Influence of Wood Knots of Chinese Weeping Cypress on Selected Physical Properties

Abstract

1. Introduction

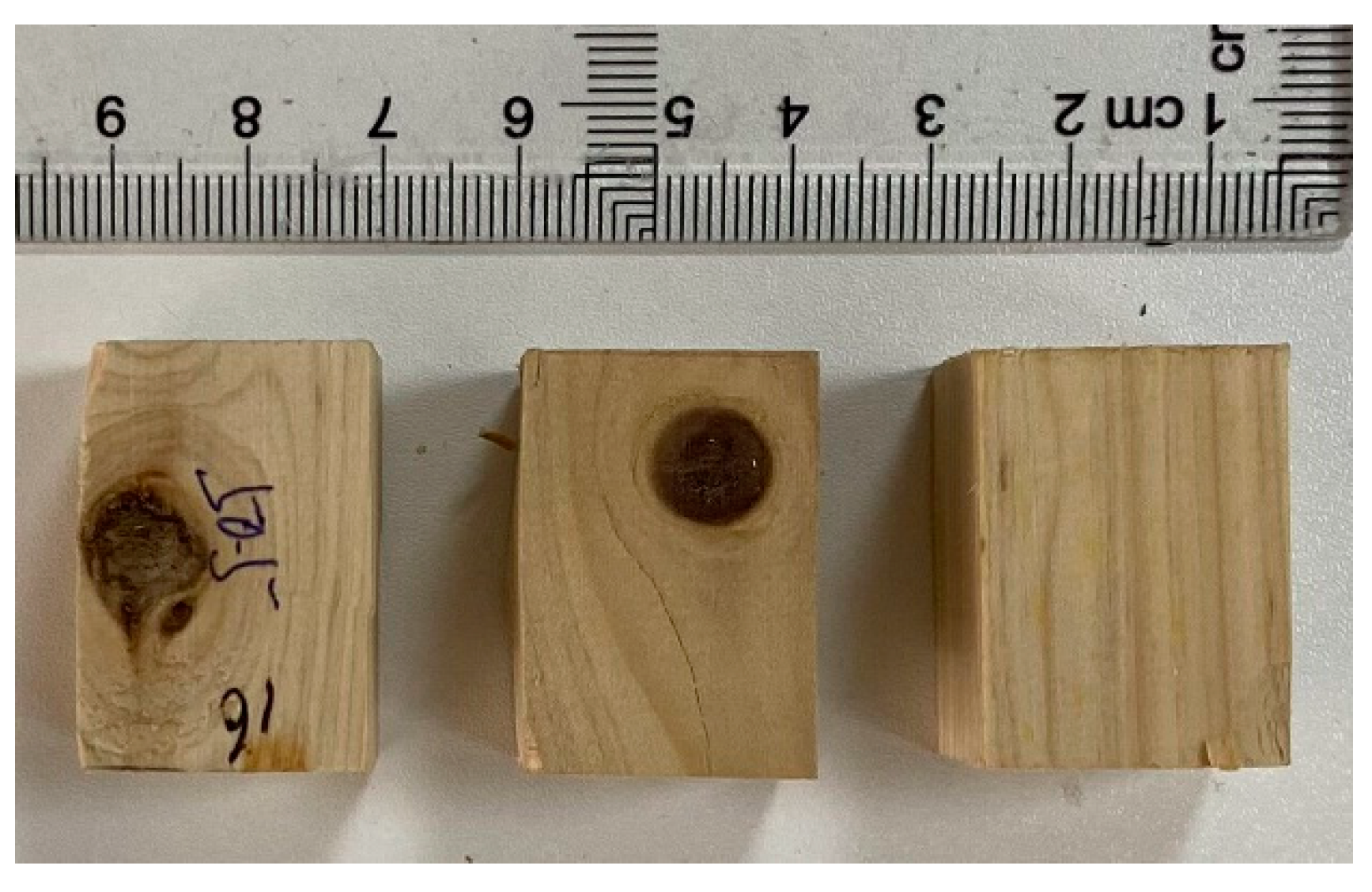

