Physical and Mechanical Properties of Plywood Produced with Thermally Treated Pinus taeda Veneers

Abstract

1. Introduction

2. Materials and Methods

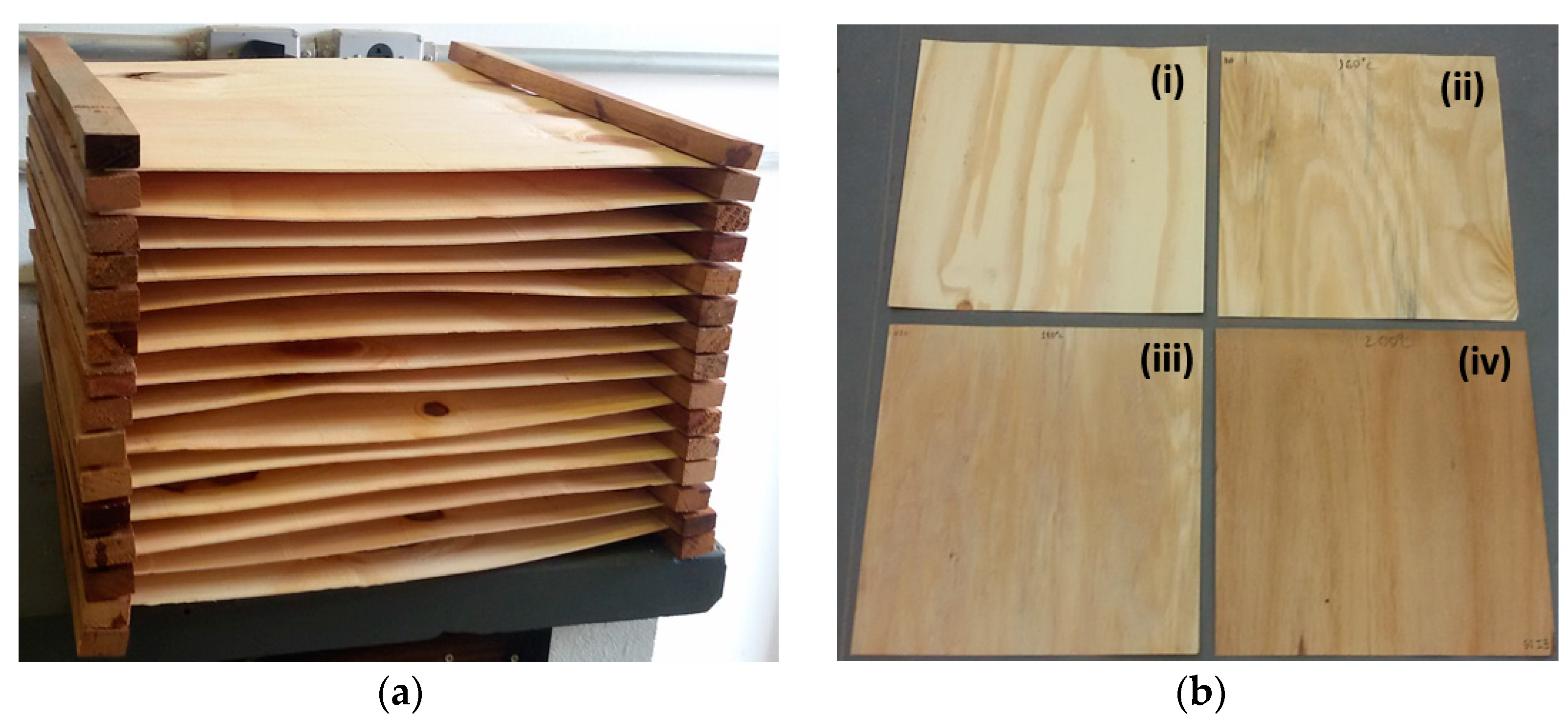

2.1. Materials

2.2. Heat Treatment

2.3. Plywood Production

2.4. Plywood Characterization

2.5. Statistical Analysis

3. Results and Discussion

4. Conclusions

- i.

