Construction of Rainbow-like Structural Color Coatings on Wood Surfaces Based on Polystyrene Microspheres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PSt Microspheres by Emulsion Polymerization

2.3. Fabrication of Structural Color Coatings on Wood Surface

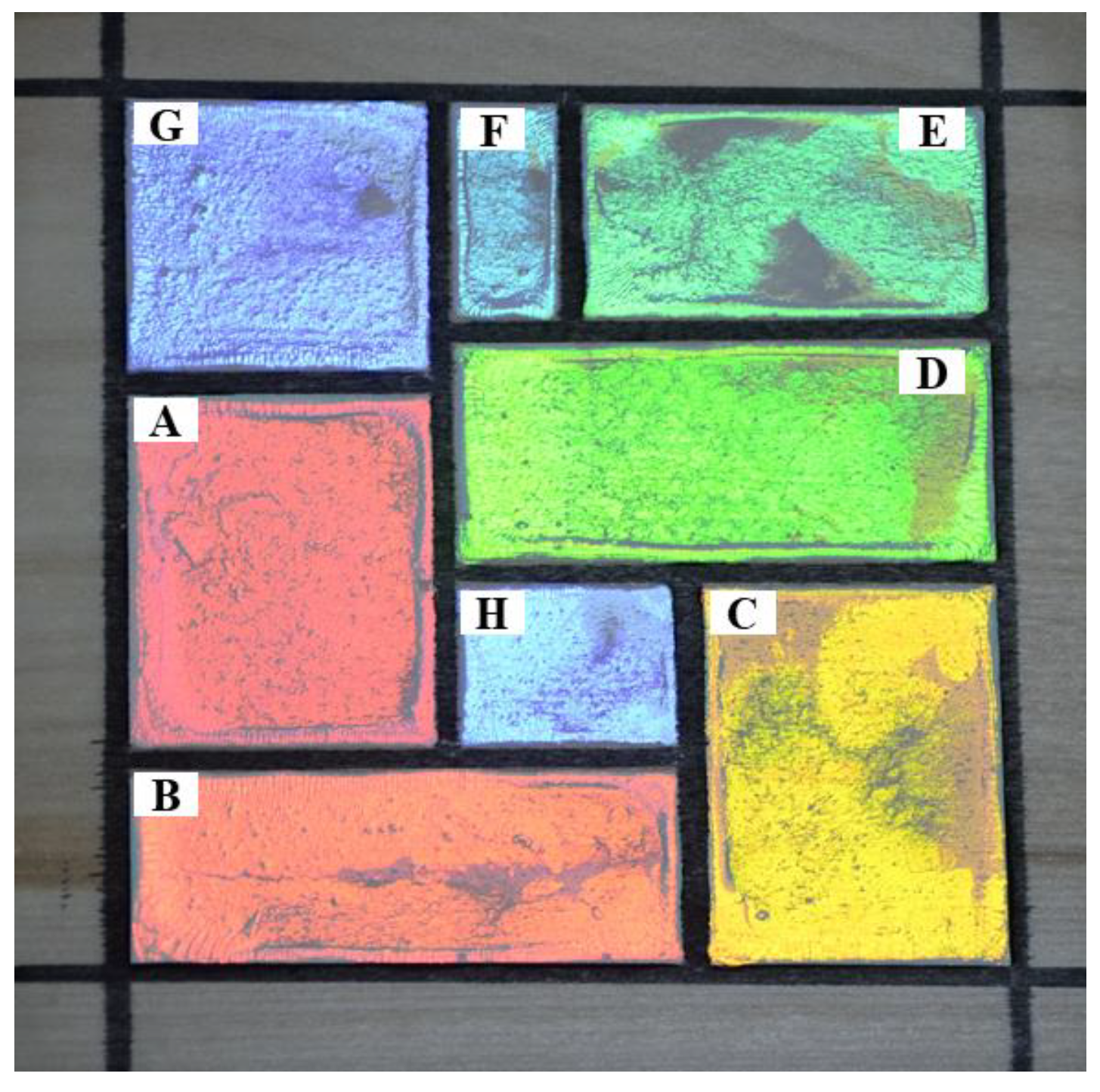

2.4. Patterning Application of Rainbow Structural Color Coatings on a Wood Surface

2.5. Characterization of PSt Microspheres and Wood Surface Structural Color Coatings

3. Results and Discussion

3.1. Effect of Polymerization Conditions on the Diameter of PSt Microspheres

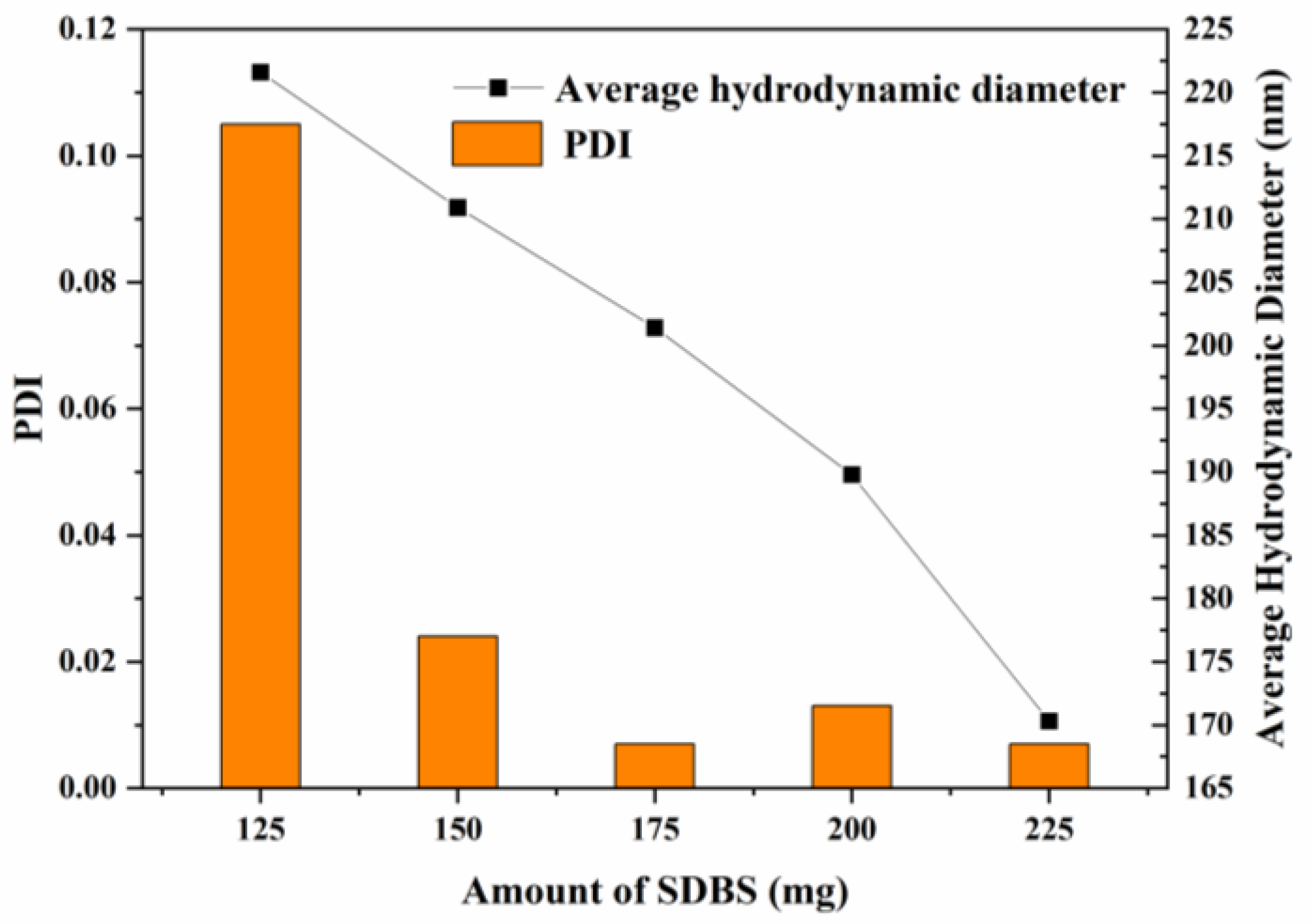

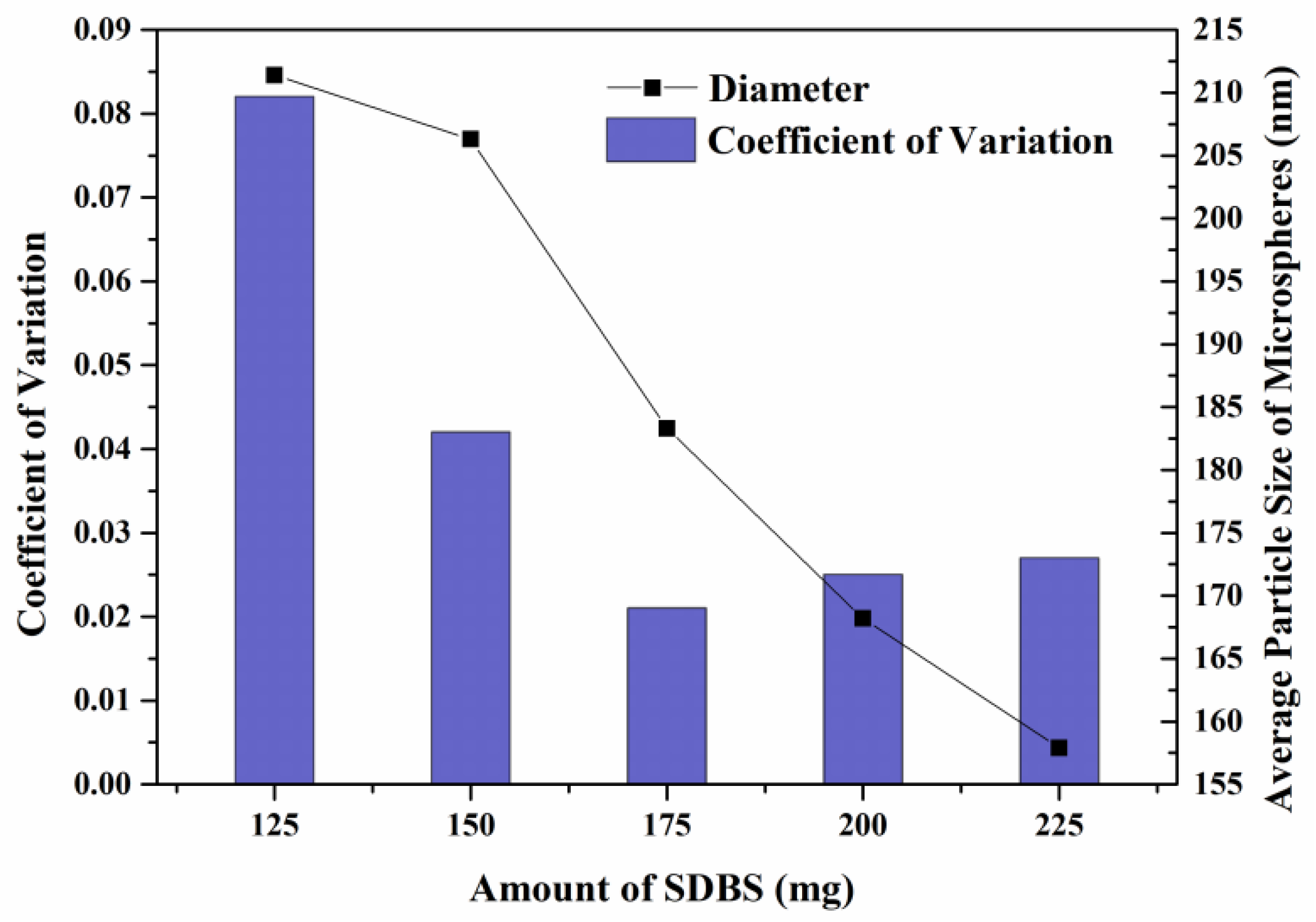

3.1.1. Effect of Emulsifier SDBS Dosage

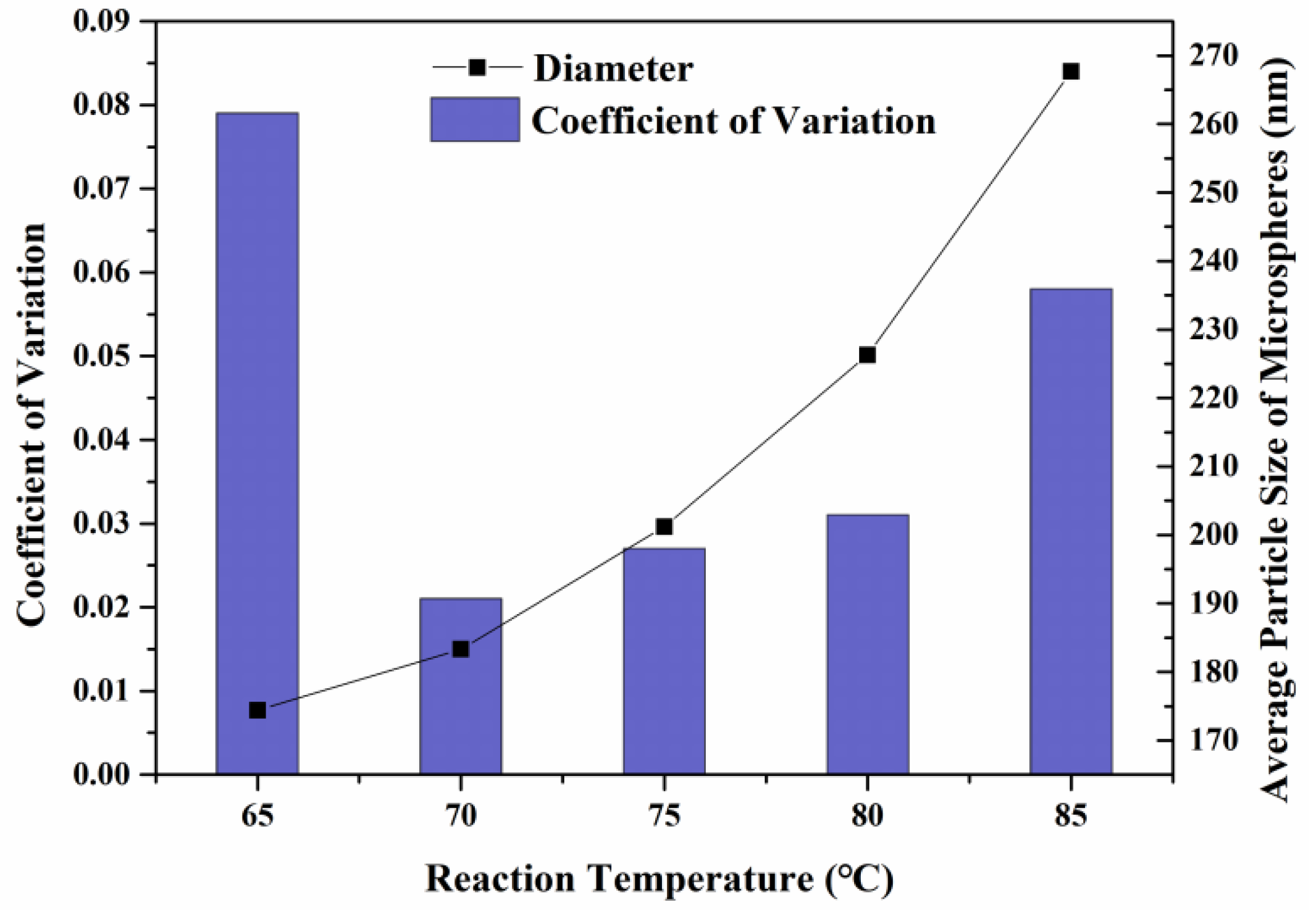

