Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock

Abstract

:1. Introduction

2. Materials and Methods

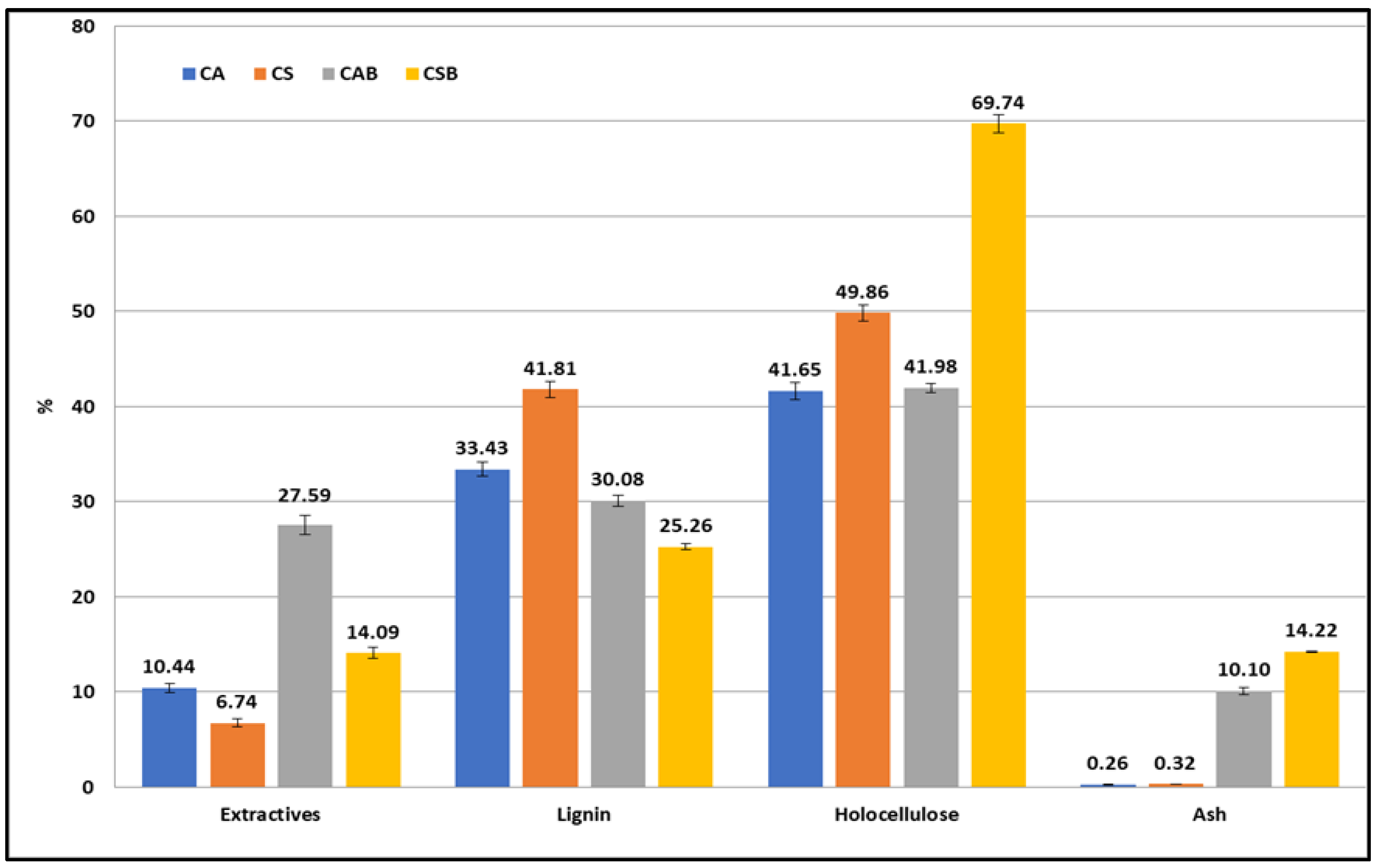

2.1. Chemical Characterization Using Analytical Methods

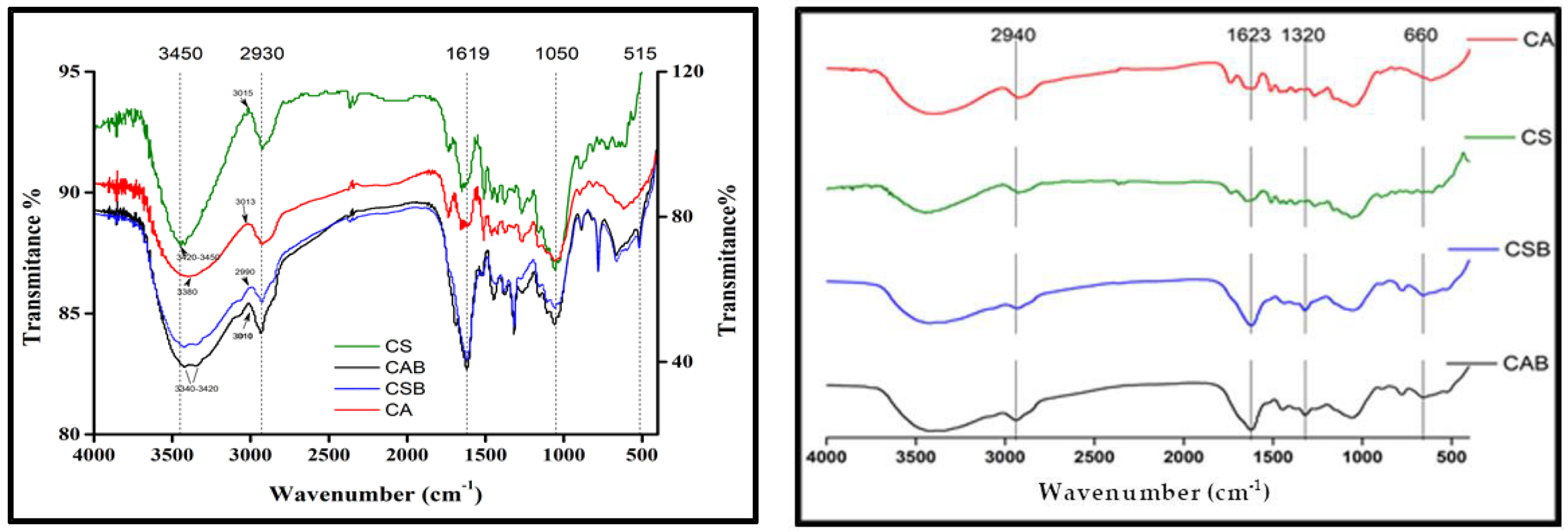

2.2. Chemical Characterization Using Infrared Spectroscopy (FTIR)

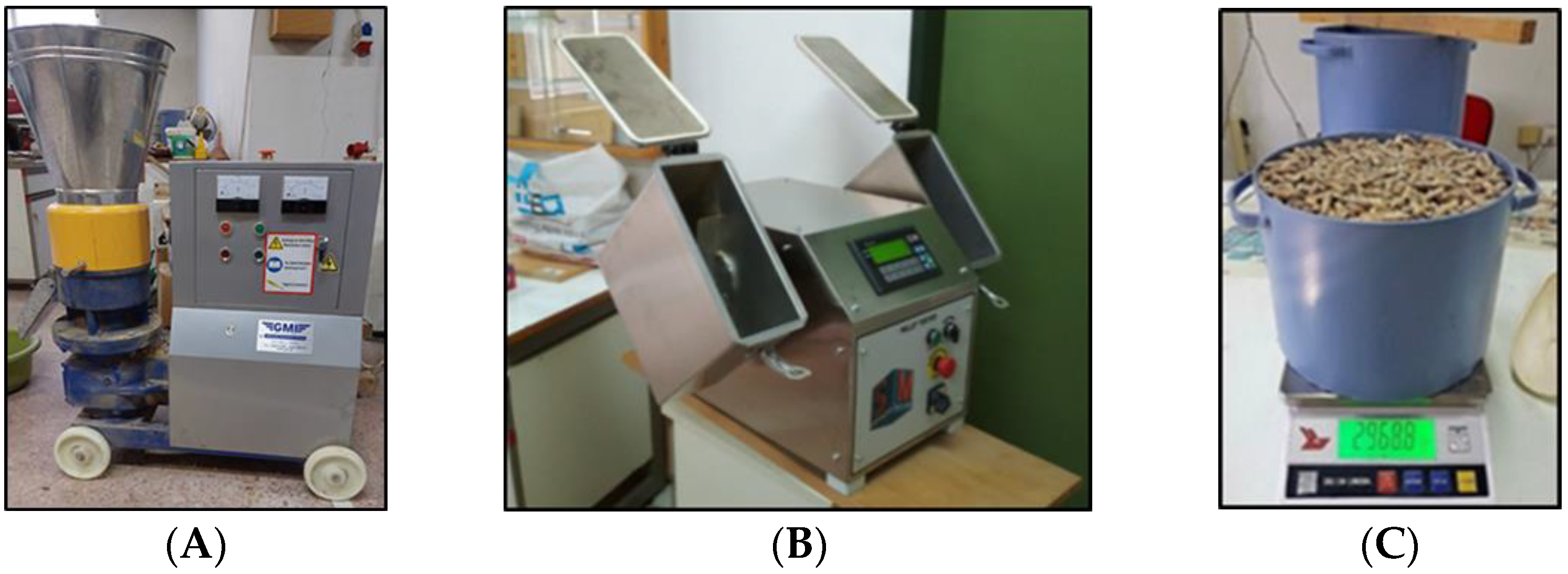

2.3. Pellet Production

2.4. Characterization of Pellets

2.5. Mechanical Strength

2.6. Bulk Density

2.7. Hygroscopic Properties-Dimensional Stability

2.8. Calorific Value

2.9. Statistical Analysis

3. Results

3.1. Raw Materials Chemical Characterization

3.2. Pellets Characterization

3.2.1. Moisture Content and Pellet Density

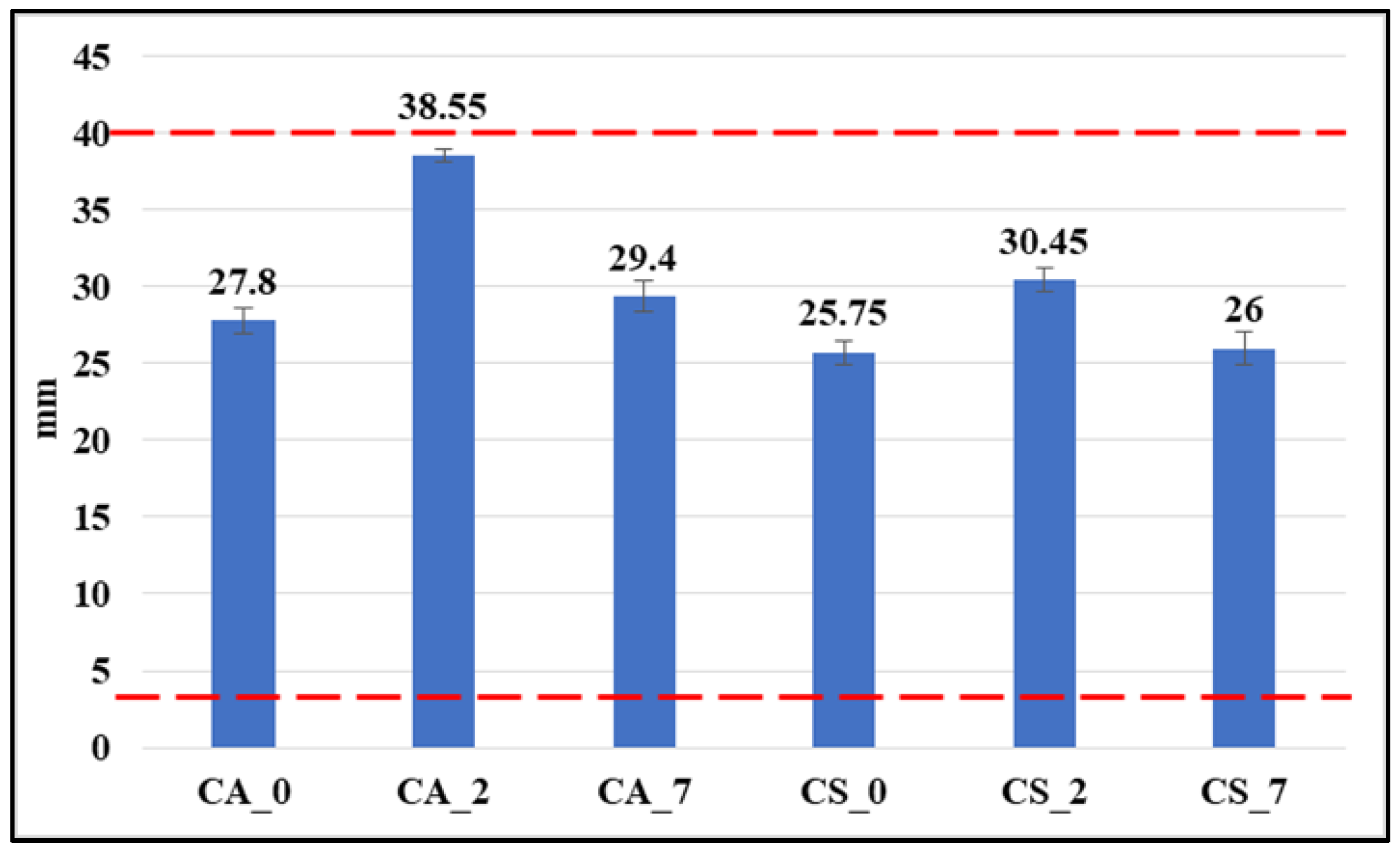

3.2.2. Dimensions

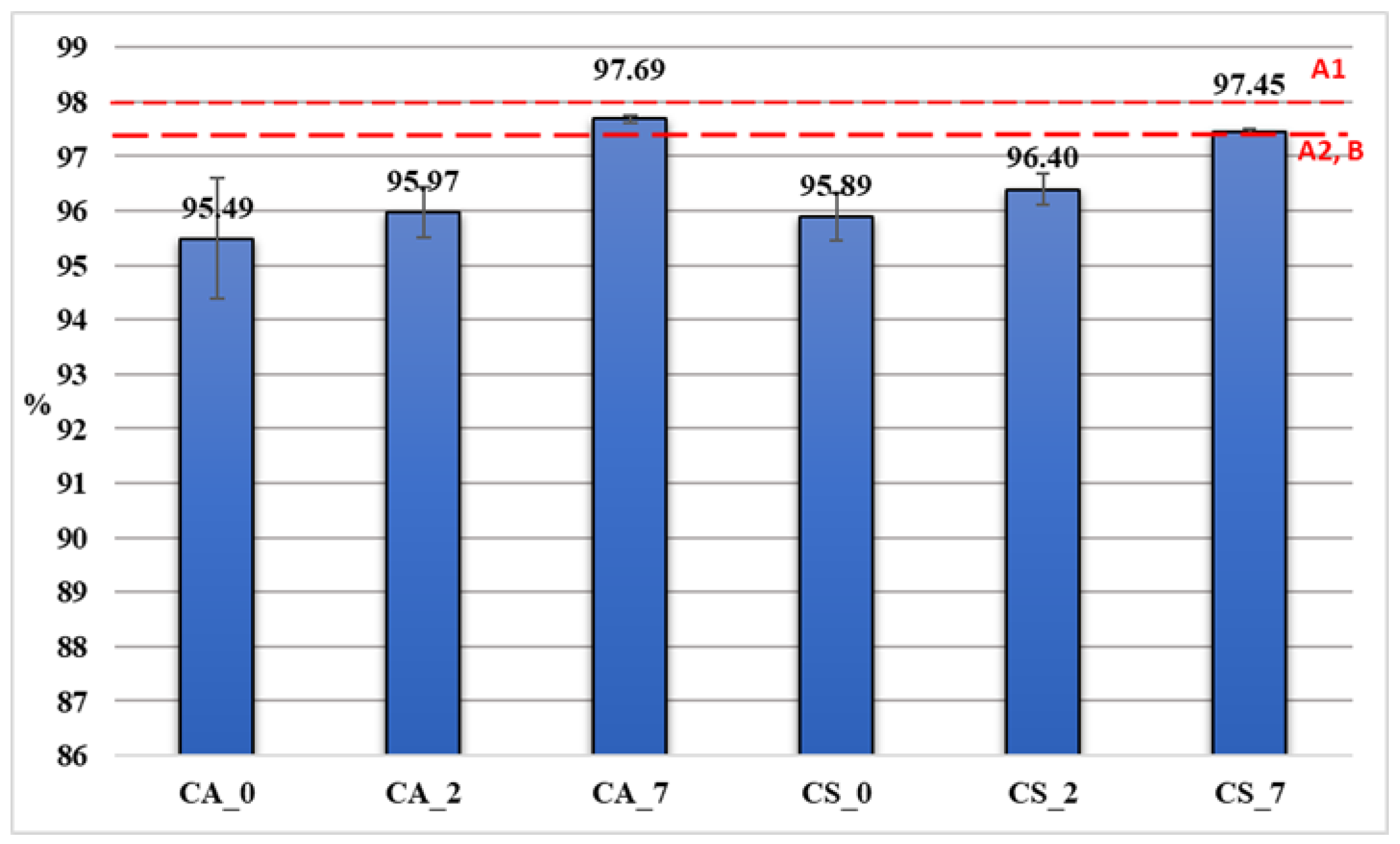

3.2.3. Mechanical Durability

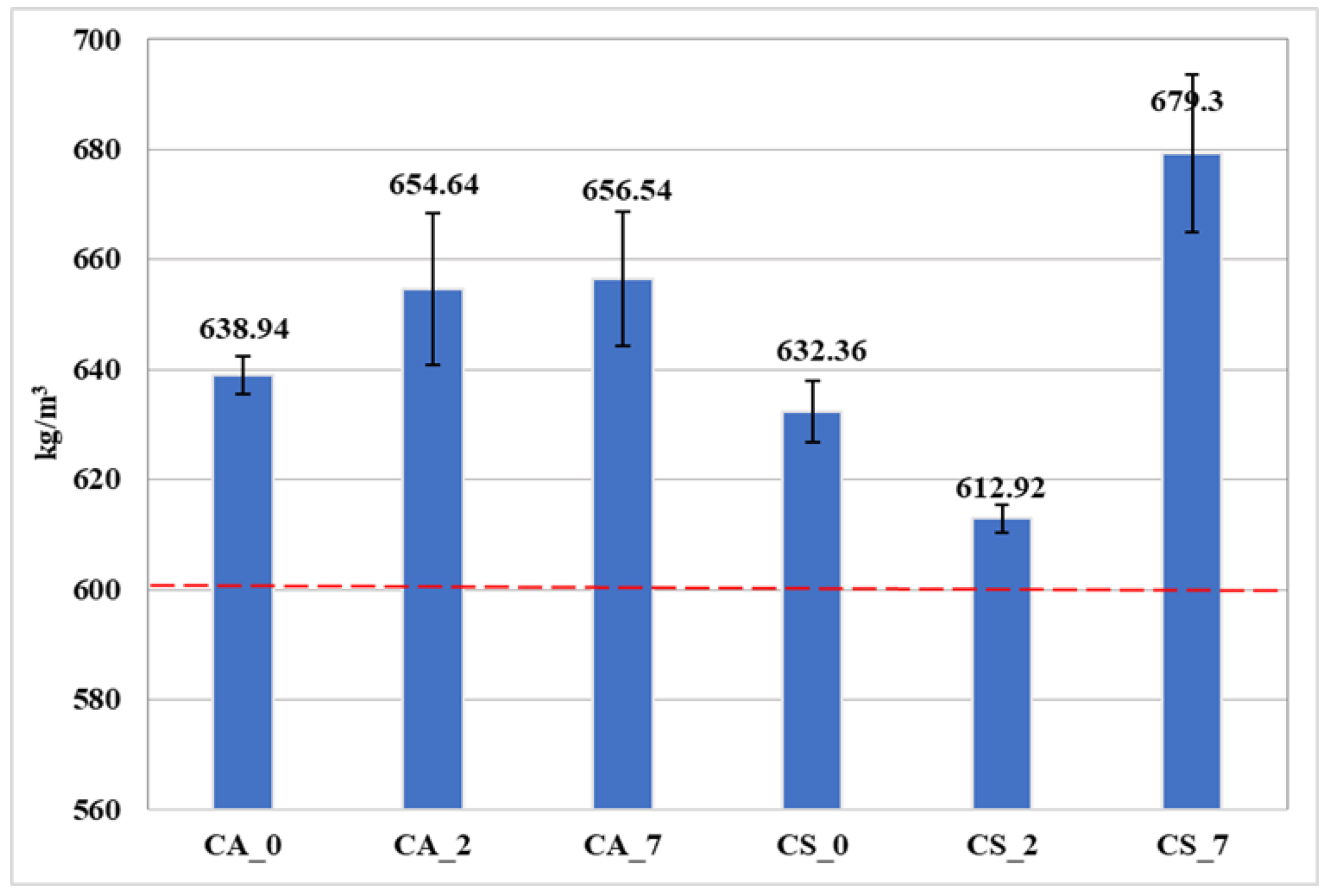

3.2.4. Bulk Density

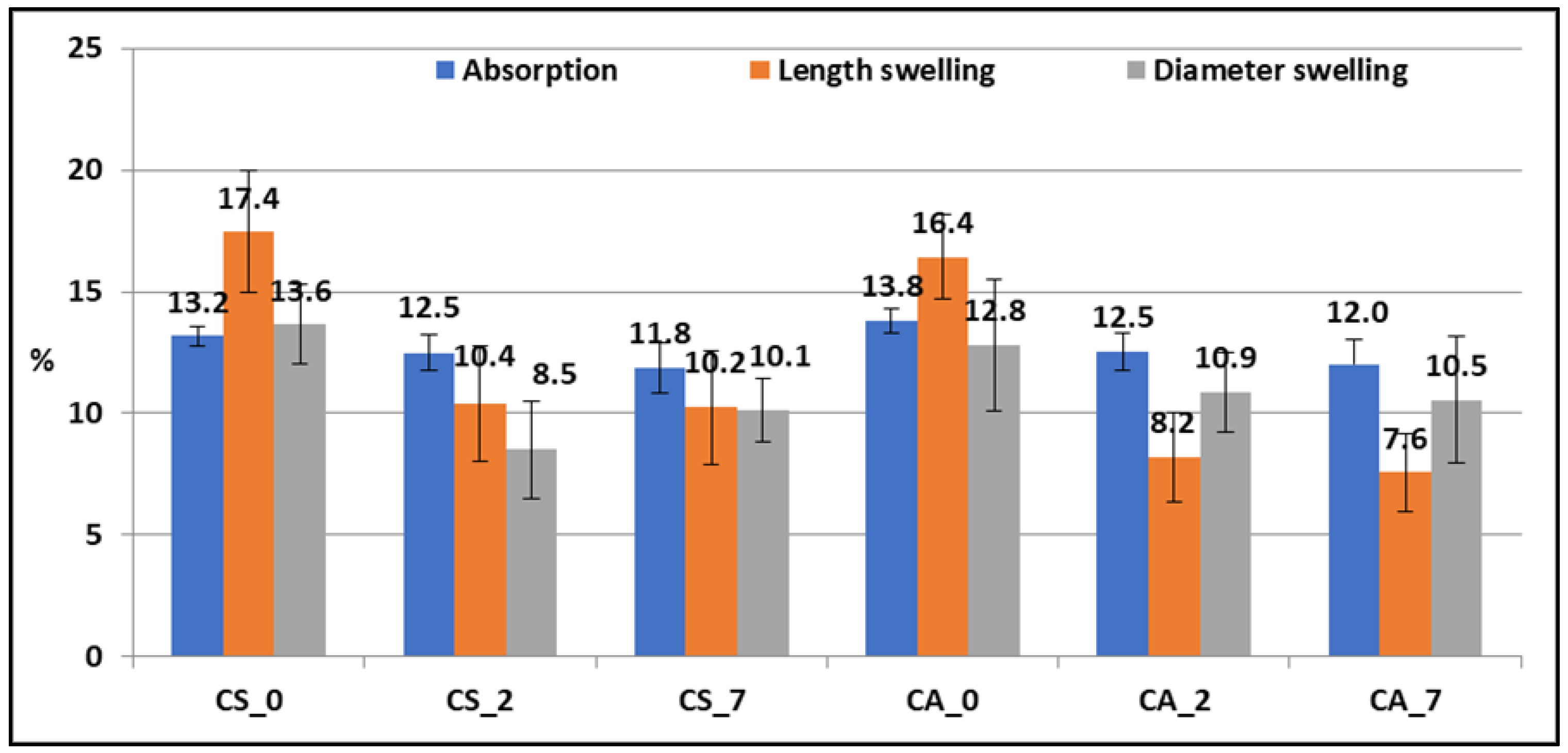

