Towards a Carbon Accounting Framework for Assessing the Benefits of Biogenic Wood Carbon to Net Zero Carbon Targets

Abstract

:1. Introduction

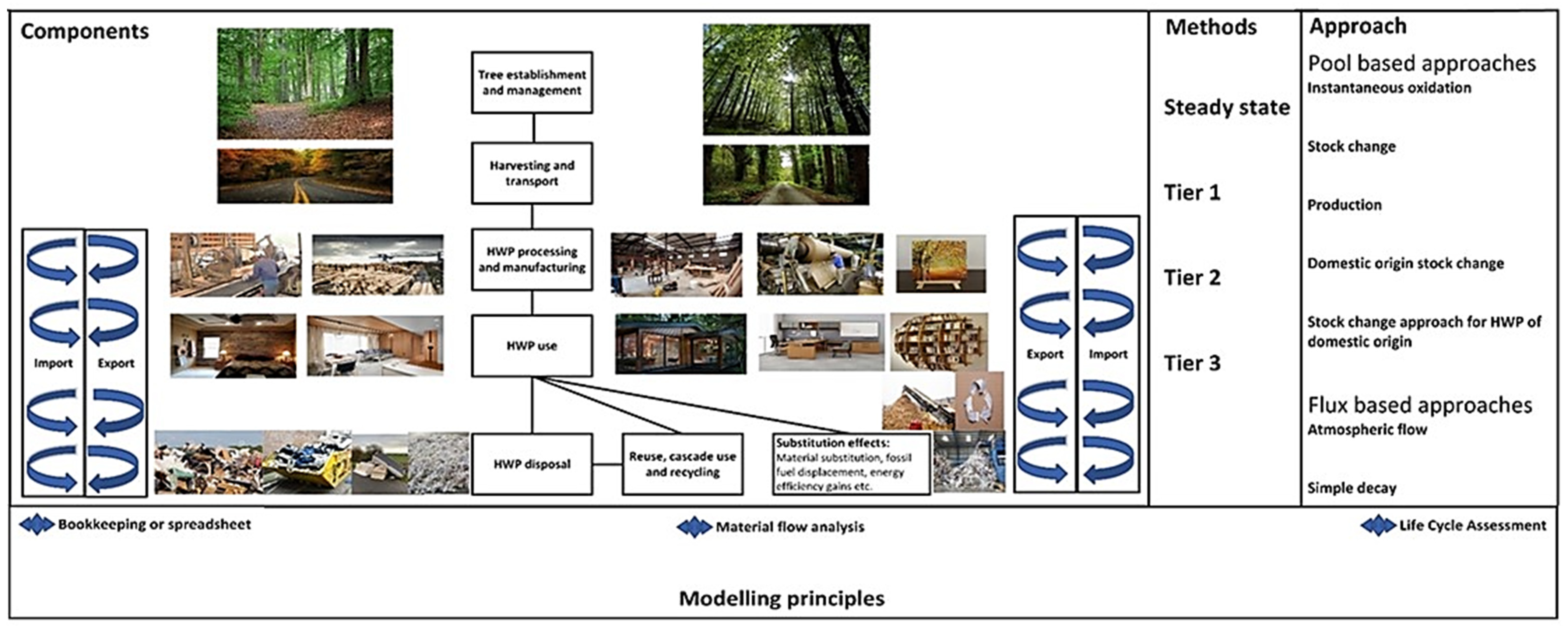

2. Features of HWP Carbon Accounting Frameworks

3. Components

4. Methods

5. Approaches

6. Modeling Principles

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Revised 1996 IPCC Guidelines for Greenhouse Gas Inventories; Houghton, J.T., Meira Filho, L.G., Lim, B., Treanton, K., Mamaty, I., Bonduki, Y., Griggs, D.J., Callender, B.A., Eds.; IPCC/OECD/IEA Report; UK Meteorological Office: Bracknell, UK, 1997; p. 76.

- Russel, M. Harvested Wood Products: A Growing Contributor to US Carbon Storage. Arbor Analytics. 2021. Available online: https://arbor-analytics.com/post/2021-05-15-harvested-wood-products-an-increasing-contributor-to-us-carbon-storage/ (accessed on 15 July 2022).

- IPCC. 2013 Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Hiraishi, T., Krug, T., Tanabe, K., Srivastava, N., Baasansuren, J., Fukuda, M., Troxler, T.G., Eds.; The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014; p. 148. Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/KP_Supplement_Entire_Report.pdf (accessed on 15 July 2022).