3.1.2. Effect of Polymerization Temperature

3.2. Effect of Construction Conditions on Structural Color Coatings on a Wood Surface

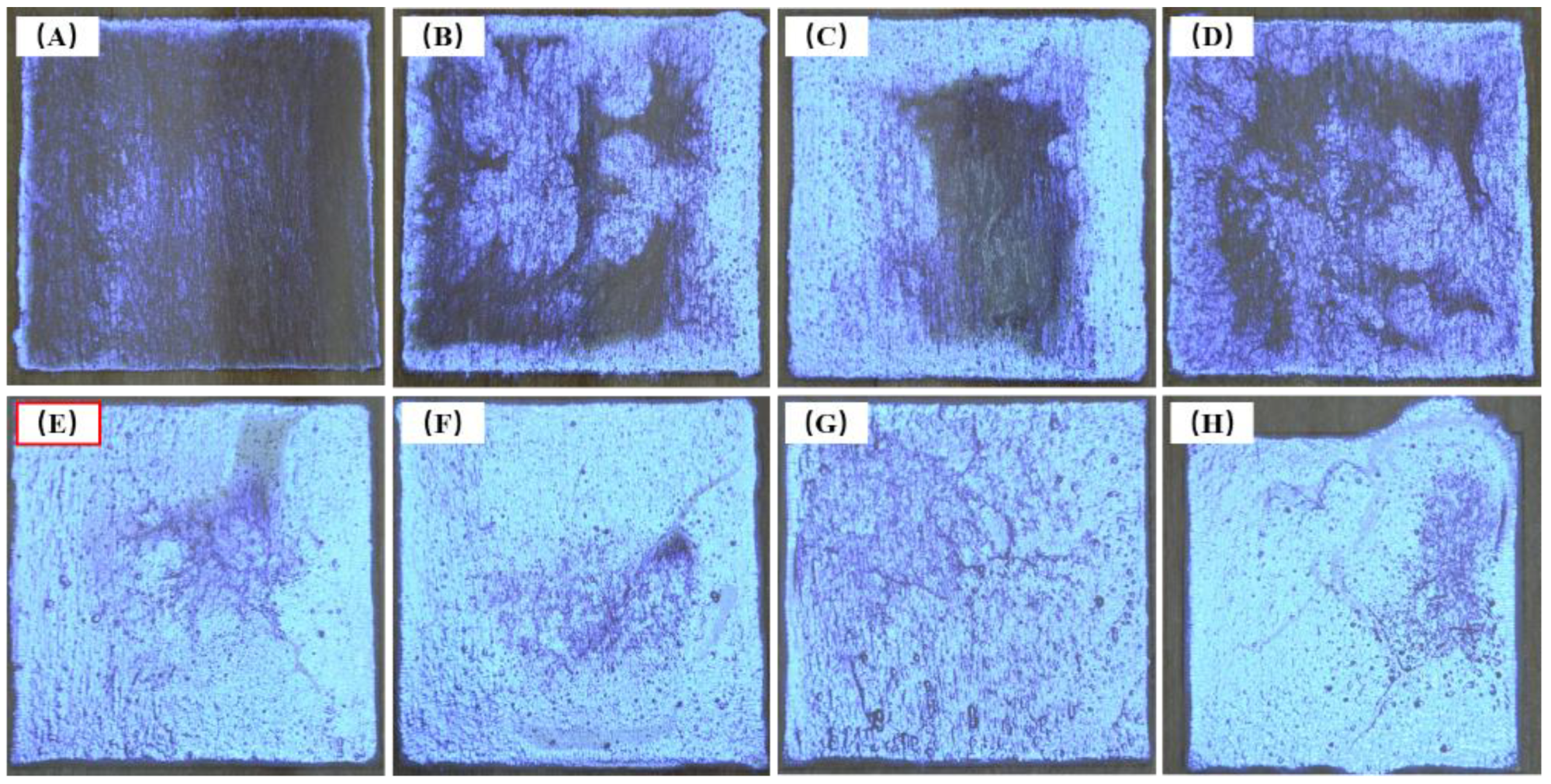

3.2.1. Effect of Emulsion Dosage

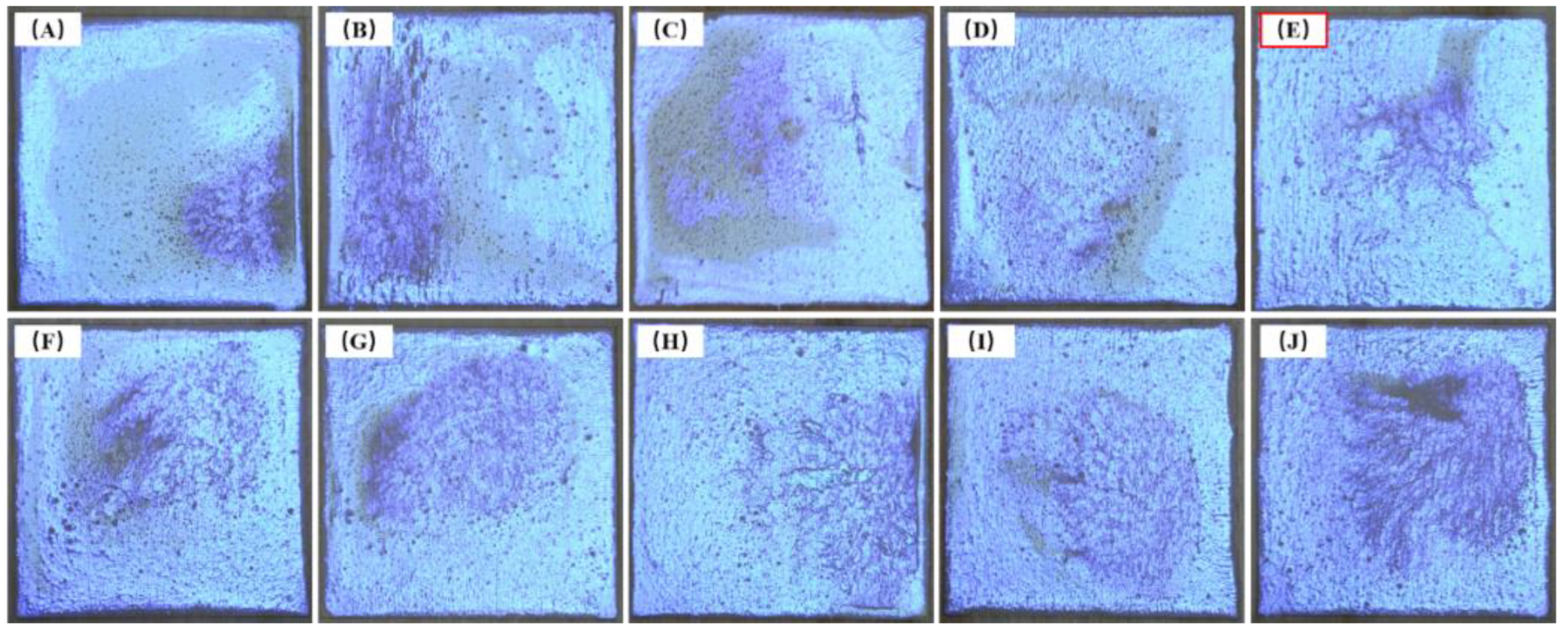

3.2.2. Effect of Self-Assembly Environment Temperature

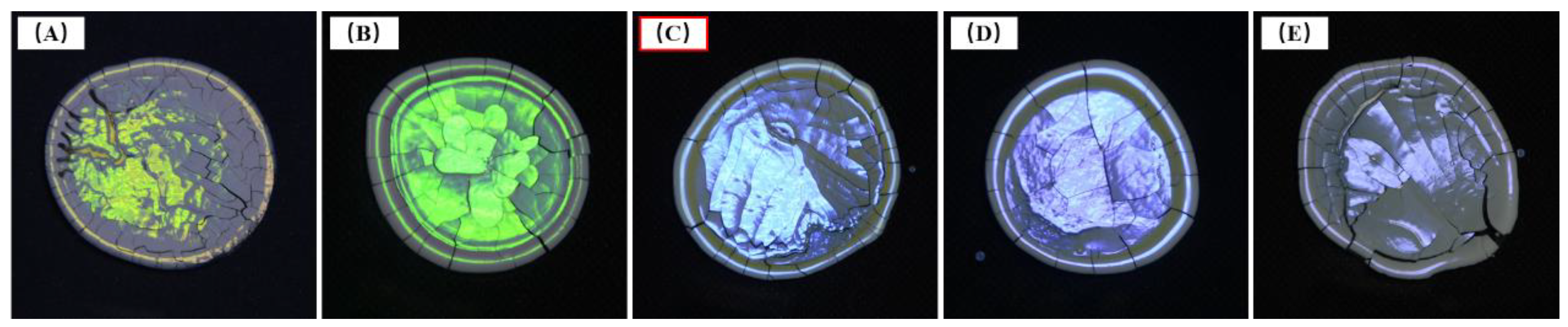

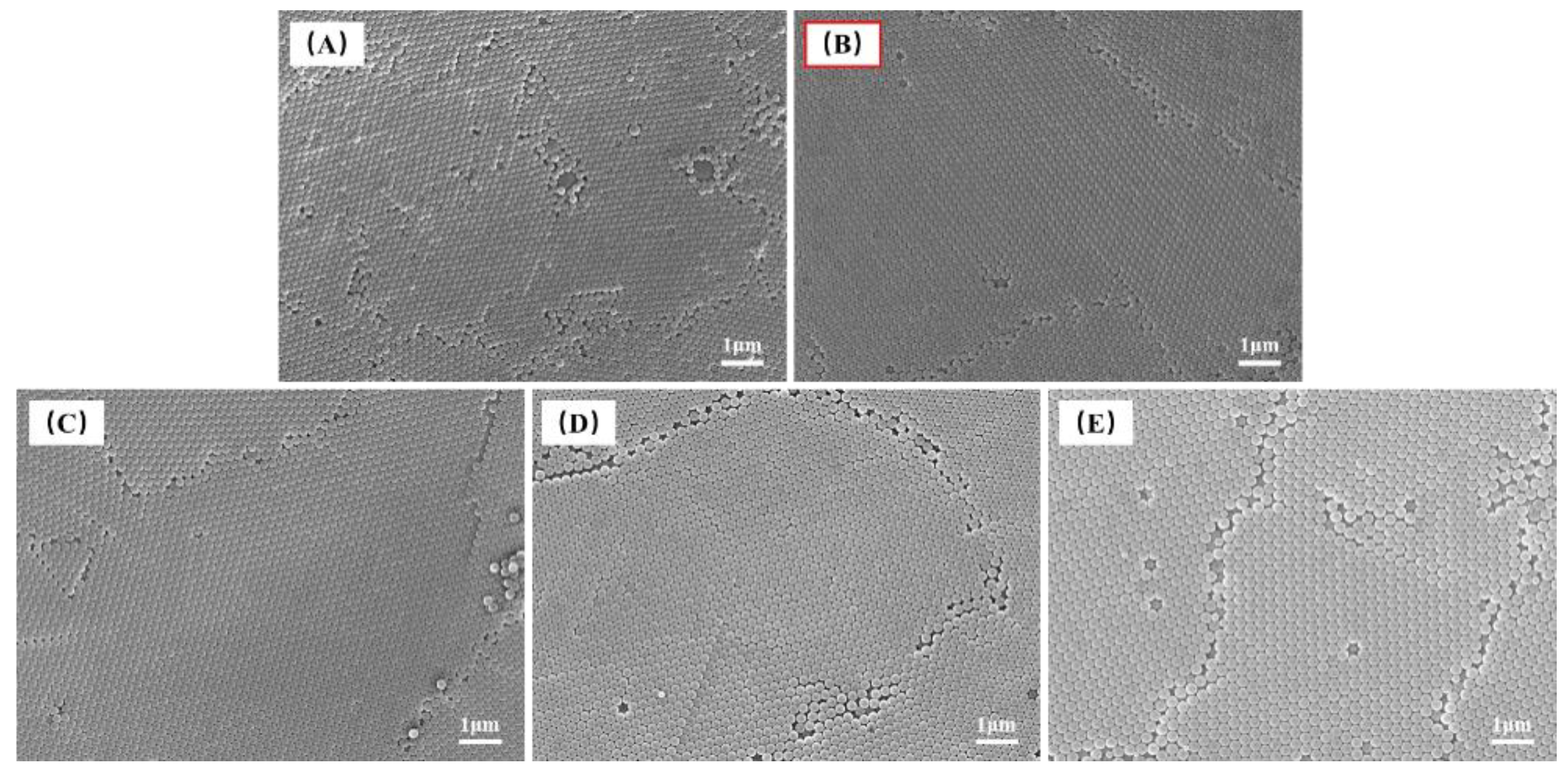

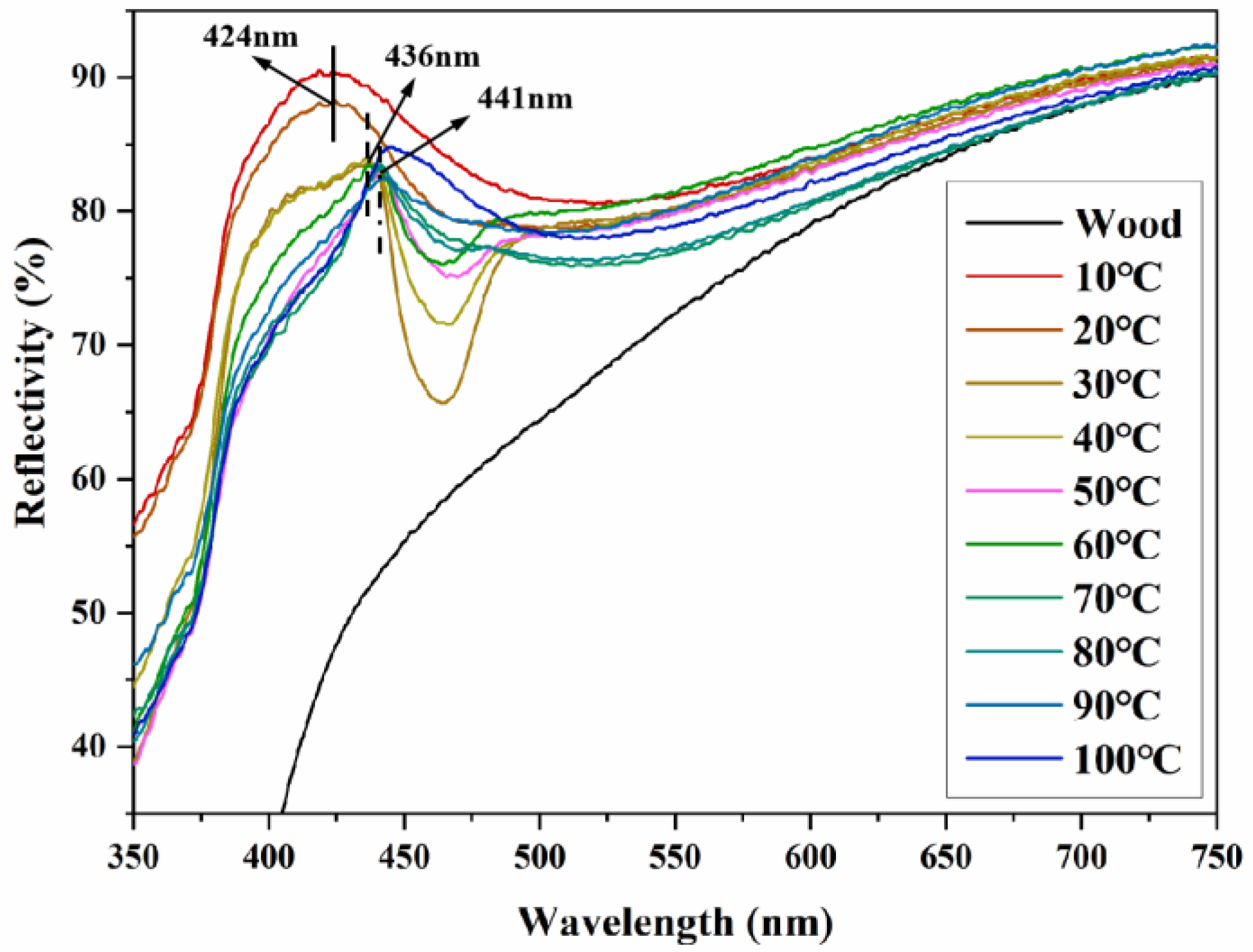

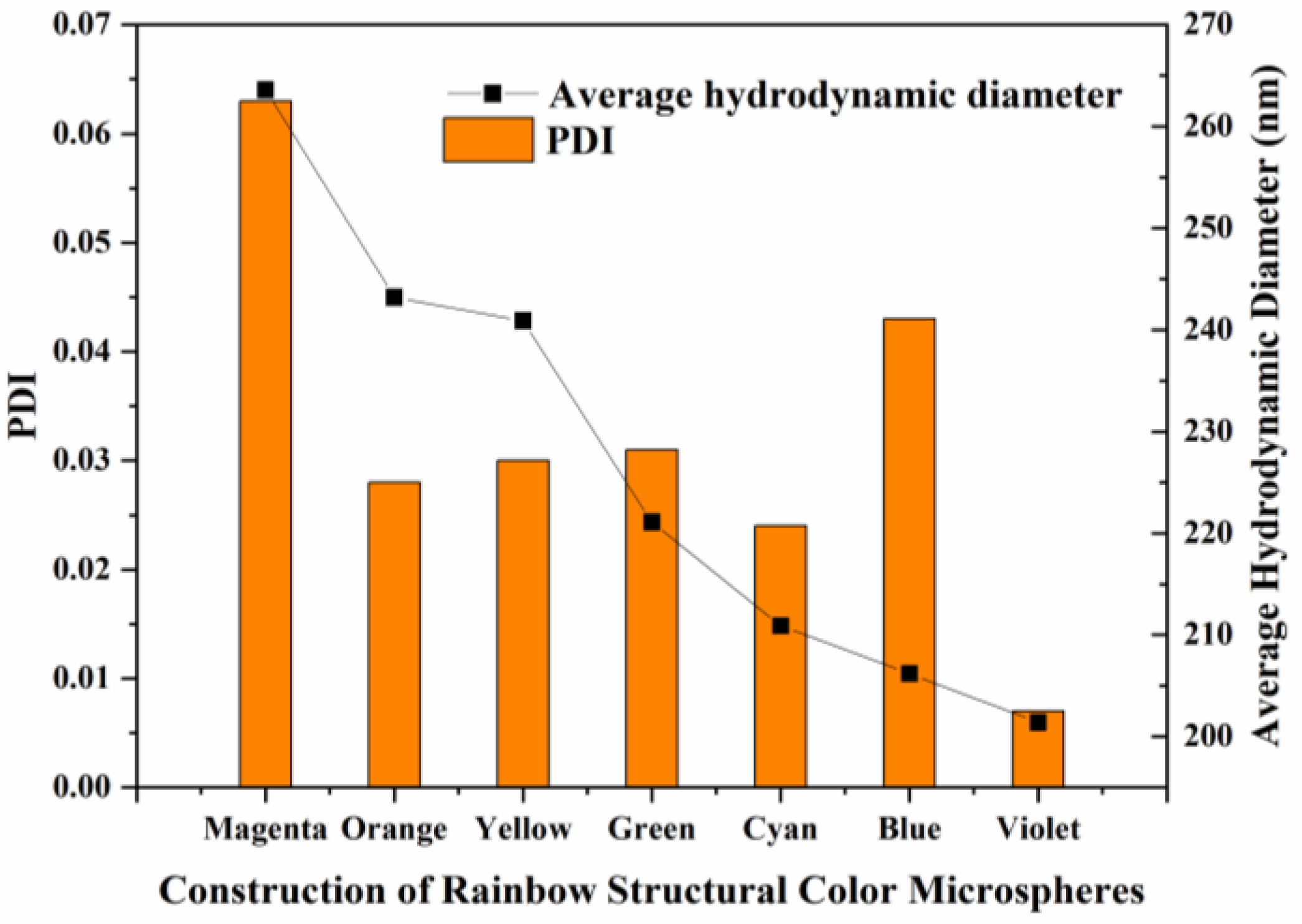

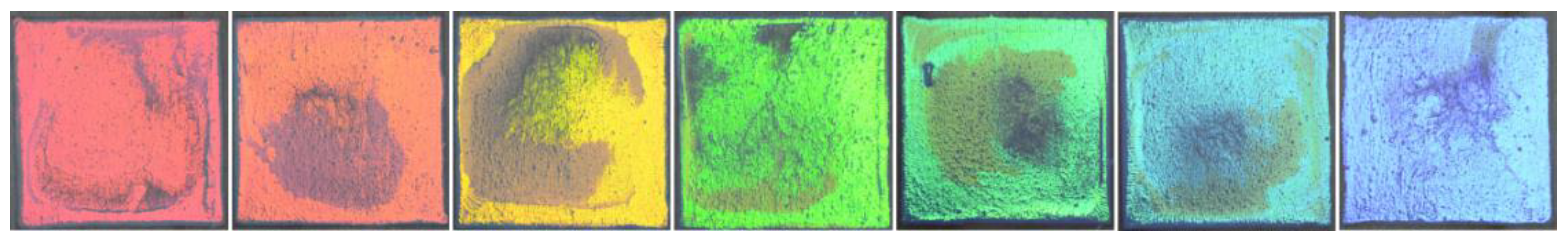

3.3. Construction and Application of Rainbow Structural Color Layer on Wood Surface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, J.; Guan, H. Study on thermal comfort of wood tabletop materials. Wood Res. 2022, 67, 326–339. [Google Scholar]

