Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK?

Abstract

:1. Introduction

2. Materials and Methods

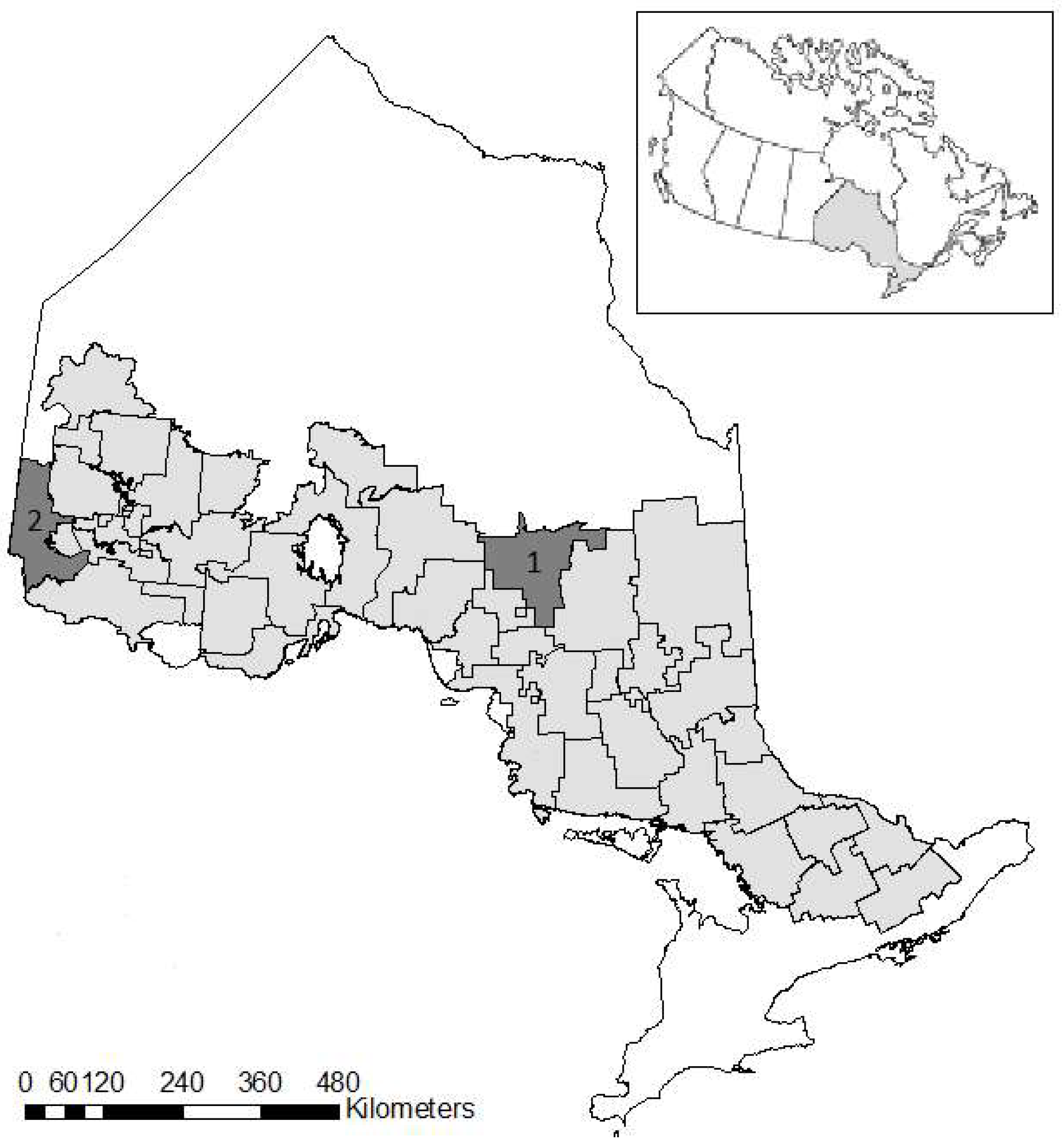

2.1. Study Area

2.2. Bioenergy Scenarios

2.3. Forest Biomass Available for Bioenergy

2.4. Analysis Framework

2.4.1. GWP-Based Mass Balance Approach

2.4.2. Dynamic LCA Approach

2.5. Changes in Forest Carbon Stocks

2.6. LCI Emissions

2.7. Sensitivity Analysis

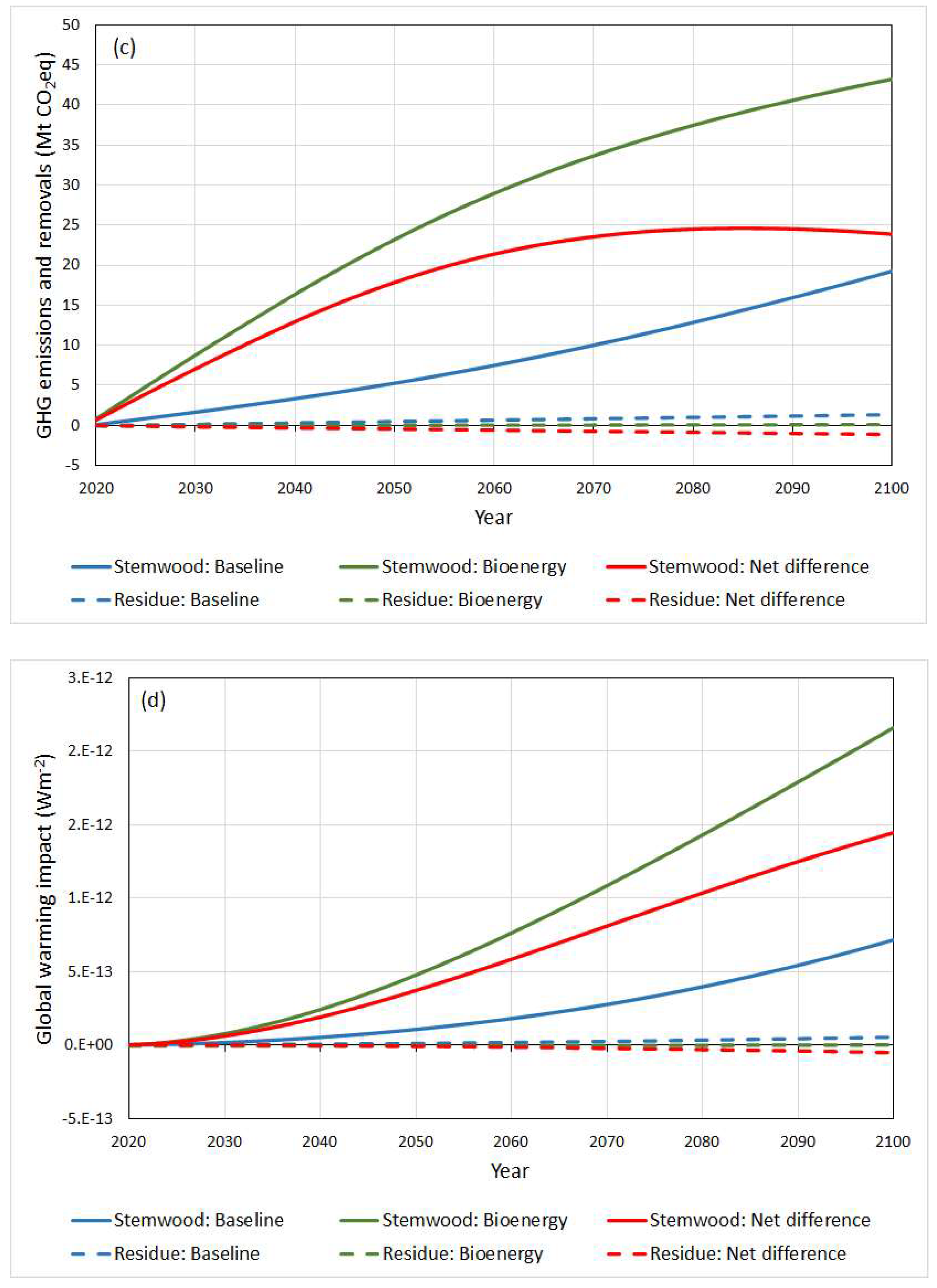

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lemprière, T.C.; Kurz, W.A.; Hogg, E.H.; Schmoll, C.; Rampley, G.J.; Yemshanov, D.; McKenney, D.W.; Gilsenan, R.; Beatch, A.; Blain, D.; et al. Canadian boreal forests and climate change mitigation. Environ. Rev. 2013, 21, 293–321. [Google Scholar] [CrossRef]

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody biomass energy potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- Buchholz, T.; Hurteau, M.D.; Gunn, J.; Saah, D. A global meta-analysis of forest bioenergy greenhouse gas emission accounting studies. Glob. Chang. Biol. Bioenergy 2016, 8, 281–289. [Google Scholar] [CrossRef]

