Moisture Content of Fresh Scots Pine Wood in Areas near Damage Caused by Harvester Head Feed Rollers

Abstract

:1. Introduction

- (I)

- Investigate the effect of the harvester head feed rollers’ spikes on the moisture content near the damaged regions of Scots pine (Pinus sylvestris L.);

- (II)

- Examine if the distance from the base of the log and bark thickness have an impact on the depth of the damage and the moisture content in damaged zone.

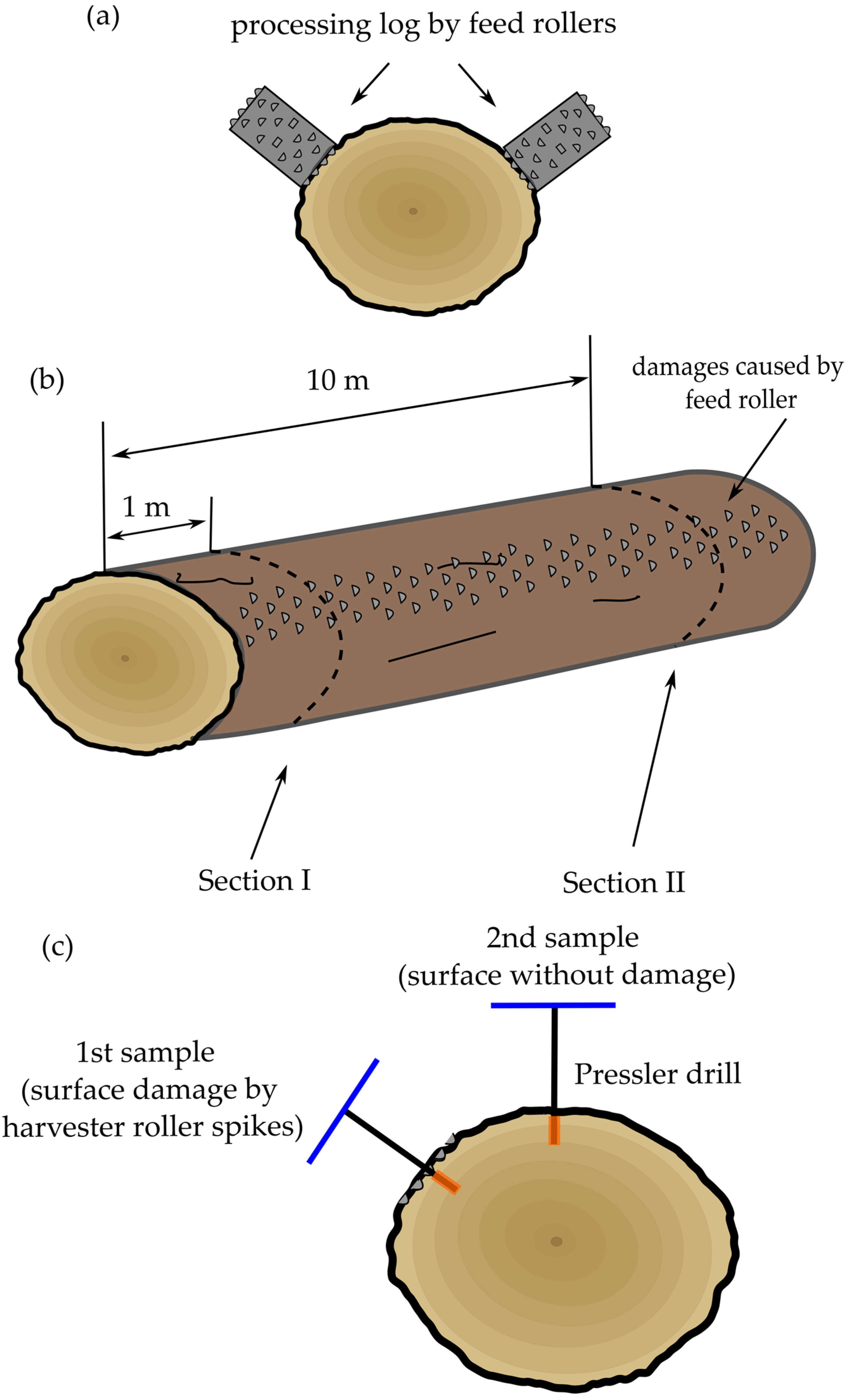

2. Materials and Methods

2.1. Study Design

2.2. Measurement of the Properties of the Wood

2.3. Statistical Analyses

3. Results and Discussion

3.1. Mean Absolute Moisture Content

3.2. Bark Thickness and Damage Depth

3.3. Absolute Moisture Content for Each Section

3.4. Possible Consequences for the Quality of Wood

3.5. Perspectives of Future Studies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spinelli, R.; Lombardini, C.; Magagnotti, N. The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fenn. 2014, 48, 1003. [Google Scholar] [CrossRef] [Green Version]

- Jiroušek, R.; Klvač, R.; Skoupý, A. Productivity and costs of the mechanised cut-to-length wood harvesting system in clear-felling operations. J. For. Sci. 2007, 53, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Petranovic, Z.; Vujanovic, M.; Duic, N. Towards a more sustainable transport sector by numerically simulating fuel spray and pollutant formation in diesel engines. J. Clean. Prod. 2015, 88, 272–279. [Google Scholar] [CrossRef]

- Haavikko, H.; Kärhä, K.; Poikela, A.; Korvenranta, M.; Palander, T. Fuel Consumption, Greenhouse Gas Emissions, and Energy Efficiency of Wood-Harve sting Operations: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2022, 43, 79–97. [Google Scholar]

- Latterini, F.; Mederski, P.S.; Jaeger, D.; Venanzi, R.; Tavankar, F.; Picchio, R. The Influence of Various Silvicultural Treatments and Forest Operations on Tree Species Biodiversity. Curr. For. Rep. 2023, 9, 59–71. [Google Scholar] [CrossRef]

