Abstract

The Ordinance on Occupational Safety and Health in Forestry proposes no more than 4 h of effective chainsaw work daily, while EU Directive 2002/44/EC proposes an EAV of 2.5 m/s2, and an ELV of 5 m/s2. The aim of this paper was to compare and assess the viability of the proposed restrictions. A case study in Croatia including 91 felled and processed trees, a detailed time study, and vibration magnitude measuring on European beech wet wood in compliance with ISO 5349-1:2001 and ISO 5349-2:2001 standards were performed. The results implied that tree species, processing method, and DBH have no influence on the time structure of working hours. Using bigger and more powerful chainsaws resulted in higher A(8) values; it was also noted that the right hand is more exposed. On average, none of the observed chainsaws exceeded 5 m/s2 of A(8). It can be concluded that state legislature, which allows a maximum of 4 h of chainsaw work a day, is appropriately protecting chainsaw workers from vibration exposure, but is also obsolete (1986) as it only uses the time limit. In contrast, European legislature requires a methodical approach to A(8) calculation and leaves room for individual evaluation of specific chainsaw work, which opens up possibilities of extending or shortening some chainsaw operations.

Keywords:

A(8); state legislature; European legislature; vibrations; felling and processing; Croatia 1. Introduction

The notion that vibrating tools such as chainsaws can cause serious health problems was first investigated in the 1960s when a technology replacement from manual to motor-manual work started on a grand scale [1,2,3,4]. The terminology for vibration-induced health problems varies; in colloquial speech “white finger disease” is used, while in medicine—secondary Raynaud’s syndrome [5]. Numbness in the hands and arms, tingling in the fingers, and deterioration of tactile perception have been detected in workers who have been exposed to hand–arm vibrations [6,7,8]. According to ISO 5349-1:2001 [9], the risk of consequences depends on the level of vibration, duration of exposure, and frequency. Hand–arm vibrations (HAV) cause disorders in the blood supply to the fingers and in the peripheral nerves of the hands and arms [10]. The exposure time needed for triggering the syndrome may vary between one month and thirty years, being influenced by the variation of the energy transfer and by the physiological responses which may differ from one individual to another. The period of time between the first vibration exposure and the onset of the disease is called the latent period. This period varies much from one individual to another [11].

Many factors influence the transmission, magnitude, and exposure to vibration. The transmission is influenced by the grip strength of a chainsaw handle which depends on the worker’s work experience, work operation, and wood hardness. According to Malinowska-Borowska et al. [12,13,14], grip is stronger in wood of higher hardness, in felling and sawing, and in less-experienced workers. Hand–arm vibrations differ with respect to the type of wood and are higher in species with higher wood density [15]. According to ISO 11681-1:2001 [16], the main factors affecting the level of vibration in chainsaws are mainly cutting mode, unbalanced moving parts, dynamic forces in the motor, impacts in bearings, gears, and other mechanisms, and also the interaction between chainsaw, worker, and wood being cut. Working hours, i.e., years of use, according to Landekić et al. [17], seem to have no influence on the vibration magnitude of used chainsaws.

There are two legislative restrictions regarding harmful HAV that are considered in this paper. According to the Ordinance on Occupational Safety and Health in Forestry [18], a worker may not work effectively with a chainsaw for more than 4 h a day in the Republic of Croatia. The second restriction is specified by EU Directive 2002/44/EC [19], which proposes daily vibration exposure A(8) values for the hand–arm system. These include a daily exposure action value (EAV) of 2.5 m/s2, and a daily exposure limit value (ELV) of 5 m/s2. In case of exceeding the EAV, the employer should establish and implement a program of technical and organizational measures intended to reduce to a minimum exposure to mechanical vibration. Should workers be exposed above the ELV, the employer shall take immediate action to reduce exposure below the ELV. In addition to the two mentioned restrictions, the International Labor Office (ILO) [20] recommends that chainsaw operators do not work for more than five hours per day in order to minimize health hazards and the development of professional diseases caused by prolonged exposure to noise, vibration, exhaust gases, wood dust, etc. In order to follow this recommendation, chainsaw workers should alternate specific activities during the day (chainsaw work, refueling, maintenance, wood sorting, measurement, etc.).

The aim of this paper was to compare and assess the viability of the state and European legislatures means to control and prevent over-exposure of chainsaw workers to hand–arm vibrations.

2. Materials and Methods

Field data collection was divided into two phases, with the third phase being video processing, database sorting, statistical analysis, and A(8) calculation, which was mostly conducted after phase one.

Phase one included a video recording of trees being felled and processed by state company loggers and private contractors using a GoPro camera. A total of 91 trees, felled and processed by 91 chainsaw workers, in state-managed forests were recorded. A random stratified sample was used for sampling chainsaw workers employed by the state company Hrvatske Šume Ltd. and private forestry contractors (sixteen groups of state chainsaw workers and three groups of licensed timber-harvesting contractors). Calculation of proportion was based on the total number of workers. The number of workers to be sampled within each group was calculated based on the proportion. The ”Research Randomizer“ calculator was used to obtain the resulting number of sampling workers within each group; all members of the group had an equal chance of being selected. Along with video recording, information about tree species, DBH, and processing methods was collected.

In phase two, vibration magnitude was measured in simulated conditions. The process of determining A(8) is very complex if the daily work consists of several elements with different durations and vibration magnitudes [21]. All-day measurement of A(8) is very complex and unwanted interruptions caused by the need to fix the accelerometer on the chainsaw handle, questionable battery life of the instrument, and harsh working conditions, may occur which would affect the accuracy of the results [22]. Therefore, vibration magnitude was measured by simulating chainsaw-handling elements on the felled tree. The measuring equipment complied with the ISO 8041:2017 [23] standard. A four-channel Brüel & Kjaer LAN-XI Type 3676-B-040 module was used along with a three-axial accelerometer type 4524-B-001 and UA 3017 mount fastened with plastic ties and positioned near the operator’s hand, i.e., to the right of the hand on the front handle and behind the hand on the rear handle. Measurements were managed with a laptop and designated software via a Wi-Fi connection to a router. The LAN-XI module and paired router required external batteries to operate (Figure 1). A backpack was used to store the measuring equipment. Guidelines of ISO 5349-1:2001 [9] and ISO 5349-2:2001 [24] standards such as organization of measurements, duration of vibration measurements, simulation of work procedures, location of accelerometer, attaching accelerometer, and evaluation of uncertainties were followed during the measurements. The instrument was calibrated prior to measurements.

