Impact of Sugar Beet Pulp Share on Selected Physical and Mechanical Properties of Particleboards

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Particleboard Manufacturing

2.3. Experimental

2.4. Statistical Analysis

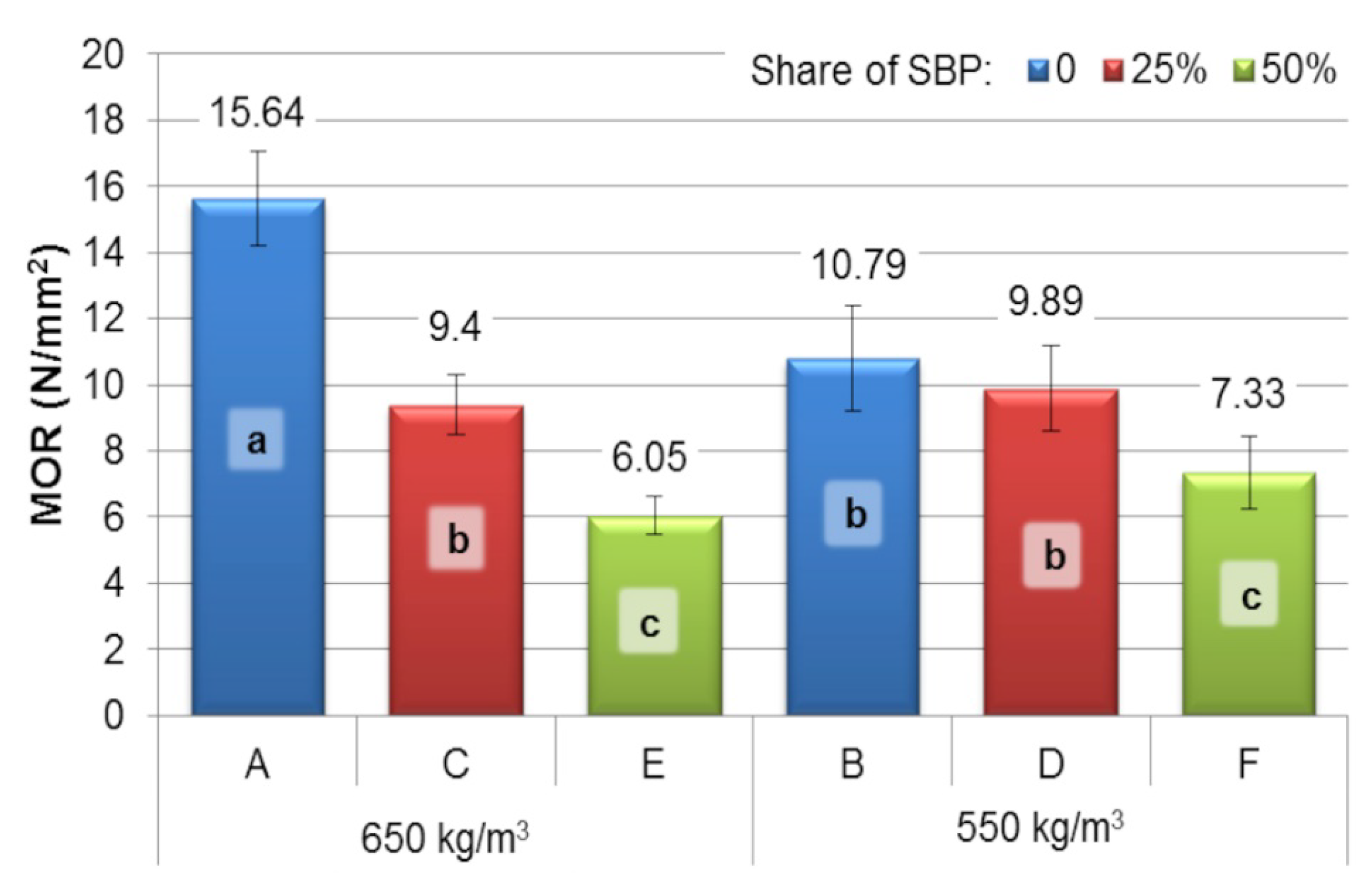

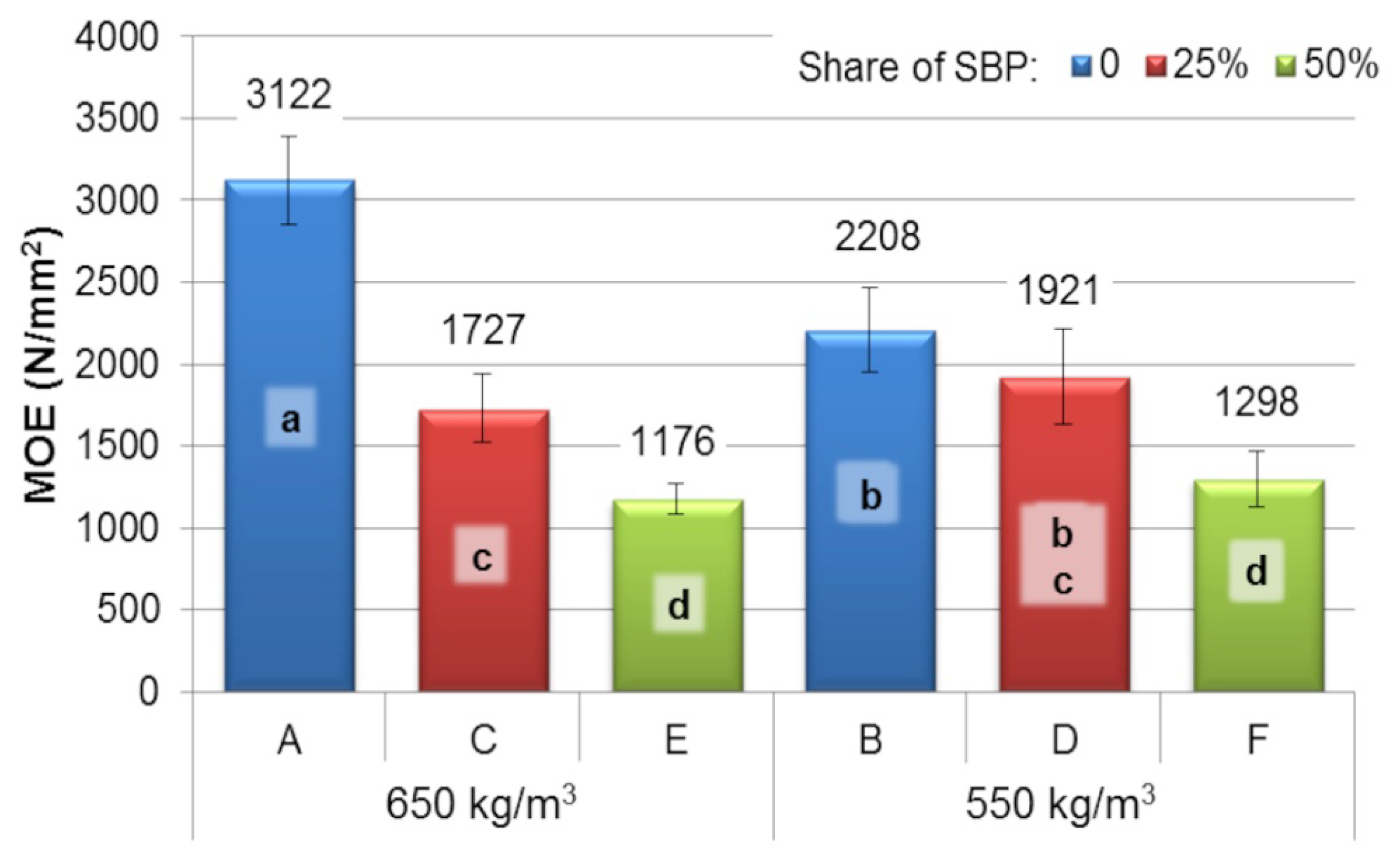

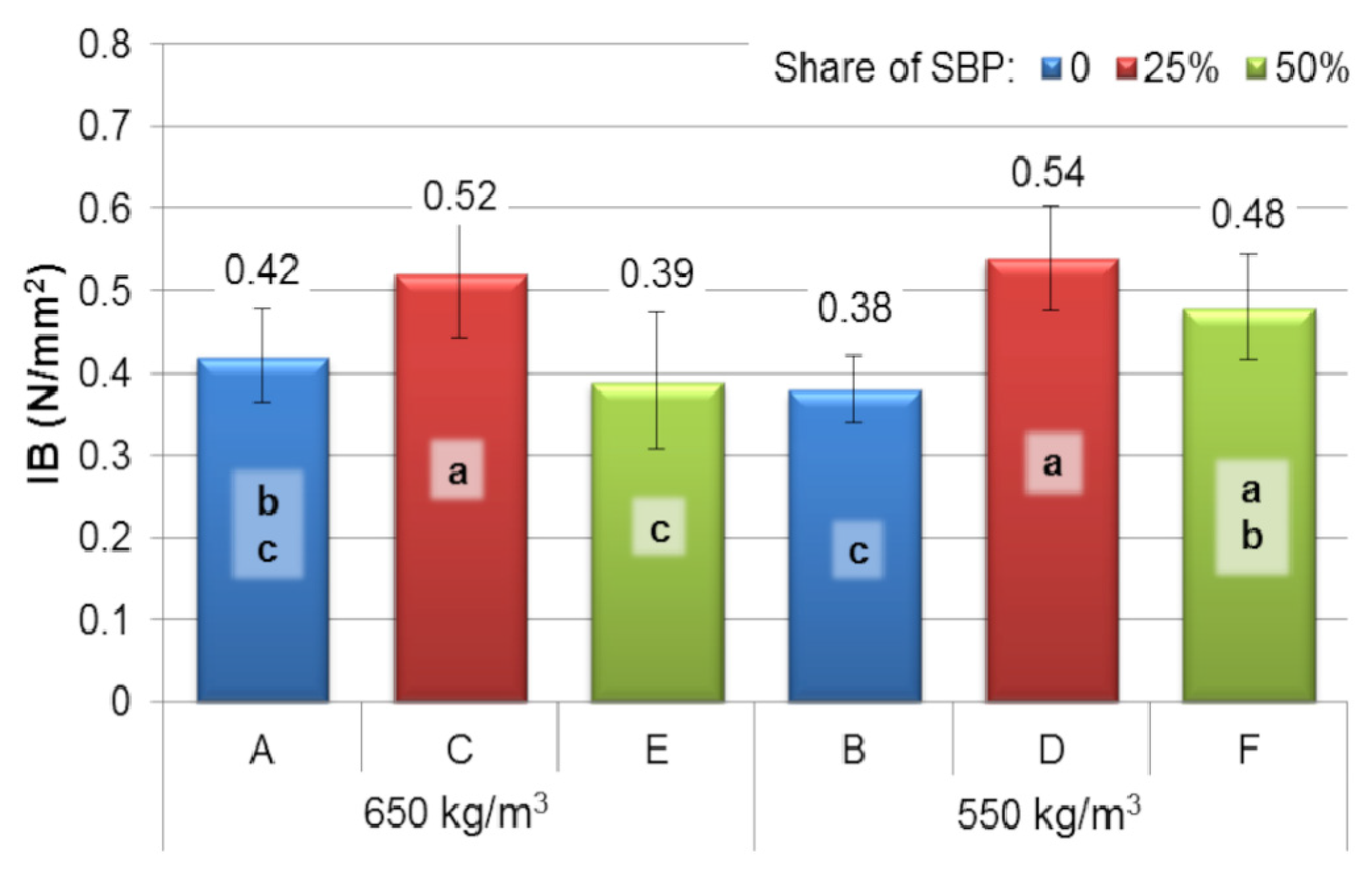

