Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith

Abstract

:1. Introduction

2. Background

3. Materials and Methods

3.1. Design of Experiments

- Clear containing no obvious defects with the exception of pith;

- Resin containing at least 25% of the cross-sectional area resinous timber and no obvious defects with the exception of pith;

- Knots containing at least 25% knot area ratio (KAR) and may contain pith.

- 1.

- The clear and resin samples are compared for MOE and strength;

- 2.

- The clear and knot samples are compared for MOE and strength;

- 3.

- Pith and no pith are compared for MOE and strength in clear, resin and knot sample types.

3.2. Test Set-Up and Procedure

3.2.1. Bending

3.2.2. CParG

3.2.3. CPerpG

3.2.4. Shear

3.2.5. Tension

3.2.6. Density

4. Results

5. Discussions

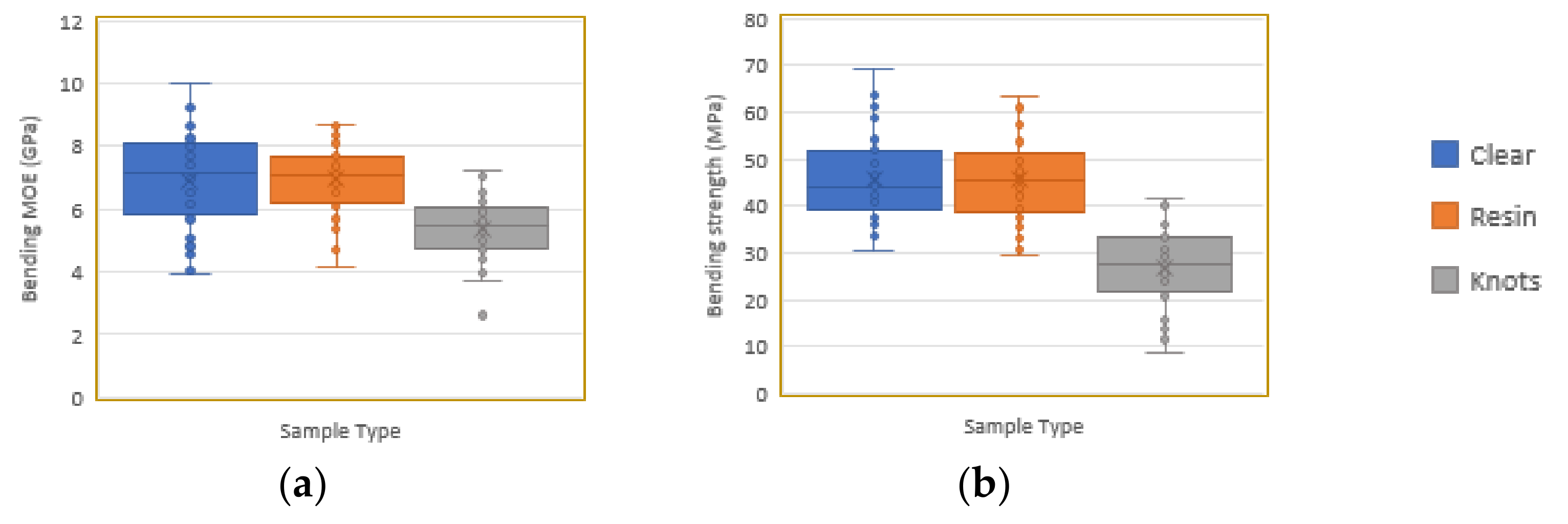

5.1. Bending

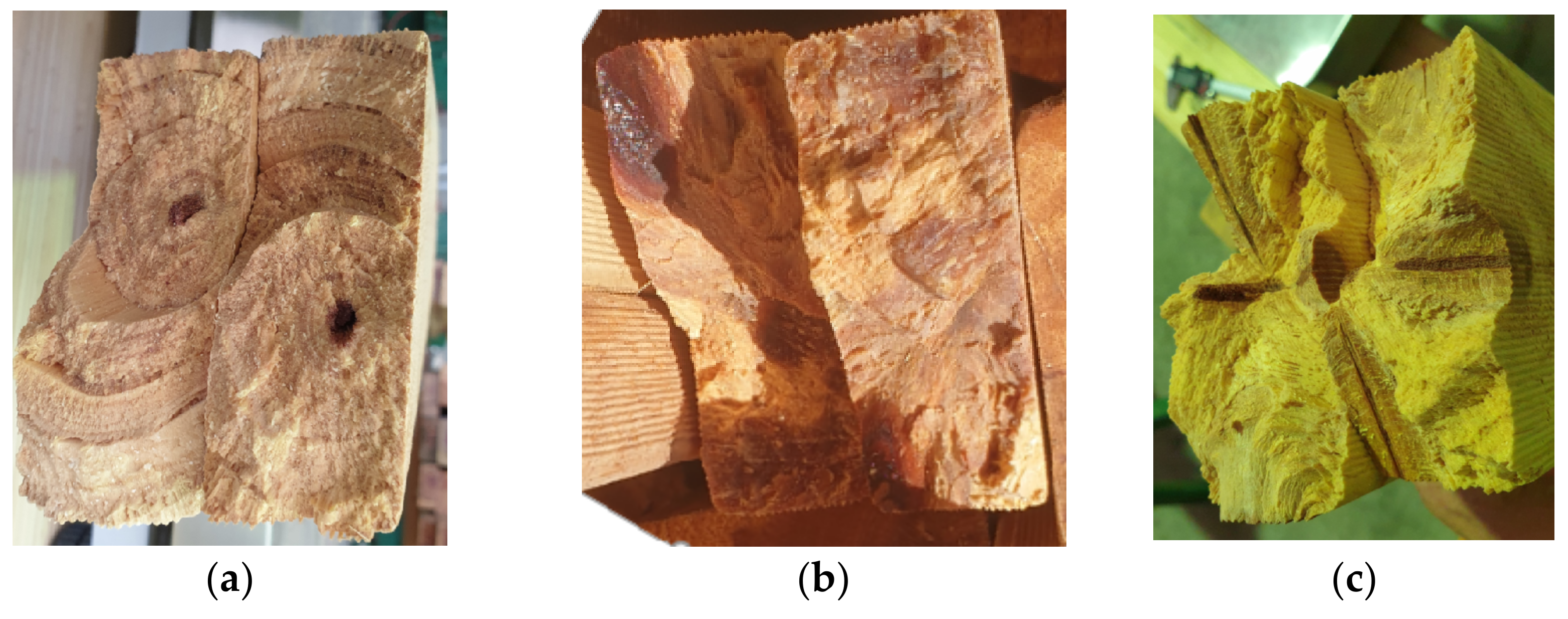

5.1.1. Failure Behaviour

5.1.2. Structural Performance

5.1.3. Effect of Resin

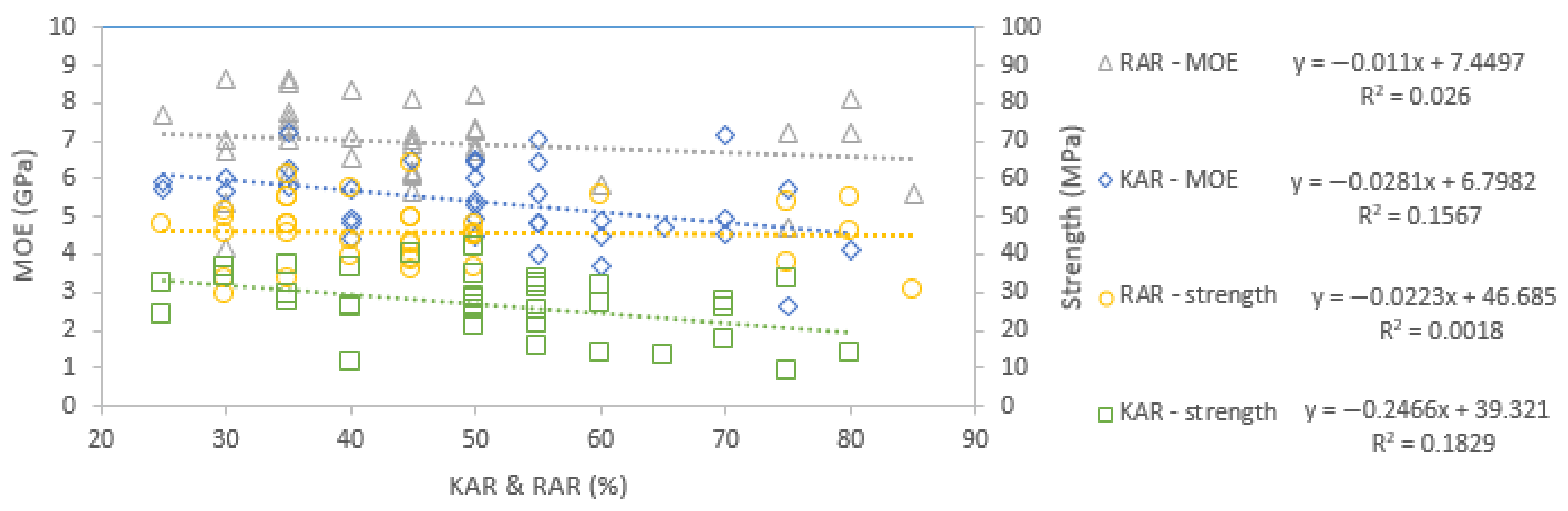

5.1.4. Effect of Knots

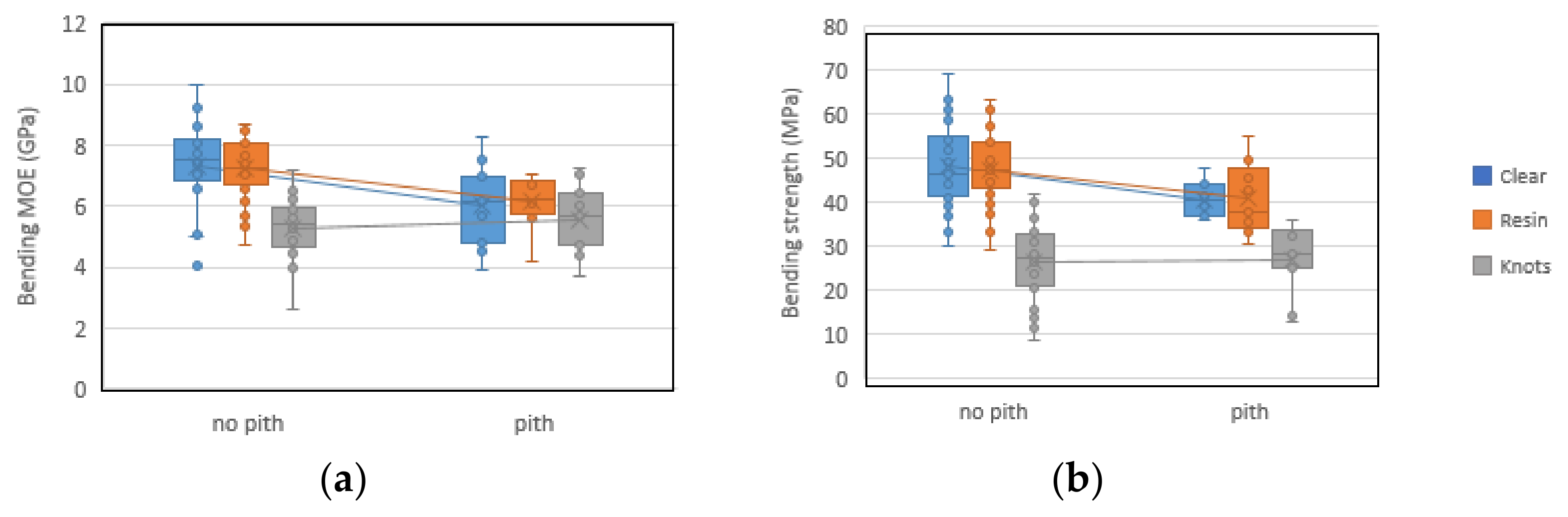

5.1.5. Effect of Pith

5.1.6. Relationship of Density and Bending Properties

5.1.7. Relationship of Bending MOE and Strength

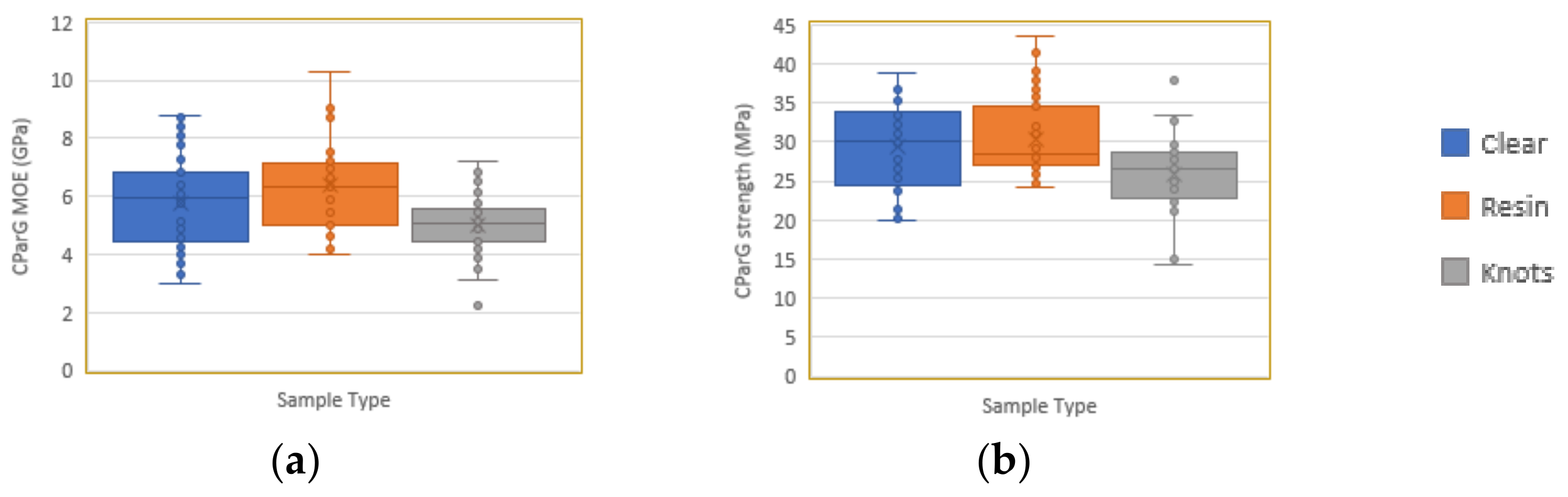

5.2. Compression Parallel to Grain

5.2.1. Failure Behaviour

5.2.2. Structural Performance

5.2.3. Effect of Resin

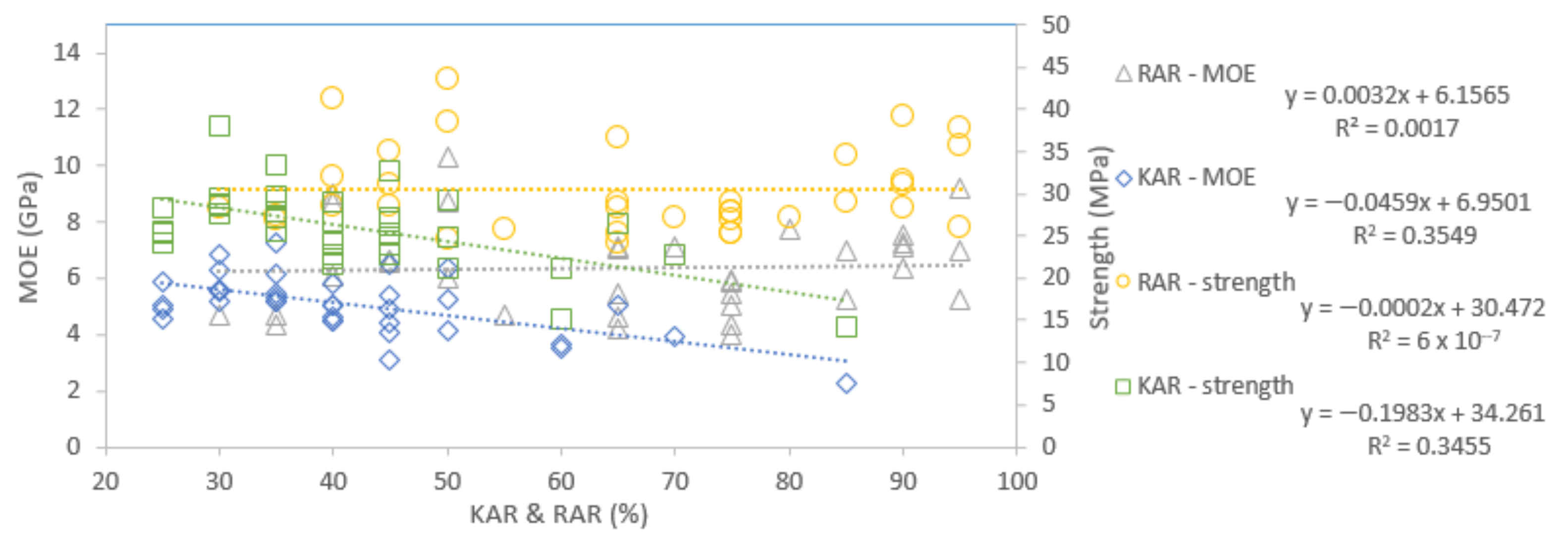

5.2.4. Effect of Knots

