Influence of the Harvesting Region on Batch Homogeneity of Ipe Wood (Tabebuia sp.) Based on Its Physical and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

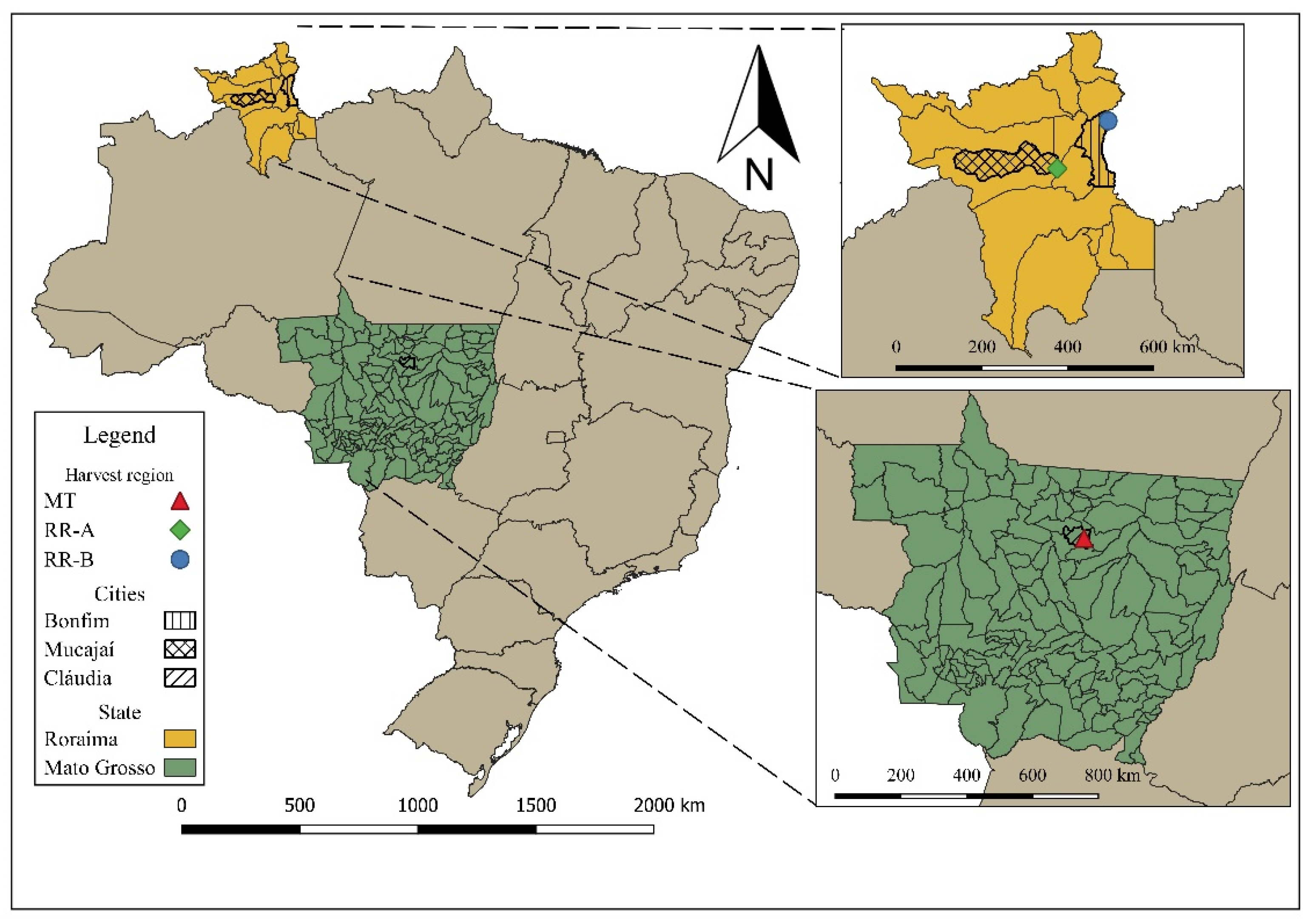

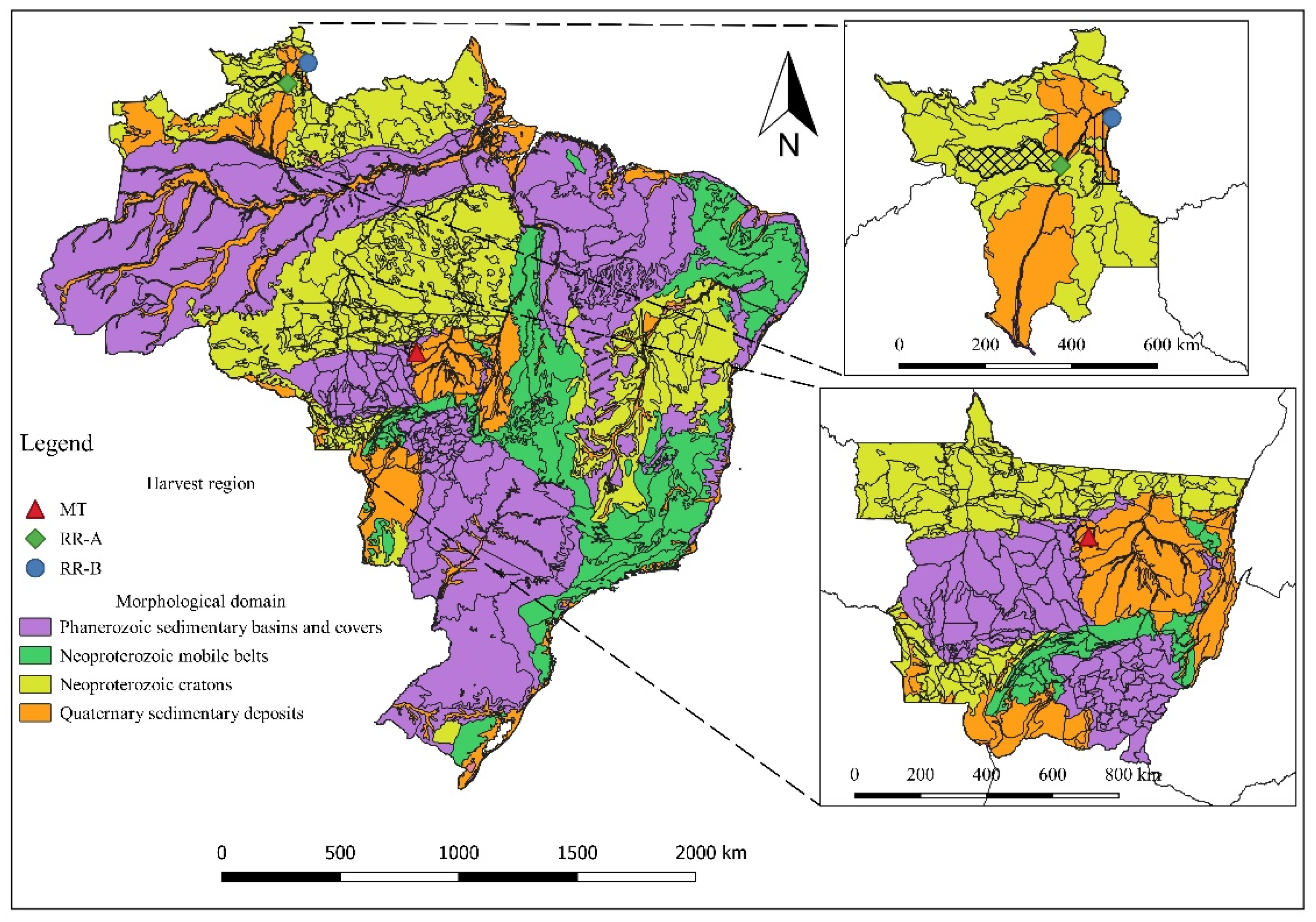

2.1. Harvesting Regions Areas

2.2. Experimental Procedure

- Apparent density (at 12% moisture) ();

- Total radial shrinkage ();

- Total tangential shrinkage ();

- Compression strength parallel to the grain ();

- Tension strength parallel to the grain ();

- Shear strength perpendicular to the grain ();

- Shear strength parallel to the grain ();

- Splitting strength ();

- Bending strength parallel to the grain ();

- Modulus of elasticity in compression parallel to the grain ();

- Modulus of elasticity in tension parallel to the grain ();

- Modulus of elasticity in bending ();

- Hardness parallel to the grain ();

- Hardness perpendicular to the grain ();

- Impact Strength in Bending ().

