1. Introduction

The concept of winch-assist timber harvest systems is now well established [

1,

2]. These systems allow the application of cost-effective ground-based harvesting on steeper terrains that were previously cable-logged [

3]. The main benefits of winch assistance include improved safety performance through the mechanisation of manual tasks such as chainsaw felling as well as overall productivity increases through system efficiency gains [

4]. They have been extensively used throughout Europe and, more recently, also in North and South America [

5,

6].

While most European winch-assist devices operate in the range of 5 to 12 tonnes of pull power [

7,

8], larger winch systems with pull power greater than 20 tonnes were developed in New Zealand to support large excavator-based felling and shovelling machines [

9,

10]. So far, over 450 such large units have been manufactured. While many are exported, over 215 are operating full-time in New Zealand, indicating that over 70% of the cable-logging crews have winch-assist capability [

11].

Cost-effectiveness is still one of the main factors used in deciding what type of harvesting system is the most appropriate [

12]. A comprehensive study of six harvesting operations in both New Zealand and Canada showed that winch assistance can be successful in a range of different configurations and operating conditions [

13]. Apart from simply accessing steeper terrain, such systems offer an opportunity to reduce road construction and cover longer cost-effective extraction distances [

14,

15].

In Europe, traction assist has primarily been developed to support wheeled harvester-forwarder operations [

16]. The relatively lower pull forces, which result in more compact winch and power systems, provide the opportunity to integrate the winch units into the harvester, forwarder or skidder. This concept proves especially valuable when operating on sensitive soils or under strict environmental constraints [

17,

18]. In such cases, winch assistance removes the need for a dense network of skid trails and allows for the minimisation of soil disturbance [

15]. The latter is the result of several factors.

First of all, a machine without winch assist needs frequent turning and repositioning in order to achieve better stability on steep terrain, whereas a winch-assist machine can move straight up and down the hill and still maintain traction with the ground, thereby disturbing less soil area [

19]. Furthermore, winch-assist minimises the spinning of wheels or tracks, which is a main cause of rutting and soil compaction [

20]. Iarocci observed this in an operation in Chile, where a Tigercat 635E Skidder tethered to an Ecoforst T-Winch with an approximately 8 tonne load operating on a 40% slope caused little to no ground disturbance from wheel spin [

21]. Similar results were also obtained in the Brazilian eucalypt plantations, where tethered extraction resulted in minimum soil disturbance [

22].

Until quite recently, in New Zealand, winch-assist technology was used mainly for felling and bunching rather than extraction [

23,

24]. Winch-assist feller-bunchers and shovels were taken on site to prepare the loads for conventional cable yarders [

25]. This was partly driven by safety requirements, as it removed all manual tasks such as chainsaw felling and choker-setting [

26]. Winch-assist-supported mechanised felling was matched with grapple yarding in order to achieve full mechanisation on steep terrain [

27].

However, it has recently become apparent that large grapple skidders can also be coupled with winch-assist machinery, and they may offer several advantages compared with cable yarders, especially on less favourable sites [

28,

29]. Unlike cable-yarding systems, winch-assist skidder systems do not require terrain that provides deflection to be productive. Getting a winch-assist skidder prepared for operation takes much less time and effort than setting up a yarder. For example, Koszman [

30] and Strimbu and Boswell [

28] suggested that winch-assist skidders will be more productive and reliable than conventional ones when working uphill or in snowy conditions. Furthermore, the downtime due to weather disturbance is reduced, as the traction assistance helps keep the equipment working when conventional equipment would have to stop.

Despite this very large potential, most available studies of larger-scale winch-assist technology have been conducted on felling machines, meaning there is limited information available on winch-assist skidders. The goal of this study is to contribute to our knowledge of winch-assist skidding, as used in a typical plantation forestry site with moderate to steep terrain. In particular, the study aims to determine the impact of winch assistance on (1) productivity and (2) soil disturbance.

2. Materials and Methods

The study site was located in Castle Downs and Blackmount Forest, north of Invercargill, on the South Island. The stand was a typical Pinus radiata plantation at a stocking of approximately 725 stems ha−1. The average tree height and stem volume were 28.9 m and 0.79 m3 over bark, respectively. The stand was clearcut and the total harvest volume was 530 m3 ha−1 over bark. The harvest site was hilly, with a mean slope gradient of approximately 30%. However, some areas were significantly steeper, with gradients in the 40–50% class, which is where the study was conducted. The soil was a Perch-Gley Pallic Soil, which is the dominant type in the seasonally dry eastern part of the South Island, where it develops on loess parent material derived from schist or greywacke. This soil type has slow permeability, medium to high bulk density and limited rooting depth. For these reasons, Perch-Gley Pallic Soil is quite susceptible to erosion.

