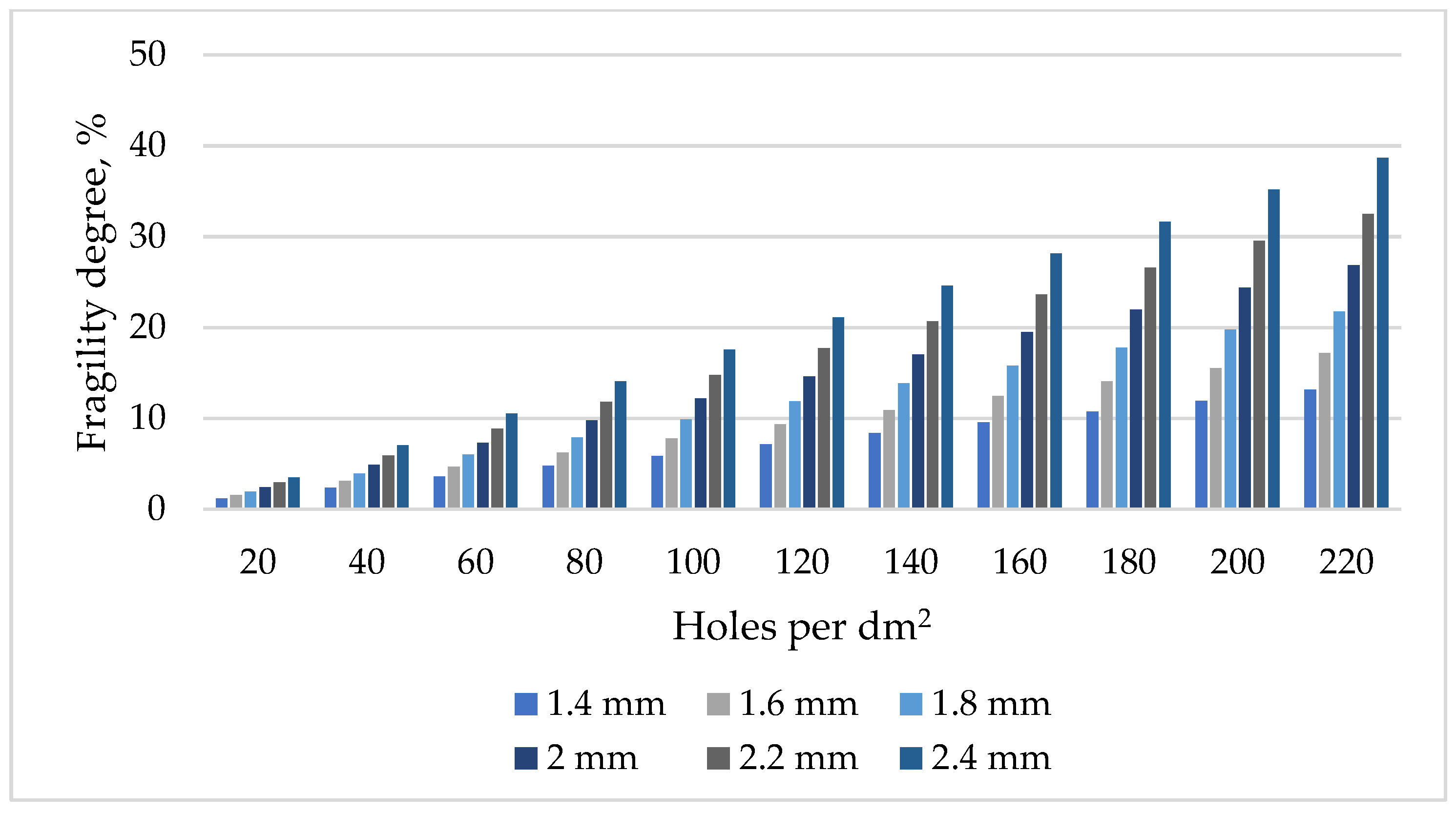

2.2. Determination of the Degree of Degradation by the Method of Excessive Porosity Caused by Xylophagous Attack

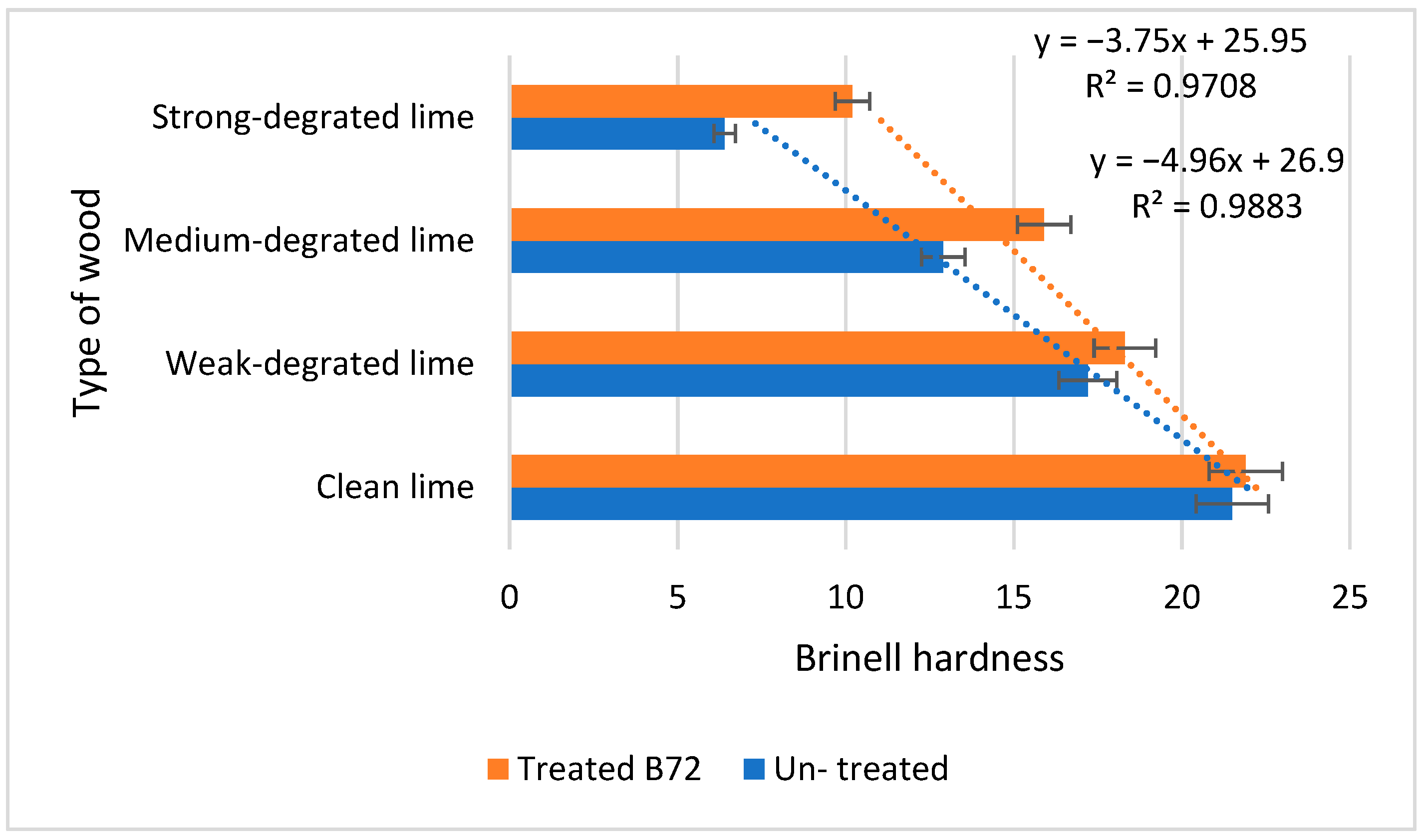

2.3. Determination of the Degree of Fragility by the Brinell Hardness Method