2. Materials and Methods

2.1. Site Sampling

2.2. Physical Tests

2.3. Surface Color Test

2.4. Statistical Analyses

3. Results and Discussion

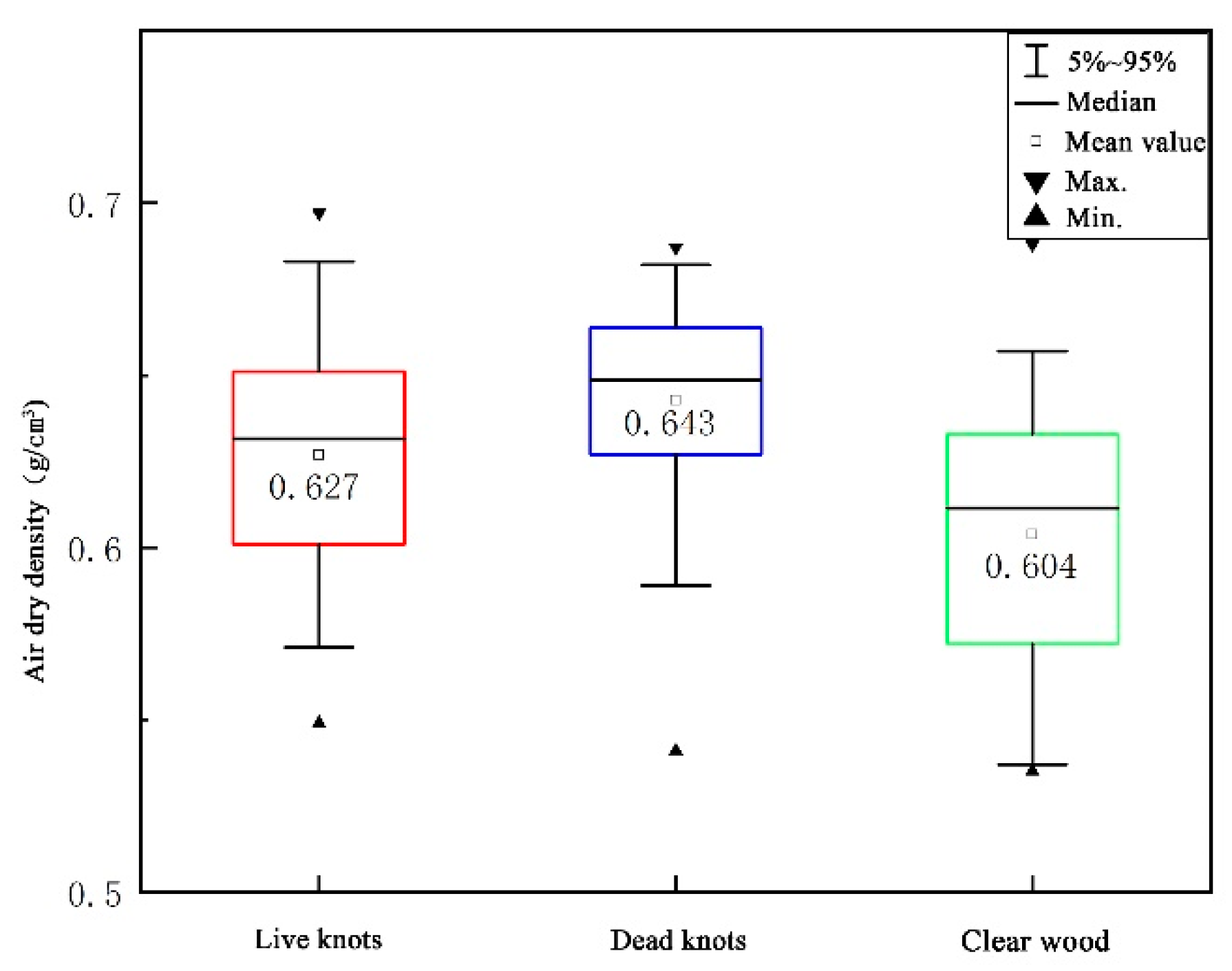

