Abstract

Bamboo requires treatment to extend its service life. However, as bamboo strips could serve as a suitable candidate for lamination, the treatment may affect its bendability. The current study investigated the effects of boric acid treatment on the physical, mechanical, adhesion, and morphological properties of bamboo strips. Owing to their availability and popularity in local industries, four Malaysian bamboo species were used in this study, namely Gigantochloa scortechinii, Gigantochloa levis, Dendrocalamus asper, and Bambusa vulgaris. These four species’ bamboo strips were treated with 5% boric acid and their properties were evaluated. The findings revealed that the boric acid treatment had varying degrees of effect on the properties of the bamboo. Despite having lower treatability and stability, both G. scortechinii and G. levis have greatly superior mechanical properties that justify their use in the production of laminated products. The boric acid treatment was found to provide several benefits to bamboo strips intended for lamination, including increased wettability, dimensional stability, and mechanical strength.

1. Introduction

Bamboo is regarded as an eco-friendly plant that grows and matures quickly, has a versatile use, a unique appearance, is efficient at photosynthesis, and has great potential as a substitute material for wood with the various fibre products that can be produced [1,2,3]. Because of its higher physical and mechanical properties, in comparison to some commercial wood species, it has also been used for engineered products, offering higher value addition and market potential [4,5,6]. Due to its high strength and rapid growth, bamboo is the best alternative for replacing timber [7]. Bamboo is no longer restricted to round forms, but has been extended to splits or strips, which have been encouraged to form in engineered products such as composites, laminated bamboo boards, and plybamboo, which can be used in structural applications [8,9,10,11,12].

In Malaysia, at least 70 bamboo species from 10 genera have been identified, with 59 of them found in Peninsular Malaysia. The top three most studied bamboo species in Malaysia are Gigantochloa scortechinii (buluh semantan), Bambusa vulgaris (buluh minyak), and Dendrocalamus asper (buluh betong), with G. scortechinii dominating the list. The basic properties of these bamboos, particularly G. scortechinii, have been extensively researched. Local researchers have extensively studied the anatomical, physical and mechanical properties, machining properties, and chemical content of G. scortechinii [13,14,15]. Several researchers [16,17] have also reported on the chemical composition, morphology, physical and mechanical strength of B. vulgaris. In the meantime, there are few reports on the basic properties of D. asper in comparison to the previous two bamboo species. D. asper, on the other hand, is a favorite bamboo species among local researchers for the production of wood-based products such as particleboard [18,19]. G. levis (buluh beting), on the other hand, has received very little attention in the country. However, Siam et al. [20] found G. levis to be a very promising bamboo species for laminated bamboo production. G. levis has a culm wall thickness of 12 mm, a high density of 750 kg/m3, and superior mechanical strength, making it a suitable candidate for laminated products. These four bamboo species have been found in abundance in the surrounding forest. Furthermore, these are the bamboo species most commonly used in the local industry and community for the production of various bamboo-based household products.

Bamboo culms, on the other hand, are easily impacted by fungus and insects due to their high carbohydrate, including starch content. Improving bamboo’s mechanical properties and fungi resistance is critical for increasing its outdoor use. Bamboo, like most lignocellulosic materials, is vulnerable to biological degradation agents [21]. As a result, treating the bamboo is required to extend the product’s service life. Chemical treatments are the best option, because they ensure that the bamboo products have a longer service life while also maintaining their quality [22]. The preservatives used determine the success of the bamboo treatment. As many wood preservatives have already been banned due to arsenic and/or chromium content, boron-based preservatives with lower toxicity, such as boric acid, have become a popular alternative [23]. Boric acid is a water-based preservative that is much less toxic than arsenic or chromium compounds. Boric acid is well-known in wood preservation for its insecticide and fungicide properties [24].

However, while boric acid treatment improves biological durability, it may also change the physical and mechanical properties of the bamboo. According to some studies, wood treated with boric acid has lower mechanical strength than untreated wood [25,26]. Simsek and Baysal [27], on the other hand, discovered that boric acid treatment increased the surface roughness, density, and modulus of elasticity (MOE) of the treated wood. Because bamboo has the potential to be used in lamination, it is necessary to investigate the effects of boric acid treatment on the adhesion and bonding characteristics of bamboo, as well as its buffering capacity [28,29], which measures the resistance of wood to changing pH levels in acid or alkaline liquid. Density, moisture content, anatomical structure, buffering capacity of the bamboo surface, and species, are all factors that influence bonding quality. Therefore, the purpose of this study was to look into the effects of boric acid treatment on the physical, mechanical, and adhesion properties of bamboo strips that will be used to make laminated bamboo boards. This study used four Malaysian bamboo species based on their abundance and importance in the local industry: G. scortechinii, G. levis, D. asper and B. vulgaris.

2. Materials and Methods

2.1. Materials Preparation

Selected culms from a matured (3–5 years old) bamboo stand were harvested in a forest area near Sik, Kedah. Four bamboo species, namely B. vulgaris (buluh minyak), D. asper (buluh betong), G. levis (buluh beting), and G. scortechinii (buluh semantan) were used in this study for the production of bamboo strips (Figure 1). These bamboos were chosen due to their extensive use in the local bamboo industry and widespread distribution in Malaysia.

Figure 1.

Splits of (a) Bambusa vulgaris (buluh minyak), (b) Gigantochloa levis (buluh beting), (c) Gigantochloa asper (buluh betong), and (d) Gigantochloa scortechinii (buluh semantan).