2.3. Physical Properties

2.3.1. Apparent Density

2.3.2. Wood Shrinkage

2.4. Mechanical Properties

2.4.1. Compression Parallel to the Grain

2.4.2. Compression Perpendicular to the Grain

2.4.3. Tension Parallel to the Grain

2.4.4. Tension Perpendicular to the Grain

2.4.5. Shear Strength

2.4.6. Splitting Parallel to the Grain

2.4.7. Static Bending

2.4.8. Janka Hardness

2.4.9. Tenacity and Impact Strength in Bending

2.5. Statistical Analyses

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Calil Júnior, C.; Dias, A.A. Utilização da madeira em construções rurais. Rev. Bras. Eng. Agríc. E Ambient. 1997, 1, 71–77. [Google Scholar] [CrossRef]

- Fonte, T.F.; Calil Júnior, C. Pontes protendidas de madeira: Alternativa técnico-econômica para vias rurais. Eng. Agríc. 2007, 27, 552–559. [Google Scholar] [CrossRef]

- Lahr, F.A.R.; Nogueira, M.C.J.A.; Araujo, V.A.; Vasconcelos, J.S.; Christoforo, A.L. Wood Utilization of Eucalyptus Grandis in Structural Elements: Densities and Mechanical Properties. Eng. Agríc. 2018, 38, 642–647. [Google Scholar] [CrossRef]

- Christoforo, A.L.; Aquino, V.B.d.M.; Wolenski, A.R.V.; Araujo, V.A.D.; Lahr, F.A.R. Evaluation of the Peltophorum vogelianum Benth. Wood Species for Structural Use. Eng. Agríc. 2019, 39, 763–768. [Google Scholar] [CrossRef]

- Christoforo, A.L.; Panzera, T.H.; Lahr, F.A.R. Estimation of Tensile Strength Parallel to Grain of Wood Species. Eng. Agríc. 2019, 39, 533–536. [Google Scholar] [CrossRef]

- Stringari, E.H.; Petrauski, A.; Petrauski, S.M.C.; Azevedo, R.L.; Savaris, G. Construction and Testing of Glued Laminated Timber Frames for Use in Laying Poultry Houses. Eng. Agríc. 2020, 40, 122–131. [Google Scholar] [CrossRef]

- Cavalheiro, R.S.; Almeida, D.H.; de Almeida, T.H.; Christoforo, A.L.; Lahr, F.A.R. Density as Estimator of Shrinkage for Some Brazilian Wood Species. Int. J. Mater. Eng. 2016, 6, 107–112. [Google Scholar] [CrossRef]

- Baar, J.; Tippner, J.; Rademacher, P. Prediction of Mechanical Properties-Modulus of Rupture and Modulus of Elasticity-of Five Tropical Species by Nondestructive Methods. Maderas Cienc. Tecnol. 2015, 17, 239–252. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, W. Nondestructive Evaluation and Reliability Analysis for Determining the Mechanical Properties of Old Wood of Ancient Timber Structure. BioResources 2017, 12, 2310–2325. [Google Scholar] [CrossRef]

- Andrade Junior, J.R.A.; de Almeida, D.H.; de Almeida, T.H.; Christoforo, A.L.; Stamato, G.C.; Lahr, F.A.R. Avaliação das estruturas de cobertura em madeira de um galpão de estoque de produtos químicos. Ambiente Construído 2014, 14, 75–85. [Google Scholar] [CrossRef] [Green Version]

- Steege, H.T.; Prado, P.I.; Lima, R.A.F.; Pos, E.; Coelho, L.S.; Lima Filho, D.A.; Salomão, R.P.; Amaral, I.L.; Almeida Matos, F.D.; Castilho, C.V.; et al. Biased-Corrected Richness Estimates for the Amazonian Tree Flora. Sci. Rep. 2020, 10, 10130. [Google Scholar] [CrossRef] [PubMed]

- Fraga, I.F. Influência dos Modelos Idealizados de Ligações No Dimensionamento de Treliças Planas de Madeira. Master’s Thesis, Universidade Federal de São Carlos—UFSCar, São Carlos, Brazil, 2020. [Google Scholar]

- Lahr, F.A.R.; Christoforo, A.L.; Silva, C.E.G.; Andrade Junior, J.R.; Pinheiro, R.V. Avaliação de Propriedades Físicas e Mecânicas de Madeiras de Jatobá (Hymenaea Stilbocarpa Hayne) Com Diferentes Teores de Umidade e Extraídas de Regiões Distintas. Rev. Árvore 2016, 40, 147–154. [Google Scholar] [CrossRef]