3.2.5. Hygroscopic Properties

3.2.6. Calorific Value

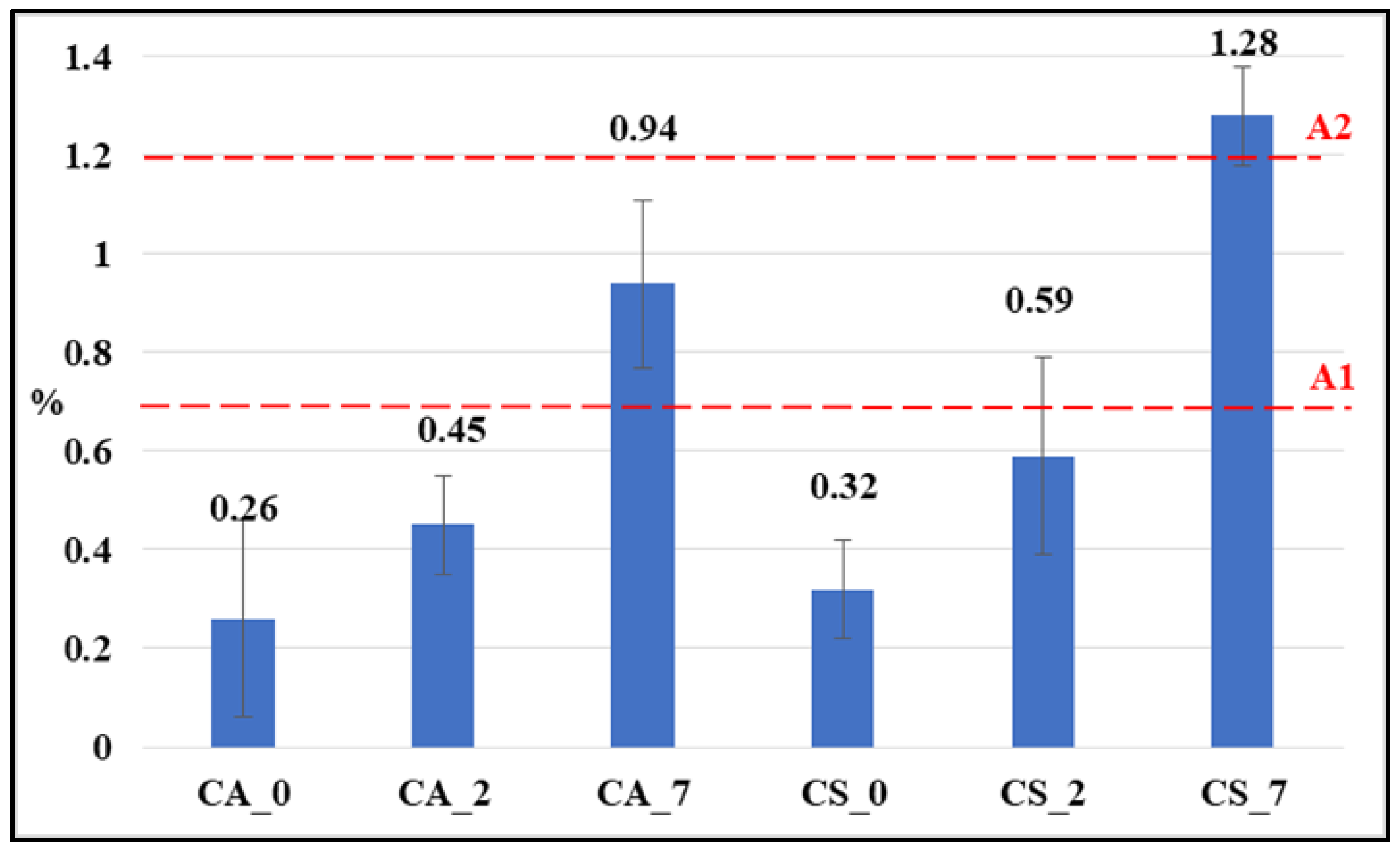

3.2.7. Ash Content

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Calderon, C.; Colla, M. Bioenernergy Europe Statistical Report 2019. Pellet Report. European Pellet Council. Available online: https://epc.bioenergyeurope.org/wp-content/uploads/2020/02/SR19_Pellet_final-web-1.pdf (accessed on 1 August 2022).

- USDA, United States—United States Department of Agriculture. European Union: EU Wood Pellet Annual. 2022. Available online: https://www.fas.usda.gov/data/european-union-eu-wood-pellet-annual (accessed on 1 August 2022).

- Svetlana, P.; Martin, J.; Jussi, H.; Beysin, T.; Esa, V. Global biomass trade for energy—Part 2: Production and trade streams of wood pellets, liquid biofuels, charcoal, industrial roundwood and emerging energy biomass. Biofuels Bioprod. Biorefin. 2018, 13, 371–387. [Google Scholar] [CrossRef]