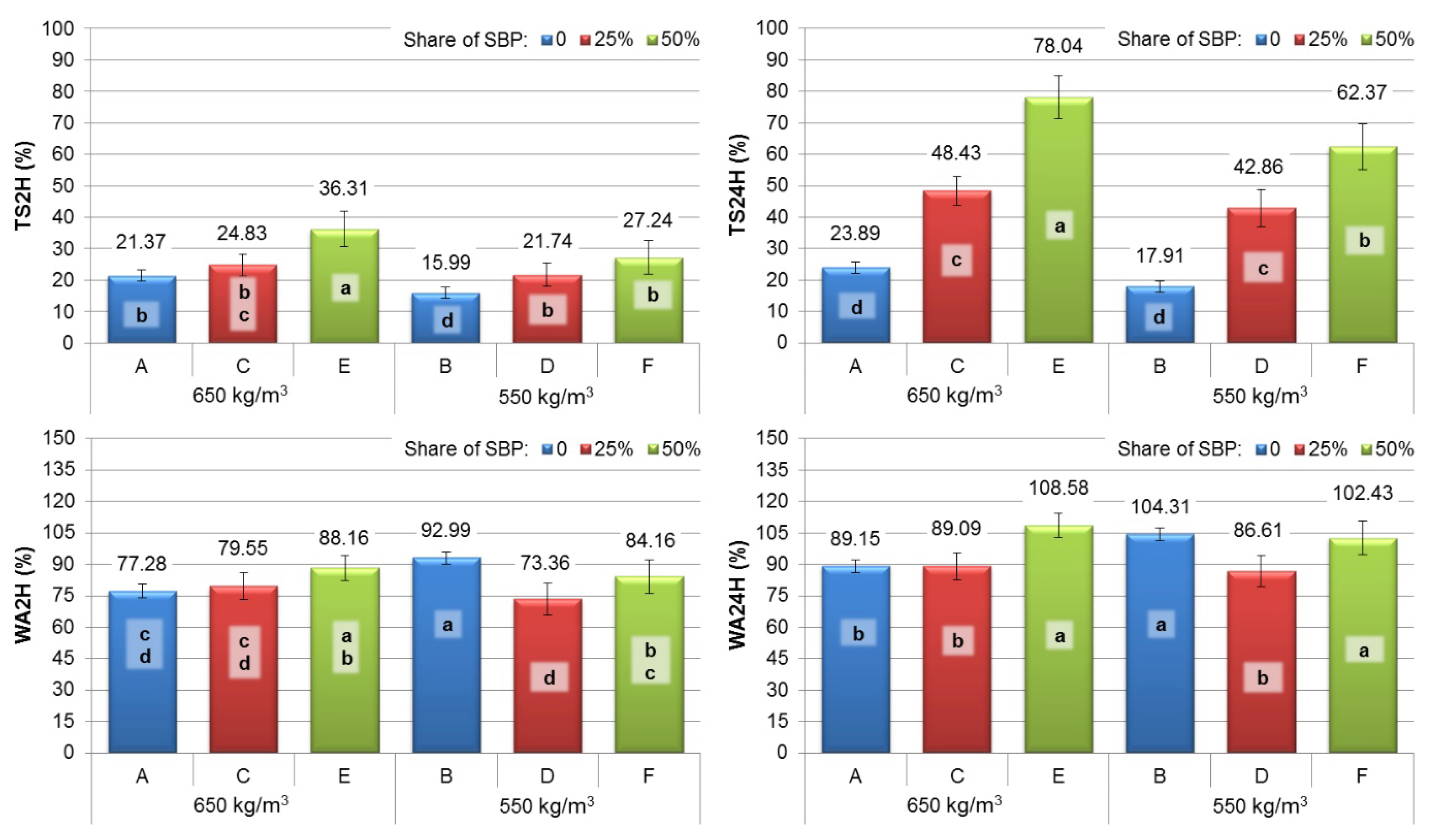

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#home (accessed on 10 October 2022).