- Thrän, D.; Peetz, D.; Schaubach, K. Global Wood Pellet Industry and Trade Study 2017. IEA Bioenergy Task 40, June 2017. Available online: https://task40.ieabioenergy.com/wp-content/uploads/sites/29/2013/09/IEA-Wood-Pellet-Study_final-july-2017.pdf (accessed on 6 November 2022).

- Giuntoli, J.; Searle, S.; Pavlenko, N.; Agostini, A. A systems perspective analysis of an increased use of forest bioenergy in Canada: Potential carbon impacts and policy recommendations. J. Clean. Prod. 2021, 321, 128889. [Google Scholar] [CrossRef]

- McKechnie, J.; Colombo, S.; Chen, J.; Mabee, W.; MacLean, H.L. Forest bioenergy or forest carbon? Assessing trade-offs in greenhouse gas mitigation with wood-based fuels. Environ. Sci. Technol. 2011, 45, 789–795. [Google Scholar] [CrossRef] [PubMed]

- Smyth, C.E.; Stinson, G.; Neilson, E.; Lemprière, T.C.; Hafer, M.; Rampley, G.J.; Kurz, W.A. Quantifying the biophysical climate change mitigation potential of Canada’s forest sector. Biogeosciences 2014, 11, 3515–3529. [Google Scholar] [CrossRef]