- Frodeson, S.; Herriksson, G.; Berghel, J. Pelletizing pure biomass substances to investigate the mechanical properties and bonding mechanisms. BioResources 2018, 13, 1202–1222. [Google Scholar] [CrossRef]

- Bergman, R.; Zerbe, J. Primer on Wood Biomass for Energy; USDA Forest Service, State and Private Forestry Technology Marketing Unit Forest Products Laboratory: Madison, WI, USA, 2004.

- Kamperidou, V. Quality Analysis of Commercially Available Wood Pellets and Correlations between Pellets Characteristics. Energies 2022, 15, 2865. [Google Scholar] [CrossRef]

- Vinterbäck, J. Pellets 2002: The first world conference on pellets. Biomass Bioenergy 2004, 27, 513–520. [Google Scholar] [CrossRef]

- Duca, D.; Riva, G.; Pedretti, E.F.; Toscano, G. Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. Colorimetric patterns of wood pellets and their relations with quality and energy parameters. Fuel 2014, 137, 70–76. [Google Scholar] [CrossRef]

- Matias, J.; Gonzalez, J. Solid biofuels: Pellets and chips. Fuel specifications and use in Extremadura Biomass. In Proceedings of the 1st International Congress on Bioenergy, Portalegre, Portugal, 23–25 May 2013. [Google Scholar]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The effect of bark content on quality parameters of Scots pine (Pinus sylvestris L.) pellets. Biomass Bioenergy 2011, 35, 3342–3349. [Google Scholar] [CrossRef]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree bark utilization in insulating bio-aggregates: A review. Biofuels Bioprod. Biorefin. 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiyari, H.R.; Papadopoulos, A.N.; et al. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2022, 1–20. [Google Scholar] [CrossRef]

- Tudor, E.M.; Barbu, M.C.; Petutschnigg, A.; Réh, R.; Krišťák, L. Analysis of larch-bark capacity for formaldehyde removal in wood. Int. J. Environ. Res. Public Health 2020, 17, 764. [Google Scholar] [CrossRef]