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels An Introduction for Specialists; Brunel University Press: London, UK, 2010; ISBN 9781902316826. [Google Scholar]

- Lertsutthiwong, P.; Khunthon, S.; Siralertmukul, K.; Noomun, K.; Chandrkrachang, S. New Insulating Particleboards Prepared from Mixture of Solid Wastes from Tissue Paper Manufacturing and Corn Peel. Bioresour. Technol. 2008, 99, 4841–4845. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.-S.; Shih, K. Recycling Contaminated Wood into Eco-Friendly Particleboard Using Green Cement and Carbon Dioxide Curing. J. Clean. Prod. 2016, 137, 861–870. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Yu, K.; Li, S.; Poon, C.S.; Dai, J.G. Upcycling Wood Waste into Fibre-Reinforced Magnesium Phosphate Cement Particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Kramár, S.; Mayer, A.K.; Schöpper, C.; Mai, C. Use of Basalt Scrim to Enhance Mechanical Properties of Particleboards. Constr. Build. Mater. 2020, 238, 117769. [Google Scholar] [CrossRef]

- Borysiuk, P.; Wilkowski, J.; Krajewski, K.; Auriga, R.; Skomorucha, A.; Auriga, A. Selected Properties of Flat-Pressed Wood-Polymer Composites for High Humidity Conditions. BioResources 2020, 15, 5141–5155. [Google Scholar] [CrossRef]

- Müller, C.; Schwarz, U.; Thole, V. Zur Nutzung von Agrar-Reststoffen in Der HolzwerkstoffindustrieOn the Utilization of Agricultural Residues in the Wood-Based Panel Industry. Eur. J. Wood Wood Prod. 2011, 70, 587–594. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Ntalos, G.A.; Grigoriou, A.H. Characterization and Utilisation of Vine Prunings as a Wood Substitute for Particleboard Production. Ind. Crops Prod. 2002, 16, 59–68. [Google Scholar] [CrossRef]

- Auriga, R.; Auriga, A.; Borysiuk, P.; Wilkowski, J.; Fornalczyk, O.; Ochmian, I. Lignocellulosic Biomass from Grapevines as Raw Material for Particleboard Production. Polymers 2022, 14, 2483. [Google Scholar] [CrossRef]

- Guntekin, E.; Karakus, B. Feasibility of Using Eggplant (Solanum Melongena) Stalks in the Production of Experimental Particleboard. Ind. Crops Prod. 2008, 27, 354–358. [Google Scholar] [CrossRef]

- Kalaycioglu, H.; Nemli, G. Producing Composite Particleboard from Kenaf (Hibiscus cannabinus L.) Stalks. Ind. Crops Prod. 2006, 24, 177–180. [Google Scholar] [CrossRef]

- Paridah, M.T.; Juliana, A.H.; El-Shekeil, Y.A.; Jawaid, M.; Alothman, O.Y. Measurement of Mechanical and Physical Properties of Particleboard by Hybridization of Kenaf with Rubberwood Particles. Meas. J. Int. Meas. Confed. 2014, 56, 70–80. [Google Scholar] [CrossRef]

- Tabarsa, T.; Jahanshahi, S.; Ashori, A. Mechanical and Physical Properties of Wheat Straw Boards Bonded with a Tannin Modified Phenol-Formaldehyde Adhesive. Compos. Part B Eng. 2011, 42, 176–180. [Google Scholar] [CrossRef]

- Taha, I.; Elkafafy, M.S.; El Mously, H. Potential of Utilizing Tomato Stalk as Raw Material for Particleboards. Ain Shams Eng. J. 2018, 9, 1457–1464. [Google Scholar] [CrossRef]

- Zeleniuc, O.; Brenci, L.M.; Cosereanu, C.; Fotin, A. Influence of Adhesive Type and Content on the Properties of Particleboard Made from Sunflower Husks. BioResources 2019, 14, 7316–7331. [Google Scholar] [CrossRef]

- Auriga, R.; Borysiuk, P.; Gumowska, A.; Smulski, P. Influence of Apple Wood Waste from the Annual Care Cut on the Mechanical Properties of Particleboards. Ann. WULS For. Wood Technol. 2019, 105, 47–53. [Google Scholar] [CrossRef]