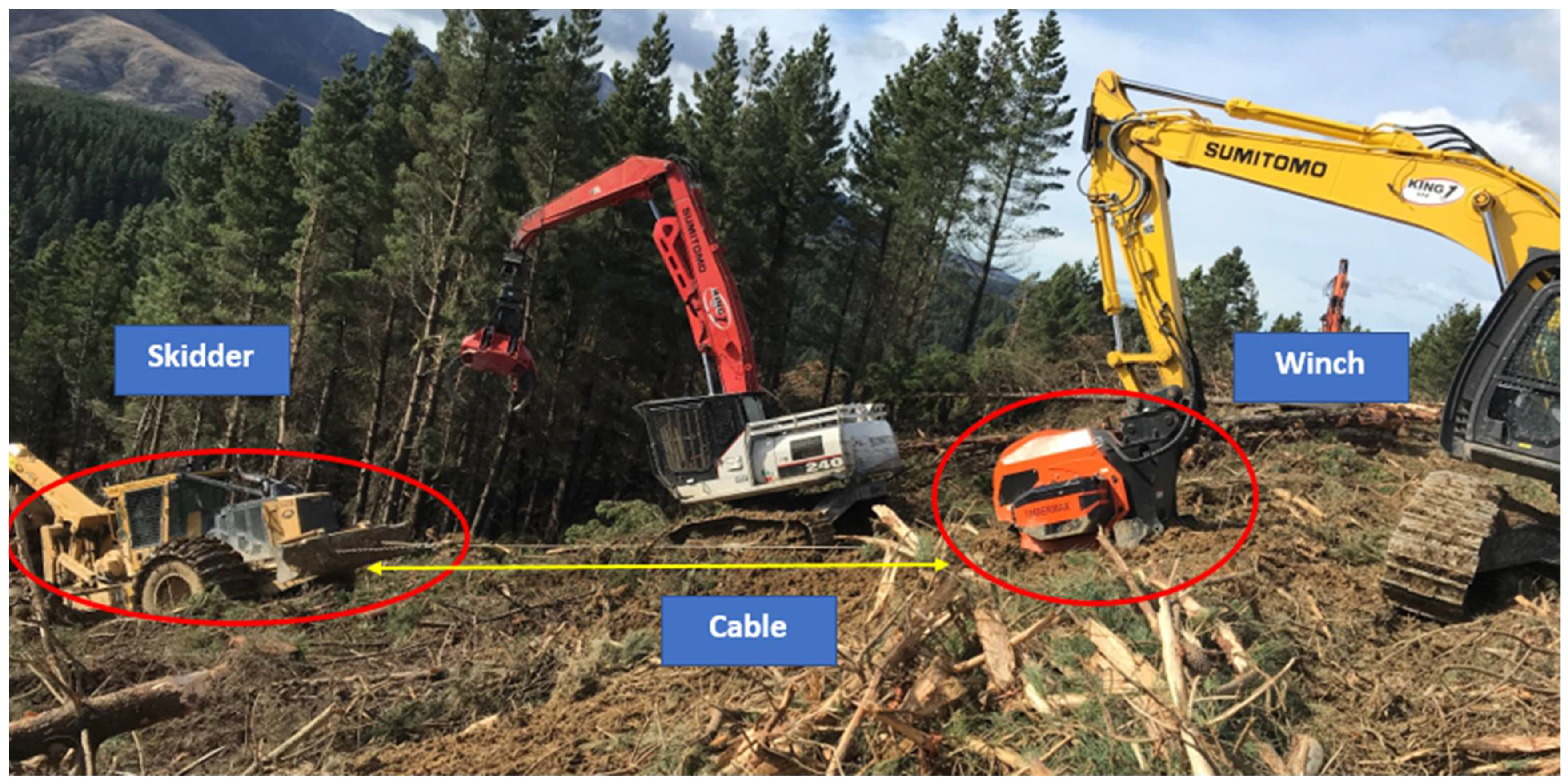

The winch-assist system was the Timber Max T20 (TimberMAX Rouyn-Noranda, QC, Canada). The system was attached to an excavator boom and used the large spike in its base for stabilisation. The winch had 20 tonnes of pull power and used 400 m of 25 mm swaged wire rope. The winch system was set up next to the landing and on the slope’s edge. The system was set to assist a two-axle Tigercat 632E Grapple Skidder (Tigercat Industries Inc., Brantford, ON, Canada) (

Figure 1). The skidder was equipped with belts on its front tyres and chains on its rear ones.