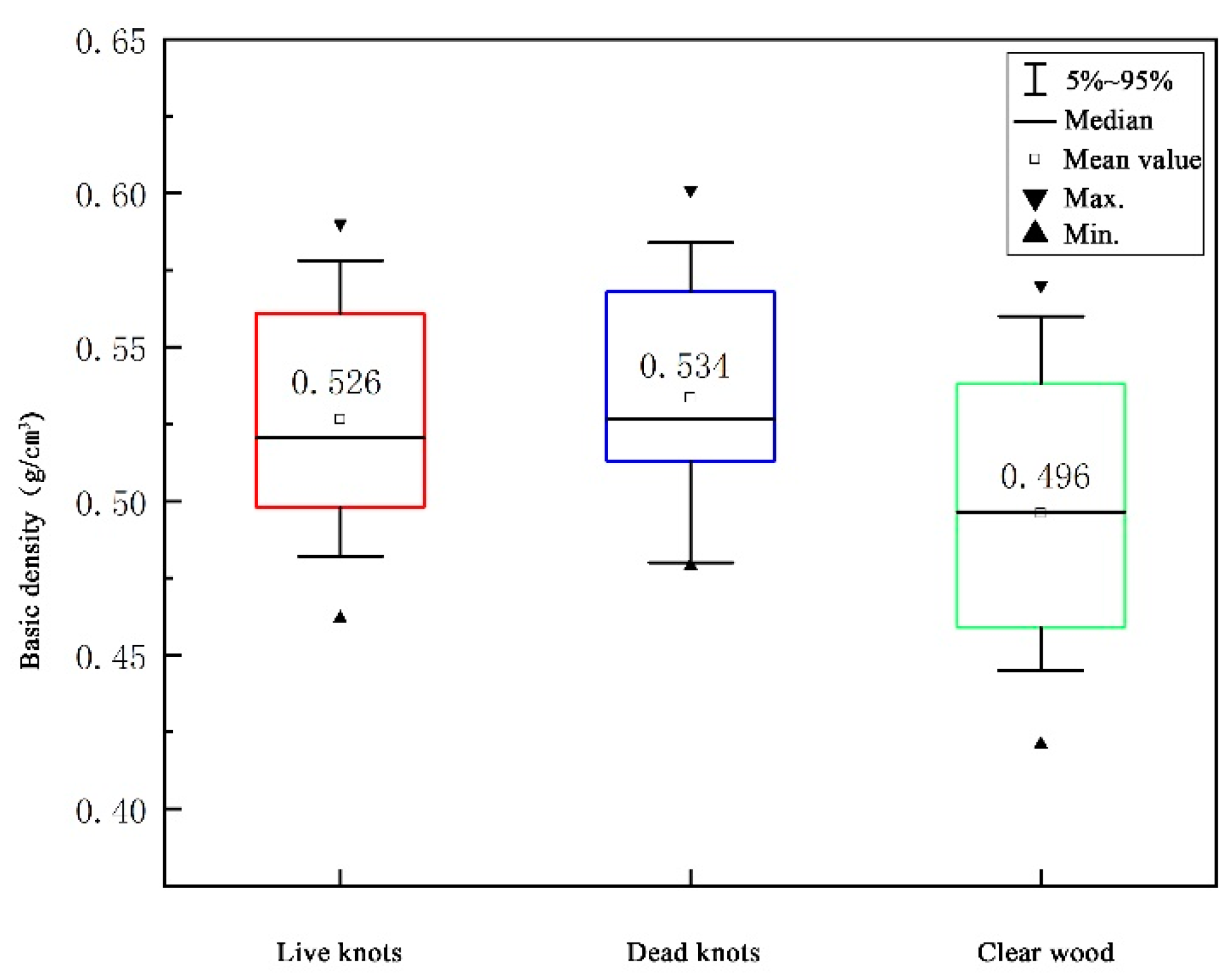

3.1. Wood Density

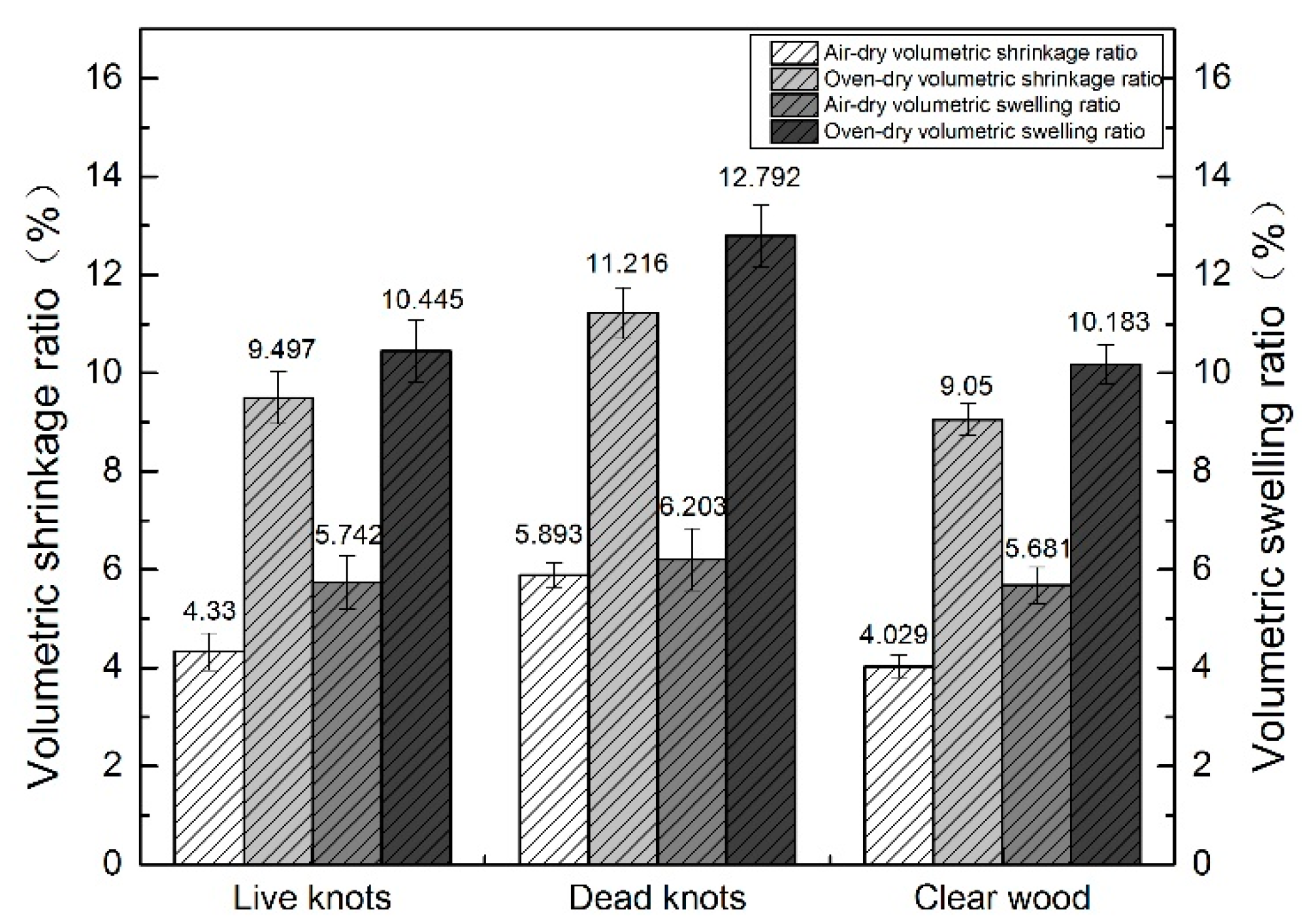

3.2. Wood Shrinkage and Wood Swelling

- (1)

