Abstract

Acoustics is a field with significant application in wood science and technology for the classification and grading, through non-destructive tests, of a large variety of products from standing trees to building structural elements and musical instruments. In this review article the following aspects are treated: (1) The theoretical background related to acoustical characterization of wood as an orthotropic material. We refer to the wave propagation in anisotropic media, to the wood anatomic structure and propagation phenomena, to the velocity of ultrasonic waves and the elastic constants of an orthotropic solid. The acoustic methods for the determination of the elastic constants of wood range from the low frequency domain to the ultrasonic domain using direct contact techniques or ultrasonic spectroscopy. (2) The acoustic and ultrasonic methods for quality assessment of trees, logs, lumber and structural timber products. Scattering-based techniques and ultrasonic tomography are used for quality assessment of standing trees and green logs. The methods are based on scanning stress waves using dry-point-contact ultrasound or air-coupled ultrasound and are discussed for quality assessment of structural composite timber products and for delamination detection in wood-based composite boards. (3) The high-power ultrasound as a field with important potential for industrial applications such as wood drying and other applications. (4) The methods for the characterization of acoustical properties of the wood species used for musical instrument manufacturing, wood anisotropy, the quality of wood for musical instruments and the factors of influence related to the environmental conditions, the natural aging of wood and the effects of long-term loading by static or dynamic regimes on wood properties. Today, the acoustics of wood is a branch of wood science with huge applications in industry.

Keywords:

acoustics; solid wood; elastic constants; ultrasound; wood products; trees; logs; lumber; LVL; glulam 1. Introduction

Acoustics is a field with significant application in wood science and technology for the classification and grading of a large variety of products, from standing trees to building structural elements and musical instruments, using non-destructive tests [1,2,3]. The acoustics of wood employs mechanical waves which are sensitive to key parameters of this material, such as the density, the grain angle, the annual ring curvature, the elastic moduli, the moisture content, the degradation by pathogenic factors, etc. The experimental data collected with different acoustic methods are difficult to interpret correctly because of numerous factors acting on the phenomena related to the propagation of acoustic waves in solid wood or wood-based composites. Therefore, there is a need to have a good understanding of phenomena related to the wave propagation in media of various complexity, such as the orthotropic media which are described in the section: Theoretical Aspects Related to Acoustical Characterization of Wood. The following sections discuss acoustic and ultrasonic methods for quality assessment of trees, logs, lumber and structural timber products. Special attention is given to methods for the characterization of acoustical properties of wood species used for musical instrument manufacturing. High power ultrasound is a field with important potential for industrial applications to wood drying, among others.

2. Theoretical Aspects Related to the Acoustical Characterization of Wood

In this section, our discussion is focused on theoretical aspects related to the characterization of the mechanical constants of wood. Currently, the engineering constants which characterize solids are Young’s modulus E, the shear modulus G and the Poisson coefficient ν. The number of these engineering constants for solids depends on their nature, which could be isotropic or anisotropic. In what follows, we will discuss the elastic symmetry of various media and the acoustical method for their characterization.

2.1. Elastic Symmetry of Propagation Media

Elastic waves can propagate in solid media of various symmetries and structural complexity. The simplest case of elastic symmetry is that of an isotropic solid. For solid wood and for wood-based composites, orthotropic and transverse isotropic symmetries are most frequently observed. For simplicity, we will start by analyzing an isotropic solid. The solids are assumed to be homogeneous.

2.1.1. Isotropic Solid

The simplest elastic symmetry is that of an isotropic solid, with only three independent constants, E, G and the Poisson ratio ν. The relationships between those constants are shown as follows: , where E is Young’s modulus (which is the ratio of longitudinal stress to longitudinal strain in the same direction of a rod), G is the shear modulus (which is the ratio of the deviatoric stress to the deviatoric strain), ν is the Poisson’s ratio (the ratio of the transverse contraction of a sample to its longitudinal extension, under tensile stress).

The velocity of propagation of a compressional longitudinal wave V in an infinite isotropic solid, of density ρ and initially assumed to be stress-free, is related to the elastic constant E by Vlongitudinal wave = .

The velocity of propagation of a shear wave V in an infinite isotropic solid, of density ρ and initially assumed to be stress-free, is related to the elastic constant G, or the shear modulus, by Vshear wave = .

2.1.2. Anisotropic Solids

The elastic properties of anisotropic solids can be defined by the generalized Hooke’s law relating the volume average of stress [σij] to the volume average of strain [εkl] by the elastic constants [Cijkl] in the form

or

where [Cijkl] are termed elastic stiffnesses and [Sijkl] the elastic compliances, and the indices i, j, k, l correspond to 1, 2, 3, 4.

[σij] = [Cijkl] [εkl]

[εkl] = [Sijkl] [σij]

Stiffnesses and compliances are fourth-rank tensors. In his book, Hearmon [4] noted that “the use of the symbols for compliances [S] and [C] for stiffness is now almost invariably followed.” This is the notation that will be used hereafter. [Cijkl] could be written, following the general convention on matrix notation, as [Cij], in terms of two-suffix stiffnesses, or symbolically as [C]. Similarly, [Sijkl] could be written as [Sij] or [S]. Stiffnesses and compliances are fourth-rank tensors.

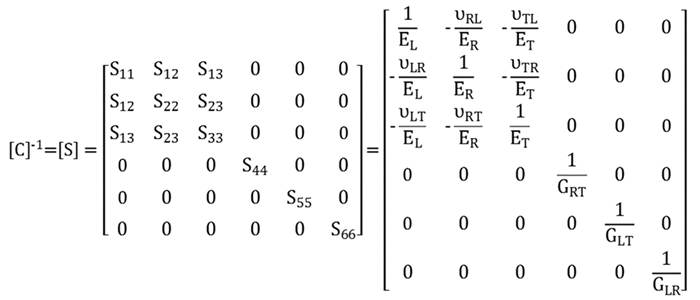

In many applications it is much simpler to write Equations (1) and (2) in the following condensed form: [C] = [S]−1 and [S] = [C]−1. The engineering constants—Young’s moduli, shear moduli and Poisson ratios—are terms of a compliance matrix. A complete set of elastic constants of wood are given in [5].

Experimentally, the terms of the [C] matrix could be determined from ultrasonic measurements, whereas those of the [S] matrix could be determined from static tests. However, the engineering constants, namely Young’s moduli E, shear moduli G and Poisson ratios can be determined by resonance frequency methods.

From Equation (1) it can be deduced that since strain is dimensionless the stiffnesses have the same dimensions as the stresses [the units used presently are Newtons per square meter (N/m2) or megapascals (MPa)]. As an example, let us take the case of spruce, for which C11 = 150 × 108 N/m2 = 15,000 MPa = 15 GPa.

For solids of different symmetries such as transverse isotropic, orthotropic, etc., the stiffness matrix can be turned into a compliance matrix, following a specific procedure [6,7,8].

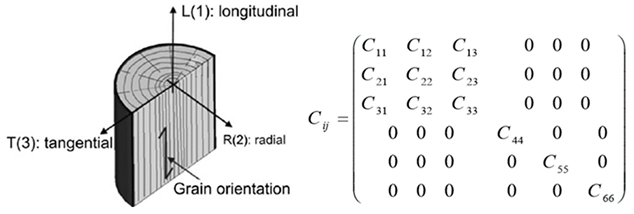

The origin of anisotropy, perceived as the variation in material response with direction of the applied stress, lies in the preferred organization of the internal structure of the material. The structure might be, for example, the atomic array in monocrystals; the morphological texture in polycrystalline aggregates such as metals, rocks, sand, etc.; the orientation of fibers in composites, in wood and in human tissue; or the orientation of layers in laminated plastics, plywood, etc. One instance of complex elastic symmetry is that of an orthotropic solid, because constants are influenced by three mutually perpendicular planes of elastic symmetry. For example, in the case of wood (Table 1), we have three symmetry axes related to the natural directions of growth of a tree, which are L axial or longitudinal and radial and tangential R and T with respect to the annual rings. Compressional waves can propagate in direction L, R, T and shear waves can propagate in the LR, LT and RT planes. Therefore, we can determine six elastic constants. The coupling between compressional and shear waves is given by three other corresponding terms. In a more general way, we define the axes L, R and T as axis 1, axis 2, axis 3. The corresponding stiffness matrix [C] contains nine independent constants: six diagonal terms (C11, C22, C33, C44, C55, C66) and three off-diagonal terms (C12, C13, C23).

Table 1.

Relationships among the terms of stiffness matric [C], compliance matrix [S] and the engineering constants of a solid of orthotropic symmetry like the wood. The symmetry axes are 1,2,3 or L, R, T.

In the case of a plywood plate, we have in total five elastic constants such as C11 and C22 = C33 and C 55 = C 66 and C12 = C13 and C23. This is the case of a solid having transverse isotropy. It can be shown that transverse isotropy is a particular case of an orthotropic solid. For isotropic materials, we have only three elastic constants: C11 = C22 = C33; C44 = C55 = C66; and C12 = C13 = C23 if we refer to the previous notation for the most complex case of an orthotropic solid. In the most general case, a material may possess only an axis of symmetry in the sense that all directions at right angles to this axis are equivalent.

The physical significance of the compliances is as follows:

- -

- S11, S22, S33 relate an extensional stress to an extensional strain, both in the same direction. For the particular symmetry of solid wood this relation gives the Young’s moduli EL, ER, and ET.

- -

- S12, S13, S23 relate an extensional strain to a perpendicular extensional stress. In this way the six Poisson’s ratios can be calculated.

- -

- S44, S55, S66 relate a shear strain to a shear stress in the same plane, and are the inverse of the terms C44, C55, C66, corresponding to planes 23, 13, 12.

Experimentally, the terms of the matrix [C] can be determined with ultrasonic methods and the terms of matrix [S] can be determined by static tests or dynamic tests in the low frequency domain. Table 2 and Table 3 give the engineering parameters of solid wood determined by static tests:

Table 2.

Engineering parameters of solid wood determined by static tests [5].

Table 3.

Poisson ratios of solid wood: determined by static tests [5].

Note the large range of variation of wood density from 200 kg/m3 to 660 kg/m3. The anisotropy of wood species can be expressed by the ratio of constants as for instance EL/GRT, for balsa is 21 and for spruce is 440 and for oak is 58.5. Wood is a very anisotropic material.

Indeed, negative values of Poisson’s ratios or values greater than 1 may contradict our intuition if our main experience is in dealing with isotropic solids, but such data have been reported for composite materials [9], foam material [10], cellular materials [11], crystals [6], wood [12,13,14,15], cell walls [16] and wood-based composites [17]. Idealized two-dimensional honeycomb patterns of a transverse wood structure could produce a Poisson’s ratio ν RT in the range: −1 to +∞.

For a very wide range of European, American and tropical species, [18,19,20,21,22] deduced statistical regression models able to predict the terms of the compliance matrix as a function of density. These data may be used by modelers in finite element calculations or with non-destructively tested lumber when the elasticity moduli are required; see Table 4.

Table 4.

Coefficients matrix of simple correlation coefficients between acoustic parameters and structural parameters of the annual ring of resonance wood [23].

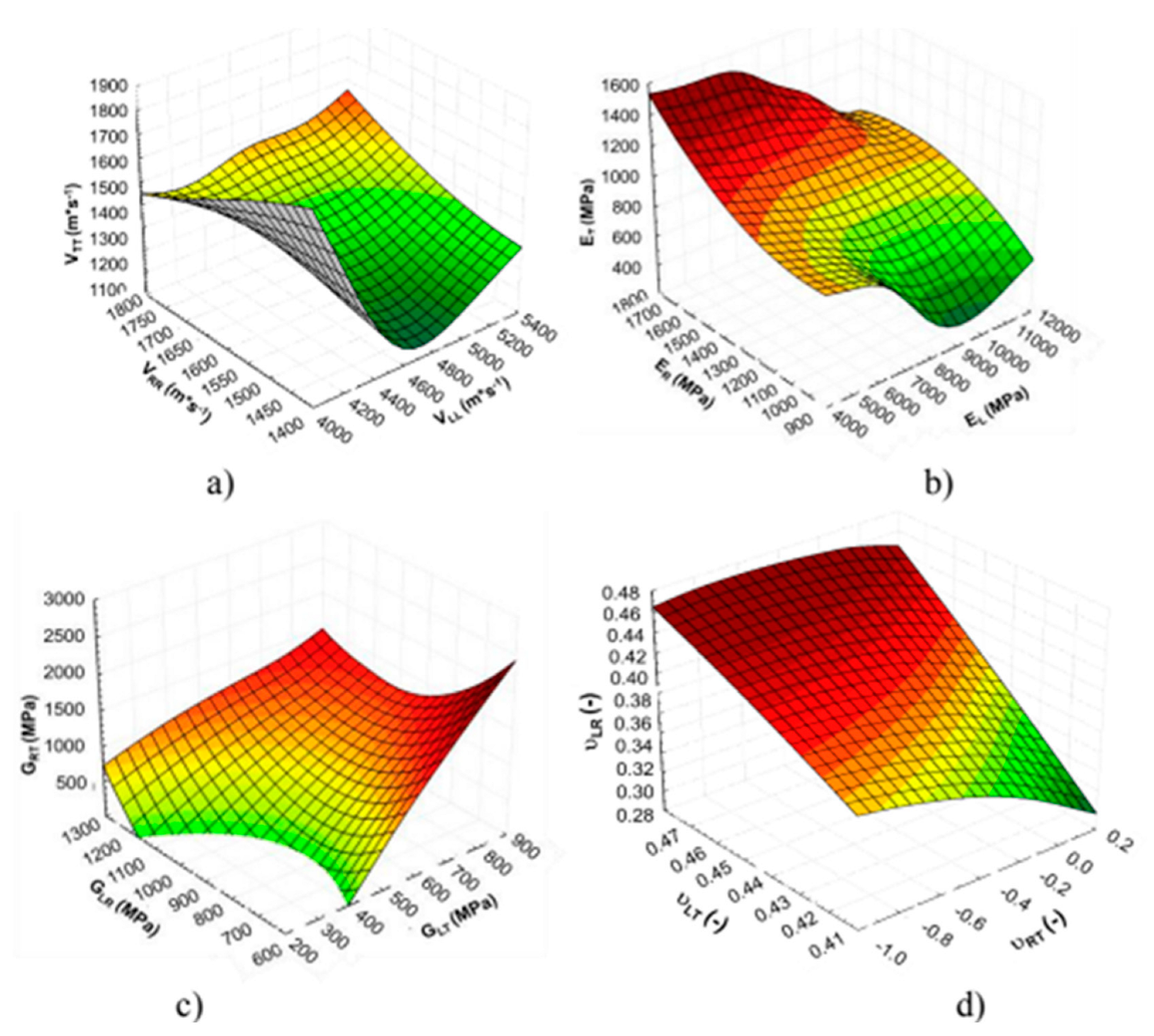

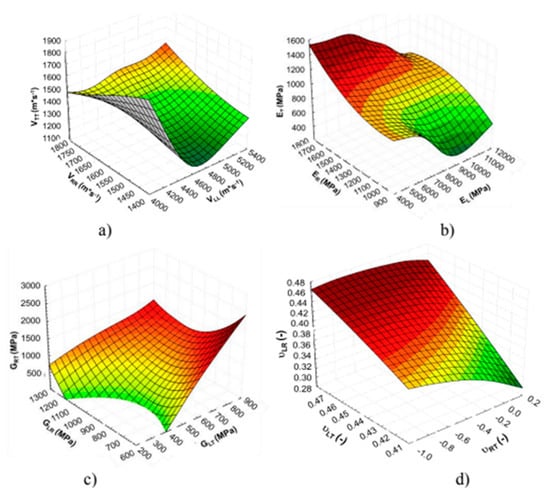

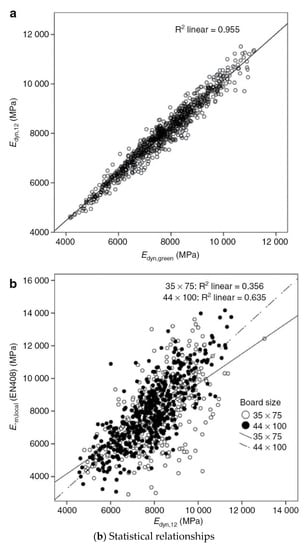

It is worth mentioning the correlation among the velocities and the engineering constants of wood as shown in Figure 1 for the resonance spruce for violins. The statistical correlations demonstrated once more that the acoustic wave propagation phenomena in wood are related to the microstructure of this material. An accurate estimation of the mechanical behavior of wood requires simultaneous views on structure and wave propagation phenomena. Wave velocities are affected by wood structure that acts as a filter. This interaction is highly revealing of the anisotropy of this material.

Figure 1.

Resonance spruce. Multiple correlations among the velocities of longitudinal waves, the moduli E and G and the Poisson ratios [22]. (a) The velocities VLL, VRR and VTT. (b) The Young’s moduli. (c) The shear moduli. (d) The Poisson ratios (r = 0.962 p < 0.001, see the red color). Lower coefficients are represented in green.

The highest simple correlation coefficient was between VLL and the width of the annual ring (r = −0.708). This means that high values of VLL are related to small and regular annual rings. VRR is very slightly correlated to the proportion of latewood (r = 0.210) as well as VTT, which increases slightly with the width of annual rings (r = 0.289) and with the width of latewood (r = 0.258). These correlation coefficients are not statistically significant.

Principal component analysis demonstrated that the variability of the resonance wood population studied is better explained by three variables, VLL and the Poisson ratios LT and RT. The explanation of the variability of wood density in the relatively low range of variation between 381 kg/m3 and 446 kg/m3 “is far from all the other measured physical and acoustical characteristics”. This needs some comment. The density is a scalar. The velocities are vectors, sensitive to wood structure and are able to explain better the variability of wood. Further research is needed to explain the effect of the density components and especially of the latewood density and proportion to the waves’ propagation phenomena.

However, we shall see further that in the large range of variation of the density there are significative correlations with the velocities of wood.

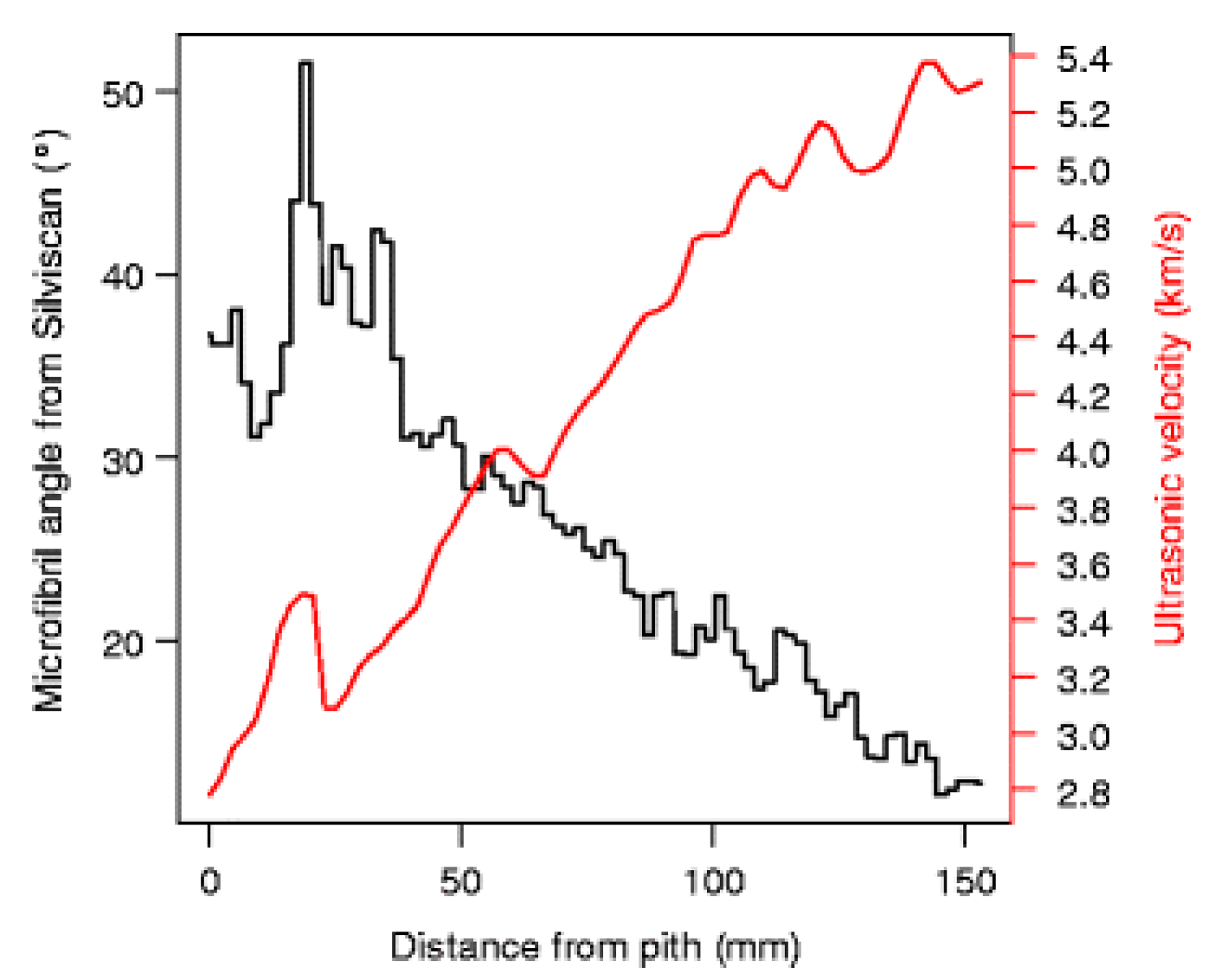

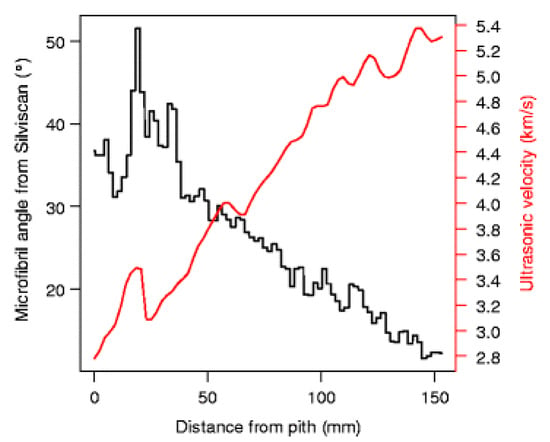

Another interesting aspect related to the quality of resonance wood is the low microfibril angle of about 5° [24]. This structural element contributes to the waves’ propagation in the L direction. The variation of ultrasonic velocity with microfibril angle was studied on a disk of Pinus radiata from the pith to the bark (Figure 2). In Pinus radiate, the value of the microfibril angle is between 5° and 35° and the ultrasonic velocity VLL is between 2800 m/s and 5400 m/s.

Figure 2.

Variation of microfibril angle, ultrasonic velocity versus the distance from the pith of a Pinus radiata disk (Figure 5, page 4 [25]).

Ultrasonic velocity in the L direction was correlated with microfibril angles and the correlation coefficient is significantly high, namely −0.86. This means that high values of ultrasonic velocity correspond to low values of microfibril angles. The correlation between the modulus of rigidity (noted MOE) and the ultrasonic velocity is 0.85. No correlation was established between the microfibril angle and the air dry density of wood of Pinus radiata.

2.2. Wave Propagation in Anisotropic Media

2.2.1. Wood Structure and Propagation Phenomena

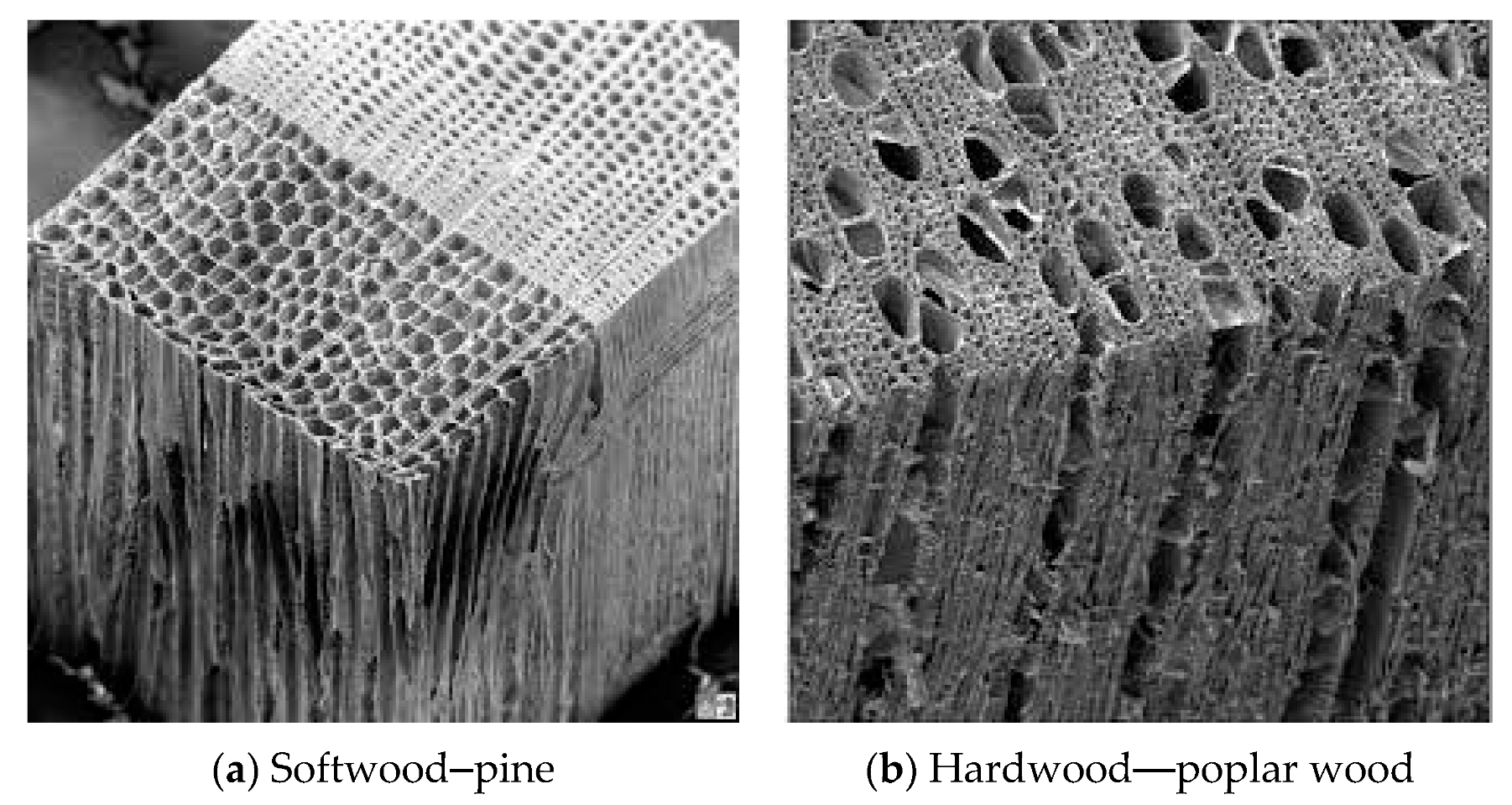

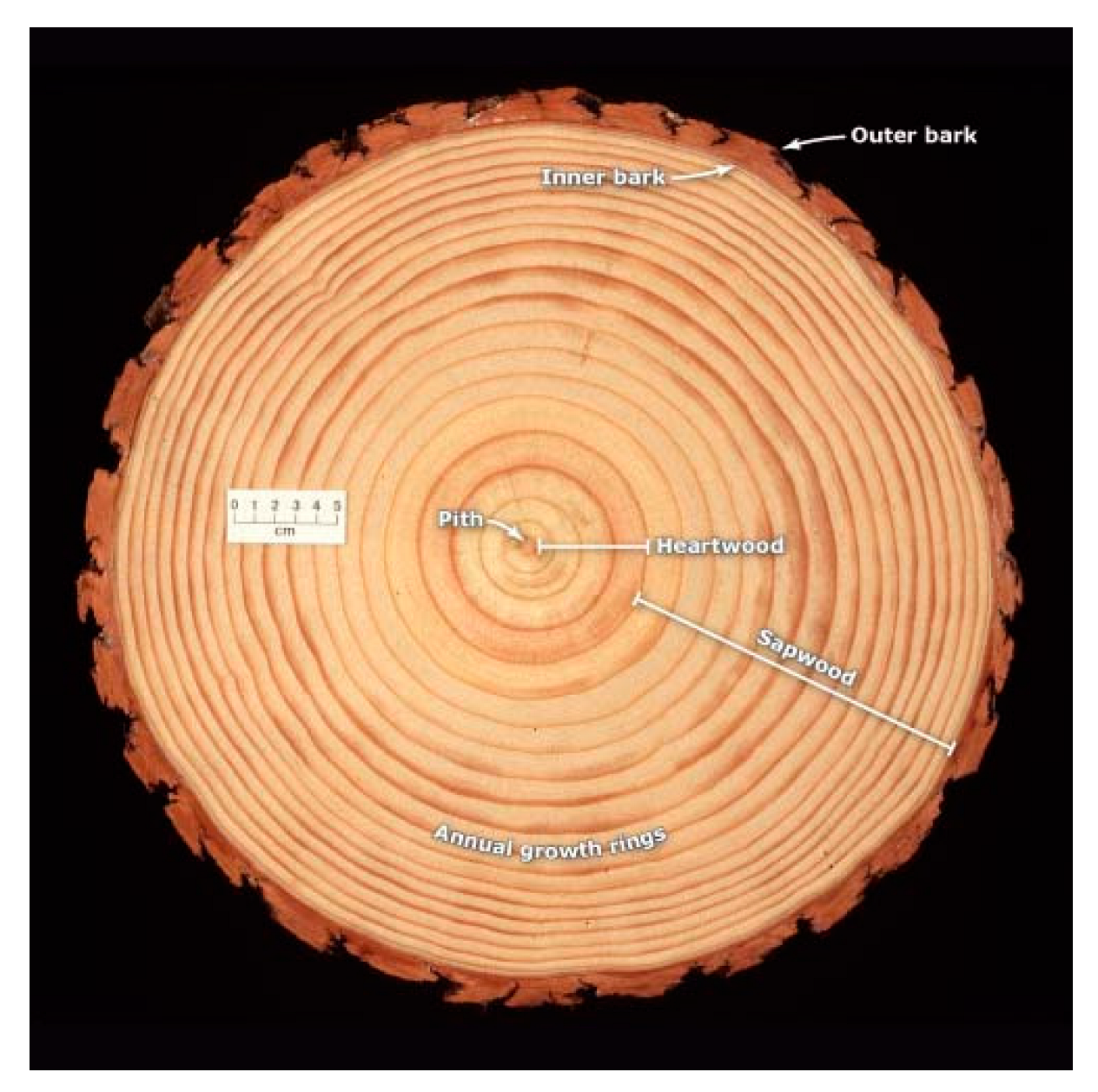

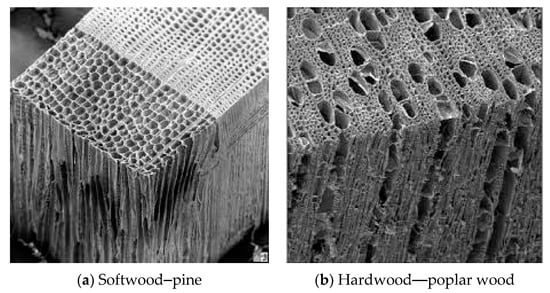

Let consider the fine structure of wood, as illustrated in Figure 3. As a first approximation wood can be considered to be made up of cellulosic tracheids or fibers oriented along the growing axis of the tree. These elements, in a simplified view are cylinders which are embedded in an amorphous lignin matrix.