- Pásztory, Z.; Mohácsiné, I.R.; Gorbacheva, G.; Börcsök, Z. The utilization of tree bark. BioResources 2016, 11, 7859–7888. [Google Scholar] [CrossRef]

- Tudor, M.E.; Scheriau, C.; Barbu, M.C.; Reh, R.; Krišták, L.; Schnabel, T. Enhanced Resistance to Fire of the Bark-Based Panels Bonded with Clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Lehtikangas, P. Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 2000, 19, 287–293. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Hawrot-Paw, M.; Koniuszy, A. Evaluation of the Quality of Wood Pellets Available on the Market. E3S Web Conf. 2020, 171, 01015. [Google Scholar] [CrossRef]

- Kemppainena, Κ.; Siika-ahoa, Μ.; Pattathilb, S.; Giovandoc, S.; Kruus, K. Spruce bark as an industrial source of condensed tannins andnon-cellulosic sugars. Ind. Crops Prod. 2014, 52, 158–168. [Google Scholar] [CrossRef]

- Holubcik, M.; Jandacka, J.; Palacka, M.; Kantova, N.; Jachniak, E.; Pavlik, P. The Impact of Bark Content in Wood Pellets on Emission Production during Combustion in Small Heat Source. Commun. Sci. Lett. Univ. Zilina 2017, 19, 94–100. [Google Scholar] [CrossRef]

- Melin, S. Bark as Feedstock for Production of Wood Pellets; Wood Pellet Association of Canada: Vancouver, BC, Canada, 2008; p. 42. [Google Scholar]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2016, 20, 351–360. [Google Scholar] [CrossRef]

- Yessoufou, K.; Elansary, H.O.; Mahmoud, E.A.; Skalicka-Woźniak, K. Antifungal, antibacterial and anticancer activities of Ficus drupacea L. stem bark extract and biologically active isolated compounds. Ind. Crops Prod. 2015, 74, 752–758. [Google Scholar] [CrossRef]

- Kamperidou, V.; Lykidis, C.; Barmpoutis, P. Utilization of wood and bark of fast-growing hardwood species in energy production. J. For. Sci. 2018, 64, 164–170. [Google Scholar] [CrossRef]