- Wood density is shown to affect the various wood shrinkages and wood swellings that occur during wood drying. Wood density is positively correlated with both radial and tangential wood shrinkage, but is also negatively correlated with longitudinal wood shrinkage [45]. The wood density is determined by the proportion of cell wall material. The proportion of tissue is a key anatomical factor in the volume shrinkage of wood [46]. The greater the wood density of the wood, which generally represents a greater number of cell walls, the greater the wood shrinkage and wood swelling ratio, and vice versa. Wood density decreases within the three groups, from the dead knots to the live knots to clear wood, so the wood shrinkage and wood swelling ratio are consistent with the wood density ranking.

- (2)

- Dead knots contain more extracts, and the chemical composition of the extracts has a greater influence on water absorption and loss, similar to other observations and studies [47]. The coefficients of variation of air-dry and oven-dry wood shrinkage and wood swelling ratios of all three groups were high and belonged to the medium variation.

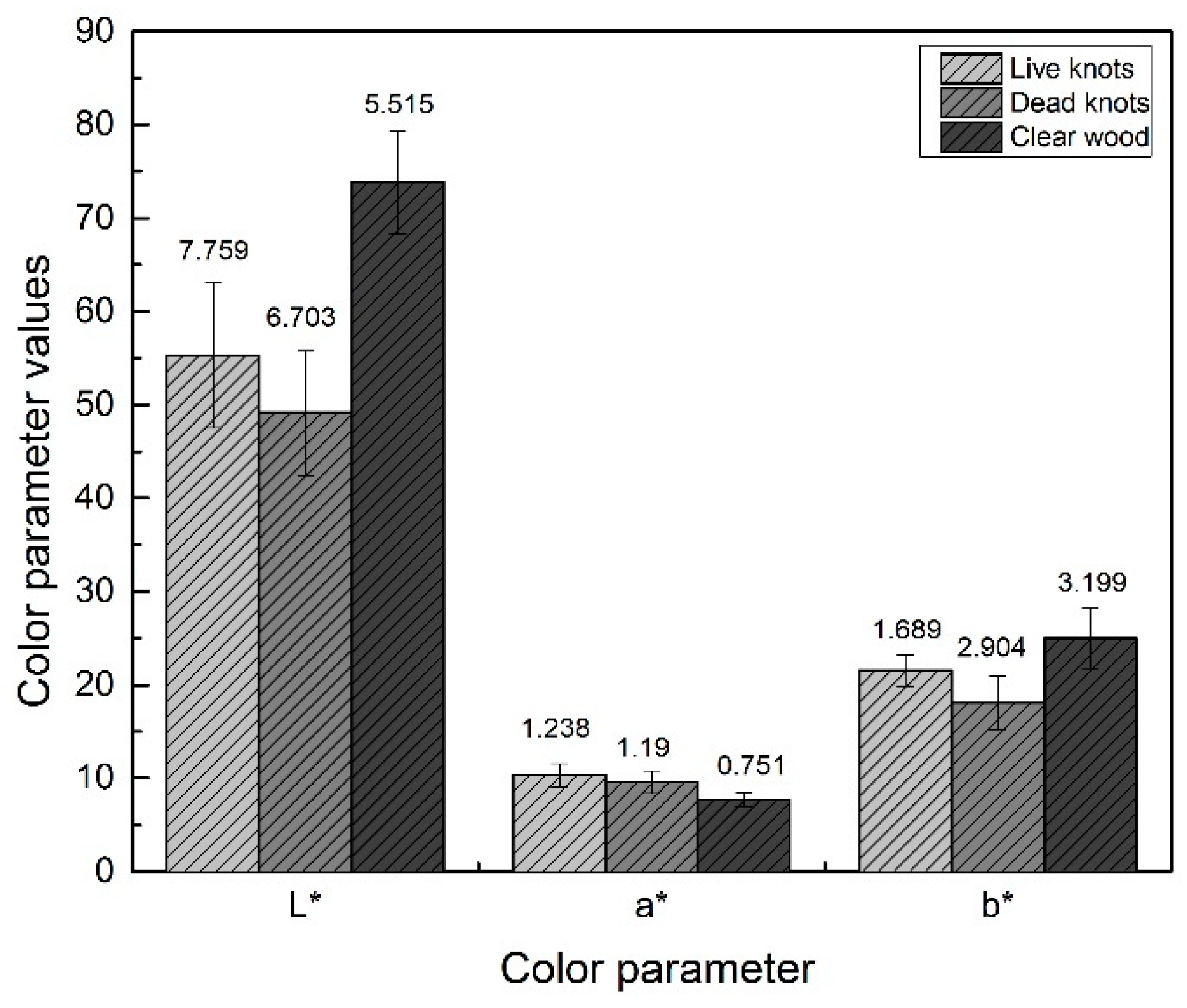

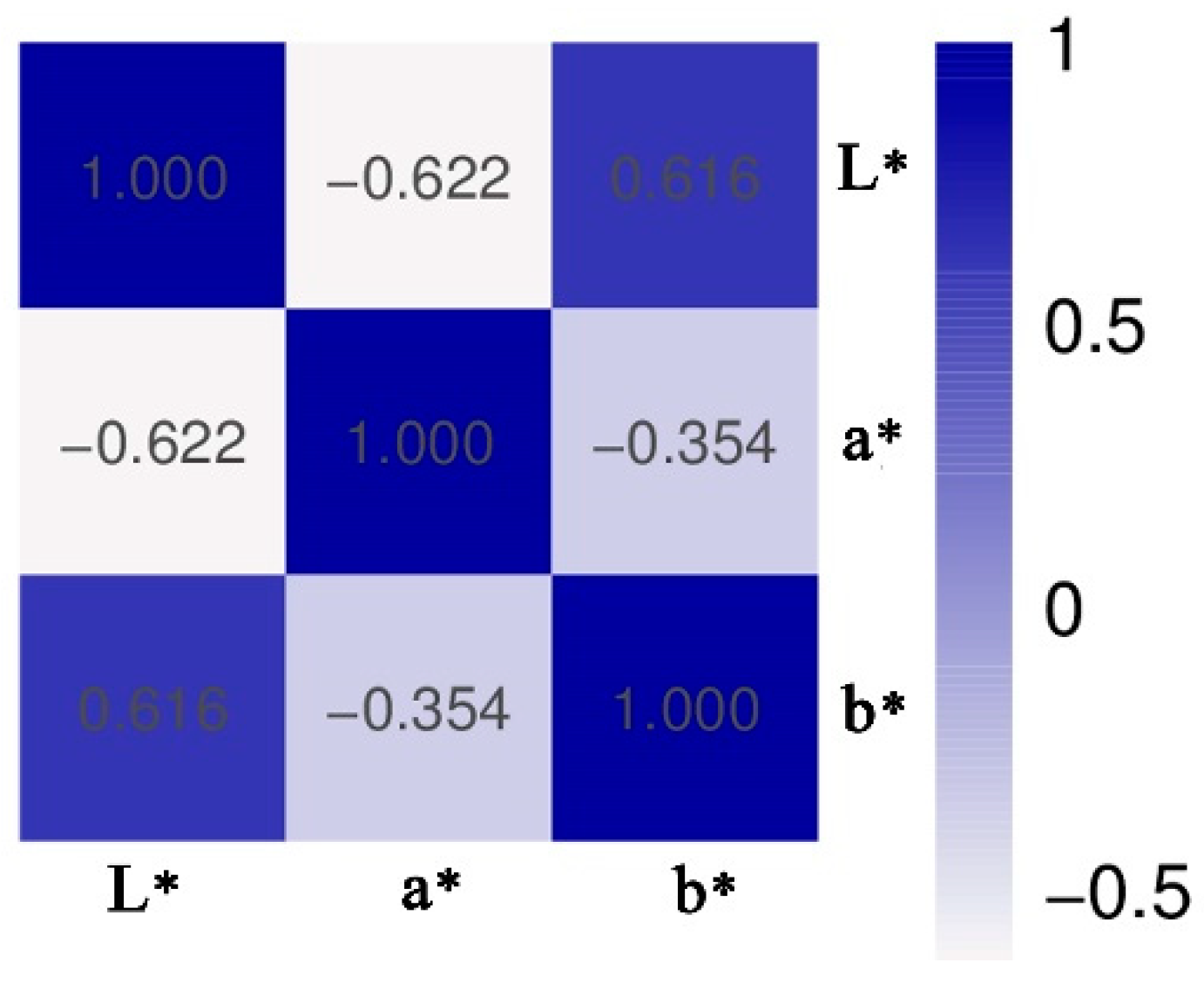

3.3. Wood Color Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, L.; Yu, Y.; Farjon, A. Flora of China 4; Science Press: Beijing, China, 1999; pp. 62–77. [Google Scholar]

- Yang, Y.; Yang, H.; Wang, Q.; Dong, Q.; Yang, J.; Wu, L.; You, C.; Hu, J.; Wu, Q. Effects of Two Management Practices on Monthly Litterfall in a Cypress Plantation. Forests 2022, 13, 1581. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.; He, W.; Ren, J.; Wen, X.; Wang, Y.; Li, X.; Chen, G.; Feng, M.; Fan, C. Shrub Diversity and Niche Characteristics in the Initial Stage of Reconstruction of Low-Efficiency Cupressus funebris Stands. Forests 2021, 12, 1492. [Google Scholar] [CrossRef]

- Wu, B.; Qi, S. Effects of Underlay on Hill-Slope Surface Runoff Process of Cupressus funebris Endl. Plantations in Southwestern China. Forests 2021, 12, 644. [Google Scholar] [CrossRef]