Figure 1.

Measuring setup and observed chainsaws.

When measuring the vibration magnitude on chainsaws, the shortness of cutting time can influence the results, i.e., the evaluation of low-frequency components. The ISO 5349-2:2001 [24] standard proposes that one measurement should not be shorter than 8 s, with the condition that the total measuring time is no less than one minute and at least three measurements are made. To extend the duration of cutting time, a 40 cm diameter log of wet wood of European beech (Fagus sylvatica L.) was used. The log was placed level on the ground. Crosscuts were made with the full throttle until the bar reached the lower part of the log (Figure 2). The measurement would start at least one second after the cutting began to isolate only full-throttle cutting. The duration of the measurements lasted between 15 and 20 s.

Figure 2.

Simulation of 1a (left) and 1b (right) chainsaw-handling elements.

Along with measurements in solid wood, a measurement of vibration magnitude while cutting small branches was made. To simulate that kind of cutting, the operator repeatedly cut smaller branches (<7 cm) in the canopy for at least 20 s per measurement (Figure 2, right). This kind of cutting included micro-stops to reposition the blade for a new cut and RPM drops between two cuts. Cleaning and small branch delimbing were simulated this way. Vibration magnitude measurement at idle was performed in three measurements of at least 20 s each. The vibration total value (ahv) was calculated as the arithmetic mean of the repeated measurements. Due to using only one accelerometer, magnitudes on the front and rear handles were measured separately. The three most common professional chainsaws for felling and processing in Croatian forestry were subjected to measurement (Table 1, Figure 1). Chainsaws were equipped with new chains. The measurement of vibration magnitude was performed at the Forest Training and Research Center (FTRC) Zagreb.

Table 1.

Chainsaw characteristics.

Phase three included reviewing video recordings, conducting a time study, creating a database, and combining data from phases one and two into results. For that purpose, VLC Media Player with an extension that allowed time to be displayed as a percentage was used. With experience from previous research [22], chainsaw-handling elements that influence the exposure time of workers’ hands to vibrations were defined (Table 2).

Table 2.

Description of chainsaw-handling elements.

By pausing the video recording, the relative share of chainsaw-handling elements was noted. Observed time per one tree included everything between the first start and last shutdown of the chainsaw. A database for the 91 trees was constructed in MS Excel; each tree had data for relative share of chainsaw-handling elements, total observed time, tree species, DBH, and processing method. Vibration total values of the three observed chainsaws obtained in phase two and arranged per chainsaw-handling element were added to the database. By adjusting time data to 4 h of felling and processing, A(8) was calculated for individual trees and also for averaged groups of trees and presented for both hands and by the three observed chainsaws using Equation (1).

A(8)—daily vibration exposure;

ahvi—vibration total value for i element;

n—total number of elements;

T0—reference working time of 4 h (14400 s);

Ti—duration of i element.

In addition to calculating A(8), the expected time to reach the ELV was calculated for individual trees and also for averaged groups of trees and presented for both hands and by the three observed chainsaws using an Excel-based hand–arm vibration exposure calculator provided by the Health and Safety Executive (HSE).