5.2.5. Effect of Pith

5.2.6. Relationship of Density and CParG

5.2.7. Relationship of CParG MOE and Strength

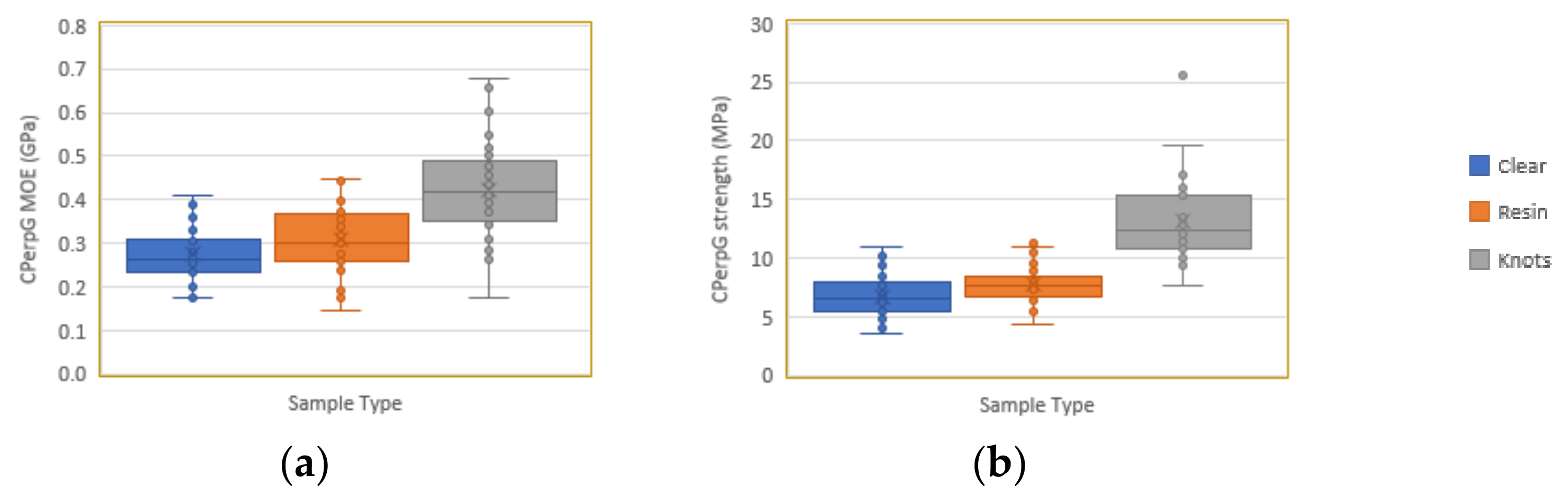

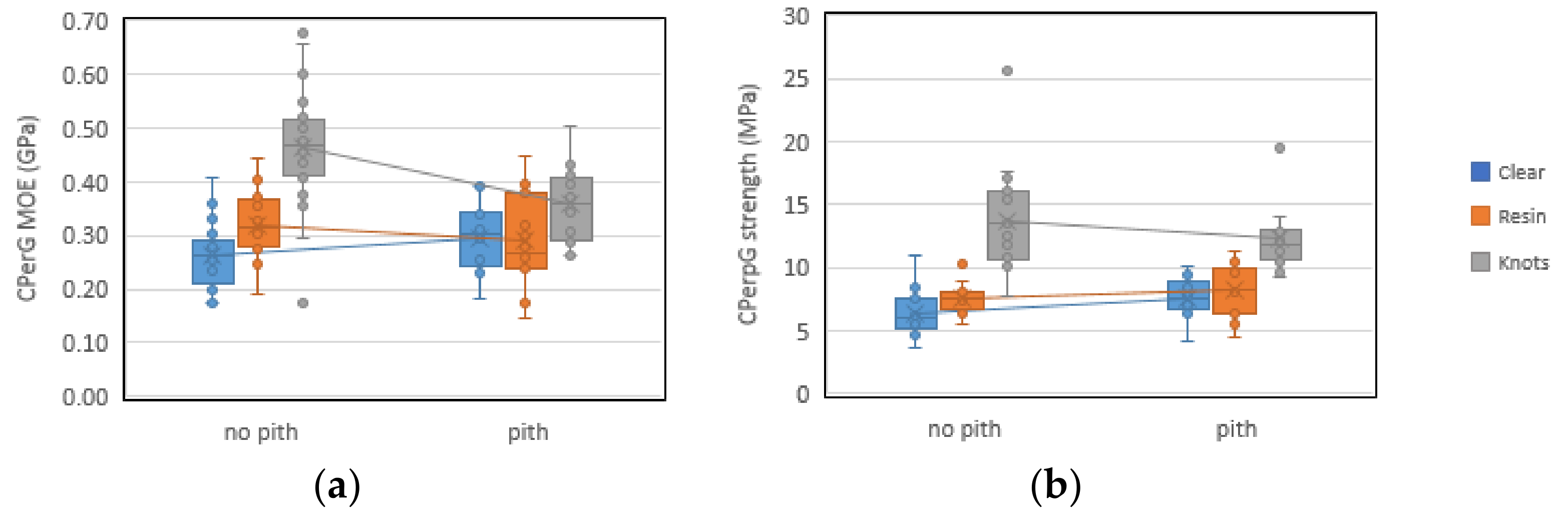

5.3. Compression Perpendicular to Grain

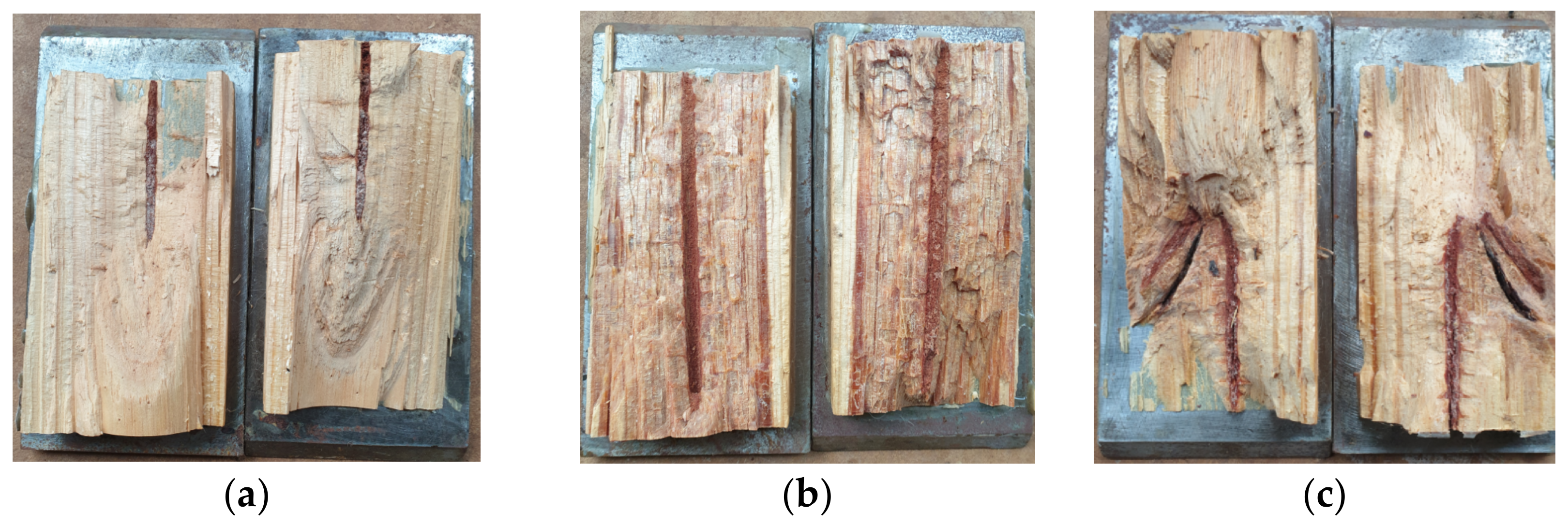

5.3.1. Failure Behaviour

5.3.2. Structural Performance

5.3.3. Effect of Resin

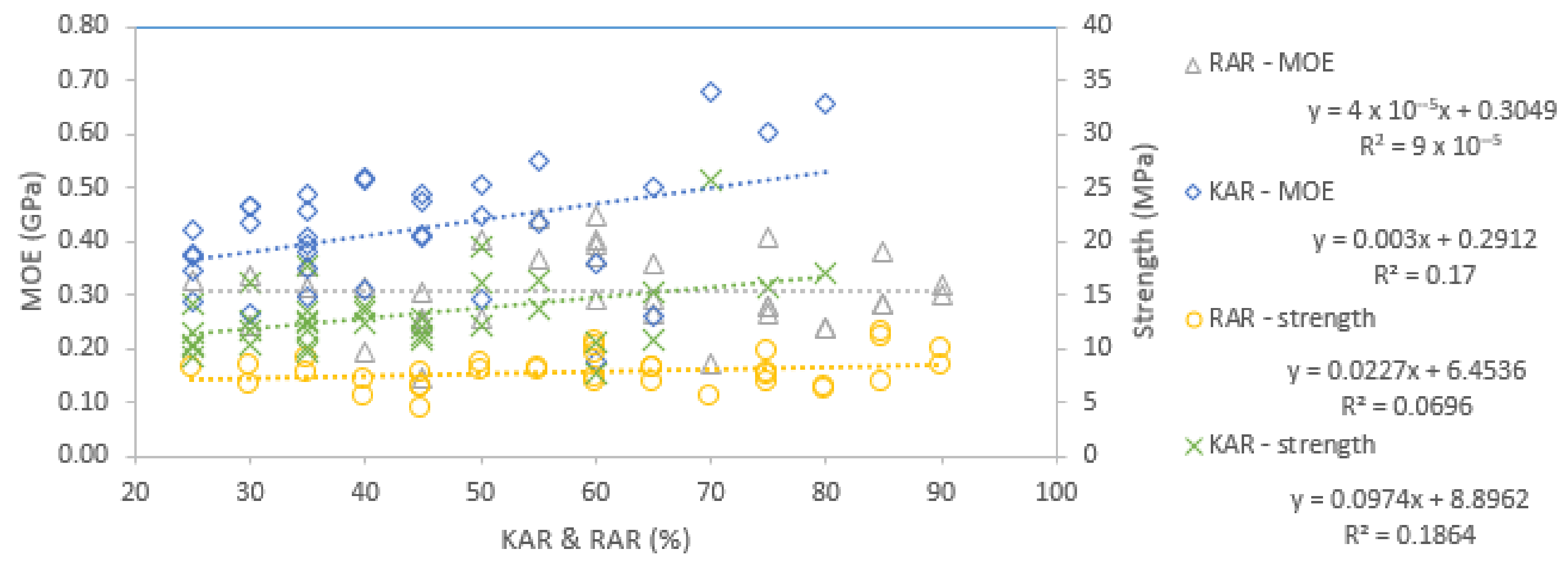

5.3.4. Effect of Knots

5.3.5. Effect of Pith

5.3.6. Relationship of Density and CPerpG

5.3.7. Relationship of CPerpG MOE and Strength

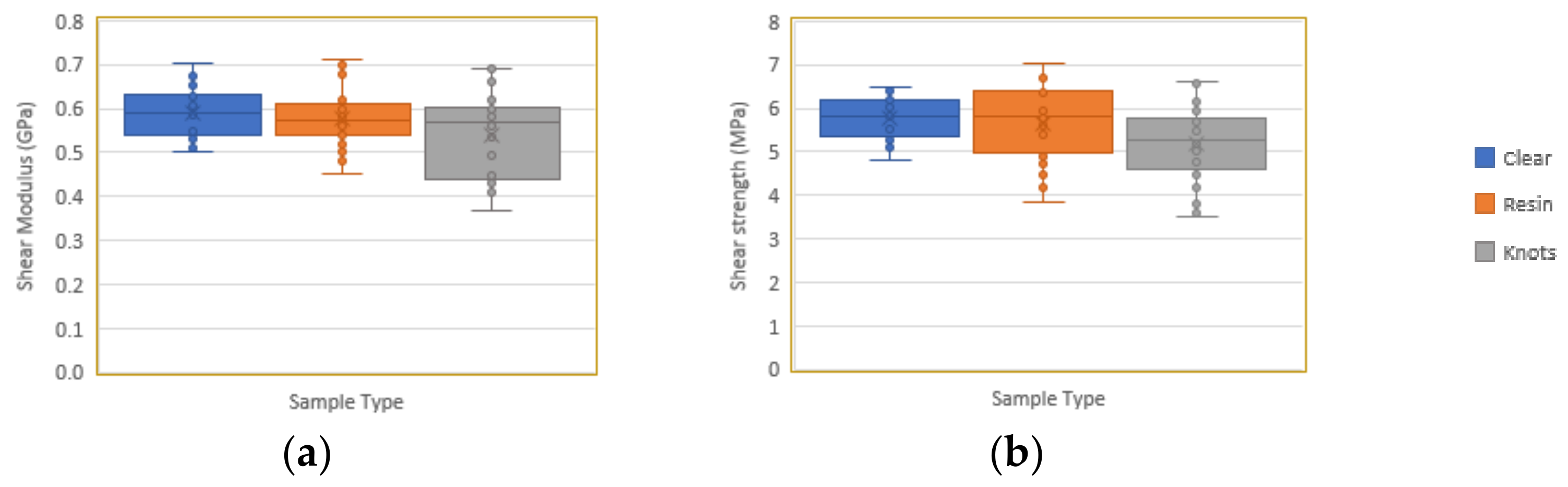

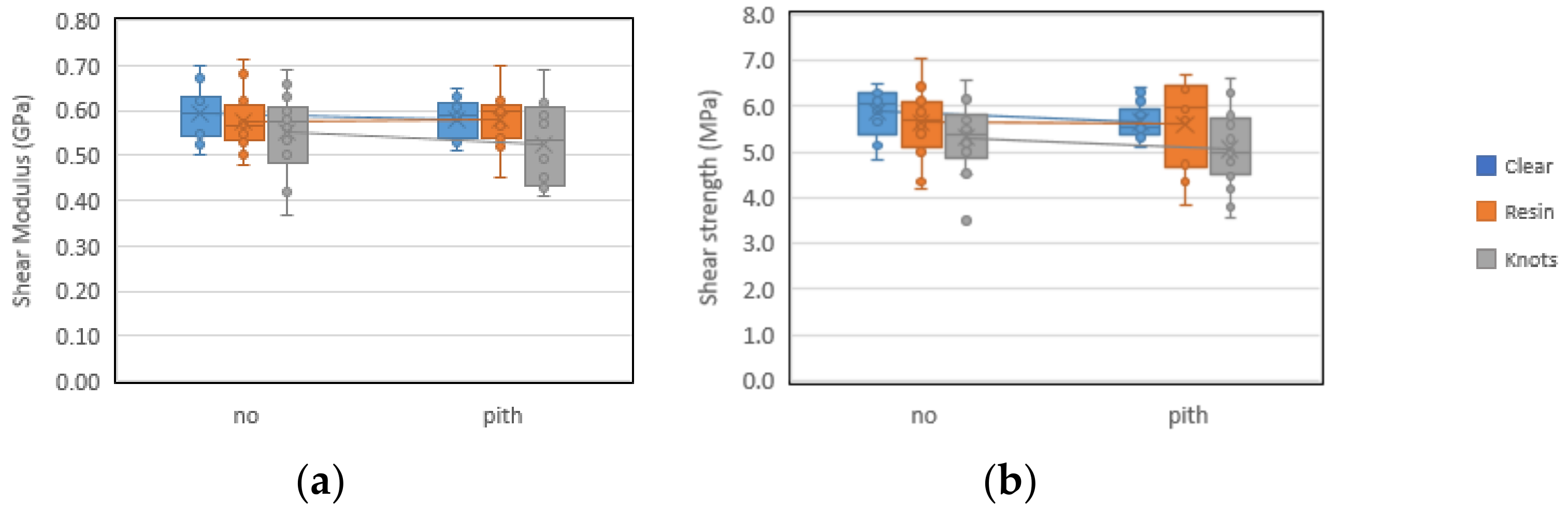

5.4. Shear

5.4.1. Failure Behaviour

5.4.2. Structural Performance

5.4.3. Effect of Resin

5.4.4. Effect of Knots

5.4.5. Effect of Pith

5.4.6. Relationship of Density and Shear

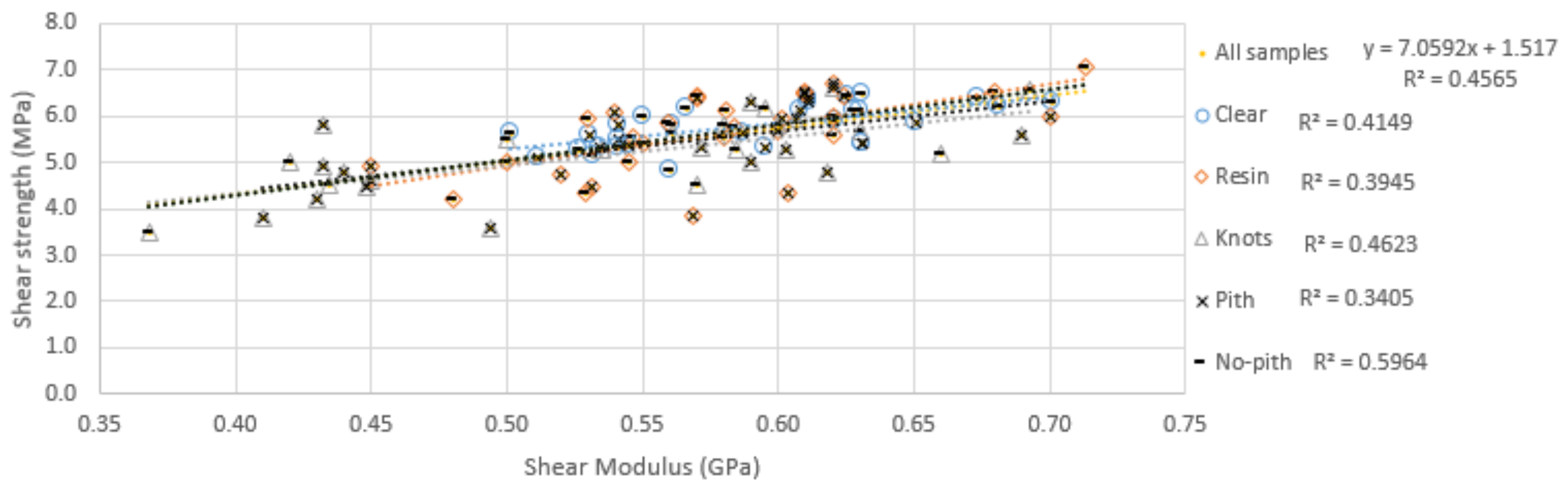

5.4.7. Relationship of Shear Modulus and Shear Strength

5.5. Tension

5.5.1. Failure Behaviour

5.5.2. Structural Performance

5.5.3. Effect of Resin

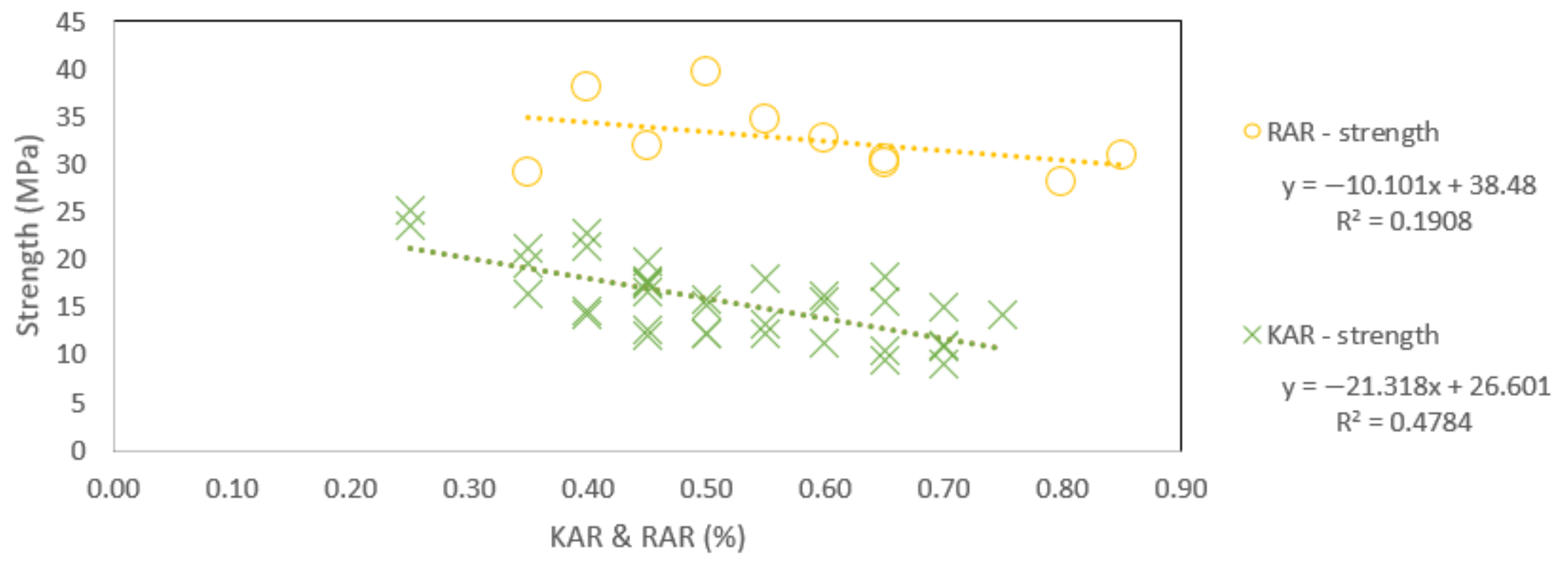

5.5.4. Effect of Knots

5.5.5. Effect of Pith

5.5.6. Relationship of Density and Tension

6. Overview

6.1. Structural Performance

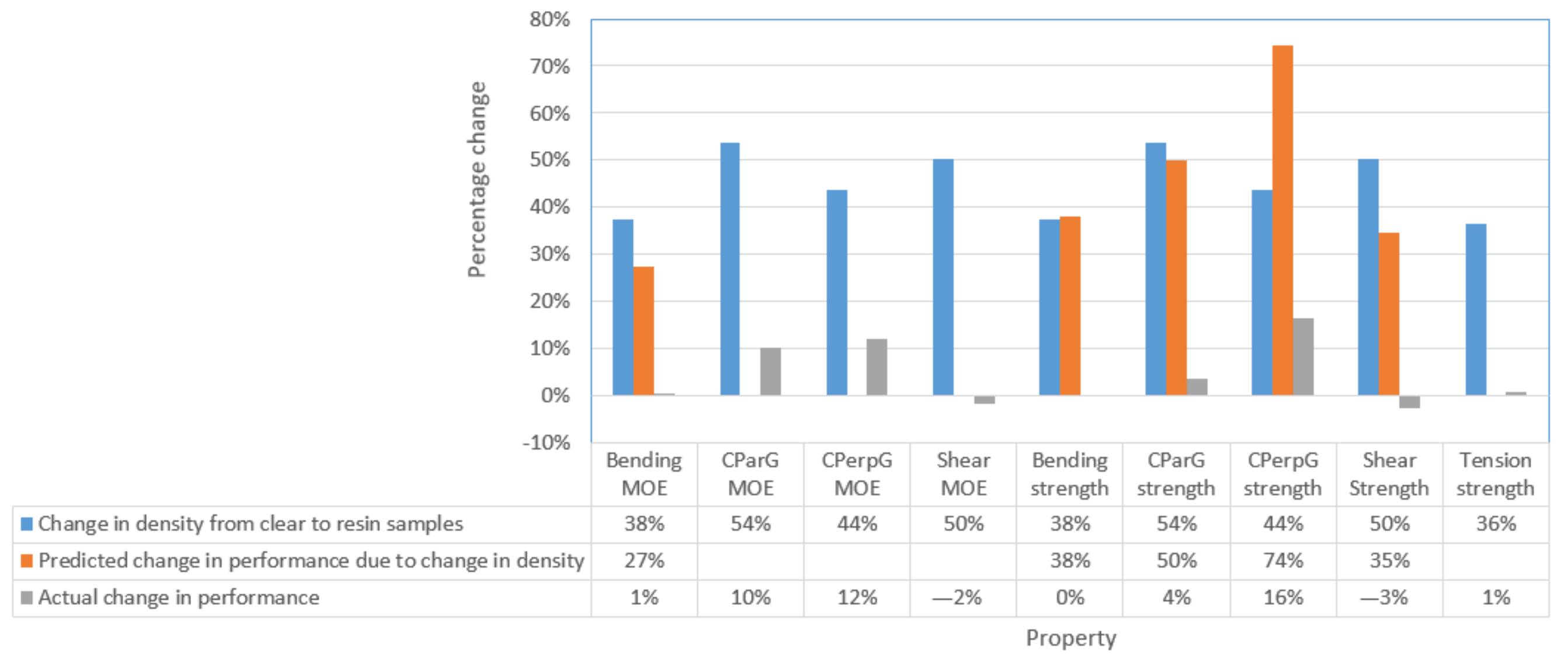

6.2. Resin

6.3. Knots

6.4. Pith

6.5. Density

7. Conclusions

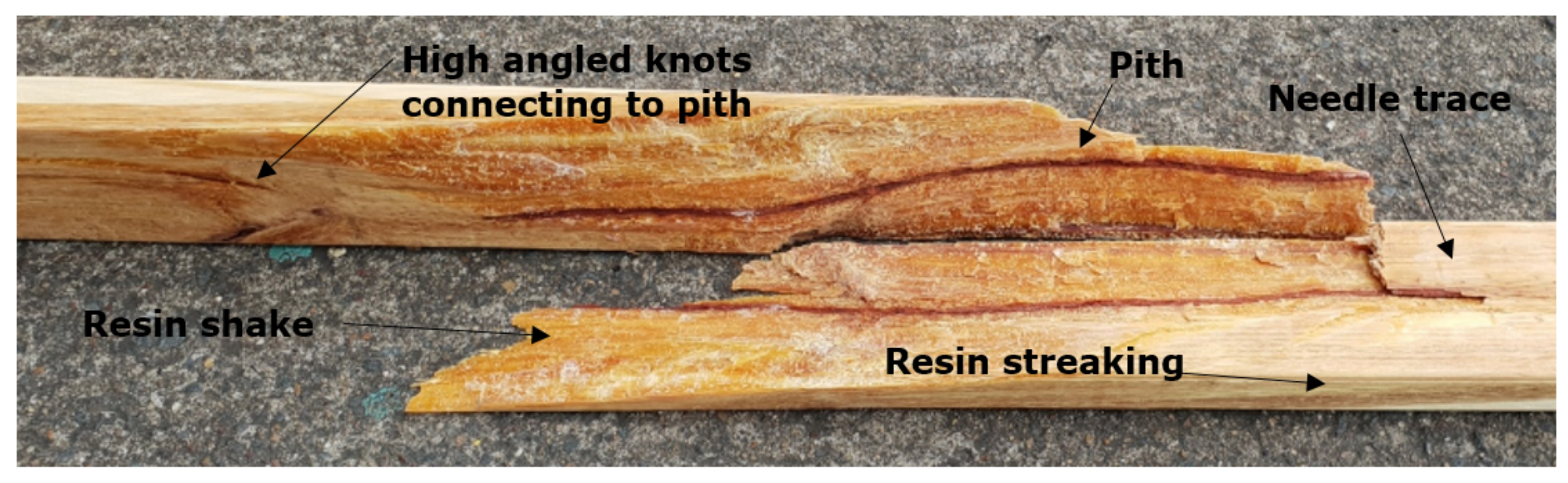