- Akinyemi, A.B.; Afolayan, J.O.; Ogunji Oluwatobi, E. Some Properties of Composite Corn Cob and Sawdust Particle Boards. Constr. Build. Mater. 2016, 127, 436–441. [Google Scholar] [CrossRef]

- Chaydarreh, K.C.; Lin, X.; Dandan, L.; Zhang, W.; Guan, L.; Hu, C. Developing 3-Layer Tea Oil Camellia (Camellia oleifera Abel.) Shells-Based Particleboard with Systematic Study on Particle Geometry and Distribution. Ind. Crops Prod. 2022, 179, 114682. [Google Scholar] [CrossRef]

- Choupani Chaydarreh, K.; Lin, X.; Guan, L.; Hu, C. Interaction between Particle Size and Mixing Ratio on Porosity and Properties of Tea Oil Camellia (Camellia oleifera Abel.) Shells-Based Particleboard. J. Wood Sci. 2022, 68, 43. [Google Scholar] [CrossRef]

- Dinand, E.; Chanzy, H.; Vignon, M.R. Parenchymal Cell Cellulose from Sugar Beet Pulp: Preparation and Properties. Cellulose 1996, 3, 183–188. [Google Scholar] [CrossRef]

- Sun, R.; Hughes, S. Fractional Extraction and Physico-Chemical Characterization of Hemicelluloses and Cellulose from Sugar Beet Pulp. Carbohydr. Polym. 1998, 36, 293–299. [Google Scholar] [CrossRef]

- Oosterveld, A.; Beldman, G.; Schols, H.A.; Voragen, A.G.J. Characterization of Arabinose and Ferulic Acid Rich Pectic Polysaccharides and Hemicelluloses from Sugar Beet Pulp. Carbohydr. Res. 2000, 328, 185–197. [Google Scholar] [CrossRef] [PubMed]

- Dinand, E.; Chanzy, H.; Vignon, R.M. Suspensions of Cellulose Microfibrils from Sugar Beet Pulp. Food Hydrocoll. 1999, 13, 275–283. [Google Scholar] [CrossRef]

- Pavier, C.; Gandini, A. Oxypropylation of Sugar Beet Pulp. 1. Optimisation of the Reaction. Ind. Crops Prod. 2000, 12, 1–8. [Google Scholar] [CrossRef]

- Leitner, J.; Hinterstoisser, B.; Wastyn, M.; Keckes, J.; Gindl, W. Sugar Beet Cellulose Nanofibril-Reinforced Composites. Cellulose 2007, 14, 419–425. [Google Scholar] [CrossRef]

- Liu, L.S.; Finkenstadt, V.L.; Liu, C.-K.; Coffin, D.R.; Willett, J.L.; Fishman, M.L.; Hicks, K.B. Green Composites from Sugar Beet Pulp and Poly(Lactic Acid): Structural and Mechanical Characterization. J. Biobased Mater. Bioenergy 2008, 1, 323–330. [Google Scholar] [CrossRef]

- Mohamed, A.A.; Finkenstadt, V.L.; Palmquist, D.E. Thermal Properties of Extruded/Injection-Molded Poly(Lactic Acid) and Biobased Composites. J. Appl. Polym. Sci. 2008, 107, 898–908. [Google Scholar] [CrossRef]

- Fišerová, M.; Gigac, J.; Butaš, R. Influence of Sugar Beet Pulp on Bond Strength and Structure of Paper. Wood Res. 2007, 52, 59–74. [Google Scholar]

- Vučurović, V.M.; Razmovski, R.N. Sugar Beet Pulp as Support for Saccharomyces Cerivisiae Immobilization in Bioethanol Production. Ind. Crops Prod. 2012, 39, 128–134. [Google Scholar] [CrossRef]

- Borysiuk, P.; Jenczyk-Tolloczko, I.; Auriga, R.; Kordzikowski, M. Sugar Beet Pulp as Raw Material for Particleboard Production. Ind. Crops Prod. 2019, 141, 111829. [Google Scholar] [CrossRef]

- Boruszewski, P.; Borysiuk, P.; Jankowska, A.; Pazik, J. Low-Density Particleboards Modified with Blowing Agents—Characteristic and Properties. Materials 2022, 15, 4528. [Google Scholar] [CrossRef] [PubMed]

- Boruszewski, P.; Borysiuk, P.; Jankowska, A.; Pazik, J. Low-Density Particleboards Modified with Expanded and Unexpanded Fillers—Characteristics and Properties. Materials 2022, 15, 4430. [Google Scholar] [CrossRef] [PubMed]

- EN 310; Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardisation: Brussels, Belgium, 1994.