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Buendia, C.E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenko, Y., Shermanau, P., Federici, S., Eds.; The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch12_HarvestedWoodProducts.pdf (accessed on 15 July 2022).

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. Modelling carbon stocks and fluxes in the wood product sector: A comparative review. Glob. Change Biol. 2006, 22, 2555–2569. [Google Scholar] [CrossRef] [PubMed]

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. The effect of increasing lifespan and recycling rate on carbon storage in wood products from theoretical model to application for the European wood sector. Mitig. Adapt. Strateg. Glob. Change 2017, 22, 1193–1205. [Google Scholar] [CrossRef] [PubMed]

- Jasinevičius, G.; Lindner, M.; Pingoud, K.; Tykkylainen, M. Review of Models for Carbon Accounting in Harvested Wood Products. Int. Wood Prod. J. 2016, 6, 198–212. [Google Scholar] [CrossRef]

- Jasinevičius, G.; Lindner, M.; Cienciala, E.; Tykkyläinen, M. Carbon Accounting in Harvested Wood Products: Assessment Using Material Flow Analysis Resulting in Larger Pools Compared to the IPCC Default Method. J. Ind. Ecol. 2018, 22, 121–131. [Google Scholar] [CrossRef]

- Grêt-Regamey, A.; Hendrick, E.; Hetsch, S.; Pingoud, K.; Rüter, S. Challenges and Opportunities of Accounting for Harvested Wood Products. In Background Paper to the Workshop on “Harvested Wood Products in the Context of Climate Change Policies”; Swiss Federal Office for the Environment (FOEN), UNECE/FAO and MCPFE: Geneva, Switzerland, 2008. [Google Scholar]

- Wakelin, S.J.; Searles, N.; Lawrence, D.; Paul, T.S.H. Estimating New Zealand’s harvested wood products carbon stocks and stock changes. Carbon Balance Manag. 2020, 15, 10–24. [Google Scholar] [CrossRef]

- Bais, A.L.S.; Lauk, C.; Kastner, T.; Erb, K.-H. Global patterns and trends of wood harvest and use between 1990 and 2010. Ecol. Econ. 2015, 119, 326–337. [Google Scholar] [CrossRef]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.-H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Domke, G.M.; Walters, B.F.; Nowak, D.J.; Smith, J.E.; Nichols, M.C.; Ogle, S.M.; Coulston, J.W.; Wirth, T.C. Greenhouse Gas Emissions and Removals from Forest Land, Woodlands, and Urban Trees in the United States, 1990–2019; Resource Update FS–307; Northern Research Station, Forest Service, U.S. Department of Agriculture: Madison, WI, USA, 2021; 5p. [CrossRef]

- Johnston, C.M.T.; Radeloff, V.C. Global mitigation potential of carbon stored in harvested wood products. Proc. Natl. Acad. Sci. USA 2019, 116, 14526–14531. [Google Scholar] [CrossRef]

- Sato, A.; Nojiri, Y. Assessing the contribution of harvested wood products under greenhouse gas estimation: Accounting under the Paris Agreement and the potential for double-counting among the choice of approaches. Carbon Balance Manag. 2019, 14, 15–34. [Google Scholar] [CrossRef]

- Lauk, C.; Haberl, H.; Erb, K.-H.; Gingrich, S.; Krausmann, F. Global socioeconomic carbon stocks in long-lived products 1900–2008. Environ. Res. Lett. 2012, 7, 34–44. [Google Scholar] [CrossRef]

- Krausmann, F.; Wiedenhofer, D.; Lauk, C.; Haas, W.; Tanikawa, H.; Fishman, T.; Miatto, A.; Schandl, H.; Haberl, H. Global socioeconomic material stocks rise 23-fold over the 20th century and require half of annual resource use. Proc. Natl. Acad. Sci. USA 2017, 114, 1880–1885. [Google Scholar] [CrossRef] [PubMed]

- Skog, K.E. Sequestration of carbon in harvested wood products for the United States. For. Prod. J. 2008, 58, 56–72. [Google Scholar]

- Walters, B.F.; Domke, G.M.; Nowak, D.J.; Smith, J.E.; Ogle, S.M. Greenhouse Gas Emissions and Removals from Forest Land, Woodlands, and Urban Trees in the United States, 1990–2019: Estimates and Quantitative Uncertainty for Individual States; Forest Service Research Data Archive: Fort Collins, CO, USA, 2021. [CrossRef]

- US EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2019; EPA 430-R-21-005; U.S. Environmental Protection Agency: Washington, DC, USA, 2021. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks (accessed on 12 July 2022).