- Athanasiadis, H.P.L. Forest Botany Part II. Trees and Shrubs of the Forests of Greece, 2nd ed.; Yahoudi-Giapouli: Thessaloniki, Greece, 1986. [Google Scholar]

- Kakaras, I. Technology of Wooden Structures; ION Publications: Athens, Greece, 2013; p. 235. [Google Scholar]

- Tsoumis, G. Structure and Properties. In Wood Science and Technology; Van Nostrand Reinhold: New York, NY, USA, 1983; p. 494. ISBN 0442239858. [Google Scholar]

- Terzopoulou, P.; Kamperidou, V. Chemical Characterization of Wood and Bark Biomass of the Invasive Species of Tree-of-Heaven (Ailanthus altissima (Mill.) Swingle), Focusing on Its Chemical Composition Horizontal Variability Assessment. Wood Mater. Sci. Eng. 2021, 1–9. [Google Scholar] [CrossRef]

- Kamperidou, V. Chemical and Structural Characterization of Poplar and Black Pine Wood Exposed to Short Thermal Modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Günzler, G.; Gremlich, H.U. IR Spectroscopy; Wiley-VCH Verlag: Weinheim, Germany, 2002. [Google Scholar]

- European Pellet Council (EPC). Part 3: Pellet Quality Requirements. In ENplus Handbook; Version 3.0; European Pellet Council (EPC): Brussels, Belgium, 2015. [Google Scholar]

- Santos, A.; Anjos, O.; Morais, M.C.; Diogo, G.; Simões, R.; Pereira, H. Characterization of cypress wood for kraft pulp production. BioResources 2014, 9, 4764–4774. [Google Scholar] [CrossRef]

- Okino, E.Y.A.; Santana, M.A.; Alves, E.M.V.; Melo, J.E.; Coradin, V.T.R.; Souza, M.R.; Teixeira, D.E.; Sousa, M.E. Technological Characterization of Cupressus spp. Wood. Floresta Ambiente 2010, 17, 1–11. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1989; p. 613. [Google Scholar] [CrossRef]

- Sarto, C.; Sansígolo, C.A. Kinetics of the removal of Eucalyptus grandis wood extractives during Kraft pulping. Acta Sci. Technol. 2010, 32, 227–235. [Google Scholar] [CrossRef]

- Hafizoglu, H.; Usta, M. Chemical composition of coniferous wood species occurring in Turkey. Eur. J. Wood Wood Prod. 2010, 63, 83–85. [Google Scholar] [CrossRef]

- Foelkel, C.E.B.; Zvinakevicius, C. Coníferas Exóticas Aptas Para Produção de Cellulose Kraft: 2-Cupressus Lusitanica; CENIBRA: Belo Oriente, Brazil, 1978; p. 18. [Google Scholar]

- Yang, D.M.; Su, W.Q.; Yue, J.Q. Teaching Reform and Practice on Plant Fiber Chemistry; Heilongjiang Pulp & Paper: Heilongjiang, China, 2015; Volume 1, pp. 42–43. [Google Scholar]

- Faust, M.W. Analysis of Physiological Reactivity in Mathematics Anxiety. Unpublished Ph.D. Thesis, Bowling Green State University, Bowling Green, OH, USA, 1992. [Google Scholar]

- Faix, O. Classifcation of lignins from different botanical origins by FT-IR spectroscopy. Holzforschung 1991, 45, 21–27. [Google Scholar] [CrossRef]

- Kayo, C.; Tojo, S.; Iwaoka, M.; Matsumoto, T. Evaluation of Biomass Production and Utilization Systems. In Research Approaches to Sustainable Biomass Systems; Academic Press: Cambridge, MA, USA, 2014; pp. 309–346. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstantinidis, A.; Koltsou, P.; Papadopoulos, S. Use of Posidonia oceanica fibres in lime mortars. Constr. Build. Mater. 2021, 298, 123881. [Google Scholar] [CrossRef]

- Filippou, I. Chemistry and Chemical Technology of Wood; Giahoudi-Giapouli Publications: Thessaloniki, Greece, 2014; p. 357. [Google Scholar]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Afungchui, D. Adopting the use of cypress as a woody biomass of choice in cameroon based on an analytic determination of the net calorific value (NCV). Int. J. Eng. Appl. Sci. 2014, 5, 16–24. [Google Scholar]

- Mancera, C.; El Mansouri, N.-E.; Vilaseca, F.; Ferrando, F.; Salvado, J. The effect of lignin as a natural adhesive on the physicochemical properties of Vitis Vinefera fiberboards. BioResources 2011, 6, 2851–2860. [Google Scholar]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy J. 2004, 27, 653–669. [Google Scholar] [CrossRef]

| Material | EMC |

|---|---|

| C. arizonica Wood—CA | 9.35 (0.50) * |

| C. sempervirens Wood—CS | 8.88 (0.79) |

| C. arizonica Bark—CAB | 8.92 (0.35) |

| C. sempervirens Bark—CSB | 10.38 (0.35) |

| CS | CA | CAB | CSB | ||||

|---|---|---|---|---|---|---|---|

| Wavenumber cm−1 | Assignment | Wavenumber cm−1 | Assignment | Wavenumber cm−1 | Assignment | Wavenumber cm−1 | Assignment |

| 3450–3420 | O–H stretching (hydrogen-bonded) | 3380 | O–H stretching (hydrogen-bonded) | 3420–3340 | O–H stretching (hydrogen-bonded) | 3428–3341 | O–H stretching (hydrogen-bonded) |

| 2930 | C–H stretching vibration in methyl and methylene groups | 2930 | C–H stretching vibration in methyl and methylene groups | 2940 | C–H stretching vibration in methyl and methylene groups | 2919 | C–H stretching vibration in methyl and methylene groups |