- Fu, L.; Yu, Y.; Mill, R.R. Taxodiaceae. In Flora of China; Wu, Z.Y., Raven, P.H., Eds.; Science Press: Beijing, China, 1999; Volume 4, pp. 54–61. [Google Scholar]

- Cool, L.G.; Hu, Z.L.; Zavarin, E. Foliage terpenoids of Chinese Cupressus species. Biochem. Syst. Ecol. 1998, 26, 899–913. [Google Scholar] [CrossRef]

- Lyu, J.; Wang, J.; Chen, Z.; Chen, M. Influence of Dowel Center Spacing on Chamfered-Joint Components Made by Cupressus funebris Wood. J. Renew. Mater. 2023, 11, 309–319. [Google Scholar] [CrossRef]

- Chen, M.; Li, S.; Lyu, J. Effects of selected joint parameters on tensile strength of steel bolt-nut connections in Cupressus funebris wood. BioResources 2019, 14, 5188–5211. [Google Scholar] [CrossRef]

- Karaszewski, Z.; Bembenek, M.; Mederski, P.S.; Szczepanska-Alvarez, A.; Byczkowski, R.; Kozlowska, A.; Michnowicz, K.; Przytula, W.; Giefing, D.F. Identifying beech round wood quality-distribution of beech timber qualities and influencing defects. Drew. Pr. Nauk. Doniesienia Komun. 2013, 56, 39–54. [Google Scholar]

- Vongkhamho, S.; Imaya, A.; Takenaka, C.; Yamamoto, K.; Yamamoto, H. Correlations among Tree Quality, Stand Characteristics, and Site Characteristics in Plantation Teak in Mountainous Areas of Lao PDR. Forests 2020, 11, 777. [Google Scholar] [CrossRef]

- Midgley, S.; Mounlamai, K.; Flanagan, A.; Phengsopha, K. Global Markets for Plantation Teak; Implications for Growers in Lao PDR; Australian Centre for International Agricultural Research: Canberra, Australia, 2015.

- Baillères, P.H.; Durand, P.Y. Non-destructive techiques for wood quality assessment of plantation-grown teak. Bois Forêts Trop. 2000, 263, 17–29. [Google Scholar]

- Longuetaud, F.; Mothe, F.; Kerautret, B.; Krähenbühl, A.; Hory, L.; Leban, J.M.; Debled-Rennesson, I. Automatic knot detection and measurements from X-ray CT images of wood: A review and validation of an improved algorithm on softwood samples. Comput. Electron. Agric. 2012, 85, 77–89. [Google Scholar] [CrossRef]

- Macdonald, E.; Hubert, J. A review of the effects of silviculture on timber quality of Sitka spruce. For. Int. J. For. Res. 2002, 75, 107–138. [Google Scholar] [CrossRef]

- Qin, G.; Hao, J.; Yang, J.; Li, R.; Yin, G. Branch Occlusion and Discoloration under the Natural Pruning of Mytilaria laosensis. Forests 2019, 10, 892. [Google Scholar] [CrossRef]

- GB/T 155–2017; Defects in Logs. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Lowell, E.C.; Maguire, D.A.; Briggs, D.G.; Turnblom, E.C.; Jayawickrama, K.J.S.; Bryce, J. Effects of Silviculture and Genetics on Branch/Knot Attributes of Coastal Pacific Northwest Douglas-Fir and Implications for Wood Quality—A Synthesis. Forests 2014, 5, 1717–1736. [Google Scholar] [CrossRef]

- Tong, Q.J.; Duchesne, I.; Belley, D.; Beaudoin, M.; Swift, E. Characterization of knots in plantation white spruce. Wood Fiber Sci. 2013, 45, 84–97. [Google Scholar]

- Cherry, R.; Karunasena, W.; Manalo, A. Mechanical Properties of Low-Stiffness Out-of-Grade Hybrid Pine—Effects of Knots, Resin and Pith. Forests 2022, 13, 927. [Google Scholar] [CrossRef]

- Yong, C.; Li, Y. Physical and mechanical properties and utilization of Chinese fir branch wood. Guizhou For. Sci. Technol. 1991, 4, 69–70. (In Chinese) [Google Scholar]

- Wang, Y.R.; Zhao, R.J.; Jiang, Z.H.; Hse, C.Y. Density analysis of stem, knot and branch of Pinus taeda. China For. Prod. Ind. 2016, 43, 14–17. (In Chinese) [Google Scholar]

- As, N.; Goker, Y.; Dundar, T. Effects of knots on the physical and mechanical properties of Scots pine (Pinus sylvestris L.). Wood Res. 2006, 51, 51–58. [Google Scholar]

- Zhou, Y.; Sun, F.; Lü, J.; Li, X. Veneer drying quality comparison of six Eucalyptus species. Sci. Silvae Sin. 2014, 50, 104–108. (In Chinese) [Google Scholar] [CrossRef]

- Bengtsson, C. Variation of moisture induced movements in Norway spruce (Picea abies). Ann. For. Sci. 2001, 58, 568–581. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood Handbook-Wood as an Engineering Material; Forest Products Laboratory: Madison, WI, USA, 2010; pp. 1–46.

