Comparing the Productivity of the Latest Models of Li-Ion Battery and Petrol Chainsaws in a Conifer Clear-Cut Site

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Description of the Equipment Used

2.3. Time Study

- -

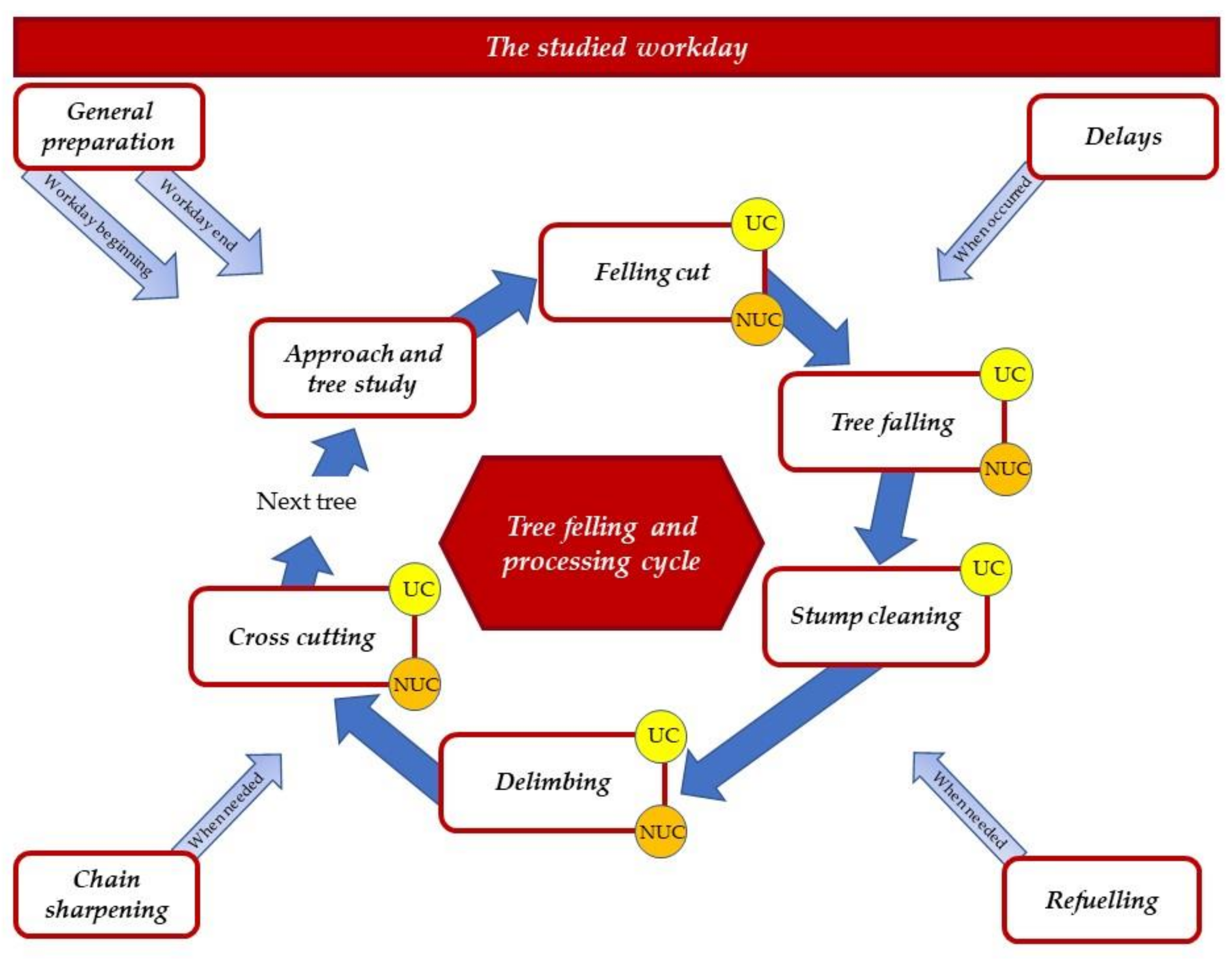

- General preparation: includes the walk from the track to the worksite at the beginning of the workday, the preparation of tools, and the operational checks before starting harvesting operations.