- The veneer heat treatment modified the specific gravity of plywood, reduced the equilibrium moisture content and did not affect swelling values.

- ii.

- There was change in the total extractive content in relation to the control treatment, where the minimum value was reached at the temperature of 160 °C.

- iii.

- The increase of heat treatment temperature caused a reduction of the roughness in the surfaces of the Pinus taeda veneers. However, no direct interference was observed in the studied properties.

- iv.

- The MOE and MOR values in both axis of the boards produced with heat treated wood did not present statistical difference with control treatment; also, mechanical properties of all treatments met the requirements for structural use specified by ABIMCI [37].

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Almeida, T.H.; de Almeida, D.H.; Icimoto, F.H.; de Campos, C.I.; Varanda, L.D.; Christoforo, A.L.; Lahr, F.A.R. Quality Assessment in Industrial Production of Plywood by Stiffness and Strength Properties in Bending. Int. J. Mater. Eng. 2013, 3, 108–111. [Google Scholar] [CrossRef]

- Ferreira, B.S.; Silva, J.V.F.; de Campos, C.I. Static Bending Strength of Heat-Treated and Chromated Copper Arsenate-Treated Plywood. BioResources 2017, 12, 6276–6282. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, J. Study on Static Lateral Load–Slip Behavior of Single-Shear Stapled Connections in Plywood for Upholstered Furniture Frame Construction. J. Wood Sci. 2021, 67, 40. [Google Scholar] [CrossRef]

- Almeida, D.H.; Ferro, F.S.; Varanda, L.D.; de Souza, A.M.; Icimoto, F.H.; Christoforo, A.L.; Lahr, F.A.R. Quality Control in Plywood Manufacturing: Physical Properties of Commercial Plywood of Pinus sp. Int. J. Compos. Mater. 2013, 3, 163–167. [Google Scholar] [CrossRef][Green Version]

- Kulmann, M.S.d.S.; Dick, G.; Schumacher, M.V. Litterfall and Accumulated Nutrients in Pinus Taeda Plantation and Native Forest in Southern Brazil. Forest 2021, 12, 1791. [Google Scholar] [CrossRef]

- Bekhta, P. Effect of Heat Treatment on Some Physical and Mechanical Properties of Birch Plywood. Eur. J. Wood Wood Prod. 2020, 78, 683–691. [Google Scholar] [CrossRef]

- Li, X.; Peng, H.; Niu, S.; Liu, X.; Li, Y. Effect of High-Temperature Hydrothermal Treatment on Chemical, Mechanical, Physical, and Surface Properties of Moso Bamboo. Forest 2022, 13, 712. [Google Scholar] [CrossRef]

- Catry, F.X.; Branco, M.; Sousa, E.; Caetano, J.; Naves, P.; Nóbrega, F. Presence and Dynamics of Ambrosia Beetles and Other Xylophagous Insects in a Mediterranean Cork Oak Forest Following Fire. For. Ecol. Manag. 2017, 404, 45–54. [Google Scholar] [CrossRef]

- Windeisen, E.; Strobel, C.; Wegener, G. Chemical Changes during the Production of Thermo-Treated Beech Wood. Wood Sci. Technol. 2007, 41, 523–536. [Google Scholar] [CrossRef]

- Guo, X.; Wu, Y.; Yan, N. In Situ Micro-FTIR Observation of Molecular Association of Adsorbed Water with Heat—Treated Wood. Wood Sci. Technol. 2018, 52, 971–985. [Google Scholar] [CrossRef]