- Ter-Mikaelian, M.T.; Colombo, S.J.; Lovekin, D.; McKechnie, J.; Reynolds, R.; Titus, B.; Laurin, E.; Chapman, A.M.; Chen, J.; MacLean, H.L. Carbon debt repayment or carbon sequestration parity? Lessons from a forest bioenergy case study in Ontario, Canada. GCB Bioenergy 2015, 7, 704–716. [Google Scholar] [CrossRef]

- Laganière, J.; Paré, D.; Thiffault, E.; Bernier, P.Y. Range and uncertainties in estimating delays in greenhouse gas mitigation potential of forest bioenergy sourced from Canadian forests. GCB Bioenergy 2017, 9, 358–369. [Google Scholar] [CrossRef]

- Röder, M.; Thiffault, E.; Martínez-Alonso, C.; Senez-Gagnon, F.; Paradis, L.; Thornley, P. Understanding the timing and variation of greenhouse gas emissions of forest bioenergy systems. Biomass Bioenergy 2019, 121, 99–114. [Google Scholar] [CrossRef]

- Lamers, P.; Junginger, M.; Dymond, C.C.; Faaij, A. Damaged forests provide an opportunity to mitigate climate change. GCB Bioenergy 2014, 6, 44–60. [Google Scholar] [CrossRef]