- -

- Approach and tree study: includes all the preparatory activities made with and without the chainsaw before starting to cut the notch (e.g., the cleaning of the worksite from undergrowth, the tree evaluation and the choice of the felling technique).

- -

- Felling cut, “UC”: includes all the felling operations made with the chainsaw, from the first cut of the notch to the beginning of tree falling.

- -

- Felling cut, “NUC”: includes all the felling operations made without the chainsaw (e.g., the check of the correct fall direction, the use of wedges, etc.).

- -

- Tree falling, “UC”: includes the time spent using the chainsaw to allow the tree to fall after the end of the felling cut. Normally it is related to resolving situations where a tree becomes caught in another.

- -

- Tree falling, “NUC”: includes the time spent to make the tree fall on the ground after the end of the felling cut.

- -

- Stump cleaning, “UC”: includes the cuts to trim both the stump and the bottom of the first trunk. It ends when the operator hooks up the meter to measure the trunks.

- -

- Delimbing, “UC”: includes all the time spent by the operator in active delimbing with the chainsaw.

- -

- Delimbing, “NUC”: includes those operations where the operator has interrupted the delimbing to move the cut branches along the trunk or to turn the trunk to complete the branches’ removal from the part below.

- -

- Cross-cutting, “UC”: includes only the time spent by the operator in cross-cutting.

- -

- Cross-cutting, “NUC”: includes the time spent to measure the trunks’ length and eventual time spent without using the chainsaw.

- -

- Refuelling: starts when the battery or petrol is used up during the operation until the chainsaw is ready again to continue.

- -

- Chain sharpening: includes the time spent for sharpening.

- -

- Rest time.

- -

- Delays: problems and drawbacks.

2.4. Productivity Calculation

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pandur, Z.; Šušnjar, M.; Bačić, M. Battery Technology–Use in Forestry. Croat. J. For. Eng. 2021, 42, 135–148. [Google Scholar] [CrossRef]

- Poje, A.; Mihelič, M. Influence of Chain Sharpness, Tension Adjustment and Type of Electric Chainsaw on Energy Consumption and Cross-Cutting Time. Forests 2020, 11, 1017. [Google Scholar] [CrossRef]

- Huber, M.; Hoffmann, S.; Brieger, F.; Hartsch, F.; Jaeger, D.; Sauter, U.H. Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests 2021, 12, 1120. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Marchi, E.; Marra, E.; Fabiano, F.; Frassinelli, N.; Foderi, C. Use of Battery-vs. Petrol-Powered Chainsaws in Forestry: Comparing Performances on Cutting Time. Forests 2022, 13, 683. [Google Scholar] [CrossRef]

- Hoffmann, S.; Jaeger, D. Insights on Motor-Manual Tree Felling in Germany, Recent Developments to Ensure Efficient Operations in Singletree Selection Harvest*. Eur. J. For. Eng. 2021, 7, 39–44. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Foderi, C.; Fabiano, F.; Bertuzzi, L.; Marchi, E. Determining Noise and Vibration Exposure in Conifer Cross-Cutting Operations by Using Li-Ion Batteries and Electric Chainsaws. Forests 2018, 9, 501. [Google Scholar] [CrossRef]

- Poje, A.; Potočnik, I.; Mihelič, M. Comparison of Electric and Petrol Chainsaws in Terms of Efficiency and Safety When Used in Young Spruce Stands in Small-Scale Private Forests. Small Scale For. 2018, 17, 411–422. [Google Scholar] [CrossRef]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable Forest Operations (SFO): A New Paradigm in a Changing World and Climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef]

- Laschi, A.; Marchi, E.; Foderi, C.; Neri, F. Identifying Causes, Dynamics and Consequences of Work Accidents in Forest Operations in an Alpine Context. Saf. Sci. 2016, 89, 28–35. [Google Scholar] [CrossRef]

- Tsioras, P.A.; Rottensteiner, C.; Stampfer, K. Wood Harvesting Accidents in the Austrian State Forest Enterprise 2000–2009. Saf. Sci. 2014, 62, 400–408. [Google Scholar] [CrossRef]

- Suchomel, J.; Belanová, K. Influence of Selected Meteorological Phenomena on Work Injury Frequency in Timber Harvesting Process. Croat. J. For. Eng. 2009, 30, 185–191. [Google Scholar]