- Fu, W.L.; Guan, H.Y. Numerical and theoretical analysis of the contact force of oval mortise and tenon joints concerning outdoor wooden furniture structure. Wood Sci. Technol. 2022, 56, 1205–1237. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J.; Wang, X. A Review on Carbon Reduction Analysis during the Design and Manufacture of Solid Wood Furniture. BioResources 2021, 16, 6212–6230. [Google Scholar] [CrossRef]

- Feng, X.; Yang, Z.; Wang, S.; Wu, Z. The reinforcing effect of lignin-containing cellulose nanofibrils in the methacrylate composites produced by stereolithography. Polym. Eng. Sci. 2022, 62, 2968–2976. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Zhang, Y.; Qi, C.; Tang, R.; Zhao, B.; Wang, H.; Han, Y. Microbial dyeing-infection behavior and influence of Lasiodiplodia theobromae in poplar veneer. Dye. Pigment. 2020, 173, 107988. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, Y.; Yang, F.; Wu, X.; Ding, G. A novel waterborne polyurethane coating modified by highly dispersed nano-boron carbide particles. J. Appl. Polym. Sci. 2020, 138, 50214. [Google Scholar] [CrossRef]

- Qin, Y.; Yan, X. Effect of the addition of shellac self-healing and discoloration microcapsules on the performance of coatings applied on ebiara solid board. Coatings 2022, 12, 1627. [Google Scholar] [CrossRef]

- Wang, L.; Han, Y.; Yan, X. Effects of adding methods of fluorane microcapsules and shellac resin microcapsules on the