Figure 3.

Fine structure of wood. Legend: (a) https://www.vcbio.science.ru.nl/public/Final-Images/PL_Final685z_201-250/PL0223_685zPinusWoodSEMTangentialRadialTransverse.jpg; (b) https://www.researchgate.net/profile/Ralf_Moeller/publication/40097978/figure/fig4/AS:669383294734347@1536604822282/Scanning-electron-microscopy-image-of-poplar-wood-In-the-upper-half-the-vessels-and.png (accessed on 5 May 2021).

From an acoustic point of view, wood structure can be considered as a rectangular system of cross ‘‘tubes’’ embedded in a matrix. It is interesting to note that in the longitudinal direction (L) the dissipation of acoustic energy takes place at the limit of the ‘‘tubes’’. Accordingly, the continuous and uniform structure of softwoods, built up by long anatomical elements, has low dissipation and provides high values for the acoustical constants. Two other aspects of microstructure could be considered: the annual ring layered structure and the difference between the R and T directions in the arrangement of cells. The fibers tend to be aligned in the R direction and randomly distributed in the T direction. This arrangement of anatomical elements could also have a significant influence on shear wave propagation and wave birefringence. The modulation of shear waves by the structure of wood must be understood in terms of both the propagation and polarization direction. The ultrasonic energy injected into a fibrous material couples into each fiber via several modes (longitudinal, transversal and circumferential). The physical properties of the cellular wall such as the density, the stiffness moduli, etc., and the shape and size of fibers or of other elements affect the transmitted ultrasonic field. Each structural element acts independently like an elementary resonator. The spatial distribution of velocities and frequencies that matched the natural fibers’ frequency could explain the acoustical behavior of wood, illustrated by its overall parameters. Wood material exhibits different length scales ranging from meters for trees and lumber and millimeters for rings as layered composites with homogeneous but anisotropic layers to micrometers for cells, rays etc., that are cellular solids with homogeneous cell walls that are fiber-reinforced laminates and to nanometers for cellulose crystals and amorphous lignin. These scales can match different acoustic wave lengths. At a 10−2 m scale, wood can be modeled as a locally orthotropic homogeneous solid. This hypothesis was used in the present discussion.

2.2.2. Type of Waves Propagation in an Anisotropic Solid

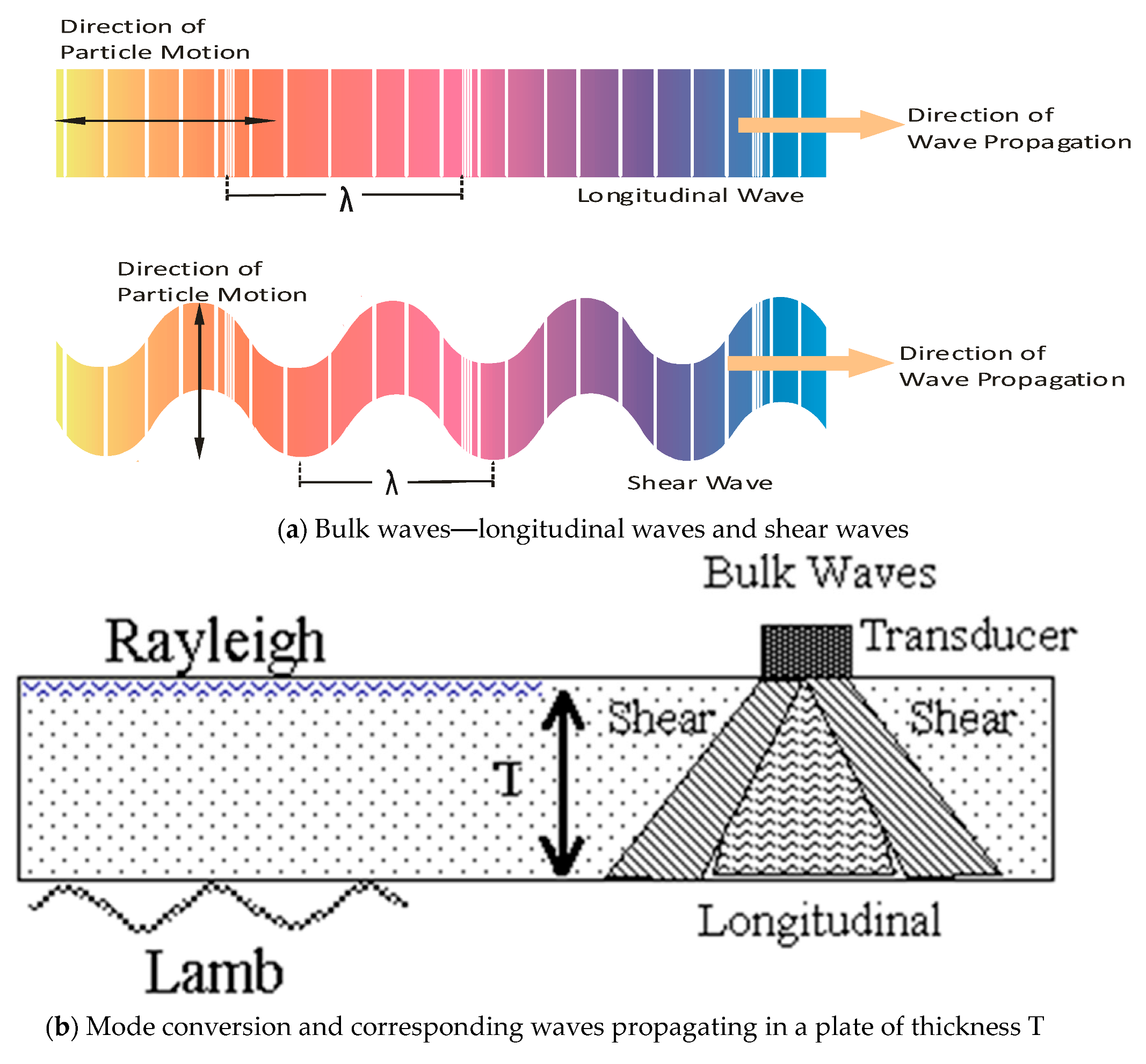

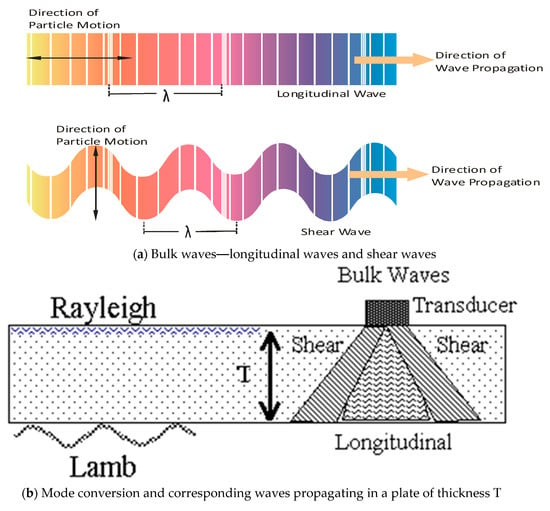

Three types of waves can propagate in solids: longitudinal waves, shear waves and surface waves (Figure 4). In longitudinal or compressional waves, particle motion in the medium is parallel to the direction of the wave front. In shear waves, particle motion is perpendicular to the wave direction. Surface waves, or Rayleigh waves, represent an oscillating motion that travels along the surface of a test piece to a depth of one wavelength. When propagated in solids depending on the specific conditions of reflection or refraction, these waves can be submitted to mode conversion. The longitudinal waves have the highest values of velocity and shear waves have the lowest velocities. Other wave modes exist such as Lamb waves or other forms of plate wave.

Figure 4.

Types of waves propagating in solids. (a) Longitudinal waves and shear waves https://static4.olympus-ims.com/data/Image/fd-tutorial/wave_propagation_modes1.jpg?rev=AE2D (accessed on 5 May 2021). (b) Surface waves—Rayleigh waves and Lamb waves generated by mode conversion https://www.ndt.net/article/wcndt00/papers/idn358/fig2.gif (accessed on 5 May 2021).

2.2.3. Velocity of Waves and the Elastic Constants

The propagation of waves in isotropic and anisotropic solids has been discussed in numerous reference books. Among them, I specify [6,8,26,27].

We have seen that he generalized Hook’s law can be written as

[σij] = [Cijkl] [εkl]

The strain tensor [εkl] for small deformation of the material under stress is related linearly to the displacement u as

The elastodynamic equations for a continuum with no forces acting on it are

By combining the elastodynamic equations for a continuum with no forces acting and the strain tensor [εkl] for small deformations of the material under stress related linearly to the displacement u, the equation of the wave can be written as

If we assume a plane harmonic wave with the displacement u propagating in the direction of the unit vector n, normal to the wavefront, we have

ui = Ai exp {i(kj xj − ωt)}

The unit wave vector kj can be written as

For the amplitude we can write Ai = A Pm where Pm are the components of the unit vector in the direction of displacement (polarization). After substitution, the equation of motion takes the form of Christoffel’s equations.

Christoffel’s equations supply the relations between the elastic constants Cijkl and the phase velocity vphase of ultrasonic waves propagating in the medium. These equations are valid for the most general kind of anisotropic solids.

where Cijkl = stiffness tensor; nk = direction cosines of the propagation vector; δik is the Kronecker tensor; if i = k, then δik = 1 and if i ≠ k, δik = 0; ρ = density; V—phase velocity; Pm—components of the unit vector in the direction of the displacement or polarization.

[Cijkl nj nk − δik ρ v2 phase] [Pm] = 0

By introducing the Kelvin–Christoffel tensor, Γ, we can write Γik = Cijkl nj nl

and the Christoffel equation can be written as

for which we can calculate the eigenvalues and the eigenvectors.

[Γik − δik ρ v2] [Pm] = 0

- (a)

- The Eigenvalues of Christoffel’s Equations

For an orthotropic solid, with nine terms of stiffness tensor [C] and three elastic symmetry planes we have the following relationships related to the eigenvalues of the Christoffel equation:

- -

- In symmetry plane 12: n1 = cos α; n2 = sin α; n3 = 0 and the stiffnesses C11; C22; C66; and Γ11 = C11n12 + C66n22; Γ22 = C22n22 + C66n12; Γ12 = (C12 + C66)n1n2;

- -

- In symmetry plane 13: n1 = cos α; n3 = sin α; n2 = 0 and the stiffnesses C11; C33; C55; and Γ11 = C11n12 + C55n32; Γ33 = C33n3 2 + C55n12; Γ23 = (C13 + C55)n1n3;

- -

- In symmetry plane 23: n2 = cos α; n3 = sin α; n1 = 0 and the stiffnesses C22; C33; C44; and Γ22 = C22n22 + C44n32; Γ33 = C33n32 + C44n22; Γ23 = (C23 + C44)n2n3;

The eigenvalues and the eigenvectors of Christoffel’s equations can be calculated for specific anisotropic materials. The nonzero values of the displacements—polarization—are obtained as characteristic eigenvectors corresponding with the characteristic eigenvalues which are the roots of the Christoffel equation. These solutions show that along every axis it is possible to have three types of waves, i.e., one longitudinal and two transverse.

Experimentally, by measuring the velocities, it is possible to calculate the elastic constants. Wave propagation velocities along the principal directions of elastic symmetry of an orthotropic solid are summarized in Table 4 and Table 5 for the propagation of waves in the principal directions.

Table 5.

Propagation along principal directions of elastic symmetry of an orthotropic solid.

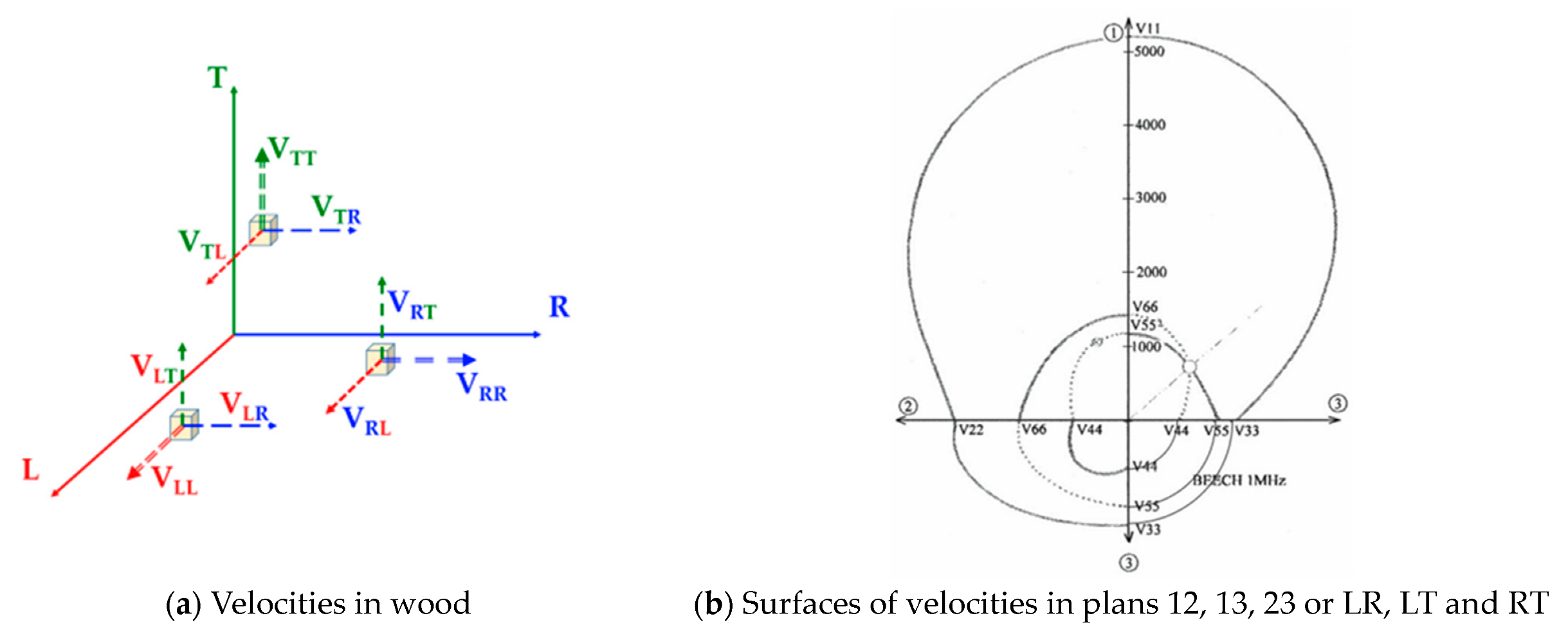

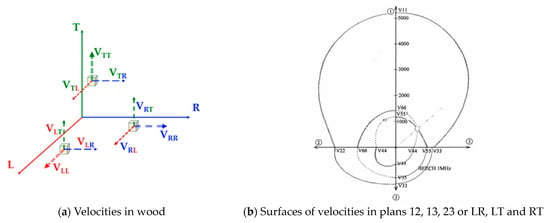

If we refer to the particular case of wood, we can define the velocities as shown in Figure 5.

Figure 5.

Velocities of propagation of ultrasonic waves in wood and the corresponding surfaces of velocities in three anisotropic planes. Principal axes of wood L, R and T. Legend: longitudinal wave velocities VLL, VRR and VTT; shear wave velocities VLR and VRL, VLT and VTL, VRT and VTR [2].

The velocities of longitudinal waves are VLL VRR and VTT. For these waves the direction of propagation is parallel to the direction of polarization. Shear waves have their polarization direction perpendicular to their propagation direction. For example, in the plan LR we can have VLR and VRL. Theoretically, for an orthotropic model of wood these velocities should be VLR = VRL. Experimentally, these values are always different because waves propagate in a real material having a particular structure.

The relationships among the velocities and the elastic constants for the case of the waves’ propagation out of principal directions of elastic symmetry for an orthotropic solid are given in Table 6.

Table 6.

Propagation out of principal directions of elastic symmetry of an orthotropic solid.

It is worth mentioning that propagation out of principal directions of elastic symmetry for an orthotropic solid generates three types of waves: QL, QR and T. The energy of these waves is different. The normal wave can generate phenomena of conical refraction of waves. Ultrasonic energy propagation through wood was studied by [28,29,30,31]. In wood, as in other anisotropic materials, the group velocity vector generally differs from the phase velocity vector. The group velocity vector is normal to the slowness surface of a wave mode.

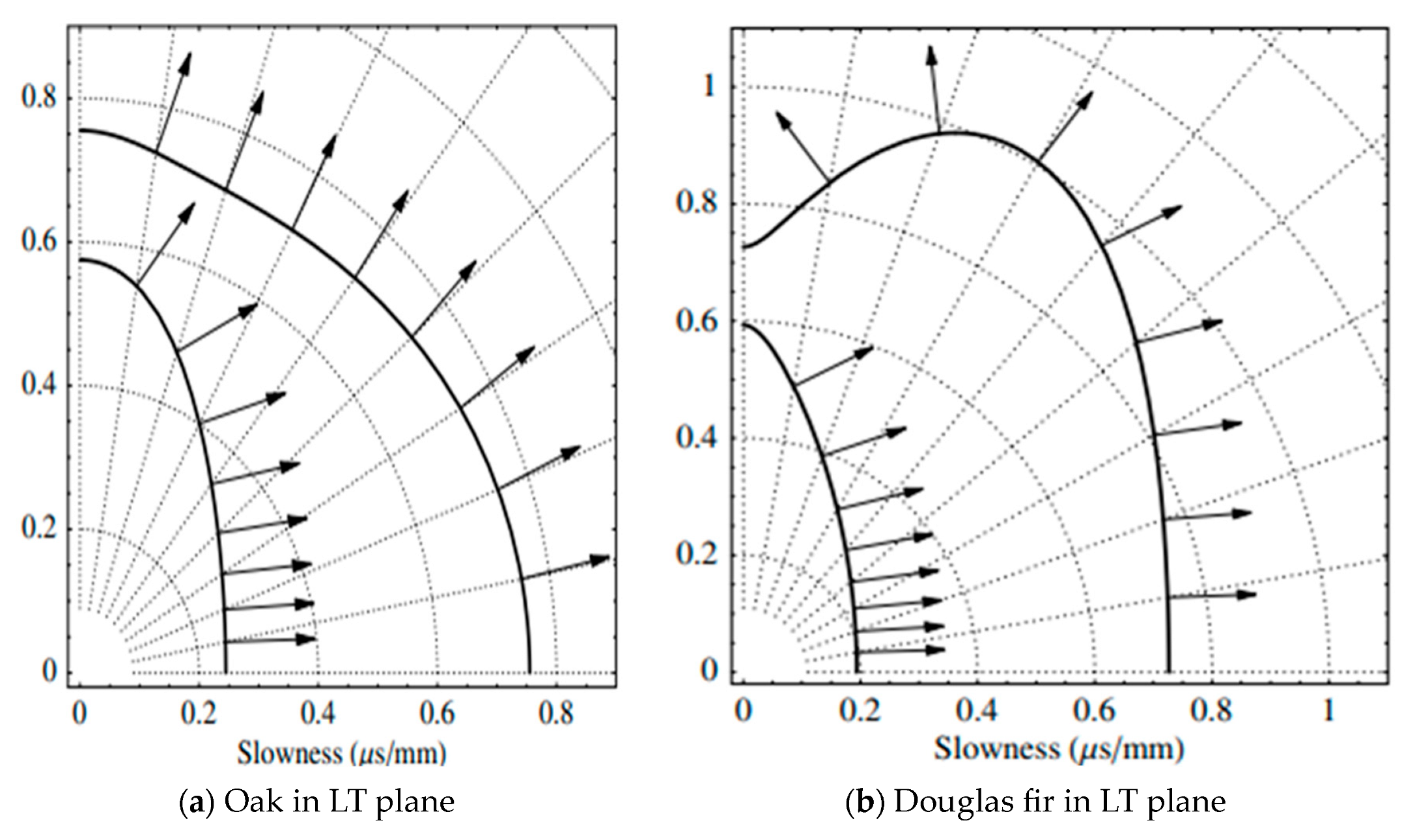

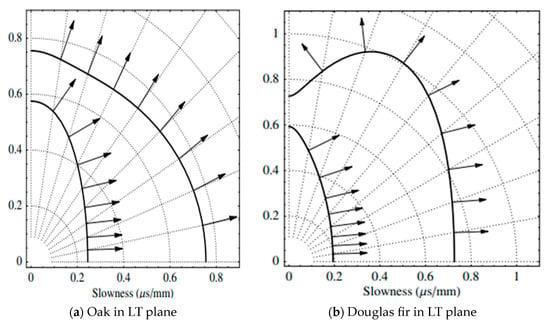

While the propagation vectors of the three modes (QL, QT and T) are identical (at the angle α), the energy flux vectors depend on the mode. The angle of energy flux deviation can be calculated and verified experimentally, by holding the sending transducer stationary while scanning with the receiving transducer for the maximum energy for each mode, keeping the transducer axes parallel. The angle of flux deviation can be calculated from the lateral beam offset and the sample thickness, using simple trigonometry [30]. The flux energy deviation angle and slowness of QL and QT waves in oak and in Douglas fir is shown in Figure 6.

Figure 6.

The flux energy deviation angle and slowness of QL and QT waves in oak and in Douglas fir [31]. (a) Oak (Figure 1 page 699). (b) Douglas fir (Figure 2 page 699). Note: data derived from elastic constants of wood reported by [12].

The choice of these species—oak and spruce—is very illustrative because of the high anisotropy in elastic properties between the L and T directions. Wave behavior in this plane is also important in the application of ultrasonics in wood evaluation because this symmetry plane is often very accessible in practical situations. The anisotropy is more pronounced for Douglas fir than for oak and leads to a large energy flux deviation of up to 45°. The QT wave mode in oak behaves almost like an isotropic mode, its phase velocities hardly changing with propagation angle. In oak, the energy flux deviations are quite small, not exceeding 12°; however, in Douglas fir, a strong maximum in the 60° propagation direction is observed. The latewood–earlywood alternance in Douglas fir of very different densities are inhomogeneities which introduce in wave propagation a stop band effect.

Mathematical modeling as well as practical experience show that the energy flux deviation of the QT wave is particularly sensitive to the magnitude of the off-diagonal elastic constants. Acknowledging the phenomena of energy partition and energy flux deviation and adjusting the experimental design to take advantage of the additional measurable quantities will significantly improve the accuracy of ultrasonic determination of the off-diagonal elastic constants of wood.

- (b)

- The Eigenvectors of Christoffel’s Equations

From Christoffel equations, we can obtain the eigenvectors in a very simple way if two off-diagonal components of the tensor are zero. In plane 12, for an orthotropic solid, the linear equation for the displacement Pm (p1, p2, 0) associated with the quadratic factor of Equation (12) for (n1, n2, 0) is as follows:

where

If we let the polarization correspond to the same sign, i.e.,

where is the displacement angle, we obtain

and

From Equation (16), the particle displacement (polarization) is expressed in terms of phase velocity, propagation direction and stiffness constants of the solid for each plane of symmetry.

It can also be deduced that the polarization angle between the displacement vector belonging to the inner sheet of the slowness surface and the corresponding wave normal on the symmetry axis is 0°. On the axis of the solid, the wave is a pure longitudinal wave. For pure shear waves, the angle between the propagation and polarization vectors is π/2. The polarization angle changes when the propagation direction is out of the principal directions.