- Smyth, C.; Kurz, W.A.; Rampley, G.; Lemprière, T.C.; Schwab, O. Climate change mitigation potential of local use of harvest residues for bioenergy in Canada. GCB Bioenergy 2017, 9, 817–832. [Google Scholar] [CrossRef]

- Smyth, C.E.; Xu, Z.; Lemprière, T.C.; Kurz, W.A. Climate change mitigation in British Columbia’s forest sector: GHG reductions, costs, and environmental impacts. Carbon Balance Manag. 2020, 15, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Gaudreault, C.; Miner, R. Temporal aspects in evaluating the greenhouse gas mitigation benefits of using residues from forest products manufacturing facilities for energy production. J. Ind. Ecol. 2015, 19, 994–1007. [Google Scholar] [CrossRef]

- Ontario Ministry of Natural Resources and Forestry. In Sustainable Growth: Ontario’s Forest Sector Strategy; Queen’s Printer for Ontario: Ontario, ON, Canada, 2020; p. 462. Available online: https://www.ontario.ca/page/sustainable-growth-ontarios-forest-sector-strategy (accessed on 6 November 2022).

- Brandão, M.; Kirschbaum, M.U.; Cowie, A.L.; Hjuler, S.V. Quantifying the climate change effects of bioenergy systems: Comparison of 15 impact assessment methods. GCB Bioenergy 2019, 11, 727–743. [Google Scholar] [CrossRef]

- Sathre, R.; Gustavsson, L. Time-dependent climate benefits of using forest residues to substitute fossil fuels. Biomass Bioenergy 2011, 35, 2506–2516. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschenes, L.; Samson, R. Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Kloss, D. Strategic Forest Management Model Version 2.0 User Guide; Ontario Ministry Natural Resources; Forest Management Branch; Forest Management Planning Section: Sault Ste. Marie, ON, Canada, 2002; 270p. [Google Scholar]

- Ontario Ministry of Natural Resources and Forestry. In State of Ontario’s Natural Resources–Forests 2021; Queen’s Printer for Ontario: Sault Ste. Marie, ON, Canada, 2021; Available online: https://www.ontario.ca/page/state-ontarios-natural-resources-forest-2021 (accessed on 6 November 2022).

- Ter-Mikaelian, M.T.; Colombo, S.J.; Chen, J. Harvest volumes and carbon stocks in boreal forests of Ontario, Canada. For. Chron. 2021, 97, 168–178. [Google Scholar] [CrossRef]

- Ralevic, P.; Ryans, M.; Cormier, D. Assessing forest biomass for bioenergy: Operational challenges and cost considerations. For. Chron. 2010, 86, 43–50. [Google Scholar] [CrossRef]

- Natural Resources Canada. Graded Wood Pellets. Solid Biofuels Bulletin No.4. 2016. Available online: https://publications.gc.ca/site/eng/9.814417/publication.html (accessed on 6 November 2022).

- Ontario Ministry of Natural Resources and Forestry. Forest Management Planning Manual; Queen’s Printer for Ontario: Toronto, ON, Canada, 2017; p. 462. Available online: https://www.ontario.ca/page/sustainable-forest-management (accessed on 6 November 2022).

- Gonzalez, J.S. Wood Density of Canadian Tree Species; Information Report No. NOR-X-315; Forestry Canada: Edmonton, AB, Canada, 1990; p. 130. [Google Scholar]

- Sharma, M.; Parton, J.; Woods, M.; Newton, P.; Penner, M.; Wang, J.; Stinson, A.; Bell, F.W. Ontario’s forest growth and yield modelling program: Advances resulting from the Forestry Research Partnership. For. Chron. 2008, 84, 694–703. [Google Scholar] [CrossRef]

- Chen, J.; Yang, H.; Man, R.; Wang, W.; Sharma, M.; Peng, C.; Parton, J.; Zhu, H.; Deng, Z. Using machine learning to synthesize spatiotemporal data for modelling DBH-height and DBH-height-age relationships in boreal forests. For. Ecol. Manag. 2020, 466, 118104. [Google Scholar] [CrossRef]