- Jasinevičius, G.; Lindner, M.; Verkerk, P.J.; Aleinikovas, M. Assessing Impacts of Wood Utilisation Scenarios for a Lithuanian Bioeconomy: Impacts on Carbon in Forests and Harvested Wood Products and on the Socio-Economic Performance of the Forest-Based Sector. Forests 2017, 8, 133. [Google Scholar] [CrossRef]

- Kayo, C.; Tsunetsugu, Y.; Tonosaki, M. Climate Change Mitigation Effect of Harvested Wood Products in Regions of Japan. Carbon Balance Manag. 2015, 10, 24. [Google Scholar] [CrossRef]

- Aleinikovas, M.; Jasinevičius, G.; Škėma, M.; Beniušienė, L.; Šilinskas, B.; Varnagirytė-Kabašinskienė, I. Assessing the Effects of Accounting Methods for Carbon Storage in Harvested Wood Products on the National Carbon Budget of Lithuania. Forests 2018, 9, 737. [Google Scholar] [CrossRef]

- Glover, J.; White, D.O.; Langrish, T.A.G. Wood versus concrete and steel in house construction a life cycle assessment. J. For. 2002, 100, 34–41. [Google Scholar]

- Sathre, R.; O’Connor, J. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ. Sci. Policy 2010, 13, 104–114. [Google Scholar] [CrossRef]

- Braun, M.; Winner, G.; Schwarzbauer, P.; Stern, T. Apparent Half-Life-Dynamics of Harvested Wood Products (HWPs) in Austria: Development and analysis of weighted time-series for 2002 to 2011. For. Policy Econ. 2016, 63, 28–34. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Cardellini, G.; Richter, K.; Muys, B. Climate mitigation by energy and material substitution of wood products has an expiry date. J. Clean. Prod. 2021, 303, 127026. [Google Scholar] [CrossRef]

- Chang, Y.-S.; Han, Y.; Park, J.-H.; Son, W.-L.; Park, J.-S.; Park, M.-J.; Yeo, H. Study on Methods for Determining Half-Life of Domestic Wooden Panel among Harvested Wood Products. J. Korean Wood Sci. Technol. 2014, 42, 309–317. [Google Scholar] [CrossRef]

- Ingerson, A. Wood Products and Carbon Storage: Can Increased Production Help Solve the Climate Crisis? The Wilderness Society: Washington, DC, USA, 2009; 39p. [Google Scholar]

- Ximenes, F.; Bi, H.; Cameron, N.; Coburn, R.; Maclean, M.; Sargeant, D.; Mo, M.; Roxburgh, S.; Ryan, M.; Williams, J.; et al. Carbon Stocks and Flows in Native Forests and Harvested Wood Products in SE Australia; Project Number: PNC285-1112; Forest & Wood Products Australia: Melbourne, Australia, 2016; 201p. [Google Scholar]

- Leskinen, P.; Cardellini, G.; González-García, S.; Hurmekoski, E.; Sathre, R.; Seppälä, J.; Smyth, C.; Stern, T.; Verkerk, P.J. Substitution Effects of Wood-Based Products in Climate Change Mitigation; From Science to Policy 7; European Forest Institute: Joensuu, Finland, 2018; 27p. [Google Scholar]

- NYSDEC. 2021 NYS Greenhouse Gas Emissions Report: Agriculture, Forestry, and Other Land Use; Sectoral Report #3; New York State Department of Environmental Conservation: Albany, NY, USA, 2021; 21p.

- Iordan, C.M.; Hu, X.; Arvesen, A.; Kauppi, P.; Cherubini, F. Contribution of forest wood products to negative emissions: Historical comparative analysis from 1960 to 2015 in Norway, Sweden and Finland. Carbon Balance Manag. 2018, 13, 12. [Google Scholar] [CrossRef] [PubMed]

- UNFCCC. Decision 24/CP.19: Revision of the UNFCCC Reporting Guidelines on Annual Inventories for Parties Included in Annex I to the Convention. 2013. Available online: https://unfccc.int/sites/default/files/resource/docs/2013/cop19/eng/10a03.pdf#Page=2 (accessed on 15 July 2022).

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies: Hayama, Japan, 2006. Available online: https://www.ipcc-nggip.iges.or.jp/support/Primer_2006GLs.pdf (accessed on 15 July 2022).