| 1730 | C=O stretching band in the lignin | 1738 | C=O stretching vibration in non-conjugated ketones and free aldehyde present in lignin and hemicellulose | ||||

| 1619 | C=C of the lignin molecules | 1619 | C=C of the lignin molecules | 1620 | C=C of the lignin molecules | 1620 | C=C of the lignin molecules |

| 1650 | Absorbed O-H and conjugated ν(C=O) Lignin | 1658 | C=O stretching in conjugated q-substituent aromatic ketenes | ||||

| 1510 | aromatic C=C deformation | 1507 | aromatic C=C deformation | ||||

| 1465 | Hemicellulose Xylan | 1460–1418 | C-H deformation in lignin and carbohydrates | 1448 | Cellulose | 1431 | CH2 stretching vibrations related to the structure of cellulose |

| 1420 | C-H deformation in lignin and carbohydrates, δ scissoring (CH2) and (CH3) of lignin | 1371 | Lignin, δ (CH)—δs (CH3), Symmetric C–H bending vibrations from methoxy group | 1378 | Lignin, δ (CH)—δs (CH3) | ||

| 1380 | Lignin δ(CH)—δs (CH3) | 1372 | Lignin & C-H deformation in cellulose and hemicellulose | 1323 | C-H vibration in cellulose and C-O vibration in syringyl derivates | 1317 | C-H vibration in cellulose and C-O vibration in syringyl derivates |

| 1268 | Lignin, ν(C-O) lignin | 1266 | Lignin, ν(C-O) lignin and mannosan | 1262 | Hemicellulose Mannosan | ||

| 1057 | Lignin | 1050 | Hemicellulose Xylan νs (C-O-C) | 1062 | Hemicellulose Mannosan, ν(C-O) | 1060 | Cellulose C–O stretching vibrations: acetyl alkoxy bond stretching vibration |

| 895 | Cellulose, v(C-C)Glucose ring stretching, C1–H deformation; C–H stretching out of plane of ring due to b-linkage | 897 | Hemicellulose Xylan, C-H deformation in cellulose | 885 | 889 | ||

| 814 | Hemicellulose Mannosan δ (C-C); Ν (mannosan) | 815 | Hemicellulose Mannosan δ (C-C); Ν (mannosan) | 779 | 779 | ||

| Pellet Categories | MC (%) | Pellet Density (kg/m3) |

|---|---|---|

| C. arizonica—0% Bark—(CA_0) | 3.75 (0.23) * | 1175.16 (50.85) |

| C. arizonica—2% Bark—(CA_2) | 3.87 (0.19) | 1251.75 (60.37) |

| C. arizonica—7% Bark—(CA_7) | 3.70 (0.22) | 1269.63 (114.77) |

| C. sempervirens—0% Bark—(CS_0) | 3.84 (0.28) | 1258.94 (65.81) |

| C. sempervirens—2% Bark—(CS_2) | 2.81 (0.22) | 1340.39 (47.48) |

| C. sempervirens—7% Bark—(CS_7) | 2.70 (0.17) | 1204.89 (52.09) |

| Species | C. sempervirens | C. arizonica | ||||||

|---|---|---|---|---|---|---|---|---|

| Net calorific value (MJ/kg) | Pure Wood CS_0 | CS_2 | CS_7 | Pure Bark | Pure Wood CA_0 | CA_2 | CA_7 | Pure Bark |

| 19.60 (0.87) | 19.61 (1.1) | 19.65 (1.7) | 20.3 (1.7) | 19.20 (1.3) | 19.21 (1.6) | 19.25 (2.1) | 19.9 (0.94) | |

| Correlation Coefficients | Mech. Durab. | Ash | Lignin | Holocellulose | Extractives | Wood–Bark | |

|---|---|---|---|---|---|---|---|

| Pearson Correl. | Mech.Durability | 1.000 | 0.665 | 0.645 | 0.829 | 0.906 | −0.794 |

| Ash | 0.665 | 1.000 | 0.687 | 0.315 | 0.375 | −0.229 | |

| Lignin | 0.645 | 0.687 | 1.000 | 0.128 | 0.296 | −0.077 | |

| Holocellulose | 0.829 | 0.315 | 0.128 | 1.000 | 0.978 | −0.986 | |

| Extractives | 0.906 | 0.375 | 0.296 | 0.978 | 1.000 | −0.974 | |

| Wood_Bark | −0.794 | −0.229 | −0.077 | −0.986 | −0.974 | 1.000 | |

| Sig. | Mech.Durability | - | 0.009 | 0.012 | 0.000 | 0.000 | 0.001 |

| Ash | 0.009 | - | 0.007 | 0.159 | 0.115 | 0.237 | |

| Lignin | 0.012 | 0.007 | - | 0.345 | 0.175 | 0.407 | |

| Holocellulose | 0.000 | 0.159 | 0.345 | - | 0.000 | 0.000 | |

| Extractives | 0.000 | 0.115 | 0.175 | 0.000 | - | 0.000 | |

| Wood_Bark | 0.001 | 0.237 | 0.407 | 0.000 | 0.000 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terzopoulou, P.; Kamperidou, V.; Lykidis, C. Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock. Forests 2022, 13, 1303. https://doi.org/10.3390/f13081303

Terzopoulou P, Kamperidou V, Lykidis C. Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock. Forests. 2022; 13(8):1303. https://doi.org/10.3390/f13081303

Chicago/Turabian StyleTerzopoulou, Paschalina, Vasiliki Kamperidou, and Charalampos Lykidis. 2022. "Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock" Forests 13, no. 8: 1303. https://doi.org/10.3390/f13081303

APA StyleTerzopoulou, P., Kamperidou, V., & Lykidis, C. (2022). Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock. Forests, 13(8), 1303. https://doi.org/10.3390/f13081303