The study was conducted on three separate skid trails: trail 1 had a length of 250 m and a convex profile, with a slope gradient increasing from 10% to 30% as one moved away from the landing; while trails 2 and 3 were nearly identical and had a similar length and profile to trail 1, but they were steeper and reached a 40% gradient towards their bottom end. The experimental design consisted of comparing the skidder performance with and without winch assistance on a moderate (A) and a steep trail (B and C). Therefore, four treatments were tested: control (no winch assist) on trail A, winch assistance on trail A, control on trail B and winch assistance on trail C. For the purpose of the study, trails B and C were taken as equivalent, which they were in terms of the distance, profile, inclination and soil type. Ideally, the control and the winch-assistance treatment should have been compared on the same trail, although that was made impossible by logistical issues, since the winch was down for an extended period of time, during which the work on trail B progressed until no more wood was available. The same logistical reasons prevented the complete randomisation of the observations, as the need for rigging the skidder would make it impractical to switch from one treatment to another in a random sequence. Therefore, the treatments were administered in batches, although extreme care was taken to accurately record the distance, which was the most important bias randomisation would have prevented in this case.

The timber was felled and pre-bunched using an excavator-based feller-buncher. At the time of extraction, another excavator-based shovel unit moved the stems towards the skid trails, accumulating pre-formed loads. The load size was agreed with the skidder operator, so as to maximise the payload, based on the pulling capacity of the skidder under the specific conditions being encountered on each trail (e.g., slope gradient and eventual availability of winch assistance). The skidder pulled the loads up the slope and dropped them into a surge pile at the front end of the landing for subsequent processing and loading onto trucks. The same experienced driver operated the skidder and winch for the whole duration of the study.

The skidder performance was assessed by means of classic cycle-level time studies [

31]. In particular, the researchers determined the cycle time, skidding distance, load size and travel speed.

The cycle time was measured using a precision stopwatch and split into the following elements (work steps):

Travel Empty: begins when the skidder leaves the landing and ends when the skidder stops to pick up its load.

Load: begins the moment the skidder stops travelling to pick up its load and ends when the skidder begins its return journey to the landing.

Travel Loaded: begins when the skidder leaves the loading site with a load and ends when it starts manoeuvring its load onto the surge pile at the landing.

Unload: begins when skidder starts the unloading manoeuvre and ends when the empty skidder realigns its frame and start backing up towards the loading zone down the hillside.

Delay: All delays were recorded separately, together with the reasons why the operation stopped.

The extraction distance (m) was measured for each cycle using a laser range finder.

The load volume was estimated by recording the number of stems in each load and multiplying that number for the average stem size. In order to increase accuracy, the stems were categorised as either small or large. The respective mean volumes were obtained by getting the processor to scale 24 stems and recording the individual merchantable volume of each of them. The 24 records were arranged by increasing size, and then the list was split in the middle in order to get two mean values, with the larger one (1.6 m3) taken as the reference volume for large trees and the smaller one (0.75 m3) for small trees. That way, we were able to get a reasonably accurate estimate of the turn volume without stopping the operation or risking an accident.

On skid trail A, the travel speed was recorded by a GPS unit (Garmin Ltd., Olathe, KS, USA) attached to the skidder and fitted with its own aerial.

The soil disturbance was assessed using the line transect method and, therefore, represented the impact over the whole area, not only on the skidding trails. Visual classes were used to simplify and standardise the assessment of the soil disturbance, which was defined as the observed degree of change from natural conditions [

32,

33]. The sampling process involved laying out transect lines perpendicular to the main skidding direction and spaced at approximately 40 m (

Figure 2) [

34]. The survey points were taken at 1 m intervals along the transect lines and along two parallel survey lines 5 m apart. The soil disturbance was visually categorised into six classes (

Table 1).