- Silva, C.E.G.; Almeida, D.H.; Almeida, T.H.; Chahud, E.; Branco, L.A.M.N.; Campos, C.I.; Rocco Lahr, F.A.; Christoforo, A.L. Influence of the Procurement Site on Physical and Mechanical Properties of Cupiúba Wood Species. BioResources 2018, 13, 4118–4131. [Google Scholar] [CrossRef]

- Aquino, V.B.M.; Panzera, T.H.; Molina, J.C.; Christoforo, A.L.; Rocco Lahr, F.A. Influence of Harvest Region on Properties of Cambará Wood. Maderas Cienc. Tecnol. 2021, 23, 1–12. [Google Scholar] [CrossRef]

- Teixeira, J.N.; Wolenski, A.R.V.; Aquino, V.B.M.; Panzera, T.H.; Silva, D.A.L.; Campos, C.I.; Silva, S.A.M.; Lahr, F.A.R.; Christoforo, A.L. Influence of Provenance on Physical and Mechanical Properties of Angelim-Pedra (Hymenolobium Petraeum Ducke.) Wood Species. Eur. J. Wood Wood Prod. 2021, 79, 1241–1251. [Google Scholar] [CrossRef]

- Moraes Neto, S.; Teles, R.; Rodrigues, T.; Vale, A.; Souza, M. Propriedades Mecânicas Da Madeira de Cinco Procedências de Pinus Caribaea Var. Hondurensis Implantadas No Cerrado Do Distrito Federal, DF. Bol. Pesqui. E Desenvolv. 2009, 251, 1–20. [Google Scholar]

- Nascimento, H.H.C.; Nogueira, R.J.M.C.; Silva, E.C.; Silva, M.A. Análise do crescimento de mudas de jatobá (Hymenaea courbaril L.) em diferentes níveis de água no solo. Rev. Árvore 2011, 35, 617–626. [Google Scholar] [CrossRef]

- Fernandes, C.; Gaspar, M.; Pires, J.; Alves, A.; Simões, R.; Rodrigues, J.; Silva, M.; Carvalho, A.; Brito, J.; Lousada, J. Physical, Chemical and Mechanical Properties of Pinus Sylvestris Wood at Five Sites in Portugal. IForest Biogeosci. For. 2017, 10, 669–679. [Google Scholar] [CrossRef]

- Amaro, C.L.; Cunha, S.D.; Grupioni, P.H.F.; Sousa, P.V.; Abadia, K.L.D.; Barros, I.B.; Mattos, F.S. Análise do crescimento de mudas de Eucalyptus sp. submetidas a diferentes doses de giberelina. AGRI-Environ. Sci. 2017, 3, 24–29. [Google Scholar]

- Mizobata, K.K.G.S.; Cassiolato, A.M.R.; Maltoni, K.L. Crescimento de mudas de Baru e Gonçalo-Alves em solo degradado, suplementado com resíduo, em Ilha Solteira-SP. Ciênc. Florest. 2017, 27, 429–444. [Google Scholar] [CrossRef]

- Tabakova, M.A.; Arzac, A.; Martínez, E.; Kirdyanov, A.V. Climatic Factors Controlling Pinus Sylvestris Radial Growth along a Transect of Increasing Continentality in Southern Siberia. Dendrochronologia 2020, 62, 125709. [Google Scholar] [CrossRef]

- Aguirre, M.I.H.; Peláez, J.D.L.; Osorio, N.W.; Correa, G.A. Effects of Nutrient Deprivation on the Growth and Development of Tabebuia Rosea Seedlings. Floresta E Ambiente 2021, 28, e20190112. [Google Scholar] [CrossRef]

- Santos, S.R. A atual classificação do antigo gênero Tabebuia (Bignoniaceae), sob o ponto de vista da anatomia da madeira. Balduinia 2017, 10–24. [Google Scholar] [CrossRef]

- Dietrichs, H.H. Desoxylapachol in Tabebuia Sp. Naturwissenschaften 1964, 51, 408–409. [Google Scholar] [CrossRef]

- Inacio, C.A.; Dianese, J.C. Some Foliicolous Fungi on Tabebuia Species. Mycol. Res. 1998, 102, 695–708. [Google Scholar] [CrossRef]