3. Results

3.1. Time Data

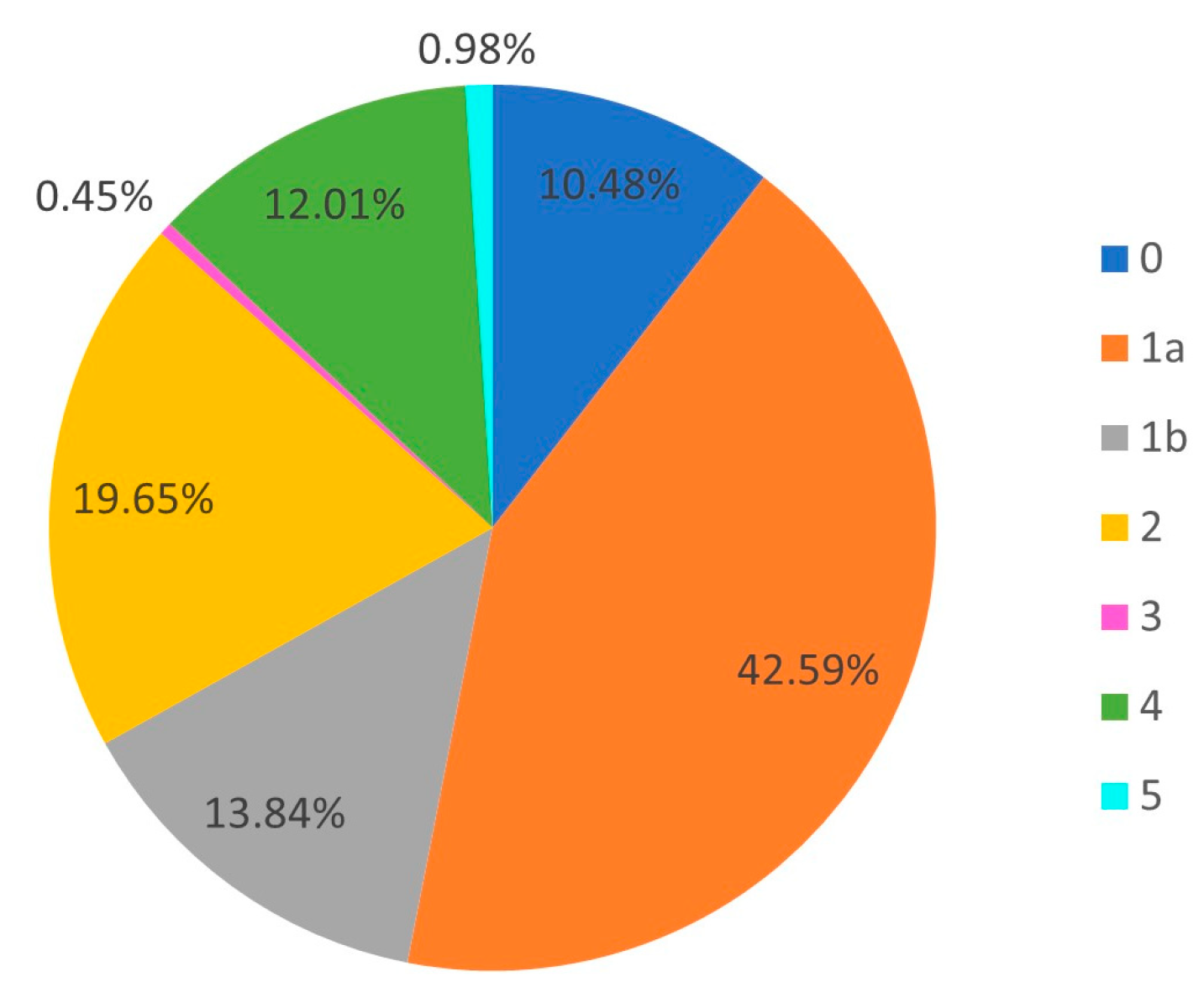

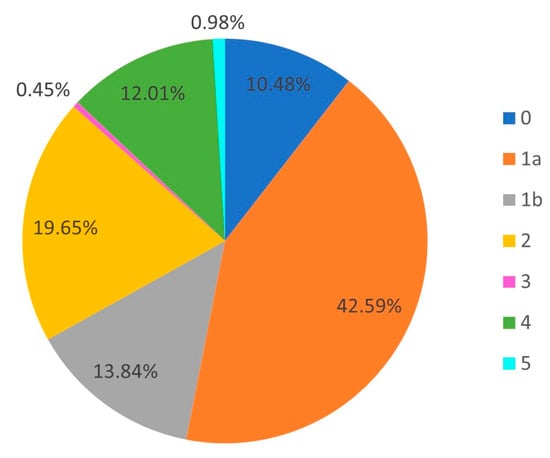

Averaged time data of all trees (Figure 3) showed that the operators were spending most of their time cutting (1a and 1b), i.e., 56 %. The chainsaw was not running (0) 10% of the time. The rest of the time, the chainsaw was held idling.

Figure 3.

Averaged time data of all trees.

To include the possible influence of tree species, processing method, and DBH on exposure time structure and thus daily vibration exposure, time data was averaged accordingly and adjusted to 4 h (Table 3). The obtained data showed that all mean chainsaw-handling element durations were consistent and within a few minutes of the overall mean (Table 4) with the exception of the common hornbeam group in chainsaw-handling element 0. Moreover, almost every chainsaw-handling element, except 1a, could amount to zero minutes.

Table 3.

Mean chainsaw-handling element duration grouped and adjusted to 4 h.

Table 4.

Descriptive statistics of chainsaw-handling element duration for all trees adjusted to 4 h.

However, descriptive statistics of time data for all trees adjusted to 4 h (Table 4), i.e., std. deviation, minimum and maximum values, implied great data dispersion.

3.2. Vibration Magnitude

In general, higher vibration magnitudes were measured on the rear handle of the observed chainsaws (Table 5). Furthermore, the lowest vibration magnitude on both handles was measured for chainsaw-handling element 1b, while the highest vibration magnitudes on the front and the rear handle were measured for chainsaw-handling elements 3/4 and 5, respectively. When observing the vibration magnitude regarding chainsaw type, it can be noticed that magnitudes were mixed during 1a and 1b. However, during handling elements 2 and 3/4, bigger chainsaws had higher vibration magnitudes. There was a distinction regarding MS 500i in handling element 5, where the vibration magnitude was half of the other two chainsaws.

Table 5.

Vibration magnitudes.