To obtain shorter and more workable pieces, the harvested culms were cut to lengths of 2 meters using a cross-cutting machine (CYM-001, Chang-hua Hsien, Taiwan). Before being ripped into splits, the culms were further cut to 1 meter lengths. The hollow bamboo culms were longitudinally split into 22 mm width segments with a thickness of 7–9 mm. The splitting of cylindrical bamboo stems resulted in slightly curved strips as shown in Figure 1. The bamboo strips were flattened and shaped using a thicknesser machine before being planed with a 2-side removal machine (PBM-TSP-001, Nagpur, Maharashtra, India). The process removed the bamboo green and bamboo yellow to ensure the middle part of the splits, called the bamboo timber, were extracted [30]. The strips had to be rectangular, flat on each side, and without an inner or outer layer to ensure proper bonding on all four sides. To ensure better bonding and no voids in the laminated bamboo sample, the bamboo S4S machine (MBXD-10B, Hangzhou, Zhejiang, China) was used to shape the strips into a fixed width and thickness (20 mm width × 5 mm thickness).

2.2. Treatment of Bamboo Strips

A 5% boric acid solution was prepared for the treatment of the bamboo strips. The treatment’s goal was to provide bamboo strips with short-term protection against biodegrading agents, such as borers, termites, and fungi, before they were laminated. For 24 h, the bamboo strips were immersed in a 1 m × 1 m tank containing a boric acid solution. The strips were removed from the treatment tank after treatment, and the excess water was drained. The strips were then kiln dried for three days at 60 °C and 40% RH until the moisture content reached around 12%. After that, the strips were conditioned at 20 ± 2 °C and 65 ± 5% RH before testing

2.3. Evaluation of Physical Properties

The conditioned bamboo strips were then cut into samples with dimensions suitable for the different properties’ evaluations. Physical properties, such as moisture content, specific gravity, moisture excluding efficiency, water absorption, thickness swelling, dry salt retention, and weight percent gain, were determined according to the formula listed in Table 1.

Table 1.

Experimental test methods of bamboo strips for the determination of physical properties.

2.4. Surface Morphology Due to Boric Acid Treatment

The presence of boric acid in the bamboo strips was observed by using a Scanning Electron Microscope (SEM, Leo 1455VP, Thornwood, NY, USA). The samples were taken from both the treated and untreated bamboo strips. Cubes of 10 × 10 × 5 mm were prepared using a sharp knife. Morphological investigations were performed on the untreated and treated bamboo (boric acid) with a Scanning Electron Microscope (SEM, Leo 1455VP, Thornwood, NY, USA) machine. The SEM instrument was used at an emission current of 58 μA and an acceleration voltage of 5.0 kV; the working distance was set at 6.2 mm. Before the SEM analysis, the samples were coated with gold.

2.5. Evaluation of Adhesion Properties

2.5.1. Evaluation of Surface Wettability by Contact Angle

The contact angle measurements were performed on bamboo green (previously removed during planing) samples measuring 60 mm in length, 20 mm in width, and 4 mm in thickness. A Theta Lite (TL100 and TL101, Västra Frölunda, Sweden) surface wettability tester was used to measure the contact angle of the specimens. A microscope with an attached camera was used to observe the contact angle. The specimens were conditioned at 20 °C and 65% RH for 24 h. Distilled water was dropped onto the surface at room temperature. To calculate the contact angle, the height and diameter of each droplet was recorded, and the contact angle was observed and measured. Thirty replicated surfaces for each species were tested.

2.5.2. Buffering Capacity

Samples of untreated bamboo strips were ground and dried. After that, fifteen grams of dry bamboo particles were boiled in a 200 mL flask for 30 min. The mixture was filtered using a glass crucible with a filter porosity (40–100 μm) (Carl Roth E562.1, Karlsruhe, Baden-Wuerttemberg, Germany) equipped with an aspirator vacuum (A-1000S, Jalan Bukit Merah, Singapore) and the filtrates were diluted with distilled water to a final volume of 200 mL each. After that, the dilute extract was cooled at 20 °C for 24 h. A digital Mettler Toledo Delta 320 pH Meter (MPN: 320, Columbus, Ohio, USA) was used to measure the actual pH of the diluted sample before proceeding to the aqueous extraction. The aqueous extract was manually titrated with 0.1 N sodium hydroxide (NaOH) and 0.1 N hydrochloride (HCl) solution until pH 10.0 and pH 3.0, respectively. The pH value was recorded after the addition of every 0.2 mL of titrant. After that, a graph of the pH vs. titrant volume (mL) was plotted to examine the change in pH [31].

2.6. Mechanical Properties

The samples were stacked in a conditioning chamber at 20 ± 2 °C and a relative humidity of 65 ± 3% (EMC 12%) for a week prior to testing. The samples for static bending and compression parallel to the grain were prepared in accordance with BS EN373:1957 [32]. A total of 240 specimens (30 samples × 4 species × 2 treatments) were tested. The test was performed on an Instron Universal Testing Machine (UTM, Instron-3366, Norwood, MA, USA) with a capacity of 100 kN. The loading rate and formula used to calculate the MOR, MOE, and compressive strength parallel to the grain, are given in Table 2. Bamboo strips were placed on the supporting span for the static bending test, with the bamboo green surface facing the load of the testing machine.

Table 2.