- Labelle, E.R.; Jaeger, D. Soil compaction caused by cut-to-length forest operations and possible short-term natural rehabilitation of soil density. Soil Sci. Soc. Am. J. 2011, 75, 2314–2329. [Google Scholar] [CrossRef] [Green Version]

- Picchio, R.; Mederski, P.S.; Tavankar, F. How and How Much, Do Harvesting Activities Affect Forest Soil, Regeneration and Stands? Curr. For. Rep. 2020, 6, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Britto, P.C.; Jaeger, D.; Hoffmann, S.; Robert, R.C.G.; Vibrans, A.C.; Fantini, A.C. Multiyear post harvesting impact assessment in neotropical secondary Atlantic Forest. Eur. J. For. Res. 2022, 141, 665–681. [Google Scholar] [CrossRef]

- Britto, P.C.; Jaeger, D.; Hoffmann, S.; Robert, R.C.G.; Vibrans, A.C.; Fantini, A.C. Impact assessment of timber harvesting operations for enhancing sustainable management in a secondary Atlantic Forest. Sustainability 2019, 11, 6272. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, D.A.; Piazza, G.; Fantini, A.C.; Vibrans, A.C. Forest management in a secondary Atlantic Rainforest: Assessing the harvest damage. Adv. For. Sci. 2018, 4, 187–193. [Google Scholar]

- Prinz, R.; Spinelli, R.; Magagnotti, N.; Routa, J.; Asikainen, A. Modifying the settings of CTL timber harvesting machines to reduce fuel consumption and CO2 emissions. J. Clean. Prod. 2018, 197, 208–217. [Google Scholar] [CrossRef]

- Freedonia. World Forestry Equipment. Ind. Study 2015, 3270, 371. [Google Scholar]

- Mederski, P.S.; Schweier, J.; Đuka, A.; Tsioras, P.; Bont, L.G.; Bembenek, M. Mechanised Harvesting of Broadleaved Tree Species in Europe. Curr. For. Rep. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Asikainen, A.; Anttila, P.; Verkerk, H.; Diaz, O.; Roser, D. Development of forest machinery and labour in the EU in 2010–2030. In Proceedings of the 44th International Symposium Forestry Mechanisation: “Pushing the Boundaries with Research and Innovation in Forest Engineering”, Graz, Australia, 9–13 October 2011; p. 8. [Google Scholar]