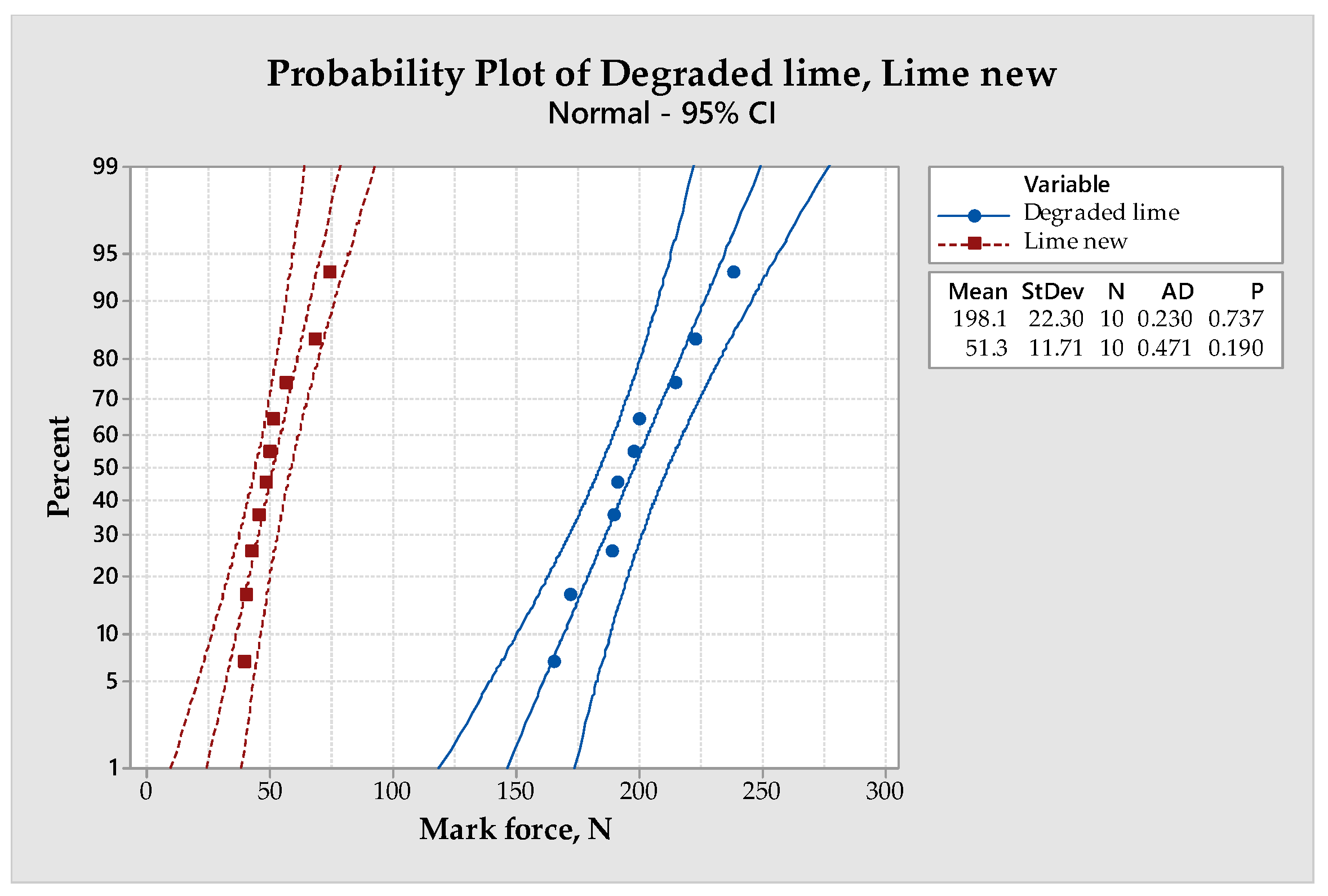

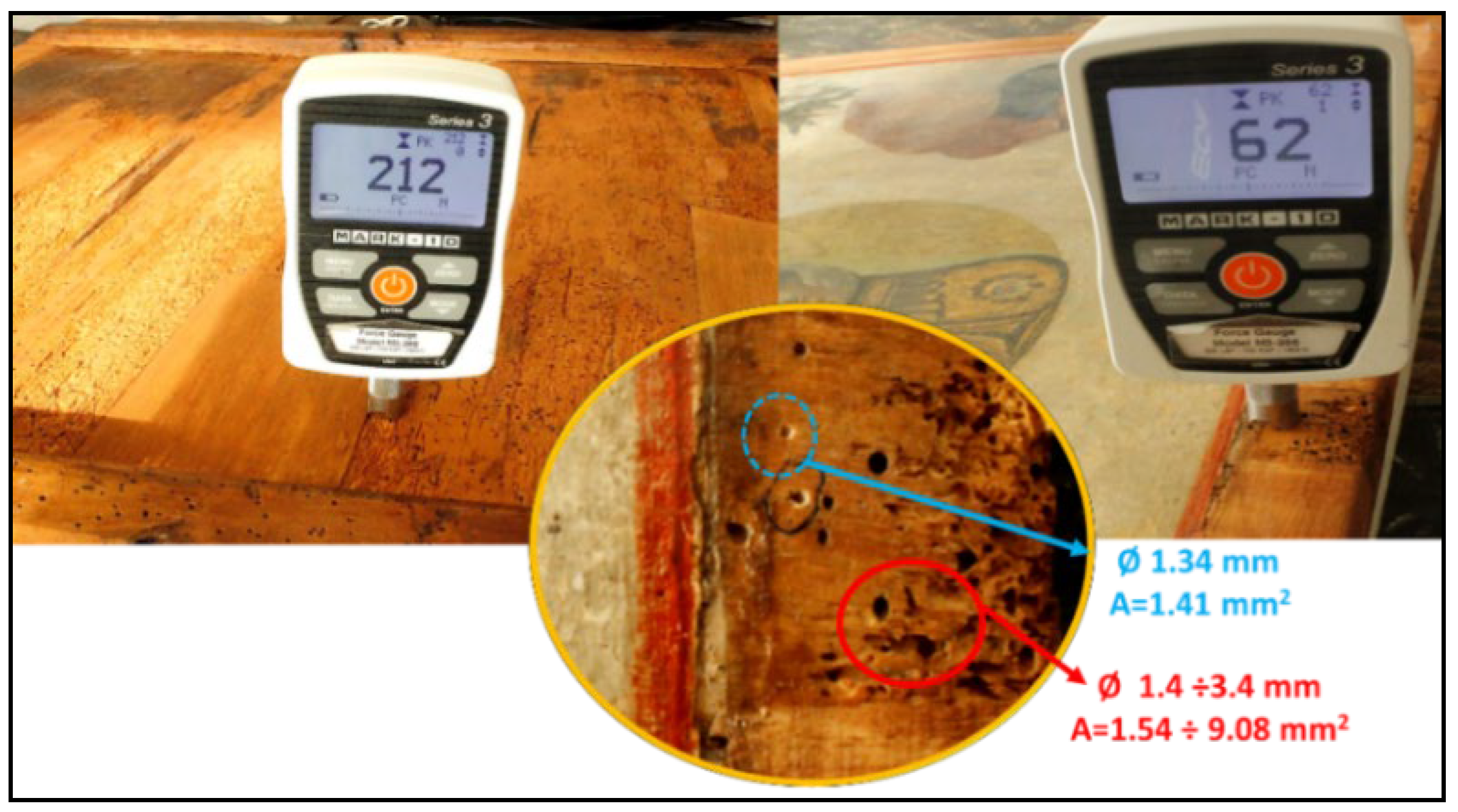

2.4. Determination of Mark Hardness as a Minimally Invasive Method

3. Results

3.1. Density Method Results

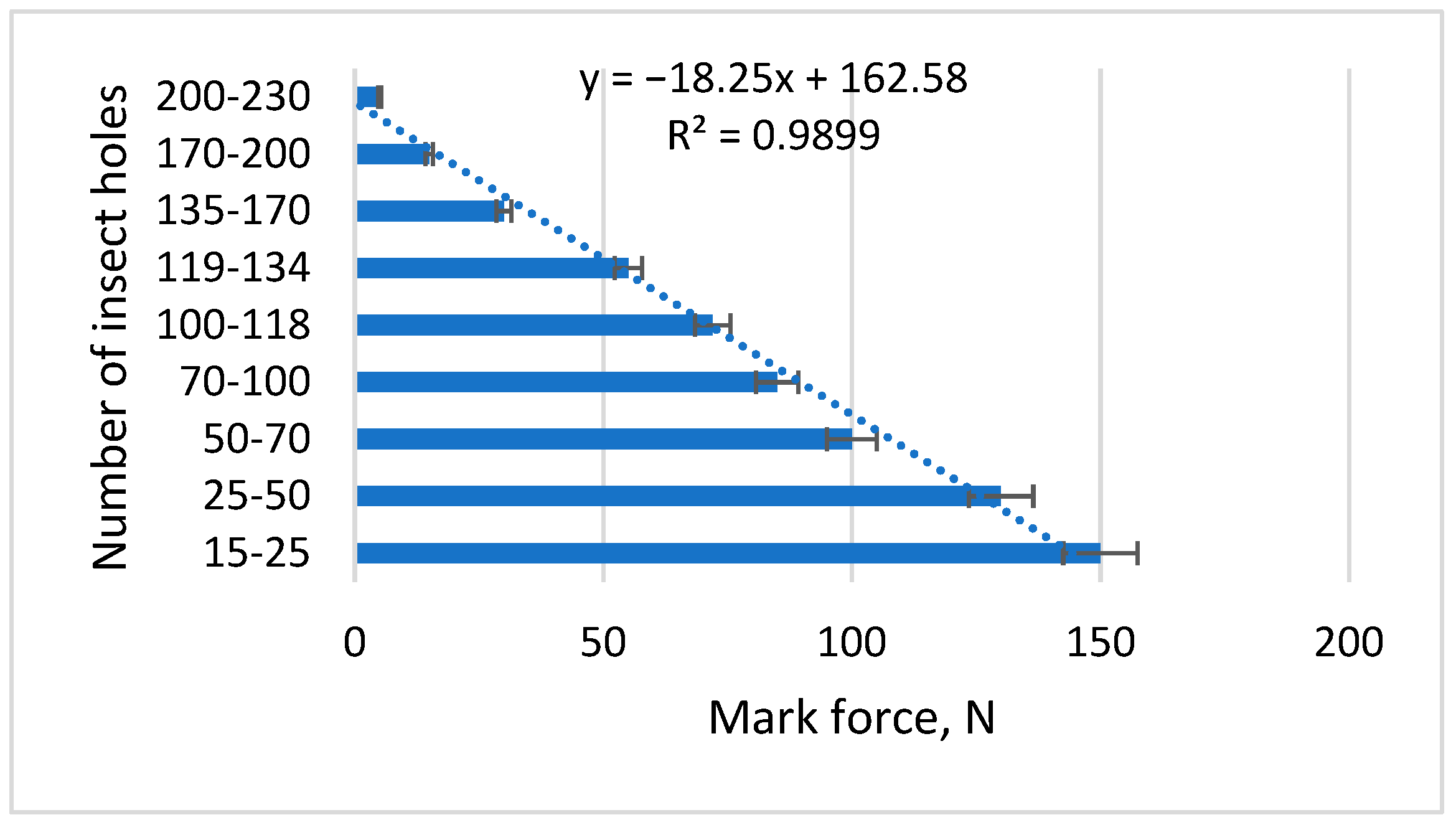

3.2. Results of Xylophagous Insect Attack