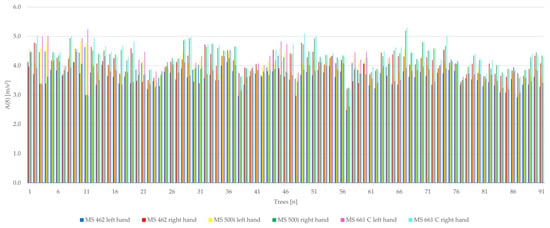

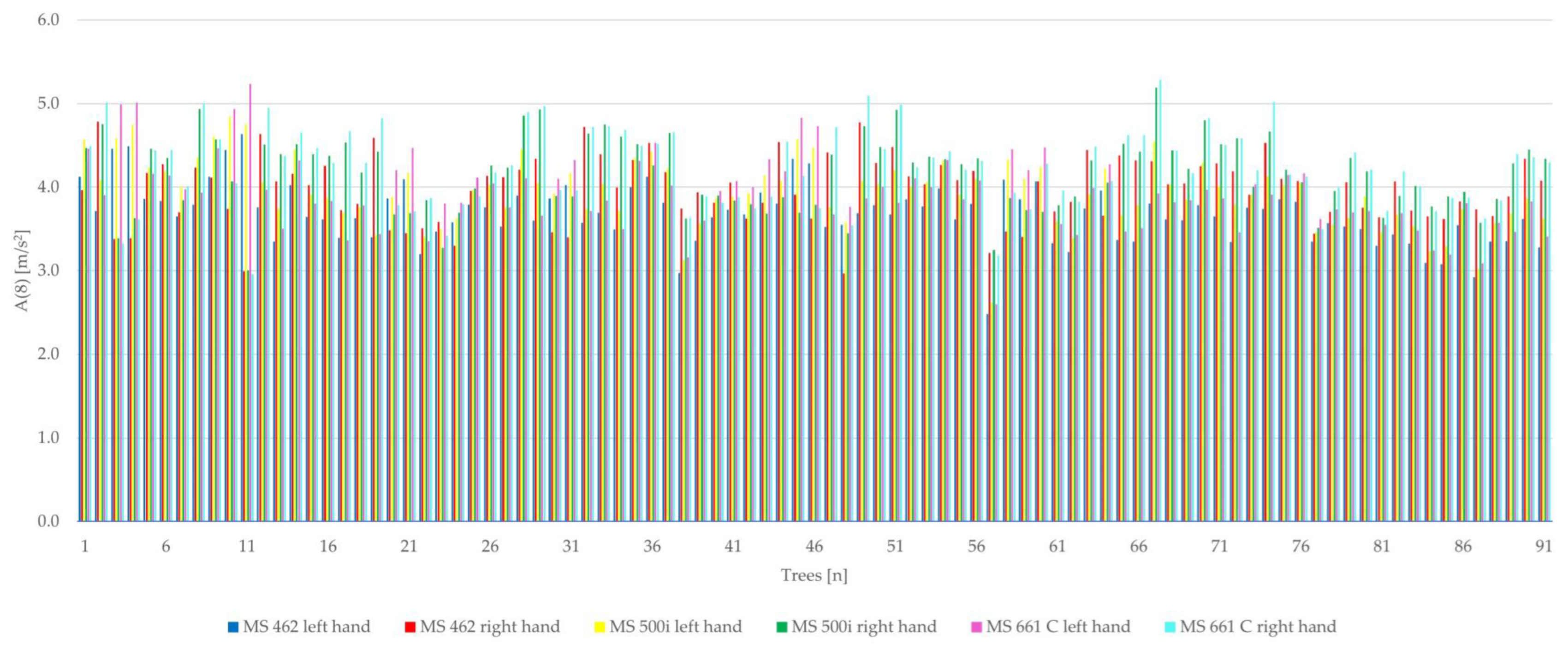

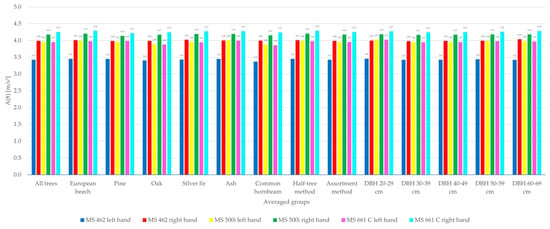

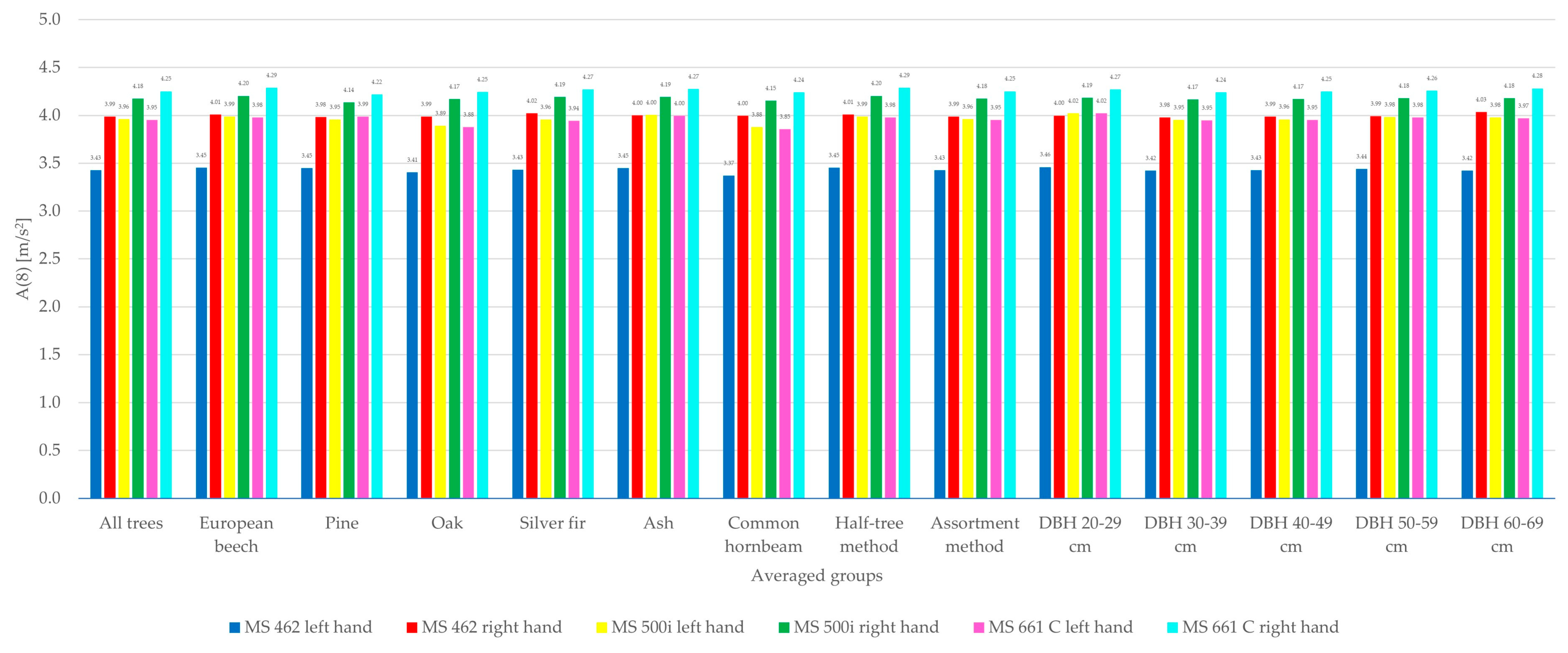

3.3. Daily Vibration Exposure and Time to Reach ELV

Descriptive statistics (Table 6) of A(8) for all trees showed that, on average, the ELV was not reached with any subjected chainsaw when adjusted to a 4 h work time. When observing an individual type of chainsaw, mean A(8) was higher on the right hand; this applies to all three chainsaws. In general, bigger and more powerful chainsaws implied higher A(8). Maximum values hinted at several instances where the ELV was exceeded. This was the case for MS 661 C (left and right hand) and for MS 500i (right hand). Individual cases can be observed on a chart showing A(8) adjusted to 4 h and presented per single tree (Figure A1). However, when observing A(8) presented per group with averaged time data (Figure A2), the ELV was never exceeded. Moreover, differences in A(8) regarding the same chainsaw/hand between the averaged groups were minimal and amounted to less than 0.15 m/s2.