- Klun, J.; Medved, M. Fatal Accidents in Forestry in Some European Countries. Croat. J. For. Eng. 2007, 28, 55–62. [Google Scholar]

- Hawker, A. Comparison of Hand-Arm Vibration Emissions of Battery Powered Tools and Tools of Other Power Sources. In Proceedings of the 54th UK Annual Conference on Human Responses to Vibration, Edinburgh, UK, 24–26 September 2019; Volume 24, p. 13. [Google Scholar]

- Kovác, J.; Krilek, J.; Dado, M.; Beňo, P. Investigating the Influence of Design Factors on Noise and Vibrations in the Case of Chainsaws for Forestry Work. FME Trans. 2018, 46, 513–519. [Google Scholar] [CrossRef]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, Exposure to Noise, and Risk of Musculoskeletal Disorders: A Case Study of Motor-Manual Tree Feeling and Processing in Poplar Clear Cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- Calvo, A. Musculoskeletal Disorders (MSD) Risks in Forestry: A Case Study to Suggest an Ergonomic Analysis. Agric. Eng. Int. CIGR J. 2009, XI, 1–9. [Google Scholar]

- Neitzel, R.; Yost, M. Task-Based Assessment of Occupational Vibration and Noise Exposures in Forestry Workers. Am. Ind. Hyg. Assoc. J. 2002, 63, 617–627. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and Health in Forest Harvesting Operations. Diagnosis and Preventive Actions. A Review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Hanisch, C.; Loellhoeffel, T.; Diekmann, J.; Markley, K.J.; Haselrieder, W.; Kwade, A. Recycling of Lithium-Ion Batteries: A Novel Method to Separate Coating and Foil of Electrodes. J. Clean. Prod. 2015, 108, 301–311. [Google Scholar] [CrossRef]

- Boubaker, K.; Colantoni, A.; Allegrini, E.; Longo, L.; Di Giacinto, S.; Monarca, D.; Cecchini, M. A Model for Musculoskeletal Disorder-Related Fatigue in Upper Limb Manipulation during Industrial Vegetables Sorting. Int. J. Ind. Ergon. 2014, 44, 601–605. [Google Scholar] [CrossRef]

- Kiehne, H.A. Battery Technology Handbook, 2nd ed.; CRC Press: New York, NY, USA, 2003; Volume 118, ISBN 0203911857. [Google Scholar]

- Spinelli, R.; Nati, C.; Magagnotti, N. Biomass Harvesting from Buffer Strips in Italy: Three Options Compared. Agrofor. Syst. 2006, 68, 113–121. [Google Scholar] [CrossRef]

- Colantoni, A.; Mazzocchi, F.; Cossio, F.; Cecchini, M.; Bedini, R.; Monarca, D. Comparisons between Battery Chainsaws and Internal Combustion Engine Chainsaws: Performance and Safety. Contemp. Eng. Sci. 2016, 9, 1315–1337. [Google Scholar] [CrossRef]

- Engelbrecht, R.; McEwan, A.; Spinelli, R. A Robust Productivity Model for Grapple Yarding in Fast-Growing Tree Plantations. Forests 2017, 8, 396. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Frassinelli, N.; Fabiano, F.; Foderi, C.; Marchi, E.; Marra, E. Battery- and Petrol-Powered Chainsaws: An Investigation of Productivity in Conifer Thinning. Forests 2023, 14, 183. [Google Scholar] [CrossRef]

- Marenče, J.; Mihelič, M.; Poje, A. Influence of Chain Filing, Tree Species and Chain Type on Cross Cutting Efficiency and Health Risk. Forests 2017, 8, 494. [Google Scholar] [CrossRef]

- Maciak, A.; Górska, U.; Zach, Ż. Impact of Saw Chain Cutters Type on Blunting Speed of Blades and Change of Cutting Efficiency. Ann. Warsaw Univ. Life Sci. Agric. 2017, 70, 27–36. [Google Scholar] [CrossRef]

- Kuvik, T.; Krilek, J.; Kováč, J.; Štefánek, M.; Dvořák, J. Impact of the Selected Factors on the Cutting Force When Using a Chainsaw. Wood Res. 2017, 62, 807–814. [Google Scholar]

- Bergstrand, K.-G. Planning and Analysis of Forestry Operations Studies; Forest Operations Institute: Kista, Sweden, 1991; Volume 63. [Google Scholar]

