Abstract

Drilling is one of the oldest and most important methods of processing wood and wood-based materials. Knowing the optimum value of factors that affect the drilling process could lead both to high-quality furniture and low-energy consumption during the manufacturing process. In this work, the artificial neural network modeling technique and response surface methodology were employed to reveal the optimum value of selected factors, namely, drill tip angle, tooth bite, and drill type of the delamination factor at the inlet and outlet, thrust force, and drilling torque. The data set that was used in this work to develop and validate the ANN models was collected from the literature. The results showed that the developed ANN models could reasonably predict the analyzed responses. By using these models and the response surface methodology, the optimum values of analyzed factors were revealed. Moreover, the influences of selected factors on the drilling process of wood particleboards were analyzed.

1. Introduction

Drilling is one of the oldest and most important methods of processing wood and wood-based materials. One of the most widespread wood-based materials is particleboards (PB), widely used nowadays in the production of storage furniture (e.g., kitchen furniture). For the manufacture of this type of furniture, PB (usually pre-laminated) is joined with dowels inserted into holes, which are made by drilling, in addition to other holes made for other purposes (holes for locks, for various accessories, for shelf supports, etc.). This can lead to a dozen holes (made by drilling), and sometimes over one hundred. For example, the IKEA BILLY bookcase (which is not a complex piece of furniture) requires 192 holes.

Given the importance of this processing method, research work has been carried out over time to study it. Hetzel’s research focused on the PB (and plywood) drill [1]. The investigations aimed to determine the influences of the adhesive on the durability of the cutting edges, the influences of the type of drill, its diameter, and the geometry of the edge on the torque and feed speed (the feed force being kept constant), as well as how the chips are formed in relation to the torque and the feed rate. Radu conducted an extensive study on the geometry of helical drills used in woodworking, the kinematics, and the dynamics of the cutting process [2]. The experiments aimed to establish the optimal parameters of drills for wood and PB, taking into account the torques, axial forces, and chip evacuation depending on: the type of drill, wood species (oak, beech, spruce, PB), feed rate, and drill depth. The results showed that the torque and the specific cutting resistance decrease, and the axial force increases, with increasing tip angle, for all four processed materials, regardless of the feed direction.

Valarmathi et al., assuming that the thrust force developed during drilling has a major role in gaining a good surface quality and minimizing the delamination tendency, analyzed the cutting conditions, which influence the thrust force in the drilling of PB [3]. The parameters considered were spindle speed, feed rate, and point angle. The drilling experiments were performed based on Taguchi’s design of experiments and a response surface methodology (RSM). A mathematical model was developed to predict the influence of cutting parameters on thrust force. The results showed that high spindle speed with a low feed rate combination minimizes the thrust force in the drilling of pre-laminated PB. Lilly Mercy et al. proposed a multi-response optimization of drilling parameters for PB processing using Gray Relational Analysis [4]. The aim was to minimize the roughness of the hole’s internal surface and the thrust force. The parameters considered were the drill rotation speed, the feed rate, and the drill diameter. The authors noted that a smaller feed speed, smaller drill diameter, and higher drill rotation speed are essential for reducing the thrust force and surface roughness in the drilling of PB.

Ispas et al. studied the influence of the tip angle of drills and feed rate on coated PB delamination, but also on the dynamic parameters (thrust force and torque) for two types of drills: flat and helical [5,6,7]. The results showed that the thrust force, the torque, and the surface delamination increased with an increase in the feed rate. An increase in the drill tip angle caused a decrease in the torque trend, which correlated well with a decrease in surface quality (delamination). As far as the thrust force was concerned, a decrease in the drill tip angle caused a decrease in the thrust force, well correlated with the surface quality around the hole.

Podziewski et al. studied the drilling machinability of several wood-based materials, including PB [8]. The machinability was expressed by the quality of the hole’s edges and the magnitude of the cutting forces and torque. Madhan Kumar and Jayakumar studied PB drilling with helical and spade drills [9]. Experiments have shown that the roughness of the hole’s internal surface has decreased as the rotational speed of the drills has increased and the feed speed has decreased.

An extensive review of scientific developments in the drilling of wood-based panels is presented in the work elaborated by Górski [10].

Stimulated by the successful application of artificial neural networks (ANNs) and response surface methodology (RSM) in the wood science area and, also, due to the fact that there is limited information regarding the application of ANN and RSM in the drilling of wood particleboards, in this paper, we aimed to apply the ANN together with RSM to reveal the optimum value of input factors (drill tip angle, tooth bite, and drill type) based on the desired responses during the drilling of PB, such as the delamination factor at the inlet and outlet, thrust force, and drilling torque.

ANN and RSM have been applied in wood science for various topics such as predicting the wood moisture content, prediction of noise emission in the machining of wood materials by means of an artificial neural network, optimum CNC cutting condition, reliability of phytosanitary treatment of wood [11,12,13,14,15]. More information about the modeling process with artificial neural networks could be found in the literature [12,16]. Moreover, the RSM has been applied to optimize the heat-treated wood dowel joints, processing parameters of medium-density of fiberboards, wood drying conditions, and energy consumption during the mechanical processing of wood [17,18,19,20]. Moreover, more details about the RSM could be found in the literature [21,22].

2. Materials and Methods

2.1. Data Colectting

The data necessary for the development and validation of the model were taken from the literature [5,6,7]. The experiments aimed to identify the influences of the drill tip angle and the drilling feed rate on the quality of drilling of laminated PB and on the dynamic parameters of the drilling (thrust force and torque). Two types of drills were used, flat and helical, respectively, with tip angles of 30°, 60°, 90°, and 120°. The feed rates used were 0.6, 1.8, 3.0, and 4.2 m/min. The rotational speed of drills had a single value, 3000 rpm as a result being four tooth bite: 0.1, 0.3, 0.5, and 0.7 mm. The drilling quality was expressed by the delamination factor for both the inlet and outlet of the drill, according to the methodology described in Ispas et al. [5,6]. To sum up, the delamination factor (Fd) was calculated with Equation (1), where Dmax is the diameter of the circle circumscribed to the defect, while D is the mean hole diameter given by caliper measurements [6]. The dynamic parameters, the thrust force, and the drilling torque were determined based on the methodology described in Ispas et al. and Ispas and Răcășan [5,7]. A total of 320 experiments were performed.