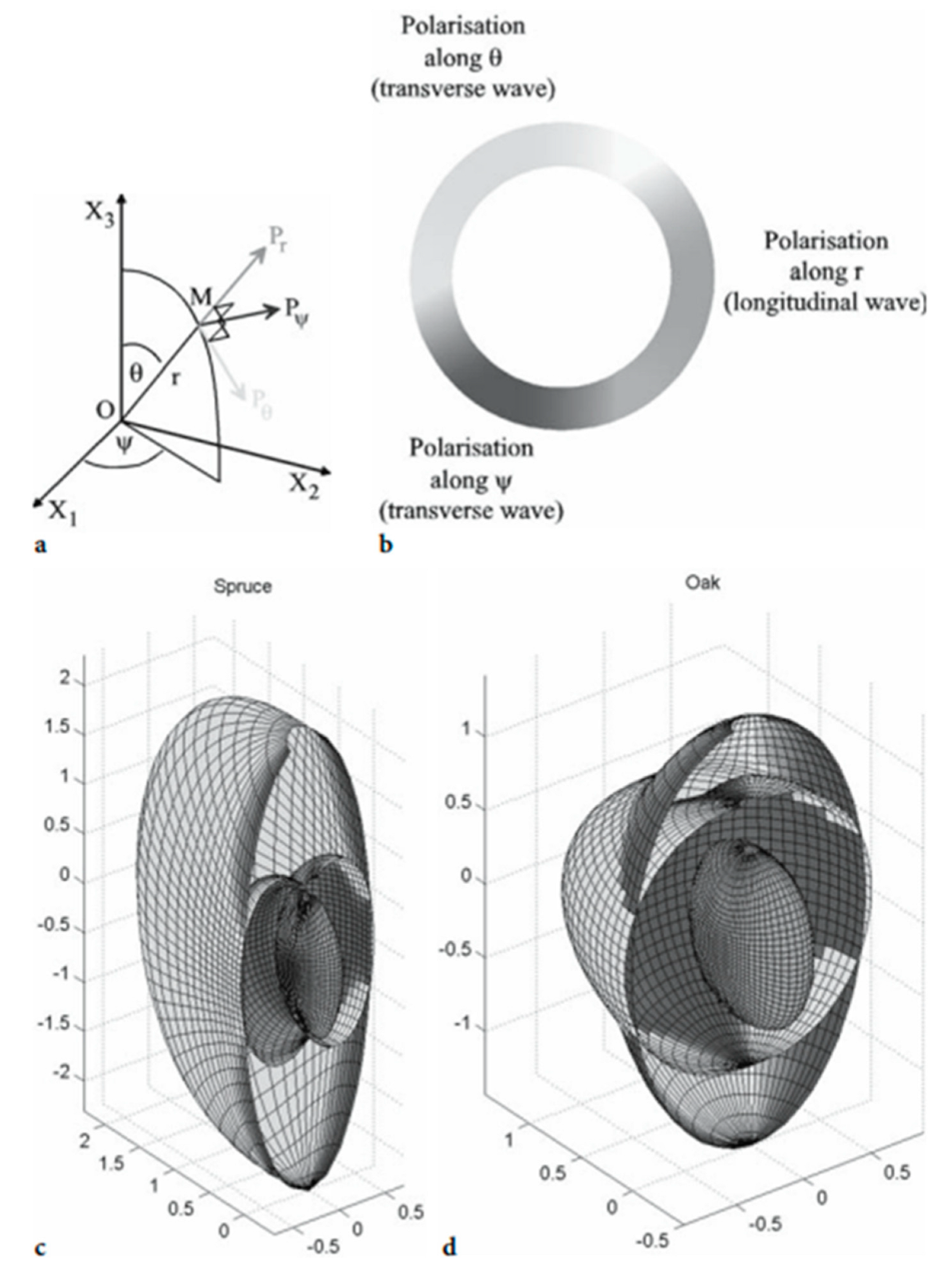

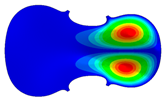

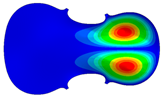

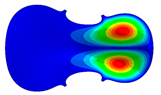

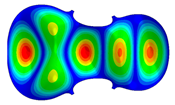

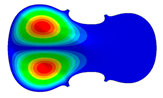

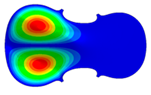

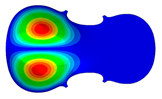

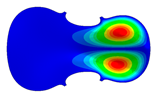

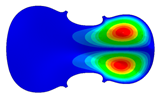

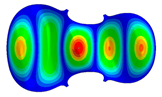

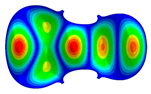

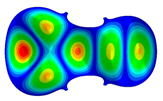

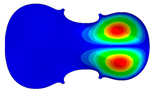

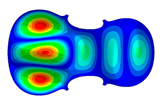

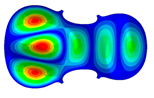

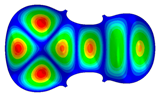

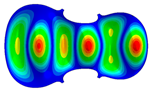

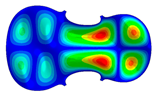

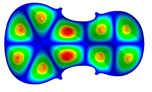

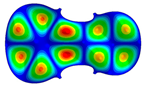

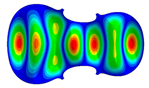

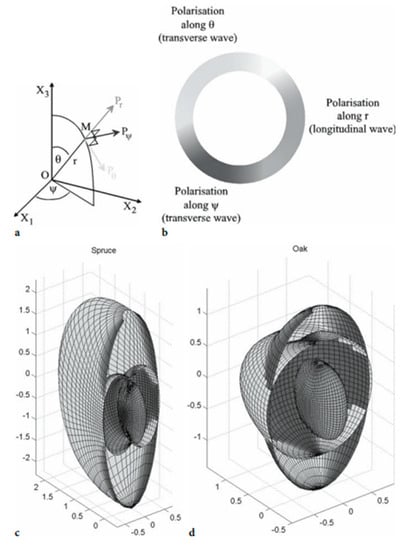

A better understanding of propagation phenomena in anisotropic solids is given by a tridimensional representation of slowness surfaces and corresponding displacements, as suggested by [32] with a numerical modeling method. The polarization vector is decomposed along local spherical coordinates in three components, corresponding to the longitudinal wave and to two shear waves, QT and T, or fast and slow shear waves. A holistic understanding of the acoustical properties of wood and of the anisotropy of this material is given in a three-dimensional representation. Figure 7 illustrates the characteristics of spruce and oak in a three-dimensional representation.

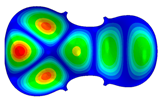

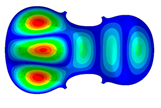

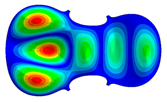

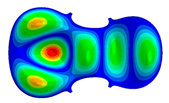

Figure 7.

Slowness curves (1/velocity) expressed in 1/(m/s) of spruce and oak in three-dimensional representation [33].

The slowness curves (the variation of the inverse of velocities versus the propagation direction of waves) show that the acoustical anisotropy of spruce is more pronounced than that of oak. For both species studied, the inner slowness sheets (which is the inverse of velocity VLL) exhibited a flattened ellipsoidal shape. In the planes X1-X2 or LR and X1-X3 or RT (axis X1 being the axis corresponding to the fibers’ direction) the color is more or less uniform. This means that the polarization is parallel to the propagation vector. In the plane X2-X3 the color varies from X2 to X3 and this means that the polarization varies more and more when the angle approaches the axis X3. This pattern was observed for both species. The shear waves are more sensitive to the differences between species than the longitudinal waves.

Based on previous considerations, we have seen that the three-dimensional representation of slowness surfaces in wood is related to the dynamic aspects of particle displacement of the ultrasonic wave and is associated with the wave front. This representation for wood species supplies a better understanding of ultrasonic wave propagation through this material and underlines kinematic aspects of wave propagation related to progressive mode conversion. The anisotropy of different species like spruce and oak, expressed by their acoustical behavior, is well represented in a global way. This representation is in agreement with the three-dimensional representation of other anisotropic materials [32].

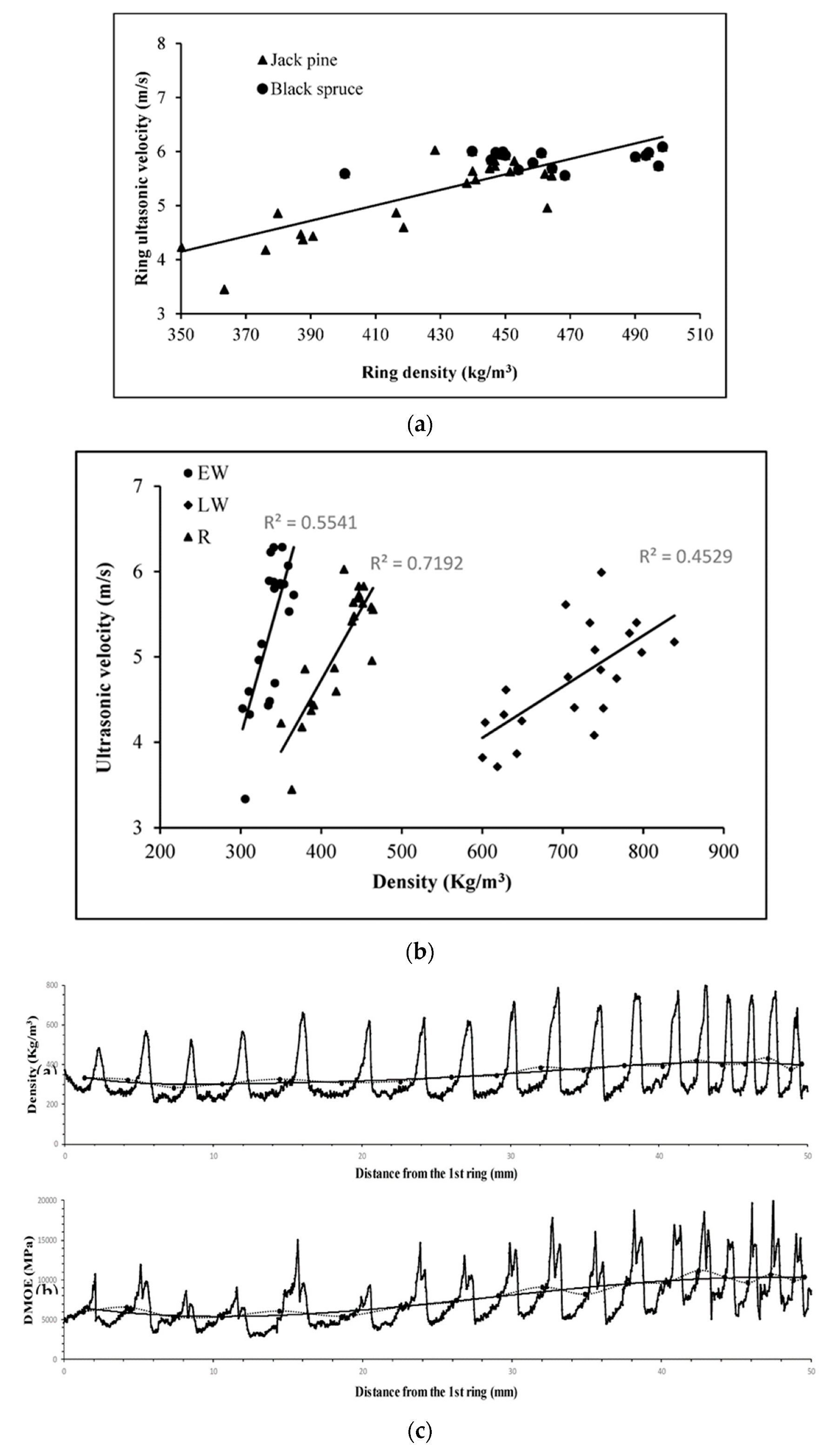

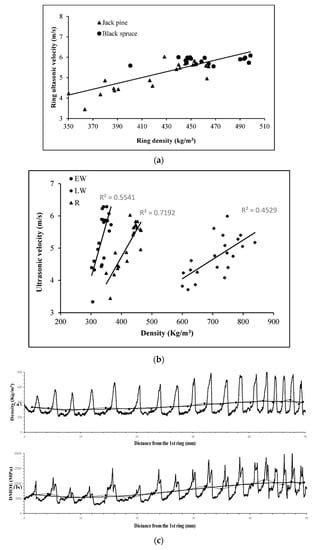

2.3. Effect of Density on Ultrasonic Velocity

We have seen previously that stiffness in the L direction is calculated as CLL = V LL2 × ρ. In what follows we will analyze the variation of the velocity in the L direction with the density of the annual rings for two softwood species: jack pine and black spruce of Canadian origin (Figure 8a) [34]. Increasing density in the range from 350 kg/m3 to 510 kg/m3 causes the increase in velocity from 4000 m/s to 6000 m/s. If we refer to the density of the latewood and of the earlywood in the annual ring, we observe the same tendency of increasing of velocity with density (Figure 8b). The variation of the density in the annual ring is similar to the variation of the modulus CLL = V LL2 × ρ. (Figure 8c). Note the density of the first nine rings corresponding to juvenile wood, followed by an increasing density for the mature wood.

Figure 8.

Variation of velocity in annual rings [34]. (a) Velocity in annual ring and density. (b) Correlations velocity density in earlywood, latewood and annual ring. (c) Variation of density and the modulus V2ρ in 19 annual rings from the pith to the bark. Note: There is a need to understand the physical difference between the density and the velocity. The density is a scalar and the velocity is a vector with projections on the axes L, R and T. Therefore, the velocity can better express the variability of wood in three anisotropic directions. There is no variation of density with anisotropic directions of wood. X-ray and ultrasonic methods are two complementary non-destructive methods used for wood characterization.

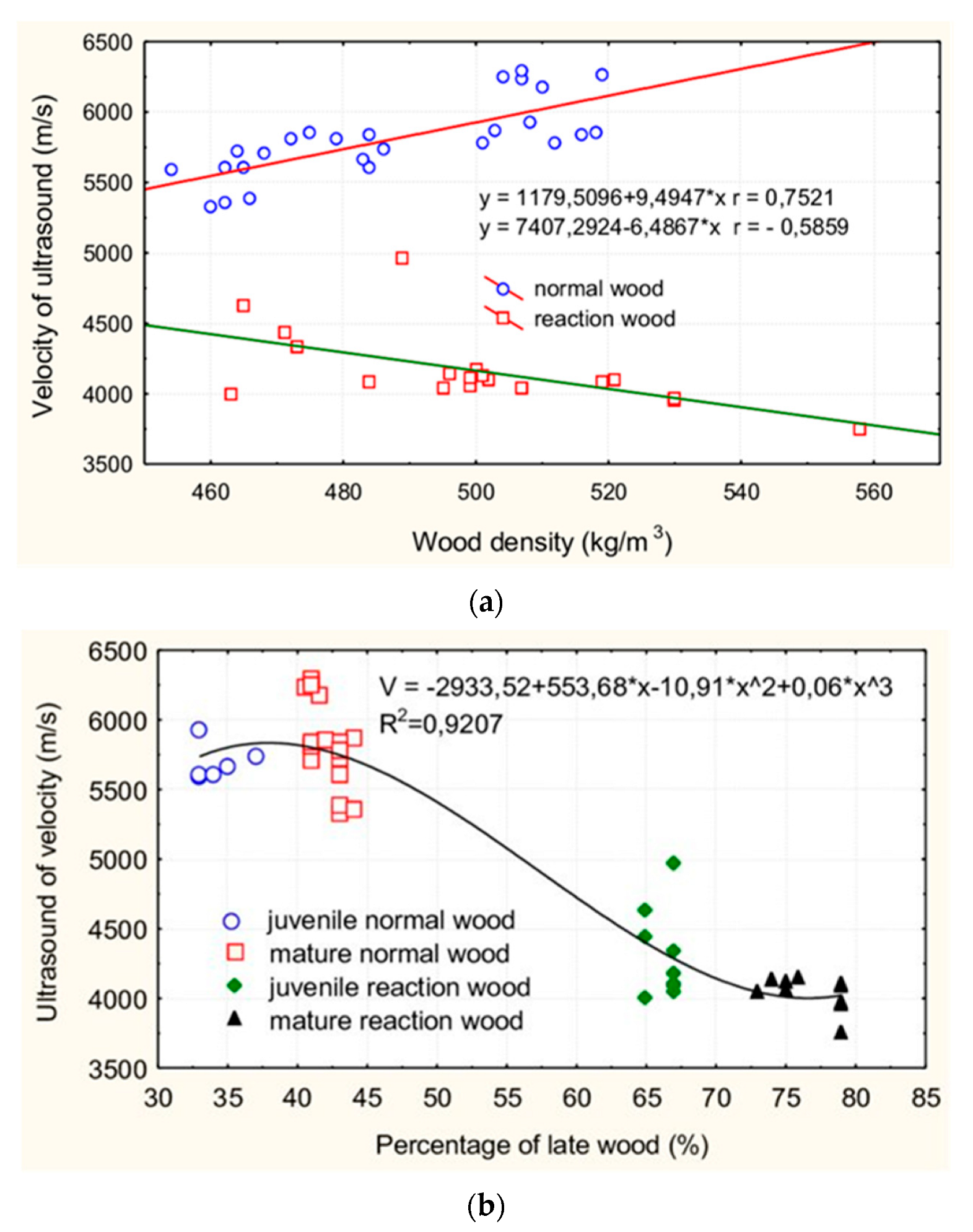

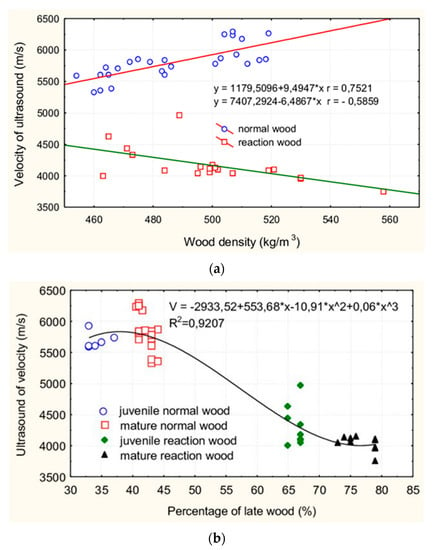

The presence of the reaction wood can be detected by an ultrasonic velocity method (Figure 9) [35]. In Pinus sylvestris, normal wood the velocity increased from 5500 m/s to 6000 m/s with the increasing proportion of latewood in the annual ring to a maximum of about 40% and decreases dramatically to 4000 m/s for reaction wood and juvenile wood for which the latewood is 80% from the width of the annual ring.

Figure 9.

Variation of VLL in normal wood and in reaction wood of Pinus sylvestris versus density) [35]. (a) Normal and reaction wood. (b) Velocity and the latewood in annual ring.

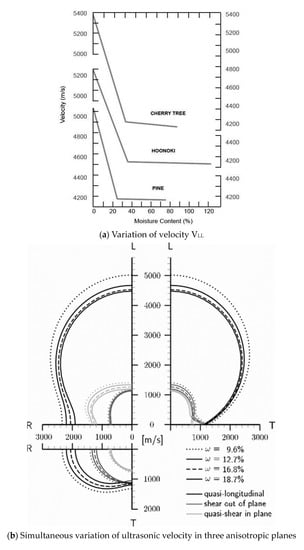

2.4. Effect of Moisture Content on Ultrasonic Velocity

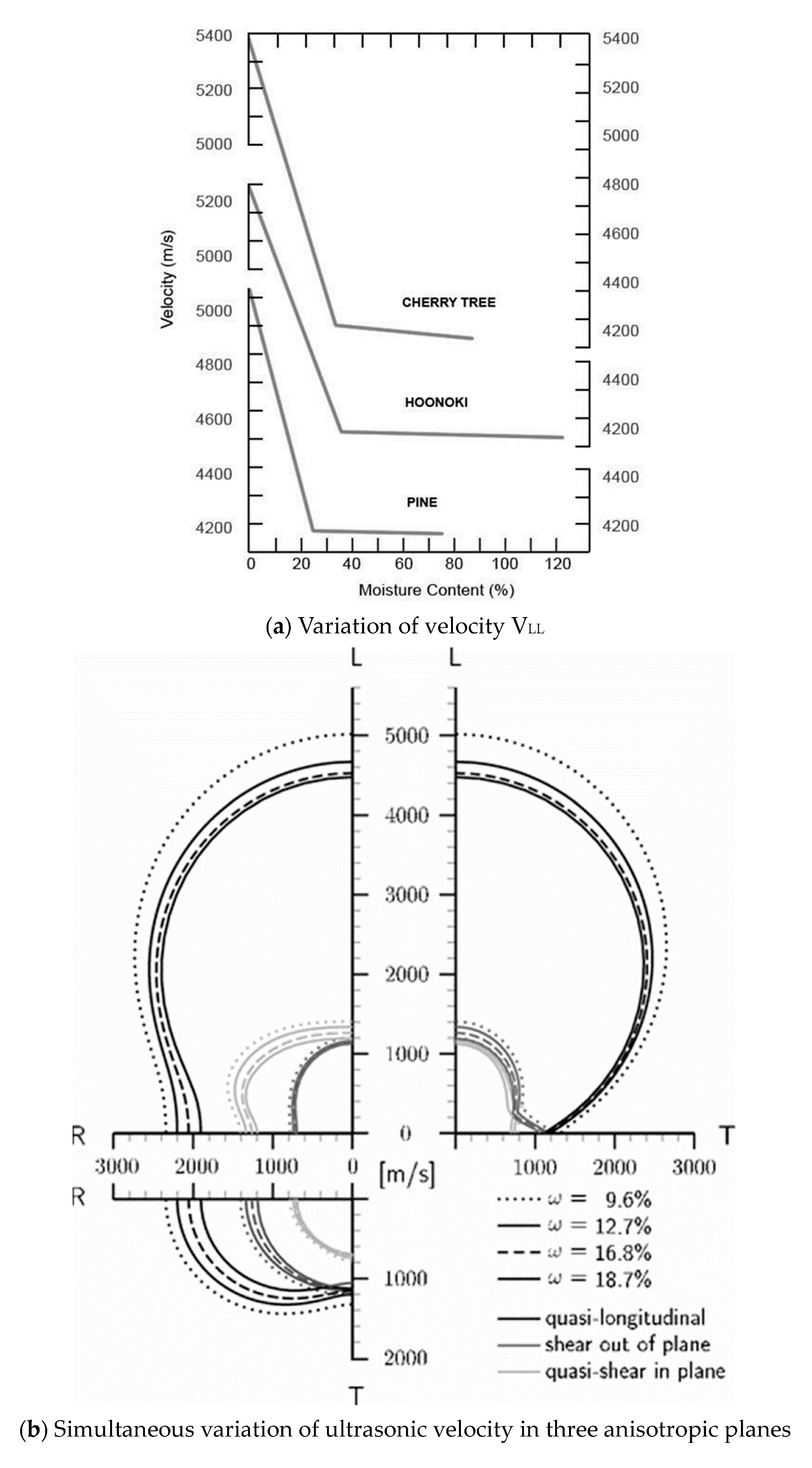

Moisture content in wood is due to the presence of water in the wood structure under two states as free water in the lumens of cells or as bound water in the cellular wall. The fiber saturation point is at about 30%. Physical and mechanical properties of wood are affected by the moisture content, with low moisture content causing high values of the mechanical properties of wood determined with ultrasonic techniques [36]. The effect of moisture content on velocity VLL is shown in Figure 10a. Note the decreasing velocity with increasing moisture content in the range 0%–30%. After the fiber saturation point the velocity VLL is relatively unaffected by increasing the moisture content. A holistic representation of the moisture content’s simultaneous variation with the longitudinal and shear ultrasonic velocities is shown in Figure 10b and in Table 7. All values of velocities decrease with increasing moisture content.

Figure 10.

Ultrasonic velocity at 1 MHz versus moisture content. (a) Variation of the velocity VLL in the moisture content range 0%–12% [37]. (b) Variation of velocities VLL, VRR, VTT, VRT, VLT and VLR for beech versus moisture content under the fiber saturation point in the range 10%–19% (Figure 3 in [38]). Note, optimization procedure for QL and QT waves with 45° specimens.

Table 7.

Beech. Effect of moisture content variation in the range 10% to 19% on ultrasonic velocities [38].

The effect of increasing moisture content on the engineering constants are shown in Table 8, Table 9 and Table 10.

Table 8.

Beech. Effect of moisture content increasing in the range 10% to 19% on E moduli and Poisson ratios [38].

Table 9.

Beech. Variation of velocities and E moduli with increasing moisture content of wood from 10% to 19%.

Table 10.

Variation of Poisson ratios with increasing moisture content of wood from 10% to 19%.

Moisture content increasing from about 10% to about 19% causes increases in all Poisson ratios. However, some of them increased spectacularly; for instance, ν LR increased by 300%, ν RL by 400% and ν RT by 160%. For Poisson ratios in the LT plane, ν:LT increased by 9.6% and ν TL increased by 7.2%. This means that the contribution of water existing mostly in the anatomic elements organized along the R direction is causing the deformation of wood. It seems that the migration of the bound water into the wood structure occurs firstly in the R direction and then in the L direction.

When comparing the values of Poisson ratios determined with ultrasonic tests and with static tests (Table 11) it can be noted that with ultrasonic tests, ν TL > 2 and ν TR > 1. The coefficients ν LR, ν LT and ν RT are in the same range. The effect of moisture content on Poisson ratios is shown in Table 12. Static measured values decrease with moisture content while values measured with an ultrasonic method increase. The ultrasonic method is more sensitive to the variation of moisture content in the anisotropic structure of wood than static tests. Table 13 gives a summary for the relationships between Poisson ratios in the same anisotropic plane.

Table 11.

Poisson ratios. Comparison of data from static tests and ultrasonic tests.

Table 12.

Effect of moisture content on Poisson ratios.

Table 13.

Summary for the relationships between Poisson ratios in the same anisotropic plane.

To summarize, we can compare the effect of ultrasonic and static methods on the values of Poisson ratios as:

2.4.1. Ultrasonic Method Effect

- -

- The Poisson ratios increase with decreasing moisture content.

- -

- The planes LT and LR are mostly affected (ν ij increased with about 40%) by moisture content increasing from 9.6% to 18.7%. Water migration is firstly along the L axis and secondly along axis R.

- -

- The RT plane is affected by about 25% (the ν RT ij increased by about 22% and ν TR 30%) by moisture content increasing from 9.6% to 18.7%. Axis T is more resistant to deformation than axis R. Migration of water is along the R axis.

2.4.2. Static Compression Effect

- -

- The Poisson ratios decrease with moisture content.

- -

- The LT and LR planes are mostly affected (the ν ij decreased with about 40%) by moisture content increasing from 9.6% to 18.7%. Water migration occurs firstly along the L axis and secondly along the R axis.

- -

- the RT plane is less affected (3%) by moisture content increasing from 9.6% to 18.7%. There is no difference between the R axis and the T axis.

Poisson ratios at constant moisture content were reported by [40]. The Poisson ratios of Eucalyptus globulus were determined with three methods—ultrasonic velocity method, 3D digital image correlation method and static compression test. Table 14 gives the values of engineering constants of Eucalyptus globulus.

Table 14.

Engineering constants (108 N/m2) of Eucalyptus globulus density 854 kg/m3, with three methods. Average values for 20 specimens [40].

The elastic values obtained via the ultrasonic velocity method are higher than those determined with static mechanical testing using conventional gauges. Static tests are isothermal processes; the temperature of the sample is constant during the tests. Ultrasonic tests are dynamic tests submitted to an adiabatic process. The energy within the specimen increases during the tests. Therefore, the values of the elastic constants measured with dynamic methods are always higher than those measured with static tests at constant moisture content.

No νij > 1 values were reported with the ultrasonic method used in this experiment on eucalyptus wood.

However, it is important to note that the ultrasonic method requires an optimization procedure for the calculation of the off-diagonal terms of the stiffness matrix [41]. For a successful optimization procedure, it is recommended to use more than one specimen at 45° in each anisotropic plane. The values of the Poisson ratios strongly depend on the optimization procedure adopted. The strong differences between static and dynamic values of these coefficients are due to the fact that they are connected with the response of the wood structure. The dynamic coefficients are more sensitive to wood structure than the static measured coefficients.

2.5. Ultrasonic Resonance Spectroscopy

Ultrasonic resonance spectroscopy excites multiple normal modes by sweeping the excitation frequency of a specimen with no internal vibrations to obtain a resonance spectrum.

These resonance frequencies greatly depend on the type of specimen being measured and also depend greatly on its physical properties—mass, shape, size, anisotropy, etc. The physical properties of the specimen influence the range of frequencies generated. In general, small specimens have megahertz frequencies while larger specimens can be only a few hundred Hertz. The more complex the specimen the more complex the resonance spectrum.

Resonance ultrasonic spectroscopy was first used on wood by [42,43] for the determination of one shear modulus by using the two lowest resonance frequencies. Ref. [44] determined all elastic stiffnesses of wood with resonance spectroscopy in the frequency range 20 kHz to 70 kHz on a beech cube measuring 2 cm × 2 cm × 2 cm.

The elastic tensor [C] is estimated by solving an inverse problem with simulations to calculate the theoretical values of these frequencies, with an initial [C] given as input. The procedure is very complex. The method is successful if the principal directions of elastic symmetry of the specimen are well defined.

2.6. Methods in the Low-Frequency Domain for Elastic Constant Determination

The most convenient technique for measuring the engineering parameters E and G with high precision depends upon measurements of the resonance frequencies of longitudinal, flexural, or torsional resonant modes of both a bar-shaped samples of circular or rectangular cross section and a plate sample. The fact that the technique is resonant ensures that frequency measurements will be highly precise. Experimental studies on the elasticity of solid wood and of wood-based composites are extensive and a very large number of techniques have been developed. Free oscillation methods and methods with forced vibrations, or resonance methods, have been used for measurements over a wide range of frequencies, ranging from 102 to 104 Hz. The modulus E is calculated for the fundamental resonance frequency of a bar as E = 4 ρ l2 f2, where f is the frequency of the longitudinal vibration. The modulus G is calculated for the fundamental frequency of a bar as G = 4 ρ l2 f2T, where f T is the frequency of the torsional vibration. This method in the low-frequency domain allows determination of the Poisson ratios.

The main disadvantage of the resonant technique is related to the shape of the specimen, rod or plate. It is well known that for solid wood it is easy to use rods or plates in the LR or LT planes, but it is more difficult in the RT plane, in which the effect of annual ring curvature is important. Moreover, care must be taken to ensure that losses through the suspension system used to support the specimen are not significant compared to those intrinsic to the specimen.