- The out-of-grade PEE × PCH hybrids from the low-quality inner core of the tree are typically characterised with pith, high-angled clustered knots, resin streaking, resin shake, needle trace and tight-radius growth rings with high percentage of earlywood.

- The clear timber in this resource performed well in bending strength (45.8 MPa) and tension strength (32.4 MPa), mid-range in bending MOE (6.9 GPa) and CParG strength (29.4 MPa) but poorly in CParG MOE (5.78 GPa), CPerpG MOE (0.27 GPa), CPerpG strength (6.7 MPa), shear modulus (0.59 GPa) and shear strength (5.7 MPa) compared to other PEE × PCH hybrids and young and low-grade similar pines. Bending strength and CPerpG strength were mid-range compared to average populations of similar pines, but all other structural properties were low which can be expected given the timber was out-of-grade and contains juvenile wood and pith.

- The ratios of structural performance for clear samples to bending MOE revealed high tensile strength, mid-range bending and CParG strength, but all other structural properties were low relative to their bending MOE performance when compared to other PEE × PCH hybrids and young and low-grade similar pines. Shear modulus, CParG and CPerpG strengths were mid-range, and all other properties were low relative to their bending MOE performance when compared to average populations of similar pines.

- The Poisson’s ratio of the pooled clear and resin samples was found to be 0.4365 which is similar to slash pines as one of its parent species.