- Bodył, M. Rozmiar Pozyskania Maszynowego w Polsce. Drwal 2019, 3, 5–9. [Google Scholar]

- Bodył, M. Rozmiar Pozyskania Maszynowego w Polsce. Drwal 2022, 4, 24–30. [Google Scholar]

- Nuutinen, Y.; Väätäinen, K.; Asikainen, A.; Prinz, R.; Heinonen, J. Operational Efficiency and Damage to Sawlogs by Feed Rollers of the Harvester Head. Silva Fenn. 2010, 44, 121–139. [Google Scholar] [CrossRef] [Green Version]

- Sowa, M.J.; Gielarowiec, K.; Gaj-Gielarowiec, D. Characteristics and development of the construction of logging harvester heads. For. Lett. 2013, 105, 57–76. (In Polish) [Google Scholar]

- Kulak, D. Damage to Harvested Pine Assortments by using Harvester. In Nowoczesne Technologie i Inżynieria w Zrównoważonym Użytkowaniu Lasu; Bieniek, J., Klamerus-Iwan, A., Eds.; Wydawnictwo Uniwersytetu Rolniczego w Krakowie: Kraków, Poland, 2020. (In Polish) [Google Scholar]

- Węgrzyn, A.; Leszczyński, N. Feed Rollers of Wood Harvesting Heads. Tech. Rol. Ogrod. Leśna 2014, 3, 6–8. (In Polish) [Google Scholar]

- Zimelis, A.; Kaleja, S.; Spalva, G.; Lazdins, A. Impact of Feed Rollers on Productivity and Fuel Consumption. In Proceedings of the Engineering for Rural Development, Jeglava, Latvia, 24–26 May 2017; pp. 756–760. [Google Scholar]

- Liiri, H.; Asikainen, A.; Erikkilä, A.; Kaipainen, H.; Aalto, J. Reducing of unwanted barking in single grip harvester cutting. In Puuenergian Teknologiaohjelman Vuosikirja, Proceedings of the VTT Symposium 231; Alakangas, E., Holviala, N., Eds.; Faculty of Forestry, University of Joensuu: Joensuu, Finland, 2004; pp. 167–184. (In Finnish) [Google Scholar]

- Granlund, P.; Hallonborg, U. Harvester impact on timber value: Part 1 Timber-damage trials, Latest harvesters are gentle on the wood. Skogforsk Result. 2001, 8, 4. (In Swedish) [Google Scholar]

- Karaszewski, Z.; Łacka, A.; Mederski, P.S.; Bembenek, M. Impact of Season and Harvester Engine RPM on Pine Wood Damage from Feed Roller Spikes. Croat. J. For. Eng. 2018, 39, 183–191. [Google Scholar]

- Karaszewski, Z.; Łacka, A.; Mederski, P.S.; Noskowiak, A.; Bembenek, M. Damage Caused by Harvester Head Feed Rollers to Alder, Pine and Spruce. Drewno 2016, 59, 77–88. [Google Scholar] [CrossRef]

- Wang, J.; LeDoux, C.B.; Vanderberg, M.; McNeel, J. Log damage and value loss associated with two ground-based harvesting systems in Central Appalachia. Int. J. For. Eng. 2004, 15, 61–69. [Google Scholar] [CrossRef]

- Kärkkäinen, M. Basic Knowledge of Timber Science; Metsälehti Kustannus Oy: Helsinki, Finland, 2003; p. 451. (In Finnish) [Google Scholar]

- Lee, K.; Gibbs, J.N. An Investigation of the Influence of Harvesting Practice on the Development of Blue-Stain in Corsican Pine Logs. For. Int. J. For. Res. 1996, 69, 137–141. [Google Scholar] [CrossRef]

- Szewczyk, G.; Jankowiak, R.; Mitka, B.; Bożek, P.; Bilański, P.; Kulak, D.; Barycza, A.; Kunys, G. Development of Blue Stain in Mechanically Harvested Scots Pine (Pinus sylvestris) Logs during Storage. Can. J. For. Res. 2020, 50, 42–50. [Google Scholar] [CrossRef]