- Barros, B.C.; Silva, J.A.A.; Ferreira, R.L.C.; Rebouças, A.C.M.N. Volumetria e Sobrevivência de Espécies Nativas e Exóticas No Polo Gesseiro Do Araripe, PE. Ciênc. Florest. 2010, 20, 641–647. [Google Scholar] [CrossRef]

- Del Menezzi, C.H.S.; Silveira, R.R.; Souza, M.R. Estimativa das propriedades de flexão estática de seis espécies de madeiras amazônicas por meio da técnica não-destrutiva de ondas de tensão. Acta Amaz. 2010, 40, 325–332. [Google Scholar] [CrossRef]

- Branco, L.A.M.N.; Chahud, E.; Christoforo, A.L.; Rocco Lahr, F.A.; Battistelle, R.A.G.; Valarelli, I.D. Influence of Moisture Content in Some Mechanical Properties of Two Brazilian Tropical Wood Species. Adv. Mater. Res. 2014, 1025–1026, 42–45. [Google Scholar] [CrossRef]

- Lima, I.L.; Longui, E.L.; Andrade, I.M.; Garcia, J.N.; Zanatto, A.C.S.; Morais, E.; Florsheim, S.M.B. Efeito da Procedência em Algumas Propriedades da Madeira de Gallesia Integrifolia (Spreng.) Harms. Effect of Provenance in Some Wood Properties of Gallesia Integrifolia (Spreng.) Harms. Rev. Inst. Florest. 2010, 22, e17. [Google Scholar]

- Krzosek, S.; Burawska-Kupniewska, I.; Mankowski, P. Geographical Origin and Log Quality Influence on the Mechanical Properties of Scots Pine Sawnwood. BioResources 2020, 16, 669–683. [Google Scholar] [CrossRef]

- Tumenjargal, B.; Ishiguri, F.; Aiso, H.; Takahashi, Y.; Nezu, I.; Takashima, Y.; Baasan, B.; Chultem, G.; Ohshima, J.; Yokota, S. Physical and Mechanical Properties of Wood and Their Geographic Variations in Larix Sibirica Trees Naturally Grown in Mongolia. Sci. Rep. 2020, 10, 12936. [Google Scholar] [CrossRef] [PubMed]

- You, R.; Zhu, N.; Deng, X.; Wang, J.; Liu, F. Variation in Wood Physical Properties and Effects of Climate for Different Geographic Sources of Chinese Fir in Subtropical Area of China. Sci. Rep. 2021, 11, 4664. [Google Scholar] [CrossRef]

- NBR 7190; Timber Structures. Associação Brasileira de Normas Técnicas—ABNT: Rio de Janeiro, Brazil, 2022.

- Instituto Brasileiro de Geografia e Estatística—IBGE. Mapas do Brasil; IBGE: Rio de Janeiro, Brazil, 2002. [Google Scholar]

- NBR 7190-1; Timber Structures Part 1: Design Criteria. Associação Brasileira de Normas Técnicas—ABNT: Rio de Janeiro, Brazil, 2022.

- NBR 7190-3; Timber Structures Part 3: Test Methods for Characterization of Defect-Free Specimens for Timber of Native Forests. Associação Brasileira de Normas Técnicas—ABNT: Rio de Janeiro, Brazil, 2022.

- Icimoto, F.H.; Ferro, F.S.; Almeida, D.H.; Cristoforo, A.L.; Rocco Lahr, F.A. Influence of Specimen Orientation on Determination of Elesticity in Static Bending. Maderas Cienc. Tecnol. 2015, 17, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Koczan, G.; Karwat, Z.; Kozakiewicz, P. An Attempt to Unify the Brinell, Janka and Monnin Hardness of Wood on the Basis of Meyer Law. J. Wood Sci. 2021, 67, 7. [Google Scholar] [CrossRef]