2.2. ANN Model Development

In this work, the selected input factors were drill point angle (X1), tooth bite (X2), and drill type (X3). The responses were the delamination factor at the outlet (Y1) and inlet (Y2), thrust force (Y3), and drilling torque (Y4). The analyzed values of the input factors are presented in Table 1.

Table 1.

The values of analyzed input factors.

During the development phase of the ANN model, 70% of available data were used for the training and testing phase. The other part (30%) was used to validate the ANN model. The experimental values were split in each subset of data by means of a randomized approach.

The NeuralWorks Predict Software (NeuralWare Inc., v.3.24.1, Carnegie, PA, USA) was employed to develop de ANN models. This software uses the cascade correlation algorithm to create the multilayer structure of ANN. More information about the software used in this work could be found in the literature [23]. The performance of developed ANN models was measured by correlation coefficient (R) and coefficient of determination (R2), according to Equations (2) and (3) [23,24,25]. A high R or R2 indicated that predicted data are close to the experimental data that were used for the validation phase. Moreover, the predicted values were plotted against experimental data to visually check how well the neural network models performed with the unseen data set.

where N is the number of data points, ai is the experimental value of the analyzed response, pi is the predicted value of the analyzed response, is the mean of the experimental values, and is the mean of the predicted values.

To find the optimal values of selected factors the Response Surface Methodology was used together with the development of ANN models. The optimization criterion aimed to minimize all the analyzed responses (Y1, Y2, Y3, and Y4). The statistical package Design-Expert® (version 9, Stat-Ease Inc., Minneapolis, MN, USA) was used to generate a central composite experimental design that is required by the Response Surface Methodology. The approach used to construct the applied experimental design is detailed in the work performed by Georgescu et al. [18]. The corresponding levels of analyzed factors and the resulted combinations among the level of factors are presented in Table 2 and Table 3. In the experimental design (Table 3) the value of analyzed responses were revealed by means of developed ANN models.

Table 2.

The values of analyzed input factors.

Table 3.

Combinations among selected factors and the value of analyzed responses.