Testing parameters of bamboo strips for the static bending and compression parallel to the grain tests.

2.7. Experimental Design and Statistical Analysis

The collected data were analyzed using an Analysis of Variance (ANOVA). Meanwhile, the mean separation was carried out using the Least Significant Difference (LSD) method.

3. Results and Discussion

3.1. Treatability of Bamboo

3.1.1. Weight Percent Gain (WPG)

Weight percent gain (WPG) represents the extent of chemical penetration into a material and indicates its treatability. The WPG of bamboo strips is tabulated in Table 3. The variation of WPG values is expected as it is highly dependent on the wood species. In this study, G. levis has a higher treatability with a WPG of 3.61% or 25.34 kg/m3 compared to D. asper, which has a WPG of only 1.47% or 8.97 kg/m3. Meanwhile, both B. vulgaris and G. scortechinii have moderate treatability, as evidenced by their WPG values, which were 2.89% or 19.06 kg/m3 and 1.98% or 13.51 kg/m3, respectively. The gain in weight is due to the precipitation of boric acid. Boric acid dissolves in water primarily in the chemical form of B(OH)3, with only a trace of boric acid dissociating into H+ and B(OH)4 [33]. Yamauchi [34] discovered that B(OH)3 is the dominant form of boric acid. According to their research, B(OH)3 localization occurs during the air-drying process. The analysis of the Fourier-transform (FT)-Raman spectra revealed that a portion of microcrystalline B(OH)3 precipitated in the lumen, while another portion of the B(OH)3 units penetrated the cell wall of the samples [34].

Table 3.

Weight percent gain of untreated and treated bamboo strips of four selected species.

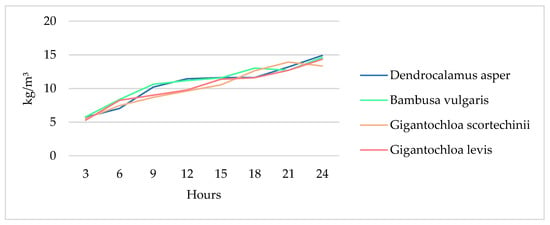

3.1.2. Dry Salt Retention (DSR)

The mean dry salt retention (DSR) of bamboo with different species of bamboo are tabulated in Figure 2. Overall, the DSR of bamboo strips after boric acid treatment ranged from 13–14 kg/m3. The highest DSR was recorded on the bamboo strips from D. asper followed by B. vulgaris, G. levis and G. scortechinii, respectively. Comparing the WPG and DSR, there are some discrepancies that occurred in terms of ranking treatability of the four bamboo species. In WPG, the rank (descending order) was G. levis, B. vulgaris, G. scortechinii and D. asper whereas in DSR, the rank was D. asper, B. vulgaris, G. levis, and G. scortechinii.

Figure 2.

Mean dry salt retention of untreated and treated bamboo strips of four selected species.

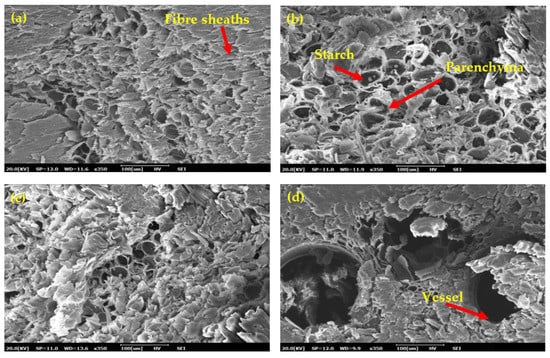

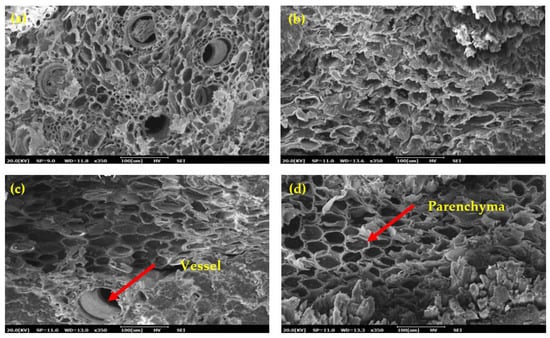

3.2. Surface Morphological Due to Boric Acid Treatment

Figure 3 and Figure 4 show the SEM images of untreated and treated bamboo strips. The bamboo strips’ fibre lumen and parenchyma cells appear to have been filled with boric acid (Figure 4). Gigantochloa genus has a complete vascular bundle structure that comprises of three parts: a central, vascular strand, and two fibre strands, on each side of the central strand [35]. Dendrocalamus genus contained two parts, a central vascular strand and one fibre strand inside the central strand, while Bambusa vulgaris contained two parts, one fibre strand at the bottom of the main vascular bundle and two fibre strands located above and below the main vascular bundle [36]. This explained the reason why semantan and beting generally behave similarly (in almost all of the properties mentioned above) as compared to minyak and betong. Boric acid can remove the starch found in parenchyma, and improve the bonding properties of bamboo strips.

Figure 3.

SEM for untreated bamboo strips of (a) Dendrocalamus asper, (b) Bambusa vulgaris, (c) Gigantochloa scortechinii, and (d) Gigantochloa levis (350×).

Figure 4.

SEM for treated bamboo strips of (a) Dendrocalamus asper, (b) Bambusa vulgaris, (c) Gigantochloa scortechinii, and (d) Gigantochloa levis (350×).