- Ross, R.J.; Forest Products Laboratory; USDA Forest Service. Wood Handbook: Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 1–509. [Google Scholar]

| Property | Cv (%) | Max | Min | CI | |

|---|---|---|---|---|---|

| (g cm−3) | 1.04 | 4.48 | 1.12 | 0.93 | 1.01; 1.06 |

| (%) | 4.70 | 3.63 | 4.99 | 4.41 | 4.61; 4.8 |

| (%) | 6.60 | 6.65 | 7.18 | 5.51 | 6.36; 6.85 |

| (MPa) | 81.73 | 9.31 | 98.50 | 71.90 | 77.43; 86.04 |

| (MPa) | 103.05 | 33.95 | 160.80 | 52.80 | 83.26; 122.84 |

| (MPa) | 3.33 | 33.22 | 4.70 | 1.20 | 2.71; 3.96 |

| (MPa) | 21.42 | 21.38 | 27.80 | 12.40 | 18.83; 24.01 |

| (MPa) | 0.66 | 27.83 | 1.00 | 0.40 | 0.55; 0.76 |

| (MPa) | 129.74 | 15.28 | 159.40 | 101.30 | 118.52; 140.96 |

| (MPa) | 16,597.27 | 7.80 | 18,926.70 | 14,116.80 | 15,864.88; 17,329.66 |

| (MPa) | 16,605.22 | 15.85 | 20,969.30 | 12,146.50 | 15,115.62; 18,094.81 |

| (MPa) | 16,645.41 | 11.01 | 21,781.70 | 14,591.60 | 15,608.41; 17,682.41 |

| (MPa) | 163.59 | 8.08 | 182.00 | 138.10 | 156.11; 171.07 |

| (MPa) | 127.01 | 19.27 | 170.20 | 76.60 | 113.16; 140.85 |

| (kJ/m²) | 34.32 | 43.87 | 66 | 15.80 | 25.80; 42.84 |

| Property | Cv (%) | Max | Min | CI | |

|---|---|---|---|---|---|

| (g cm−3) | 1.11 | 2.47 | 1.16 | 1.05 | 1.09; 1.12 |

| (%) | 5.70 | 8.68 | 6.35 | 4.79 | 5.42; 5.98 |

| (%) | 9.39 | 10.14 | 10.73 | 7.51 | 8.85; 9.93 |

| (MPa) | 68.13 | 13.56 | 84.40 | 55.40 | 62.9; 73.36 |

| (MPa) | 92.05 | 27.15 | 151.10 | 64.00 | 77.91; 106.19 |

| (MPa) | 2.66 | 47.95 | 6.30 | 1.50 | 1.94; 3.38 |

| (MPa) | 22.40 | 14.07 | 26.70 | 17.60 | 20.62; 24.18 |

| (MPa) | 0.81 | 26.69 | 1.20 | 0.40 | 0.69; 0.94 |

| (MPa) | 107.98 | 17.41 | 148.30 | 76.50 | 97.34; 118.61 |

| (MPa) | 17,840.00 | 10.19 | 20,596.60 | 13,842.00 | 16,811.2; 18,868.8 |

| (MPa) | 16,330.23 | 10.48 | 19,534.70 | 14,038.00 | 15,362.08; 17,298.38 |

| (MPa) | 16,167.70 | 9.93 | 19,463.70 | 13,823.00 | 15,259.75; 17,075.65 |

| (MPa) | 142.47 | 12.05 | 161.00 | 107.70 | 132.76; 152.18 |

| (MPa) | 123.56 | 10.35 | 142.00 | 101.50 | 116.32; 130.79 |

| (kJ/m²) | 40.95 | 25.64 | 58.88 | 20.73 | 35.01; 46.89 |

| Property | Cv (%) | Max | Min | CI | |

|---|---|---|---|---|---|

| (g cm−3) | 1.06 | 4.27 | 1.12 | 0.98 | 1.03; 1.08 |

| (%) | 5.42 | 9.57 | 6.26 | 4.86 | 5.13; 5.71 |

| (%) | 7.62 | 12.07 | 9.65 | 6.52 | 7.1; 8.14 |

| (MPa) | 73.68 | 16.04 | 88.30 | 49.90 | 66.99; 80.36 |

| (MPa) | 93.25 | 20.08 | 132.00 | 57.80 | 82.66; 103.84 |

| (MPa) | 3.47 | 38.94 | 6.10 | 2.00 | 2.7; 4.23 |

| (MPa) | 21.76 | 15.47 | 28.70 | 16.90 | 19.85; 23.66 |

| (MPa) | 0.68 | 37.97 | 1.30 | 0.30 | 0.53; 0.82 |

| (MPa) | 117.41 | 17.10 | 153.20 | 88.90 | 106.05; 128.77 |

| (MPa) | 17,363.31 | 14.97 | 21,427.40 | 13,399.50 | 15,892.92; 18,833.7 |

| (MPa) | 18,332.11 | 13.03 | 22,804.90 | 15,132.00 | 16,980.63; 19,683.58 |