- Lambert, M.C.; Ung, C.H.; Raulier, F. Canadian national tree aboveground biomass equations. Can. J. For. Res. 2005, 35, 1996–2018. [Google Scholar] [CrossRef]

- Chen, J.; Colombo, S.J.; Ter-Mikaelian, M.T.; Heath, L.S. Carbon budget of Ontario’s managed forests and harvested wood products, 2001–2100. For. Ecol. Manag. 2010, 259, 1385–1398. [Google Scholar] [CrossRef]

- Heath, L.S.; Nichols, M.C.; Smith, J.E.; Mills, J.R. FORCARB2: An Updated Version of the US Forest Carbon Budget Model; General Technical Report NRS-67; USDA Forest Service, Northern Research Station: Newtown Square, PA, USA, 2010. [Google Scholar]

- Belleau, A.; Brais, S.; Paré, D. Soil nutrient dynamics after harvesting and slash treatments in boreal aspen stands. Soil Sci. Soc. Am. J. 2006, 70, 1189–1199. [Google Scholar] [CrossRef]

- Klockow, P.A.; D’Amato, A.W.; Bradford, J.B. Impacts of post-harvest slash and live-tree retention on biomass and nutrient stocks in Populus tremuloides Michx.-dominated forests, northern Minnesota, USA. For. Ecol. Manag. 2013, 291, 278–288. [Google Scholar] [CrossRef]

- Hytönen, J.; Moilanen, M. Short-term effects of whole-tree harvesting on nutrition of Scots pine on drained peatlands. In After Wise Use–the Future of Peatlands, Proceedings of the 13th International Peat Congress, Tullamore, Ireland, 8–13 June 2008; International Peat Society: Jyväskylä, Finland, 2008. [Google Scholar]

- Dymond, C.C.; Titus, B.D.; Stinson, G.; Kurz, W.A. Future quantities and spatial distribution of harvesting residue and dead wood from natural disturbances in Canada. For. Ecol. Manag. 2010, 260, 181–192. [Google Scholar] [CrossRef]

- Tarasov, D. Comparative Analysis of Wood Pellet Parameters: Canadian Case Study. Ph.D. Thesis, Lakehead University, Thunder Bay, ON, Canada, defended on 16 August 2013. 2014. Available online: https://knowledgecommons.lakeheadu.ca/bitstream/handle/2453/473/TarasovD2013m-1b.pdf?sequence=1 (accessed on 6 November 2022).

- Beér, J.M. High efficiency electric power generation: The environmental role. Prog. Energy Combust. Sci. 2007, 33, 107–134. [Google Scholar] [CrossRef]

- European Commission. United Kingdom Investment Contract for Biomass Conversion of the First Unit of the Drax Power Plant, 2016. Available online: https://ec.europa.eu/competition/state_aid/cases/257954/257954_1720554_105_2.pdf (accessed on 6 November 2022).

- Ganguly, I.; Pierobon, F.; Sonne Hall, E. Global warming mitigating role of wood products from Washington state’s private forests. Forests 2020, 11, 194. [Google Scholar] [CrossRef]

- Chen, J.; Ter-Mikaelian, M.T.; Ng, P.Q.; Colombo, S.J. Ontario’s managed forests and harvested wood products contribute to greenhouse gas mitigation from 2020 to 2100. For. Chron. 2018, 43, 269–282. [Google Scholar] [CrossRef]

- Chen, J.; Colombo, S.J.; Ter-Mikaelian, M.T.; Heath, L.S. Carbon profile of the managed forest sector in Canada in the 20th century: Sink or source? Environ. Sci. Technol. 2014, 48, 9859–9866. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. For. Int. J. For. Res. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Smith, J.E.; Heath, L.S.; Jenkins, J.C. Forest Volume-to-Biomass Models and Estimates of Mass for Live and Standing Dead Trees of US Forests; NE-GTR-298; USDA Forest Service, Northeastern Research Station: Newtown Square, PA, USA, 2003. [Google Scholar]