- EN 319; Particleboards and Fibreboards-Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardisation: Brussels, Belgium, 1999.

- EN 323; Wood-Based Panels-Determination of Density. European Committee for Standardisation: Brussels, Belgium, 1999.

- EN 317; Particleboards and Fibreboards-Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardisation: Brussels, Belgium, 1999.

- EN 312; Particleboards-Specyfications. European Committee for Standardisation: Brussels, Belgium, 2011.

| Variant | Core Layer SBP Share (%) | Density (kg/m3) |

|---|---|---|

| A | 0 | 650 |

| B | 0 | 550 |

| C | 25 | 650 |

| D | 25 | 550 |

| E | 50 | 650 |

| F | 50 | 550 |

| Variant | Particleboards Density (kg/m3) | |

|---|---|---|

| Average | Std. Dev. | |

| A | 663 a | 32 |

| B | 553 b | 27 |

| C | 648 a | 34 |

| D | 566 b | 22 |

| E | 644 a | 34 |

| F | 562 b | 31 |

| MOR | MOE | IB | ||||

|---|---|---|---|---|---|---|

| p | X | p | X | p | X | |

| Share | 0.000 | 67.68 | 0.000 | 74.13 | 0.000 | 38.98 |

| Density | 0.001 | 2.51 | 0.001 | 2.15 | 0.212 | 1.48 |

| Share × Density | 0.000 | 17.66 | 0.000 | 13.83 | 0.009 | 9.46 |

| Error | 12.15 | 9.89 | 50.07 | |||

| TS2H | TS24H | WA2H | WA24H | |||||

|---|---|---|---|---|---|---|---|---|

| p | X | p | X | p | X | p | X | |

| Share | 0.000 | 55.31 | 0.000 | 88.97 | 0.000 | 24.90 | 0.000 | 44.88 |

| Density | 0.000 | 16.07 | 0.000 | 4.52 | 0.237 | 1.11 | 0.216 | 1.02 |

| Share × Density | 0.058 | 2.86 | 0.004 | 1.20 | 0.000 | 31.87 | 0.000 | 18.71 |

| Error | 25.75 | 5.31 | 42.11 | 35.38 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Auriga, R.; Borysiuk, P.; Latos, M.; Auriga, A.; Kwaśny, Ł.; Walkiewicz, J. Impact of Sugar Beet Pulp Share on Selected Physical and Mechanical Properties of Particleboards. Forests 2023, 14, 40. https://doi.org/10.3390/f14010040

Auriga R, Borysiuk P, Latos M, Auriga A, Kwaśny Ł, Walkiewicz J. Impact of Sugar Beet Pulp Share on Selected Physical and Mechanical Properties of Particleboards. Forests. 2023; 14(1):40. https://doi.org/10.3390/f14010040

Chicago/Turabian StyleAuriga, Radosław, Piotr Borysiuk, Maciej Latos, Alicja Auriga, Łukasz Kwaśny, and Joanna Walkiewicz. 2023. "Impact of Sugar Beet Pulp Share on Selected Physical and Mechanical Properties of Particleboards" Forests 14, no. 1: 40. https://doi.org/10.3390/f14010040

APA StyleAuriga, R., Borysiuk, P., Latos, M., Auriga, A., Kwaśny, Ł., & Walkiewicz, J. (2023). Impact of Sugar Beet Pulp Share on Selected Physical and Mechanical Properties of Particleboards. Forests, 14(1), 40. https://doi.org/10.3390/f14010040