Using the frequency resonance method, the following constants could be determined:

- -

- Bar length in L, transverse section RT, moduli EL, GLR, G LT, and ν LR and ν LT

- -

- Bar length in R, transverse section LT, moduli ER, GRL, G RT, and ν RL and ν RT

- -

- Bar length in T, transverse section RL, moduli ET, GTL, G TR, and ν TL and ν TR

3. Acoustic Methods for Quality Assessment of Trees, Logs and Lumber

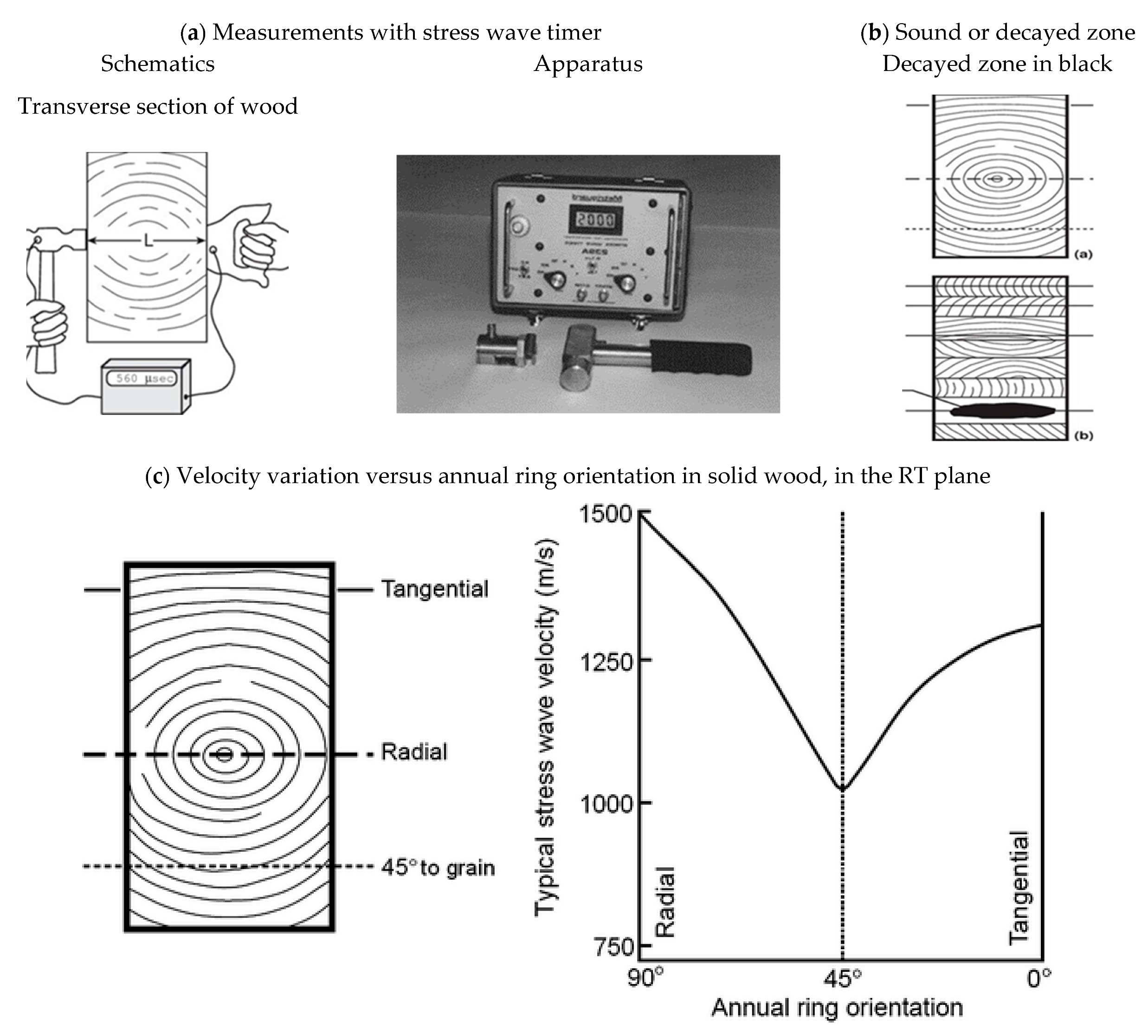

3.1. The Background

Acoustic techniques have been successfully developed for inspection of standing trees, green logs or structural umber because they are robust, inexpensive, allow collecting of data in real time and are non-harmful for the operators. The devices are portable and can be handled by one operator. The applications range widely from structural elements to sawmills and wood-based composites [3,45] or to forestry applications like screening families of clones, estimation of genetic parameters, forest inventory, monitoring within-tree variation, establishing correlations with product properties, etc. [46]. In most cases, the main parameter measured is the time of propagation of a longitudinal wave (or the time of flight) which allows calculation of the velocity V. Knowing the density of the medium ρ, it is possible to calculate the corresponding modulus of elasticity, currently noted in the literature as MOE = ρ · V2 is in fact a stiffness coefficient. Legg and Bradley [47] provided a thorough review of the literature concerning the stiffness of trees, logs and lumber. Acoustic methodology was reviewed by [46,48].

During the last three decades, numerous studies have been published acknowledging the benefits of acoustic technology to forestry and to the wood industry. The goal of acoustic technology was to detect and characterize internal defects (knots, deviation of grain angle, splits, rot) and to assess the overall strength of wood products [49,50,51,52,53,54,55,56,57,58,59,60,61,62,63].

3.2. Quality Assessment of Standing Trees and Green Logs

Quality assessment of standing trees has two aspects, namely for trees in an urban environment and for trees in forests, natural forests or plantations. Trees in urban environments are planted mostly in parks or in large urban spaces. Forest trees are harvested at various ages. Trees decline in health with age because of various attacks by fungi and insects. When harvested, forest trees produce green logs for saw mills, the paper industry, etc. Defects in standing trees can generally be classified as defects induced by different irregularities from natural growth patterns (grain deviation, knots, pitch pockets, etc.) and abnormalities induced by biological attacks of fungi, insects, etc. There are different methods for inspecting the state of the trees. In this chapter we consider ultrasonic methodology. The various stages that are usually taken into consideration during ultrasonic inspection of trees are detection, localization, characterization and the decision to act if the defect is important enough. The ultrasonic techniques currently used are scattering-based techniques that use the time of wave propagation or other wave parameters and ultrasonic tomographic imaging techniques, which seek to provide a high-resolution picture of the defect [64,65]. These techniques will be discussed further.

3.2.1. Scattering Based Techniques

These techniques are related to the measurement of the velocity of propagation of ultrasonic waves in trees along the generator of the trunk or across the diameter of the tree [66]. The measurements along the generator can be used for detection of the slope of the grain on standing trees, for the detection of pruning treatment and for the presence of wavy structure on trees. The effect of pruning on wood quality is related to the improvement of the cylindrical shape of the trees, the reduction of juvenile wood, the reduction of wood shrinkage, the improvement of mechanical properties, the reduction of the proportion of knots, etc. The improvement in wood mechanical properties can be correlated with an increasing ultrasonic velocity in the longitudinal and radial direction of the tree. With pruning, the increase in the velocity in the radial direction is 25% and of the velocity in the longitudinal direction is 8.6%. The velocity in the radial direction is more related to the uniformity of annual rings induced by pruning while the increase in the velocity in the longitudinal direction is related to the increase in fiber length. It can be noted that there is less dispersion for all values of parameters measured on pruned trees than in control trees.

3.2.2. Ultrasonic Tomography

Wood quality assessment of standing trees can be observed with ultrasonic diffraction tomography. As for X-ray computed tomography, ultrasonic tomography refers to the cross-sectional imaging of an object from data collected by illuminating the tree with ultrasonic waves from different directions [65].

Ultrasonic tomographic reconstruction techniques can be classified as:

- -

- Techniques based on the projection-slice theorem (filtered back-projection and direct Fourier transform), which are fast but restricted to projection data that are sets of straight rays.

- -

- Techniques based on iteration procedures (algebraic reconstruction techniques and simultaneous iterative reconstruction techniques), which are relatively slow but may be used with complex sampling geometries and a bending ray path.

The resolution of ultrasonic imaging techniques is very much limited by the wave length and by the size and energy of the transducers. Ultrasonic imaging techniques applied to wood must be able to distinguish between the natural structure of the material and its pathological features. Ultrasonic velocities and attenuation in different anisotropic directions, the reflective properties of wood surfaces and the back scatter of ultrasonic waves from the inhomogeneities must all be considered.

Proper signal processing methods must be chosen according to the structural characteristics of wood at macroscopic and microscopic scales. The computationally most intensive part of the ultrasonic tomography technique, based on ray theory, is the tracing of the acoustic ray paths through the medium. In wood science, pioneering works on wood structure imaging reconstruction by scanning, from such ultrasonic data as velocities have been reported on trees by [67,68], on lumber by [69] and as stiffnesses have been reported by [70]. There are three main types of algorithms that can be used to form tomographic images from ultrasonic data: transform techniques, iterative methods and direct inversion techniques. The algebraic algorithms used most frequently are represented by the following acronyms:

- -

- ART—algebraic reconstruction technique—in which each equation corresponds to a ray projection. The computed ray sums are a poor approximation to the measured ones and the image suffers from significant noise.

- -

- SIRT—simultaneous iterative reconstructive technique—reduces the noise of ART by relaxation and produces better images than ART. The relaxation parameter becomes progressively smaller with an increasing number of iterations.

The factors that limit the accuracy of the images obtained with diffraction tomographic reconstruction are related to the theoretical approach of the approximations in the derivation of the reconstruction process and to the experimental limitations.

High resolution images for wood of transmitted and reflected energy were presented by [29] and the group in the Geophysics Department at Politecnico di Torino, Italy, under the direction of Sambuelli and Socco within the laboratory of Biotechnology of Florence University [71,72] and the group from the University of Torino, under the direction of Nicolotti [73]. Ultrasonic tomographic images were obtained with living trees in, for example, the tomography at 54 kHz by a direct ultrasonic transmission technique, which corresponds to the transverse section of a tree (Platanus acerifolia) of 40 cm diameter. The central zone of the section, about 10 cm in diameter, is degraded by fungi. In this zone, the values of ultrasonic velocity are very low (600–1000 m/s) because of structural degradations induced by the fungi. Ref. [74] presented a literature review on acoustic and ultrasonic tomography in standing trees. Ref. [75] accounts for the effect of wood anisotropy on ultrasonic tomography. Wood anisotropy leads to deformed wavefronts and curved trajectories of wavefronts which were considered for a better reconstruction of the image.

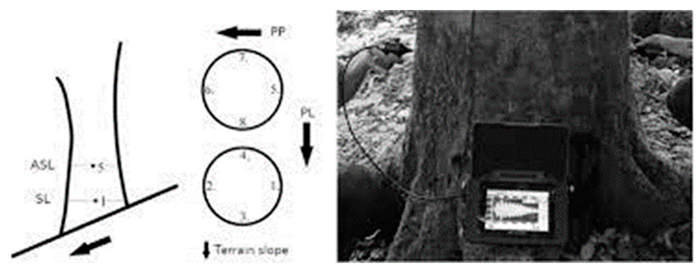

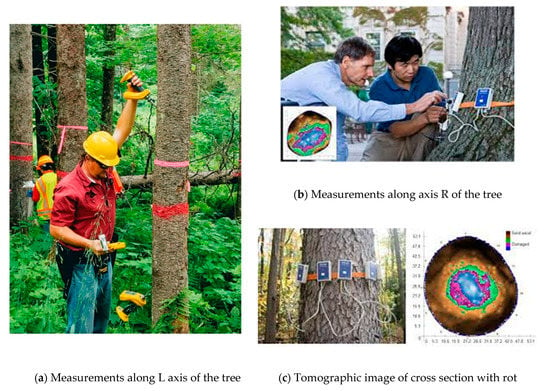

3.3. Quality Assessment of Standing Trees

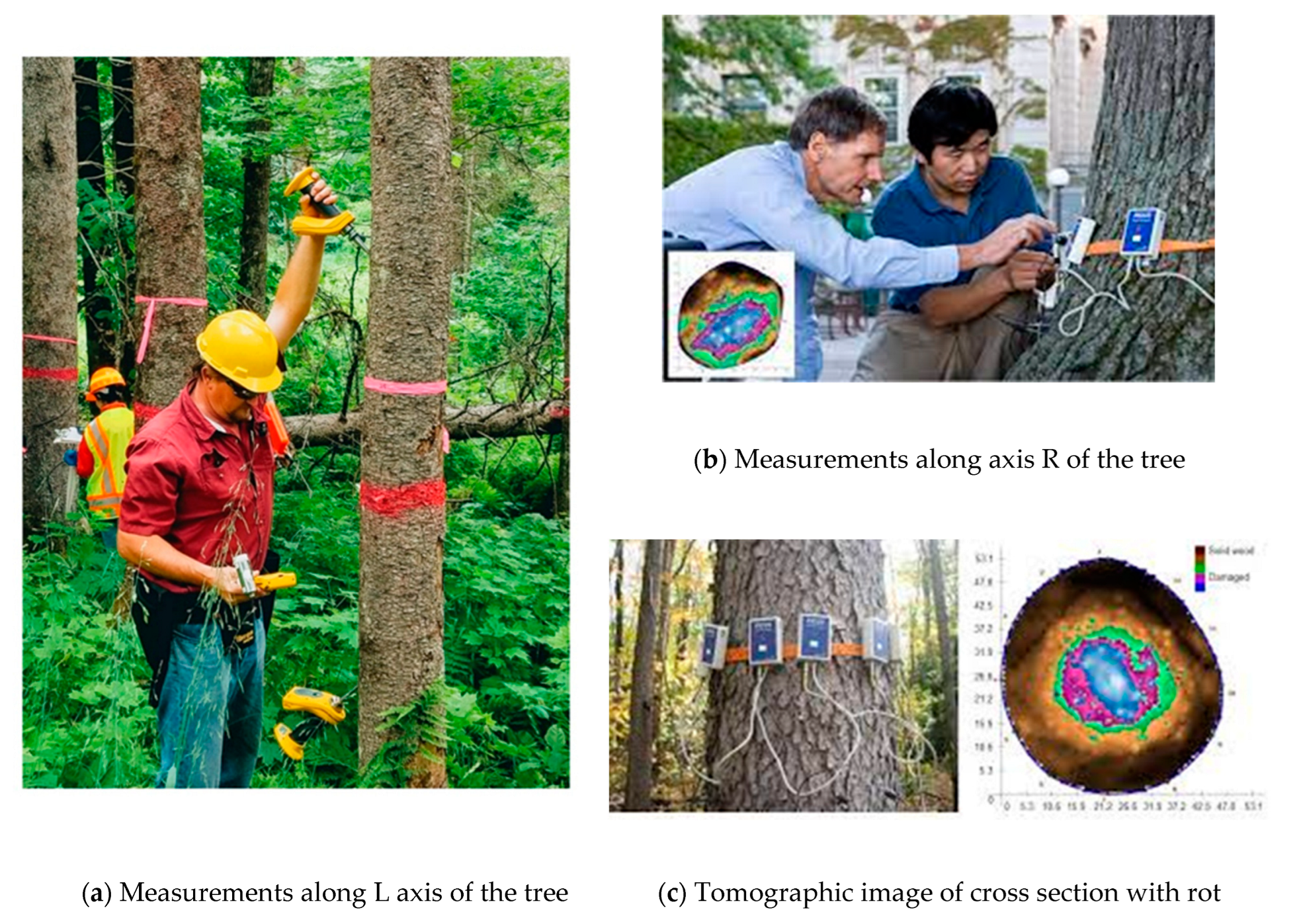

Acoustic nondestructive testing of trees involves two types of waves: impact stress waves and bulk ultrasonic waves. The stress waves are most convenient for numerous field measurements [76]. Measurements along the growth axis of the tree are shown in Figure 11. Ultrasonic images can be reconstructed from all characteristic parameters of the wave: time of flight, amplitude, frequency spectra of the waveform, the phase, etc. The energy distribution and energy flow are important parameters for enhancing image contrast. Figure 11b,c illustrate a stress-wave tomography test on a black cherry tree with PiCUS Sonic Tomograph tool (Argus Electronic GMBH, Rostock, Germany). The tomogram revealed internal rot in the central zone of the tree. Ref. [77] provided a list of velocities measured in the RT plane of sound urban trees of various species. They also introduced the parameter “time of flight per unit length”, which is in fact a specific time of flight.

Figure 11.

Stress wave measurements on standing trees. (a) Forest tree—time of wave propagation along the L axis of the tree in a forest (photo credit Xiping Wang). (b) Urban tree—time of wave propagation along the R axis of the tree. (c) Tomographic image of the cross section of a tree with rot—PiCUS Sonic Tomograph tool—Argus Electronic GMBH, Rostock, Germany; (Figure 3 in [78]).

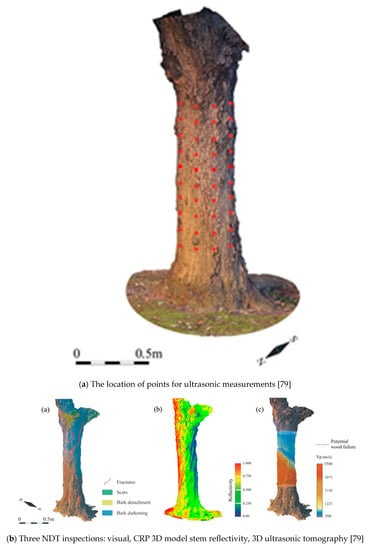

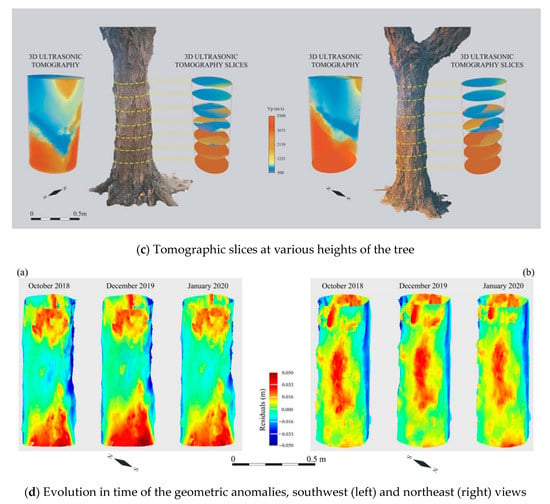

3.3.1. Urban Trees

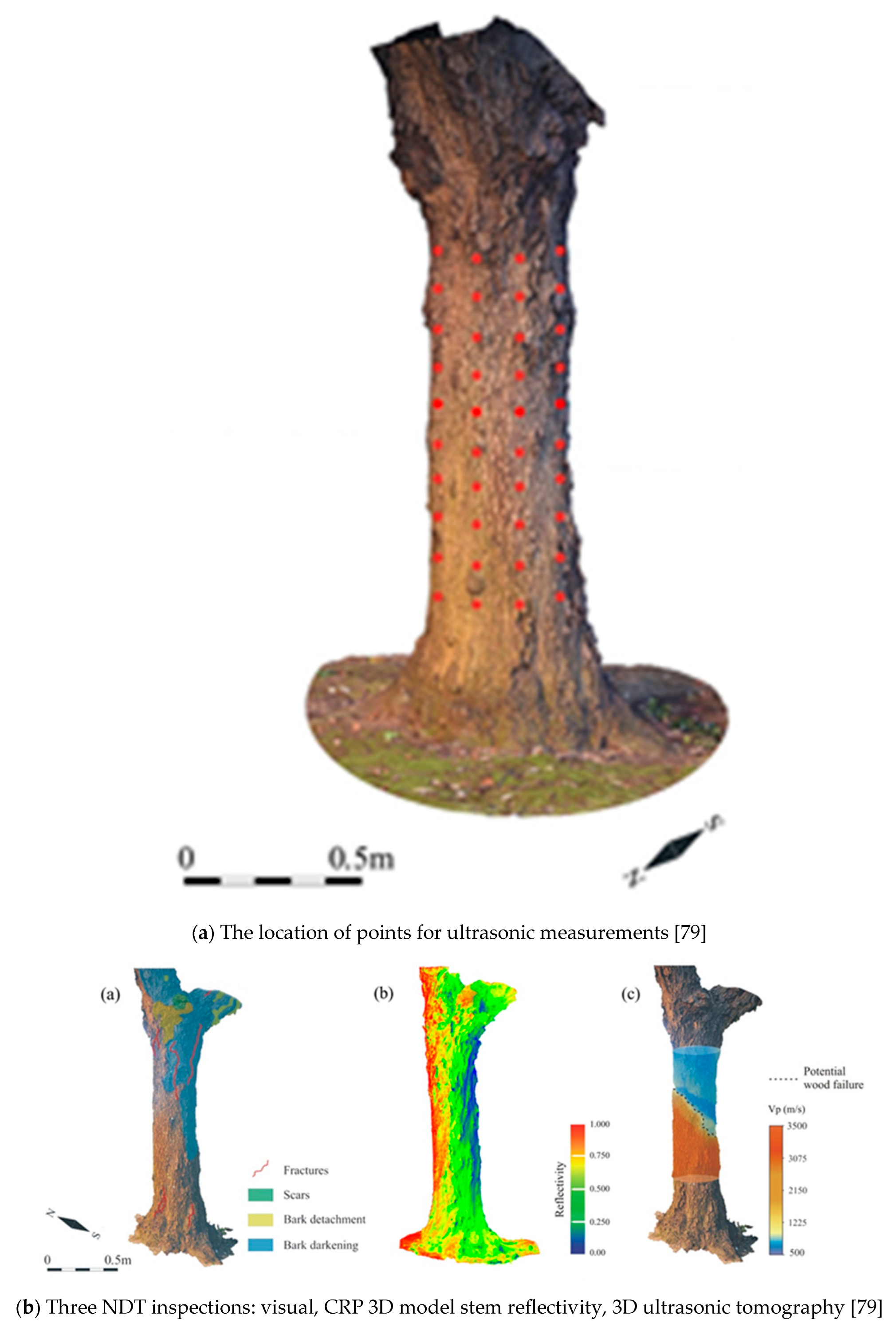

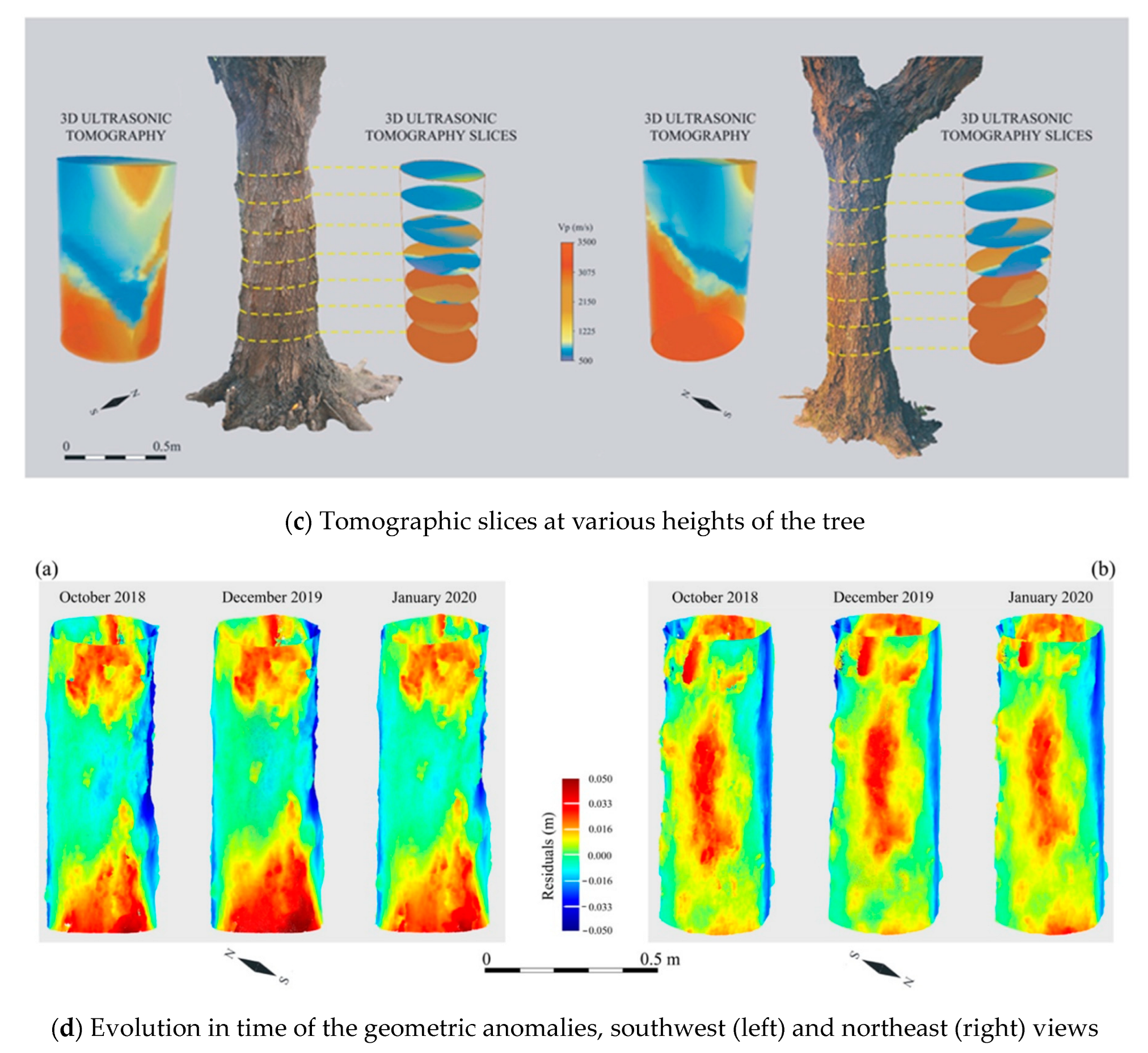

Urban trees are often affected by decay. To detect the presence of decay and the evolution of three years of decay in an old urban tree, the efficiency of ultrasonic tomography can be improved by combining ultrasonic tomography with close range photometry as demonstrated by [79]. Firstly, visual inspection allows observation of the presence of decay patterns at the surface of the tree trunk. Field-integrated tomography integrates a non-contact method, close-range photogrammetry, widely used in forestry inventory with the ultrasonic velocity method using 54 kHz frequency transducers for longitudinal waves in direct transmission mode. The propagation time of ultrasonic wave was measured and the velocity was calculated with 1% accuracy; see Figure 12.

Figure 12.

Combined nondestructive methodology for imaging deterioration over three years, from 2018 to 2020, of the internal structure of a Quercus ilex old tree [79]. (a) The location of points for ultrasonic measurements (Figure 6, page 9). (b) Three nondestructive techniques for inspection of the trees: visual inspection for scars, bark detachment and bark darkening, CRP-3D model stem reflectivity; 3D-ultrasonic tomography (Figure 12). (c) Tomographic slices at various heights of the tree (Figure 13). (d) Evolution over time of the geometric anomalies, views from the southwest (left) and northeast (right) (Figure 8) [79].

With the proposed methodological sequence by [79], it was possible to detect and reconstruct in 3D the distribution and the evolution over time of the decay and to assess the potential wood failure zones as a sudden transition from good to poor elastic parameters of wood in well-defined zones in the internal structure of the tree.

3.3.2. Forest Trees

In a forest, the trees should be harvested to provide timber with the best mechanical properties. Several sylvicultural treatments are applied, such as, for instance, thinning. In forests, some trees are removed for various purposes, namely for selection of competitors of higher quality, for the maintenance of stand health and vigor, and to provide access for future forest management. The utilization of products obtained from these trees submitted to various silvicultural treatments requires knowledge of physical and mechanical properties of wood. Currently increment cores are extracted from these trees which are used to determine the density of wood which is then statistically correlated with the mechanical properties of wood. On the other hand, using increment cores with an ultrasonic velocity method, it is possible to determine the following wood stiffnesses CLL, CRR, CTT using transducers of longitudinal waves, and using transducers of shear waves allows determination of GLT and GTL, GRL and GRT, GLR and GTR. The anisotropy of wood can be determined with these nine parameters [80,81,82]. Since the main uses of the sawn timber are structural applications, mechanical properties of wood expressed by the nine stiffnesses are important parameters in wood quality studies for resource assessment and breeding programs. By correlating statistically, the density of increment cores and the elastic parameters of wood measured on cores with mechanical properties of wood measured on standard specimens or on lumber, it is possible to estimate the potential quality of the studied trees. A review of measurement methods used on standing trees for the prediction of some mechanical properties of timber was presented by [83]. Old standing trees can be subjects for the development of non-destructive testing methodology and for studies on long term behavior of wood under permanent load combined with the evolution of the sanitary state of the tree, as, for instance, in the detection of rot.

- (a)

- Detection of rot in old standing trees

Degradation of old trees by fungi attack is one of the most important factors in the degradation of wood quality. Laboratory studies with the ultrasonic velocity method [84,85] and in situ measurements [3,42,86] were used for the detection of decay. Ref. [87] used an ultrasonic velocity method at breast height to measure the velocity along the R and T axis on spruce standing trees with diameters D < 25 cm and D > 25 cm and observed no statistically significant differences (Table 15).

Table 15.

Velocity in radial and tangential directions measured at breast height measured on spruce trees having a diameter higher or lower than 25 cm [87].

Differences between a sound tree and a rotted tree were observed at the stump and above the stump level using the radial velocity and the corresponding attenuation of the ultrasonic are given in Table 16. Note the velocity which decreased by a maximum of 19% in a tree with rot compared with a sound tree.

Table 16.

Velocity measured in the radial direction at stump level and above stump level and corresponding ultrasonic damping on spruce standing trees (sound or with rot) (average values) [87].