Table 6.

Descriptive statistics of A(8) for all trees adjusted to 4 h.

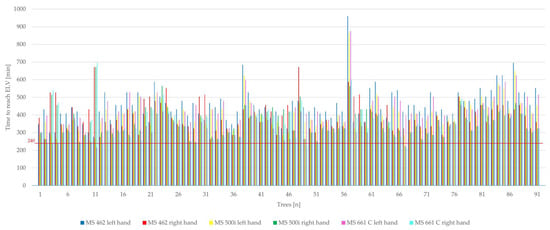

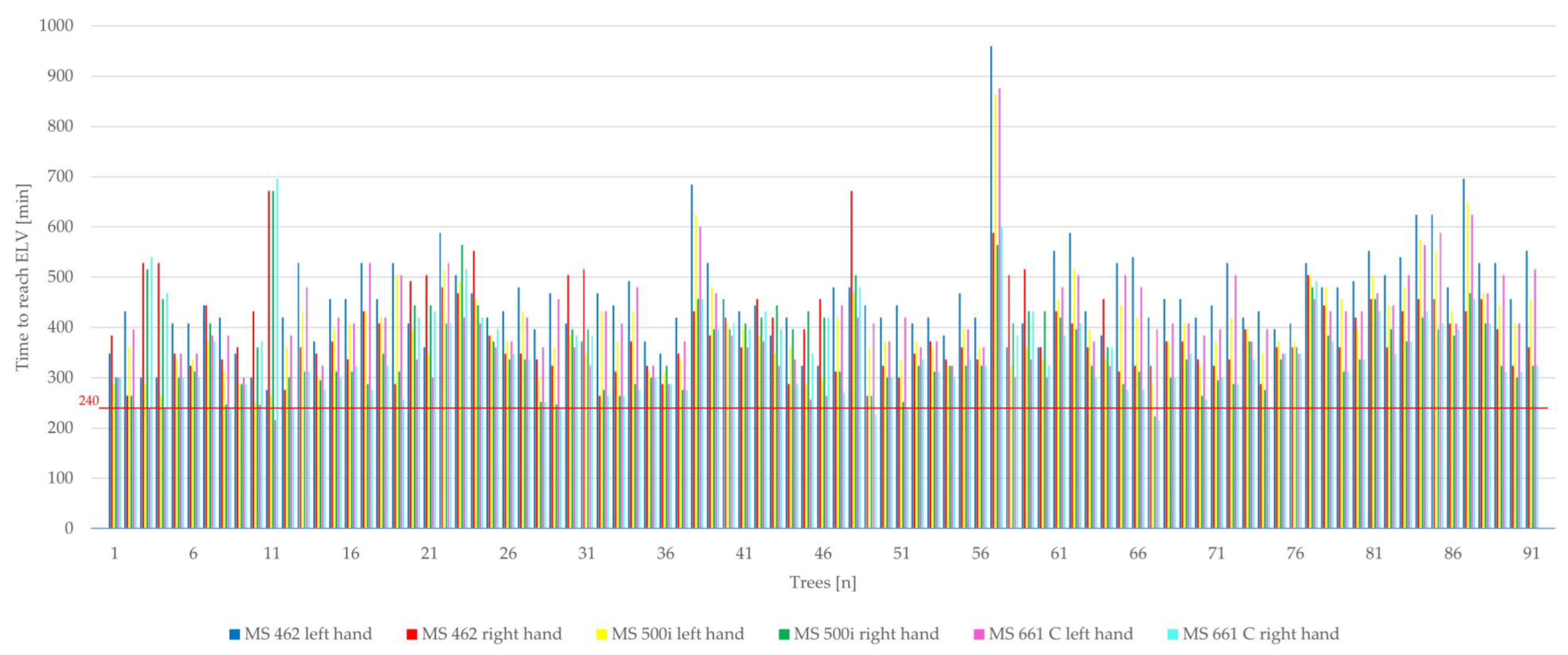

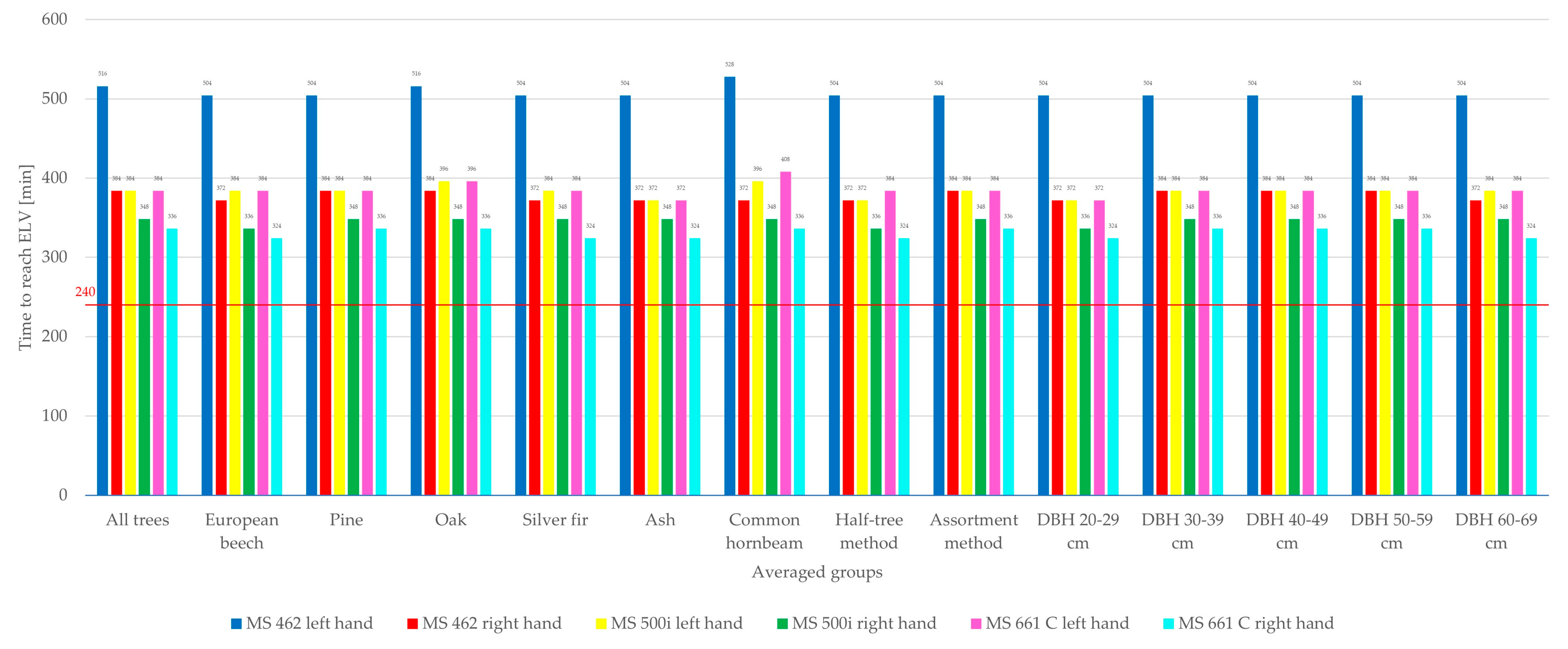

Table 7 shows descriptive statistics of the time to reach the ELV for all trees. All mean values were well above 240 min (4 h). Corresponding to Table 6, the minimum values showed that the ELV was reached before 240 min for MS 661 C (left and right hand) and for MS 500i (right hand). Individual cases can be observed on a chart showing the time to reach the ELV and presented per single tree (Figure A3). The extremely high time of 960 min to reach the ELV on MS 462/left hand for tree 57 was mainly a result of a high percentage of handling element 0, along with a lower vibration magnitude recorded on MS 462. Corresponding to Figure A2, the time to reach the ELV presented per group with averaged time data showed that all values were well above 240 min (Figure A4). Differences in time to reach the ELV regarding the same chainsaw/hand between the averaged groups amounted to a maximum of 24 min. It should be noted that mean values in Table 6 and Table 7 differ from values in the “All trees” group in Figure A2 and Figure A4 due to differences in the calculating procedure.

Table 7.

Descriptive statistics of time to reach ELV for all trees.

4. Discussion

Since the time study in this paper was conducted to predict exposure duration and ultimately calculate the A(8), it does not perfectly correlate with typical time consumption studies of motor-manual work in forestry. The emphasis was on chainsaw-handling elements, rather than standardized operations. Handling elements sometimes include several operations, such as handling element 1b, which includes shrub cleaning and part of the delimbing. However, a comparison with previous studies is possible for some elements. Ciubotaru and Maria [25], in their time consumption study on a sample of 500 spruce trees with a two-man team, reported a mean effective cutting time of 42% and a mean non-working time of the engine of 10%, which corresponds with data obtained for chainsaw-handling elements 1a and 0, respectively. Furthermore, Jourgholami et al. [26] conducted a time study on a sample of 451 trees using the stopwatch/paper method. In their findings, it is stated that on average, only for felling operations, 32% of total felling time consisted of undercut and backcut, which corresponds to handling element 1a. However, it should be noted that the mentioned study did not include crosscuts in its analysis. Velid et al. [27] reported in their time