3.3. Physical Properties of Untreated and Treated Bamboo Strips

After a week of conditioning, the moisture content of the bamboo strips was within the range of 7%–9.5%. The density and specific gravity (SG) for the treated and untreated bamboo strips are shown in Table 4. The density of the strips varied between the four species, ranging from 623.17 to 701.7 kg/m3 for treated and 604.63 to 689.91 kg/m3 for untreated. The culms’ specific gravity ranged from 0.62 to 0.70 for treated and 0.60 to 0.69 for untreated. The moisture content of the bamboo strips ranged from 6.9 to 9.5% for treated and 7.2 to 8.0% for untreated bamboo strips. The density of G. scortechinii was higher than the others, with an average density of 713.35 kg/m3, closely followed by G. levis (696.28 kg/m3) and B. vulgaris (672.24 kg/m3), while D. asper had the lowest density at 625.68 kg/m3. The density result was close to previous research performed by Siam et al. [20]. In general, the boric acid treatment increased both the density and specific gravity, slightly. The increment in density and SG is mainly contributed to by the increment in WPG mentioned above. The treatment, however, had the greatest impact on D. asper.

Table 4.

Density and specific gravity of treated and untreated bamboo strips of four selected species.

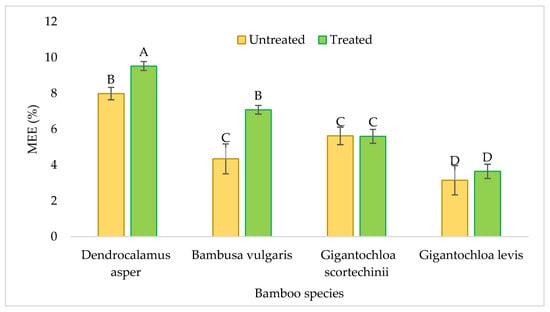

The moisture excluding efficiency (MEE) was calculated from the EMC to evaluate the hydrophobic or hydrophilic properties of the material at high humidity [37]. Figure 5 depicts the effects of boric acid treatment on the MEE values. According to Figure 5, the MEE for treated bamboo strips was higher than for untreated strips. For D. asper, B. vulgaris, G. scortechinii and G. levis, the results were 7.98%, 4.34%, 5.62%, and 3.15% for untreated strips and 9.52%, 7.08%, 5.60%, and 3.64% for treated strips. The results show that there was no significant difference between the untreated and treated strips of G. scortechinii and G. levis when compared to D. asper and B. vulgaris. However, bamboo strips treated with boric acid become more hydrophobic when compared to untreated strips by an average of 12%–20%. D. asper had the highest MEE in this study, indicating that it is more resistant to moisture uptake than the other species. All of the MEE values of the bamboo strips increased after being treated with boric acid, regardless of species. Although D. asper maintained its superiority, B. vulgaris improved significantly in resisting moisture uptake. This characteristic may have a significant impact on bamboo bonding and coating.

Figure 5.

Moisture Excluding Efficiency (MEE) of untreated and treated bamboo strips for four selected species. Note: Bars of mean followed with the same letters A,B,C,D were not significantly different at p ≤ 0.05.

The water absorption and thickness swelling of the bamboo strips for the four bamboo species are shown in Table 5. A different pattern was observed for both water absorption and thickness swelling, with the treated strips having the lowest values. After soaking in water for 24 h, the untreated strips absorbed 2%–5% more water and swelled 1%–2% more than the treated strips. Meanwhile, treated bamboo strips from D. asper, G. scortechinii, B. vulgaris, and G. levis outperformed the untreated bamboo strips by 5.52%, 4.13%, 3.31% and 2.04%, respectively. The bamboo strips with a higher density had a lower WA value and a higher TS value. Biswas et al. [38] found similar trends in both WA and TS for bamboo strips, which supported this finding. A study by Borthakur and Gogoi [39] stated that the bulking of the cell wall confers better dimension stabilization in bamboo. D. asper had the least swelling, which could be attributed to its lower density. As evidenced by the high WA of D. asper, low density bamboo has more void volume and, thus, can accommodate more water. The reduction in WA could be attributed to the precipitation of boric acid on the bamboo and the reduced availability of voids for water absorption [40]. The reduction of thickness swelling and water absorption of the treated bamboo strips could confer better dimensional stability to the laminated products.

Table 5.

Water absorption and thickness swelling of untreated and treated bamboo strips for four selected species.

3.4. Adhesion Properties of Untreated and Treated Bamboo Strips

3.4.1. Wettability

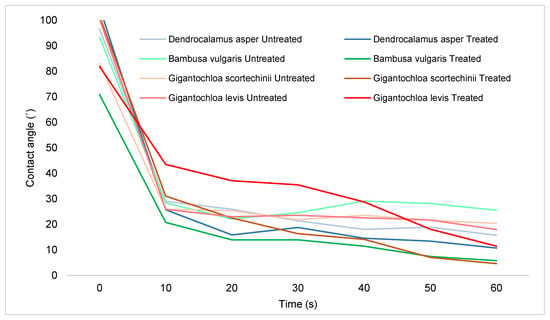

The contact angle is formed between the surface and a liquid, and this provides useful information about how well an adhesive wets, spreads, and penetrates into wood samples, according to Paridah et al. [41]. In this study, all of the contact angles reached less than 30° after 60 s (Figure 6). Based on the smaller contact angle after 60 s, treated bamboo strips appear to have better wettability than untreated bamboo strips, implying that the surface of treated bamboo strips is more wettable and hydrophilic [42]. Boric acid treatment increased the surface roughness of the bamboo, most likely due to raised fibres on the bamboo surface. Higher roughness causes increased wettability [31], which explains the increased wettability in treated bamboo. Lesar et al. [43] discovered that wood treated with boric acid is more hygroscopic than untreated wood. When compared to other bamboo species, G. levis appears to be the least wettable, while B. vulgaris appears to be the most wettable. It took more than 40 s for D. asper to reach the contact angle obtained for other species. The increased wettability of the bamboo strips after boric acid treatment may benefit the bonding quality of laminated bamboo boards by allowing the adhesive to spread more easily.