- Awoyemi, L.; Jones, I.P. Anatomical Explanations for the Changes in Properties of Western Red Cedar (Thuja Plicata) Wood during Heat Treatment. Wood Sci. Technol. 2011, 45, 261–267. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Kegel, E.; Stevens, M. Optimisation of a Two-Stage Heat Treatment Process: Durability Aspects. Wood Sci. Technol. 2011, 41, 31–57. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Gérardin, P.; Zoulalian, A. Investigations of the Reasons for Fungal Durability of Heat-Treated Beech Wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; Wiley Series; John Wiley & Sons Ltd.: West Sussex, UK, 2006; ISBN 9780470021729. [Google Scholar]

- Luo, J.; Luo, J.; Gao, Q.; Li, J. Effects of Heat Treatment on Wet Shear Strength of Plywood Bonded with Soybean Meal-Based Adhesive. Ind. Crop. Prod. 2015, 63, 281–286. [Google Scholar] [CrossRef]

- Safin, R.R.; Khasanshin, R.R.; Shaikhutdinova, A.R.; Ziatdinov, R.R. The Technology for Creating of Decorative Plywood with Low Formaldehyde Emission. Mater. Sci. Eng. 2015, 93, 7. [Google Scholar] [CrossRef]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of Wood Veneers by Compression Combined with Heat and Steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Ferreira, B.S.; de Campos, C.I.; Rangel, E.C. Efeito Da Termorretificação Na Qualidade de Colagem de Lâminas de Madeira Para a Produção de Compensado. Cienc. Florest. 2018, 28, 274–282. [Google Scholar] [CrossRef]

- Kamperidou, V.; Barboutis, J.I.; Vasileiou, V. Influence of Thermal Treatment on Mechanical Strength of Scots Pine (Pinus sylvestris L.) Wood. Wood Res. 2014, 59, 373–378. [Google Scholar]

- Iwakiri, S. Painéis de madeira aglomerada. In Painéis de Madeira Reconstituída; Fupef: Curitiba, Brazil, 2005; pp. 123–158. [Google Scholar]

- ABNT NBR ISO 2426-3; PLYWOOD—Classification by Surface Appearance—Part 3: Softwood. ABNT: São Paulo, Brazil, 2006; p. 8.

- TAPPI-204-cm-97; Technical Association of the Pulp and Paper Industry: Solvent Extractive of Wood and Pulp 1997. Available online: https://www.tappi.org/content/sarg/t204.pdf (accessed on 28 August 2022).

- ABNT NBR 9485; PLYWOOD—Determination of the Specific Apparent Mass. ABNT: São Paulo, Brazil, 2022; p. 3.

- ABNT NBR 9484; PLYWOOD—Determination of Moisture Content. ABNT: São Paulo, Brazil, 2011; p. 2.

- ABNT NBR 9535; PLYWOOD—Determination of Swelling—Test Method. ABNT: São Paulo, Brazil, 2011; p. 7.

- ABNT NBR 9533; PLYWOOD—Determination of Bending Resistance. ABNT: São Paulo, Brazil, 2013; p. 5.

- R A Language and Environment for Statistical Computing—R Foundation for Statistical Computing 2016. Available online: https://www.gbif.org/pt/tool/81287/r-a-language-and-environment-for-statistical-computing (accessed on 28 August 2022).

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of Heat-Treated Wood. Holz Roh Werkst. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Candana, Z.; Hiziroglu, S.; McDonald, A.G. Surface Quality of Thermally Compressed Douglas Fir Veneer. Mater. Des. 2010, 31, 3574–3577. [Google Scholar] [CrossRef]

- Yildiz, S.; Gezer, E.D.; Yildiz, U.C. Mechanical and Chemical Behavior of Spruce Wood Modified by Heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Da Silva Poubel, D.; Garcia, R.A.; dos Santos, W.A.; de Lima Oliveira, G.; dos Santos Abreu, H. Efeito Da Termorretificação Nas Propriedades Físicas e Químicas Da Madeira de Pinus Caribaea. Cerne 2013, 19, 391–398. [Google Scholar] [CrossRef]