- Olsen, E.D.; Hossain, M.M.; Miller, M.E. Statistical Comparison of Methods Used in Harvesting Work Studies; Forest Research Laboratory, Oregon State University: Corvallis, OR, USA, 1998. [Google Scholar]

- Gullberg, T. Evaluating Operator-Machine Interactions in Comparative Time Studies. J. For. Eng. 1995, 7, 51–61. [Google Scholar] [CrossRef]

- De Mello Sant’Anna, C.; Malinovski, J.R. Use of Multivariated Analysis in the Study of Human Factors in Chainsaw Operators. Cerne 2002, 8, 98–104. [Google Scholar]

- Campu, R.V.; Ciubotaru, A. Time Consumption and Productivity in Manual Tree Felling with a Chainsaw–A Case Study of Resinous Stands from Mountainous Areas. Silva Fenn. 2017, 51, 1657. [Google Scholar] [CrossRef]

- Wang, J.; Long, C.; McNeel, J.; Baumgras, J. Productivity and Cost of Manual Felling and Cable Skidding in Central Appalachian Hardwood Forests. For. Prod. J. 2004, 54, 45–51. [Google Scholar]

- Nikoie, M. Optimization of Production Costs and Reducing Logging Damages in Caspian Forests; University of Tehran, Faculty of Natural Resources: Tehran, Iran, 2007; Volume 214. [Google Scholar]

- Behjou, F.K.; Majnounian, B.; Dvořák, J.; Namiranian, M.; Saeed, A.; Feghhi, J. Productivity and Cost of Manual Felling with a Chainsaw in Caspian Forests. J. For. Sci. 2009, 55, 96–100. [Google Scholar] [CrossRef]

- Miyata, E.S. Determining Fixed and Operating Costs of Logging Equipment; General Technical Report NC-GTR-55; U.S. Department of Agriculture, Forest Service, North Central Forest Experiment Station: St. Paul, MN, USA, 1980. [Google Scholar]

- Grosjean, C.; Miranda, P.H.; Perrin, M.; Poggi, P. Assessment of World Lithium Resources and Consequences of Their Geographic Distribution on the Expected Development of the Electric Vehicle Industry. Renew. Sustain. Energy Rev. 2012, 16, 1735–1744. [Google Scholar] [CrossRef]

- Wu, D.; Ren, J.; Davies, H.; Shang, J.; Haas, O. Intelligent Hydrogen Fuel Cell Range Extender for Battery Electric Vehicles. World Electr. Veh. J. 2019, 10, 29. [Google Scholar] [CrossRef]

| Stihl MSA 300 | Stihl MS 261 C-M | |

|---|---|---|

| Technical Specification | BAT | MIX |

| Power | 3.0 kW | 4.1 kW |

| Saw-bar length | 40 cm | 40 cm |

| Chain type | Half-chisel | Half-chisel |

| Chain pitch | 0.325” (0.8255 cm) | 0.325” (0.8255 cm) |

| Drive-link thickness | 1.3 mm | 1.3 mm |

| Number of drive links | 67 | 67 |

| Fuel supply | Electricity (battery) | Mixed (gasoline + oil) |

| Battery/Fuel type | AP500S | Stihl MotoMix |

| Maximum chain speed (ISO 11681) | 30 m·s−1 | 25.6 m·s−1 |

| Total weight * | 7.7 kg | 6.9 kg |

| Working Phase (Using Chainsaw “UC” or Not Using Chainsaw “NUC”) | Productivity | ||||