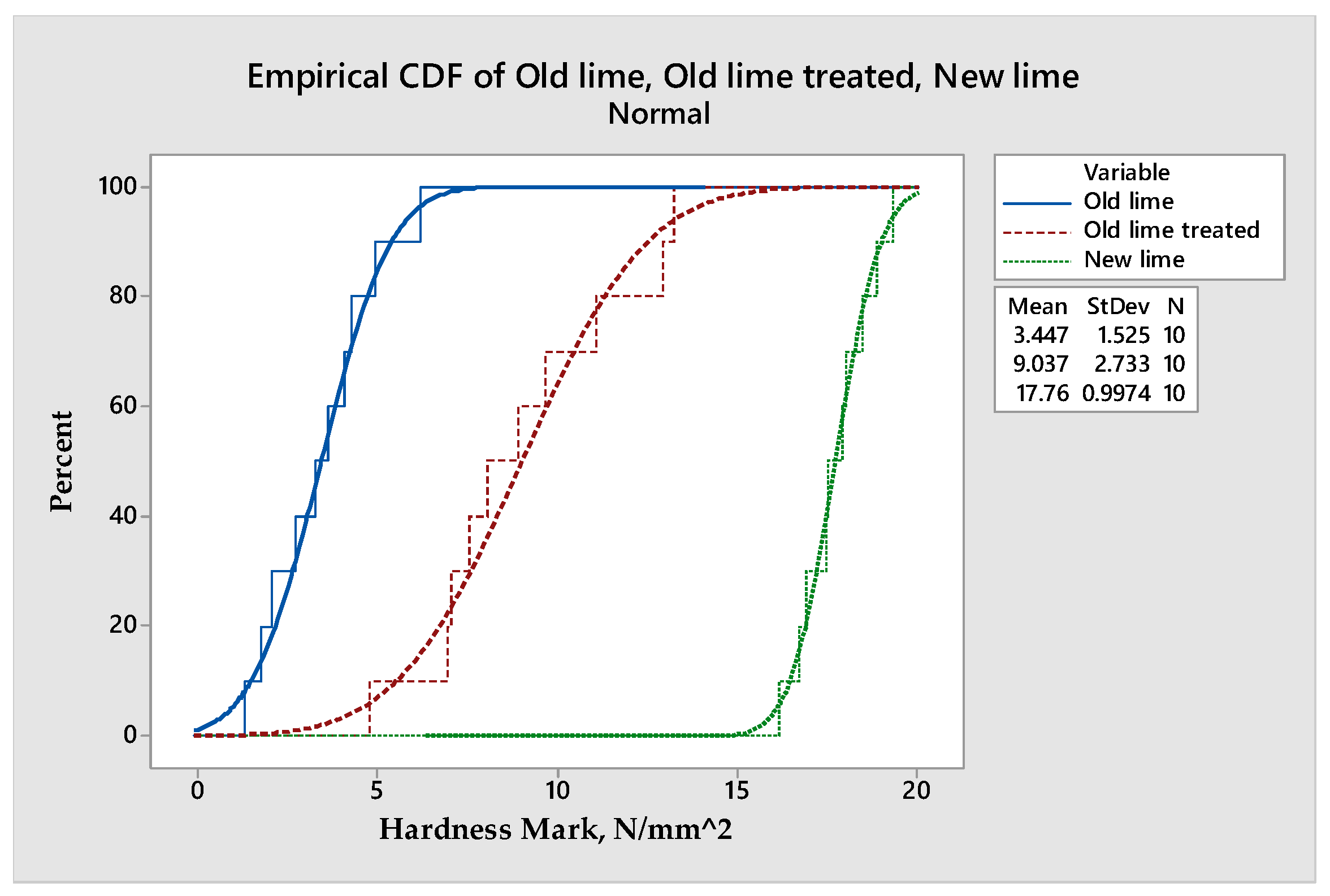

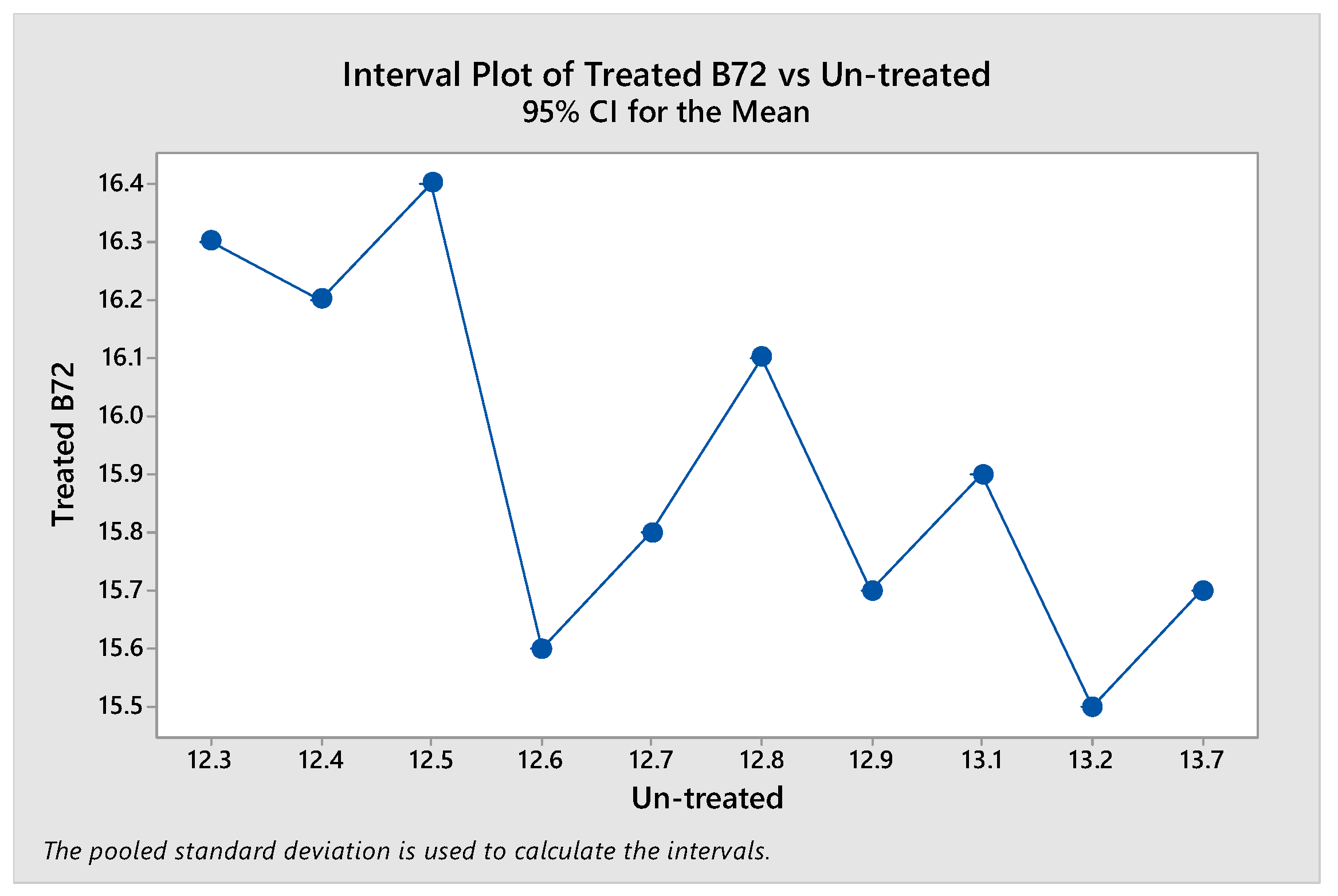

3.3. Results of Brinell Methods

- 17–24 N/mm2 (with an average of 21.5 N/mm2) for new Tillia cordata wood;

- 15.1–18.7 N/mm2 (with an average of 17.2 N/mm2) for slightly degraded and untreated lime;

- 16.9–19.3 N/mm2 (with an average of 18.3 N/mm2) for lime treated with B72 10% in case of light xylophagous degradation;

- 10.8–15.2 N/mm2 (with an average of 12.9 N/mm2) for medium and untreated degraded lime;

- 12.5–17.5 N/mm2 (with an average of 15.9 N/mm2) for lime treated for an average degradation;

- 4.1–9.2 N/mm2 (with an average of 6.4 N/mm2) for strongly degraded and untreated lime;

- 7.7–13.1 N/mm2 (with an average of 10.2 N/mm2) for high xylophagous degradation and B72 treatment.