- Labelle, E.R.; Breinig, L.; Spinelli, R. Extent and Severity of Damages Caused to Spruce Roundwood by Harvesting Heads in Standard versus Debarking Configurations. Eur. J. For. Res. 2019, 138, 151–163. [Google Scholar] [CrossRef]

- Kirisits, T. Fungal associates of European bark beetles with special emphasis on the ophiostomatoid fungi. In Bark and Wood Boring Insects in Living Trees in Europe, A Synthesis; Lieutier, F., Day, K.R., Battisti, A., Grégoire, J.C., Evans, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 185–223. [Google Scholar]

- Jankowiak, R.; Szewczyk, G.; Bilański, P.; Jazłowiecka, D.; Harabin, B.; Linnakoski, R. Blue-stain fungi isolated from freshly felled Scots pine logs in Poland, including Leptographium sosnaicola sp. nov. For. Pathol. 2021, 51, e12672. [Google Scholar] [CrossRef]

- Humar, M.; Vek, V.; Bučar, B. Properties of blue-stained wood. Drv. Ind. 2008, 59, 75–79. [Google Scholar]

- Friedl, K. Blue Stain on Pinewood—Damage Quantification and Impact on the Storage Period; FORMEC: Forli, Italy, 2004; pp. 1–8. [Google Scholar]

- Millers, M. The proportion of heartwood in conifer (Pinus sylvestris L., Picea abies H. Karst.) trunks and its influence on trunk wood moisture. J. For. Sci. 2013, 59, 295–300. [Google Scholar] [CrossRef] [Green Version]

- Tomczak, K.; Tomczak, A.; Jelonek, T. Effect of Natural Drying Methods on Moisture Content and Mass Change of Scots Pine Roundwood. Forests 2020, 11, 668. [Google Scholar] [CrossRef]

- Wilms, F.; Duppel, N.; Cremer, T.; Berendt, F. Bark Thickness and Heights of the Bark Transition Area of Scots Pine. Forests 2021, 12, 1386. [Google Scholar] [CrossRef]

- Pérez-Harguindeguy, N.; Díaz, S.; Garnier, E.; Lavorel, S.; Poorter, H.; Jaureguiberry, P.; Bret-Harte, M.S.; Cornwell, W.K.; Craine, J.M.; Gurvich, D.E.; et al. New Handbook for Standardised Measurement of Plant Functional Traits Worldwide. Aust. J. Bot. 2016, 61, 167–234. [Google Scholar] [CrossRef]

- EN 13183-1:2002; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. European Committee for Standardization: Brussels, Belgium, 2002.

- Tomczak, K.; Tomczak, A.; Naskrent, B.; Jelonek, T. The Radial Gradient of Moisture Content of Silver Birch Wood in Different Seasons. Silva Fenn. 2021, 55, 10545. [Google Scholar] [CrossRef]

- Tomczak, A.; Tomczak, K.; Rutkowski, N.S.K.; Wenda, M.; Jelonek, T. The Gradient of Wood Moisture Within-Stem of Sessile Oak (Quercus Petraea (Matt.) Liebl.) in Summer. Wood Res. 2018, 63, 809–820. [Google Scholar]

- National State Forests, Poland. Order No. 51/2019 of the Director General of the State Forests Dated 30 September 2019 on the Introduction of Technical Conditions in the Turnover of Wood Raw Material in the State Forests in Poland (Mark: ZM.800.8.2019). Available online: https://drewno.zilp.lasy.gov.pl/drewno/Normy/zarzadzenie_nr_51_z_30_wrzesnia_2019_r._w_sprawie_warunkow_technicznych.pdf (accessed on 16 February 2023). (In Polish)

- Millers, M.; Magaznieks, J. Scots Pine (Pinus Sylvestris [L.]) Stem Wood and Bark Moisture and Density Influencing Factors. In Proceedings of the Annual 18th International, Scientific Conference Proceeding, Research for Rural Development, Jelgava, Latvia, 16–18 May 2012; Latvia University of Agriculture: Jelgava, Latvia, 2012; pp. 91–97. [Google Scholar]