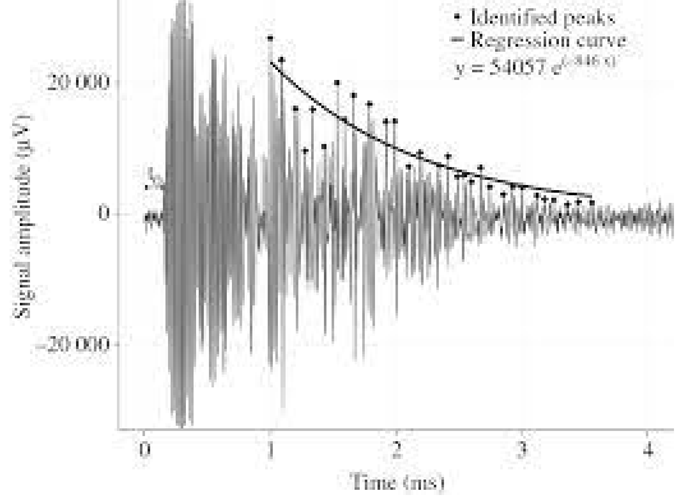

The calculated ultrasonic damping at the stump level increases in trees with rot. Above stump level, the damping has hieratic values. Ultrasonic attenuation depends on the specific measurement conditions [88]. The methodology of ultrasonic attenuation measurements proposed by [87] should be improved by a more advanced signal treatment in the frequency domain.

For the detection of internal rot and associated defects in standing trees of European Norway spruce (Picea abies). Ref. [87] proposed two predictive models, one based on the radial velocity and another based on attenuation (Table 17). The overall prediction accuracy and sensitivity is around 0.82%.

Table 17.

Prediction models for the detection of internal rot and associated defects in standing trees of European Norway spruce (Picea abies) based on the determination of velocity and damping of ultrasound in the radial direction at stump level [87].

- (b)

- Effect of thinning

The main objective of thinning as a silvicultural operation is to reduce the density of trees in a stand to improve the quality and the growth rate of the remaining trees. Thinning is done by harvesting smaller diameter and bad quality trees. The effect of thinning on hardwood species with acoustic technology was studied less in hardwood species than in softwood species. The following section gives some data explaining the correlations between the properties of wood measured on standing trees, on small diameter round timber and in dry logs for the prediction of mechanical properties of wood for three hardwood species (alder, ash, sycamore) of Irish origin [89]. The parameters of the trees are given in Table 18.

Table 18.

The effect of thinning on the characteristics of trees and the velocity of stress waves propagating along the L axis [89].

The effect of the thinning treatment can be seen in

- -

- An increase with age of the diameter of the tree at breast height (DBH) and of the height of the tree;

- -

- Increasing velocity after the second thinning in standing trees and in logs;

- -

- The velocity, VL, measured on standing trees with a greater VL measured on green logs by about 20%. This can be explained by the fact that the velocity on trees is measured under the stress created by the mass of the crown, the branches, the leaves.

3.3.3. Trees from Plantations

Plantation trees are usually of one species and are destined to produce a high volume of wood in a relative short period of time. These monoculture forests can be of a softwood or hardwood species, indigenous or exotic. The plants used for these forests are often genetically modified to resist pests and diseases or to have stem straightness for a high-volume production of wood. Selected plants grown in seed orchards are an appropriate source for seeds to develop adequate planting material for monoculture forests. In general, plantations of fast-growing species commonly yield between 20 and 30 m3/ha per year. Natural forest production is about 3 m3/ha per year. Of course, the quality of wood produced is not the same. In 2020, the total area of planted forests globally was estimated at 294 million ha, which is 7 percent of the world forest area. It was estimated that they supplied about 35% of the world’s roundwood. Therefore, the development of acoustic methods for the nondestructive detection of the quality of round wood is of utmost economic importance.

“The main idea for commercial forest planting is that instead of cutting down natural forest to supply industries, such forests are created and managed to avoid exploitation of native trees and also protect natural ecosystems. In addition, commercial forests acquire the capability to absorb substantial amount of carbon dioxide of the atmosphere and provide citizens with jobs and improve country economy” http://www.florestal.gov.br/snif/recursos-florestais/as-florestas-plantadas (accessed on 11 November 2022).

In this section, we discuss the grading of logs of plantations of Pinus radiata, Sitka spruce and Eucalyptus spp.

- (a)

- Plantation of Pinus radiata

Pinus radiata is the most frequently planted species in countries of the Southern Hemisphere and also in Europe in the south of Spain. Wood of this species is valued for its fast growth and utility for construction lumber as well as for pulp and the paper industry. “It is a tree which is suited to a considerable range of growing conditions, is easily raised and planted, and provides larger yields of usable timber in a shorter time than many native species. The timber is particularly useful: it can be readily sawn, peeled, or converted to pulp, has good nail-holding power, works well, can be easily stained, and when treated with preservatives, is suitable for long-life applications in the ground” (https://www.forestrycorporation.com.au/).

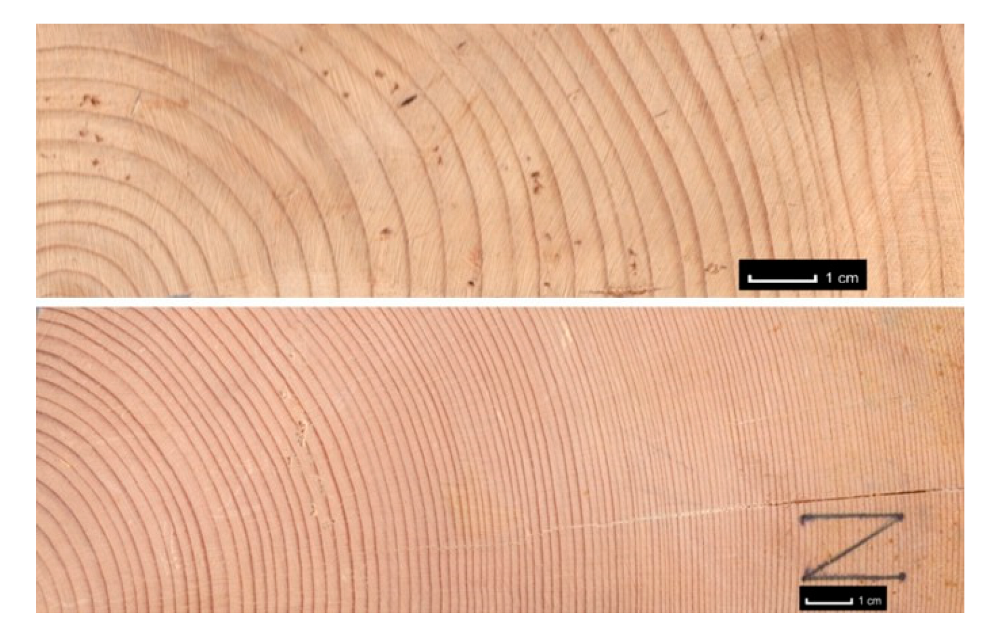

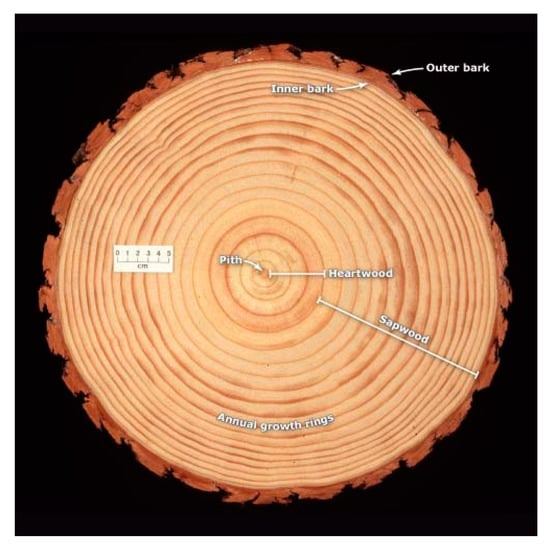

The macroscopic structure of Pinus radiata on the transverse section of a tree is illustrated in Figure 13. Note the large variation of the width of the annual rings and the presence of the compression wood due to the response of the young tree to the external stress of wind and other factors. This structural anatomical variation creates a very large variation in wood stiffness both within and amongst the trees. Therefore, the production of high-grade lumber could be expected from some trees while from others a low-grade lumber could be expected.

Figure 13.

Cross section of Pinus radiata tree, 20 years old, with an annual ring width ranging from very large >10 mm to <5 mm. Juvenile wood is about 5 years old with a corresponding very large width of annual rings. Compression wood is present mostly on the right side of the disc and on the latewood zone of the annual ring. https://teara.govt.nz/files/di16849enz.jpg (accessed on 11 November 2022).

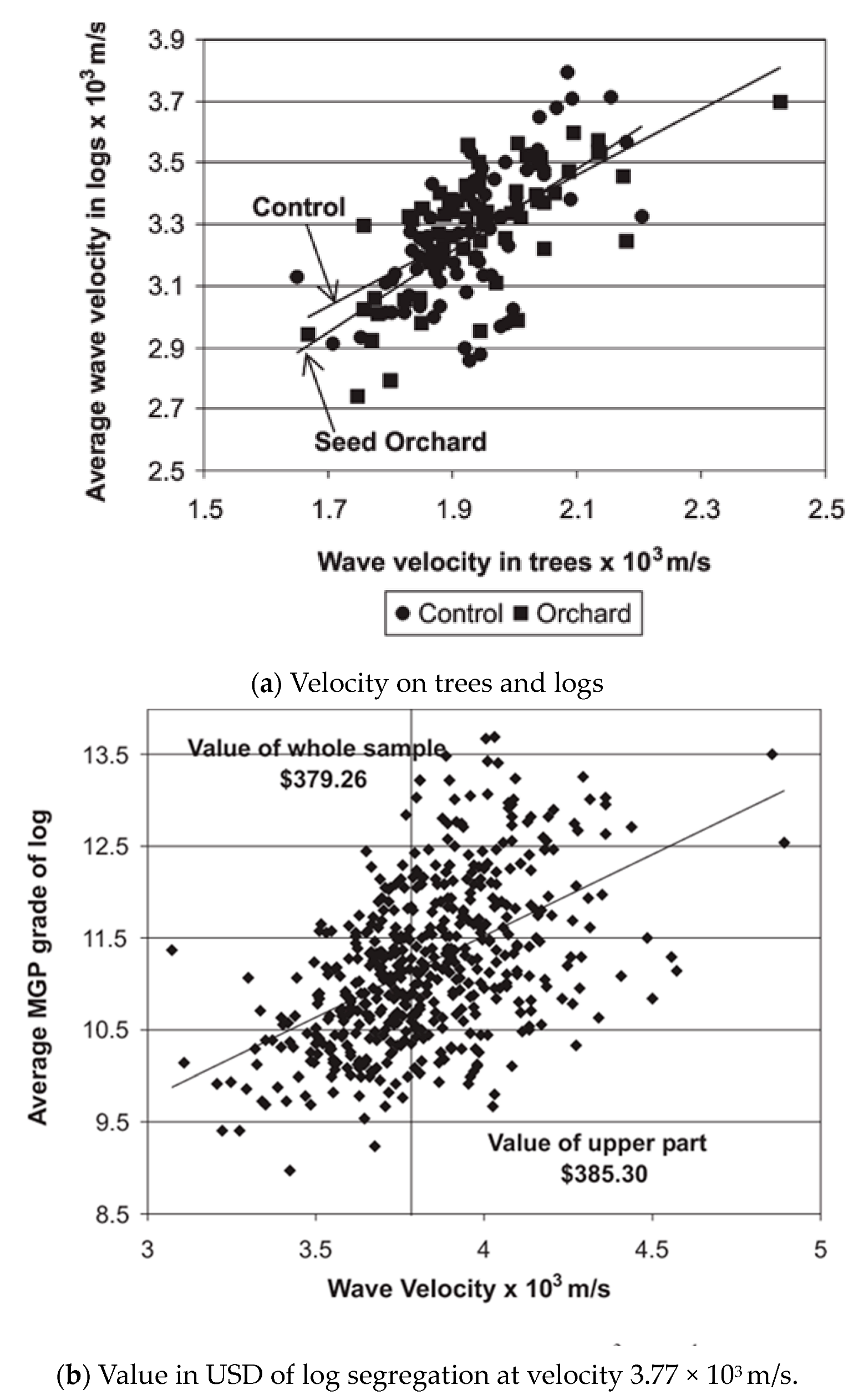

The segregation of standing trees in forests for logs with predominantly high stiffness wood can be achieved by measuring the velocity of stress waves at breast height on each tree. The correlation coefficient between the velocity on trees and on logs is highly significant (r = 0.62**), as was established using 316 logs [90].

Generally, trees from plantations have more defects than orchard trees.

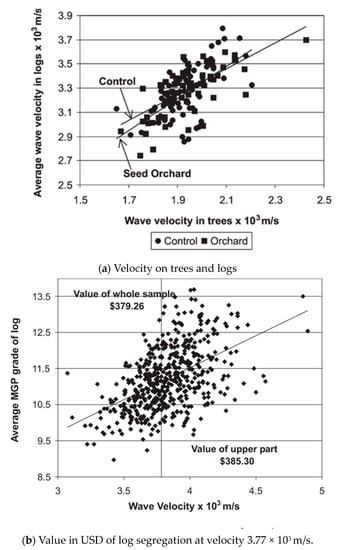

A comparison between the velocity measured on trees from plantations and from orchards is given in Figure 14. It was mentioned that lumber boards from seed orchard trees had lower average stiffness than lumber boards from control trees in a plantation but greater minimum stiffness.

Figure 14.

Relationships between the velocity measured on trees and on logs [91]. (a) Comparison between wave velocities in standing trees and on logs. Each data point represents the average of two measurements for standing trees and represents the average of both measurements over all logs in a tree for cut logs. (b) Value in USD of log segregation at 3.77 × 103 m s–1. Each data point represents a single log; see Figure 2, page 475.

For defining lumber of good quality, a segregation threshold of 3770 m/s was proposed and, at the same time, it was proposed to estimate the cost of “the value of the timber with greater velocity was USD 385.30 m–3 compared with a value of the whole set of USD 379.26 m–3. There is a difference of USD 6.04 m–3 which is the extra revenue due to the segregation of logs. For a mill capacity of 600,000 m3 year–1, this extra revenue would be USD 3,624,000 year–1” [91]. The benefit of acoustic segregation does not need more arguments compared with the costs of acoustic technology.

- (b)

- Plantation of Sitka spruce

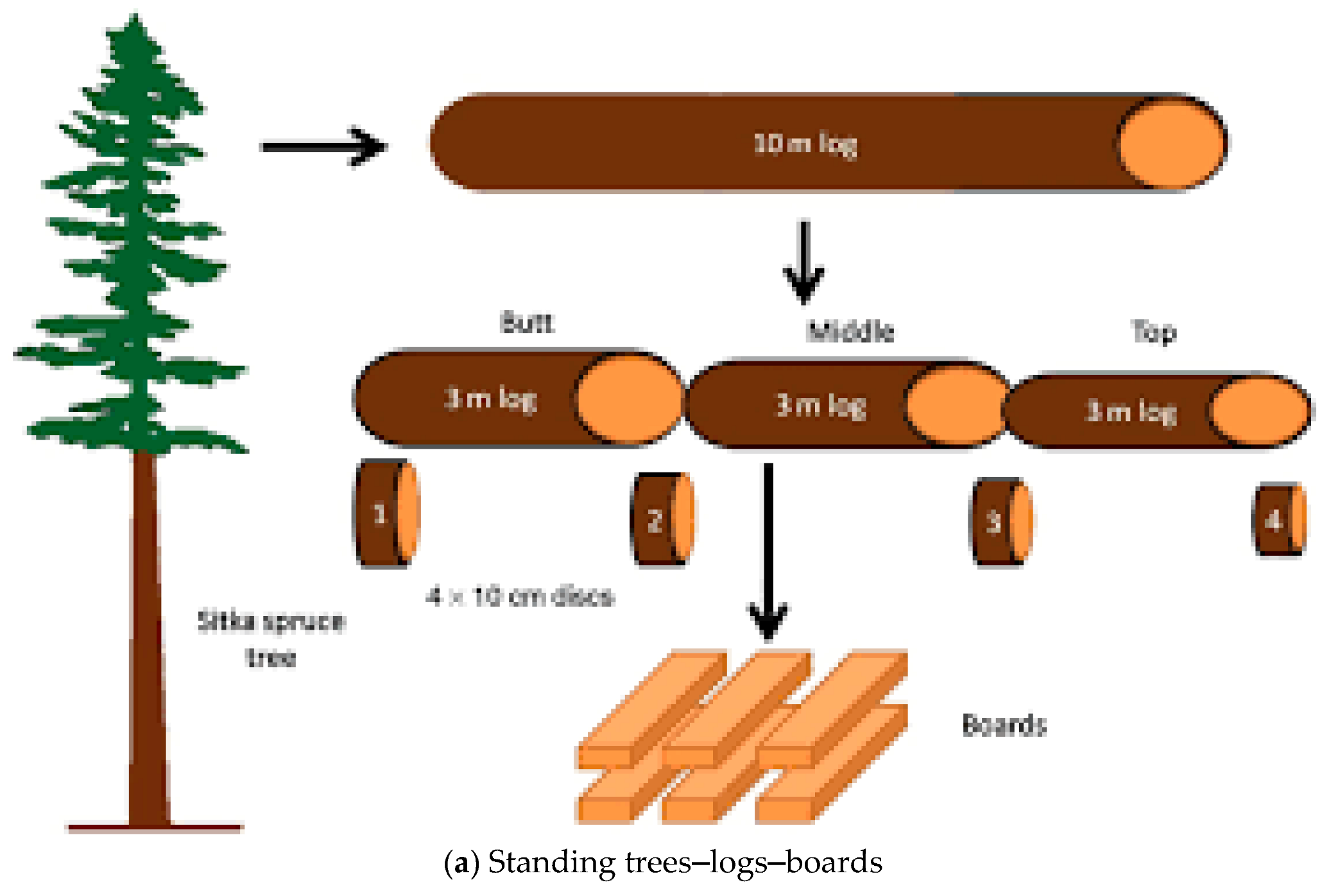

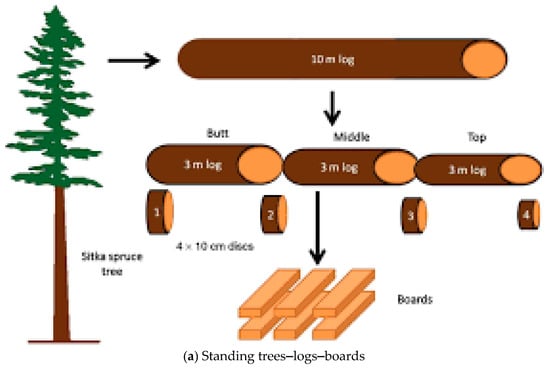

Sitka spruce (Picea sitchensis) plantations cover important surfaces in the North European countries. Ref. [92] mentioned that in Ireland this species occupies about 52% of the total forest area. In Ireland, most structural timber is machine-graded into the C16 strength class [93].

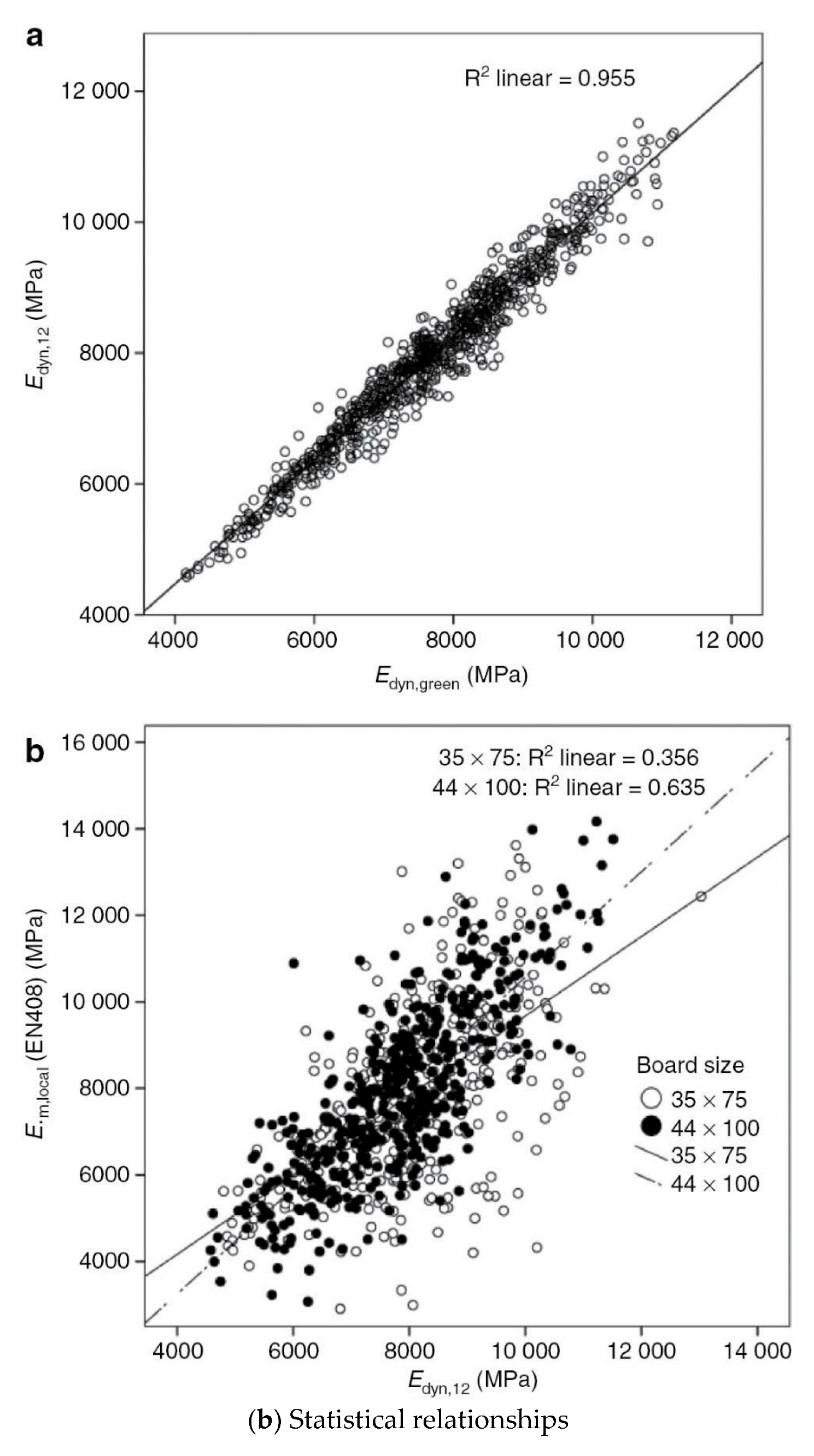

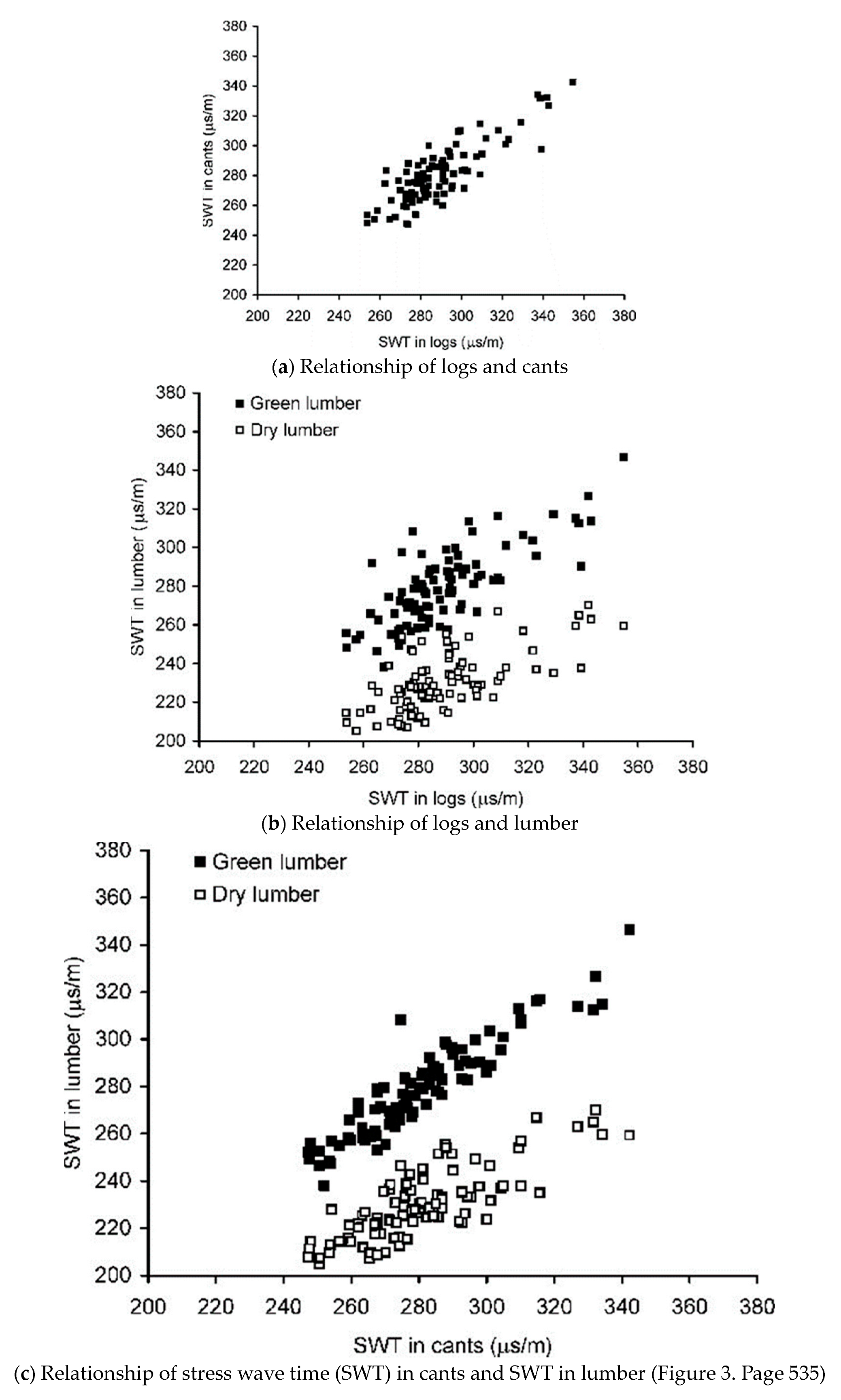

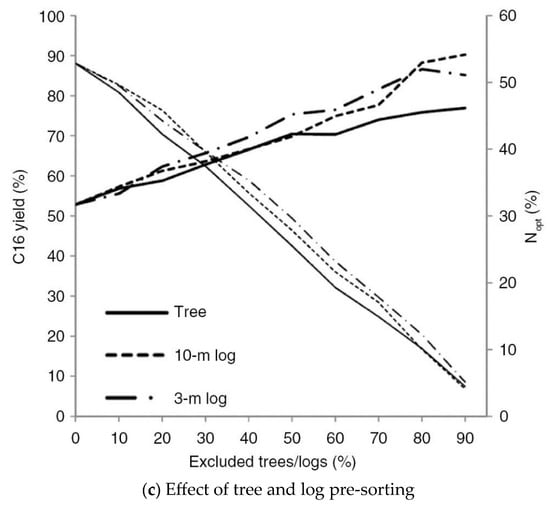

The increasing demand of structural timber from young trees requires objective criteria for pre-sorting small diameter trees from thinning. For this purpose, a combined methodology based on the measurement of the frequency resonance frequency of logs and corresponding boards was proposed, combined with stress wave velocity measurements and with pilodyne pin penetration depth. Felled trees were cut into logs of 10 m (Figure 15a). These logs were cut in 3 m long logs on which resonance frequency was measured. Static bending tests were made on boards to determine the MOE. Statistical correlation models were derived with all mentioned parameters. Figure 15b displays the correlations between the MOE of green and dry boards in general (R2 = 0.955) and of different cross sections (35 mm × 75 mm, R2 = 0.356 and 44 mm × 100 mm, R2 = 0.635). The beneficial effect of tree and log pre-sorting on C16 yield and on the proportion of optimum grade boards is illustrated in Figure 15c. The beneficial effect is very strong if the proportion of the excluded trees was greater than 50%. Acoustic technology is very effective for pre-sorting young trees for the benefit of high-quality boards and structural lumber. All data refer to measurements along the L-axis of the wood.

Figure 15.

Acoustic technology for processing the wood quality from Sitka spruce plantation, standing trees to boards [92]. (a) Processing on trees, logs and boards (Figure 1, page 141). (b) Statistical relationships and coefficients of determination for MOE lumber dry and green with the acoustic method and with static bending tests; European norm EN 408 [94] (Figure 3, page 145). (c) Effect of tree and log pre-sorting on C16 yield and absolute proportion of optimum grade boards (Figure 5, page 146).