- Resin samples performed similar to and within a range of 98% to 116% of the clear samples. Resin significantly increased the density at 45% higher than clear but only CPerpG MOE performed significantly different; however, no clear relationship was found between RAR and CPerpG MOE. The resin in cell walls rather than in cell lumen is believed to have provided the increased performance. The increase in density due to resin caused large errors in predictive models that were based on density and should be subtracted from these equations. RAR showed low correlation with all structural properties with R2 values all below 0.2 and moderate correlation with density with R2 of 0.659.

- Knots performed significantly different to clear samples for all test types and within a range of 48% to 196%. Knots were high in CPerpG MOE and strength and lower for all other properties with the largest negative impact being on tensile strength followed by bending strength. The increase in density was similar to that for resin and knot-associated resin streaking was common which would have added to density. KAR was moderately correlated with tension strength and CParG MOE with R2 of 0.48 and 0.35, respectively. All other correlations were low or non-existent with R2 below 0.2.

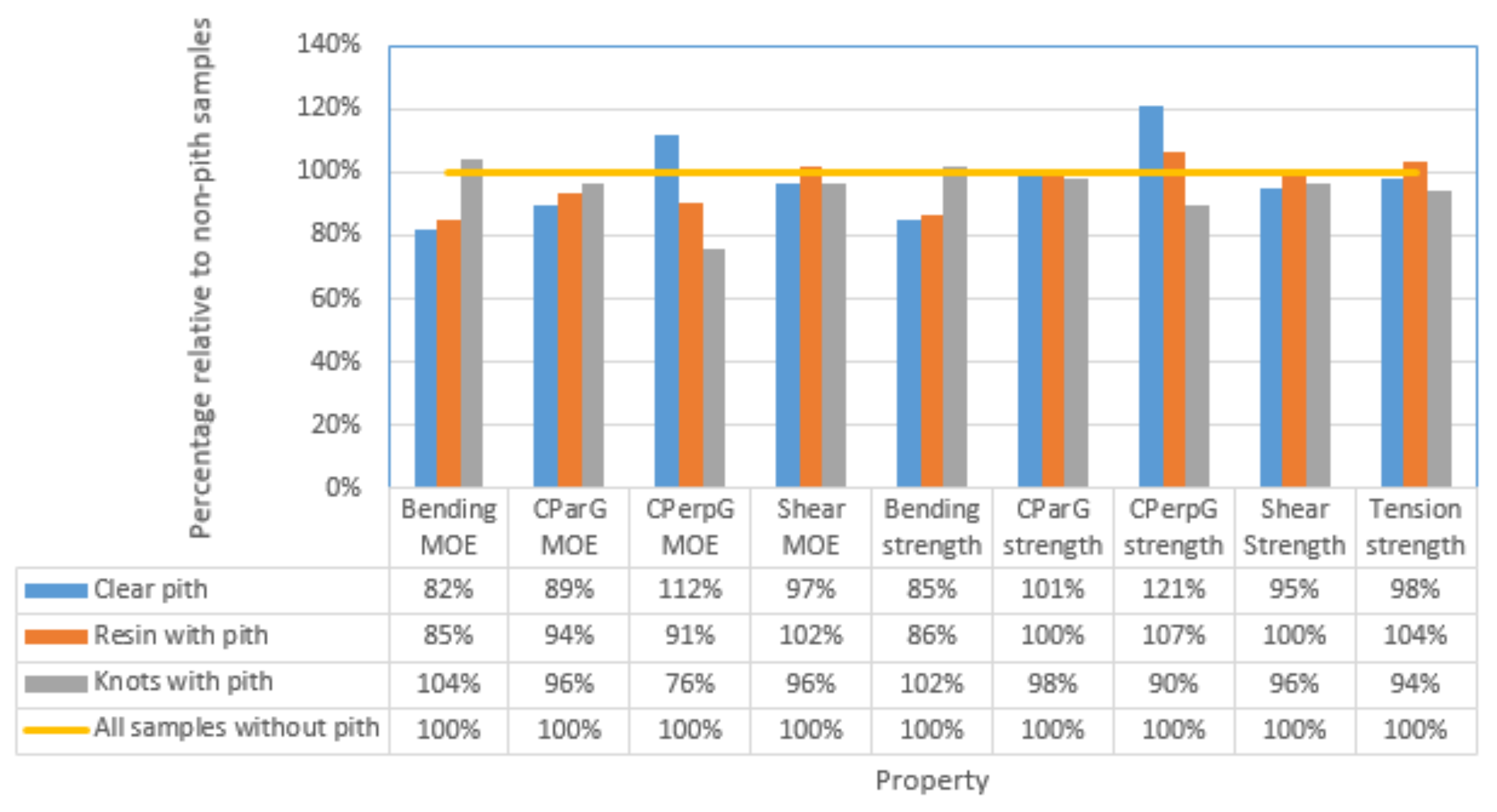

- Pith samples were within the range of 76% to 121% of non-pith samples. Clear pith samples were significantly different and lower in bending MOE and strength and higher in CPerpG strength. Resin pith samples were significantly different and lower in bending MOE and strength. Knot pith samples were significantly different and lower in CPerpG MOE. Pith in knots for CPerpG strength had the third largest negative impact and is believed to be due to the discontinuity and connection of the conical-shaped knot wood spearing into the weak pith. Pith samples were higher in density than non-pith samples for clear, resin and knots in bending MOE and strength; knots had the largest negative impact, followed by pith for the clear and resin sample types, while resin had minimal impact and pith in knots increased performance.

- In CparG MOE and strength, knots had the largest negative impact, followed by pith. Resin had a positive impact with increased performance.

- In CPerpG MOE and strength, knots had the largest positive impact, followed by resin. Pith in clear samples also had a positive impact. Pith in resin reduced CPerpG MOE and increased strength while pith had the largest negative impact.

- In shear modulus and strength, knots had the largest negative impact, followed by pith in knot and clear samples. Resin had a small negative impact while pith in resin increased performance slightly.

- In tension strength, knots had the largest negative impact, followed by pith in knot and clear samples. Resin had little difference and pith in resin samples increased performance slightly.