- Pratt, R.B.; Jacobsen, A.L.; Ewers, F.W.; Davis, S.D. Relationships among Xylem Transport, Biomechanics and Storage in Stems and Roots of Nine (Rhamnaceae) Species of the California Chaparral. New Phytol. 2007, 174, 787–798. [Google Scholar] [CrossRef]

- Makela, M.; Pennanen, O. Damage to sawlogs during processing and storage: The effect of different delimbing methods. Metsatehon Tied. 1980, 361, 14. [Google Scholar]

- Millers, M.; Magaznieks, J.; Gzibovska, Z. Blue Stain Development of Scots Pine (Pinus Sylvestris L.) Roundwood and Its Influencing Factors. In Proceedings of the Research for Rural Development, Jelgava, Latvia, 17–19 May 2017; Latvia University of Agriculture: Jelgava, Latvia, 2017; Volume 1, pp. 120–126. [Google Scholar]

- Erber, G.; Huber, C.; Stampfer, K. To Split or Not to Split: Feasibility of Pre-Storage Splitting of Large Poplar (Populus spp. L.) Fuelwood Logs. Fuel 2018, 220, 817–825. [Google Scholar] [CrossRef]

- Defo, M.; Brunette, G. A Log Drying Model and Its Application to the Simulation of the Impact of Bark Loss. For. Prod. J. 2006, 56, 71. [Google Scholar]

| Type of Wood | Mean | SD | Min | Max | Q25 | Median | Q75 |

|---|---|---|---|---|---|---|---|

| DW | 71.17 | 26.67 | 29.53 | 141.71 | 51.40 | 63.91 | 87.56 |

| UDW | 84.10 | 30.85 | 42.86 | 161.67 | 58.87 | 80.00 | 102.84 |

| Mean | 77.63 | 29.47 | 29.53 | 161.67 | 53.52 | 70.77 | 96.18 |

| Bark Thickness [mm] | |||||||

|---|---|---|---|---|---|---|---|

| Section | Mean | SD | Min | Max | Q25 | Median | Q75 |

| I | 11.2 | 5.7 | 5.1 | 30.5 | 7.7 | 9.1 | 12.2 |

| II | 1.8 | 1.4 | 0.7 | 8.0 | 1.0 | 1.3 | 1.8 |

| All | 6.5 | 6.3 | 0.7 | 30.5 | 1.4 | 5.8 | 9.1 |

| Depth of damage [mm] | |||||||

| I | 3.9 | 2.3 | 0.7 | 12.2 | 2.5 | 3.6 | 4.9 |

| II | 3.8 | 1.9 | 1.3 | 10.6 | 2.7 | 3.4 | 4.3 |

| All | 3.9 | 2.1 | 0.7 | 12.2 | 2.5 | 3.5 | 4.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomczak, K.; Latterini, F.; Smarul, N.; Stanula, Z.; Jelonek, T.; Kuźmiński, R.; Łakomy, P.; Tomczak, A. Moisture Content of Fresh Scots Pine Wood in Areas near Damage Caused by Harvester Head Feed Rollers. Forests 2023, 14, 1276. https://doi.org/10.3390/f14061276

Tomczak K, Latterini F, Smarul N, Stanula Z, Jelonek T, Kuźmiński R, Łakomy P, Tomczak A. Moisture Content of Fresh Scots Pine Wood in Areas near Damage Caused by Harvester Head Feed Rollers. Forests. 2023; 14(6):1276. https://doi.org/10.3390/f14061276

Chicago/Turabian StyleTomczak, Karol, Francesco Latterini, Natalia Smarul, Zygmunt Stanula, Tomasz Jelonek, Robert Kuźmiński, Piotr Łakomy, and Arkadiusz Tomczak. 2023. "Moisture Content of Fresh Scots Pine Wood in Areas near Damage Caused by Harvester Head Feed Rollers" Forests 14, no. 6: 1276. https://doi.org/10.3390/f14061276