study on 495 sessile oak trees with the stopwatch/paper method, that 59% of total felling and processing time consisted of chainsaw-related work, which corresponds to handling elements 1a and 1b. Furthermore, Liepinš et al. [28] in their study on the productivity of mechanized and motor-manual harvesting of grey alder, reported percentages of the total productive time for felling, clearing, and delimbing of 20.1%, 12%, and 46.5%, respectively. Despite great data dispersion, the results of this study indicate that the mean time consumption of individual chainsaw-handling elements is not greatly affected by tree species, processing method, or DBH. This would suggest that, despite named factors that might influence the duration of standardized operations, workers are adopting a pattern of handling a chainsaw in the sense of time spent during cutting or holding during idle by various handle/hand combinations.

Regarding vibration magnitude, the results show that higher vibration magnitudes, when observing the individual handling element, were occurring on the rear handle. The latter was also reported by Landekić et al. [17] for MS 660 during idle and by Goglia et al. [29] for MS 260 during cutting and idle. Chainsaw-handling elements that include cutting defined in this study were simplified with the intention of simpler measurement of vibration magnitude that complies with ISO 5349-1:2001 [9] and ISO 5349-2:2001 [24] standards. In that regard, Staněk et al. [30] investigated differences between vibration magnitudes on front and rear handles during cleaning, butt, felling, and delimbing of wet and dry wood and reported a significant difference in 69.23 % of cases. The vibration measurement in this study was conducted on a single tree species (European beech), as it is the most represented species in the Republic of Croatia. Previous studies [12,15] reported the influence of wood hardness and density on vibration magnitude, while a new study by Feyzi et al. [31] put emphasis on the cutting process rather than tree species. Furthermore, Rukat et al. [32] state objectively that the vibrations of a petrol saw do not depend on the direction of wood cutting. A very high vibration magnitude measured on MS 462 and MS 661 C during handling element 5 was a result of a rough idling engine. The reason for this is that the measurement was performed with the bar facing the ground and the chainsaw held only by the rear handle. This position seems to cause rough idle on MS 462 and MS 661 C which are carbureted, while MS 500i has direct injection and a smoother idle in the mentioned position.