- The density of clear samples at 500 kg/m3 was high compared to other PEE × PCH hybrids and young and low-grade similar pines and mid-range compared to average populations of similar pines. The ratio of density to bending MOE was mid-range compared to other PEE × PCH hybrids and young and low-grade similar pines and high compared to average populations of similar pines.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lopez, J.; Abt, R.; Dovorak, W.; Hodge, G.; Phillips, R. Tree breeding model to assess financial performance of pine hybrids and pure species: Deterministic and stochastic approaches for South Africa. New For. 2018, 49, 123–142. [Google Scholar] [CrossRef]

- Nel, A.; Malan, F.; Braunstein, R.; Wessels, C.B.; Kanzler, A. Sawn-timber and kraft pulp properties of Pinus elliotti x Pinus caribaea var. hondurensis and Pinus patula x Pinus tecunumanii hybrid and their parent species. South. For. J. For. Sci. 2017, 80, 159–168. [Google Scholar]

- Dieters, M.; Brawner, J. Productivity of Pinus elliottii, P. caribaea and their F1 and F2 hybrids to 15 years in Queensland, Australia. Ann. For. Sci 2007, 64, 691–698. [Google Scholar] [CrossRef] [Green Version]

- Stanger, T.K.; Shaw, M.J.P.; Braunstein, R.; Nikles, D.G. A Comparison of the kraft pulp properties of P. elliottii and the P. elliotti x P. caribaea var. hondurensis hybrid grown in Queensland, Australia. South. Afr. For. J. 1999, 186, 9–14. [Google Scholar]

- Lv, C.; Huang, B. Stem Tissue Culture of Pinus elliottii x Pinus caribaea. In Proceedings of the International Conference on Biomedical Engineering and Biotechnology, Macao, China, 28–30 May 2012. [Google Scholar]

- Yang, H.; Luo, R.; Zhao, F.; Liu, T.; Liu, C.; Huang, S. Constructing genetic linkage maps for Pinus elliotti var. elliotti and Pinus caribaea var. hondurensis using SRAP, SSR, EST and ISSR markers. Trees 2013, 27, 1429–1442. [Google Scholar] [CrossRef]

- Cappa, E.P.; Marco, M.; Nikles, D.G.; Last, I.S. Performance of Pinus elliottii, Pinus caribaea, their F1, F2 and backcross hybrids and Pinus taeda to 10 years in the Mesopotamia region, Argentina. New For. 2012, 44, 197–218. [Google Scholar] [CrossRef]

- Gauchar, M.; Belaber, E.; Vera Bravo, C.; Gonzalez, P. Integrating vegetative propagation into conifer improvement programs in Mesopotamia Region, Argentina. In Proceedings of the 4th International Conference of the IUFRO, Buenos Aires, Argentina, 28 December 2016. [Google Scholar]

- ABARES, Australian Plantation Statistics 2016. Australian Bureau of Agricultural Resource Economics and Sciences, Ed. Canberra. 2016. Available online: https://data.gov.au/data/dataset/pb_aplnsd9abfe20160816 (accessed on 1 February 2022).

- Dewbury, M. Improving Thermal Efficiency in Lightweight Construction: Mass Timber as Thermal Mass; Project number: PNA289-1213a; Forest & Wood Products Australia: Melbourne, Australia, 2016. [Google Scholar]

- AS/NZS 1748.1 c. Timber-Solid-Stress-graded for structural purposes-General Requirements. Available online: https://www.standards.govt.nz/shop/asnzs-1748-12011/ (accessed on 1 February 2022).

- AS 1720.1—2010; Australian Standard, Timber Structures, Part 1: Design Methods. SAI Global Limited: Sydney, Australia, 2010.

- Cherry, R.; Manalo, A.; Karunasena, W.; Stringer, G. Out-of-grade sawn pine: A state-of-the-art review on challenges and new opportunities in Cross Laminated Timber (CLT). Const. Build. Mater. 2019, 211, 858–868. [Google Scholar] [CrossRef]

- Bailleres, H.; Lee, D.; Kumar, C.; Psaltis, S.; Hopewell, G.; Brancheriau, L. Improving Returns from Southern Pine Plantations through Innovative Resource Characterization; PNC361-1415; Forest & Wood Products Australia Limited: Melbourne, Australia, 2019. [Google Scholar]

- Fridley, K. Wood and wood-based materials: Current status and future of a structural material. J. Mater. Civ. Eng. 2002, 14, 91–96. [Google Scholar] [CrossRef]

- Dahlen, J.; Jones, P.D.; Seale, R.D.; Shulsky, R. Bending strength and stiffness of wide dimension southern pine No. 2 lumber. Eur. J. Wood Wood Prod. 2014, 72, 759–768. [Google Scholar] [CrossRef]

- Steffan, A.; Johansson, C.; Wormuth, E. Study of the relationship between flatwise and edgewise moduli of elasticity of sawn timber as a means to improve mechanical strength grading technology. Holz Roh Werkst. 1997, 55, 245–253. [Google Scholar] [CrossRef]

- Ramage, M.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; REynolds, T.; Shah, D.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Surdi, P.G.; Junior, G.B.; Mendes, R.F.; Almeida, N.F. Use of hybrid Pinus elliotti var. elliotti x Pinus caribaea var. hondurensis and Pinus taeda L. in the production of OSB panels. For. Sci. 2015, 43, 763–772. [Google Scholar] [CrossRef] [Green Version]

- De Almeida, N.F.; Junior, G.B.; Mendes, R.F.; Surdi, P.G. Evaluation of Pinus elliotti var. elliotti x Pinus caribaea var. hondurensis wood for plywood production. For. Sci. 2012, 40, 435–443. [Google Scholar]

- Burdon, R.; Kibblewhite, R.; Walker, J.; Megraw, R.; Evans, R.; Cown, D. Juvenile versus mature wood: A new concept orthogonal to corewood versus outerwood, with special reference to Pinus radiata and P. taeda. For. Sci. 2004, 50, 399–415. [Google Scholar]

- Malan, F. Corewood in South African pine: Necessity and opportunities for improvement. South. For. J. For. Sci. 2010, 72, 99–105. [Google Scholar] [CrossRef]

- Takeda, T.; Hashizue, T. Differences of tensile strength distribution between mechanically high-grade and low-grade Japanese larch lumber II: Effect of knots on tensile strength distribution. J. Wood Sci. 1999, 45, 207–212. [Google Scholar] [CrossRef]

- Phillips, G.; Bodig, J.; Goodman, J. Flow-grain analogy. Wood Sci. 1981, 14, 55–64. [Google Scholar]

- Guindos, P.; Guaita, M. The analytical influence of all types of knots on bending. Wood Sci. Technol. 2014, 48, 533–552. [Google Scholar] [CrossRef]

- Guindos, P.; Guaita, M. A three-dimensional wood material model to simulate the behavior of wood with any type of knot at the macro-scale. Wood Sci. Technol. 2013, 47, 585–599. [Google Scholar] [CrossRef]

- Wessels, C.B.; Dowse, G.P.; Smit, H.C. The flexural properties of young Pinus elliotti x Pinus caribaea var. hondurensis timber from the Southern Cape and their prediction from acoustic measurements. South. For. J. For. Sci. 2011, 73, 137–147. [Google Scholar] [CrossRef]

- Malan, F.S. The Basic Wood Properties and Sawtimber Quality of South African Grown Pinus elliottii x Pinus caribaea. S. Afr. For. J. 1995, 173, 35–41. [Google Scholar]

- Harding, K.; Copley, T.; Peters, R.; Dieters, M.J.; Nester, M.R.; Keys, M.; Toon, P. Selecting hybrid pine clones for deployment—The pointy end of wood quality improvement. N. Z. J. For. Sci. 2008, 38, 120–131. [Google Scholar]

- Leggate, W.; Shirmohammadi, M.; McGavin, R.L.; Chandra, K.; Knackstedt, M.; Knuefing, L.; Turner, M. Influence of Wood’s Anatomical and Resin Traits on the Radial Permeability of the Hybrid Pine (Pinus elliottii x Pinus caribaea) Wood in Australia. BioResources 2020, 15, 6851–6873. [Google Scholar] [CrossRef]

- Malan, F. The wood quality of the South African timber resource for high-value solid wood products and its role in sustainable forestry. South Afr. For. J. 2003, 198, 53–62. [Google Scholar] [CrossRef]

- Adusumalli, R.-B.; Raghavan, R.; Ghisleni, R.; Zimmermann, T.; Michler, J. Deformation and failure mechanism of secondary cell wall in Spruce late wood. Appl. Phys. A Mater. Sci. Process. 2010, 100, 447–452. [Google Scholar] [CrossRef]

- Koch, P. Utilization of the Southern Pines—Volume 1; Agricultural Handbook SFES-AH-420; U.S. Dept. of Agriculture Forest Service, Southern Forest Experiment Station: Washington, DC, USA, 1972.

- Grabner, M.; Muller, U.; Gierlinger, N.; Wimmer, R. Effects of heartwood extractives on mechanical properties of larch. Int. Assoc. Wood Anatom. 2005, 26, 211–220. [Google Scholar] [CrossRef]

- Garcia-Iruela, A.; Esteban, L.G.; de Palacios, P.; Francisisco Garcia-Fernandez, A.d.M.T.; Iriarte, E.V.; Simon, C. Resinous wood of Pinus pinaster Ait.: Physico-mechanical properties. BioResources 2016, 11, 5230–5241. [Google Scholar] [CrossRef] [Green Version]

- Forest Products Laboratory. Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-190; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison WI, USA, 2010.

- Doyle, D.V.; Markwardt, L.J. Tension Parallel-to-Grain Properties of Southern Pine Dimension Lumber; U.S. Forest Service Research Paper FPL84; US Department of Agriculture Forest Service: Madison, WI, USA, 1967.

- Baño, V.; Arguelles-Bustillo, R.; Regueira, R.; Guaita, M. Determination of the stress-strain curve in specimens of Scots pine for numerical simulation of defect free beams. Mater. Constr. 2012, 62, 269–284. [Google Scholar] [CrossRef] [Green Version]

- AS/NZS 4063.1: 2010; Characterization of Structural Timber: Part 1: Test Methods. 2010. Retrieved from Standards On-line Premium database. Standards Australia: Sydney, Australia, 2010.

- ISO 13910; International Standard: Timber Structures—Strength Graded Timber—Test Methods for Structural Properties. International Organization for Standardization: Geneva, Switzerland, 2014.