- Shelbourne, C.J.A. Cupressus and Other Conifers. In Tree Breeding and Genetics in New Zealand; Shelbourne, C.J.A., Carson, M., Eds.; Springer: Cham, Switzerland, 2019; pp. 93–96. [Google Scholar] [CrossRef]

- Gao, M.; Qi, D.; Mu, H.; Chen, J. A Transfer Residual Neural Network Based on ResNet-34 for Detection of Wood Knot Defects. Forests 2021, 12, 212. [Google Scholar] [CrossRef]

- Hălălișan, A.-F.; Dinulică, F.; Gurean, D.M.; Codrean, C.; Neykov, N.; Antov, P.; Bardarov, N. Wood Colour Variations of Quercus Species in Romania. Forests 2023, 14, 230. [Google Scholar] [CrossRef]

- Li, J. Ecological Properties of Wood: Wood as the Contributor to the Green Environment and Human Health. J. Northeast For. Univ. 2010, 38, 1–8. (In Chinese) [Google Scholar] [CrossRef]

- Budakci, M.; Ozcifci, A.; Cinar, H.; Sonmez, A. Effects of application methods and species of wood on color changes of varnishes. Afr. J. Biotechnol. 2009, 8, 5964–5970. [Google Scholar] [CrossRef]

- Rüther, P.; Jelle, B.P. Color changes of wood and wood-based materials due to natural and artificial weathering. Wood Mater. Sci. Eng. 2013, 8, 13–25. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar] [CrossRef]

- Li, P.; Li, F.T.; Fan, C.; Li, X.W.; Zhang, J.; Huang, M.L. Effects of plant diversity on soil organic carbon under different reconstructing patterns in low efficiency stands of Cupressus funebris in the hilly region of central Sichuan. Acta Ecol. Sin. 2015, 35, 2667–2675. [Google Scholar] [CrossRef]

- Zhang, Z.; Jin, G.; Chen, T.; Zhou, Z. Effects of CaO on the Clonal Growth and Root Adaptability of Cypress in Acidic Soils. Forests 2021, 12, 922. [Google Scholar] [CrossRef]

- Lyu, J.; Zhao, J.; Xie, J.; Li, X.; Chen, M. Distribution and composition analysis of essential oils extracted from different parts of Cupressus funebris and Juniperus chinensis. BioResources 2018, 13, 5778–5792. [Google Scholar] [CrossRef]

- Lyu, J.; Huang, W.; Chen, M.; Li, X.; Zhong, S.; Chen, S.; Xie, J. Analysis of tracheid morphological characteristics, annual rings width and latewood rate of Cupressus funebris in relation to climate factors. Wood Res. 2020, 65, 565–578. [Google Scholar] [CrossRef]

- Tang, J.; Yang, D. The macro-ecological variation of wood quality factors with Cupressus funebris Endl. in Sichuan. J. Sichuan Agric. Univ. 1993, 11, 138–144. (In Chinese) [Google Scholar] [CrossRef]

- Li, M.Y.; Chen, D.S.; Wang, X.Y.; Ren, H.Q. Nature of the Knot and Its Impact on Wood Properties. J. Northwest For. Univ. 2020, 35, 197–204. (In Chinese) [Google Scholar] [CrossRef]

- GB/T 1928–2009; General Requirements for Physical and Mechanical Tests of Wood. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- GB/T 1929–2009; Method of Sample Logs Sawing and Test Specimens Selection for Physical and Mechanical Tests of Wood. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- GB/T 1932–2009; Method for Determination of the Shrinkage of Wood. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- GB/T 1933–2009; Method for Determination of the Density of Wood. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- GB/T 1934.2–2009; Method for determination of the swelling of wood. National Standard of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Zhao, L.; Qiu, X. Study on the variation of physical and mechanical properties of Chinese fir seedling forest in different stand ages. J. Anhui Agric. Univ. 2021, 48, 726–732. (In Chinese) [Google Scholar] [CrossRef]

- Pliura, A.; Yu, Q.; Zhang, S.Y.; MacKay, J.; Perinet, P.; Bousquet, J. Variation in Wood Density and Shrinkage and Their Relationship to Growth of Selected Young Poplar Hybrid Crosses. For. Sci. 2005, 51, 472–482. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Zhong, Y. Structure-property relationship of wood in East-Liaoning oak. Wood Sci. Technol. 1992, 51, 139–149. [Google Scholar] [CrossRef]

- Zhou, F.; Fu, Z.; Gao, X.; Zhou, Y.; Jiang, J. Within-tree variation of physical properties of Acacia melanoxylon wood. Chin. J. Wood Sci. Technol. 2021, 35, 30–36. (In Chinese) [Google Scholar] [CrossRef]

- Duan, X. Wood Color Control Technology; China Building Materials Industry Press: Beijing, China, 2002; pp. 45–47. (In Chinese) [Google Scholar]