3. Results and Discussion

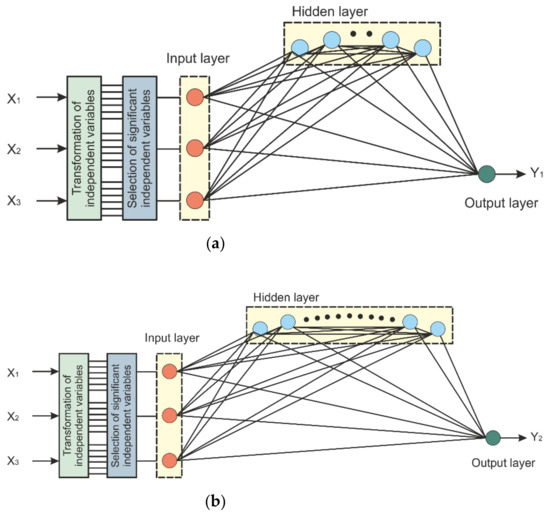

3.1. ANN Models

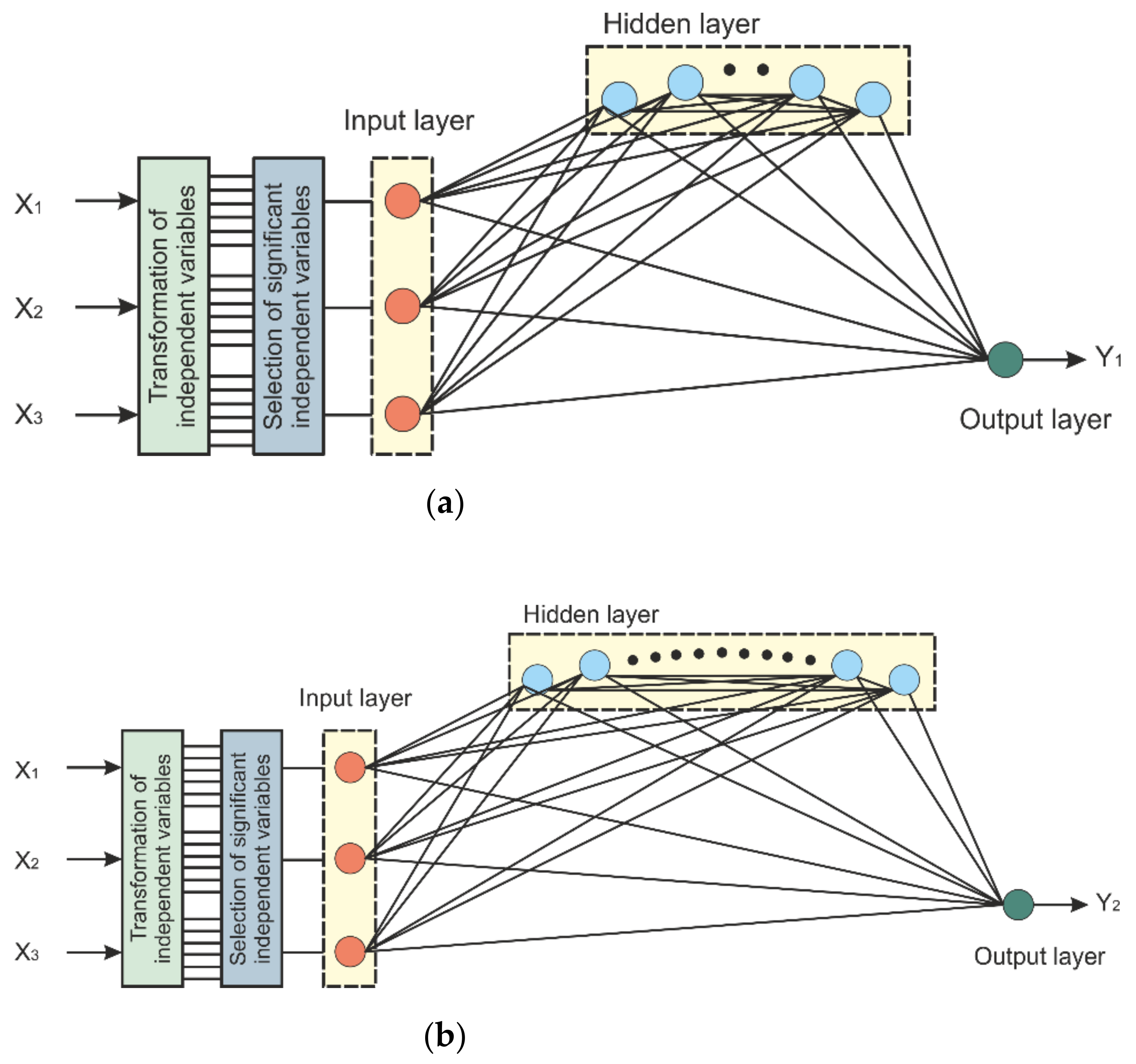

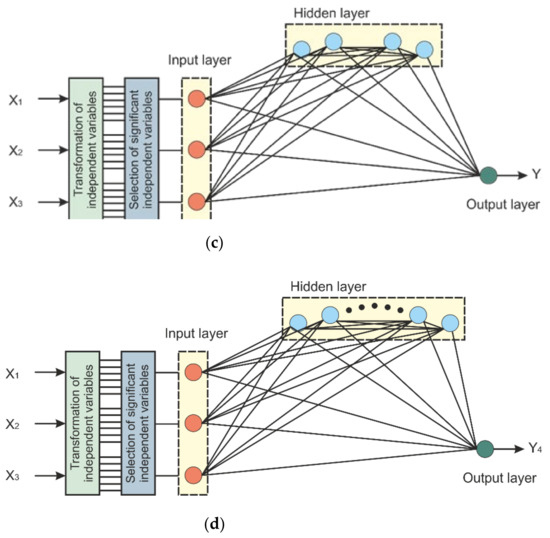

The optimum structure of developed ANN models is presented in Figure 1. The number of neurons in the input, hidden and output layers and the performance indicators are presented in Table 4. One could observe that the developed ANN models could reasonably predict the delamination factor at the outlet (0.98–2.14) and the inlet (1–1.51), thrust force (12–274 N), and drilling torque (0.12–1.55 Nm) based on drill point angle (30–120°), tooth bite (0.1–0.7 mm) and drill type (Flat or Helical). The coefficient of correlation (R) during the validation phase ranged between 0.67 and 0.98, and the coefficient of determination (R2) was between 0.44 and 0.97. By comparing the obtained value of the coefficient of determination (R2) with the values that are reported in previous studies, regarding the application of ANN in the wood science, one may observe that the lower R2 value (0.44) is close to the lower value (0.43) that was obtained by Mansfield et al. to predict the modulus of rupture (MOR) in western hemlock [26]. Moreover, the higher value of R2 (0.97) is close to 0.99, which was reported by Tiryaki et al. when the ANN was applied to reveal the power consumption during wood processing [20]. Therefore, it could be concluded that the developed networks could explain at least 44% of the experimental values in the case of the model to predict the delamination factor at the inlet and a least 97% of the experimental values in the case of the model to predict the drilling torque.

Figure 1.

The optimum structure of developed cascade ANN models that could predict the: (a) delamination factor at the outlet; (b) delamination factor at the inlet; (c) thrust force; (d) drilling torque.

Table 4.

The structure of ANN models and the performance criteria during the development and validation phase.