| (MPa) | 18,052.48 | 10.91 | 21,400.40 | 15,177.00 | 16,937.98; 19,166.97 |

| (MPa) | 143.59 | 21.78 | 195.40 | 98.60 | 125.9; 161.29 |

| (MPa) | 119.31 | 23.77 | 172.30 | 82.30 | 103.26; 135.35 |

| (kJ/m²) | 41.67 | 30.44 | 71.50 | 20.25 | 34.49; 48.84 |

| Property | RR-A | RR-B | MT | |||

|---|---|---|---|---|---|---|

| Grading | Grading | Grading | ||||

| (MPa) | 78.63 | D60 | 52.93 | D50 | 53.37 | D50 |

| (MPa) | 64.15 | 62.13 | 67.69 | |||

| (MPa) | 1.03 | 1.67 | 1.58 | |||

| (MPa) | 12.54 | 20.22 | 19.54 | |||

| (MPa) | 0.29 | 0.51 | 0.40 | |||

| (MPa) | 106.08 | 84.66 | 94.53 | |||

| (MPa) | 154.79 | 114.49 | 97.57 | |||

| (MPa) | 100.76 | 114.97 | 90.49 | |||

| Property | p-Valor | Tukey (Grouping) | ||||

|---|---|---|---|---|---|---|

| ANOVA | A-D | C-M | RR-A | RR-B | MT | |

| (g cm−3) | 0.001 | 0.053 | 0.245 | B | A | B |

| (%) | 0.001 | 0.984 | 0.063 | B | A | A |

| (%) | 0.001 | 0.908 | 0.075 | A | C | B |

| (MPa) | 0.006 | 0.814 | 0.538 | A | B | AB |

| (MPa) | 0.557 | 0.190 | 0.145 | A | A | A |

| (MPa) | 0.250 | 0.225 | 0.827 | A | A | A |

| (MPa) | 0.810 | 0.159 | 0.415 | A | A | A |

| (MPa) | 0.187 | 0.293 | 0.454 | A | A | A |

| (MPa) | 0.035 | 0.890 | 0.974 | A | B | AB |

| (MPa) | 0.312 | 0.762 | 0.054 | A | A | A |

| (MPa) | 0.080 | 0.374 | 0.297 | A | A | A |

| (MPa) | 0.041 | 0.019 | 0.777 | AB | B | A |

| (MPa) | 0.057 | 0.349 | 0.072 | A | A | A |

| (MPa) | 0.713 | 0.093 | 0.101 | A | A | A |

| (kJ/m²) | 0.318 | 0.516 | 0.546 | A | A | A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, H.F.; de Moraes, M.H.M.; de Oliveira, I.A.; de Freitas, L.; de Moura Aquino, V.B.; Menezes, I.S.; Fraga, I.F.; Lahr, F.A.R.; Mascarenhas, F.J.R.; de Almeida Filho, F.M.; et al. Influence of the Harvesting Region on Batch Homogeneity of Ipe Wood (Tabebuia sp.) Based on Its Physical and Mechanical Properties. Forests 2022, 13, 1385. https://doi.org/10.3390/f13091385

dos Santos HF, de Moraes MHM, de Oliveira IA, de Freitas L, de Moura Aquino VB, Menezes IS, Fraga IF, Lahr FAR, Mascarenhas FJR, de Almeida Filho FM, et al. Influence of the Harvesting Region on Batch Homogeneity of Ipe Wood (Tabebuia sp.) Based on Its Physical and Mechanical Properties. Forests. 2022; 13(9):1385. https://doi.org/10.3390/f13091385

Chicago/Turabian Styledos Santos, Herisson Ferreira, Matheus Henrique Morato de Moraes, Ivanildo Amorim de Oliveira, Ludmila de Freitas, Vinícius Borges de Moura Aquino, Isabella Silva Menezes, Iuri Fazolin Fraga, Francisco Antonio Rocco Lahr, Fernando Júnior Resende Mascarenhas, Fernando Menezes de Almeida Filho, and et al. 2022. "Influence of the Harvesting Region on Batch Homogeneity of Ipe Wood (Tabebuia sp.) Based on Its Physical and Mechanical Properties" Forests 13, no. 9: 1385. https://doi.org/10.3390/f13091385