|---|---|---|---|---|---|

| Gross | Net | Felling/Processing | UC | NUC | |

| General preparation | x | ||||

| Approach and tree study | x | ||||

| Felling cut—UC | x | x | x | x | |

| Felling cut—NUC | x | x | x | x | |

| Tree falling—UC | x | x | x | x | |

| Tree falling—NUC | x | x | x | x | |

| Stump cleaning—UC | x | x | x | x | |

| Delimbing—UC | x | x | x | x | |

| Delimbing—NUC | x | x | x | x | |

| Cross-cutting—UC | x | x | x | x | |

| Cross-cutting—NUC | x | x | x | x | |

| Refuelling | x | x | |||

| Chain sharpening | x | ||||

| Rest time | x | ||||

| Delays | x | ||||

| Chainsaw Model | Operator | N. | Minimum | Maximum | Mean | SD |

|---|---|---|---|---|---|---|

| BAT | 1 | 54 | 16.00 | 37.00 | 27.04 a | 5.85 |

| 2 | 71 | 18.00 | 44.00 | 27.70 a | 4.79 | |

| Overall | 125 | 16.00 | 44.00 | 27.42 a | 5.26 | |

| MIX | 1 | 59 | 19.00 | 39.00 | 28.20 a | 4.20 |

| 2 | 61 | 16.00 | 42.00 | 28.40 a | 5.80 | |

| Overall | 120 | 16.00 | 42.00 | 28.35 a | 5.05 |

| Source of Variance for Productivity | |||||

|---|---|---|---|---|---|

| Gross | Net | Felling/Processing | “UC” | “NUC” | |

| Chainsaw model | - | - | - | - | * |

| Operator | ** | ** | * | - | * |

| Chainsaw model x Operator | - | - | - | NA | - |

| Productivity (m3h−1) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gross | Net | Felling/Processing | Using Chainsaw “UC” | Not Using Chainsaw “NUC” | ||||||||||||||||

| Operator | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | ||||||||||

| Chainsaw model | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX | BAT | MIX |

| Mean | 1.47 a | 1.76 b | 1.93 a | 1.92 a | 2.35 a | 2.64 a | 2.89 a | 3.00 a | 2.62 a | 2.89 a | 3.12 a | 3.17 a | 3.30 a | 3.46 a | 4.13 a | 3.69 a | 5.87 a | 7.46 a | 7.85 a | 10.42 a |

| Min | 1.42 | 1.71 | 1.69 | 1.78 | 2.15 | 2.54 | 2.48 | 2.84 | 2.31 | 2.75 | 2.66 | 2.99 | 3.08 | 3.25 | 3.45 | 3.36 | 5.5 | 6.45 | 7.25 | 8.36 |

| Max | 1.55 | 1.82 | 2.11 | 2.09 | 2.46 | 2.81 | 3.11 | 3.21 | 2.86 | 3.05 | 3.38 | 3.39 | 3.47 | 3.83 | 4.5 | 4.28 | 6.47 | 9.33 | 8.18 | 12.74 |

| SD | 0.07 | 0.06 | 0.22 | 0.16 | 0.17 | 0.14 | 0.35 | 0.18 | 0.28 | 0.15 | 0.4 | 0.2 | 0.2 | 0.32 | 0.59 | 0.51 | 0.52 | 1.62 | 0.52 | 2.2 |

| Overall operator | 1.62 a | 1.93 b | 2.50 a | 2.95 b | 2.76 a | 3.14 b | 3.38 a | 3.91 a | 6.67 a | 9.13 b | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laschi, A.; Neri, F.; Marra, E.; Fabiano, F.; Frassinelli, N.; Marchi, E.; Paoloni, R.; Foderi, C. Comparing the Productivity of the Latest Models of Li-Ion Battery and Petrol Chainsaws in a Conifer Clear-Cut Site. Forests 2023, 14, 585. https://doi.org/10.3390/f14030585

Laschi A, Neri F, Marra E, Fabiano F, Frassinelli N, Marchi E, Paoloni R, Foderi C. Comparing the Productivity of the Latest Models of Li-Ion Battery and Petrol Chainsaws in a Conifer Clear-Cut Site. Forests. 2023; 14(3):585. https://doi.org/10.3390/f14030585

Chicago/Turabian StyleLaschi, Andrea, Francesco Neri, Elena Marra, Fabio Fabiano, Niccolò Frassinelli, Enrico Marchi, Riccardo Paoloni, and Cristiano Foderi. 2023. "Comparing the Productivity of the Latest Models of Li-Ion Battery and Petrol Chainsaws in a Conifer Clear-Cut Site" Forests 14, no. 3: 585. https://doi.org/10.3390/f14030585

APA StyleLaschi, A., Neri, F., Marra, E., Fabiano, F., Frassinelli, N., Marchi, E., Paoloni, R., & Foderi, C. (2023). Comparing the Productivity of the Latest Models of Li-Ion Battery and Petrol Chainsaws in a Conifer Clear-Cut Site. Forests, 14(3), 585. https://doi.org/10.3390/f14030585