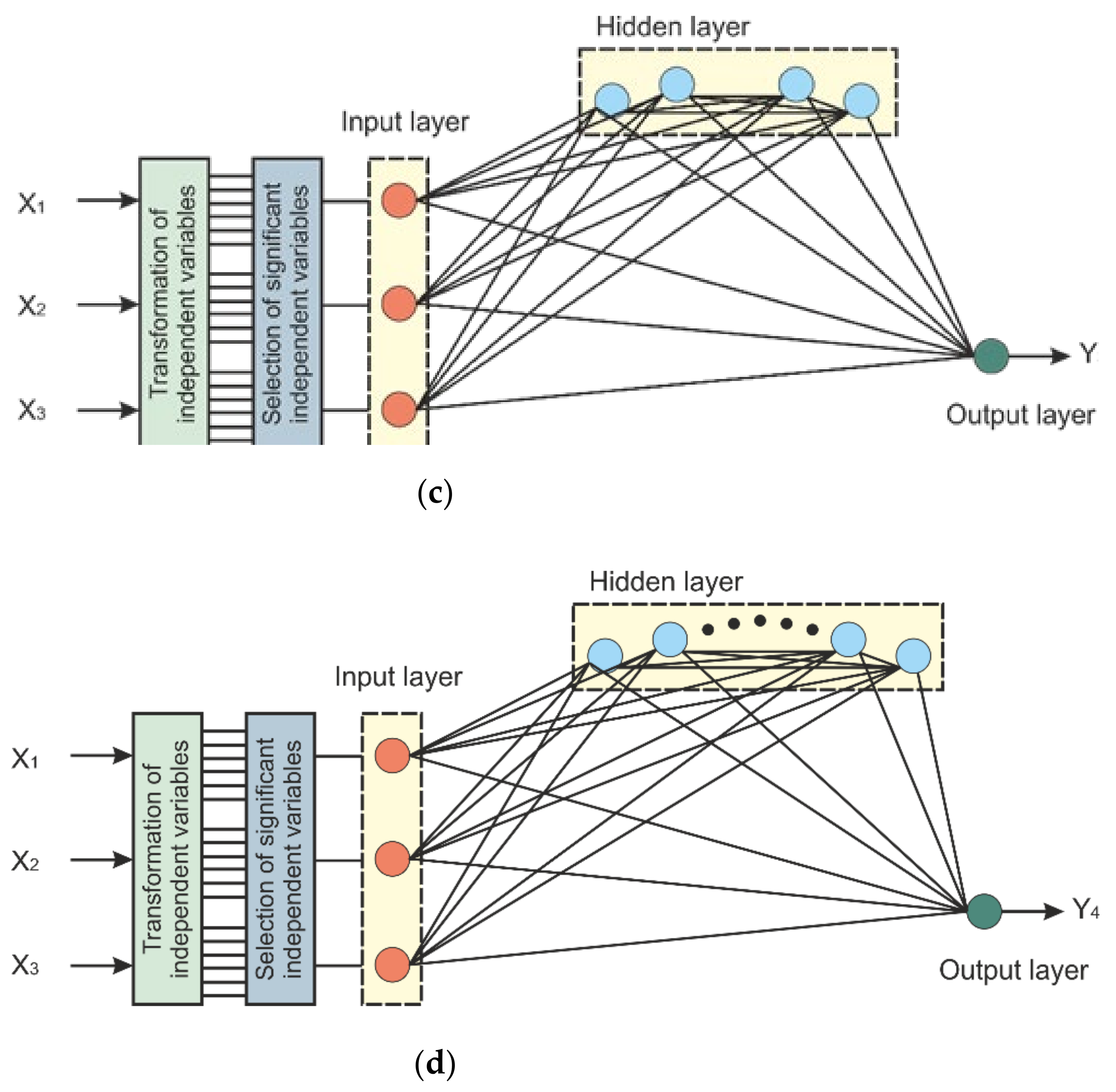

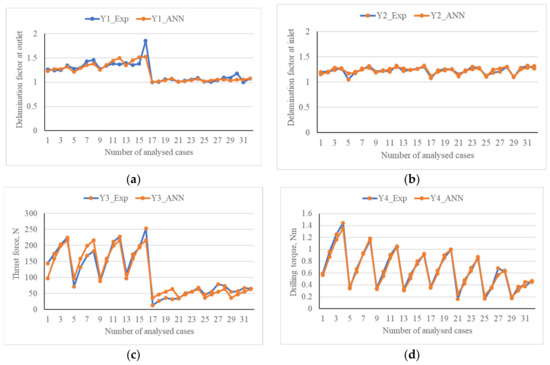

A comparison between the predicted and experimental values of the analyzed responses is presented in Figure 2. Once the graphics are analyzed, it can be observed that most of the predicted values are close to the experimental ones.

Figure 2.

Comparison between predicted vs. experimental values: (a) delamination factor at the outlet; (b) delamination factor at the inlet; (c) thrust force; (d) drilling torque.

To increase the accuracy of the developed model to predict delamination factor at the inlet, other variables should be taken into account in a further study.

3.2. RSM Results

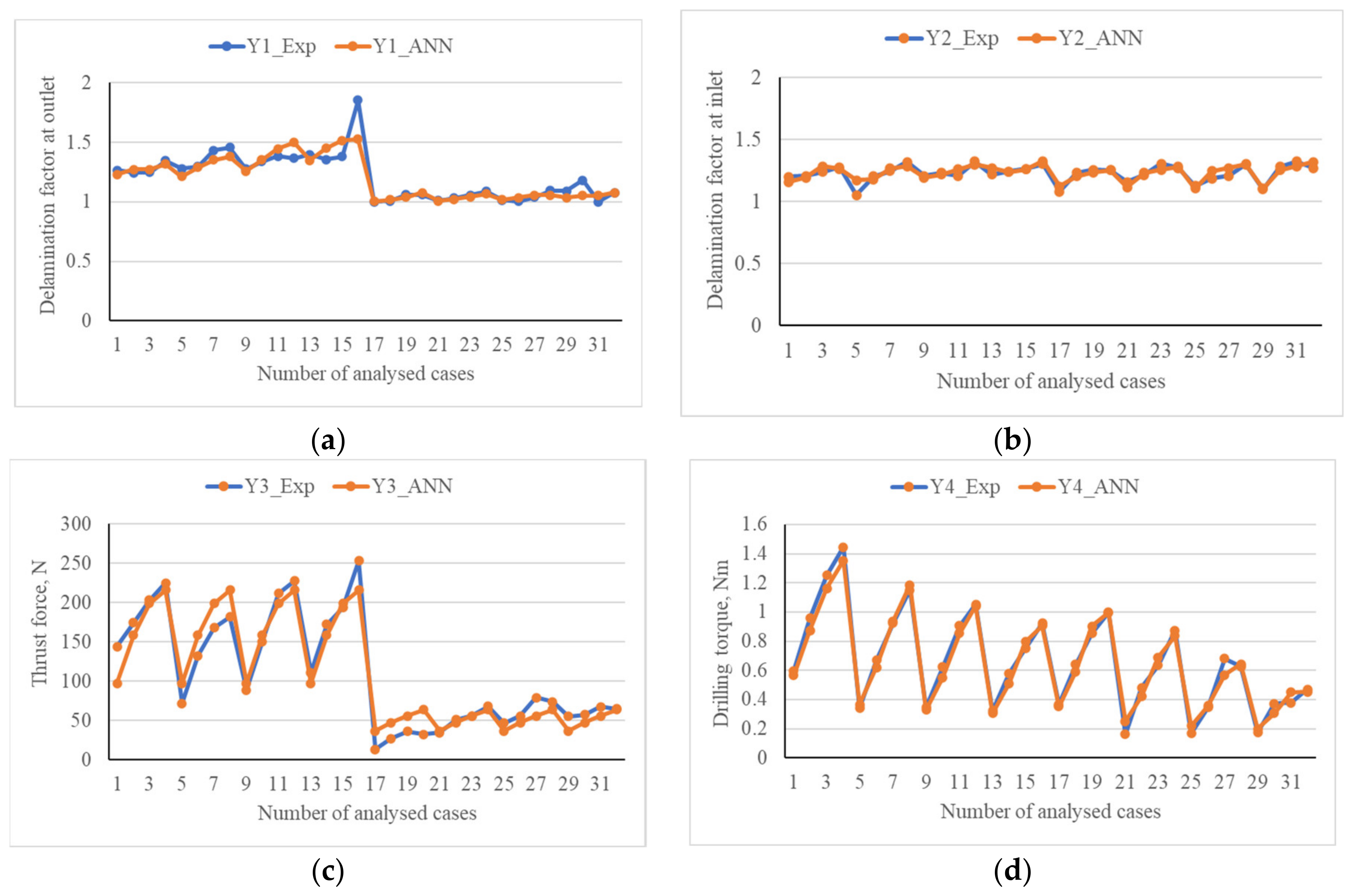

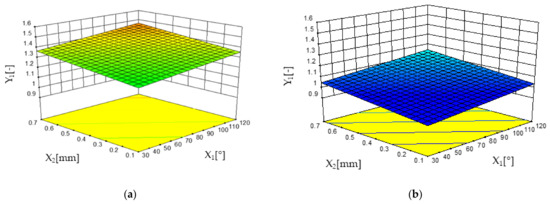

3.2.1. Delamination Factor at the Outlet (Y1)

A linear model was suggested via the Design Expert software, to describe the relationships among the selected factors and the delamination factor at the outlet (Y1). The model is significant at 1% level and its coded form is presented in Equation (4). Based on the value of coefficients, one could observe that drill type (flat or helical) has a bigger influence than the other two input variables, namely, drill tip angle (X1) and tooth bite (X2), which have almost the same influence, on the delamination factor on outlet.

In Equations (5) and (6), the models that could be used to predict the data (in the cases of a flat or a helical drill) are presented.

According to ANOVA results (Table 5), all main factors are statically significant at the 5% level.