- Evans, J.D. Straightforward Statistics for the Behavioral Sciences; Thomson Brooks/Cole Publishing Co.: Three Lakes, WI, USA, 1996. [Google Scholar]

| Knots Type | Regression Equation of Basic Wood Density (X) and Air-Dry Wood Density (Y) | Regression Equation of Basic Wood Density (X) and Oven-Dry Wood Density (Y) | Regression Equation of Air-Dry Wood Density (X) and Oven-Dry Wood Density (Y) |

|---|---|---|---|

| Live knots | Y = 0.206 + 0.799X R2 = 0.557 ** (p < 0.01) | Y = 0.046 + 1.025X R2 = 0.884 ** (p < 0.01) | Y = 0.057 + 0.844X R2 = 0.675 ** (p < 0.01) |

| Dead knots | Y = 0.437 + 0.385X R2 = 0.184 * (p < 0.05) | Y = 0.084 + 0.967X R2 = 0.759 ** (p < 0.01) | Y = 0.185 + 0.646X R2 = 0.273 ** (p < 0.01) |

| Clear wood | Y = 0.196 + 0.834X R2 = 0.672 ** (p < 0.01) | Y = 0.003 + 1.098X R2 = 0.942 ** (p < 0.01) | Y = 0.181 + 0.621X R2 = 0.685 ** (p < 0.01) |

| Properties Type | Knots Type | Number of Samples | Mean Value | Standard Deviation | Standard Error | Coefficient of Variation | Accuracy Index |

|---|---|---|---|---|---|---|---|

| Air-dry volumetric wood shrinkage ratio | Live knots | 30 | 4.33 | 2.08 | 0.38 | 22.14% | 18.49% |

| Dead knots | 30 | 5.89 | 1.38 | 0.25 | 15.38% | 8.36% | |

| Clear wood | 30 | 4.03 | 1.25 | 0.23 | 16.65% | 10.32% | |

| Oven-dry volumetric wood shrinkage ratio | Live knots | 30 | 9.50 | 2.90 | 0.53 | 18.33% | 11.42% |

| Dead knots | 30 | 11.22 | 2.84 | 0.52 | 14.24% | 9.05% | |

| Clear wood | 30 | 9.05 | 1.75 | 0.32 | 13.54% | 6.64% | |

| Air-dry volumetric wood swelling ratio | Live knots | 30 | 5.74 | 2.98 | 0.54 | 21.90% | 18.58% |

| Dead knots | 30 | 6.20 | 3.46 | 0.63 | 19.05% | 19.95% | |

| Clear wood | 30 | 5.68 | 2.00 | 0.37 | 19.97% | 12.61% | |

| Oven-dry volumetric wood swelling ratio | Live knots | 30 | 10.45 | 3.52 | 0.64 | 18.72% | 12.42% |

| Dead knots | 30 | 12.79 | 3.70 | 0.68 | 14.89% | 10.36% | |

| Clear wood | 30 | 10.18 | 2.16 | 0.39 | 14.53% | 7.38% |

| Properties Type | Live Knots and Clear Wood | Live Knots and Dead Knots | Dead Knots and Clear Wood |

|---|---|---|---|

| Air-dry volumetric wood shrinkage ratio | −0.695 | −4.102 ** | 4.602 ** |

| Oven-dry volumetric wood shrinkage ratio | −0.581 | −2.702 ** | 2.698 ** |

| Air-dry volumetric wood swelling ratio | −0.059 | −0.362 | 0.36 |

| Oven-dry volumetric wood swelling ratio | −0.487 | −2.660 * | 2.701 ** |

| Type of Wood | Number of Samples | Wood Color Parameters | Mean Value | Standard Deviation | Standard Error | Coefficient of Variation | Accuracy Index |

|---|---|---|---|---|---|---|---|

| Live knots | 30 | L* | 55.29 | 7.76 | 1.74 | 14.03% | 6.15% |

| a* | 10.30 | 1.24 | 0.28 | 12.02% | 5.27% | ||

| b* | 21.58 | 1.69 | 0.38 | 7.83% | 3.43% | ||

| Dead knots | 30 | L* | 49.17 | 6.70 | 1.34 | 13.63% | 5.34% |

| a* | 9.60 | 1.19 | 0.24 | 12.40% | 4.86% | ||

| b* | 18.10 | 2.90 | 0.58 | 16.04% | 6.29% | ||

| Clear wood | 30 | L* | 73.83 | 5.52 | 1.23 | 7.47% | 3.27% |

| a* | 7.70 | 0.75 | 0.17 | 9.74% | 4.27% | ||

| b* | 24.99 | 3.20 | 0.72 | 12.80% | 5.61% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, J.; Qu, H.; Chen, M. Influence of Wood Knots of Chinese Weeping Cypress on Selected Physical Properties. Forests 2023, 14, 1148. https://doi.org/10.3390/f14061148

Lyu J, Qu H, Chen M. Influence of Wood Knots of Chinese Weeping Cypress on Selected Physical Properties. Forests. 2023; 14(6):1148. https://doi.org/10.3390/f14061148

Chicago/Turabian StyleLyu, Jianhua, Hongyue Qu, and Ming Chen. 2023. "Influence of Wood Knots of Chinese Weeping Cypress on Selected Physical Properties" Forests 14, no. 6: 1148. https://doi.org/10.3390/f14061148

APA StyleLyu, J., Qu, H., & Chen, M. (2023). Influence of Wood Knots of Chinese Weeping Cypress on Selected Physical Properties. Forests, 14(6), 1148. https://doi.org/10.3390/f14061148