These categories were aligned with operational considerations. A disturbance greater than 5 cm poses the risk of accelerated erosion, and a deep disturbance greater than 15 cm is effectively a gouge or rut that can readily accumulate and accelerate water runoff, which makes it the category of greatest concern regarding environmental impact (e.g. erosion).

The data analysis aimed at finding the relationship between the cycle time, element time, load size and productivity (dependent variables) and the slope gradient and winch-assist treatment (on or off) (independent variables). This was tested using the general linear model technique (GLM), which is especially robust against violations of the parametric assumptions and can deal with unbalanced datasets (an uneven number of observations). The GLM technique was used to check if the mean values estimated for the dependent variables would show statistically significant differences between the treatments. Four treatments were identified, as derived from the combination of two trail gradient levels (moderate or steep) and two winch-assistance modes (winch or no winch). Both independent variables were categorical.

3. Results

The productivity data were collected by observing 114 valid skidder cycles over 3 days, which were distributed as follows: Path A, winch assist = 18 cycles; Path A, no winch assist = 39 cycles; Path B no winch assist = 23 cycles; and Path C, winch assist = 34 cycles. Descriptive statistics are shown in

Table 2.

Table 2 shows that the skidder covered different distances over different trails, and this difference introduced a significant bias when trying to compare the cycle time and productivity figures across the treatments. The load volume was the only parameter among those reported in

Table 2 that might not have been affected by the extraction distance bias. In order to standardise the comparison for equal extraction distances, the travel speed was calculated separately for the empty and the loaded trip (

Table 3). The empty travel speed was 70% to 90% higher without winch assistance, regardless of the slope gradient. The interaction factor “winch assist” × “slope gradient” was not significant, and the winch-assist treatment alone explained over 80% of the variability in the data.

Conversely, the travel loaded speed was significantly affected by both the winch-assist treatment and the slope gradient, as well as by their interaction (

Table 4). In particular, the high significance of the interaction factor pointed at the fact that when working on the moderate slope, the winch assistance allowed for a significant increase in both the travel loaded speed and load size, while on the steeper trail, it again allowed for an increase in the load size but could not prevent a severe drop in the travel speed. Conversely, without the winch assistance, the loaded speed remained relatively high on the steep slope too, although the load size dropped dramatically. Therefore, under the conditions of this study, the winch assistance may have a greater specific impact on the payload capacity than on the mobility.

The loading time was not affected by either the slope gradient or winch treatment (

Table 5), and only the number of pieces per load seemed to have an effect on its duration, although even this effect was very weak (

Table 6). In addition, the effect was not logical, since the regression analysis pointed at the loading time decreasing, not increasing, with the number of pieces in a load (loading in s = 14.1–0.37 n° of pieces, R2 = 0.01). The most likely explanation is that when the loading time was the shortest, it was because the skidder was being fed by the shovel, which was packing the bunches on the slope.

By contrast, the unloading time was only affected by the winch treatment, which explained over 50% of the variability in the dataset. The explanation for this might be the different arrangement at the landing once the winch was installed, including the need not to run over the cable and the presence of an anchor machine. This likely led to more manoeuvring on the way in and/or out of the unloading place. Therefore, for the purpose of modelling, two levels of unloading time were selected, corresponding to the average values under the winch and no-winch treatments: these were 37 s and 13 s, respectively.

Finally, the load size was significantly affected by the treatment, gradient and their interaction, as expected. The results were logical and indicated that using the winch always resulted in a significant increase in the load size, both on the moderately steep trail (from 4.3 to 5.7 m3, or a 33% increase) and on the steep trail (from 3.9 to 4.7 m3, or a 20% increase). By contrast, moving without winch from a moderate to a steep trail resulted in a decreased load size (from 4.3 to 3.9 m3, or a. 10% decrease) although the difference was not statistically significant (A vs. C).

For the purpose of modelling, the average load size figures in

Table 5 were adopted unmodified. A caveat must be issued regarding the different piece size recorded for trail C, which was in another compartment of the same forest, since it was not possible to test all the treatments in exactly the same compartment due to logistical reasons. Apparently, the tree size in this second compartment was much larger than in the first one: 1.5 m

3 vs. 0.8 m

3. That might have affected the results of the study, if it was not for the fact that the loads were pre-bunched by a shovel that tried to build single accumulations matching the optimum for the skidder under the specific conditions. Larger trees would imply less flexibility when trying to assemble accurately sized loads, since the shovel could only add or subtract 1.5 m

3 increments on average. Whatever the alignment between the bunch size and load capacity, the effect would be reflected in the combination of the load size and travel speed, both of which were included in our model. Therefore, while the model may or may not accurately represent best practice, it does accurately represent the observed practice in this study.