Table 5.

Analysis of variance results for the regression equation in the case of the delamination factor at the outlet.

The interaction effects of the drill tip angle (X1) and tooth bite (X2) on the delamination factor at the outlet are shown in Figure 3.

Figure 3.

The 3D plots showing interaction effects of the drill tip angle (X1) and tooth bite (X2) on the delamination factor at the outlet (Y1) when the holes were ‘performed’ with a flat drill (a) and with a helical drill (b).

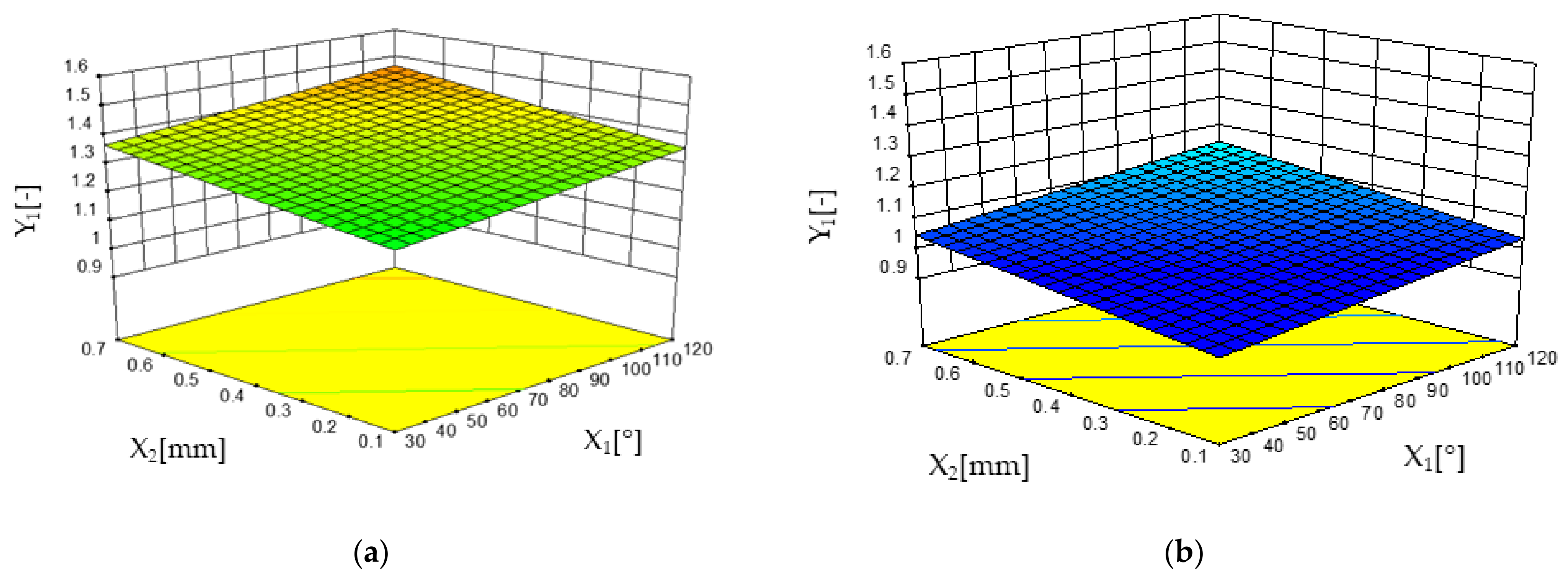

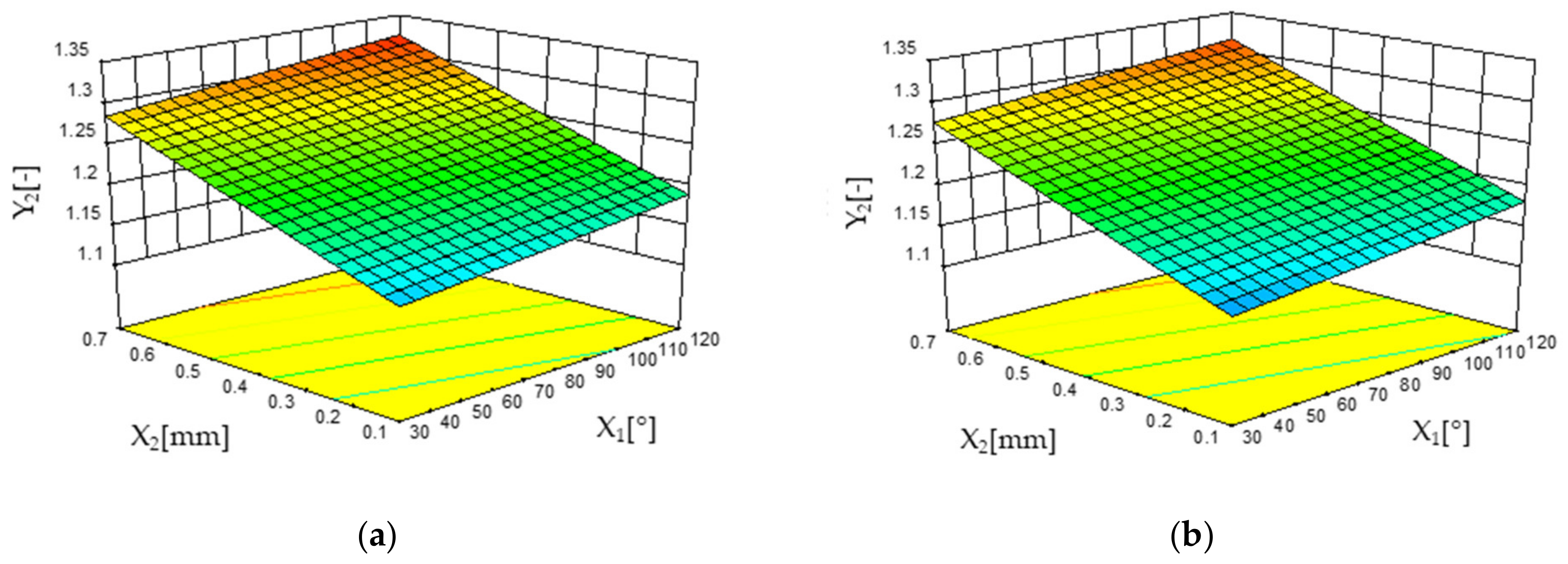

3.2.2. Delamination Factor at the Inlet (Y2)

The same as in the case of the delamination factor at the outlet, the Design Expert software suggested a linear model to predict the relationships among the analyzed inputs and the delamination factor at the inlet (Y2). Its coded and actual forms are presented in Equations (7)–(9). The delamination factor at the inlet is more affected by the tooth bite (X2), followed by drill tip angle (X1) and drill type (X3). Contrary to the delamination factor at the outlet, which was mostly affected by the drill type, the delamination factor at the inlet is mostly affected by the tooth bite.