Figure 6.

Changes in the contact angle of untreated and treated bamboo strips for four selected species.

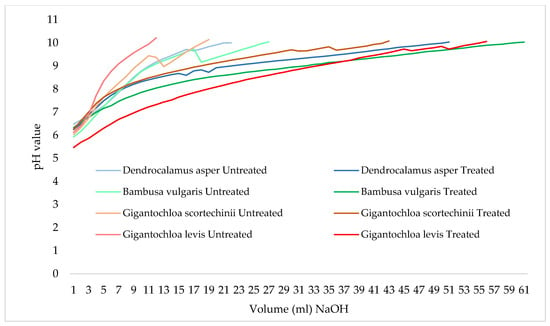

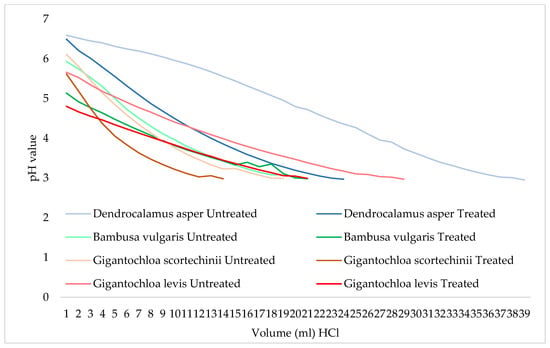

3.4.2. Buffering Capacity of Bamboo Strips

Buffering capacity is the resistance of wood and non-wood materials to changes in pH. Understanding the pH value and buffering capacity is critical because they influence the curing behavior of resin [31,41,42]. The pH and buffering capacity values of untreated and treated strips from the four bamboo species are shown in Table 6. As shown in Table 6 and Figure 7 and Figure 8, all of the untreated bamboo appeared to be more stable in acidic conditions than in alkaline conditions because this required more HCl (20–40 mL) to reach pH 3.0 rather than NaOH (12–27 mL) to reach pH 10.0. In contrast, treated bamboo is more stable in alkaline conditions than in acidic conditions because a greater amount of NaOH (43–61 mL) was used compared to HCl (15–25 mL) to achieve a pH 10.0 and 3.0, respectively.

Table 6.

The pH and buffering capacity values of untreated and treated strips from four bamboo species.

Figure 7.

Stability of untreated and treated bamboo strips of four selected species in alkaline conditions.

Figure 8.

Stability of untreated and treated bamboo strips of four selected species in acidic conditions.

3.5. Mechanical Properties of Untreated and Treated Bamboo Strips

Table 7 shows the mechanical properties of the treated and untreated bamboo strips of four bamboo species. Treated strips appears to be much stronger compared to untreated strips. Treatment with boric acid increased the MOR, MOE, and maximum load in bending, as well as the compressive strength and the maximum load parallel to the grain. G. scortechinii showed superior bending properties, while D. asper was the least strong irrespective of the treatment. Similarly, concerning compression parallel to the grain, G. scortechinii tops other species in both compressive strength and maximum load. D. asper remained the weakest among the four species. The strength values for G. scortechinii and G. levis were rather close, which may be due to being in the same genus and having a similar structure of wall thickness among the bamboo species, and the internode lengths were longer than those for D. asper and B. vulgaris, even though the wall thickness for both bamboo species, from the bottom to the top portions, were the greatest [35]. The increased strength value can be correlated with the formation of boric acid (salt crystals) within the bamboo’s microstructure, which may aid in accommodating the applied force during loading [44]. Nevertheless, some studies did report the negative effects of boric acid treatment towards the mechanical strength of bamboo [25,26]. It could be because water-based preservative formulations undergo hydrolytic reduction when they come into contact with wood sugars, causing a reaction with the cell wall components. Wood strength may be diminished due to fixation, a process that oxidizes the components of wood cell walls [45]. However, the goal of the boric acid treatment in this study is only to provide the bamboo with short-term protection against biodegradation agents. The concentration of boric acid used was relatively low, at 5%, and the WPG recorded was also low, ranging from 1.47 to 3.61% (Table 3). Therefore, the increase in MOR and MOE could be attributed, primarily, to an increase in the density of the treated bamboo strips.

Table 7.

Mean values for the mechanical properties of untreated and treated bamboo strips from different species.