- (c)

- Eucalyptus species

Selection of eucalyptus clones resistant to the strong wind in Brazil is a major economic problem. Ref. [95] selected 21 different clones of Eucalyptus grandis and Eucalyptus urophylla species of Brazilian origin and from these clones the corresponding 189 trees. The mean diameter of the stem of clones varied between 107 mm and 142 mm. The velocity of ultrasonic waves measured on the standing trees in the longitudinal direction with 45 kHz transducers varied between about 3500 m/s and 4500 m/s. The round wood obtained from the standing trees of 5–6 years of age was tested statically to determine the modulus of rupture and the static bending modulus of a cantilever beam. This test simulated the effect of wind on standing trees. The following regression equations have been deduced from this very big experimental data set:

- -

- Modulus of rupture in static cantilever test and the velocities—mean and minimum

MOR = −103 + 0.042 V min; R = 0.81 R2 = 0.653 − non explained variability 34.7%

MOR = −94 + 0.038 V mean; R = 0.78 R2 = 0.573 − non explained variability 42.7%;

- -

- Velocities (m/s) and diameter (m) of the tree

V mean = 5 797 − 152.7 × Diameter; R = −0.49 R2 = 0.24 − non explained variability 76%

V min = 5 788 − 165.6 × Diameter; R = −0.49 R2 = 0.24 − non explained variability 76%;

- -

- Multiple regression modulus of rupture, the velocities and the diameter

MOR = −163 + 0.049 V min + 0.28 Diameter; R2 = 0.693 − non explained variability 30.7%

MOR = −131 + 0.042 V mean + 0.18 Diameter; R2 = 0.591 − non explained variability 40.9%.

The variability is better explained by introducing V min into the regression. There is an effect of the diameter of the tree on the measured velocity along the fibers in the L direction. For a small diameter, the tree can be simulated by a bar. The measured velocity corresponds approximately to the propagation of a longitudinal ultrasonic wave. In the case of larger diameters there is a mode conversion of the longitudinal waves, probably in Love-type surface waves, which propagate with lower velocity. The effect observed on V min and V mean needs to be studied in more detail using a more elaborate statistical treatment of data. In any case, it has been proved that acoustic technology can substantially improve selection of clones of Eucalyptus which are more resistant to wind.

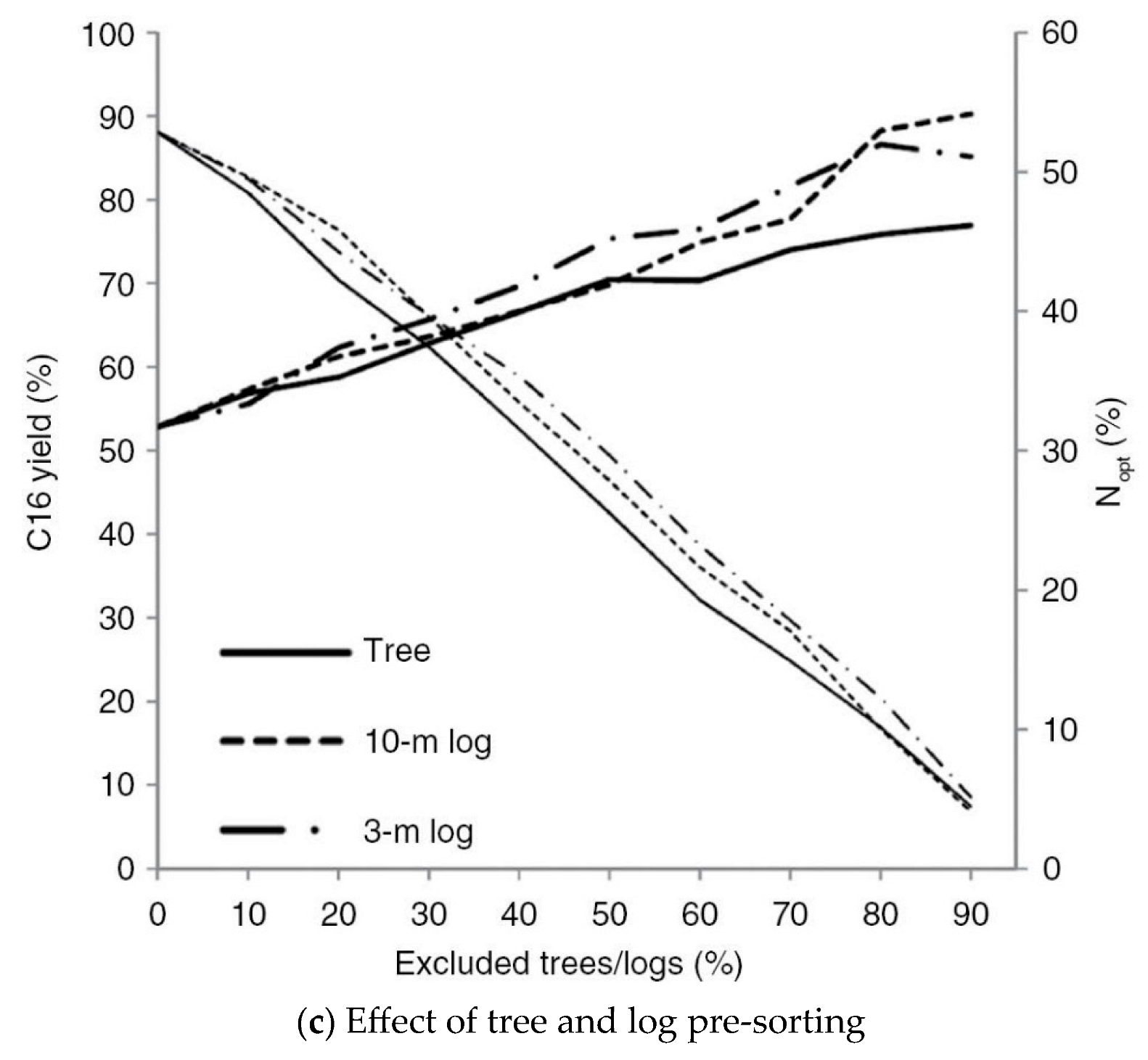

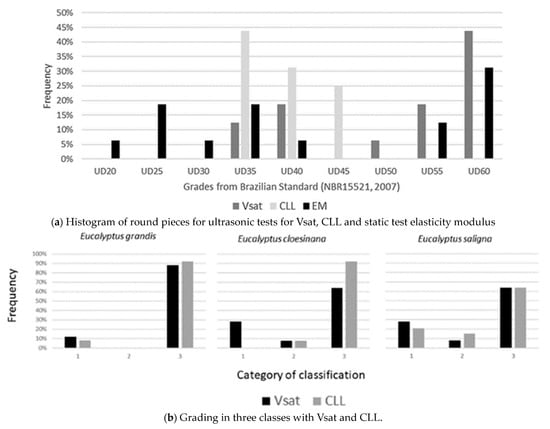

Grading of round timber of Eucalyptus species of low diameter is essential for correct utilization of this raw material. Three varieties of eucalypts, namely Eucalyptus grandis, Eucalyptus cloeziana, Eucalyptus saligna have been tested with the ultrasonic velocity method and with a static bending test (Table 19) to determine the potential of these materials for further utilization as sustainable resources. The round timber was graded with static bending and the ultrasonic velocity method—Brazilian standard NBR 15521 (2007)—Nondestructive testing, ultrasonic testing, mechanical classification of dicotyledonous sawn wood [96]. The transducers of 45 kHz frequency were equipped with an exponential tip. The frequency statistical distribution of round wood green pieces was determined by three methods—ultrasonic velocity V saturate, the corresponding stiffness coefficient CLL and the modulus of elasticity determined in the static bending test (Figure 16a). Grading of these pieces in three classes was possible using the velocity and the corresponding stiffness constant (Figure 16b). It was concluded that the velocity measured in the longitudinal direction on round wood of small diameter in saturated condition is “the simplest and most appropriate parameter for acoustic grading of round Eucalyptus timber “. This acoustic technology can be incorporated into an automatic control system at a relatively low cost. Figure 17 shows some aspects of plantations of Eucalyptus in Brazil.

Table 19.

Average parameters of the Eucalyptus grandis, Eucalyptus cloeziana, Eucalyptus saligna round timber, diameter between 151 mm and 207 mm and density 740 kg/m3 and 820 kg/m3 [62].

Figure 16.

Ultrasound grading of small diameter round Eucalyptus timber of Brazilian origin [62]. (a) Percent distribution of the round pieces of Eucalyptus grandis in the stiffness grades of Brazilian standard NBR 15521 (2007) [96] [using the static modulus of elasticity (EM) the saturated velocity (Vsat) measured in the longitudinal direction at 45 kHz and the corresponding stiffness coefficient (CLL) as input parameters (Figure 2 page 893)]. (b) Grades by velocity under saturated conditions (Vsat) and by the stiffness coefficient (CLL) obtained for the lots composed of round timber Eucalyptus grandis, Eucalyptus cloeziana and Eucalyptus saligna. Diameters ranging from 15 cm to >20 cm (Figure 8 page 896).

Figure 17.

Plantation of Eucalyptus in Brazil. (a) In situ measurement (Figure 1, page 113c. [95]). (b) Ultrasonic measurements on logs (Figure 1 [62]). (c). Plantation of eucalypts in Brazil https://tunza.eco-generation.org/file/396.jpg (accessed on 22 June 2020) (d) Harvesting of eucalypt timber in Brazil.

3.4. The Quality of Logs and Lumber for Structural Purpose

3.4.1. Stress Wave Method on Logs and Lumber

Relationships between the properties of trees, logs and lumber for structural purposes have been widely studied by [59,97,98] for the case of red maple (Acer rubrum), widely used in the USA. As mentioned by [99], the value per unit volume for red maple logs and lumber is strongly increased if the raw material is subjected to an objective segregation of logs with acoustic methods, as, for example:

- -

- For log grade F1, the value in USD is 178 for logs, 243 for dimension lumber and 329 for factory lumber.

- -

- For log grade F2, the value in USD is 99 for logs, 236 for dimension lumber and 272 for factory lumber.

- -

- For log grade F3, the value in USD is 81 for logs, 211 for dimension lumber and 227 for factory lumber.

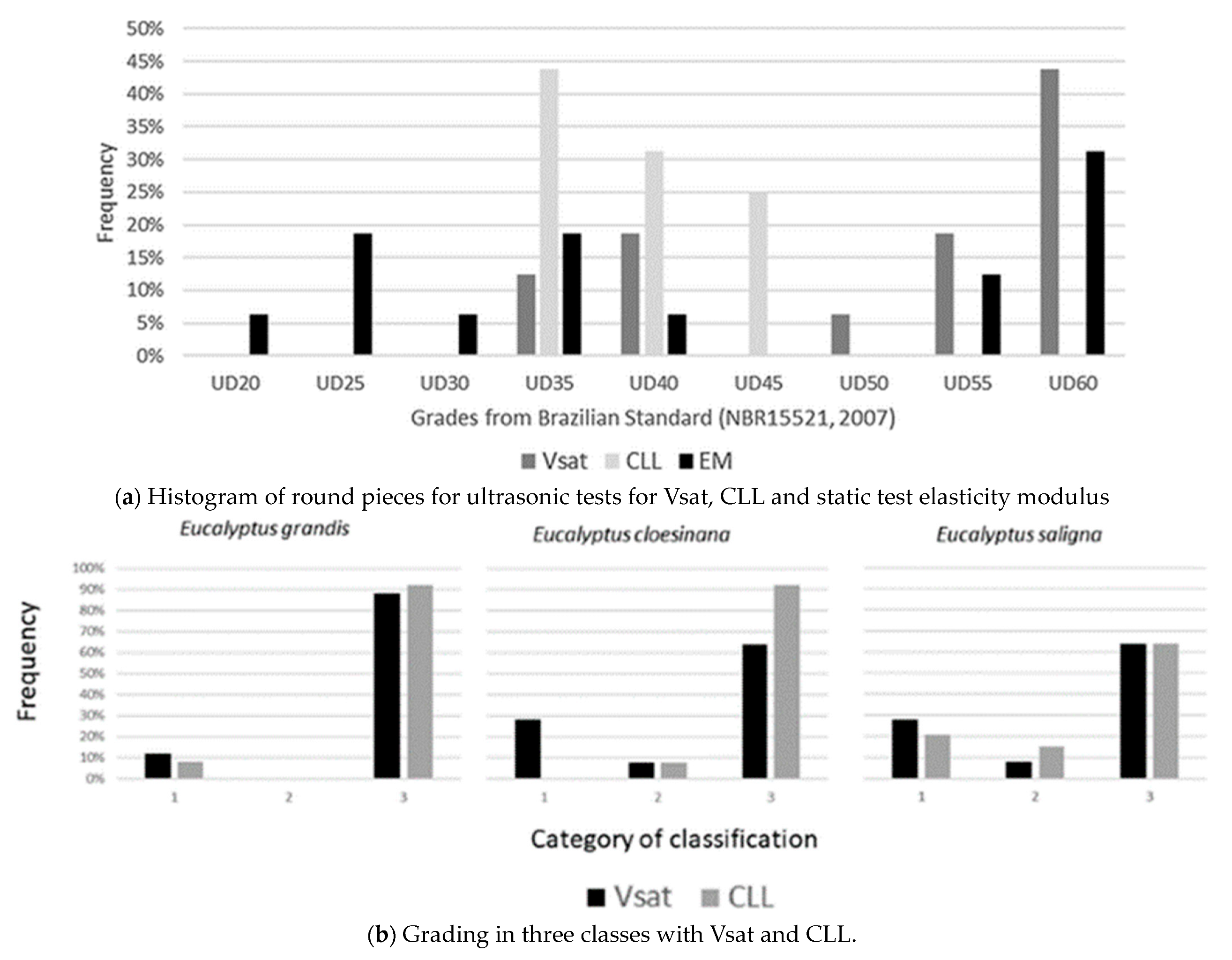

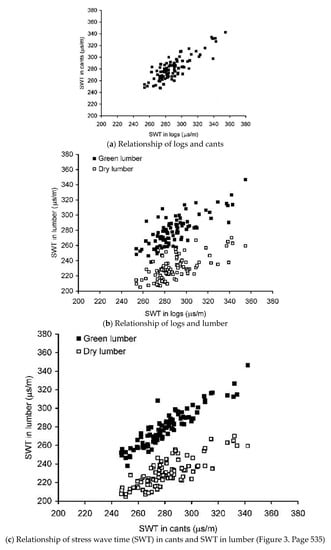

Wang et al. [59] evaluated ninety-five red maple logs with longitudinal stress wave techniques, and they were sorted into four stress wave grades. The logs were then sawn into cants and lumber. (Cant section: 152-× 203-mm. Lumber section: 51 mm × 152 mm). The same experimental methodology was used to obtain the time of propagation of stress waves in cants and lumber, green and dry. The green lumber was dried. Green and dry lumber was graded into four classes using a transverse vibration technique. With the values of the specific stress wave times expressed as (μs/m), velocities (m/s) have been calculated for logs, cants, green and dry lumber (Table 20).

Table 20.

Values of specific stress waves propagation time (μs/m) and the corresponding calculated velocities (m/s) for logs, cants, green lumber and dry lumber of red maple (Acer rubrum) [59].

The velocities for logs, cants and green lumber are smaller because of the presence of bark. The velocity of dry lumber (12% mc) is 17% higher than for green lumber. Lumbers are on average in the range 3469 m/s to 3703 m/s. The velocity on logs is 3400 m/s.

Table 21 gives data on the stress wave method for segregation of maple logs into four classes: G1, G2, G3 and G4 and the corresponding resulting mechanical parameter of lumber, ranging from >13.79 GPa to less than 8.27 GPa. Simple statistical correlation coefficients corresponding to the relationships between logs and cants, cants and green and dry lumber produced from the logs are given in Table 22, in which are given the coefficients of correlation for simple regression analysis of stress wave times (SWT) for red maple logs and corresponding cants and lumber produced from the logs.

Table 21.

Stress wave method for segregation of maple logs and lumber [59].

Table 22.

Coefficient of correlation for simple regression analysis of stress wave times (SWT) for red maple logs and corresponding cants and lumber produced from the logs [59].

In Figure 18 are shown the high correlation between the stress wave time of propagation (expressed in μs/m) between logs and cants, logs and green lumber and between dry and green lumber.

Figure 18.

Relationship of stress wave time (SWT) in red maple logs, in cants and in lumber [59]. (a) Relationship of stress wave specific time (SWT) in logs and SWT in cants (Figure 1. page 534). (b) Relationship of stress wave specific time (SWT) in logs and SWT in lumber (Figure 2 page 534). (c) Relationship of stress wave time (SWT) in cants and SWT in lumber (Figure 3. page 535).

The logs have been segregated into four classes as:

- -

- The first class has the highest velocity of the stress waves (3676 m/s) and the highest MOE (13.51 GPa). For lumber, the MOE is in the same range (13.79 GPa)

- -

- The last class has the lowest velocity (3048 m/s), the lowest MOE (9.29 GPa). For lumber, the MOE is 8.27 GPa.

- -

- Comparing the class G1 to G4, note the decrease in velocity of 17% for logs and of

- -

- 30% in the MOE for logs and 40% for lumber.

- -

- Correlation coefficients between the stress wave propagation time in logs and cants or lumber are highly significant, between 0.72 and 0.95 (Figure 18).

In conclusion, the proposed methodology is appropriate for grading logs, cants and lumber by measuring the time of propagation of longitudinal stress waves. From red maple logs with high acoustical properties, it is possible to produce lumber of high mechanical properties for structural purposes.

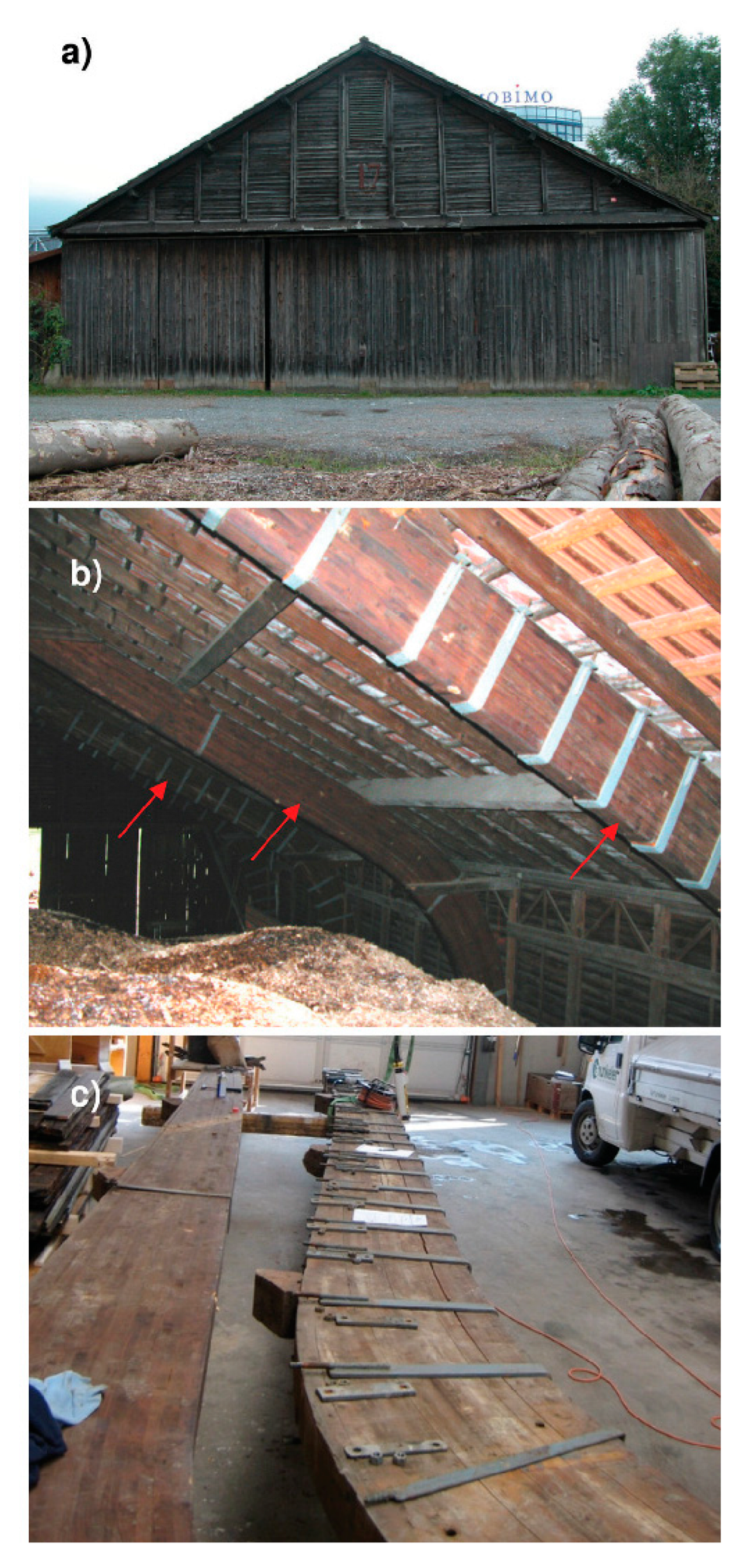

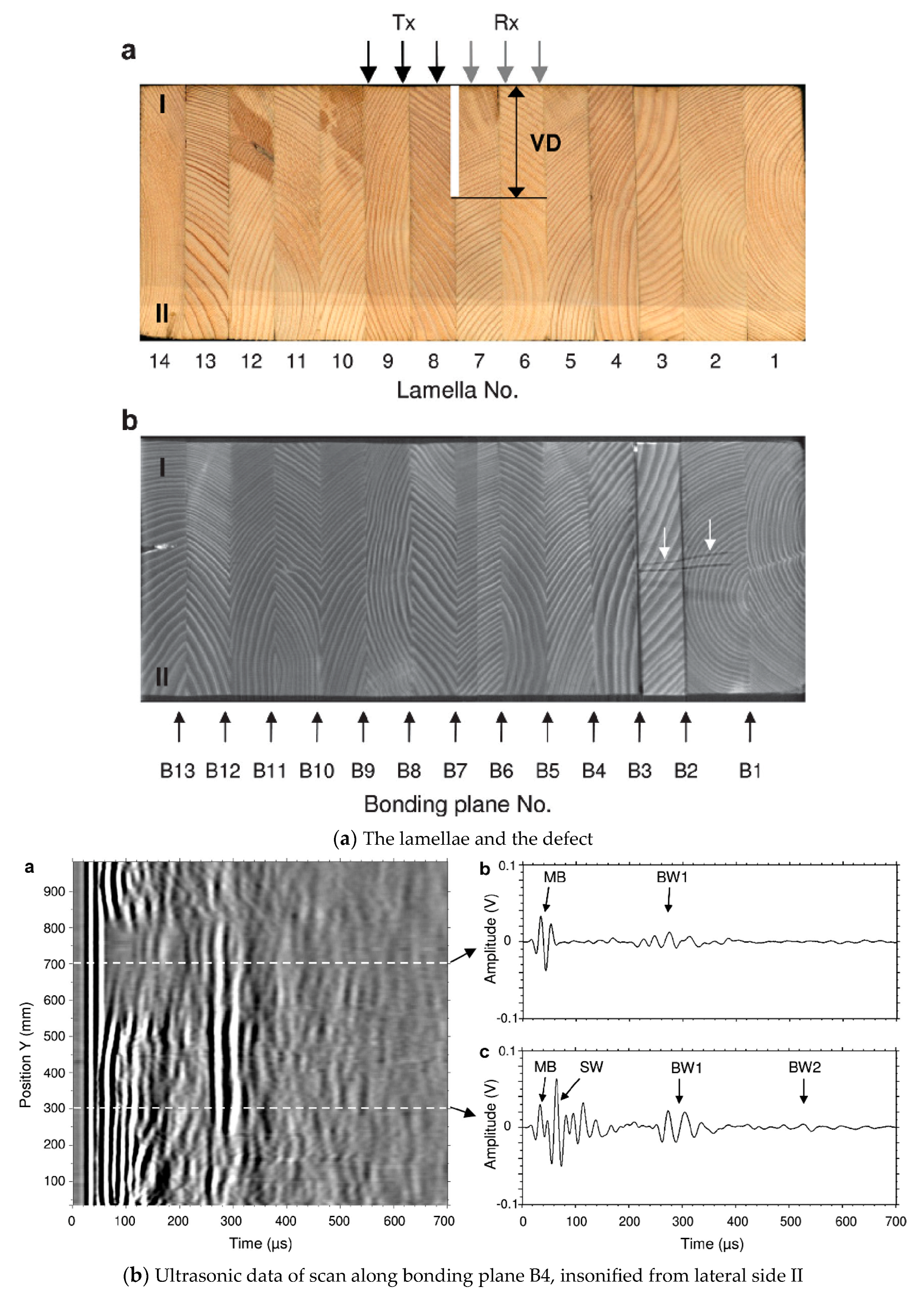

3.4.2. Frequency Resonance Method on Lumber

Restoration of wooden structures for historical buildings requires precise determination of mechanical parameters of existing structural elements. The parameter currently preferred for these elements is the modulus of elasticity, which can be determined with the ultrasonic propagation method, by measurements in situ of the time of propagation of ultrasonic waves and without affecting the piece. Higher values of MOE are associated with greater load capacity and less deformation of the piece under static load. It is generally accepted that with static tests we can directly access a value of Young’s modulus, noted in the literature with the acronym MOE. With the ultrasonic technique we measure the stiffness as the product of density and the squared velocity. In the case of large pieces of lumber, these two parameters are considered equivalent because there is no need for correction of Poisson ratios, given the size of the elements. Therefore, in the literature, it was accepted to find MOE static for the Young’s modulus determined with static tests and MOE dynamic for the elastic constant, the stiffness, measured with ultrasound on large pieces of wood. In general, MOE dynamic > MOE static, with the difference between the two values ranging between 5% and 20% depending on wood species. Strong statistical relationships have been established between these moduli with simple regression correlation coefficients.