- Harding, K. Review of Wood Quality Studies in Queensland and Northern New South Wales Exotic Pine Plantations: Report for PN06.3016 Resource Characterisation of Slash Pine Plantation Wood Quality; Forest and Wood Products Australia Limited: Melbourne, Australia, 2008. [Google Scholar]

- Moya, L.; Laguarda, M.; Cagno, M.; Cardoso, A.; Gatto, F.; O’Neill, H. Physical and Mechanical Properties of Loblolly and Slash Pine Wood from Uruguayan Plantations. For. Prod. J. 2013, 63, 128–137. [Google Scholar] [CrossRef]

- Kretschmann, D.E.; Bendtsen, B.A. Ultimiate tensile stress and modulus of elasticity of fast-grown plantation loblolly pine lumber. Wood Fiber Sci. 1992, 24, 189–203. [Google Scholar]

- Franke, S.; Quenneville, P. Compression behavior and material parameters of radiata pine at different orientations to the grain. J. Mater. Civ. Eng. 2013, 25, 1514–1523. [Google Scholar] [CrossRef]

- Bolza, E.; Kloot, N.H. The Mechanical Properties of 174 Australian Timbers; Commonwealth Scientific and Industrial Research Organization: Melbourne, Australia, 1963. [Google Scholar]

- Arganbright, D.G. Influence of extractives on bending strength of redwood (Sequoia sempervirens). Wood Fiber Sci. 1971, 2, 367–372. [Google Scholar]

- Luxford, R.F. Effect of extractives on the strength of wood. J. Agric. Res. 1931, 42, 801–826. [Google Scholar]

- Zhao, D.; Yu, H.; Bao, X.; Liu, J.; Yuan, H.; Wang, Y.; Xue, Z. Effects of removal of extractives on the chemical composition and mechanical properties of wood. Bioresources 2020, 15, 8631–8647. [Google Scholar] [CrossRef]

- Green, D.W. Wood: Strength and Stiffness, 2nd ed.; Elsevier Science Ltd.: Oxford, UK, 2001; pp. 9732–9736. [Google Scholar]

- Samson, M.; Blanchet, L. Effect of knots on the flatwise bending stiffness of lumber members. Eur. J. Wood Wood Prod. 1992, 50, 148–152. [Google Scholar] [CrossRef]

- As, N.; Goker, Y.; Dundar, T. Effect of knots on the physical and machanical properties of scots pine (Pinus sylvestris L.). Wood Res. 2006, 51, 51–58. [Google Scholar]

- Grant, D.J.; Anton, A.; Lind, P. Bending Strength, Stiffness, and Stress-grade of Structural Pinus Radiata. N. Z. J. For. Sci. 1984, 14, 331–348. [Google Scholar]

- Stringer, J.; Dakin, A.; Fernando, D. The use of flatwise structural properties in the design of timber-framed residential buildings. In Proceedings of the World Conference on Timber Engineering 2016, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Doyle, D.V.; Markwardt, L.J. Properties of Southern Pine in Relation to Strength Grading of Dimension Lumber; U.S. Department of Agriculture Forest Service and Forest Products Laboratory: Madison, WI, USA, 1966.

- Missanjo, E.; Matsumura, J. Wood density and mechanical properties of Pinus kesiya Royle ex Gordon in Malawi. Forests 2016, 7, 135–145. [Google Scholar] [CrossRef] [Green Version]

- Benabou, L. Kink band formation in wood species under compressive loading. Exp. Mech. 2008, 48, 647–656. [Google Scholar] [CrossRef]

- Dinwoodie, J.M. Timber: Its Nature and Behaviour, 2nd ed.; Taylor & Francis: New York, NY, USA, 2002. [Google Scholar]

- Shim, K.-B.; Kim, K.-M.; Park, J.-S. Improvement of prediction accuracy of glulam modulus of elasticity by considering neutral axis shift in bending. Wood Fiber Sci. 2009, 41, 90–96. [Google Scholar]

- Conners, T.E.; Medvecz, P.J. Wood as a bimodular material. Wood Fiber Sci. 1992, 24, 413–423. [Google Scholar]

- Hakkila, P. Utilization of Residual Forest Biomass; Springer: Berlin/Heigelberg, Germany, 2012. [Google Scholar]

- Ajuong, E.-M.A.; Breese, M.C. Role of extractives on short-term creep in compression parallel to the grain of pai wood. Wood Fiber Sci. 1997, 29, 161–170. [Google Scholar]

- Hernandez, R.E. Influence of accessory substances, wood density and interlocking grain on the compressive properties of hardwoods. Wood Sci. Technol. 2007, 41, 249–265. [Google Scholar] [CrossRef]

- Gagnon, S.; Popovski, M. Chapter 3: Structural design of cross-laminated timber elements. In FPInnovations CLT Handbook; FPInnovations and Binational Softwood Lumber Council: Quebec, QC, Canada, 2011. [Google Scholar]

- Porteous, J.; Kermani, A. Structural Timber Design to Eurocode 5; Blackwell Publishing Ltd.: Oxford, UK, 2007. [Google Scholar]

- Franke, S.; Quenneville, P. Compression strength perpendicular to the grain of New Zealand Radiata Pine lumber. Aust. J. Struct. Eng. 2010, 12, 23–34. [Google Scholar]

- Basta, C.; Gupta, R.; Leichti, R.; Sinha, A. Applications of perpendicular-to-grain compression behaviour in real wood construction assemblies. Wood Fiber Sci. 2012, 44, 155–167. [Google Scholar]

- Ando, K.; Onda, H. Mechanism for deformation of wood as a honeycomb structure I: Effect of anatomy on the initial deformation process during redial compression. J. Wood Sci. 1999, 45, 120–126. [Google Scholar] [CrossRef]

- Ido, H.; Nagao, H.; Kato, H.; Miyatake, A.; Hiramatsu, Y. Strength properties of laminated veneer lumber in compression perpendicular to its grain. J. Wood Sci. 2010, 56, 422–428. [Google Scholar] [CrossRef]

- Kijidani, Y.; Morita, H.; Aratake, S.; Tsuyama, T.; Arima, T. Partial compression strength of sugi (Japanese cedar, Cryptomeria japonica) wood near the pith perpendicular to the grain. J. Wood Sci. 2019, 65, 16. [Google Scholar] [CrossRef]

- Li, M.; Zhang, S.; Wang, Y.; Ren, H. Effect of Microstructures on the Shear Strength of Larix kaempferi. Forests 2021, 12, 830. [Google Scholar] [CrossRef]

- Bodner, J.; Schlag, M.G.; Grull, G. Fracture Initiation and Progress in Wood Specimens Stressed in Tension. Part III. Clear Wood Specimens with Various Slopes of Grain. Holzforsch. Int. J. Biol. Chem. Phys. Technol. Wood 1998, 52, 95–101. [Google Scholar] [CrossRef]

- Xavier, J.; Avril, S.; Pierron, F.; Morais, J. Variation of transverse and shear stiffness properties of wood in a tree. Compos. Part A 2009, 40, 1953–1960. [Google Scholar] [CrossRef]

- Muller, U.; Sretenovic, A.; Gindl, W.; Teischinger, A. Longitudinal shear properties of European larch wood related to cell-wall structure. Wood Fiber Sci. 2004, 36, 143–151. [Google Scholar]

- Keunecke, D.; Songeregger, W.; Pereteanu, K.; Luthi, T.; Niemz, P. Determiniation of Young’s and shear moduli of common yew and Norway spruce by means of ultrasonic waves. Wood Sci. Technol. 2007, 41, 309–327. [Google Scholar] [CrossRef] [Green Version]

- Laveielle, L.; Gibier, O.; Stringer, G. A shear strength assessment of resin shakes in Australian grown slash pine. In Proceedings of the 25th Forests Products Research Conference, Victoria, Australia, 18–21 November 1996; Volume 1. [Google Scholar]

- Chui, Y.H. Simultaneous evaluation of bending and shear moduli of wood and the influence of knots on these parameters. Wood Sci. Technol. 1991, 25, 125–134. [Google Scholar] [CrossRef]

- Gupta, R.; Basta, C.; Kent, S.M. Effect of knots on longitudinal shear strength of Douglas-fir using shear blocks. For. Prod. J. 2004, 54, 77–83. [Google Scholar]

- Rajput, S.S.; Gupta, V.K.; Lohani, R.C. A study of effect of knot on the strength of timber. J. Indian Acad. Wood Sci. 1980, 11, 8–15. [Google Scholar]

- Cao, Y.; Street, J.; Mitchell, B.; To, F.; DuBien, J.; Seale, R.D.; Shmulsky, R. Effect of Knots on Horizontal Shear Strength in Southern Yellow Pine. Bioresources 2018, 13, 4509–4520. [Google Scholar] [CrossRef] [Green Version]

- Galicki, J.; Czech, M. Tensile strength of softwood in LR orthotropy plane. Mech. Mater. 2005, 37, 677–686. [Google Scholar] [CrossRef]

- Mitsuhashi, K.; Poussa, M.; Puttonen, J. Method for predicting tension capacity of sawn timber considering slope of grain around knots. J. Wood Sci. 2008, 54, 189–195. [Google Scholar] [CrossRef]

- Nagai, H.; Murata, K.; Nakano, T. Strain analysis of lumber containing a knot during tensile failure. J. Wood Sci. 2011, 57, 114–118. [Google Scholar] [CrossRef]

- Moody, R.C. Ultimate Tensile Stress of Finger Joints in Pith-Associated and Nonpith-Associated Southern Pine Lumber; Research paper FPL 138; U.S. Department of Agriculture Forest Service and Forest Products Laboratory: Madison, WI, USA, 1970.

- Krauss, A.; Moliński, W.; Kúdela, J.; Čunderlík, I. Differences in the mechanical properties of early and latewood within individual annual rings in dominant pine tree (Pinus sylvestris L.). Wood Res. 2011, 56, 1–12. [Google Scholar]

- Mackes, K.; Shepperd, W. Evaluating the bending properties of clear wood specimens produced from small-diameter ponderosa pine trees. For. Prod. J. 2005, 55, 72–80. [Google Scholar]

| Test Type | ||||||

|---|---|---|---|---|---|---|

| Bending | CParG | CPerpG | Shear | Tension | Total | |

| Sample Length | 700 mm | 140 mm | 210 mm | 200 mm | 1800 mm | |

| Clear | 35 (11) | 35 (10) | 35 (12) | 30 (14) | 35 (20) | 170 (67) |

| Resin | 35 (9) | 35 (18) | 35 (15) | 30 (14) | 35 (20) | 170 (76) |

| Knots | 35 (11) | 35 (14) | 35 (14) | 30 (16) | 35 (22) | 170 (77) |

| Total | 105 (31) | 105 (42) | 105 (41) | 90 (44) | 105 (62) | 510 (220) |

| Type | Average MOE (GPa) | MOE (5th %ile) | Average Strength (Mpa) | Strength (5th %ile) | Average Density (kg/m3) | Average Moisture Content (%) |