3.6. Failure Behavior of Bamboo Strips in Mechanical Testing

The failure of bamboo strips loaded in static bending, for untreated and treated bamboo, is depicted in Figure 9. The bamboo fails in in two ways: (a) brittle shear tension mode, and (b) splintering tension mode. Brittle shear tension failure was caused primarily by extensive longitudinal shear in the node section and occurred in all portions of the node. Meanwhile, splintering tension failure was caused by splintering failure at the radial edge of the lower layer of the specimen and was common in the internodes of all portions. This finding is consistent with previous research using Gigantochloa scortechinii bamboo strips [46]. The bending failure for both the untreated and treated bamboo strips appeared in the node of the strips and in the lower layer, for which the failure in both the parenchyma and vascular bundles regions was due to the mechanical load applied to the specimens. The parenchyma and vascular bundles were crushed and split extensively in the node, whereas in the internodes, the failure only occurred in the parenchyma without any failure in the vascular bundles.

Figure 9.

Failure mode of strips from four bamboo species loaded in static bending: (a) brittle shear tension mode, (b) splintering tension mode.

Figure 10 depicts the failure in compression of the bamboo strips, with various failure behaviors observed in both the untreated and treated strips. The failure is illustrated in Figure 10a, showing crushing from the bottom end and shear splitting in the middle and upwards; the shear splitting propagated above the crushed area and upwards, due to a weakness in compression. Figure 10b shows, on the other hand, that the crack tended to form from the bottom end and from the middle, upwards, and sheared perpendicularly to the maximum shear plane along 45° but terminated below the nodal area. At the node, the crack occurred from the bottom end and sheared perpendicularly, while for the internode, the crushing started from the bottom end and the shear splitting occurred in the middle, upwards. After about 80% of the stress load, creases appeared on the compression side of the bamboo. This could be attributed to the vascular bundle’s thick polylamellated layer of fibre and the high percentage of parenchyma found in stress-resistant bamboo complements. The frequency of occurrence of these failures in bending and compression was nearly identical for both treated and untreated bamboo strips, indicating that the boric acid treatment had no effect on bamboo strip failure behavior. Table 7 shows that, despite the increased bending and compression of the treated bamboo strips, the values are not statistically different from the untreated bamboo strips, with the exception of compression in treated G. scortechinii.

Figure 10.

Failure mode of strips from four bamboo species for compression parallel to the grain: (a) failure due to crushing, (b) shearing failure in the bamboo strip.

4. Conclusions

The present study determines the effect of boric acid treatment on the physical, mechanical, adhesion and morphological properties of strips from four bamboo species (Dendrocalamus asper, Bambusa vulgaris, Gigantochloa scortechinii and Gigantochloa levis). All four species of bamboo can be treated easily with boric acid, with a reasonable DSR and WPG. Based on the DSR and WPG values, the treatability of these bamboo species ranked (in descending order) as follows: B. vulgaris, D. asper, G. levis and G. scortechinii. In general, treatment with boric acid increased both the density and specific gravity slightly. D. asper was the most affected by the treatment. Treatment with boric acid reduced the WA and TS of the bamboo strips significantly. Based on the WA and TS results, D. asper was the most stable (high WA, low TS) while the most unstable was B. vulgaris (high WA, high TS). G. scortechinii showed superior bending properties, while D. asper was the least strong, irrespective of treatment. Similarly, concerning compression parallel to the grain, G. scortechinii tops other species in both compressive strength and maximum load. D. asper remained the weakest among the four species. Compared to B. vulgaris and D. asper, G. levis possessed acceptable strength next to G. scortechinii. Based on the overall properties, and despite having relatively poorer treatability and stability, both G. scortechinii and G. levis had greatly superior mechanical properties, which warrants these species being considered for the production of laminated products. Boric acid treatment was found to provide several benefits to bamboo strips intended for lamination, including increased wettability, dimensional stability, and mechanical strength.

Author Contributions

Conceptualization, L.S.H. and P.M.T.; methodology, P.M.T.; software, S.S.O.A.-E.; validation, A.S.M.R., L.K. and R.R.; formal analysis, M.A.R.L. and W.F.; investigation, N.M.Y., R.M.S.J. and R.D.; resources, P.M.T.; data curation, N.M.Y., R.M.S.J. and R.D.; writing—original draft preparation, N.M.Y.; writing—review and editing, L.S.H., L.K., M.A.R.L., W.F. and R.R.; visualization, S.S.O.A.-E.; supervision, L.S.H. and P.M.T.; project administration, L.S.H. and P.M.T.; funding acquisition, L.S.H. and P.M.T. All authors have read and agreed to the published version of the manuscript.

Funding

The presented work is supported by the Fundamental Research Grant Scheme (FRGS 2019-1), Reference code: FRGS/1/2019/WAB07/UPM/02/3; by the Ministry of Higher Education, Malaysia; a Higher Institution Centre of Excellence (HICoE) grant; and an RMK11 collaboration with the Malaysian Timber Industry Board (MTIB).

Data Availability Statement

Not applicable.