The majority of daily vibration exposures calculated for individual trees and adjusted to 4 h of total working time in felling and processing were between the EAV and ELV, with only one below the EAV (MS 462 left hand) and several above the ELV (MS 500 right hand and MS 661 C left and right hand). There was a clear distinction in exposure values between the left and right hand, and between three of the observed chainsaws. Higher vibration magnitudes on the rear handle contributed to higher A(8) on the right hand, which mostly occupies the rear handle. This was the case for all the observed chainsaws. Goglia et al. [33] and Bačić et al. [22] also reported higher A(8) on the right hand for MS 260 and MS 261, respectively. Likewise, Papandrea et al. [34], in their ergonomic assessment of nine different chainsaws, reported a higher mean A(8) on the rear handle of MS 461. Although all the chainsaws were equipped with identical bars and chains, using a bigger and more powerful chainsaw resulted in a higher A(8). Obviously, forces produced in more powerful chainsaws contributed to higher vibration magnitudes and thus, higher A(8). When observing A(8) calculated using time data averaged by tree species, processing method, and DBH and adjusted to 4 h, it can be observed that none of the calculated exposures were above the ELV. Moreover, differences in A(8) calculated per chainsaw/handle between the averaged groups were minimal, which implies that tree species, processing method, and DBH have little influence on the relative time structure of felling and processing which results in consistent A(8). Mirroring the daily vibration exposure results, the majority of the time to reach the ELV for individual trees was above 4 h, while in several cases where the A(8) was above the ELV, the time to reach the ELV was below 4 h. Likewise, the time to reach the ELV calculated using time data averaged by tree species, processing method, and DBH showed all values above 4 h. Even the most severe A(8), observed on the MS 661 C/right hand, showed that, on average, there is almost a 100 min long buffer zone above 4 h to reach the ELV, which is closer to the 5 h time cap proposed by the ILO [20].

5. Conclusions

Despite great time data dispersion of chainsaw-handling elements, time structures of groups averaged by tree species, processing method, and DBH had little to no influence on A(8). Higher vibration magnitudes were observed on the rear handle of the individual chainsaw for the same chainsaw-handling element. On average, right hand was more exposed to HAV. Furthermore, bigger and more powerful chainsaws implied higher A(8) and shorter time to reach the ELV. The obtained results suggest that state legislature, which allows a maximum of 4 h of chainsaw work a day, is properly protecting chainsaw workers from vibration exposure, but is also obsolete (1986) as it only uses the time limit. Furthermore, the state legislature bases its proposals on research that is 40 years old or more. In addition, as proven in this paper, chainsaw type (power and size) is a big influencing factor on A(8). In that regard, professional chainsaws today are much more humanized tools than 40 years ago and single-factor work restriction cannot be applied in all cases (smaller and bigger chainsaws). In contrast, European legislature requires a methodical approach to A(8) calculation, i.e., a detailed time study and vibration magnitude measurement, as described in this paper, and leaves room for individual evaluation of specific chainsaw work, which opens up possibilities of extending or shortening some chainsaw operations. For example, if a chainsaw operator’s effective working time consisted of 70% percent performing crosscuts at a landing site and 30% holding an idling chainsaw, their time to reach the ELV would be longer in comparison to a chainsaw operator at a felling site where the effective time structure was different and had a higher percentage of holding an idling chainsaw where vibration magnitudes are more severe.

Author Contributions

Conceptualization, M.B. and Z.P.; methodology, M.B. and Z.P.; validation, Z.P., M.L. and M.Š. (Marijan Šušnjar); formal analysis, M.B. and Z.P.; data curation, M.B. and Z.P.; writing—original draft preparation, M.B.; writing—review and editing, M.Š. (Marijan Šušnjar) and M.Š. (Mario Šporčić); visualization, M.Š. (Marijan Šušnjar). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Croatian Science Foundation under grant number IP-2020-02-7637. The APC was funded by the Croatian Science Foundation and the Faculty of Forestry and Wood Technology of Zagreb University.

Institutional Review Board Statement

This study was conducted according to the guidelines of the Declaration of Helsinki and approved by the Ethics Committee of the Faculty of Forestry and Wood Technology of Zagreb University (protocol code 251-72-06-20-1, 22 January 2020).

Data Availability Statement

The data supporting this study may be provided upon reasonable request to the authors of the study.

Acknowledgments

The research was funded by the Croatian Science Foundation within the project «Increasing the Competitiveness of the Forestry Sector Through the Development of Safety Culture (ForSaf2024)», project number IP-2020-02-7637. Special thanks to the company Unikomerc-uvoz Ltd. for the provided technical support.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

A(8) per single tree and adjusted to 4 h.

Figure A1.

A(8) per single tree and adjusted to 4 h.

Figure A2.

A(8) per group with averaged time data.

Figure A2.

A(8) per group with averaged time data.

Appendix B

Figure A3.

Time to reach ELV per single tree.

Figure A3.

Time to reach ELV per single tree.

Figure A4.

Time to reach ELV per group with averaged time data.

Figure A4.

Time to reach ELV per group with averaged time data.

References

- Miura, T.; Kimura, K.; Tominaga, Y.; Kimotsuki, K. On the Raynaud’s Phenomenon of Occupational Origin due to Vibrating Tools—Its Incidence in Japan. J. Sci. Labour 1965, 42, 725–747. [Google Scholar]

- Axelsson, S.-A. Analysis of Vibration in Power Saws. Stud. For. Suec. 1968, 59, 1–47. [Google Scholar]

- Barnes, R.; Longley, E.O.; Smith, A.R.B.; Allen, J.G. Vibration disease. Med. J. Aust. 1969, 1, 901–905. [Google Scholar] [CrossRef]

- Taylor, W.; Pearson, J.; Kell, R.L.; Keighley, G.D. Vibration syndrome in Forestry Commission chain saw operators. Br. J. Ind. Med. 1971, 28, 83–89. [Google Scholar] [CrossRef]

- Tambić Bukovac, L.; Šenjug Perica, M. Raynaudov sindrom. Paediatr. Croat. 2017, 61, 38–42. [Google Scholar]

- Seppäläinen, A.M. Peripheral neuropathy in forest workers. A field study. Work Environ. Health 1972, 9, 106–111. [Google Scholar]

- Araki, S.; Honma, T.; Aoyama, K. Peripheral nerve conduction velocities in chainsaw operators. Jpn. J. Ind. Health 1976, 18, 516–520. [Google Scholar]

- Brammer, A.J.; Pyykkö, I. Vibration-induced neuropathy: Detection by nerve conduction measurements. Work Environ. Health 1987, 13, 317–322. [Google Scholar] [CrossRef]

- ISO 5349-1:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand Transmitted Vibration. Part 1: General requirements. International Standard organization: Geneva, Switzerland, 2001; pp. 1–26.