The simulated standardised comparison was conducted using the parameters described above, and it is depicted in

Figure 3. Based on this result, winch assistance was beneficial on the less inclined trail (30% gradient) but not on the steeper one (40% gradient). In both cases, winch assistance resulted in a decreased travel speed and an increased payload size. While on the 30% gradient the payload increase was much larger than the speed reduction, the contrary was true on the 40% gradient.

With the skidder being tracked by a GPS unit on trail A, detailed information on its speed could be calculated at 2–5 s intervals, or approximately 15 and 30 times per trip. The speed graphs offered a detailed insight into the skidder’s movements (

Figure 4). They showed steep speed peaks for the machine travelling fast downhill, followed by a sudden halt for picking up the load, and slowly increasing speed as the loaded skidder moved uphill onto an increasingly gentle slope, all the way to the surge pile. The data collected using the GPS were consistent with those obtained from the time study. Both found that the empty speed was much lower under the winch-assist treatment, while it did not change significantly with the trail gradient when the skidder worked without winch assistance. Conversely, the loaded speed was higher for the winch-assist treatment (peaks at ca. 2 m s

−1 vs. 1 m s

−1).

Concerning soil disturbance, “slash” accumulations and “no disturbance” were the most represented soil state classes before the skidding commenced. After the skidding had been completed, the most represented soil state classes were “soil mixing” and again “slash” accumulation (

Table 7). Essentially, skidding resulted in a sharp increase in soil mixing and a small but steady increase in rutting (

Figure 4 and

Figure 5). However, rutting was relatively infrequent, while deep rutting was contained well below the 5% bar, even after the skidding. The overall incidence of slash accumulations remained approximately the same before and after skidding. What varied was the thickness of the observed accumulations. However, this result was inconsistent, as the proportion of thick accumulations increased after skidding in one transect and decreased in the other, followed by a compensatory decrease (or increase) in the proportion of shallow accumulations. Overall, the surface area covered by slash remained the same.

4. Discussion

The results of this study are interesting, although somewhat puzzling. The study set out to determine how much winch assistance would improve skidder productivity in steep terrain applications. The ultimate goal was to obtain productivity increment figures that prospective users could balance against the estimated cost increment figures when assessing the cost-effectiveness of winch-assist skidding operations. On the moderately steep trail, the results matched expectations: winch assistance resulted in increased productivity. Whether that would offset the additional cost of the winch set-up is something each user should calculate based on their own cost figures. However, when the trail got steeper, winch assistance resulted in a productivity loss, not an increment.

The general mechanics are clear and logical: winch assistance results in a loss of speed on the empty trip downhill, although it allows for an increased payload on the way back up without incurring a significant loss of speed (or traction) compared with the control treatment. So far so good: all is as expected. However, as the trail becomes steeper, the drop in the empty travel speed far exceeds the increase in the payload, and the productivity is lower for the winch-assist treatment than for the control.

There are a few possible explanations for what happened. The first one to consider depends on the fact that the operator chooses the tension setting for both the uphill and downhill operations. The winch-assist unit will then either support or restrict the movement of the skidder. When operating downhill on steeper slopes, the operator will choose a greater level of tension support, although that will effectively reduce the speed. With the unit undergoing substantial repairs between trails B and C, and despite service team assurances to the contrary, there may have been a change in the settings. A second explanation is a deliberate action by the driver, who after experiencing machinery problems may have held back on loading for fear of exceeding machine capacity, while he should have formed larger loads than he did once under the winch-assist treatment.

Otherwise, if no error intruded, then one should consider the fact that when the trail is steeper than 30%, winch assistance does not allow for building a large enough load to offset the decrease in the empty speed. As a matter of fact, winch assistance was originally developed for slow-moving machines, such as fellers, shovels, harvesters and forwarders. Applying winch assistance to fast-moving equipment is something new, for which the technology was not designed. While in this case winch-assist skidding might be stretching the limits of current winch technology, it should be noted that all the main manufacturers are currently reconfiguring their winch-assist units to support the higher speed of skidder operations. Skidding is fast-paced work, and the speed advantage lost through winch assistance is offset only by pulling a significantly larger payload than would otherwise be possible.