Acknowledgments

The authors also wish to express gratitude to the Faculty of Forestry and Environment, Universiti Putra Malaysia, for providing the mechanical testing facilities. This work was also supported by the Slovak Research and Development Agency under contracts No. APVV-19-0269 and No. SK-CZ-RD-21-0100.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, H.; Qian, Z.; Zhuang, S. Effects of soil temperature, water content, species, and fertilization on soil respiration in bamboo forest in subtropical China. Forests 2020, 11, 99. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Amin, Y.I.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Iswanto, A.H.N.; Fudholi, A.; Asrofi, M.; et al. A Comprehensive Review on Natural Fibres: Technological and Socio-Economical Aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef] [PubMed]

- Fatriasari, W.; Syafii, W.; Wistara, N.J.; Syamsu, K.; Prasetya, B. The Characteristic Changes of Betung Bamboo (Dendrocalamus asper) Pretreated by Fungal Pretreatment. Int. J. Renew. Energy Dev. 2014, 3, 133–143. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.Z.; Shan, B. Production, environmental impact and mechanical properties of glubam. Constr. Build. Mater. 2013, 44, 765–773. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, K.J. Effect of glow-discharge plasma treatment on contact angle and micromorphology of bamboo green surface. Forests 2020, 11, 1293. [Google Scholar] [CrossRef]

- Huang, X.Y.; Qi, J.Q.; Xie, J.L.; Hao, J.F.; Qin, B.D.; Chen, S.M. Variation in anatomical characteristics of bamboo, Bambusa rigida. Sains Malays. 2015, 44, 17–23. [Google Scholar]

- Hanim, A.R.; Zaidon, A.; Anwar, U.M.K.; Rafidah, S. Effects of chemical treatments on durability properties of Gigantochloa scortechinii strips and ply-bamboo. Asian J. Biol. Sci. 2013, 6, 153–160. [Google Scholar] [CrossRef]

- Hamdan, H.; Anwar, U.M.K.; Zaidon, A.; Tamizi, M.M. Mechanical properties and failure behaviour of Gigantochloa scortechinii. J. Trop. For. Sci. 2009, 21, 336–344. [Google Scholar]

- Yang, S.; Li, H.; Fei, B.; Zhang, X.; Wang, X. Bond quality and durability of cross-laminated flattened bamboo and timber (CLBT). Forests 2022, 13, 1271. [Google Scholar] [CrossRef]

- Bakar, E.S.; Nazip, M.N.M.; Anokye, R.; Lee, S.H. Comparison of three processing methods for laminated bamboo timber production. J. For. Res. 2019, 30, 363–369. [Google Scholar] [CrossRef]

- Ashaari, Z.; Lee, S.H.; Zahali, M.R. Performance of compreg laminated bamboo/wood hybrid using phenolic-resin-treated strips as core layer. Eur. J. Wood Wood Prod. 2016, 74, 621–624. [Google Scholar] [CrossRef]

- Mohmod, A.L.; Ariffin, W.T.W.; Ahmad, F. Anatomical features and mechanical properties of three Malaysian bamboos. J. Trop. For. Sci. 1990, 2, 227–234. [Google Scholar]

- Mohmod, A.L.; Amin, A.H.; Kasim, J.; Jusuh, M.Z. Effects of anatomical characteristics on the physical and mechanical properties of Bambusa blumeana. J. Trop. For. Sci. 1993, 6, 159–170. [Google Scholar]

- Wahab, R.; Mustafa, M.T.; Salam, M.A.; Sudin, M.; Samsi, H.W.; Rasat, M.S.M. Chemical composition of four cultivated tropical bamboo in genus Gigantochloa. J. Agric. Sci. 2013, 5, 66. [Google Scholar] [CrossRef]

- Wahab, R.; Mohammed, A.S.; Aminuddin, M.; Samsi, H.W.; Shafiqur, R.; Mohd, S.; Izyan, K. Evaluation on strength of chemically treated 2 and 4 year-old bamboo Bambusa vulgaris through pressurized treatment. Res. J. Pharm. Biol. Chem. Sci. 2015, 6, 1282–1288. [Google Scholar]

- Kasim, J.; Ahmad, A.J.; Mohamod, A.L.; Khoo, K.C. A note on the proximate chemical composition and fibre morphology of Bambusa vulgaris. J. Trop. For. Sci. 1994, 6, 356–358. [Google Scholar]

- Nurhazwani, O.; Jawaid, M.; Tahir, P.M.; Abdul, J.H.; Hamid, S.A. Hybrid particleboard made from bamboo (Dendrocalamus asper) veneer waste and rubberwood (Hevea brasilienses). BioResources 2016, 11, 306–323. [Google Scholar] [CrossRef]

- Wong, J.W.; Yeo, W.S.; Paridah, M.T. Sound absorption properties of kenaf bamboo particleboard at various mixing ratio and density. AIP Conf. Proc. 2017, 1902, 020001. [Google Scholar]

- Siam, N.A.; Uyup, M.K.A.; Husain, H.; Awalludin, M.F. Anatomical, physical, and mechanical properties of thirteen Malaysian bamboo species. BioResources 2019, 14, 3925–3943. [Google Scholar] [CrossRef]

- Luo, C.; Li, Y.; Chen, Y.; Fu, C.; Nong, X.; Yang, Y. Degradation of bamboo lignocellulose by bamboo snout beetle Cyrtotrachelus buqueti in vivo and vitro: Efficiency and mechanism. Biotechnol. Biofuels 2019, 12, 75. [Google Scholar] [CrossRef]

- Satish, K.; Dobriyal, P.B. Preservative treatment of bamboo for structural uses. In Proceedings of the Bamboos. Current Research. International Bamboo Workshop, Cochin, India, 14–18 November 1990; Kerala Forest Research Institute: Kerala, India, 1990; pp. 199–206. [Google Scholar]

- Baharuddin, N.; Lee, S.H.; Uyup, M.K.A.; Tahir, P.M. Effect of Preservative Treatment on Physical and Mechanical Properties of Bamboo (Gigantochloa scortechinii) Strips. BioResources 2022, 17, 5129–5145. [Google Scholar] [CrossRef]