|---|---|---|---|---|---|---|

| Bending | ||||||

| Clear | 6.90 (1.53) | 4.16 | 45.8 (9.1) | 35.2 | 510 (50) | 13.1 (1.8) |

| Pith | 6.01 (1.27) | 4.24 | 40.8 (3.9) | 36.3 | 509 (60) | 12.6 (1.9) |

| No Pith | 7.31 (1.49) | 4.30 | 48.2 (9.8) | 34.0 | 510 (46) | 13.4 (1.8) |

| Resin | 6.94 (1.08) | 5.16 | 45.7 (8.4) | 32.4 | 701 (83) | 13.3 (1.8) |

| Pith | 6.14 (0.90) | 4.73 | 40.8 (8.1) | 31.6 | 711 (83) | 13.9 (2.0) |

| No Pith | 7.22 (1.01) | 5.43 | 47.3 (8.0) | 34.5 | 697 (84) | 13.1 (1.7) |

| Knots | 5.37 (1.03) | 3.90 | 26.7 (8.4) | 12.6 | 661 (113) | 12.8 (2.1) |

| Pith | 5.51 (1.12) | 4.04 | 27.1 (7.6) | 13.5 | 728 (114) | 11.4 (2.1) |

| No Pith | 5.29 (1.00) | 4.01 | 26.6 (8.8) | 11.8 | 630 (100) | 13.5 (1.8) |

| CParG | ||||||

| Clear | 5.78 (1.67) | 3.56 | 29.4 (5.7) | 21.1 | 490 (42) | 12.4 (1.7) |

| Pith | 5.33 (1.64) | 3.56 | 29.63 (5.96) | 22.93 | 503 (48) | 11.2 (1.1) |

| No Pith | 5.97 (1.67) | 3.71 | 29.32 (5.66) | 20.49 | 485 (39) | 12.8 (1.6) |

| Resin | 6.37 (1.58) | 4.30 | 30.5 (5.1) | 25.1 | 753 (94) | 12.1 (1.4) |

| Pith | 6.24 (0.88) | 4.71 | 30.4 (4.2) | 25.3 | 768 (94) | 11.8 (1.4) |

| No Pith | 6.66 (2.07) | 4.30 | 30.5 (6.2) | 24.6 | 730 (91) | 12.3 (1.5) |

| Knots | 5.04 (1.04) | 3.38 | 26.0 (4.6) | 19.4 | 746 (117) | 11.6 (1.7) |

| Pith | 4.89 (0.73) | 3.79 | 25.7 (2.7) | 21.9 | 771 (115) | 10.7 (1.7) |

| No Pith | 5.07 (1.21) | 3.50 | 26.3 (5.4) | 15.4 | 734 (118) | 12.3 (1.4) |

| CPerpG | ||||||

| Clear | 0.27 (0.06) | 0.18 | 6.7 (1.7) | 4.5 | 494 (30) | 11.9 (1.6) |

| Pith | 0.29 (0.06) | 0.21 | 7.61 (1.6) | 5.3 | 498 (32) | 10.7 (1.3) |

| No Pith | 0.26 (0.06) | 0.17 | 6.28 (1.6) | 4.6 | 491 (29) | 12.6 (1.3) |

| Resin | 0.31 (0.07) | 0.19 | 7.8 (1.6) | 5.5 | 710 (89) | 11.3 (1.5) |

| Pith | 0.29 (0.09) | 0.16 | 8.1 (2.1) | 5.1 | 764 (96) | 11.2 (1.6) |

| No Pith | 0.32 (0.06) | 0.24 | 7.6 (1.0) | 6.4 | 668 (57) | 11.3 (1.5) |

| Knots | 0.42 (0.11) | 0.27 | 13.1 (3.4) | 9.5 | 718 (116) | 11.7 (1.8) |

| Pith | 0.35 (0.07) | 0.26 | 12.3 (2.5) | 9.5 | 758 (104) | 11.7 (2.1) |

| No Pith | 0.46 (0.11) | 0.29 | 13.7 (3.9) | 10.0 | 690 (117) | 11.7 (1.6) |

| Shear | ||||||

| Clear | 0.59 (0.06) | 0.51 | 5.7 (0.5) | 5.1 | 499 (23) | 12.9 (1.3) |

| Pith | 0.58 (0.05) | 0.51 | 5.6 (0.4) | 5.1 | 499 (25) | 12.7 (1.4) |

| No Pith | 0.60 (0.06) | 0.52 | 5.9 (0.5) | 5.1 | 499 (22) | 13.0 (1.3) |

| Resin | 0.58 (0.06) | 0.49 | 5.6 (0.8) | 4.3 | 750 (86) | 13.0 (1.0) |

| Pith | 0.58 (0.06) | 0.50 | 5.6 (1.0) | 4.2 | 758 (92) | 13.0 (1.0) |

| No Pith | 0.57 (0.06) | 0.50 | 5.6 (0.8) | 4.3 | 742 (83) | 13.0 (1.0) |

| Knots | 0.54 (0.09) | 0.41 | 5.2 (0.8) | 3.7 | 720 (78) | 12.6 (1.3) |

| Pith | 0.53 (0.09) | 0.43 | 5.1 (0.9) | 3.7 | 741 (61) | 12.7 (1.3) |

| No Pith | 0.55 (0.09) | 0.40 | 5.3 (0.8) | 4.1 | 696 (89) | 12.6 (1.5) |

| Tension | ||||||

| Clear | 32.4 (2.7) | 28.1 | 528 (54) | 11.9 (1.6) | ||

| Pith | 32.1 (2.6) | 28.5 | 549 (39) | 11.4 (1.8) | ||

| No Pith | 32.7 (3.0) | 29.3 | 511 (62) | 12.4 (1.4) | ||

| Resin | 32.6 (3.8) | 28.6 | 720 (66) | 11.9 (1.2) | ||

| Pith | 33.1 (4.7) | 28.7 | 724 (50) | 11.8 (1.4) | ||

| No Pith | 31.9 (2.4) | 29.4 | 715 (93) | 12.1 (1.1) | ||

| Knots | 15.7 (4.1) | 10.1 | 635 (95) | 12.1 (1.6) | ||

| Pith | 15.4 (4.3) | 9.5 | 636 (95) | 12.1 (1.6) | ||

| No Pith | 16.4 (3.7) | 11.6 | 634 (98) | 12.1 (1.6) | ||

| Bending MOE Eb (Gpa) | CParG MOE EC,0 (Gpa) | CPerpG MOE Ec,90 (Gpa) | Shear Modulus G0 (Gpa) | Bending Strength fb (Mpa) | CParG Strength fc,0 (Mpa) | CPerpG Strength fc,90 (Mpa) | Shear Strength fv,0 (Mpa) | Tensile Strength ft,0 (Mpa) | Density (kg/m3) | Comment | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. This Study—PEE × PCH | |||||||||||

| Clear | 6.90 | 5.78 (0.8377) | 0.274 (0.0397) | 0.590 (0.0855) | 45.8 (0.0066) | 29.4 (0.0043) | 6.7 (0.0010) | 5.7 (0.0008) | 32.4 (0.0047) | 498 (0.0722) | |

| Resin | 6.94 | 6.37 (0.9232) | 0.307 (0.0445) | 0.580 (0.0841) | 45.7 (0.0066) | 30.5 (0.0044) | 7.8 (0.0011) | 5.6 (0.0008) | 32.6 (0.0047) | 721 (0.1045) | |

| Knots | 5.37 | 5.04 (0.9385) | 0.422 (0.0786) | 0.535 (0.0996) | 26.7 (0.0050) | 26.0 (0.0048) | 13.1 (0.0024) | 5.2 (0.0010) | 15.7 (0.0029) | 708 (0.1320) | |

| 2. Other studies—PEE × PCH Hybrid | |||||||||||

| Bragg, 1990 [41] | 8.17 | 33.10 (0.0041) | 497.00 (0.0609) | 19 years—70 × 35 mm | |||||||

| Harding et al., 2008 [41] | 7.26 | 42.36 (0.0058) | 6.8 years—70 × 35 mm | ||||||||

| Nel et al., 2017 [2] | 5.65 | 30.00 (0.0053) | 479.00 (0.0847) | 15 to 19 years—38 × 152 mm | |||||||

| Wessels, Dowse, and Smit, 2011 [27] | 4.04 | 13.4 5th %ile | 386.50 (0.0958) | 10 years 35 × 110 mm | |||||||

| 3. Other similar pines—similar timber characteristics | |||||||||||

| Slash and Loblolly Moya et al., 2013 [42] | 7.20 | 62.40 (0.0087) | 33.70 (0.0047) | 9.70 (0.0013) | 9.00 (0.0013) | 477.00 (0.0663) | 25 years old | ||||

| Slash and Loblolly Moya et al., 2013 [42] | 4.95 | 44.50 (0.0090) | 24.60 (0.0050) | 7.10 (0.0014) | 7.60 (0.0015) | 393.00 (0.0793) | 15 years old | ||||

| Loblolly Kretschmann and Bendtsen, 1992 [43] | 6.15 | 18.90 (0.0031) | Juvenile wood | ||||||||

| Southern Yellow Pines Doyle and Markwardt, 1967 [37] | 9.83 | 10.18 (1.0356) | 0.920 (0.0939) | 39.00 (0.0040) | 28.68 (0.0029) | 11.90 (0.0012) | 9.17 (0.0009) | 520.00 (0.0529) | 50 × 100 mm Grade 3 | ||

| Radiata Franke and Quenneville, 2013 [44] | 8.00 | 0.52 (0.0644) | 9.90 (0.0012) | 496.00 (0.0620) | MSG8 Grade | ||||||

| 4. Other similar pines—average values for species population | |||||||||||

| Caribbea Forest Products Laboratory, 2010 [36] | 15.40 | 115.10 (0.0075) | 58.90 (0.0038) | 14.40 (0.0009) | 680.00 (0.0442) | average population | |||||

| Slash Bolza and Kloot, 1963 [45] | 9.45 | 11.79 (1.2481) | 75.15 (0.0080) | 41.58 (0.0044) | 10.10 (0.0011) | 9.79 (0.0010) | 506.00 (0.0536) | average population | |||

| Slash Forest Products Laboratory, 2010 [36] | 13.70 | 0.82 (0.0595) | (1.19) | 112.00 (0.0082) | 56.00 (0.0041) | 7.00 (0.0005) | 11.60 (0.0008) | 590.00 (0.0431) | average population | ||

| Loblolly Forest Products Laboratory, 2010 [36] | 12.30 | 1.17 (0.0955) | (0.81) | 88.00 (0.0072) | 49.20 (0.0040) | 5.40 (0.0004) | 80.00 (0.0065) | 510.00 (0.0415) | average population | ||

| Loblolly Bolza and Kloot, 1963 [45] | 7.24 | 8.48 (1.1716) | 64.60 (0.0089) | 35.70 (0.0049) | 8.68 (0.0012) | 9.48 (0.0013) | 482.00 (0.0666) | average population | |||

| Radiata Bolza and Kloot, 1963 [45] | 10.20 | 11.38 (1.1149) | 80.70 (0.0079) | 41.92 (0.0041) | 9.93 (0.0010) | 11.03 (0.0011) | 525.00 (0.0515) | average population | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cherry, R.; Karunasena, W.; Manalo, A. Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith. Forests 2022, 13, 927. https://doi.org/10.3390/f13060927

Cherry R, Karunasena W, Manalo A. Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith. Forests. 2022; 13(6):927. https://doi.org/10.3390/f13060927

Chicago/Turabian StyleCherry, Rebecca, Warna Karunasena, and Allan Manalo. 2022. "Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith" Forests 13, no. 6: 927. https://doi.org/10.3390/f13060927

APA StyleCherry, R., Karunasena, W., & Manalo, A. (2022). Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith. Forests, 13(6), 927. https://doi.org/10.3390/f13060927