- Ter-Mikaelian, M.T.; Colombo, S.J.; Chen, J. Greenhouse gas emission effect of suspending slash pile burning in Ontario’s managed forests. For. Chron. 2016, 92, 345–356. [Google Scholar] [CrossRef]

- Hardy, C.C. Guidelines for Estimating Volume, Biomass, and Smoke Production for Piled Slash; General Technical Report PNW-GTR-364; U.S. Department of Agriculture Forest Service: Washington, DC, USA; Pacific Northwest Research Station: Portland, OR, USA, 1996.

- [IPCC] Intergovernmental Panel on Climate Change. Good Practice Guidance for Land Use, Land-Use Change and Forestry. Intergovernmental Panel on Climate Change National Greenhouse Gas Inventories Programme, 2003. Available online: https://www.ipcc-nggip.iges.or.jp/public/gpglulucf/gpglulucf_files/GPG_LULUCF_FULL.pdf (accessed on 6 November 2022).

- Smith, C.; Nicholls, Z.R.J.; Armour, K.; Collins, W.; Forster, P.; Meinshausen, M.; Palmer, M.D.; Watanabe, M. The Earth’s energy budget, climate feedbacks, and climate sensitivity supplementary material. In Climate Change 2021: The Physical Science Basis; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M., et al., Eds.; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; 2021; Available online: https://www.ipcc.ch/ (accessed on 6 November 2022).

- Magelli, F.; Boucher, K.; Bi, H.T.; Melin, S.; Bonoli, A. An environmental impact assessment of exported wood pellets from Canada to Europe. Biomass Bioenergy 2009, 33, 434–441. [Google Scholar] [CrossRef]

- McCloy, B.W. NWT Wood Pellet Pre-Feasibility Analysis. 2009. Available online: http://www.nlcpr.com/NWT%20Wood%20Pellet%20Public%20Report%20Jan%2014%202010.pdf (accessed on 6 November 2022).

- Zhang, Y.; McKechnie, J.; Cormier, D.; Lyng, R.; Mabee, W.; Ogino, A.; Maclean, H.L. Life cycle emissions and cost of producing electricity from coal, natural gas, and wood pellets in Ontario, Canada. Environ. Sci. Technol. 2010, 44, 538–544. [Google Scholar] [CrossRef] [PubMed]

- [IPCC] Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Prepared by the National Greenhouse Gas Inventories Programme; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IGES: Hayama, Japan, 2006; Available online: https://www.ipcc.ch/report/2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 6 November 2022).

- Odeh, N.A.; Cockerill, T.T. Life cycle analysis of UK coal fired power plants. Energy Convers. Manag. 2008, 49, 212–220. [Google Scholar] [CrossRef]

- Chen, J.; Colombo, S.J.; Ter-Mikaelian, M.T. Carbon Stocks and Flows from Harvest to Disposal in Harvested Wood Products from Ontario and Canada (No. CCRR-33); Ontario Forest Research Institute: Sault Ste. Marie, ON, Canada, 2013. [Google Scholar]

- Laschi, A.; Marchi, E.; González-García, S. Environmental performance of wood pellets’ production through life cycle analysis. Energy 2016, 103, 469–480. [Google Scholar] [CrossRef]

- Ghafghazi, S.; Lochhead, K.; Mathey, A.H.; Forsell, N.; Leduc, S.; Mabee, W.; Bull, G. Estimating mill residue surplus in Canada: A spatial forest fiber cascade modeling approach. For. Prod. J. 2017, 67, 205–218. [Google Scholar] [CrossRef]

- Dymond, C.C.; Kamp, A. Fibre use, net calorific value, and consumption of forest-derived bioenergy in British Columbia, Canada. Biomass Bioenergy 2014, 70, 217–224. [Google Scholar] [CrossRef]

- Wiltsee, G.A.C.I. Lessons Learned from Existing Biomass Power Plants; (No. NREL/SR-570-26946); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2000. Available online: https://www.nrel.gov/docs/fy00osti/26946.pdf (accessed on 6 November 2022).