- Pizzi, A.; Baecker, A. A new boron fixation mechanism for environment friendly wood preservatives. Holzforschung 1996, 50, 507–510. [Google Scholar] [CrossRef]

- Colakoglu, G.; Colak, S.; Aydin, I.; Yildiz, U.C.; Yildiz, S. Effects of boric acid treatment on mechanical properties of laminated beech veneer lumber. Silva Fenn. 2003, 37, 505–510. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kartal, S.N.; Laufenberg, T.L.; Winandy, J.E.; White, R.H. Physical and mechanical properties and fire, decay, and termite resistance of treated oriented strandboard. For. Prod. J. 2005, 55, 74–81. [Google Scholar]

- Simsek, H.; Baysal, E. Some physical and mechanical properties of borate-treated oriental beech wood. Drv. Ind. 2015, 66, 97–103. [Google Scholar] [CrossRef]

- Paridah, M.T.; Chin, A.M.E.; Zaidon, A. Bonding properties of Azadirachta excelsa. J. Trop. For. Prod. 2001, 7, 161–171. [Google Scholar]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 2022, 109776. [Google Scholar] [CrossRef]

- Li, J.; Zheng, H.; Sun, Q.; Han, S.; Fan, B.; Yao, Q.; Jin, C. Fabrication of superhydrophobic bamboo timber based on an anatase TiO2 film for acid rain protection and flame retardancy. RSC Adv. 2015, 5, 62265–62272. [Google Scholar] [CrossRef]

- Redzuan, M.S.J.; Paridah, M.T.; Anwar, U.M.K.; Juliana, A.H.; Lee, S.H.; Norwahyuni, M.Y. Effects of Surface Pretreatment on Wettability of Acacia Mangium Wood. J. Trop. For. Sci. 2019, 31, 249–258. [Google Scholar] [CrossRef]

- BS EN 373; Methods of Testing Small Clear Specimens of Timber. BSI: London, UK, 1957.

- Yamauchi, S. Raman spectroscopic study on the behavior of boric acid in wood. J. Wood Sci. 2003, 49, 227–234. [Google Scholar] [CrossRef]

- Yamauchi, S.; Sakai, Y.; Watanabe, Y.; Kubo, M.K.; Matsue, H. Distribution of boron in wood treated with aqueous and methanolic boric acid solutions. J. Wood Sci. 2007, 53, 324–331. [Google Scholar] [CrossRef]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.B.H.H.; Majid, D.L.A.A. Morphological, mechanical, and physical properties of four bamboo species. BioResources 2017, 12, 2479–2495. [Google Scholar] [CrossRef]

- Darwis, A.; Iswanto, A.H. Morphological Characteristics of Bambusa vulgaris and the Distribution and Shape of Vascular Bundles therein. J. Korean Wood Sci. Technol. 2018, 46, 315–322. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Zaidon, A.; Maminski, M. Microstructural, mechanical and physical properties of post heat-treated melamine-fortified urea formaldehyde-bonded particleboard. Eur. J. Wood Wood Prod. 2015, 73, 607–616. [Google Scholar] [CrossRef]

- Biswas, D.; Bose, S.K.; Hossain, M.M. Physical and mechanical properties of urea formaldehyde-bonded particleboard made from bamboo waste. Int. J. Adhes. Adhes. 2011, 31, 84–87. [Google Scholar] [CrossRef]

- Borthakur, R.D.; Gogoi, P. Studies of Dimensional Stability, Thermal Stability and Biodegradation Resistance Capacity of Chemically Treated Bamboo. Asian J. Biochem. 2014, 9, 16–29. [Google Scholar] [CrossRef]

- Priadi, T.; Lestari, M.D.; Cahyono, T.D. Posttreatment Effects of Castor Bean Oil and Heating in Treated Jabon Wood on Boron Leaching, Dimensional Stability, and Decay Fungi Inhibition. J. Korean Wood Sci. Technol. 2021, 49, 602–615. [Google Scholar] [CrossRef]

- Paridah, M.T.; Hafizah, A.N.; Zaidon, A.; Azmi, I.; Nor, M.M.; Yuziah, M.N. Bonding properties and performance of multi-layered kenaf board. J. Trop. For. Sci. 2009, 21, 113–122. [Google Scholar]

- He, G.; Yan, N. Effect of wood on the curing behavior of commercial phenolic resin systems. J. Appl. Polym. Sci. 2005, 95, 185–192. [Google Scholar] [CrossRef]

- Lesar, B.; Straže, A.; Humar, M. Sorption properties of wood impregnated with aqueous solution of boric acid and montan wax emulsion. J. Appl. Polym. Sci. 2011, 120, 1337–1345. [Google Scholar] [CrossRef]

- Gauss, C.; Kadivar, M.; Savastano, H., Jr. Effect of disodium octaborate tetrahydrate on the mechanical properties of Dendrocalamus asper bamboo treated by vacuum/pressure method. J. Wood Sci. 2019, 65, 27. [Google Scholar] [CrossRef]

- Winandy, J.E.; Margaret, E.H. Wood Protection Techniques and the Use of Treated Wood in Construction; Forest Products Research: Madison, WI, USA, 1988; pp. 54–62. [Google Scholar]

- Bahari, S.A.; Ahmad, M. Failure Behaviour of Semantan Bamboo Strips Loaded in Bending and Shear. Key Eng. Mater. Trans Technol. Publ. 2011, 462–463, 1176–1181. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).