- Yu, Z.; Zhang, H.; Tu, Q.; Yang, H. Methodological Comparison of the Production Approach 2013 and 2019 for Quantifying the Carbon Stock in Harvested Wood Products in China. Front. Environ. Sci. 2022, 10, 758857. [Google Scholar] [CrossRef]

- Li, L.; Wei, X.; Zhao, J.; Hayes, D.; Daigneault, A.; Weiskittel, A.; Kizha, A.R.; O’Neill, S.R. Technological advancement expands carbon storage in harvested wood products in Maine, USA. Biomass Bioenergy 2022, 161, 106457. [Google Scholar] [CrossRef]

- Rüter, S. The Contribution of the Material Wood Use to Climate Protection—The WoodCarbonMonitor Model (de). Ph.D. Thesis, Wissenschaftszentrum Weihenstephan für Ernährung, Landnutzung und Umwelt, Technische Universität München, Munich, Germany, 2017; 270p. [Google Scholar]

- New York State Climate Action Council. New York State Climate Action Council Scoping Plan. 2022. Available online: https://climate.ny.gov/resources/scoping-plan/ (accessed on 15 July 2023).

- Krausmann, F.; Erb, K.-H.; Gingrich, S.; Haberl, H.; Bondeau, A.; Gaube, V.; Lauk, C.; Plutzar, C.; Searchinger, T.D. Global human appropriation of net primary production doubled in the 20th century. Proc. Natl. Acad. Sci. USA 2013, 110, 10324–10329. [Google Scholar] [CrossRef] [PubMed]

- Nichols, M.C.; Morgan, T.A.; Christensen, G.; Tase, N. Estimated Carbon Stored in Harvested Wood Products in Washington, USA: 1906–2018; Draft Report; Forest Service and the Washington Department of Natural Resources: Olympia, WA, USA, 2020; 31p.

- Morgan, T.A.; Donahue, S.T.; Dillon, T.; Yost, A.; Groom, J. Oregon Harvested Wood Products Carbon Inventory 1906–2018; Draft Report for Forest Inventory and Analysis Program; USDA Forest Service: Portland, OR, USA; Oregon Department of Forestry: Salem, OR, USA, 2022; 61p.

- Laurent, A.B.; Menard, J.F.; Lesage, P.; Beauregard, R. Cradle-to-gate- life cycle assessment of the portfolio of an innovative forest products manufacturing unit. Bioresources 2016, 11, 8981–9001. [Google Scholar] [CrossRef]

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. Forestry 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Suominen, T.; Kunttu, J.; Jasinevičius, G.; Tuomasjukka, D.; Lindner, M. Trade-offs in sustainability impacts of introducing cascade use of wood. Scand. J. For. Res. 2017, 32, 588–597. [Google Scholar] [CrossRef]

- Stockmann, K.D.; Anderson, N.M.; Skog, K.E.; Healey, S.P.; Loeffler, D.R.; Greg, J.; Morrison, J.F. Estimates of carbon stored in harvested wood products from the United States Forest Service Northern Region, 1906–2010. Carbon Balance Manag. 2012, 7, 1–16. [Google Scholar] [CrossRef]

- Anderson, N.; Young, J.; Stockmann, K.; Skog, K.; Healey, S.; Loeffler, D.; Jones, J.G.; Morrison, J. Regional and Forest-Level Estimates of Carbon Stored in Harvested Wood Products from the United States Forest Service Northern Region, 1906–2010; RMRS-GTR-31: General Technical Report; Rocky Mountain Research Station, Forest Service, U.S. Department of Agriculture: Fort Collins, CO, USA, 2013; 114p.

- Stockmann, K.; Anderson, N.; Young, J.; Skog, K.; Healey, S.; Loeffler, D.; Butler, E.; Jones, J.G.; Morrison, J. Estimates of Carbon Stored in Harvested Wood Products from United States Forest Service Rocky Mountain Region, 1906–2012; Draft Report; Forestry Sciences Laboratory, Rocky Mountain Research Station, Forest Service, U.S. Department of Agriculture: Missoula, MT, USA, 2014; 27p.

- Pilli, R.; Fiorese, G.; Grassi, G. EU mitigation potential of harvested wood products. Carbon Balance Manag. 2015, 10, 6–22. [Google Scholar] [CrossRef]

- Zhu, Z.; Bergamaschi, B.; Bernknopf, R.; Clow, D.; Dye, D.; Faulkner, S.; Forney, W.; Gleason, R.; Hawbaker, T.; Liu, J.; et al. A Method for Assessing Carbon Stocks, Carbon Sequestration, and Greenhouse-Gas Fluxes in Ecosystems of the United States under Present Conditions and Future Scenarios; U.S. Geological Survey Scientific Investigations Report 2010–5233; USGS: Reston, VA, USA, 2010; 190p. Available online: http://pubs.usgs.gov/sir/2010/5233/ (accessed on 15 July 2022).