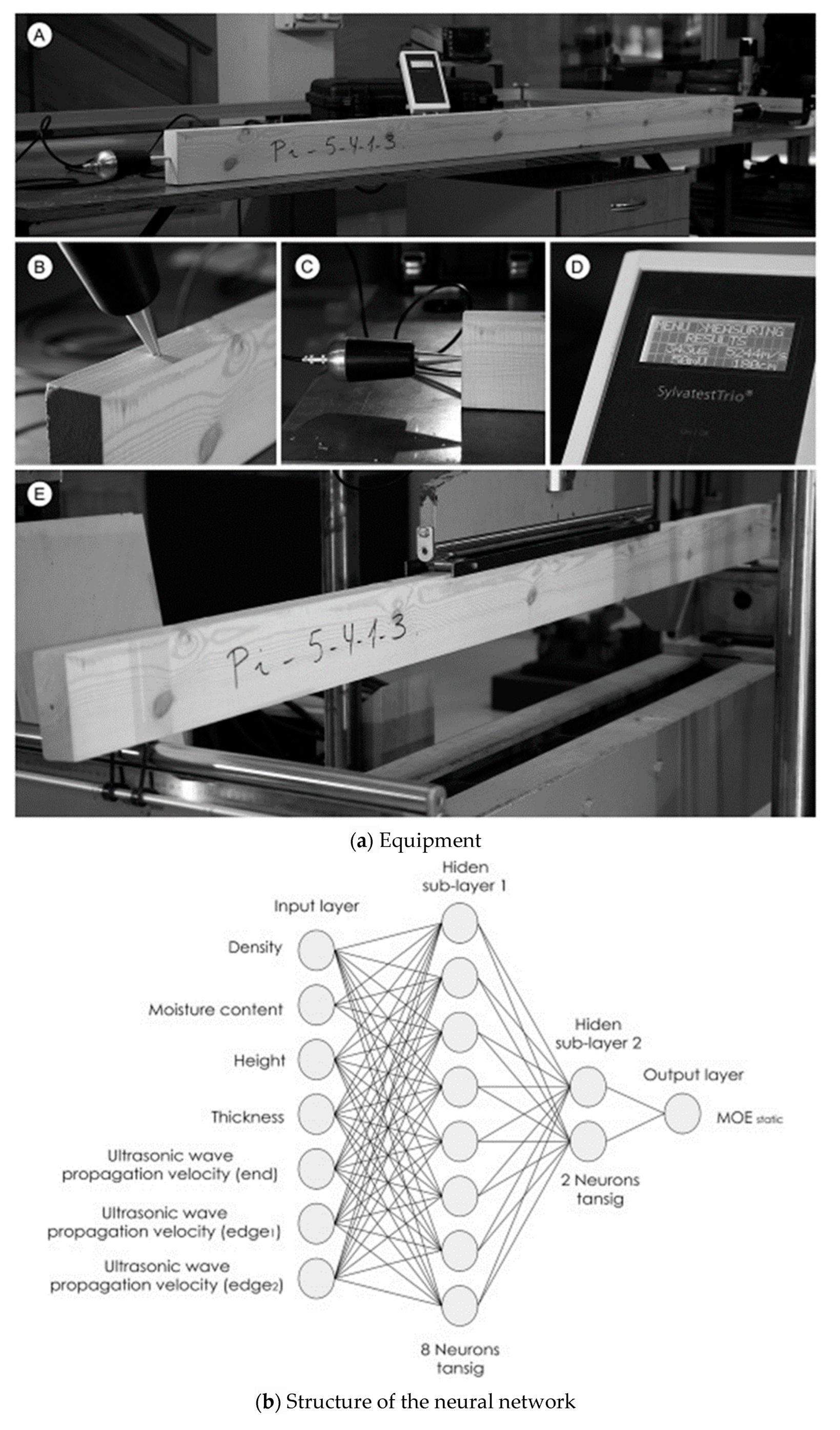

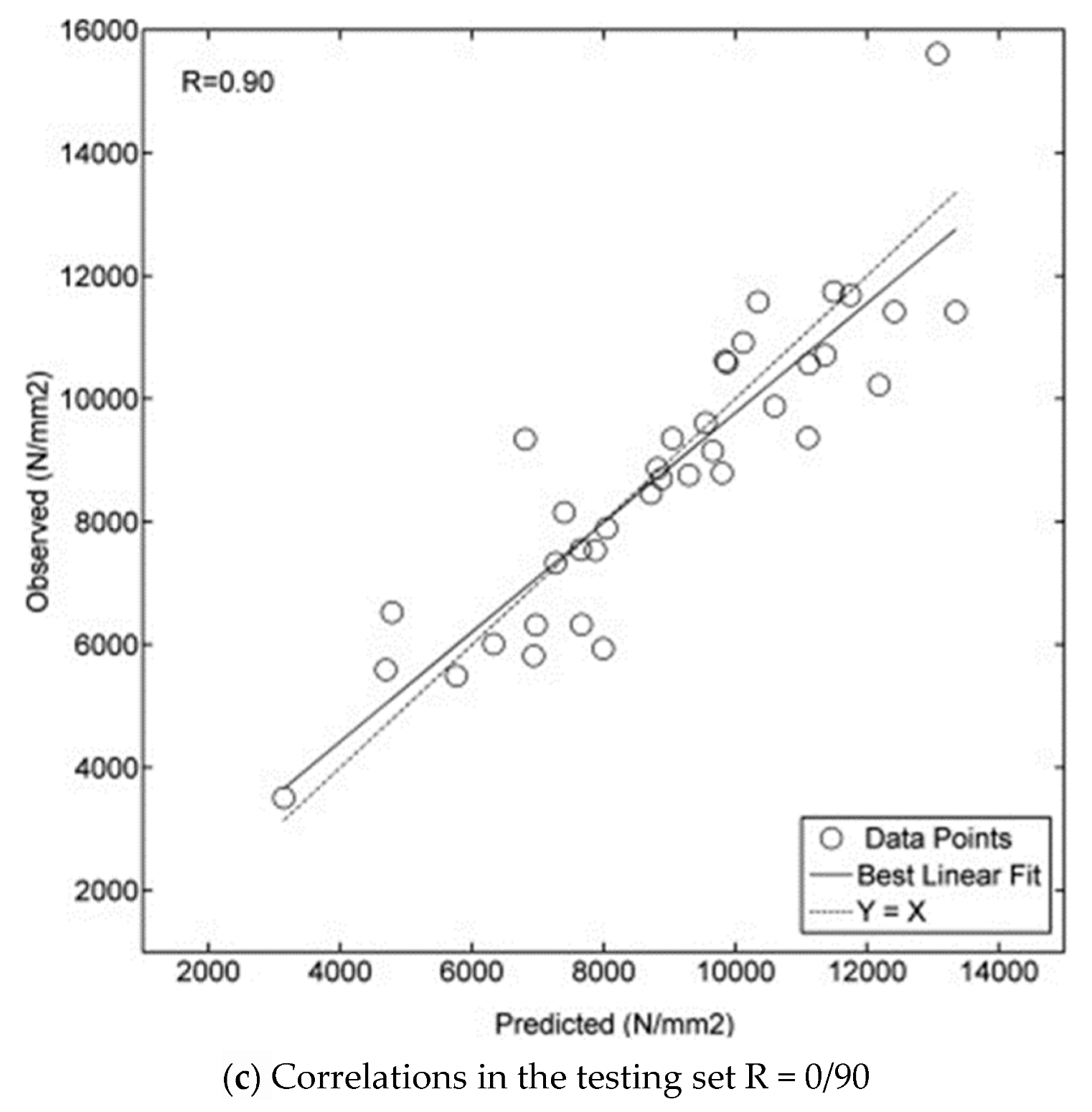

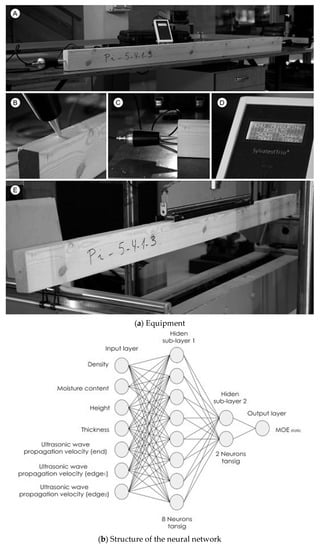

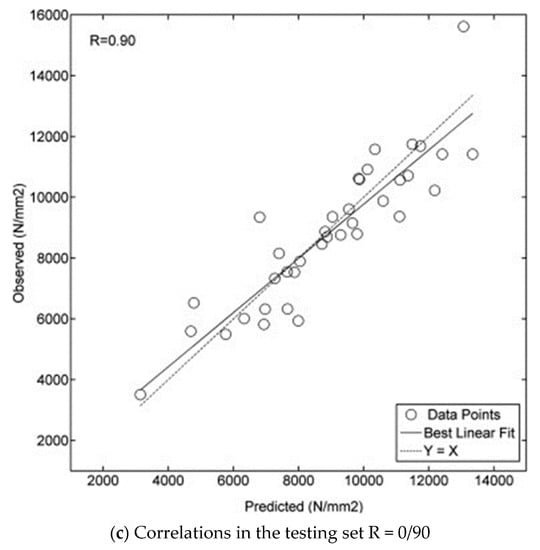

Classical statistical regression modeling can be substantially improved by using artificial neural networks. Ref. [100] compared the statistical regression modelling which explains 70% of the variability of the population studied, to artificial neural networks which can explain 80% of the variability taking into account the size of the transverse section of the pieces, the density, the moisture content, the ultrasonic velocity and the modulus of elasticity determined with a static bending test (Figure 19a). The structure of the neural network is given in Figure 19b The artificial neural network has a transfer function, which is defined by the Equation (17).

where f (x) is the output value of the neuron and x is the input value of the neuron.