3.4. Mark Hardness Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vecco, M. A definition of cultural heritage: From the tangible to the intangible. J. Cult. Herit. 2010, 11, 321–324. [Google Scholar] [CrossRef]

- Ross, R.J. Wood Handbook: Wood as an Engineering Material; General Technical Report FPL–GTR–190; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Volume 190, p. 510. [CrossRef]

- Pădurețu, A.; Gheorghiţă, V. Culture and connections preliminary research and preservation restoration interventions for wood icons. Eur. Sci. J. ESJ 2015, 2, 117–123. [Google Scholar]

- Bucsa, L.; Bucsa, C. Degradari Biologice ale Structurilor de Lemn la Monumentele Istorice din Romania. Transsylvania Nostra, 2009, 2, pp. 22–30. Available online: http://www.transsylvanianostra.eu/download/05_livia_bucsa_degr_biologice_str_lemn.pdf (accessed on 4 January 2019).

- The Wood Database. Available online: https://www.wood-database.com/wood-articles/wood-identification-guide/ (accessed on 23 January 2021).

- Macchioni, N.; Bertolini, C.; Tannert, T. Review of Codes and Standards. In In Situ Assessment of Structural Timber: State of the Art Report of the RILEM Technical Committee 215-AST; Kasal, B., Tannert, T., Eds.; RILEM State of the Art Reports; Springer: Dordrecht, The Netherlands, 2011; pp. 115–121. ISBN 978-94-007-0560-9. [Google Scholar]

- Macchioni, N. Diagnosis and Conservation of Wooden Cultural Heritage, 2015. Available online: https://www.ivalsa.cnr.it/en/research/diagnosis-and-conservation-of-wooden-cultural-heritage.htm (accessed on 13 June 2018).

- UNI 11161; Cultural Heritage-Wooden Artefacts-Guideline for Conservation, Restoration and Maintenance. Ente Nazionale Italiano di Unificazione (UNI): Rome, Italy, 2005.

- Fassina, V. CEN TC 346 Conservation of Cultural Heritage-Update of the Activity after a Height Year Period. In Proceedings of the Engineering Geology for Society and Territory—Volume 8; Lollino, G., Giordan, D., Marunteanu, C., Christaras, B., Yoshinori, I., Margottini, C., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 37–41. [Google Scholar]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance, 1st ed.; John Wileys & Sons: Chichester, UK, 2016; p. 376. ISBN 9781119106531. [Google Scholar]

- Pournou, A. Biodeterioration of Wooden Cultural Heritage; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Sakuno, T.; Schniewind, A.P. Adhesive Qualities of Consolidants for Deteriorated Wood. J. Am. Inst. Conserv. 1990, 29, 33. [Google Scholar] [CrossRef]

- Cataldi, A.; Dorigato, A.; Deflorian, F.; Pegoretti, A. Effect of the Water Sorption on the Mechanical Response of Microcrystalline Cellulose-Based Composites for Art Protection and Restoration. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.-P. The effects on bamboo paper from wood materials used in the conservation of Chinese wooden boxes. J. Inst. Conserv. 2017, 40, 212–225. [Google Scholar] [CrossRef]

- Cataldi, A.; Deflorian, F.; Pegoretti, A. Microcrystalline cellulose filled composites for wooden artwork consolidation: Application and physic-mechanical characterization. Mater. Des. 2015, 83, 611–619. [Google Scholar] [CrossRef]

- Cataldi, A.; Deflorian, F.; Pegoretti, A. Poly 2-ethyl-2-oxazoline/microcrystalline cellulose composites for cultural heritage conservation: Mechanical characterization in dry and wet state and application as lining adhesives of canvas. Int. J. Adhes. Adhes. 2015, 62, 92–100. [Google Scholar] [CrossRef]

- Cataldi, A.; Dorigato, A.; Deflorian, F.; Pegoretti, A. Innovative microcrystalline cellulose composites as lining adhesives for canvas. Polym. Eng. Sci. 2015, 55, 1349–1354. [Google Scholar] [CrossRef]

- Mankowski, P.; Kozakiewicz, P.; Krzosek, S. Retention of Polymer in Lime Wood Impregnated with Paraloid B-72 Solution in Butyl Acetate. Ann. Wars. Univ. Life Sci. 2015, 92, 263–267. [Google Scholar]

- Charola, A.E.; Tucci, A.; Koestler, R.J. On the Reversibility of Treatments with Acrylic/Silicone Resin Mixtures. J. Am. Inst. Conserv. 1986, 25, 83–92. [Google Scholar] [CrossRef]

- Timar, M.C.; Sandu, I.C.A.; Beldean, E.; Sandu, I. FTIR Investigation of Paraloid B72 as Consolidant for Old Wooden Artefacts Principle and Methods. Mater. Plast. 2014, 51, 382–387. [Google Scholar]