- Neri, F.; Laschi, A.; Foderi, C.; Fabiano, F.; Bertuzzi, L.; Marchi, E. Determining noise and vibration exposure in conifer cross-cutting operations by using li-ion batteries and electric chainsaws. Forests 2018, 9, 501. [Google Scholar] [CrossRef]

- Pelmear, P.L.; Leong, D. Review of ccupational Standards and Guidelines for Hand-Arm (Segmental) Vibration Syndrome (HAVS). Appl. Occup. Environ. Hyg. 2000, 15, 291–302. [Google Scholar] [CrossRef]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. The influence of wood hardness and logging operation on coupling forces exerted by lumberjacks during wood harvesting. Int. J. Ind. Ergon. 2011, 41, 546–550. [Google Scholar] [CrossRef]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. Measuring coupling forces woodcutters exert on saws in real working conditions. Int. J. Occup. Saf. Ergon. 2012, 18, 77–83. [Google Scholar] [CrossRef]

- Malinowska-Borowska, J.; Zieliński, G. Coupling forces exerted on chain saws by inexperienced tree fellers. Int. J. Ind. Ergon. 2013, 43, 283–287. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Tsioras, P.; Stampfer, K. Wood density impact on hand-arm vibration. Croat. J. For. Eng. 2012, 33, 303–312. [Google Scholar]

- ISO 11681-1:2011; Machinery for Forestry—Portable Chain-Saw Safety Requirements and Testing—Part 1: Chain-Saws for Forest Service. International Standard organization: Geneva, Switzerland, 2004; pp. 1–22.

- Landekić, M.; Bačić, M.; Pandur, Z.; Šušnjar, M. Vibration Levels of Used Chainsaws. Forests 2020, 11, 249. [Google Scholar] [CrossRef]

- Republic Committee for Work and Employment. Ordinance on Occupational Safety and Health in Forestry. Off. Gaz. 1986, 10/86, 1–18. [Google Scholar]

- The European Parliament and the Council if the European Union. Directive 2002/44/EC, The mimimum health requirement regarding the exposure of workers to the risks arising from physical agents (vibration). Off. J. Eur. Communities 2002, 177, 13–19. [Google Scholar]

- ILO. Safety and Health in Forestry Work-Code of Practice; International Labour Office: Geneva, Switzerland, 1998; pp. 1–132. [Google Scholar]

- McGeoch, K.L.; Lawson, I.J.; Burke, F.; Proud, G.; Miles, J. Diagnostic criteria and staging of hand-arm vibration syndrome in the United Kingdom. Ind. Health 2005, 43, 527–534. [Google Scholar] [CrossRef]

- Bačić, M.; Landekić, M.; Šušnjar, M.; Šporčić, M.; Pandur, Z. Vibration levels and daily vibration exposure while using different tools in a forest cleaning. Cent. Eur. For. J. 2023, 69, 49–58. [Google Scholar] [CrossRef]

- ISO 8041-1:2017; Human Response to Vibration—Measuring Instrumentation—Part 1: General Purpose Vibration Meters. International Standard Organization: Geneva, Switzerland, 2017; pp. 1–106.

- ISO 5349-2:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 2: Practical Guidance for Measurement at the Workplace. International Standard Organization: Geneva, Switzerland, 2001; pp. 1–39.

- Ciubotaru, A.; Maria, G.D. Research regarding structure of working time in spruce felling with mechanical chainsaw Husqvarna 365. Bull. Transilv. Univ. Bras. 2012, 5, 43–48. [Google Scholar]

- Jourgholami, M.; Majnounian, B.; Zargham, N. Performance, Capability and Costs of Motor-Manual Tree Felling in Hyrcanian Hardwood Forest. Croat. J. For. Eng. 2013, 34, 283–293. [Google Scholar]

- Halilović, V.; Gurda, S.; Musić, J.; Sokolović, D.; Bajrić, M.; Knežević, J.; Brnić, A. Analysis of time consumption during sessile oak felling and processing works applying the full-length method. Work. Fac. For. Univ. Sarajevo 2017, 47, 19–35. [Google Scholar] [CrossRef]

- Liepinš, K.; Lazdinš, A.; Liepinš, J.; Prindulis, U. Productivity and Cost–Effectiveness of Mechanized and Motor-Manual Harvesting of Grey Alder (Alnus incana (L.) Moench): A Case Study in Latvia. Small-Scale For. 2015, 14, 493–506. [Google Scholar] [CrossRef]

- Goglia, V.; Žgela, J.; Suchomel, J.; Đukić, I. The effectiveness of forest pre-commercial thinning in the context of Directive 2002/44/EC. Šumarski List 2012, 136, 471–478. [Google Scholar]

- Stanëk, L.; Neruda, J.; Mergl, V.; Kotek, T. Difference in the magnitude of power saw vibrations affecting the operator during forest felling. Cent. Eur. For. J. 2023, 69, 59–67. [Google Scholar] [CrossRef]

- Feyzi, M.; Jafari, A.; Ahmadi, H. The effect of wood species on chainsaw vibrations during bucking operations. Int. J. For. Eng. 2023. [Google Scholar] [CrossRef]

- Rukat, W.; Jakubek, B.; Barczewski, R.; Wróbel, M. The Influence of the Direction of Wood Cutting on the Vibration and Noise of Chainsaws. Teh. Vjesn. 2020, 27, 1879–1886. [Google Scholar] [CrossRef]

- Goglia, V.; Žgela, J.; Suchomel, J.; Đukić, I. Exposure to hand-arm Transmitted vibration at forest nursery and thinning. Hum. Resour. Manag. Ergon. 2011, 5, 45–55. [Google Scholar]

- Papandrea, S.F.; Cataldo, M.F.; Zimbalatti, G.; Grigolato, S.; Proto, A.R. What Is the Current Ergonomic Condition of Chainsaws in Non-Professional Use? A Case Study to Determine Vibrations and Noises in Small-Scale Agroforestry Farms. Forests 2022, 13, 1876. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).