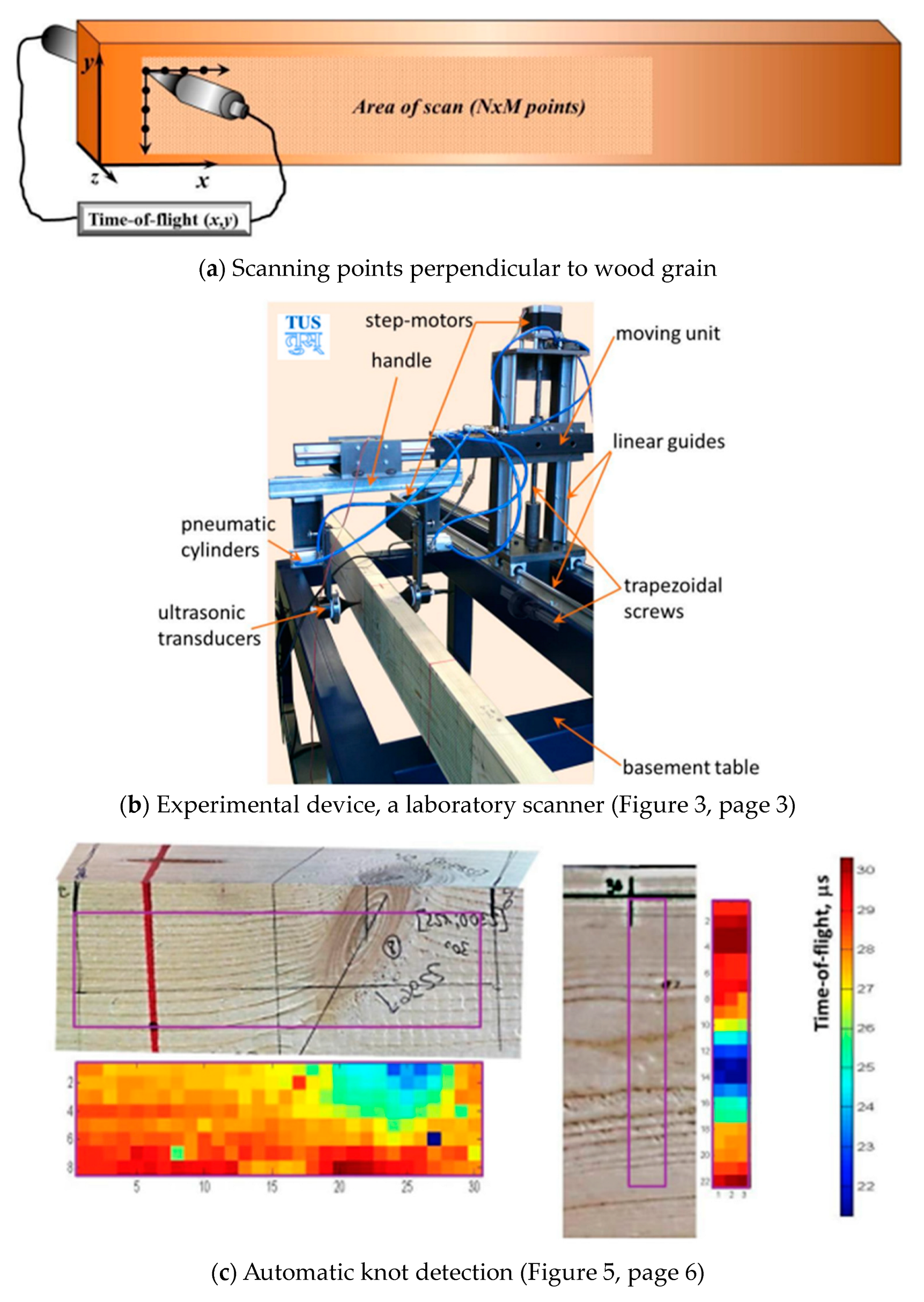

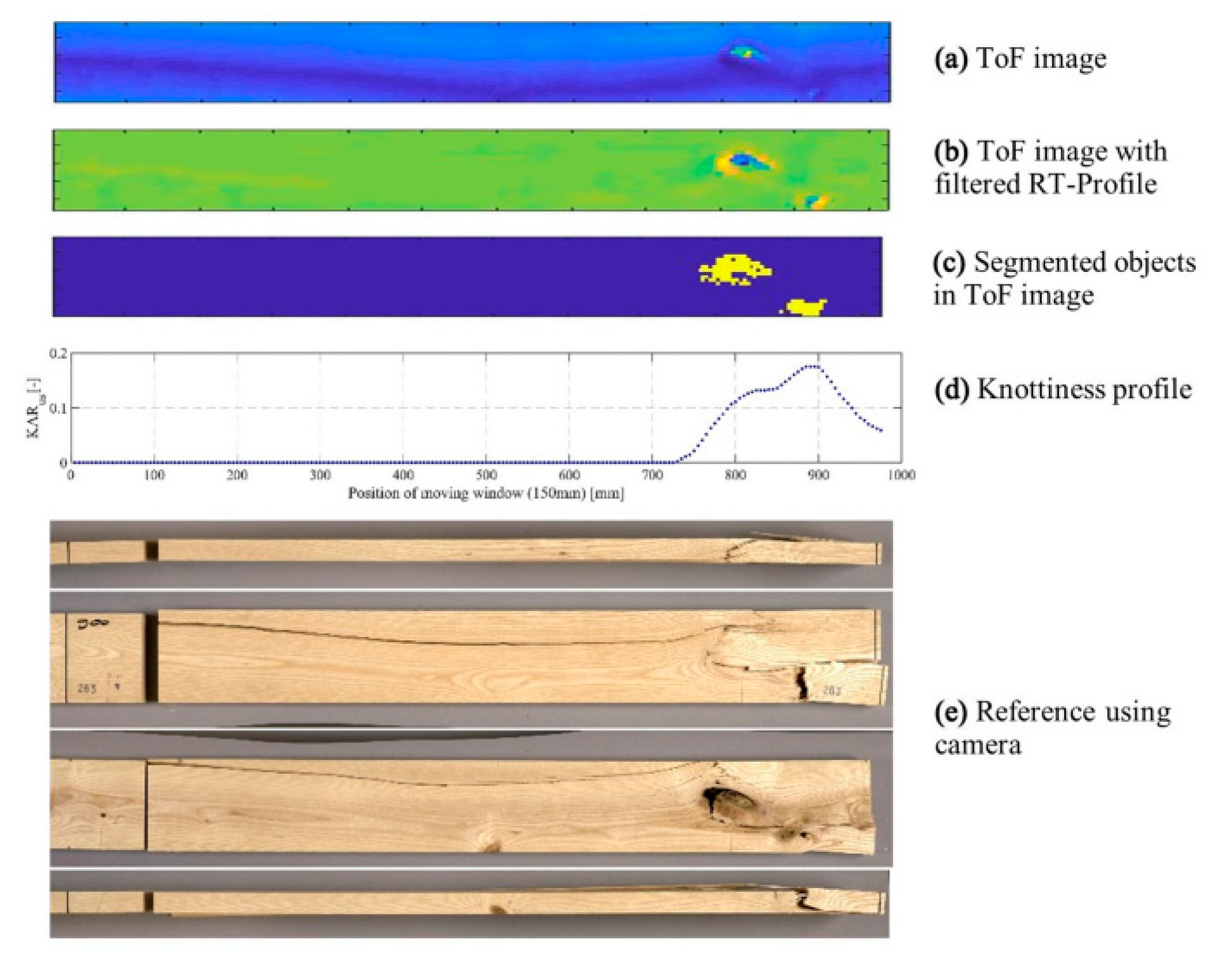

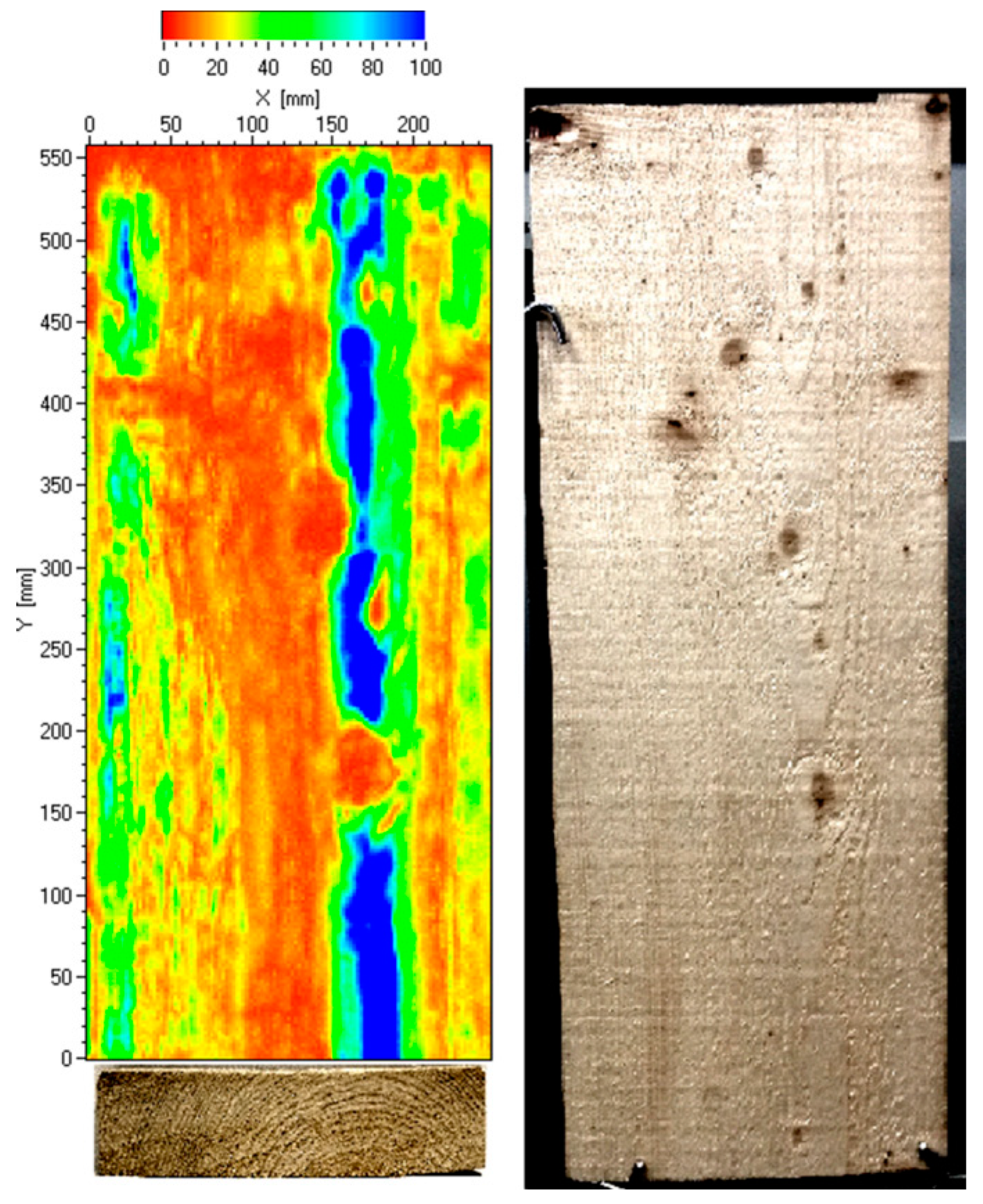

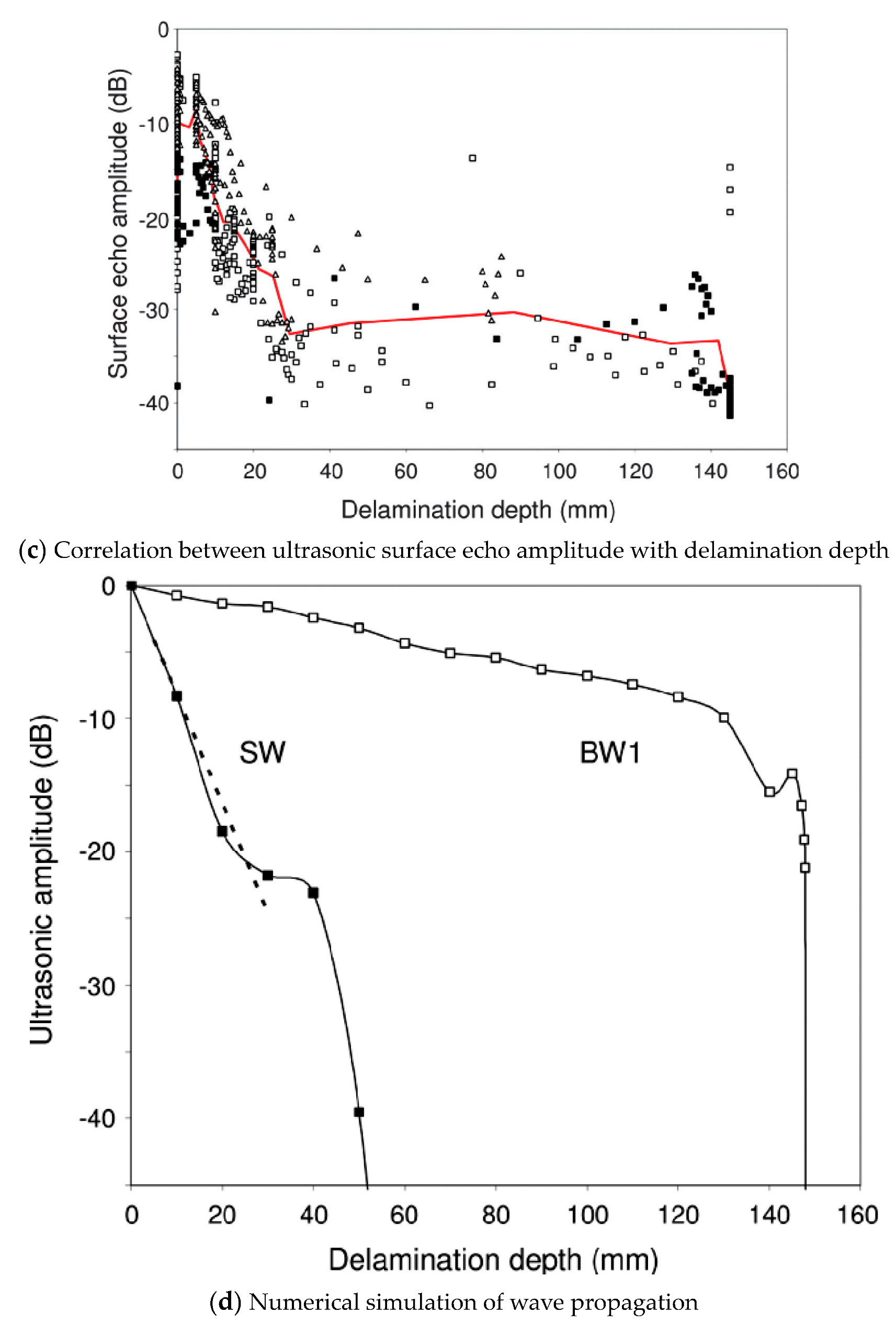

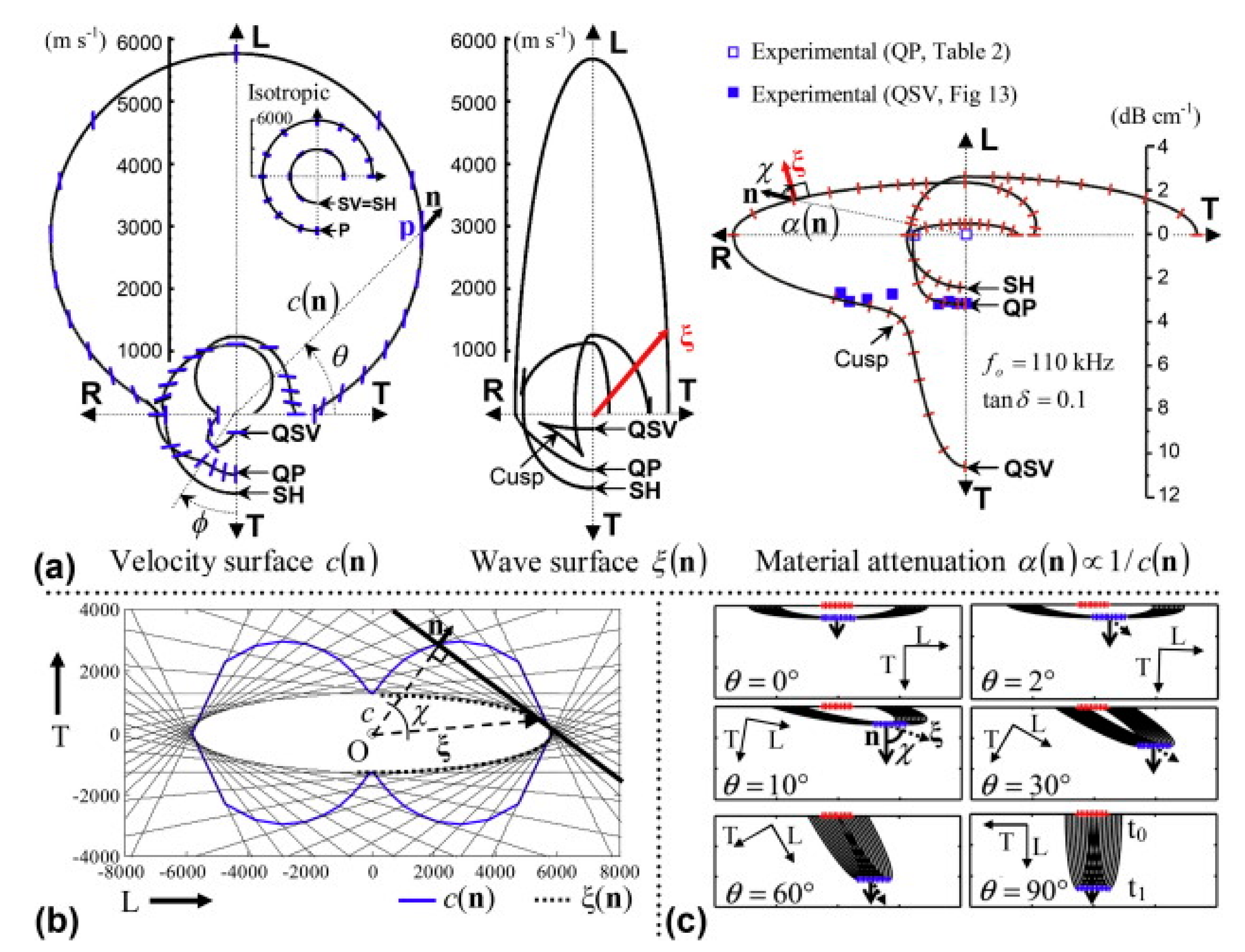

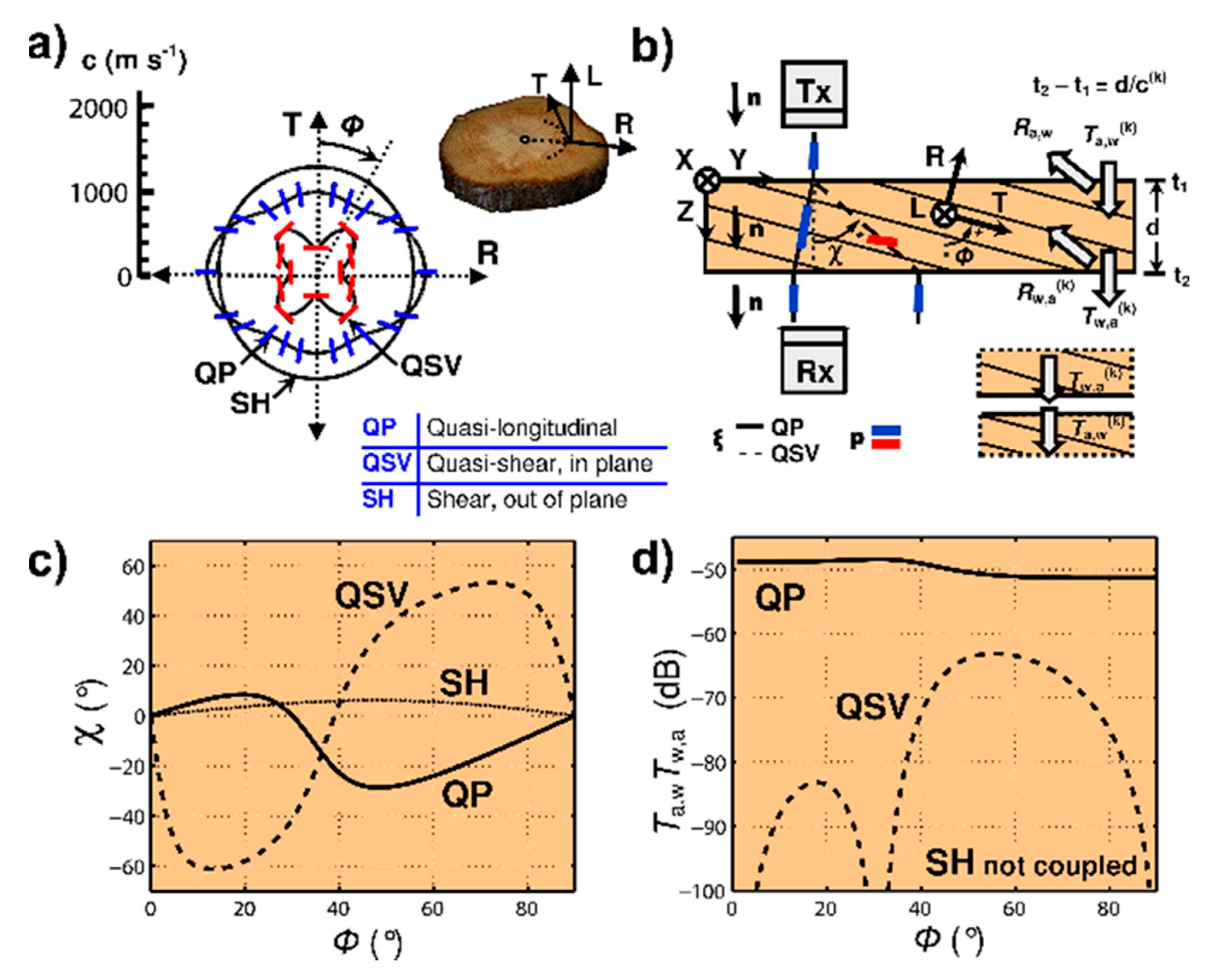

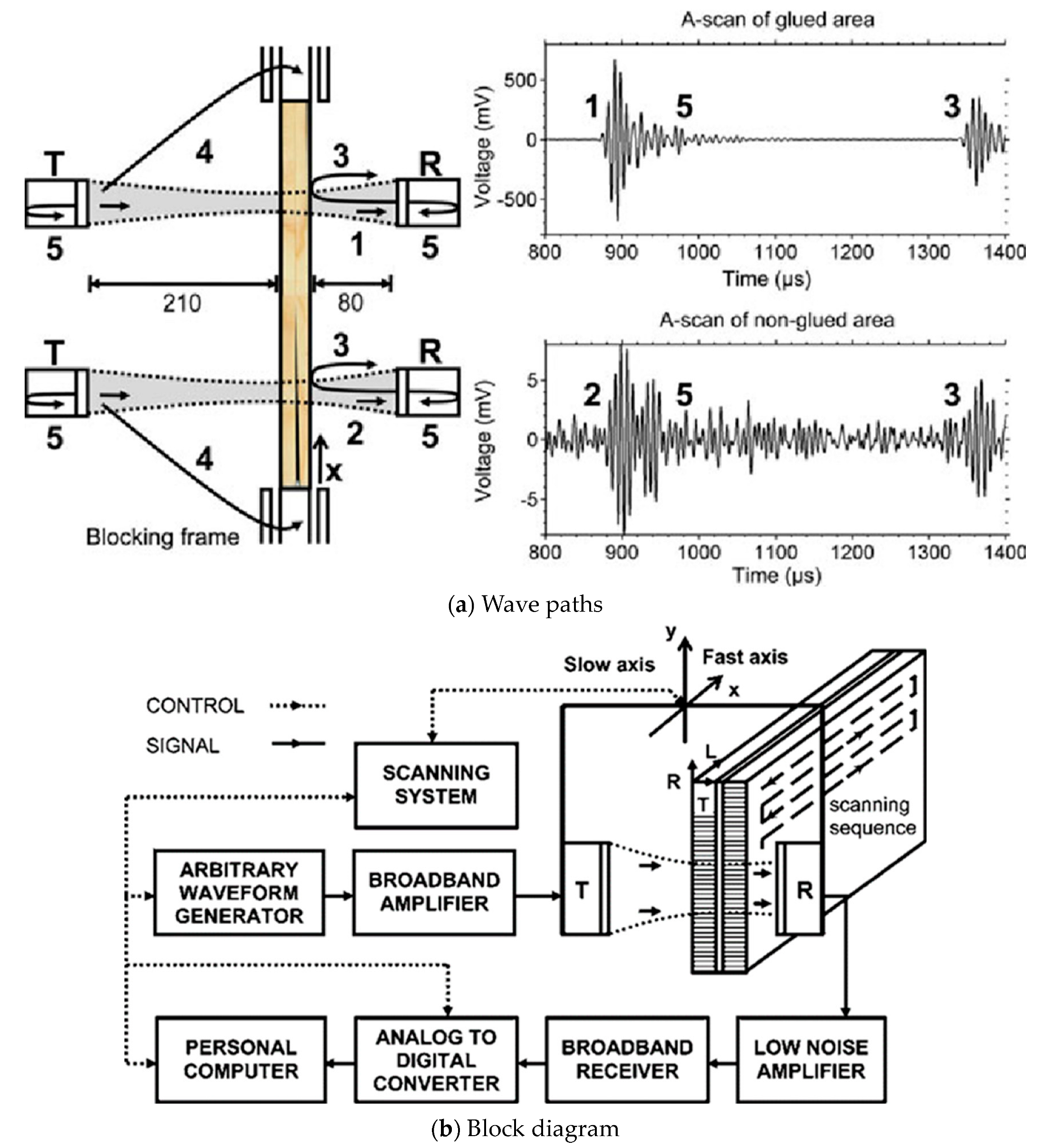

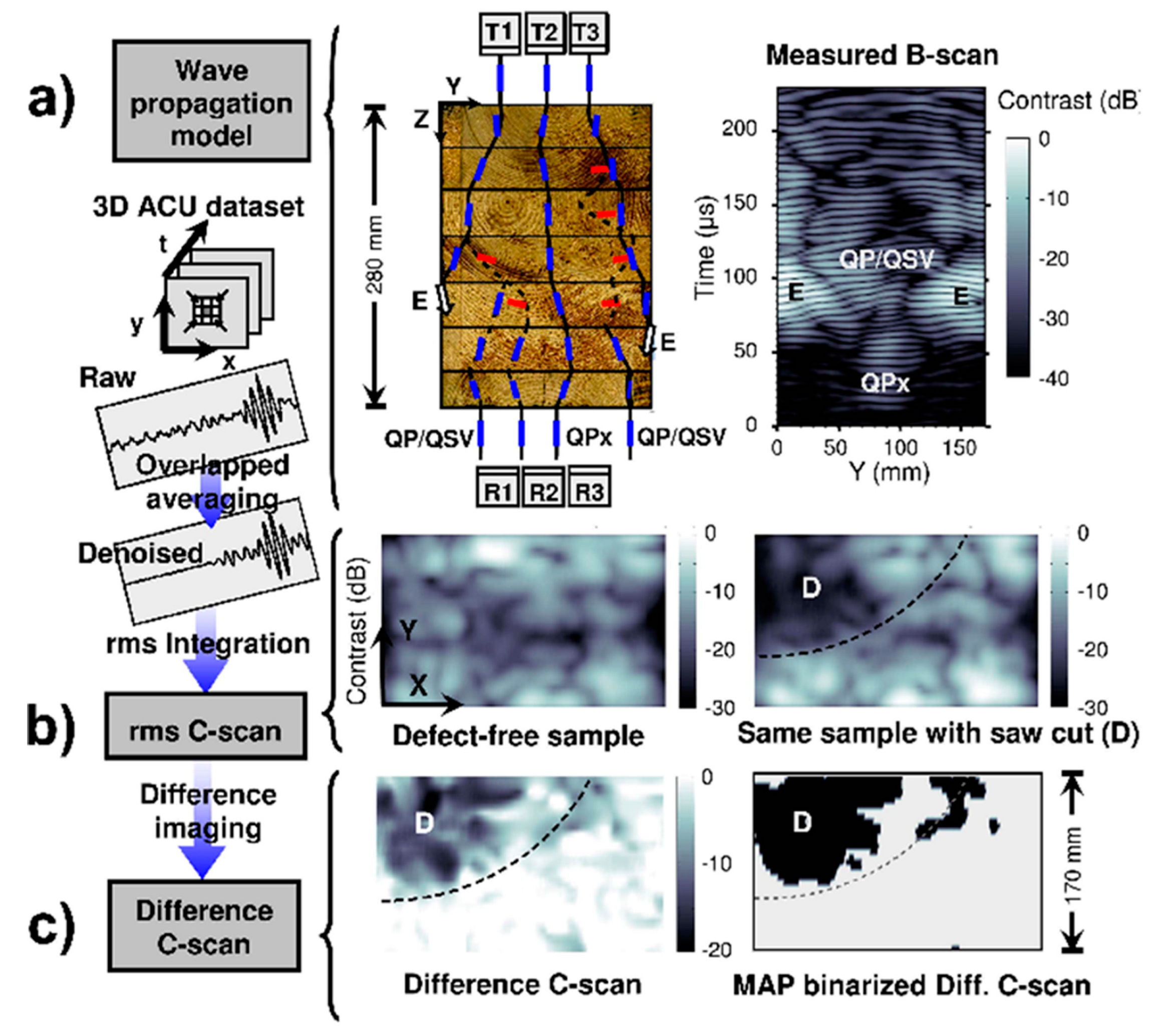

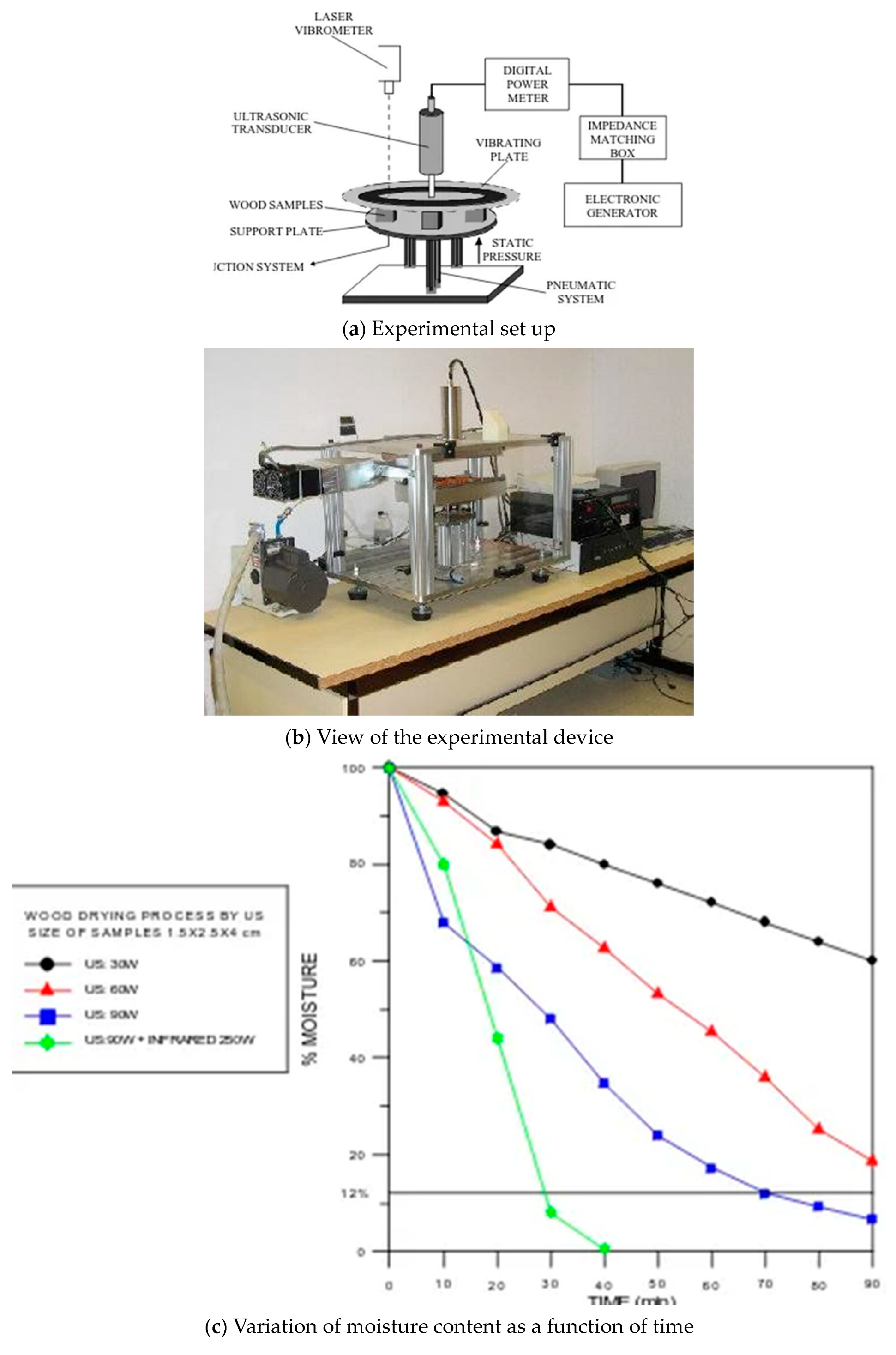

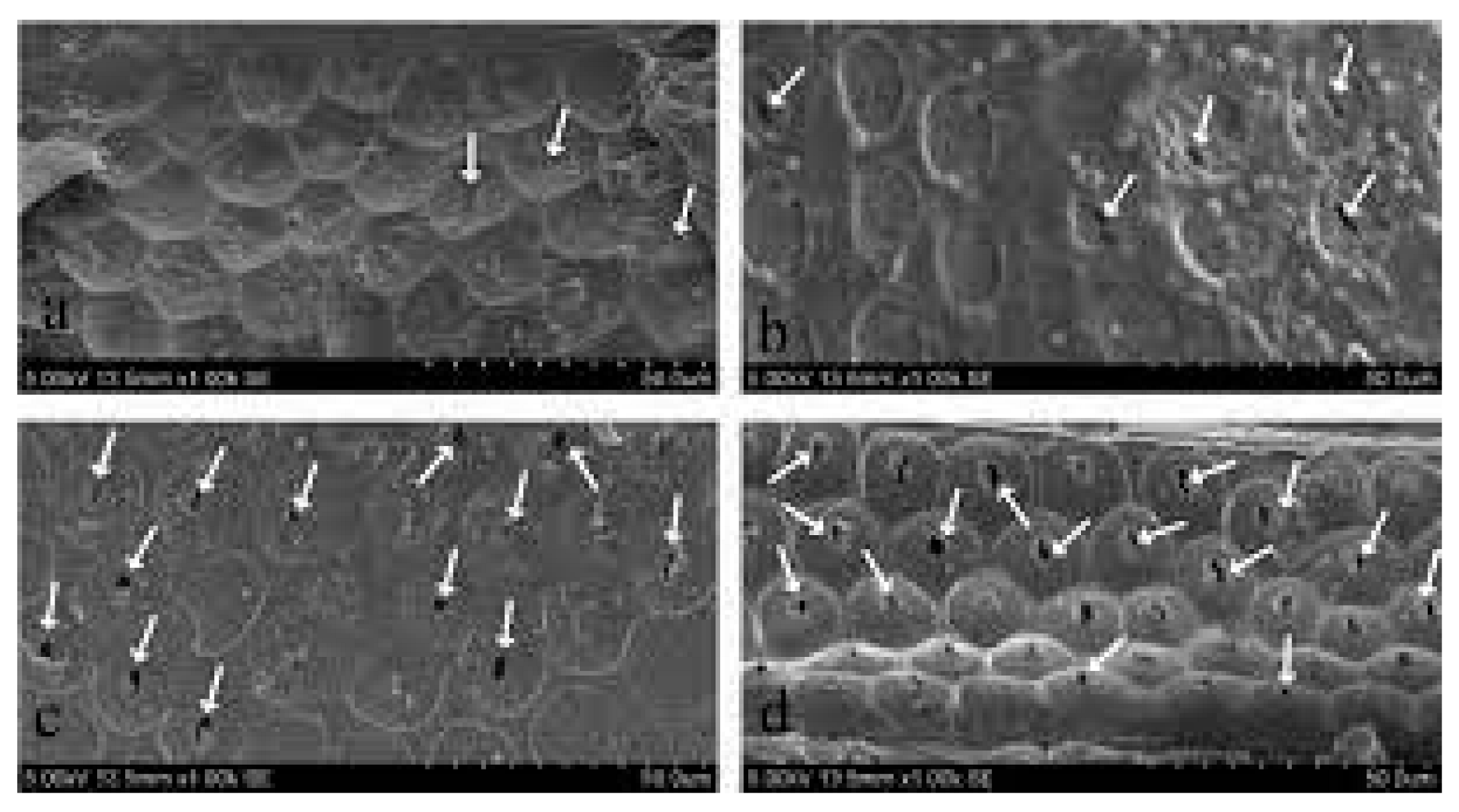

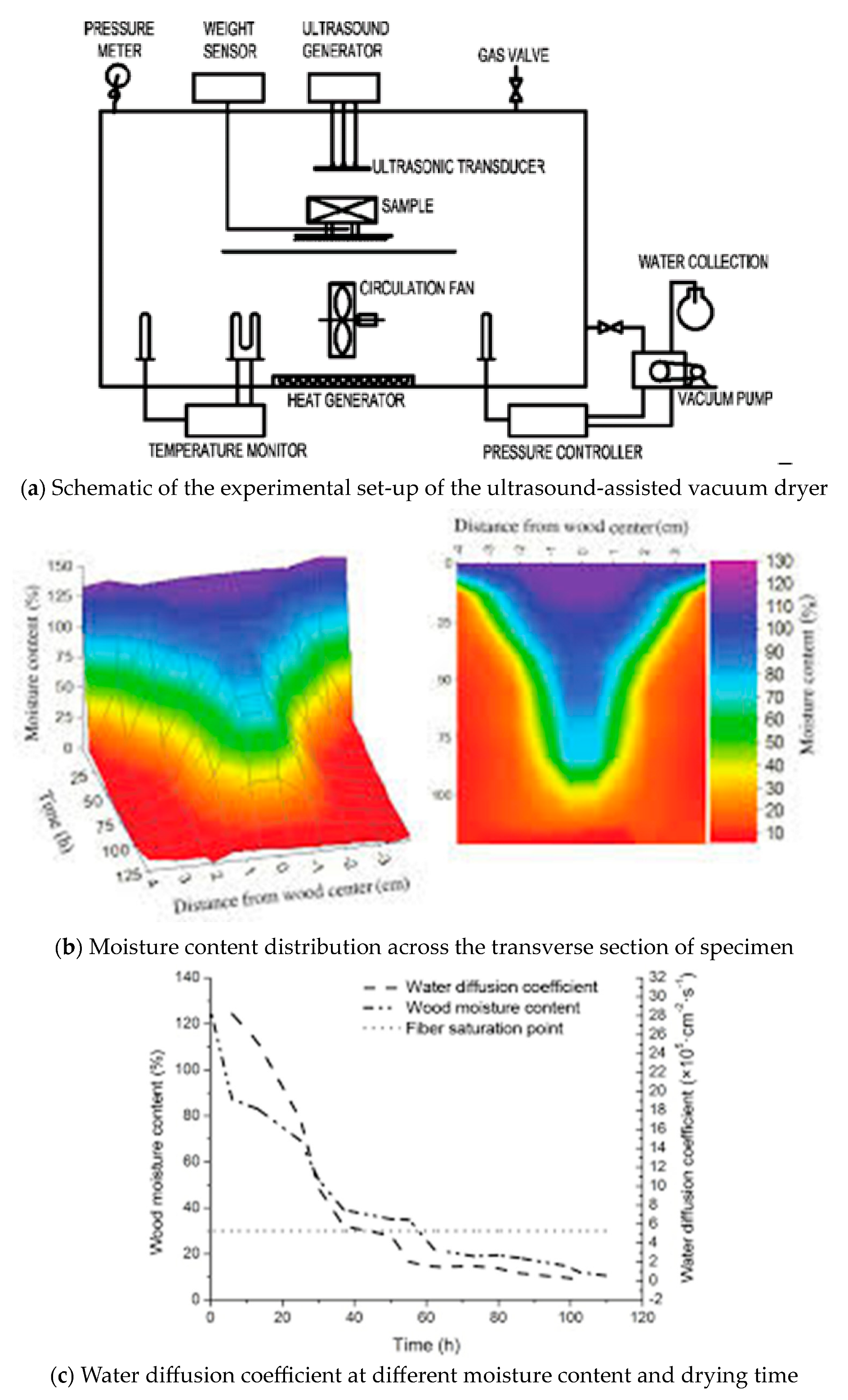

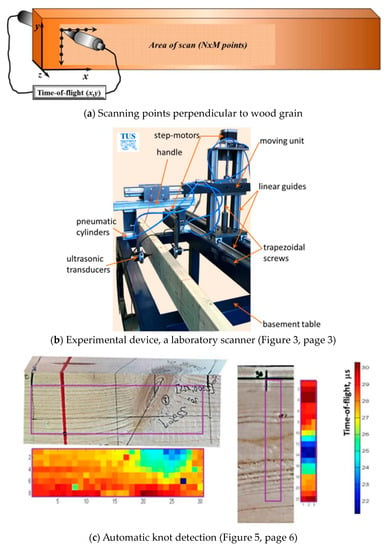

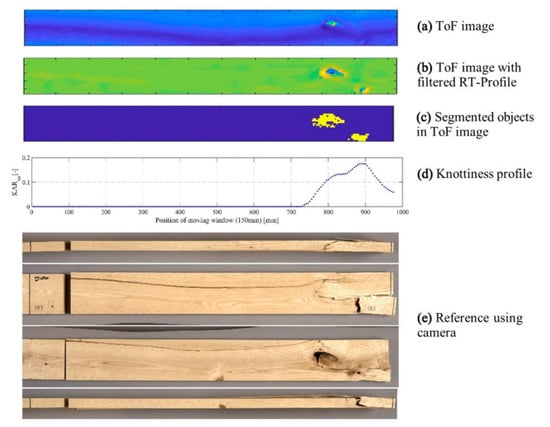

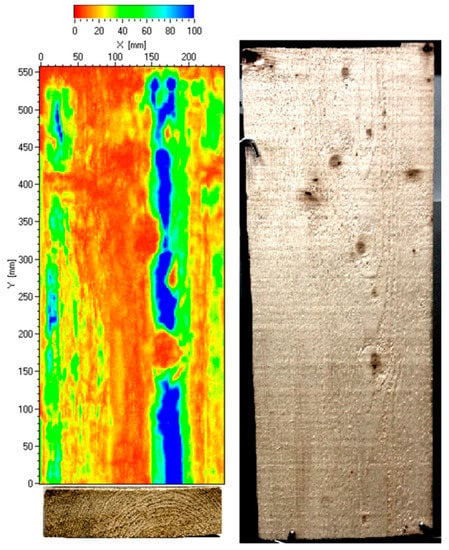

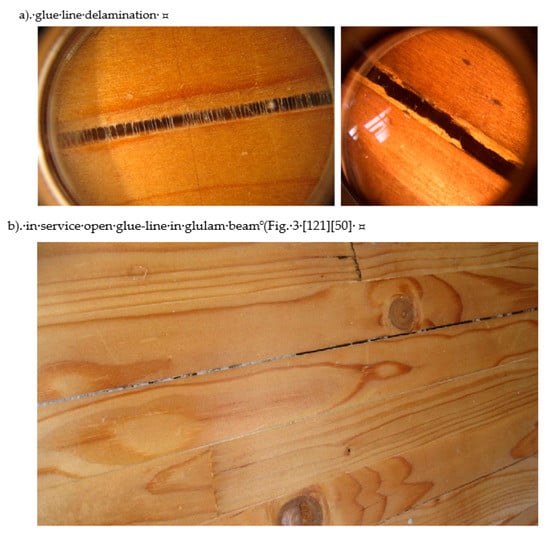

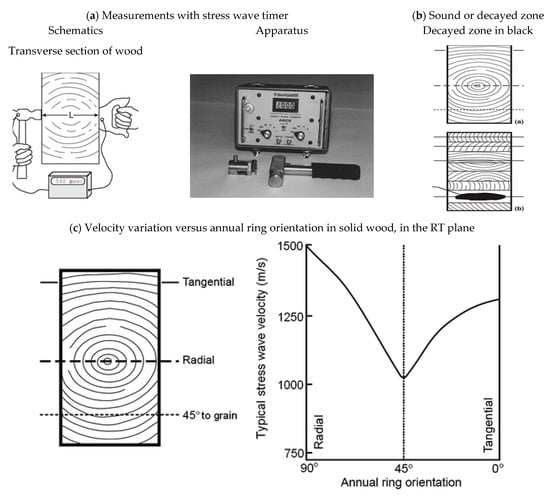

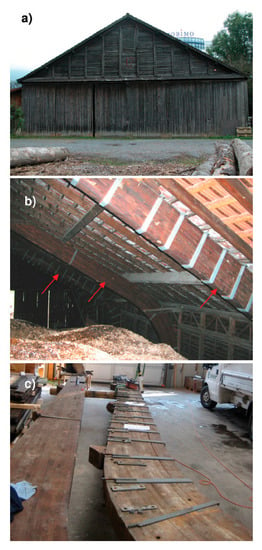

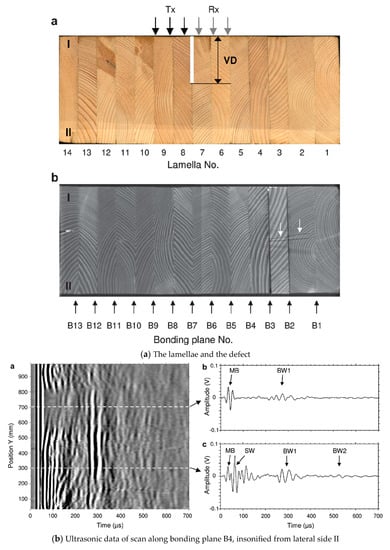

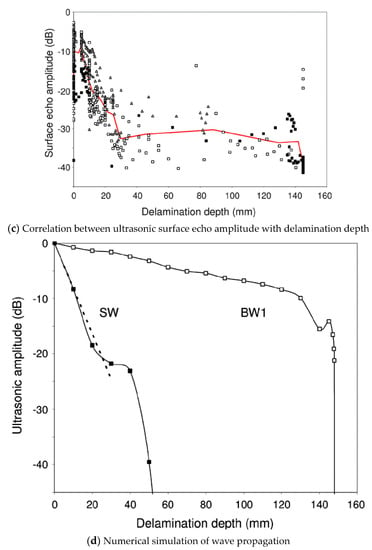

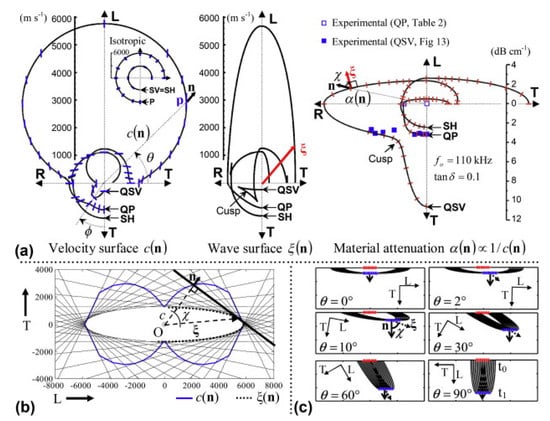

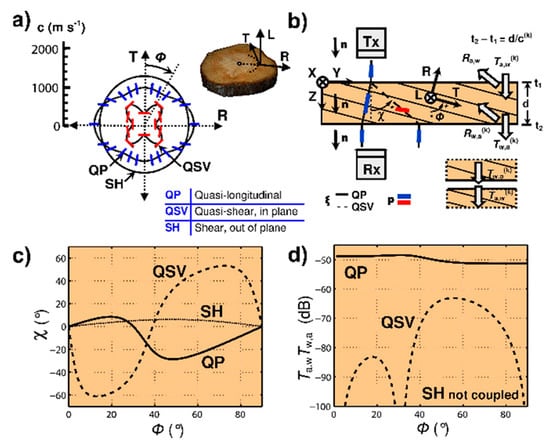

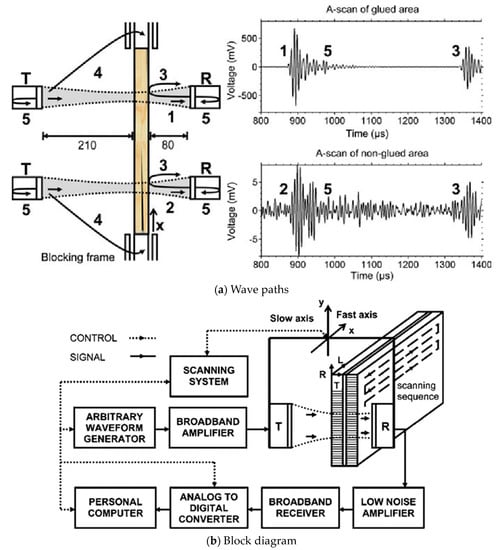

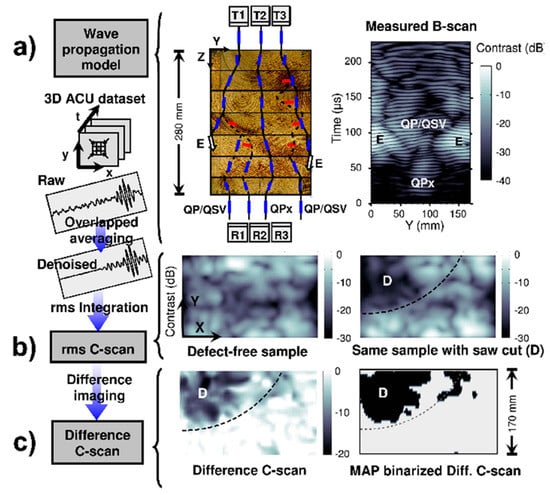

Figure 19.