preparation and properties of bifunctional waterborne coatings for basswood. Polymers 2022, 14, 3919. [Google Scholar] [CrossRef]

- He, R.; Qiu, J.; He, H.; Luo, B. Research status and progress trend of wood fungal staining. J. For. Eng. 2019, 4, 19–24. [Google Scholar]

- Cai, C.; Haapala, A.; Rahman, M.H.; Tiitta, M.; Tiitta, V.; Tomppo, L.; Lappalainen, R.; Heräjärvi, H. Effects of two-year weather exposure on thermally modified Picea abies, Pinus sylvestris, and Fraxinus excelsior wood. Can. J. For. Res. 2020, 50, 1160–1171. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, J.; Li, C. Studies on the lightfastness of dyed veneer of I-214 poplar. Sci. Silvae Sin. 2006, 42, 29–34. [Google Scholar]

- Liu, Y.; Shao, L.; Gao, J.; Guo, H.; Chen, Y.; Cheng, Q.; Via, B.K. Surface photo-discoloration and degradation of dyed wood veneer exposed to different wavelengths of artificial light. Appl. Surf. Sci. 2015, 331, 353–361. [Google Scholar] [CrossRef]

- Kinshita, S.; Yoshioka, S.; Miyazaki, J. Physics of structural colors. Rep. Prog. Phys. 2008, 71, 076401. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, Q.S.; Yuan, W.; Zhou, N.; Zhang, K.Q. The mechanism and its application of amorphous photonic crystals with structural color. Mat. Rev. 2017, 1, 43–56. [Google Scholar]

- Prum, R.O.; Cole, J.A.; Torres, R.H. Blue integumentary structural colours in dragonflies (Odonata) are not produced by incoherent Tyndall scattering. J. Exp. Biol. 2004, 207, 3999–4009. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lopez-Garcia, M.; Masters, N.; O’brien, H.E.; Lennon, J.; Atkinson, G.; Cryan, M.J.; Oulton, R.; Whitney, H.M. Light-induced dynamic structural color by intracellular 3D photonic crystals in brown algae. Sci. Adv. 2018, 4, eaan8917. [Google Scholar] [CrossRef] [Green Version]

- Cong, H.; Yu, B.; Tang, J.; Li, Z.; Liu, X. Current status and future developments in preparation and application of colloidal crystals. Chem. Soc. Rev. 2013, 42, 7774–7800. [Google Scholar] [CrossRef]

- Ge, J.; Lee, H.; He, L.; Kim, J.; Lu, Z.; Kim, H.; Goebl, J.; Kwon, S.; Yin, Y. Magnetochromatic microspheres: Rotating photonic crystals. J. Am. Chem. Soc. 2009, 131, 15687–15694. [Google Scholar] [CrossRef]