- Deng, Y.; Chen, Y.; Zhang, Y.; Wang, S.; Zhang, F.; Sun, F. ICON: 3D reconstruction with ‘missing-information’ restoration in biological electron tomography. J. Struct. Biol. 2016, 195, 100–112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schniewind, A.P.; Eastman, P.Y. Consolidant Distribution in Deteriorated Wood Treated with Soluble Resins. J. Am. Inst. Conserv. 1994, 33, 247–255. [Google Scholar] [CrossRef]

- Pavlidis, G.; Tsiafakis, D.; Koutsoudis, A.; Arnaoutoglou, F.; Tsioukas, V.; Chamzas, C. Preservation of Architectural Heritage through 3D Digitization. Int. J. Arch. Comput. 2007, 5, 221–237. [Google Scholar] [CrossRef]

- Rivers, S.; Umney, N. Conservation of Furniture; Routledge: London, UK, 2003; ISBN 978-0-08-052464-1. [Google Scholar]

- Siau, J.F. Transport Processes in Wood; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Walsh-Korb, Z.; Avérous, L. Recent developments in the conservation of materials properties of historical wood. Prog. Mater. Sci. 2018, 102, 167–221. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, T.; Wu, Z.; Sun, T. Reinforced Strength Evaluation of Binding Material for the Restoration of Chinese Ancient Lacquer Furniture. BioResources 2019, 14, 7182–7192. [Google Scholar] [CrossRef]

- Fierascu, R.C.; Doni, M.; Fierascu, I. Selected Aspects Regarding the Restoration/Conservation of Traditional Wood and Masonry Building Materials: A Short Overview of the Last Decade Findings. Appl. Sci. 2020, 10, 1164. [Google Scholar] [CrossRef] [Green Version]

- Lahanier, C.; Preusser, F.; Van Zelst, L. Study and conservation of museum objects: Use of classical analytical techniques. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1986, 14, 1–9. [Google Scholar] [CrossRef]

- Madhoushi, M. Species and Mechanical Strengths of Wood Members in a Historical Timber Building in Gorgan (North of Iran). BioResources 2016, 11, 5180. [Google Scholar] [CrossRef]

- Mohamed Hamed, S.A.; Ali, M.F.; Nabil Elhadidi, N.M. Assessment of Commonly Used Cleaning Methods on The Anatomical Structure of Archaeological Wood. Int. J. Conserv. Sci. 2013, 4, 153–160. [Google Scholar]

- Teacă, C.-A.; Roşu, D.; Mustaţă, F.; Rusu, T.; Roşu, L.; Roşca, I.; Varganici, C.-D. Natural bio-based products for wood coating and protection against degradation: A Review. BioResources 2019, 14, 4873–4901. [Google Scholar] [CrossRef]

- Zhou, K.; Li, A.; Xie, L.; Wang, C.-C.; Wang, P.; Wang, X. Mechanism and effect of alkoxysilanes on the restoration of decayed wood used in historic buildings. J. Cult. Herit. 2020, 43, 64–72. [Google Scholar] [CrossRef]

- Vitali, F.; Caldi, C.; Benucci, M.; Marzaioli, F.; Moioli, P.; Seccaroni, C.; De Ruggieri, B.; Romagnoli, M. The vernacular sculpture of Saint Anthony the Abbot of Museo Colle del Duomo in Viterbo (Italy). Diagnostic and Wood dating. J. Cult. Herit. 2021, 48, 299–304. [Google Scholar] [CrossRef]

- Neamțu, C.; Bratu, I.; Măruțoiu, C.; Măruțoiu, V.; Nemeș, O.; Comes, R.; Bodi, B.Z.; Popescu, D. Component Materials, 3D Digital Restoration, and Documentation of the Imperial Gates from the Wooden Church of Voivodeni, Sălaj County, Romania. Appl. Sci. 2021, 11, 3422. [Google Scholar] [CrossRef]

- Crisci, G.M.; La Russa, M.F.; Malagodi, M.; Ruffolo, S.A. Consolidating properties of Regalrez 1126 and Paraloid B72 applied to wood. J. Cult. Herit. 2010, 11, 304–308. [Google Scholar] [CrossRef]

- Salem, M.Z.M.; Mansour, M.M.A.; Mohamed, W.S.; Ali, H.M.; Hatamleh, A.A. Evaluation of the antifungal activity of treated Acacia saligna wood with Paraloid B-72/TiO2 nanocomposites against the growth of Alternaria tenuissima, Trichoderma harzi-anum, and Fusarium culmorum. BioResources 2017, 12, 7615–7627. [Google Scholar] [CrossRef]

- Dogu, D.; Yilgör, N.; Mantanis, G.; Tuncer, F.D. Structural Evaluation of a Timber Construction Element Originating from the Great Metéoron Monastery in Greece. BioResources 2017, 12, 2433–2451. [Google Scholar] [CrossRef] [Green Version]

- Olarescu, C.M.; Campean, M.; Cosereanu, C. Thermal Conductivity of Solid Wood Panels Made from Heat-Treated Spruce and Lime Wood Strips. Pro Ligno 2015, 11, 377–382. [Google Scholar]

- Ulker, O.; Hiziroglu, S. Thermo Mechanical Processing of Cappadocian Maple (Acer C.). Pro Ligno 2018, 14, 13–20. [Google Scholar]

- Popescu, C.-M.; Popescu, M.-C.; Vasile, C. Characterization of fungal degraded lime wood by FT-IR and 2D IR correlation spectroscopy. Microchem. J. 2010, 95, 377–387. [Google Scholar] [CrossRef]

- Paris, J.L.; Kamke, F.A.; Xiao, X. X-ray computed tomography of wood-adhesive bondlines: Attenuation and phase-contrast effects. Wood Sci. Technol. 2015, 49, 1185–1208. [Google Scholar] [CrossRef]

- EN 1534:2003; Wood and Parquet Flooring. Determination of Resistance to Indentation (Brinell)—Test Method. European Committee for Standardization: Brussels, Belgium, 2003.