- Donlan, J.; Skog, K.; Byrne, K. Carbon storage in harvested wood products for Ireland 1961–2009. Biomass Bioenergy 2012, 46, 731–738. [Google Scholar] [CrossRef]

- Profft, I.; Mund, M.; Weber, G.E.; Weller, E.; Schulze, E.D. Forest management and carbon sequestration in wood products. Eur. J. For. Res. 2009, 128, 399–413. [Google Scholar] [CrossRef]

- Somogyi, Z.; Hidy, D.; Gelybó, G.; Barcza, Z.; Churkina, G.; Haszpra, L.; Horváth, L.; Machon, A.; Grosz, B. Modeling of biosphere–atmosphere exchange of greenhouse gases—Models and their adaptation. In Atmospheric Greenhouse Gases: The Hungarian Perspective; Springer Science+Business Media B.V.: Budapest, Hungary, 2010; pp. 201–228. [Google Scholar] [CrossRef]

- Binder, C.R.; Hofer, C.; Wiek, A.; Scholz, R.W. Transition towards improved regional wood flows by integrating material flux analysis and agent analysis: The case of Appenzell Ausserrhoden, Switzerland. Ecol. Econ. 2004, 49, 1–17. [Google Scholar] [CrossRef]

- Mantau, U. Wood flow analysis: Quantification of resource potentials, cascades and carbon effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Lenglet, J.; Courtonne, J.-Y.; Caurla, S. Material flow analysis of the forest-wood supply chain: A consequential approach for log export policies in France. J. Clean. Prod. 2017, 165, 1296–1305. [Google Scholar] [CrossRef]

- Arodudu, O.T.; Helming, K.; Wiggering, H.; Voinov, A. Towards a more holistic sustainability assessment framework for agro-bioenergy systems—A review. Environ. Impact Assess. Rev. 2017, 62, 61–75. [Google Scholar] [CrossRef]

- Lun, F.; Liu, M.; Zhang, D.; Li, W.; Liu, J. Life Cycle Analysis of Carbon Flow and Carbon Footprint of Harvested Wood Products of Larix principis-rupprechtii in China. Sustainability 2016, 8, 247. [Google Scholar] [CrossRef]

- Gu, H.; Liang, S.; Pierobon, F.; Puettmann, M.; Ganguly, I.; Chen, C.; Pasternack, R.; Wishnie, M.; Jones, S.; Maples, I. Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies. Sustainability 2021, 13, 1403. [Google Scholar] [CrossRef]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Kroiher, F.; Muys, B. Effect of cascade use on the carbon balance of the German and European wood sectors. J. Clean. Prod. 2018, 170, 137–146. [Google Scholar] [CrossRef]

- Leturcq, P. GHG displacement factors of harvested wood products: The myth of substitution. Sci. Rep. 2020, 10, 20752. [Google Scholar] [CrossRef]

- Harmon, M.E. Have product substitution carbon benefits been overestimated? A sensitivity analysis of key assumptions. Environ. Res. Lett. 2019, 14, 065008. [Google Scholar] [CrossRef]

- Howard, C.; Dymond, C.C.; Griess, V.C.; Tolkien-Spurr, D.; van Kooten, G.C. Wood product carbon substitution benefits: A critical review of assumptions. Carbon Balance Manag. 2021, 16, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Hurmekoski, E.; Smyth, C.E.; Stern, T.; Verkerk, P.J.; Asada, R. Substitution impacts of wood use at the market level: A systematic review. Environ. Res. Lett. 2021, 16, 123004. [Google Scholar] [CrossRef]

- Myllyviita, T.; Soimakallio, S.; Judl, J.; Seppälä, J. Wood substitution potential in greenhouse gas emission reduction–review on current state and application of displacement factors. For. Ecosyst. 2021, 8, 1–18. [Google Scholar] [CrossRef]

- Loiseau, E.; Roux, P.; Junqua, G.; Maurel, P.; Bellon-Maurel, V. Adapting the LCA framework to environmental assessment in land planning. Int. J. LCA 2013, 18, 1533–1548. [Google Scholar] [CrossRef]