- Titus, B.D.; Brown, K.; Helmisaari, H.S.; Vanguelova, E.; Stupak, I.; Evans, A.; Clarke, N.; Guidi, C.; Bruckman, V.J.; Varnagiryte-Kabasinskiene, I.; et al. Sustainable forest biomass: A review of current residue harvesting guidelines. Energy Sustain. Soc. 2021, 11, 1–32. [Google Scholar] [CrossRef]

- Aurell, J.; Gullett, B.K.; Tabor, D.; Yonker, N. Emissions from prescribed burning of timber slash piles in Oregon. Atmos. Environ. 2017, 150, 395–406. [Google Scholar] [CrossRef]

- Ward, D.E.; Susott, R.; Kauffman, J.B.; Babbitt, R.E.; Cummings, D.L.; Dias, B.; Holben, B.N.; Kaufman, Y.J.; Rasmussen, R.A.; Setzer, A.W. Smoke and fire characteristics for cerrado and deforestation burns in Brazil: BASE-B experiment. J. Geophys. Res. Atmos. 1992, 97, 14601–14619. [Google Scholar] [CrossRef]

- Springsteen, B.; Christofk, T.; Eubanks, S.; Mason, T.; Clavin, C.; Storey, B. Emission reductions from woody biomass waste for energy as an alternative to open burning. J. Air Waste Manag. Assoc. 2011, 61, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Cowie, A.L.; Berndes, G.; Bentsen, N.S.; Brandão, M.; Cherubini, F.; Egnell, G.; George, B.; Gustavsson, L.; Hanewinkel, M.; Harris, Z.M.; et al. Applying a science-based systems perspective to dispel misconceptions about climate effects of forest bioenergy. GCB Bioenergy 2021, 13, 1210–1231. [Google Scholar] [CrossRef]

- Favero, A.; Daigneault, A.; Sohngen, B. Forests: Carbon sequestration, biomass energy, or both? Sci. Adv. 2020, 6, p.eaay6792. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, F.X.; Mirzaee, A.; McGarvey, R.G.; Shifley, S.R.; Burtraw, D. Expansion of US wood pellet industry points to positive trends but the need for continued monitoring. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Giuntoli, J.; Searle, S.; Jonsson, R.; Agostini, A.; Robert, N.; Amaducci, S.; Marelli, L.; Camia, A. Carbon accounting of bioenergy and forest management nexus. A reality-check of modeling assumptions and expectations. Renew. Sustain. Energy Rev. 2020, 134, 110368. [Google Scholar] [CrossRef]

- Davin, E.L.; de Noblet-Ducoudré, N. Climatic impact of global-scale deforestation: Radiative versus nonradiative processes. J. Clim. 2010, 23, 97–112. [Google Scholar] [CrossRef]

- Arvesen, A.; Cherubini, F.; del Alamo Serrano, G.; Astrup, R.; Becidan, M.; Belbo, H.; Goile, F.; Grytli, T.; Guest, G.; Lausselet, C.; et al. Cooling aerosols and changes in albedo counteract warming from CO2 and black carbon from forest bioenergy in Norway. Sci. Rep. 2018, 8, 3299. [Google Scholar] [CrossRef]

- Drever, C.R.; Cook-Patton, S.C.; Akhter, F.; Badiou, P.H.; Chmura, G.L.; Davidson, S.J.; Desjardins, R.L.; Dyk, A.; Fargione, J.E.; Fellows, M.; et al. Natural climate solutions for Canada. Sci. Adv. 2021, 7, eabd6034. [Google Scholar] [CrossRef]

- Serin, E. What Is the UK’s Policy Approach to Carbon Capture, Usage and Storage (CCUS)? The London School of Economics and Political Science: London, UK, 2023; Available online: https://www.lse.ac.uk/granthaminstitute/explainers/what-is-the-uks-policy-approach-to-carbon-capture-usage-and-storage-ccus/ (accessed on 16 May 2023).