- EN 17121:2019; Conservation of Cultural Heritage—Historic Timber Structures—Guidelines for the On-Site Assessment. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 323:1993; Wood-Based Panels—Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

| Icon | Initial Mass, g | Loss of Wood, % | Reconstituted Mass, g | Panel Dimensions, mm | Icon Density, kg/m3 | New Wood Density, kg/m3 | Loss of Density, % |

|---|---|---|---|---|---|---|---|

| 1 | 791 | 3.3 | 818 | 280 × 335 × 30 | 290.69 | 509.8 | 42.97 |

| 2 | 1243 | 2.1 | 1270 | 415 × 345 × 28 | 316.7 | 509.8 | 37.87 |

| 3 | 1380 | 0 | 1380 | 415 × 345 × 28 | 344.3 | 509.8 | 32.46 |

| 4 | 9494 | 1.2 | 9610 | 970 × 730 × 34 | 399.1 | 514.4 | 22.41 |

| 5 | 5135 | 0 | 5135 | 780 × 630 × 24 | 435.4 | 514.4 | 15.35 |

| Icon | Planar Dimensions, mm | Total Number of Holes | Average Diameter, mm | Number of Holes/dm2 | Fragility, % |

|---|---|---|---|---|---|

| 1 | 172 × 100 | 346 | 2.03 | 201 | 25.2 |

| 2 | 80 × 100 | 122 | 1.92 | 152 | 17.1 |

| 3 | 180 × 150 | 390 | 2.11 | 144 | 19.5 |

| 4 | 100 × 35 | 46 | 1.91 | 131 | 14.5 |

| 5 | 170 × 125 | 252 | 1.84 | 118 | 12.1 |

| Icon | 1 | 2 | 3 | 4 | 5 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Xylophagous Evaluation | Avg. * | Ext. ** | Avg. | Ext. | Ext. | Ext. | Ext. | Avg. | Low |

| Force, N | 73 | 21 | 79 | 36 | 36 | 25 | 36 | 84 | 127 |

| Mark hardness, N/mm2 | 3.43 | 0.98 | 3.71 | 1.69 | 1.69 | 1.17 | 1.69 | 3.94 | 5.96 |

| Fragility degree, % | 64.38 | 89.8 | 61.47 | 82.45 | 82.45 | 87.85 | 82.45 | 59.08 | 38.1 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Un-treated | 9 | 0.8760 | 0.09733 | * | * |

| Error | 0 | * | * | ||

| Total | 9 | 0.8760 |

| Degree | Level | Method | Fragility-Degradation Values | Icon Status |

|---|---|---|---|---|

| 1. | Good | Density method, % | 10–15 | Acceptable. It is not being restored |

| Excessive porosity | 2–10 | |||

| Number of holes/dm2 | 20–40 | |||

| Brinell hardness | 4–35 | |||

| Hardness Mark | 4–35 | |||

| 2. | Weak | Density method, % | 15.1–25 | Worrying. Light restoration activities (surface consolidation treatments are needed) |

| Number of holes/dm2 | 40.1–80 | |||

| Excessive porosity | 10.1–15 | |||

| Hardness Mark | 35–50 | |||

| Brinell hardness | 35.1–50 | |||

| 3. | Average | Density method, % | 25.1–35 | Alarming. Medium restoration activities (surface and internal treatments are needed) |

| Number of holes/dm2 | 80–160 | |||

| Excessive porosity | 15.1–20 | |||

| Hardness Mark | 36–50 | |||

| Brinell hardness | 50.1–65 | |||

| 4. | Extended | Density method, % | 35.1–45 | Critical. Complex restoration activities, including replacement of wooden areas, are needed |

| Number of holes/dm2 | 160–200 | |||

| Excessive porosity | 20.1–25 | |||

| Brinell hardness | 65.1–80 | |||

| Hardness Mark | 51–60 | |||

| 5. | Exitus | Visual, all methods | Exceeding previous values | Unrecoverable icon. It is not being restored |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avram, A.; Ionescu, C.Ș.; Lunguleasa, A. Some Methods for the Degradation-Fragility Degree Determination and for the Consolidation of Treatments with Paraloid B72 of Wood Panels from Icon-Type Heritage Objects. Forests 2022, 13, 801. https://doi.org/10.3390/f13050801

Avram A, Ionescu CȘ, Lunguleasa A. Some Methods for the Degradation-Fragility Degree Determination and for the Consolidation of Treatments with Paraloid B72 of Wood Panels from Icon-Type Heritage Objects. Forests. 2022; 13(5):801. https://doi.org/10.3390/f13050801

Chicago/Turabian StyleAvram, Anamaria, Constantin Ștefan Ionescu, and Aurel Lunguleasa. 2022. "Some Methods for the Degradation-Fragility Degree Determination and for the Consolidation of Treatments with Paraloid B72 of Wood Panels from Icon-Type Heritage Objects" Forests 13, no. 5: 801. https://doi.org/10.3390/f13050801

APA StyleAvram, A., Ionescu, C. Ș., & Lunguleasa, A. (2022). Some Methods for the Degradation-Fragility Degree Determination and for the Consolidation of Treatments with Paraloid B72 of Wood Panels from Icon-Type Heritage Objects. Forests, 13(5), 801. https://doi.org/10.3390/f13050801