- Gu, M.; Jia, B.; Li, J.; Ventura, M.J. Fabrication of three-dimensional photonic crystals in quantum-dot-based materials. Laser Photonics Rev. 2010, 4, 414–431. [Google Scholar] [CrossRef]

- Braun, P.V.; Rinne, S.A.; García-Santamaría, F. Introducing defects in 3D photonic crystals: State of the art. Adv. Mater. 2006, 18, 2665–2678. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhong, J.; Hu, X.; Song, F.; Ren, K.; Wei, H. Fabrication and optical properties of silica shell photonic crystals. Colloid Surf. A 2012, 415, 202–208. [Google Scholar] [CrossRef]

- Starczewska, A.; Kępińska, M.; Szperlich, P.; Duka, P.; Nowak, M. Influence of temperature on optical spectra of SbSI photonic crystals. Opt. Mater. 2020, 100, 109606. [Google Scholar] [CrossRef]

- You, B.; Wen, N.; Shi, L.; Wu, L.; Zi, J. Facile fabrication of a three-dimensional colloidal crystal film with large-area and robust mechanical properties. J. Mater. Chem. 2009, 19, 3594–3597. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, J.; Taha, M. Synthesis of monodisperse styrene/methyl methacrylate/acrylic acid latex using surfactant-free emulsion copolymerization in air. J. Appl. Polym. Sci. 2009, 114, 1598–1605. [Google Scholar] [CrossRef]

- Meng, Y.; Tang, B.; Xiu, J.; Zheng, X.; Ma, W.; Ju, B.; Zhang, S. Simple fabrication of colloidal crystal structural color films with good mechanical stability and high hydrophobicity. Dye. Pigment. 2015, 123, 420–426. [Google Scholar] [CrossRef]

- Imura, Y.; Nakazawa, H.; Matsushita, E.; Morita, C.; Kondo, T.; Kawai, T. Characterization of colloidal crystal film of polystyrene particles at the air-suspension interface. J. Colloid Interface Sci. 2009, 336, 607–611. [Google Scholar] [CrossRef]

- Kawamura, A.; Kohri, M.; Morimoto, G.; Nannichi, Y.; Taniguchi, T.; Kishikawa, K. Full-color biomimetic photonic materials with iridescent and non-Iridescent structural colors. Sci. Rep. 2016, 6, 33984. [Google Scholar] [CrossRef]

- Lichti, G.; Hawkett, B.S.; Gilbert, R.G.; Napper, D.H.; Sangster, D.F. Styrene emulsion polymerization: Particle-size distributions. J. Polym. Sci. Polym. Chem. Ed. 1981, 19, 925–938. [Google Scholar] [CrossRef]

- Joumaa, N.; Lansalot, M.; Théretz, A.; Elaissari, A.; Sukhanova, A.; Artemyev, M.; Nabiev, I.; Cohen, J.H.M. Synthesis of quantum dot-tagged submicrometer polystyrene particles by miniemulsion polymerization. Langmuir 2014, 22, 1810–1816. [Google Scholar] [CrossRef] [PubMed]

- Chern, C.S. Emulsion polymerization mechanisms and kinetics. Prog. Polym. Sci. 2006, 31, 443–486. [Google Scholar] [CrossRef]

- Shen, Z.; Yang, Y.; Lu, F.; Bao, B.; You, B. Self-assembly of binary particles and application as structural colors. Polym. Chem. 2012, 3, 2495–2501. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wu, Z.; Pang, X. Construction of bionic structural color coating on wood surface based on polystyrene microspheres. J. For. Eng. 2021, 6, 35–42. [Google Scholar]

- Waterhouse, G.I.N.; Waterland, M.R. Opal and inverse opal photonic crystals: Fabrication and characterization. Polyhedron 2007, 26, 356–368. [Google Scholar] [CrossRef]

- Jiang, P.; Bertone, J.F.; Hwang, K.S.; Colvin, V.L. Single-crystal colloidal multilayers of controlled thickness. Chem. Mater. 1999, 11, 2132–2140. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, J.; Wang, X.T.; Wang, X.G.; Li, Y.; Wang, C.W. Bandgap engineering of TiO2 nanotube photonic crystals for enhancement of photocatalytic capability. CrystEngComm 2020, 22, 1929–1938. [Google Scholar] [CrossRef]

- Xie, J.; Duan, M.; Bai, P.; Wang, H. Gas adsorption behavior of silica photonic crystals with different size of initial particles. J. Ceram. Soc. Jpn. 2020, 128, 19–23. [Google Scholar] [CrossRef] [Green Version]

- Sapour, G.; Lattuana, M. Bioinspired stimuli-responsive color-changing systems. Adv. Mater. 2018, 30, 1707069. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Wu, Z. Fabrication of coatings with structural color on a wood surface. Coatings 2020, 10, 32. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Zhou, L.; Wu, Y.; Wang, C.; Fan, Q.; Shao, J. Optical properties of three-dimensional P(St-MAA) photonic crystals on polyester fabrics. Opt. Mater. 2015, 42, 72–79. [Google Scholar] [CrossRef]

| Amount of Emulsion (μL) | Temperature (°C) |

|---|---|

| 100, 200, 300, 400, 500, 600, 700, 800 | 50 |

| 500 | 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Liu, Y.; Xu, W.; Wu, Z.; Pang, X. Construction of Rainbow-like Structural Color Coatings on Wood Surfaces Based on Polystyrene Microspheres. Forests 2023, 14, 76. https://doi.org/10.3390/f14010076

Hu J, Liu Y, Xu W, Wu Z, Pang X. Construction of Rainbow-like Structural Color Coatings on Wood Surfaces Based on Polystyrene Microspheres. Forests. 2023; 14(1):76. https://doi.org/10.3390/f14010076

Chicago/Turabian StyleHu, Jing, Yi Liu, Wei Xu, Zhihui Wu, and Xiaoren Pang. 2023. "Construction of Rainbow-like Structural Color Coatings on Wood Surfaces Based on Polystyrene Microspheres" Forests 14, no. 1: 76. https://doi.org/10.3390/f14010076