According to ANOVA results (Table 6), the developed model is statically significant at 1% level. Moreover, one could observe that only the tooth bite is a significant model term.

Table 6.

Analysis of variance results in the case of a regression equation that was developed for the delamination factor at the inlet.

The interaction effects of the drill tip angle (X1) and tooth bite (X2) on the delamination factor at the inlet are shown in Figure 4.

Figure 4.

The 3D plots showing interaction effects of the drill tip angle (X1) and tooth bite (X2) on the delamination factor at the inlet (Y2) when the holes were ‘performed’ with a flat drill (a) and with a helical drill (b).

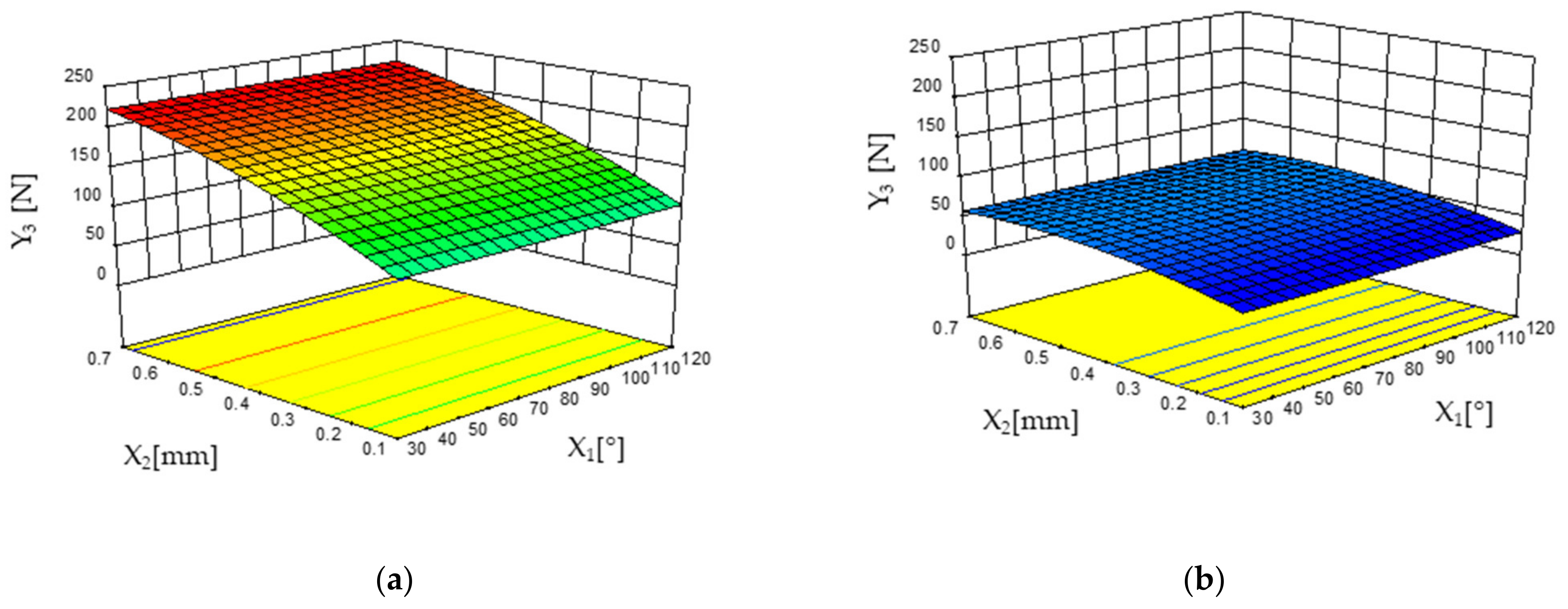

3.2.3. Thrust Force (Y3)

In the case of thrust force, the RSM method suggested a quadratic model, which is significant at 1%. The coded and actual forms are presented in Equations (10)–(12). In the case of this model, only the terms X2, X3, X2X3, and X22 were significant (Table 7). Based on these results, it could be stated that the most important term that affects the thrust force is the drill type (flat or helical) followed by the tooth bite and drill tip angle. There was a synergetic effect among the analyzed factors. Since the magnitude of these interactions was X2X3 > X1X2 > X1X3, the most important interaction is between tooth bite and drill type. Moreover, there is a non-linear effect on the tooth bite factor on the thrust force. Therefore, it could be stated that the optimum value of the tooth bite could be found inside the analyzed range, namely, 0.1–0.7 mm.

Table 7.

Analysis of variance results for the quadratic equation in the case of thrust force.

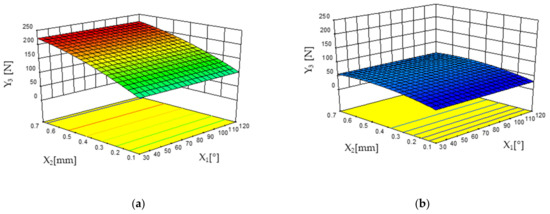

The 3D plots showing the interaction effects of the drill tip angle (X1) and tooth bite (X2) on the thrust force are presented in Figure 5.

Figure 5.

The 3D plots showing interaction effects of the drill tip angle (X1) and tooth bite (X2) on the thrust force (Y3) when the holes were ‘performed’ with a flat drill (a) and with a helical drill (b).