Furthermore, skidding is best applied to downhill extraction. Then, the system tested in our study bends the basic rules of skidding not once but twice: first by moving the loads uphill and second by making the skidder slow. On steeper terrain, many landings are placed above the cutover to suit road access. Normally, those landings are designed for yarder extraction, not skidding, although many of them present “blind spots” that are difficult to reach with the yarder.

The main limitation of this study is that it covered one machine and operation. This is why it is crucial that further comparison studies are conducted using the same methods but on a larger variety of machines, crews and operations. Nevertheless, one can still match some of the results of our study against the individual figures reported in the only two other studies conducted on the same subject. This would allow gauging the general reliability of our results and flag blatant inconsistency, if any is present. As a matter of fact, the 25–30% payload increase recorded in this study is a close match to the 24% increase reported by Strimbu and Boswell in a similar comparison study conducted in Canada [

28]. Furthermore, our productivity figures (70 to 90 m

3 PMH

−1 on distances varying between 150 and 200 m) fall between the 80–100 m

3 PMH

−1 reported by Pedofsky and Visser [

29] and the 50–60 m

3 PMH

−1 reported by Strimbu and Boswell [

28] for the same range of distances.

Similar corroboration is obtained for load size: the 3.9–5.8 m

3 range reported in this study overlaps almost exactly with the 4.6–5.7 m

3 reported by Strimbu and Boswell [

28] and is still comparable with the 7–8 m

3 reported by Pedofsky and Visser [

29], although a bit smaller. In addition, in all cases, the load size was estimated based on the tree count and combined with the average piece size. That was considered a source of uncertainty when analysing the data from the present study, although it is probably not such an inaccurate method for estimating the payload size, considering the general consistency of the results.

Similar corroboration is also obtained for the site impact, which was covered by all three studies. Although each study used a slightly different soil disturbance assessment method, the results can be generally reconciled after consolidating some of their categories. In fact, all the studies clearly identify deep rutting and show that this impact category accounts for a very limited proportion of the study area: 9% here, 12% in Pedofsky and Visser [

29], and 8–10% in Strimbu and Boswell [

28]. The latter study is the only one to offer a direct comparison of winch assistance vs. conventional in terms of the site disturbance and indicates a reduction of ca. 25% in soil scalping and rutting when under the winch-assist treatment, which matches expectations. Unfortunately, our study cannot offer a similar comparison because both treatments (i.e. winch assistance and conventional) were tested over the same trails. Yet, winch-assist extraction is already promoted in Europe and in North America for its lower soil impact, as derived from the avoidance (or dramatic reduction) of wheel slipping and machine sinking, and the incidence of deep soil disturbance found in this study is comparable or lower than that found for traditional lightly mechanised operations in the Mediterranean mountains [

35]. Of course, the visual assessment method used in all these studies offers an incomplete evaluation of the soil impact, as it cannot account for compaction, which is another major component of traffic-induced damage. However, on the steep slopes where winch-assist technology is deployed, rutting is an equally serious concern, due to the high risk of erosion incurred by mountain sites. In that regard, our study may relieve some of these concerns, since it indicates that the surface affected by rutting is very small. Of course, this may change with changing soil conditions, especially with variations in the soil moisture content (m.c.). Unfortunately, the study did not determine the soil moisture content at the time of traffic, so we cannot offer a reference moisture content value for the encouraging results of this study. However, the operations manager introduced the skidder under what he assessed to be favourable soil conditions and would have halted operations if the soil was too wet for safe, environmentally sound operation. Therefore, we can state that, under suitable work conditions, winch-assist uphill skidding causes very little rutting.

5. Conclusions

Winch-assist technology is used to extend ground-based harvesting to challenging terrain conditions, including uphill skidding on steep terrain. This study confirms that such technology works as intended, but also that it must be used with some caution. In particular, winch assistance improves skidder productivity on moderately steep terrain, but not on the steepest sites. When the terrain gets too steep, the increment in the load size allowed through winch assistance does not compensate for the decreased travel speed, meaning that a general reduction in the load size seems to be the preferable option.