- Loiseau, E.; Roux, P.; Junqua, G.; Maurel, P.; Bellon-Maurel, V. Implementation of an adapted LCA framework to environmental assessment of a territory: Important learning points from a French Mediterranean case study. J. Clean. Prod. 2014, 80, 17–29. [Google Scholar] [CrossRef]

- Beaussier, T.; Caurla, S.; Bellon-Maurel, V.; Delacote, P.; Loiseau, E. Deepening the territorial Life Cycle Assessment approach with partial equilibrium modelling: First insights from an application to a wood energy incentive in a French region. Resour. Conserv. Recycl. 2022, 179, 106024. [Google Scholar] [CrossRef]

- Loiseau, E.; Aissani, L.; Le Féon, S.; Laurent, F.; Cerceau, J.; Sala, S.; Roux, P. Territorial Life Cycle Assessment (LCA): What exactly is it about? A proposal towards using a common terminology and a research agenda. J. Clean. Prod. 2018, 176, 474–485. [Google Scholar] [CrossRef]

| Method | Activity Data | Conversion Factors | Calculation Procedures |

|---|---|---|---|

| Steady-state HWP pool | No activity data | Assumes steady state over gap years when there are no data. No new estimates and no new conversion factors. Rough estimates of steady-state HWP pool may rely on or apply production harvest for a single year or takes an average over five years and assumes the same for a gap year or for gap years with no data. | No new calculation and estimates |

| Tier 1 | Activity data are available | No country/region-specific conversion factors/methods, neither of local direct measurements and estimations of stored carbon and half-life are available (default IPCC carbon and half-life fluxes/values are adopted or assumed), no clearly defined system boundaries. | Calculation based on activity data and default IPCC conversion factors (i.e., carbon and half-life fluxes/values) |

| Tier 2 | Activity data are available | Some country/region specific conversion factors/methods are available. A combination of direct inventory and flux estimation is applied i.e., either of local direct measurement or estimations of carbon and half-life is available (default IPCC carbon and half-life fluxes/values are adopted or assumed when not available locally). System boundaries are more clearly defined than Tier 1. | Calculation based on activity data and a mix of locally measured and default IPCC conversion factors (i.e., carbon and half-life fluxes/values) |

| Tier 3 | Activity data are available | Country/region-specific conversion factors/methods are available. Mostly based on direct inventory (i.e., local direct measurement or estimations of carbon and half-life are mostly available). Local measurements are sometimes supplemented with default IPCC carbon and half-life fluxes/values if they are consistent with country/region-specific values or under advanced modelling scenarios (for comparison). Well-defined system boundaries. | Calculation based on activity data and mostly locally measured and estimated conversion factors (i.e., carbon and half-life fluxes/values). |

| HWP Approaches | Components and Boundaries | ||||

|---|---|---|---|---|---|

| Pool-Based Approaches | Flux-Based Approaches | Forest Land Carbon Pool/Fluxes | HWP Pool Domestically Produced and Utilized | HWP Pool Exported and Utilized in Other Regions | HWP Pool Imported and Utilized Domestically |

| Instantaneous oxidation (IO) | - | √ | |||

| Stock change approach for HWP of domestic origin (SCAD) | - | √ | √ | ||

| Production (P) | Simple decay (SD) | √ | √ | √ | |

| Stock change (SC) | Atmospheric flow (AF) | √ | √ | √ | |

| Domestic origin-stock change (DOSC) | - | √ | √ | √ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arodudu, O.; Therasme, O.; Volk, T.; Malmsheimer, R.; Crovella, P.; Germain, R.; Kloster, D.; Kumar, D. Towards a Carbon Accounting Framework for Assessing the Benefits of Biogenic Wood Carbon to Net Zero Carbon Targets. Forests 2023, 14, 1959. https://doi.org/10.3390/f14101959

Arodudu O, Therasme O, Volk T, Malmsheimer R, Crovella P, Germain R, Kloster D, Kumar D. Towards a Carbon Accounting Framework for Assessing the Benefits of Biogenic Wood Carbon to Net Zero Carbon Targets. Forests. 2023; 14(10):1959. https://doi.org/10.3390/f14101959

Chicago/Turabian StyleArodudu, Oludunsin, Obste Therasme, Timothy Volk, Robert Malmsheimer, Paul Crovella, René Germain, Danielle Kloster, and Deepak Kumar. 2023. "Towards a Carbon Accounting Framework for Assessing the Benefits of Biogenic Wood Carbon to Net Zero Carbon Targets" Forests 14, no. 10: 1959. https://doi.org/10.3390/f14101959