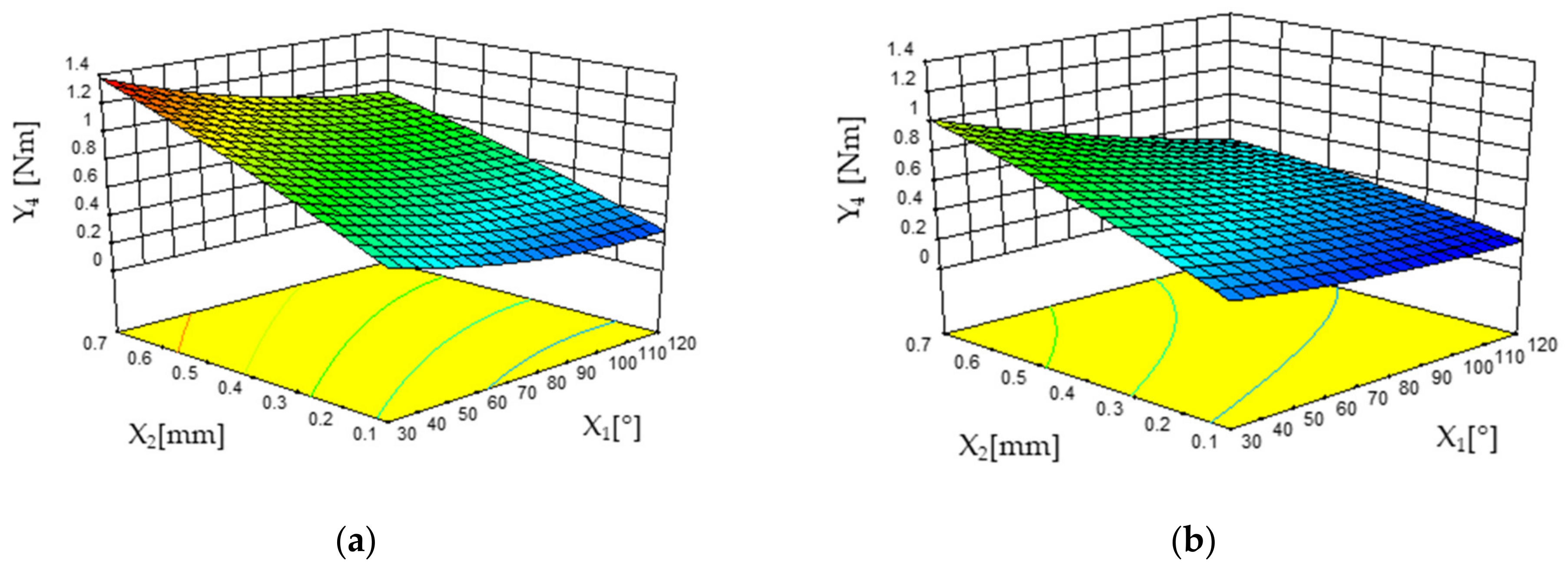

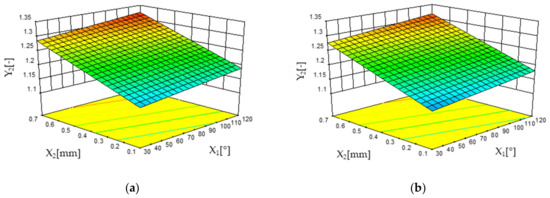

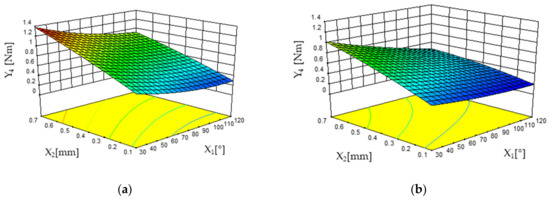

3.2.4. Drilling Torque (Y4)

A quadratic regression equation was revealed by the Design Expert software to predict the drilling torque based on the drill tip angle, tooth bite, and drill type. The coded form of the selected mathematical model is presented in Equation (13). The actual forms of regression equations are presented in Equations (14) and (15). The most important factor that affects the drilling torque is tooth bite, followed by the drill tip angle and drill type (flat or helical). There are synergetic effects of the input variables on the drilling torque. The relative magnitude of these interactions was X1X2 > X2X3 > X1X3. Based on Table 8, one may observe that the selected model is significant at 0.01%. Moreover, it could be noticed that most of the model terms are significant at 0.05%.

Table 8.

Analysis of variance results for the quadratic equation for the drilling torque.

The 3D plots showing the interaction effects of drill tip angle (X1) and tooth bite (X2) on the drilling torque are presented in Figure 6.

Figure 6.

The 3D plots showing interaction effects of the drill tip angle (X1) and tooth bite (X2) on the drilling torque (Y4) when the holes were ‘performed’ with a flat drill (a) and with a helical drill (b).

To reveal the optimal value of analyzed factors, the criteria that are presented in Table 9 were specified as input values of the optimization algorithm, which is used by the Design Expert software. The solutions with the highest desirability coefficient were selected as the optimum value of the analyzed factors both in the case of a helical or a flat drill. The optimum solutions are presented in Table 10. To figure out the relative error of the selected regression equation, Equation (16) was applied. In this equation, the experimental value (Y) was considered the mean of measured response, and was considered taken from the employed data set:

where ER represents the relative error (%), Y is the experimental value and is the predicted value.

Table 9.

Criteria for different factors and responses in optimization of wood particleboard drilling.

Table 10.

The selected optimum solution of input factors and the corresponding numerical and experimental value of analyzed responses.

The relative error was between 0.8 and 5.5% for the delamination factor, between 12 and 40% for the thrust force, and between 6 and 29% in the case of the drilling torque. Based on the obtained results, it could be stated that the Response Surface Methodology could represent a suitable approach to figure out the optimum values of input factors during drilling the particleboards (PB), which are widely used nowadays in the production of furniture. Moreover, based on the obtained results, it could be stated that the helical drill leads to a lower delamination factor, a lower thrust force, and a lower drilling torque than the case of a flat drill.

4. Conclusions

In this work, the artificial neural network modeling technique and response surface methodology were employed to reveal the optimum values of selected factors, namely, drill tip angle, tooth bite, and drill type, on the delamination factor at the outlet and inlet, thrust force, and drilling torque. Both applied modeling techniques (ANN and RSM) could be used to predict the delamination factor at the outlet, the thrust force, and the drilling torque with a higher performance indicator (R2) than in the case of the delamination factor at the inlet. The helical drill leads to a lower delamination factor, a lower thrust force, and a lower drilling torque than the case of a flat drill. The delamination factor at the outlet is more affected by drill type than the drill tip angle and tooth bite, which have almost the same influence. On the other hand, the delamination factor at the inlet is more affected by the tooth bite, followed by drill tip angle and drill type. The most important analyzed factor that affects the thrust force is the drill type followed by the tooth bite and drill tip angle. The drilling torque is most affected by the tooth bite, followed by the drill tip angle and drill type. Other factors that affect the drilling process of wood and wood-based boards must be considered in further studies. These kinds of studies are underway by our group.