- Giuntoli, J.; Barredo, J.I.; Avitabile, V.; Camia, A.; Cazzaniga, N.E.; Grassi, G.; Jasinevičius, G.; Jonsson, R.; Marelli, L.; Robert, N.; et al. The quest for sustainable forest bioenergy: Win-win solutions for climate and biodiversity. Renew. Sustain. Energy Rev. 2022, 159, 112180. [Google Scholar] [CrossRef]

- Birdsey, R.; Duffy, P.; Smyth, C.; Kurz, W.A.; Dugan, A.J.; Houghton, R. Climate, economic, and environmental impacts of producing wood for bioenergy. Environ. Res. Lett. 2018, 13, 050201. [Google Scholar] [CrossRef]

- Durocher, C.; Thiffault, E.; Achim, A.; Auty, D.; Barrette, J. Untapped volume of surplus forest growth as feedstock for bioenergy. Biomass Bioenergy 2019, 120, 376–386. [Google Scholar] [CrossRef]

- Norton, M.; Baldi, A.; Buda, V.; Carli, B.; Cudlin, P.; Jones, M.B.; Korhola, A.; Michalski, R.; Novo, F.; Oszlányi, J.; et al. Serious mismatches continue between science and policy in forest bioenergy. GCB Bioenergy 2019, 11, 1256–1263. [Google Scholar] [CrossRef]

| FMU | Biomass | Source | Bioenergy Scenario | Baseline Scenario |

|---|---|---|---|---|

| Hearst Forest | Stemwood | Standing live trees from forest stands available for harvesting in the FMP but not harvested for traditional HWP. | Stands are harvested for bioenergy; harvest residue is left to decay in the slash piles at roadside. | Stands continue to develop naturally. |

| Residue | Harvest residue from stands harvested for traditional HWP. | Harvest residue is collected from slash piles at roadside. | Harvest residue is left to decay in slash piles at roadside. | |

| Kenora Forest | Stemwood | Standing live trees from forest stands available for harvesting in the FMP but not harvested for traditional HWP. | Stands are harvested for bioenergy; harvest residue is burned in the slash piles at roadside. | Stands continue to develop naturally. |

| Residue | Harvest residue from stands harvested for traditional HWP. | Harvest residue is collected from slash piles at roadside. | Harvest residue is burned in slash piles at roadside. |

| Gas, kg∙MWh−1 | Hearst FMU | Kenora FMU | Coal Scenario | ||

|---|---|---|---|---|---|

| Stemwood Scenario | Residue Scenario | Stemwood Scenario | Residue Scenario | ||

| CO2 | 119.975 | 78.476 | 126.220 | 84.721 | 875.0 |

| CH4 | 0.227 | 0.202 | 0.233 | 0.100 | 2.90 |

| N2O | 0.038 | 0.027 | 0.040 | 0.015 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ter-Mikaelian, M.T.; Chen, J.; Desjardins, S.M.; Colombo, S.J. Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK? Forests 2023, 14, 1090. https://doi.org/10.3390/f14061090

Ter-Mikaelian MT, Chen J, Desjardins SM, Colombo SJ. Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK? Forests. 2023; 14(6):1090. https://doi.org/10.3390/f14061090

Chicago/Turabian StyleTer-Mikaelian, Michael T., Jiaxin Chen, Sabrina M. Desjardins, and Stephen J. Colombo. 2023. "Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK?" Forests 14, no. 6: 1090. https://doi.org/10.3390/f14061090

APA StyleTer-Mikaelian, M. T., Chen, J., Desjardins, S. M., & Colombo, S. J. (2023). Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK? Forests, 14(6), 1090. https://doi.org/10.3390/f14061090