- Mendes, R.F.; Júnior, G.B.; De Almeida, N.F.; Surdi, P.G.; Barbeiro, I.N. Effect of Thermal Treatment on Properties of OSB Panels. Wood Sci. Technol. 2013, 47, 243–256. [Google Scholar] [CrossRef]

- Weiland, J.J.; Guyonnet, R. Study of Chemical Modifications and Fungi Degradation of Thermally Modified Wood Using DRIFT Spectroscopy. Holz Roh Werkst. 2003, 61, 216–220. [Google Scholar] [CrossRef]

- Brito, J.O.; Garcia, J.N.; Bortoletto Júnior, G.; das Chagas Pessoa, A.M.; da Silva, P.H.M. Densidade Básica e Retratibilidade Da Madeira de Eucalyptus Grandis, Submetida a Diferentes Temperaturas de Termorretificação. Cerne 2006, 12, 182–188. [Google Scholar]

- Kačíková, D.; Kačík, F.; Čabalová, I.; Ďurkovič, J. Effects of Thermal Treatment on Chemical, Mechanical and Colour Traits in Norway Spruce Wood. Bioresour. Technol. 2013, 144, 669–674. [Google Scholar] [CrossRef]

- Mendes, R.F.; Bortoletto Júnior, G.; de Almeida, N.F.; Surdi, P.G.; Barbeiro, I.N. Effects of Thermal Pre-Treatment and Variables of Production on Properties of OSB Panels of Pinus Taeda. Maderas Cienc. Tecnol. 2013, 15, 141–152. [Google Scholar] [CrossRef][Green Version]

- ABIMCI. Catálogo Técnico de Compensado de Pinus; ABIMCI: Curitiba, Brazil, 2007. [Google Scholar]

| Property | Functions | Adjusted R2 | p-Value |

|---|---|---|---|

| Specific gravity | 0.4460 | <5% | |

| Moisture content | 0.3120 | <5% | |

| Thickness swelling | 0.6157 | <5% | |

| Extractive content | 0.9625 | <5% | |

| MOE (major axis) | 10,459 | −0.0265 | >5% |

| MOE (minor axis) | −0.0998 | >5% | |

| MOR (major axis) | −0.0499 | >5% | |

| MOR (minor axis) | 0.0895 | >5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, B.S.; Arroyo, F.N.; Kondo, M.Y.; Santos, H.F.d.; Barreto, R.L.; Dias, A.M.P.G.; Lahr, F.A.R.; Christoforo, A.L.; Campos, C.I.d. Physical and Mechanical Properties of Plywood Produced with Thermally Treated Pinus taeda Veneers. Forests 2022, 13, 1398. https://doi.org/10.3390/f13091398

Ferreira BS, Arroyo FN, Kondo MY, Santos HFd, Barreto RL, Dias AMPG, Lahr FAR, Christoforo AL, Campos CId. Physical and Mechanical Properties of Plywood Produced with Thermally Treated Pinus taeda Veneers. Forests. 2022; 13(9):1398. https://doi.org/10.3390/f13091398

Chicago/Turabian StyleFerreira, Bruno Santos, Felipe Nascimento Arroyo, Marcel Yuzo Kondo, Herisson Ferreira dos Santos, Rogério Lima Barreto, Alfredo Manuel Pereira Geraldes Dias, Francisco Antônio Rocco Lahr, André Luis Christoforo, and Cristiane Inácio de Campos. 2022. "Physical and Mechanical Properties of Plywood Produced with Thermally Treated Pinus taeda Veneers" Forests 13, no. 9: 1398. https://doi.org/10.3390/f13091398

APA StyleFerreira, B. S., Arroyo, F. N., Kondo, M. Y., Santos, H. F. d., Barreto, R. L., Dias, A. M. P. G., Lahr, F. A. R., Christoforo, A. L., & Campos, C. I. d. (2022). Physical and Mechanical Properties of Plywood Produced with Thermally Treated Pinus taeda Veneers. Forests, 13(9), 1398. https://doi.org/10.3390/f13091398