Author Contributions

Conceptualization, B.B. and M.I.; methodology, B.B. and M.I.; software, B.B.; validation, B.B.; resources, S.R. and M.N.B.; writing—original draft preparation, B.B. and M.I.; writing—review and editing, M.I. and B.B.; visualization, S.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hetzel, F. About the Workability of Chipboard and Plywood—Drilling and Punching. Ph.D. Thesis, Technische Hochschule Dresden, Dresden, Germany, 1928. (In German). [Google Scholar]

- Radu, A. Contributions to the Establishment of the Optimal Parameters of Wood Drills. Ph.D. Thesis, Polytechnic Institute of Brasov, Brasov, Romania, 1967. (In Romanian). [Google Scholar]

- Valarmathi, T.N.; Palanikumar, K.; Latha, B. Measurement and analysis of thrust force in drilling of particle board (PB) composite panels. Measurement 2013, 46, 1220–1230. [Google Scholar] [CrossRef]

- Lilly, M.J.; Prakash, S.; Vijayalakshmi, P.; Putti, V.S.T. Multi response optimization of drilling parameters during drilling of particle board using Grey Relational Analysis. Appl. Mech. Mater. 2013, 592–594, 530–533. [Google Scholar] [CrossRef]

- Ispas, M.; Gurău, L.; Răcăşan, S. Study regarding the variation of the thrust force, drilling torque and surface delamination with the feed per tooth and drill tip angle at drilling pre-laminated particleboard. Pro Ligno 2014, 10, 40–52. [Google Scholar]

- Ispas, M.; Gurău, L.; Răcăşan, S. The influence of the tool point angle and feed rate on the delamination at drilling of pre-laminated particleboard. Pro Ligno 2015, 11, 494–500. [Google Scholar]

- Ispas, M.; Răcăşan, S. The influence of the tool point angle and feed rate on the dynamic parameters at drilling coated particleboard. Pro Ligno 2015, 11, 457–463. [Google Scholar]

- Podziewski, P.; Szymanowski, K.; Gorski, J.; Czarniak, P. Relative Machinability of Wood-Based Boards in the Case of Drilling—Experimental Study. Bioresources 2018, 13, 1761–1772. [Google Scholar] [CrossRef] [Green Version]

- Madhan Kumar, A.; Jayakumar, K. Drilling studies on particle board composite using HSS twist drill and spade drill. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012029. [Google Scholar] [CrossRef] [Green Version]

- Górski, J. The review of new scientific developments in drilling in wood-based panels with particular emphasis on the latest research trends in drill condition monitoring. Forests 2022, 13, 242. [Google Scholar] [CrossRef]

- Gürgen, A.; Çakmak, A.; Yıldız, S.; Malkoçoğlu, A. Optimization of CNC operating parameters to minimize surface roughness of Pinus sylvestris using integrated artificial neural network and genetic algorithm. Maderas-Cienc. Tecnol. 2022, 24, 1–12. Available online: http://revistas.ubiobio.cl/index.php/MCT/article/view/5163 (accessed on 5 May 2022). [CrossRef]

- Özşahin, Ş.; Singer, H. Prediction of noise emission in the machining of wood materials by means of an artificial neural network. N. Z. J. For. Sci. 2022, 52, 1–11. [Google Scholar] [CrossRef]

- Rahimi, S.; Avramidis, S. Predicting moisture content in kiln dried timbers using machine learning. Eur. J. Wood Prod. 2022, 80, 681–692. [Google Scholar] [CrossRef]

- Chai, H.; Chen, X.; Cai, Y.; Zhao, J. Artificial neural network modeling for predicting wood moisture content in high frequency vacuum drying process. Forests 2019, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Bedelean, B. Application of artificial neural networks and Monte Carlo method for predicting the reliability of RF phytosanitary treatment of wood. Eur. J. Wood Prod. 2018, 76, 1113–1120. [Google Scholar] [CrossRef]

- Avramidis, S.; Iliadis, L. Predicting wood thermal conductivity using artificial neural networks. Wood Fiber Sci. 2005, 37, 682–690. [Google Scholar]

- De Melo, D.J.; Guedes, T.O.; da Silva, J.R.M.; de Paiva, A.P. Robust optimization of energy consumption during mechanical processing of wood. Eur. J. Wood Prod. 2019, 77, 1211–1220. [Google Scholar] [CrossRef]

- Georgescu, S.; Varodi, A.M.; Răcășan, S.; Bedelean, B. Effect of the dowel length, dowel diameter, and adhesive consumption on bending moment capacity of heat-treated wood dowel joints. BioResources 2019, 14, 6619–6632. [Google Scholar] [CrossRef]

- Sova, D.; Bedelean, B.; Venetia, S. Application of response surface methodology to optimization of wood drying conditions in a pilot-scale kiln. Balt. For. 2016, 22, 348–356. [Google Scholar]

- Tiryaki, S.; Özşahin, Ş.; Aydin, A. Employing artificial neural networks for minimizing surface roughness and power consumption in abrasive machining of wood. Eur. J. Wood Prod. 2017, 75, 347–358. [Google Scholar] [CrossRef]

- Anderson, M.J.; Whitcomb, P.J. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2005. [Google Scholar]

- Ariaee, S.; Tutunchi, A.; Kianvash, A.; Entezami, A.A. Modeling and optimization of mechanical behavior of bonded composite–steel single lap joints by response surface methodology. Int. J. Adhes. Adhes. 2014, 54, 30–39. [Google Scholar] [CrossRef]

- Watanabe, K.; Korai, H.; Matsushita, Y.; Hayashi, T. Predicting internal bond strength of particleboard under outdoor exposure based on climate data: Comparison of multiple linear regression and artificial neural network. J. Wood Sci. 2015, 61, 151–158. [Google Scholar] [CrossRef]

- Tiryaki, S.; Aydin, A. An artificial neural network model for predicting compression strength of heat-treated woods and comparison with a multiple linear regression model. Constr. Build. Mater. 2014, 62, 102–108. [Google Scholar] [CrossRef]

- Fu, Z.; Avramidis, S.; Zhao, J.; Cai, Y. Artificial neural network modeling for predicting elastic strain of white birch disks during drying. Eur. J. Wood Prod. 2017, 75, 949–955. [Google Scholar] [CrossRef]

- Mansfield, S.D.; Iliadis, L.; Avramidis, S. Neural network prediction of bending strength and stiffness in western hemlock (Tsuga heterophylla Raf.). Holzforschung 2007, 61, 707–716. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).